Patents

Literature

101results about How to "Accurate coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

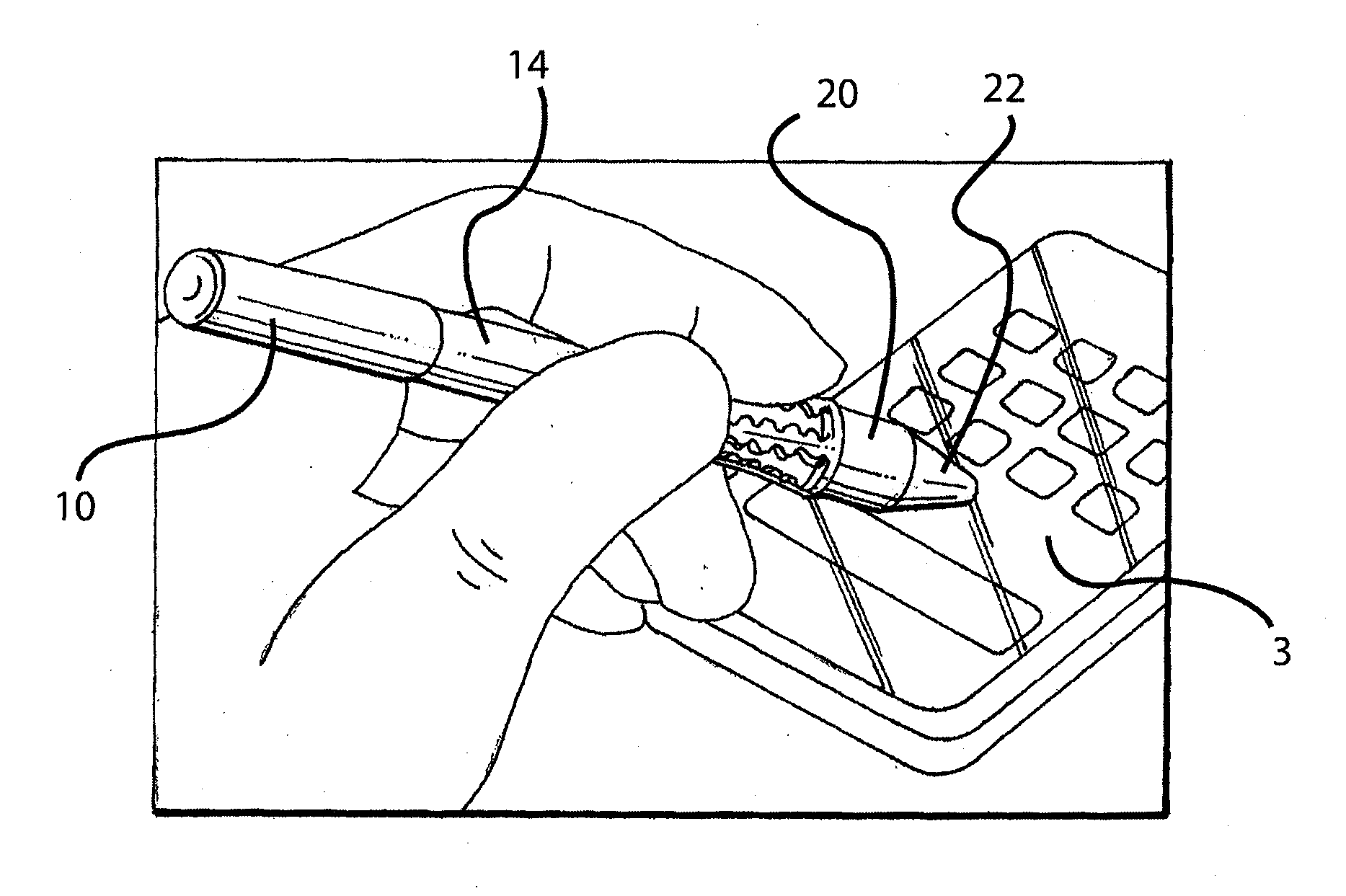

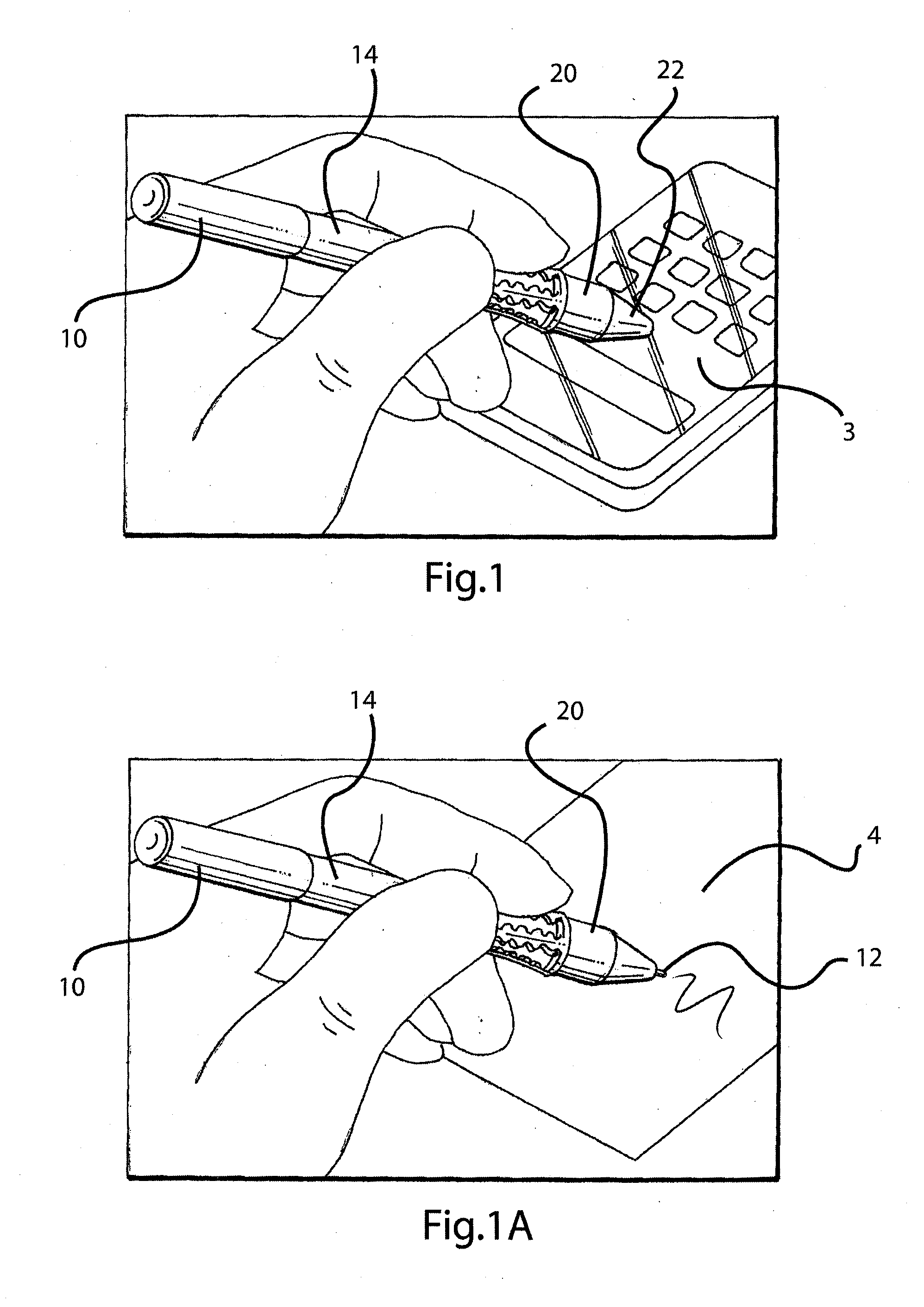

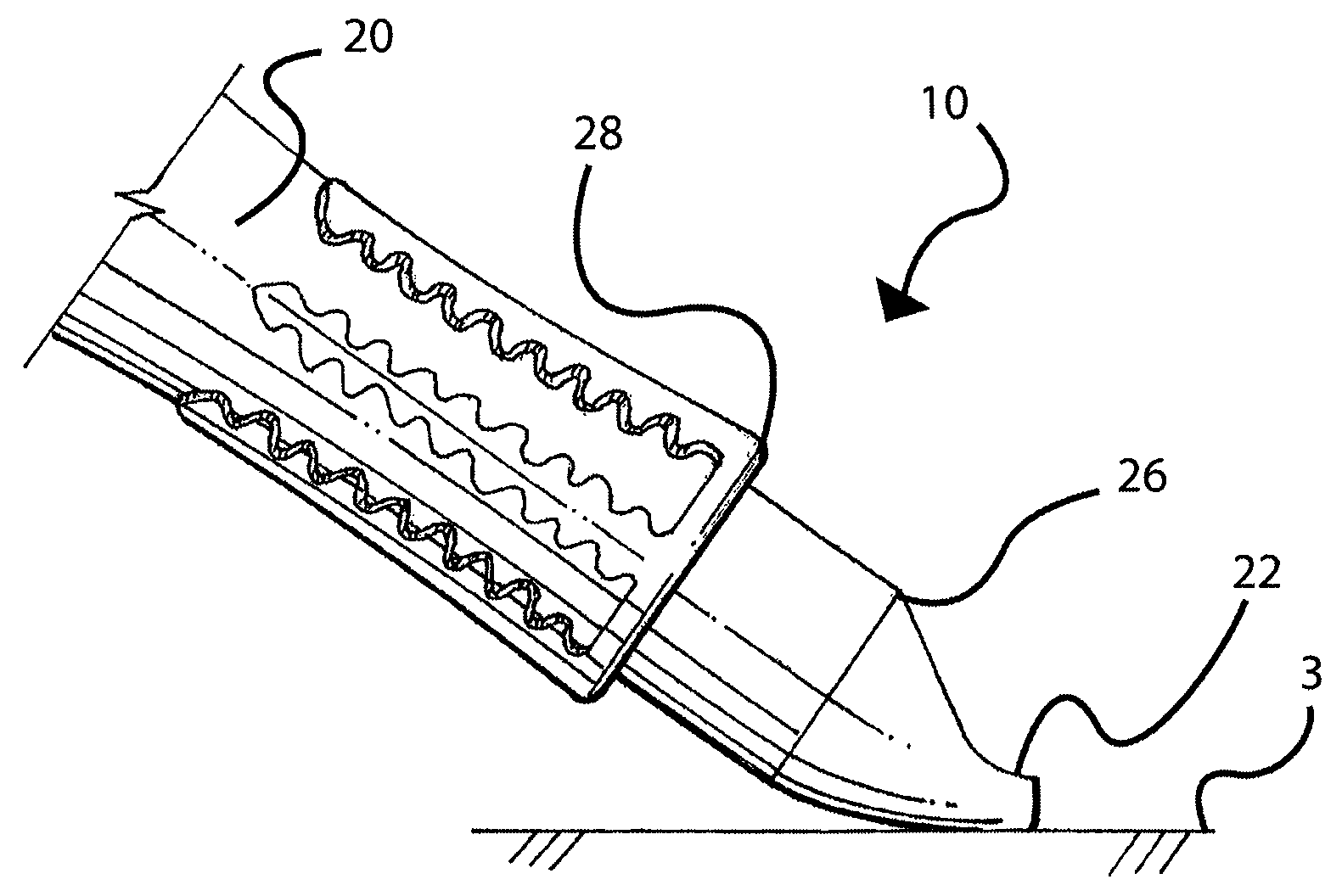

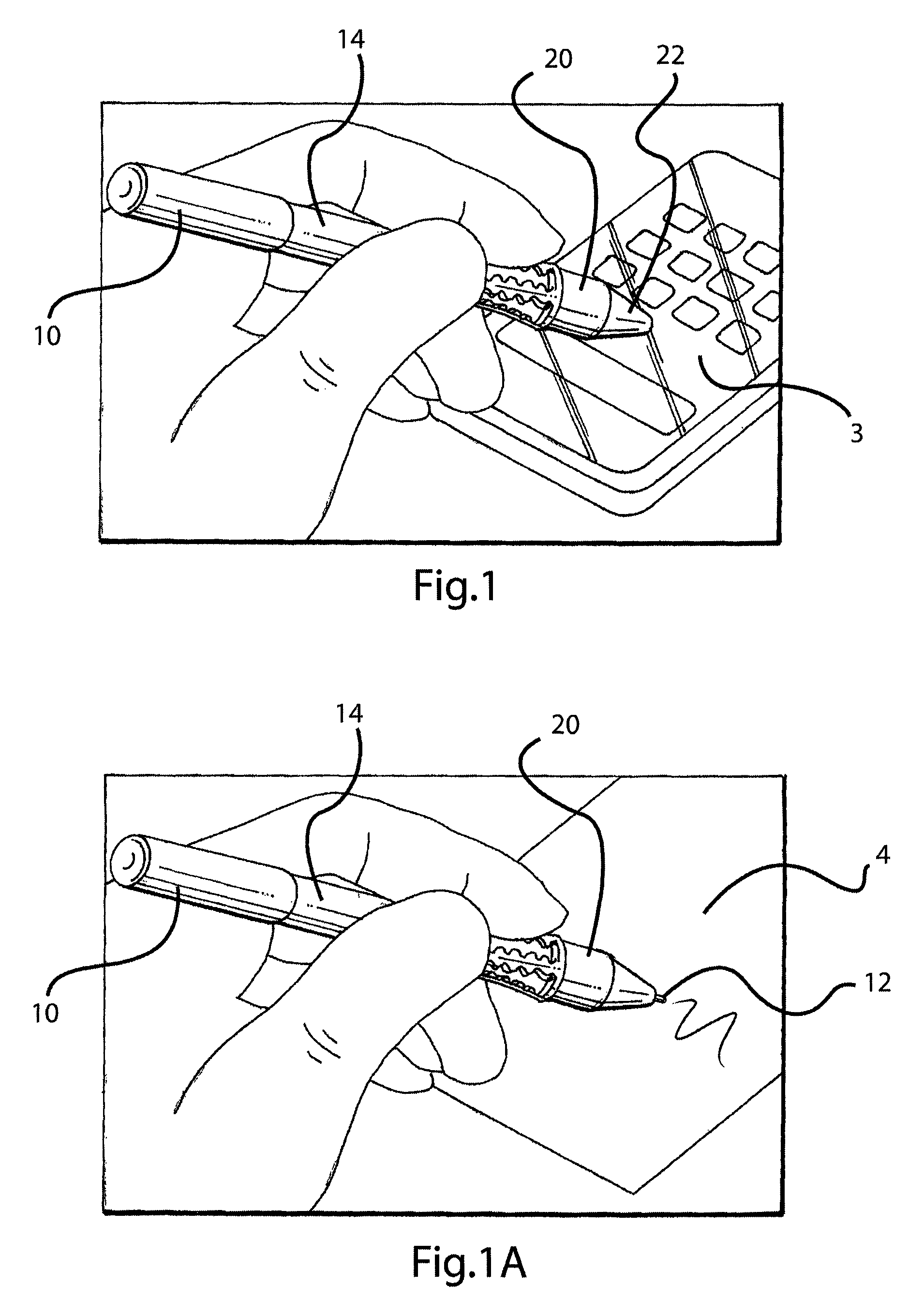

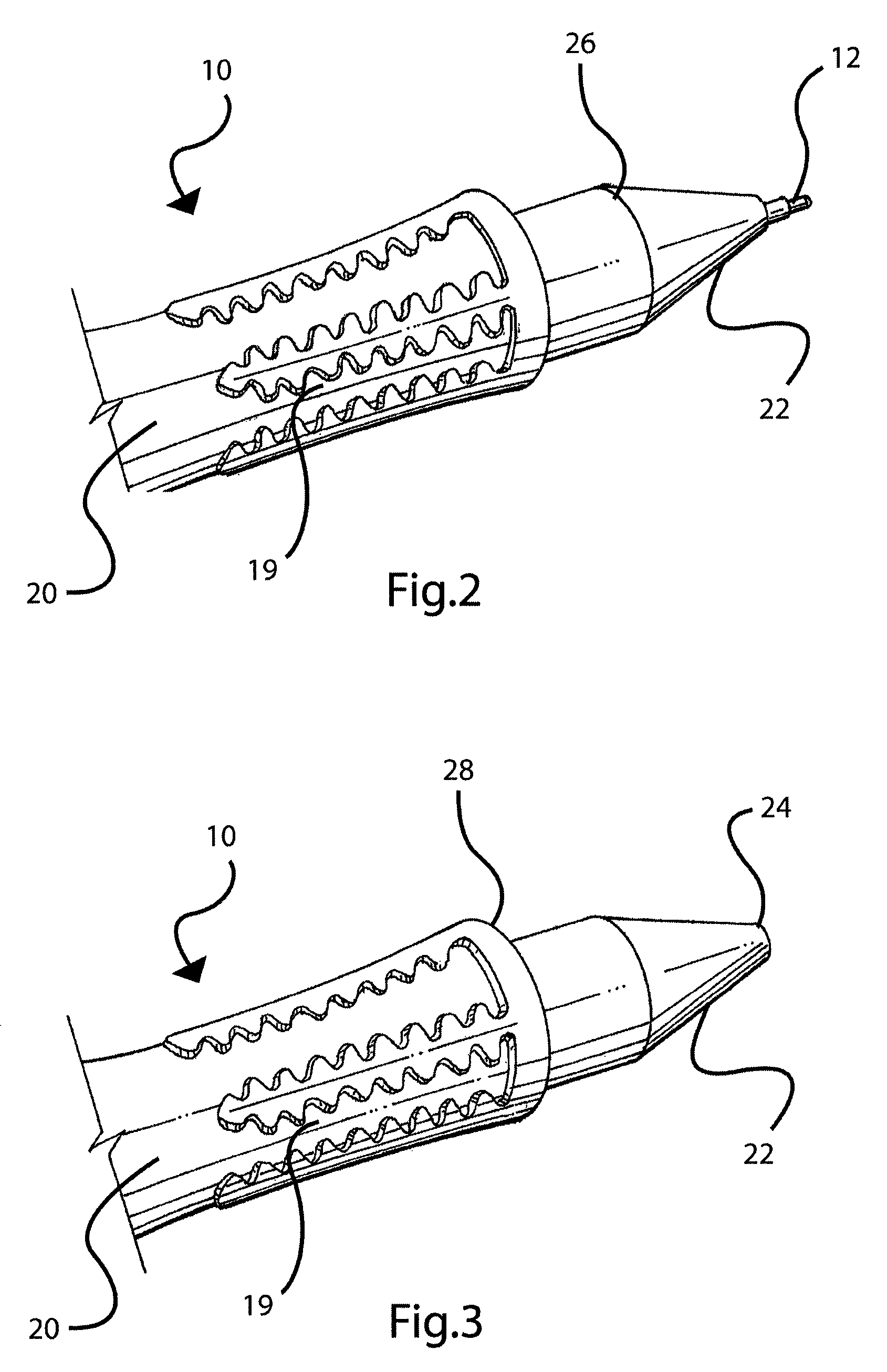

Electrically conductive touch pen

ActiveUS20130038579A1Easy to useEffective insulationWriting connectorsBall-point pensEngineeringTouchscreen

A combination writing pen and stylus is disclosed. The device has an internal ink cartridge deployable through a hole in the stylus tip. The stylus tip extends from a sleeve that is formed of a conductive elastomeric material. The sleeve extends up a rigid shaft of the device such that it contacts a sufficient ground. The stylus tip may be coated with a protective material that adjusts the coefficient of friction and prevents carbon deposits on the touch screen. A sufficient contact patch is achieved to simulate a human finger so as to overcome false positives from common touch screen logic. This is done by altering tip geometries around an air cavity within the sleeve.

