Foil stamping method and corresponding device

A foil and pressure technology, which is applied in the field of foil stamping and the device used for the same, can solve the problem that it cannot be carried out on the side.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

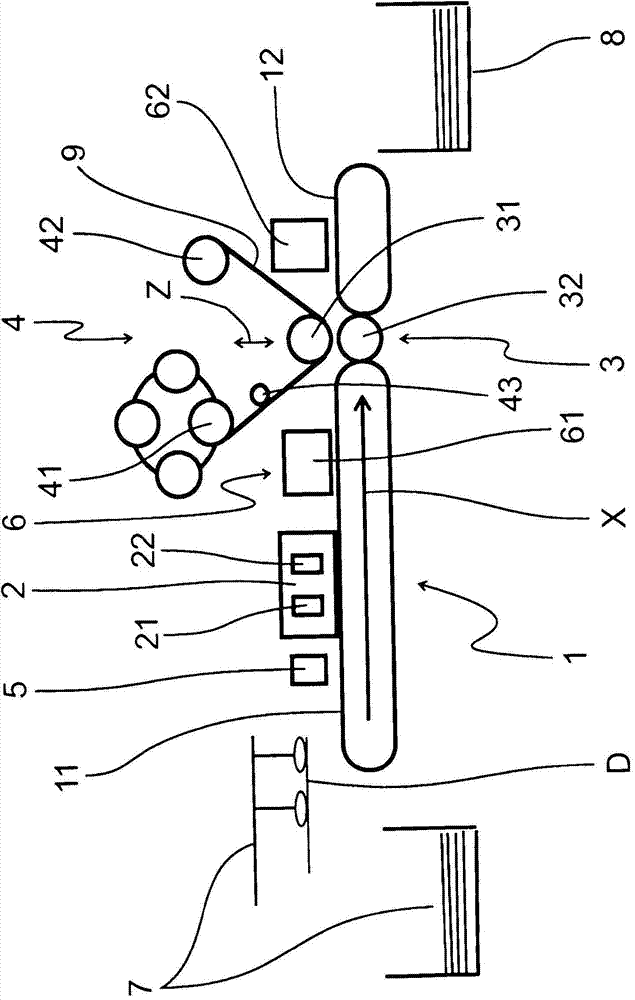

[0019] exist figure 1 A schematic diagram of the foil stamping setup is shown in . The features described next are here suitably given the figure 1 The direction of work indicated by the arrow X in the middle is discussed.

[0020] In the illustrated embodiment, individual webs are used as printed products D, that is to say printed sheets suitably cut into a defined format, which are deposited by means of a web feeder 7 to the transport mechanism 1, ie here the suction belt works on stage. The conveying mechanism 1 has a first suction belt table 11 and downstream a second suction belt table 12 .

[0021] Downstream of the abutment region of the first suction belt table 11, a printed sheet orientation device and a printed product sensor 5, for example in the form of a printed sheet leading edge and / or a printed sheet trailing edge sensor, are provided. Sheet orientators are known from printing presses or other graphics-like machines. Downstream of the printed product senso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com