Owner:PIXEL PEN LLC

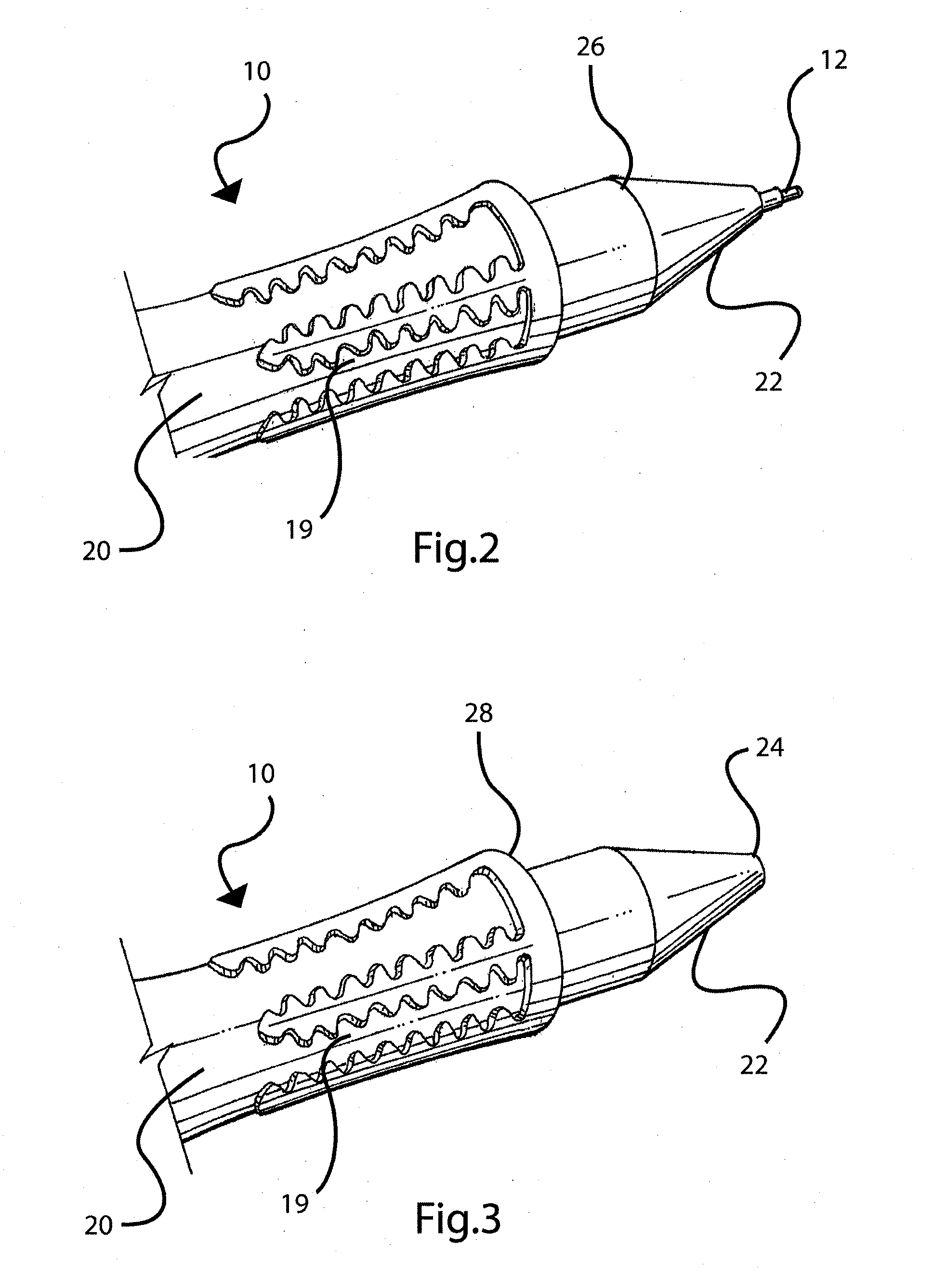

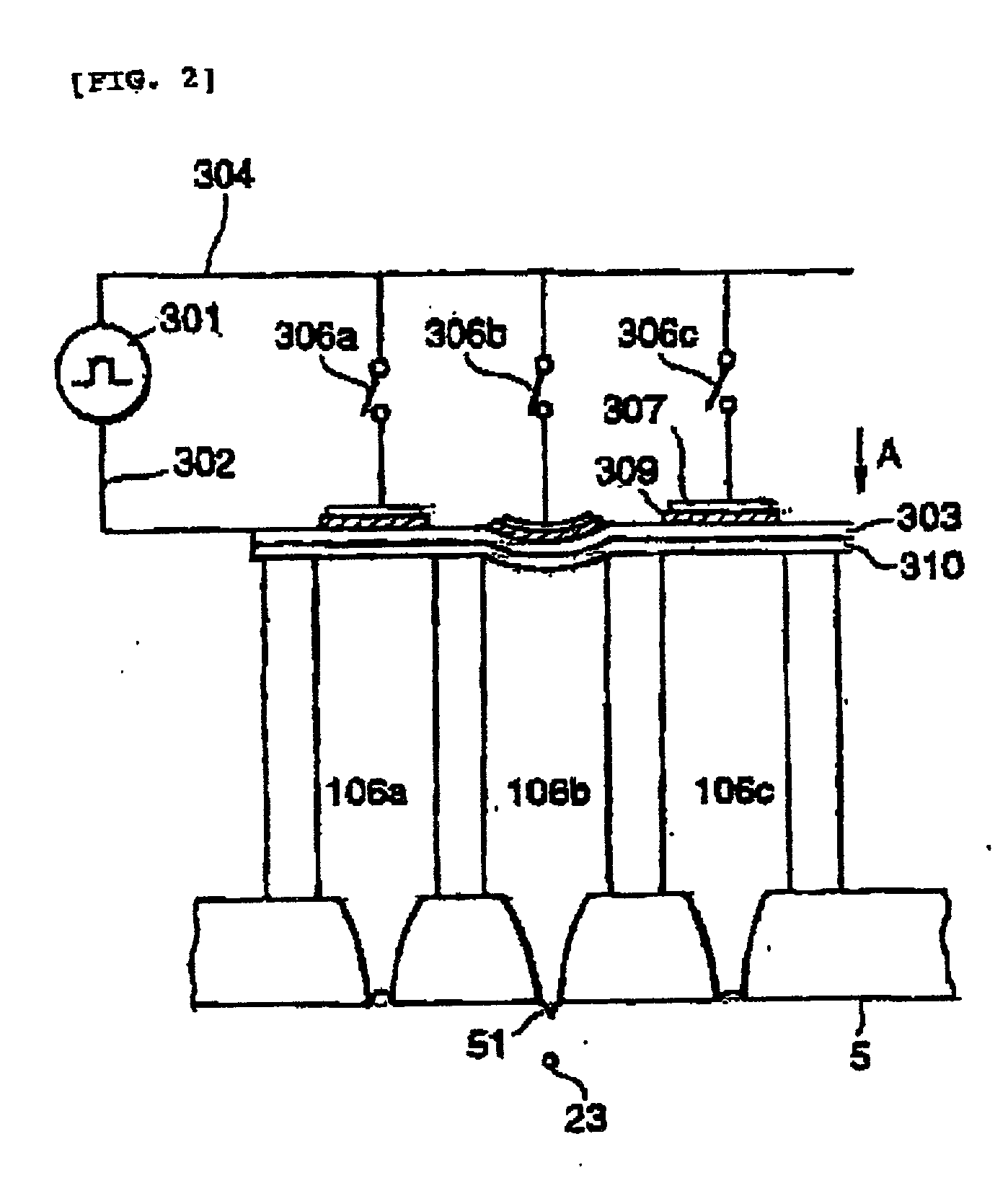

Memory device and manufacturing method therefor

InactiveUS20010039124A1Easy to changeAccurate coatingNanoinformaticsSolid-state devicesSemiconductorStorage cell

A technique for manufacturing memory devices which can easily manufacture ROM semiconductors having various write patterns at lower cost in a short period of time is disclosed. Since a simple matrix structure in which each memory cell is formed at a cross-point of an upper and a lower linear electrode is employed, and an insulating material is selectively ejected to surfaces of electrodes at predetermined memory cell positions by using an inkjet head, the surfaces of the electrode at the predetermined memory cell positions are covered with the insulating material. A state is stored in accordance with the presence or the absence of the covering insulating film on the surface of the electrode at each memory cell position.

Owner:SEIKO EPSON CORP

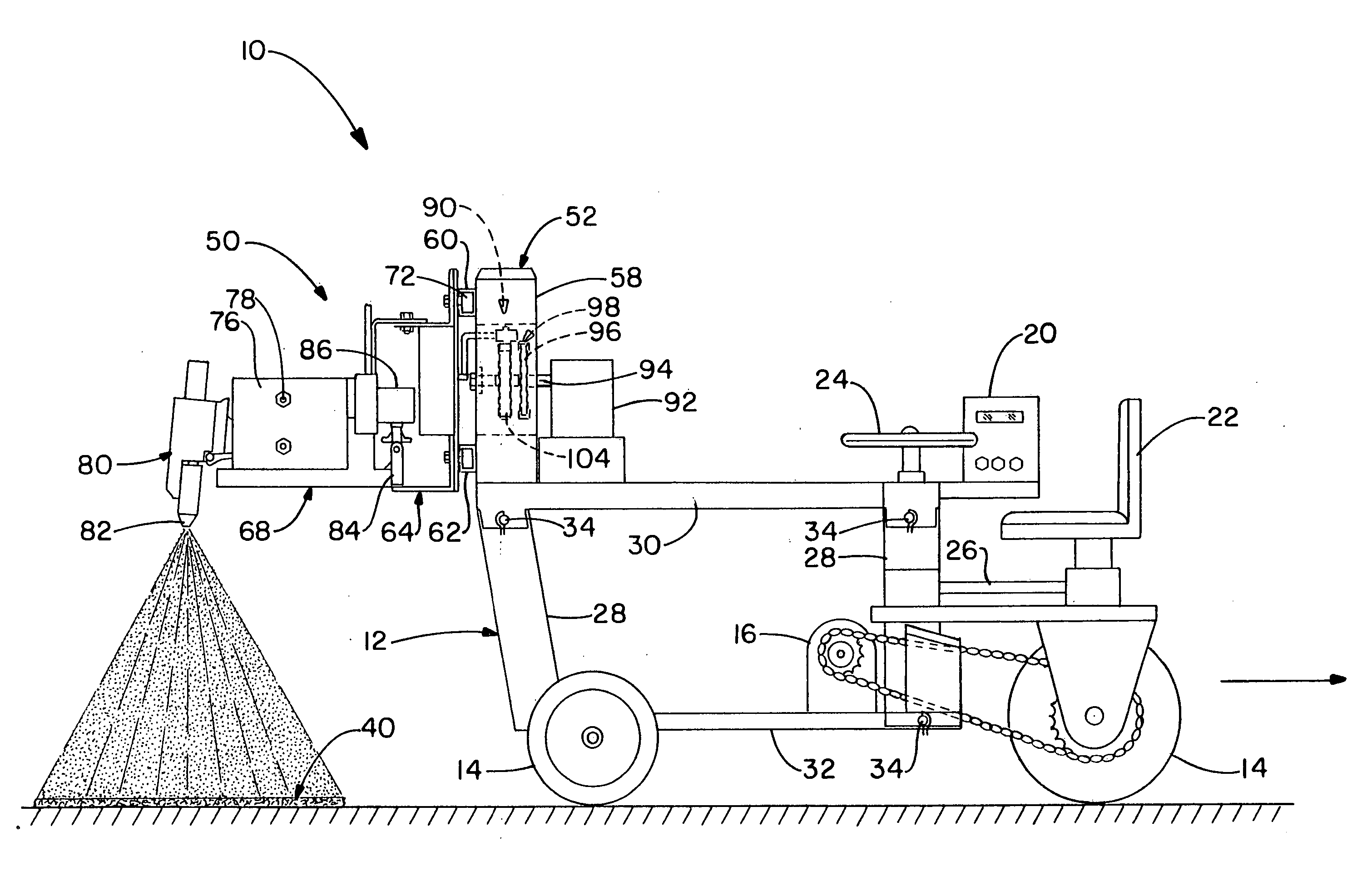

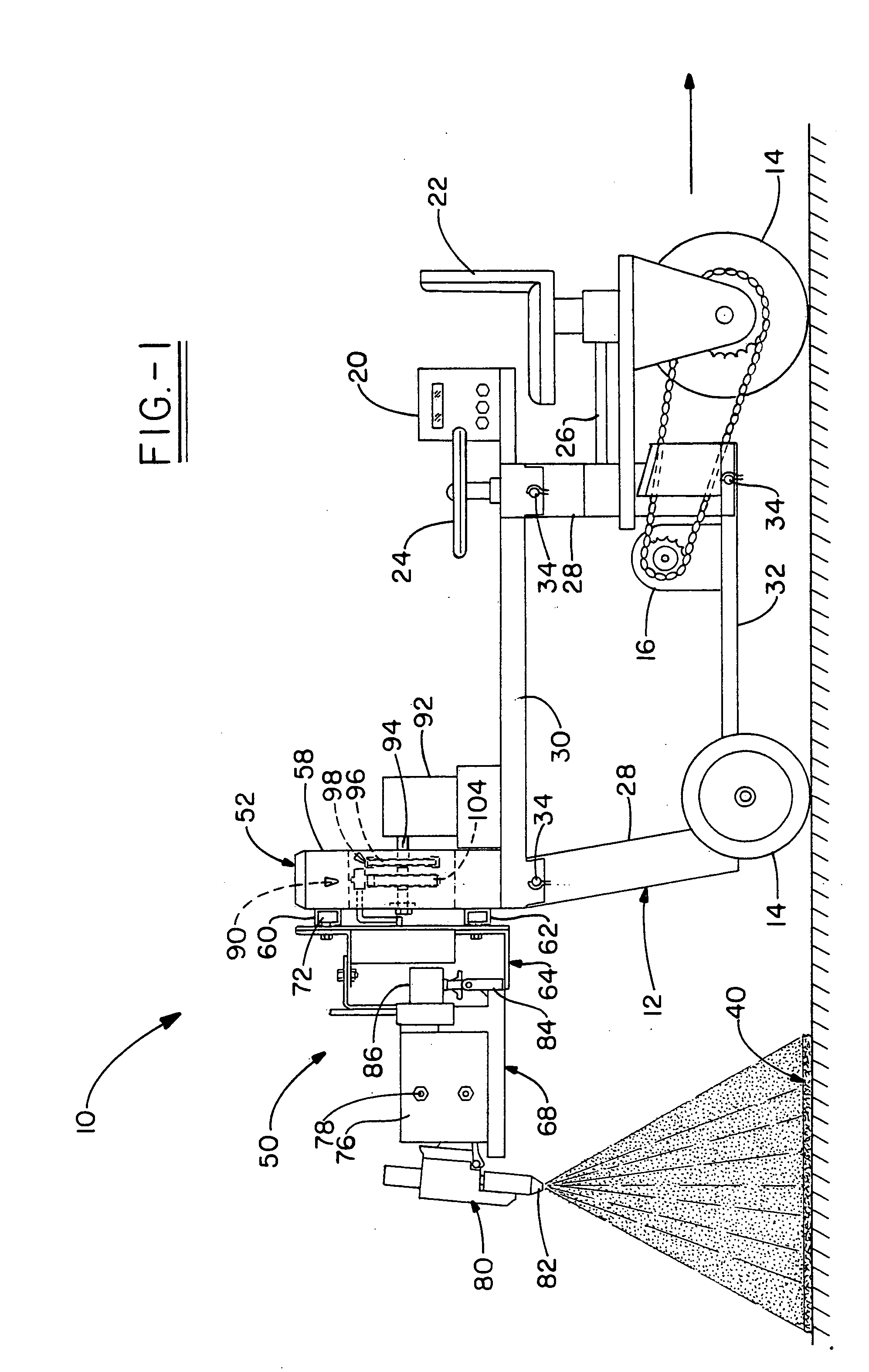

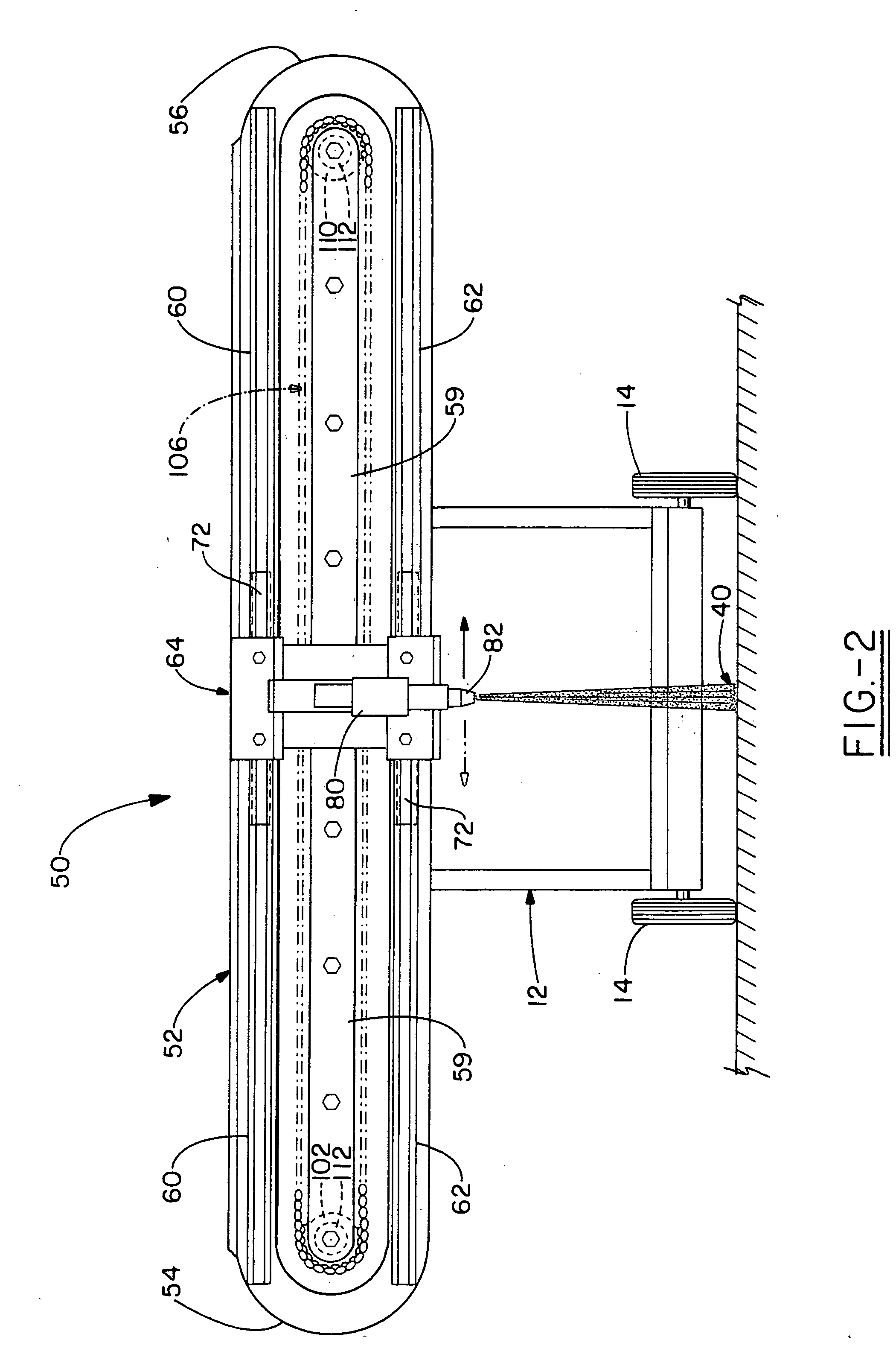

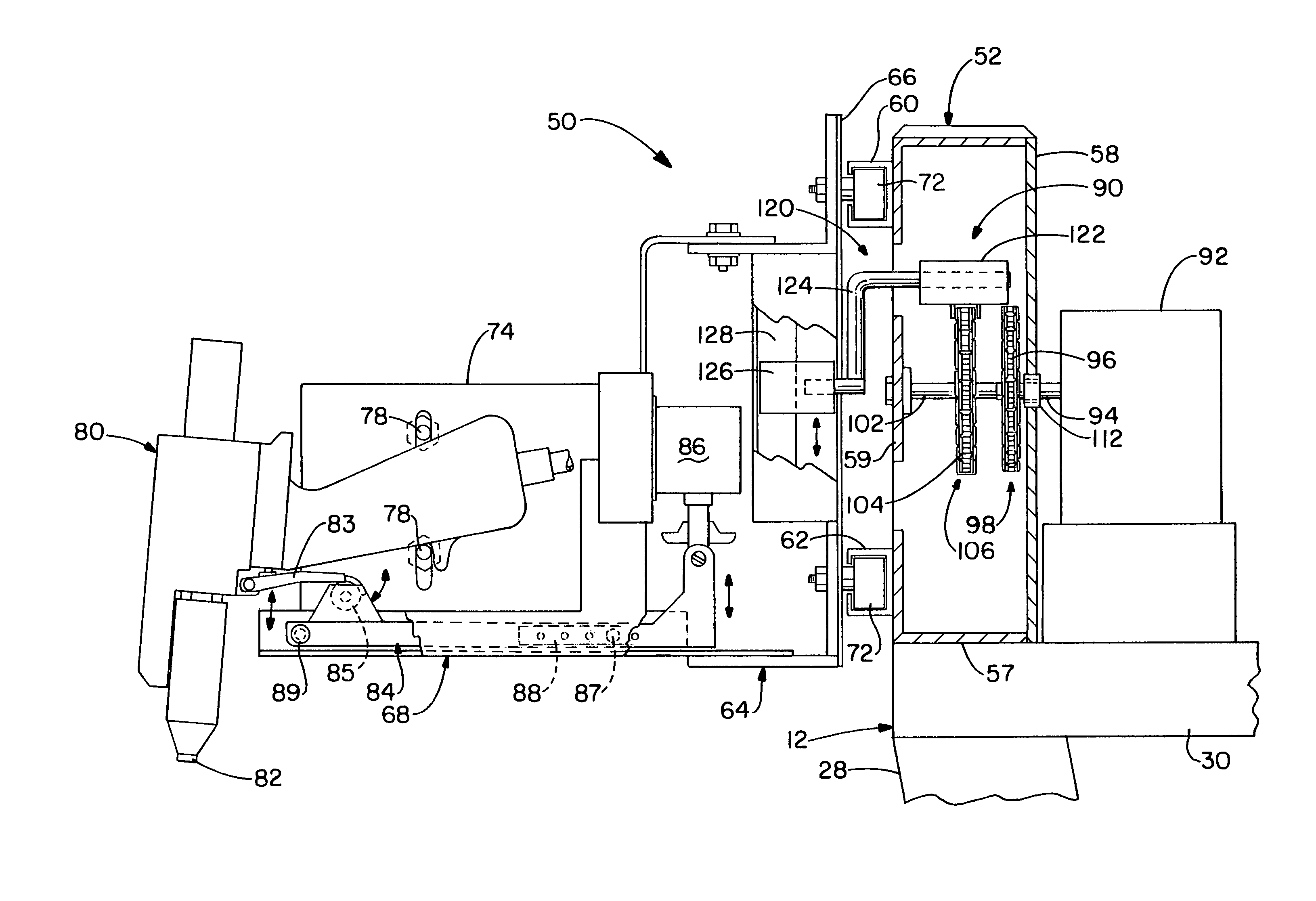

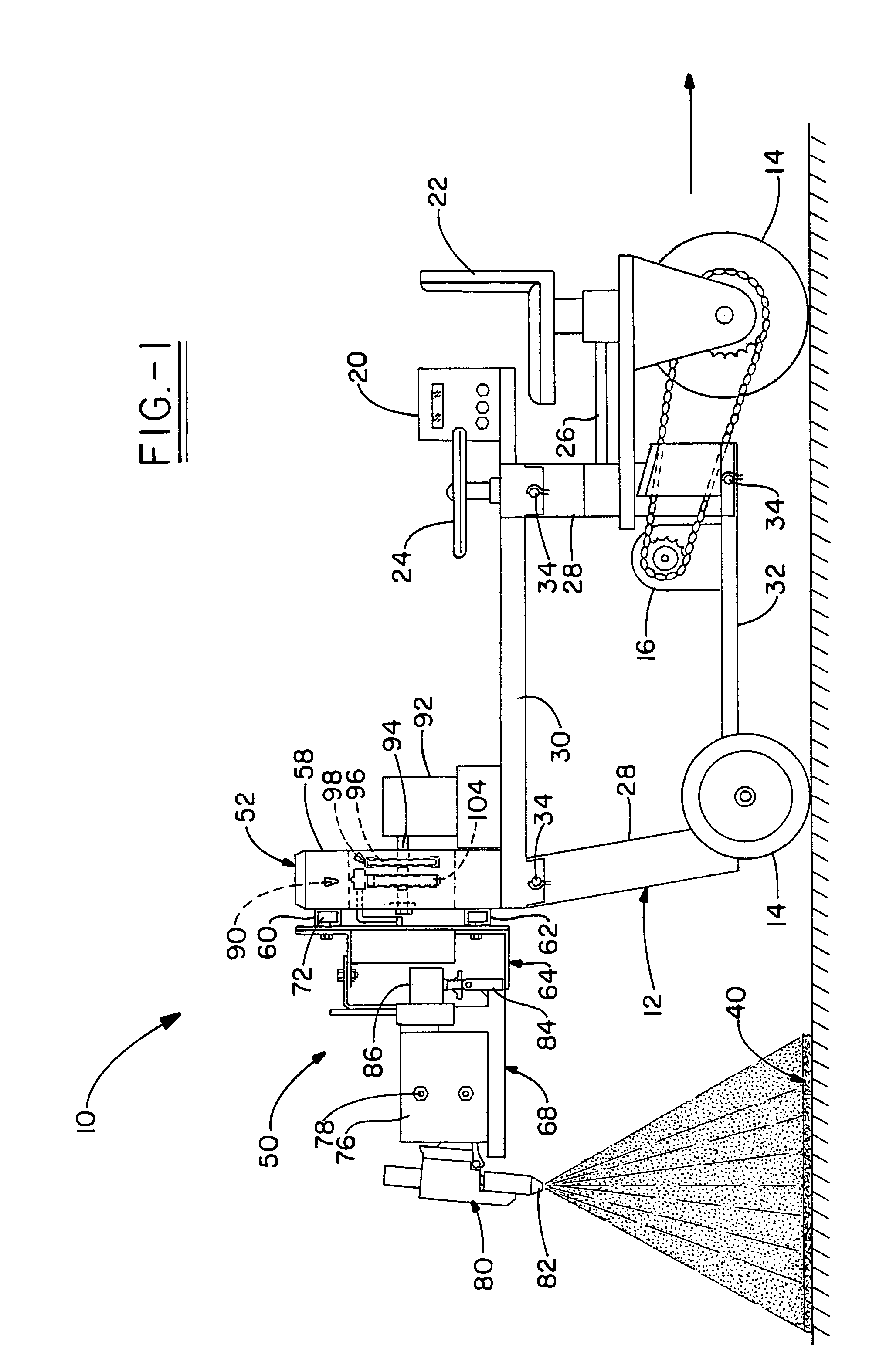

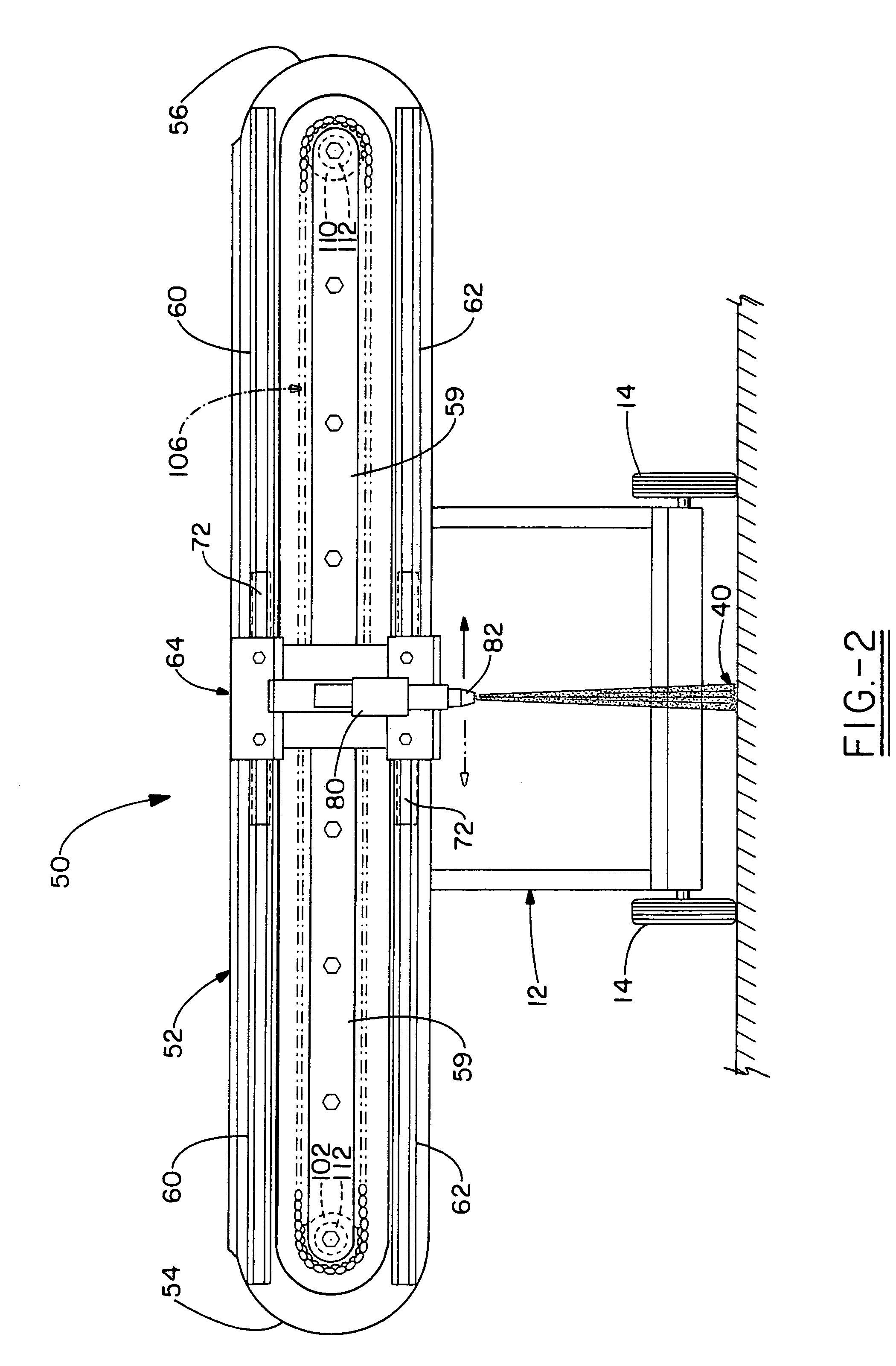

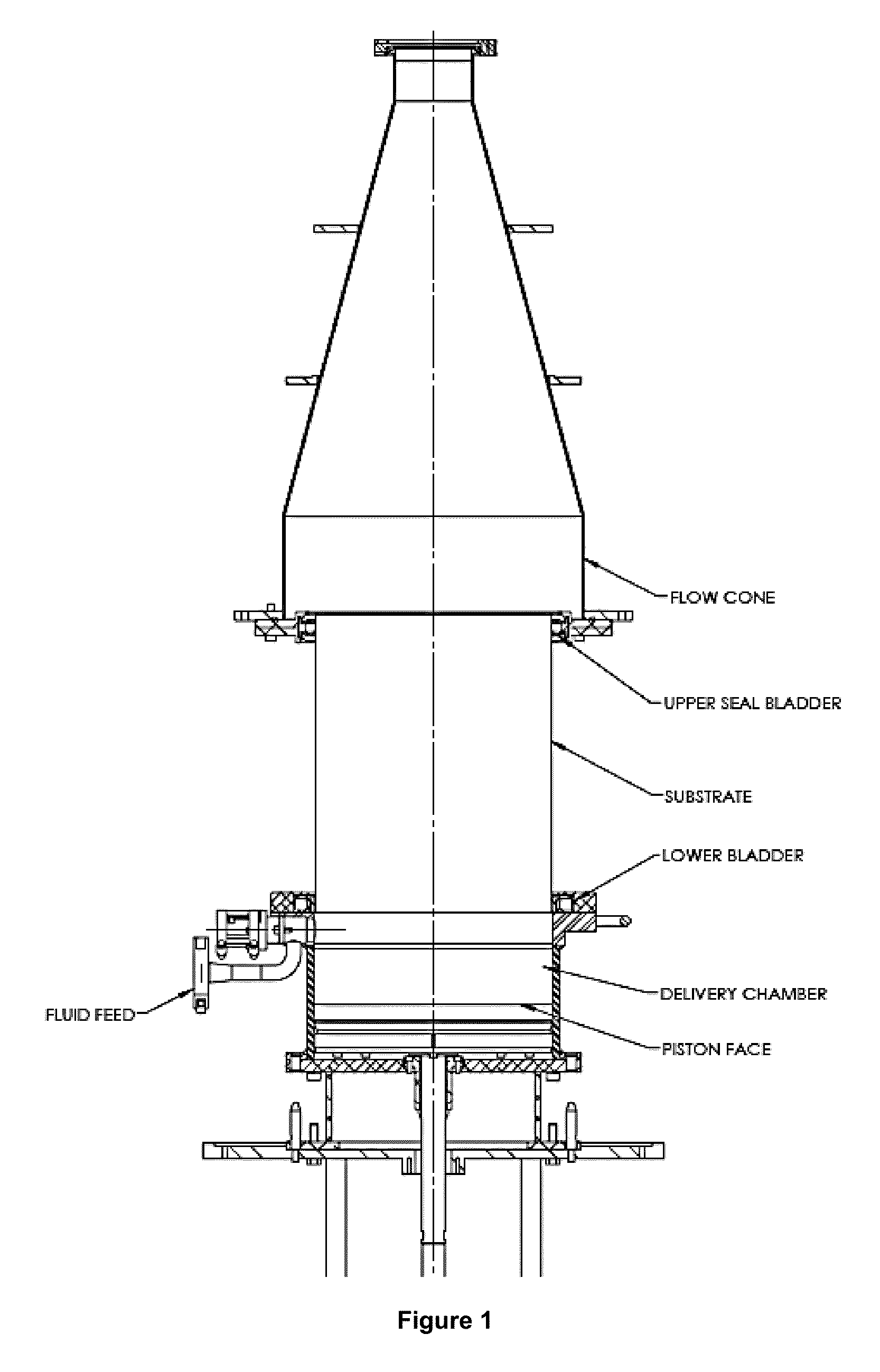

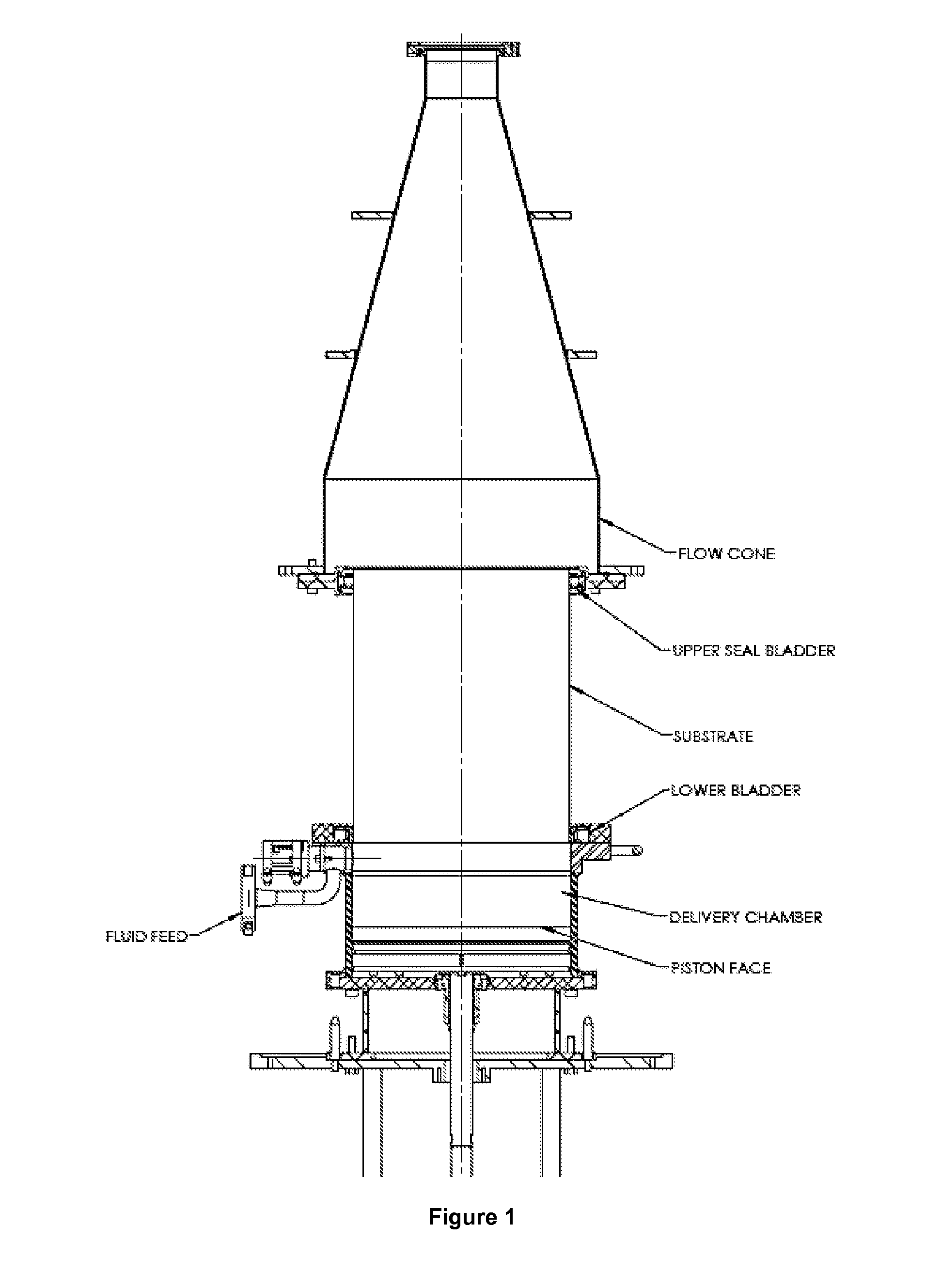

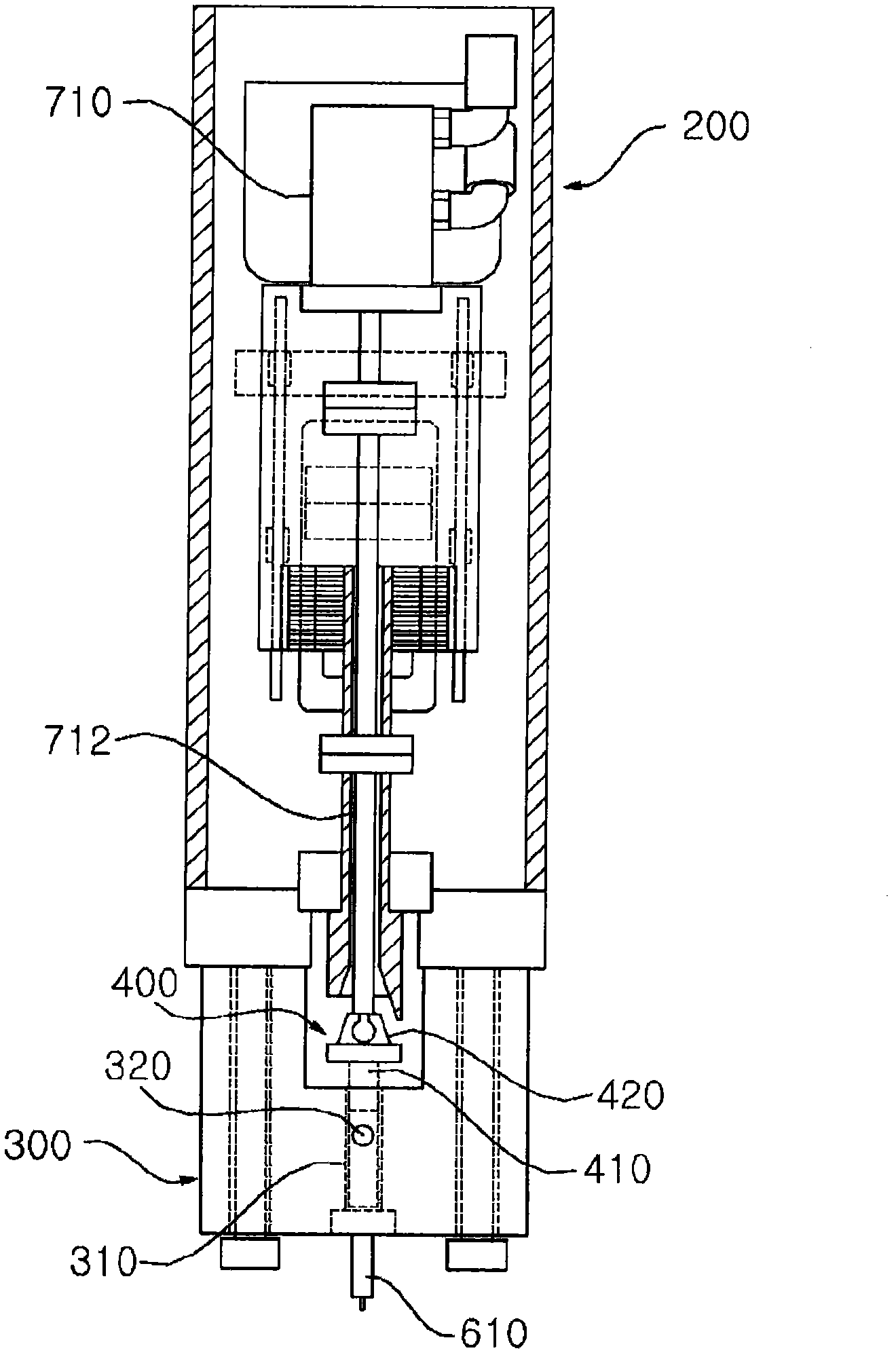

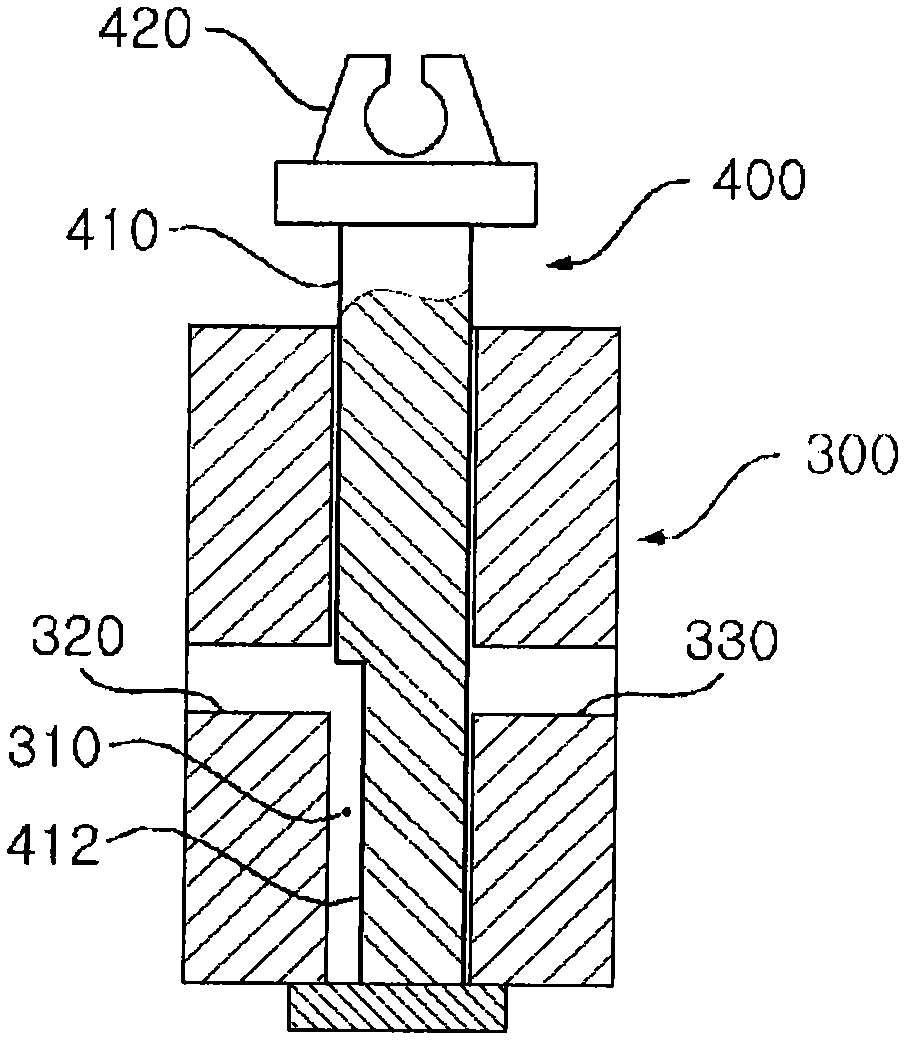

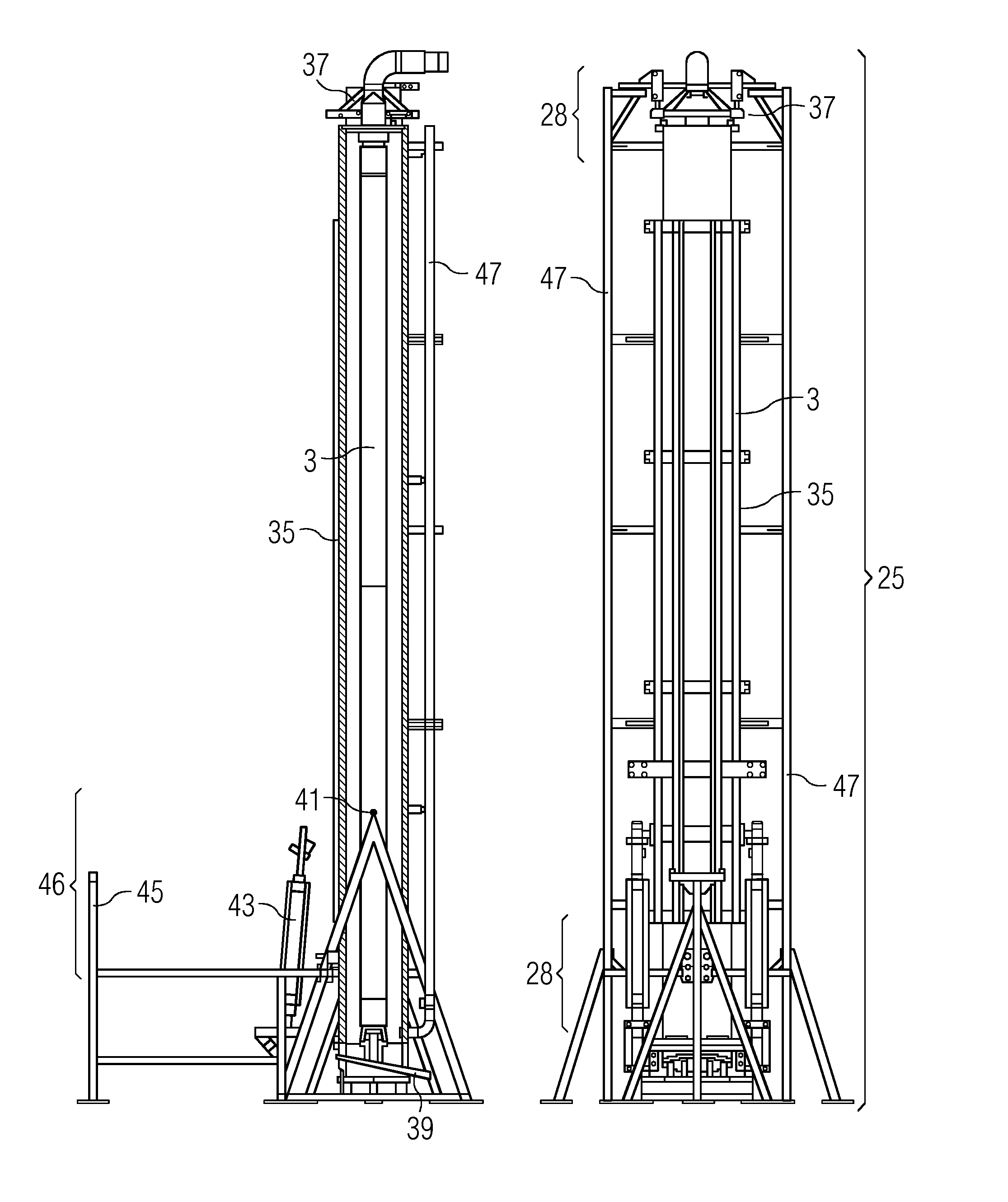

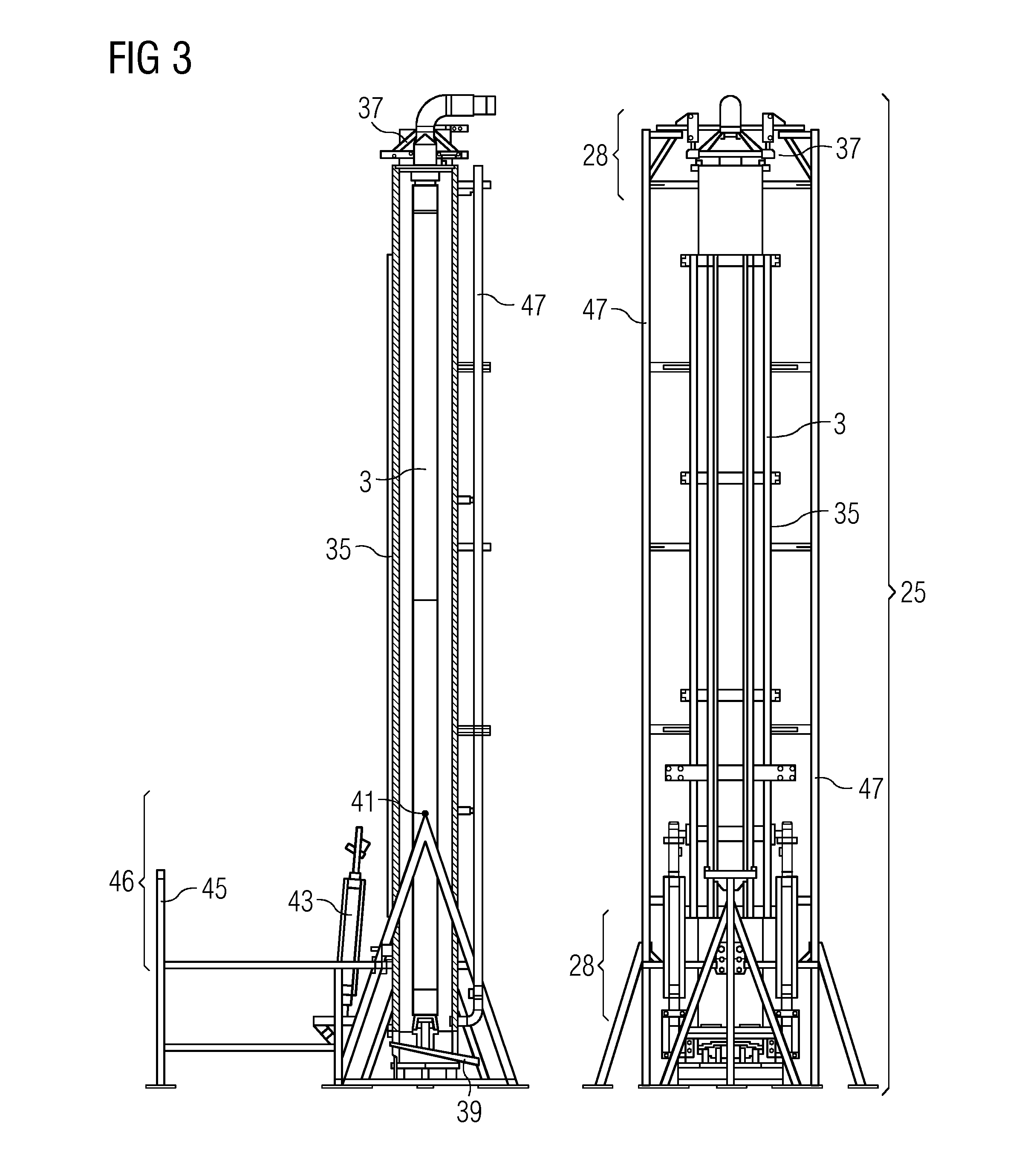

Apparatus for applying a coating to a roof or other substrate

ActiveUS20060005765A1Accurate coatingQuick changeLiquid surface applicatorsMovable spraying apparatusReciprocating motionSpray coating

A device adapted to dispense or spray a coating such as a foam in a predetermined pattern or manner on a substrate, preferably a roof. The spray coating apparatus comprises a spray assembly having a carriage which is operatively mounted on a track that preferably provides a linear travel path. The carriage is controlled by a drive mechanism which causes reciprocating movement of the carriage. A spray gun is mounted on a holder of the carriage and controlled by an actuator and is used to uniformly apply coatings at a predetermined thickness controlled in part by a spray rate on the intended substrate. In one embodiment, the apparatus includes a cart which is either motorized or manual. The apparatus is lightweight and easily disassembled into sections in order to transport the device from a ground surface to a roof.

Owner:DAVIDSON JAMES W

Electrically conductive touch pen

ActiveUS8847930B2Easy to useEffective insulationWriting connectorsBall-point pensEngineeringCarbon deposit

A combination writing pen and stylus is disclosed. The device has an internal ink cartridge deployable through a hole in the stylus tip. The stylus tip extends from a sleeve that is formed of a conductive elastomeric material. The sleeve extends up a rigid shaft of the device such that it contacts a sufficient ground. The stylus tip may be coated with a protective material that adjusts the coefficient of friction and prevents carbon deposits on the touch screen. A sufficient contact patch is achieved to simulate a human finger so as to overcome false positives from common touch screen logic. This is done by altering tip geometries around an air cavity within the sleeve.

Owner:PIXEL PEN LLC

Apparatus for applying a coating to a roof or other substrate

ActiveUS7118629B2Accurate coatingQuick changeLiquid surface applicatorsMovable spraying apparatusReciprocating motionSpray coating

A device adapted to dispense or spray a coating such as a foam in a predetermined pattern or manner on a substrate, preferably a roof. The spray coating apparatus comprises a spray assembly having a carriage which is operatively mounted on a track that preferably provides a linear travel path. The carriage is controlled by a drive mechanism which causes reciprocating movement of the carriage. A spray gun is mounted on a holder of the carriage and controlled by an actuator and is used to uniformly apply coatings at a predetermined thickness controlled in part by a spray rate on the intended substrate. In one embodiment, the apparatus includes a cart which is either motorized or manual. The apparatus is lightweight and easily disassembled into sections in order to transport the device from a ground surface to a roof.

Owner:DAVIDSON JAMES W

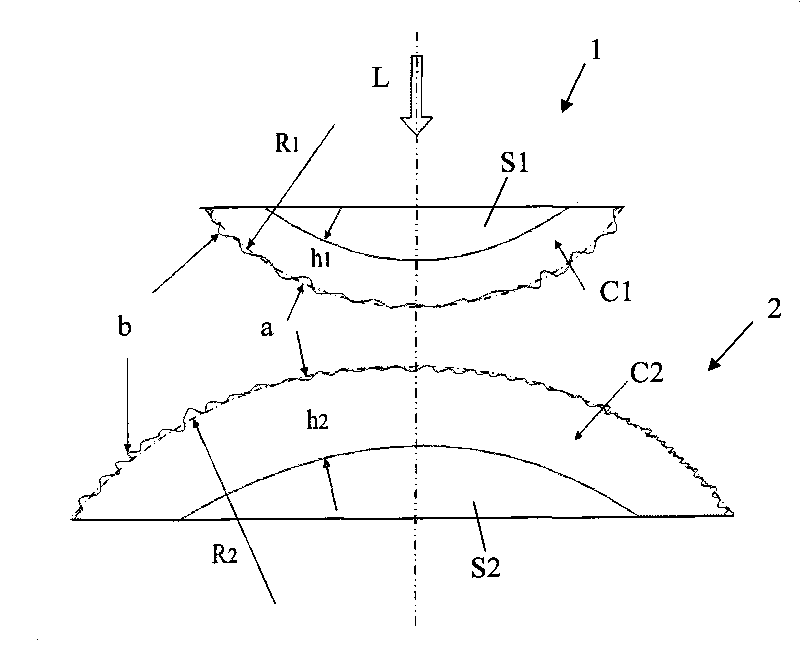

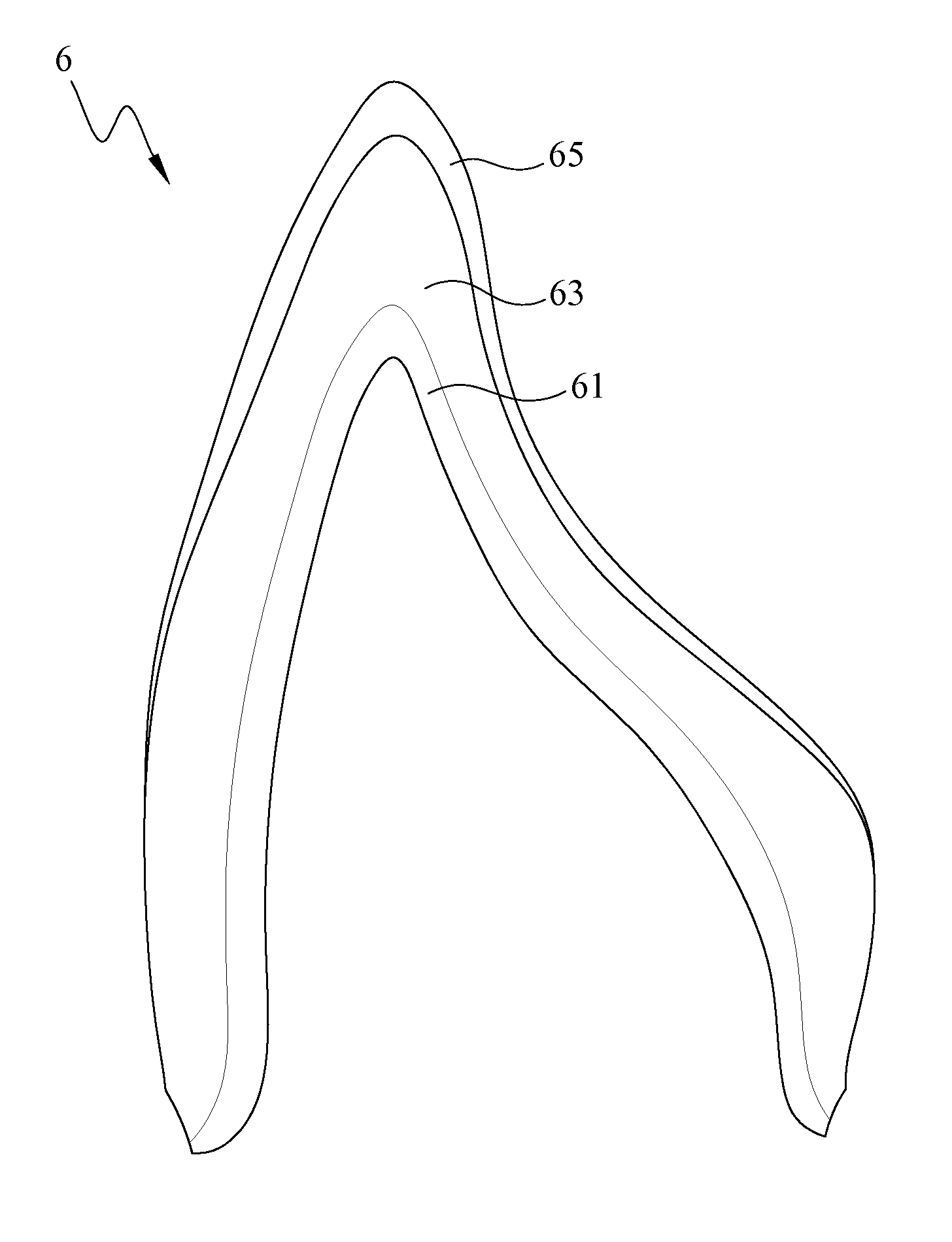

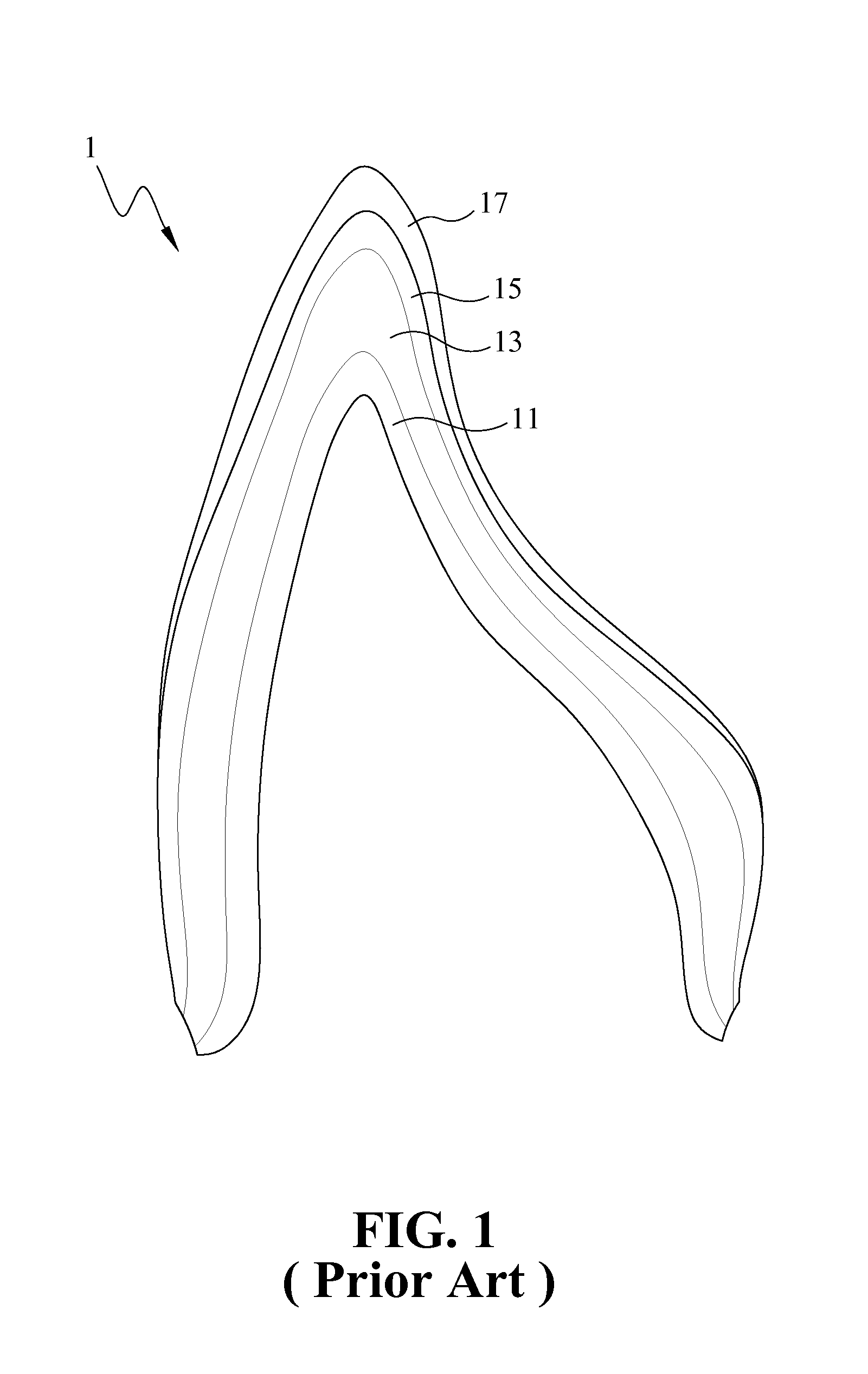

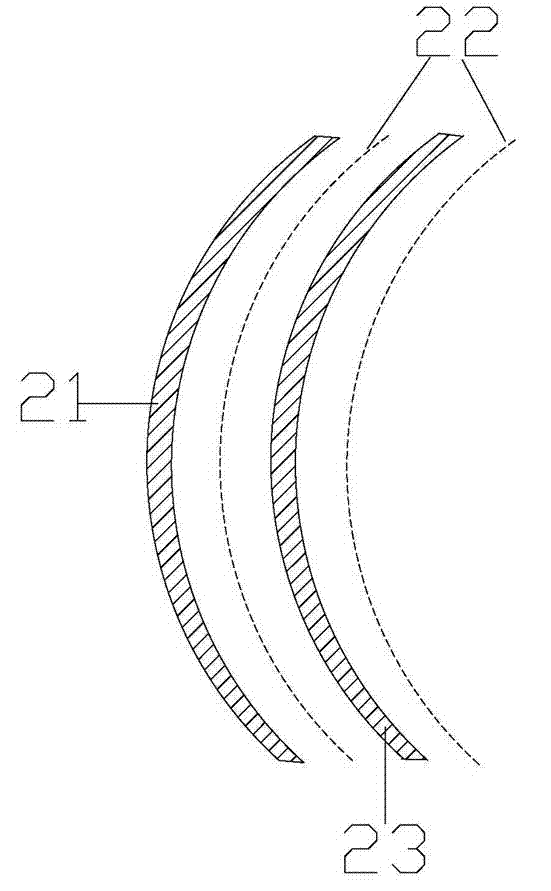

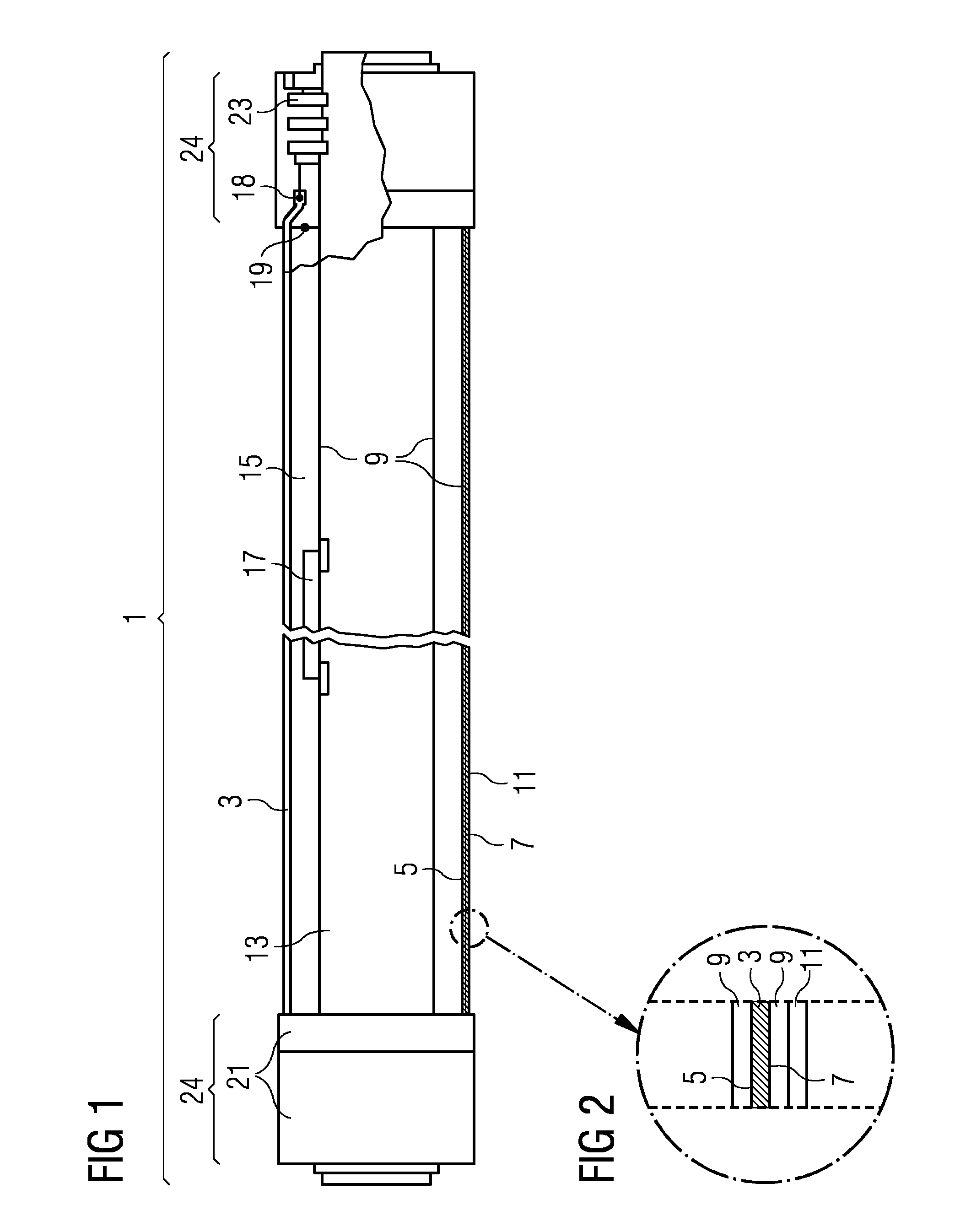

Method for determining amount of wear, method for manufacturing sliding contact, and sliding contact

InactiveCN102278966AImprove reliability and service lifeExtended service lifeLinear bearingsSliding contact bearingsBiomedical engineeringOperating life

The invention discloses a method for determining abrasion amount of a solid lubricating coating for a sliding contact component, and the sliding contact component and a manufacturing method of the sliding contact component. The method for determining the abrasion amount comprises the following steps of: on the basis of a load, the geometrical shape of a contact part and material parameters, computing distribution of contact pressure between the sliding contact component and a matched body; and on the basis of the distribution of the contact pressure, the relative movement velocity of the contact part and an abrasion coefficient of the solid lubricating coating, determining the time-related abrasion amount of the solid lubricating coating. The manufacturing method comprises the following steps of: after determining the time-related abrasion amount of the solid lubricating coating, acquiring initial outline parameters of the solid lubricating coating on the basis of the abrasion amount and the service life of the sliding contact component; and on the basis of the initial outline parameters, forming the solid lubricating coating on a base body of the sliding contact component. The solid lubricating coating on the sliding contact component can be quickly determined and has the precise size and surface outline; the reliability of the sliding contact component is improved; and the service life of the sliding contact component is prolonged.

Owner:ROBERT BOSCH GMBH +1

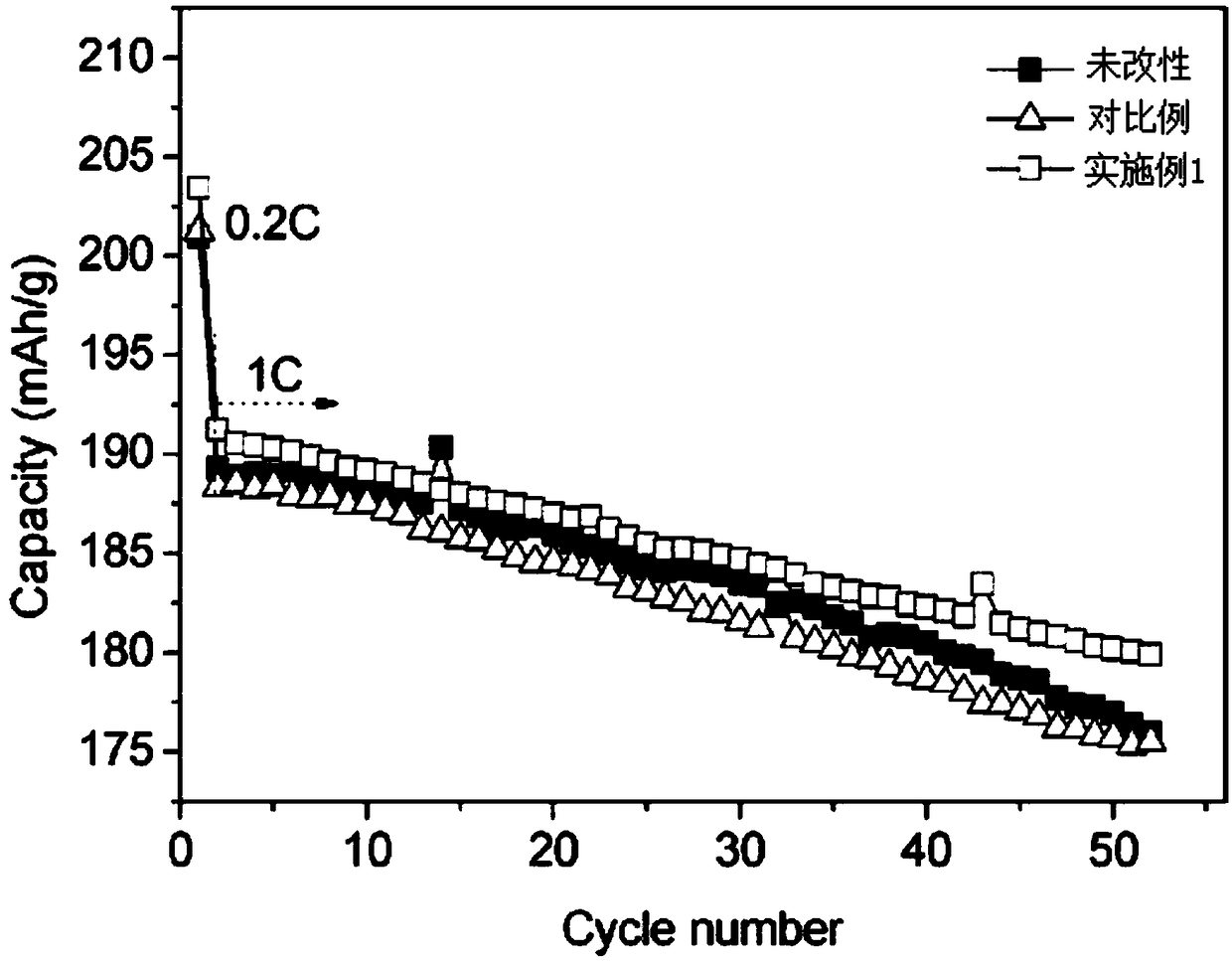

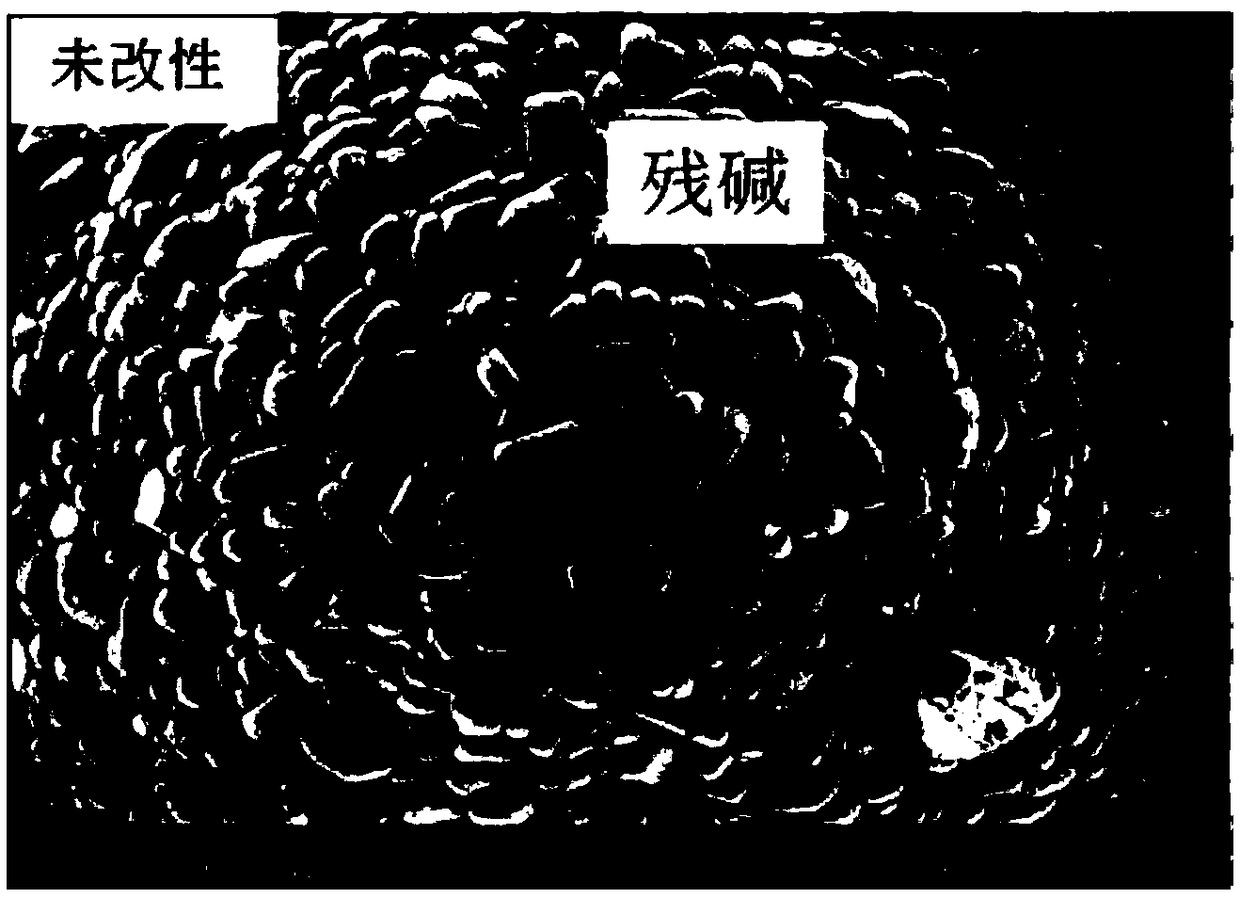

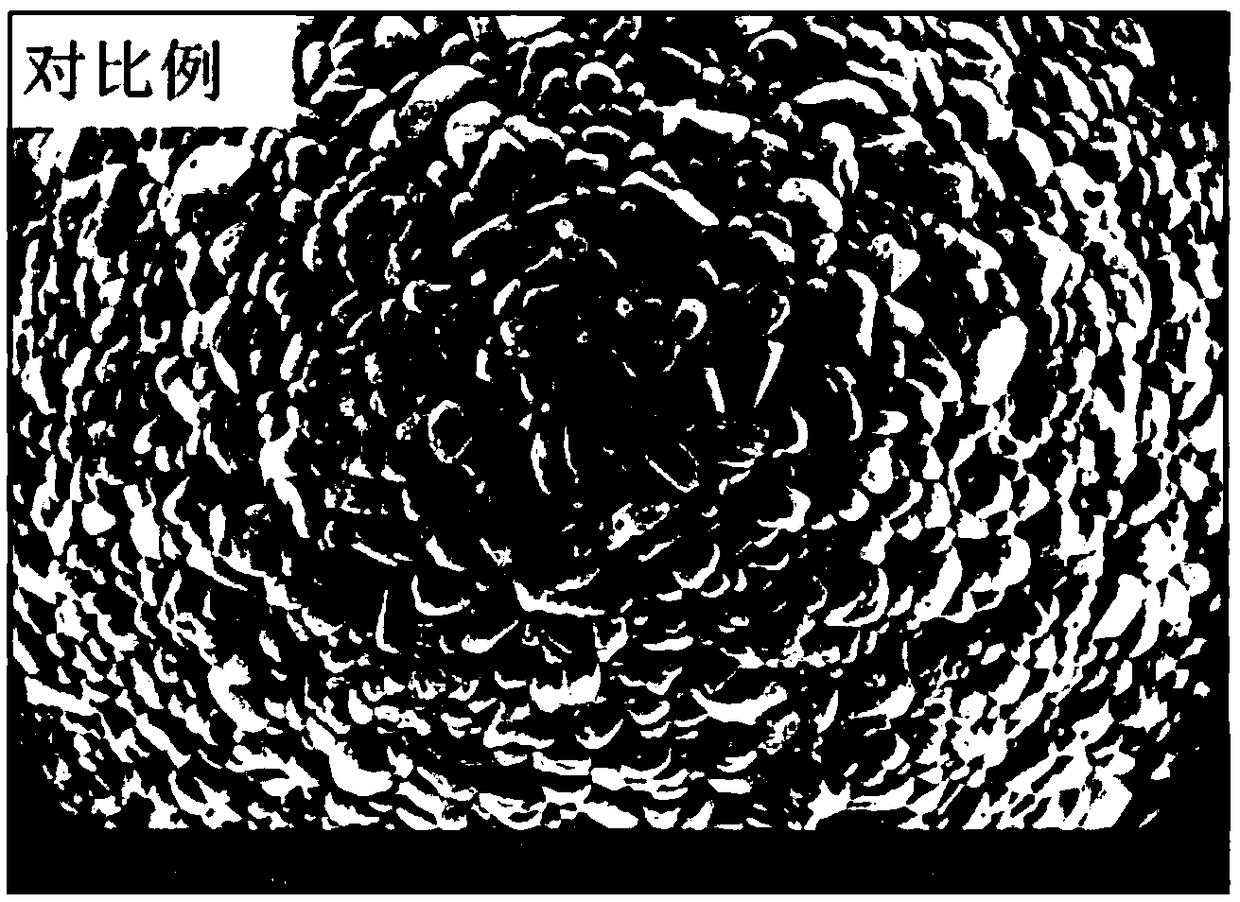

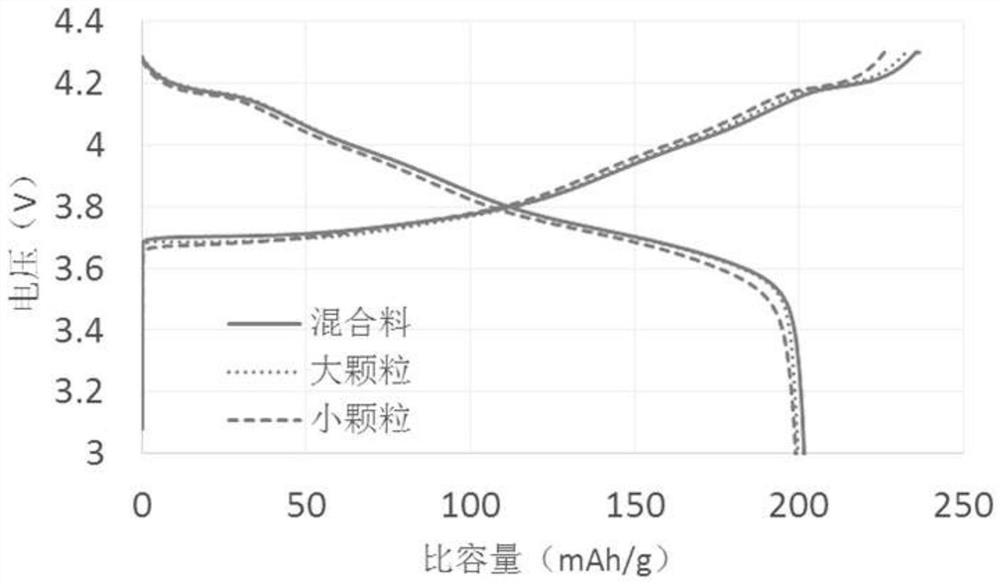

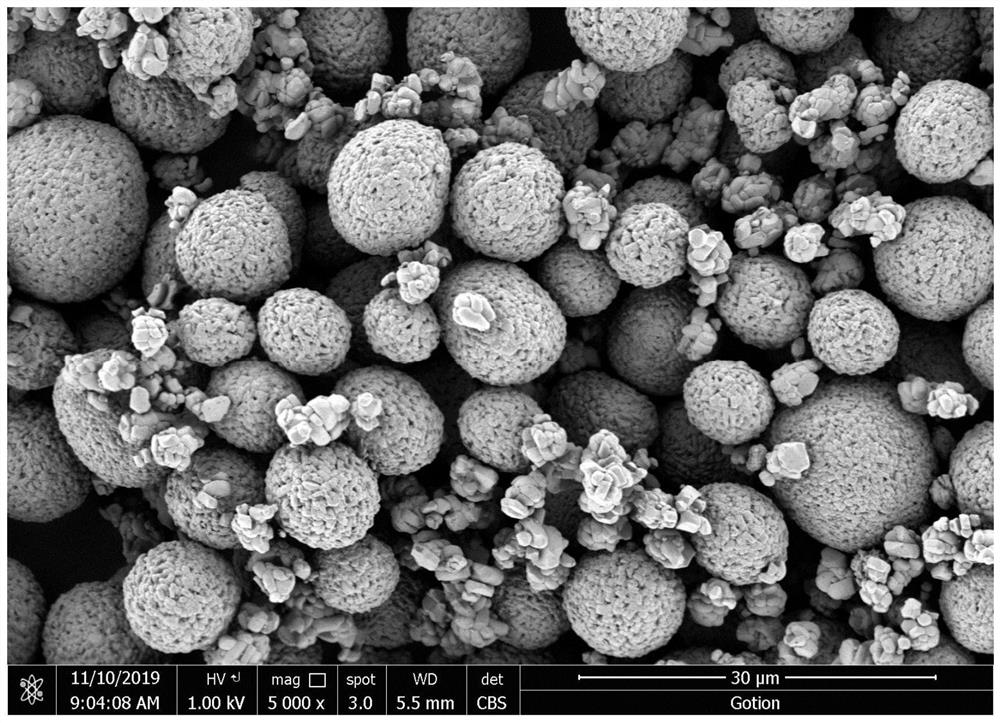

Preparation method for high-nickel ternary material of lithium ion battery

ActiveCN109473652ATargetedEasy to modifyMaterial nanotechnologyCell electrodesLithium hydroxideSodium-ion battery

The invention discloses a preparation method for a high-nickel ternary material of a lithium ion battery. Firstly, a high-nickel ternary hydroxide precursor prepared in a continuous co-precipitation method and micro-powder lithium hydroxide are mixed and sintered to prepare high-nickel ternary materials; then, the high-nickel ternary materials are graded according to the size, and the graded two-stage materials are respectively subjected to centrifugal dewatering, vacuum drying, coating of nanometer oxide in a dry method, secondary sintering, crushing and degaussing; and finally, the two-stagematerials are fully mixed to obtain the high-nickel ternary material of the lithium ion battery. According to the method in the invention, the high-nickel ternary materials are graded; then, the graded size particles are washed and coated respectively; and finally, the modified high-nickel ternary materials are mixed, thereby eliminating the difference of the high-nickel ternary materials with different particle diameters in the water washing and coating processes.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

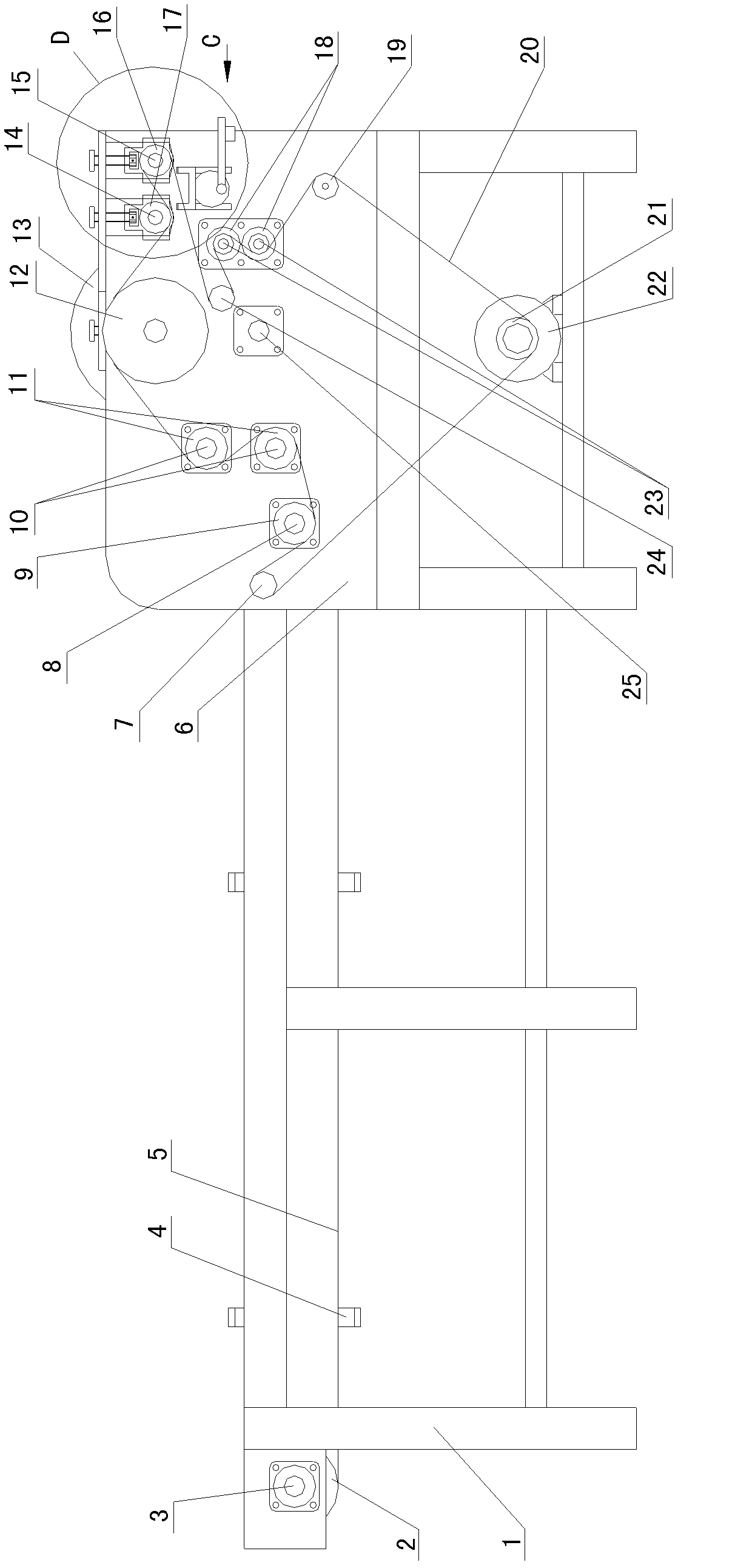

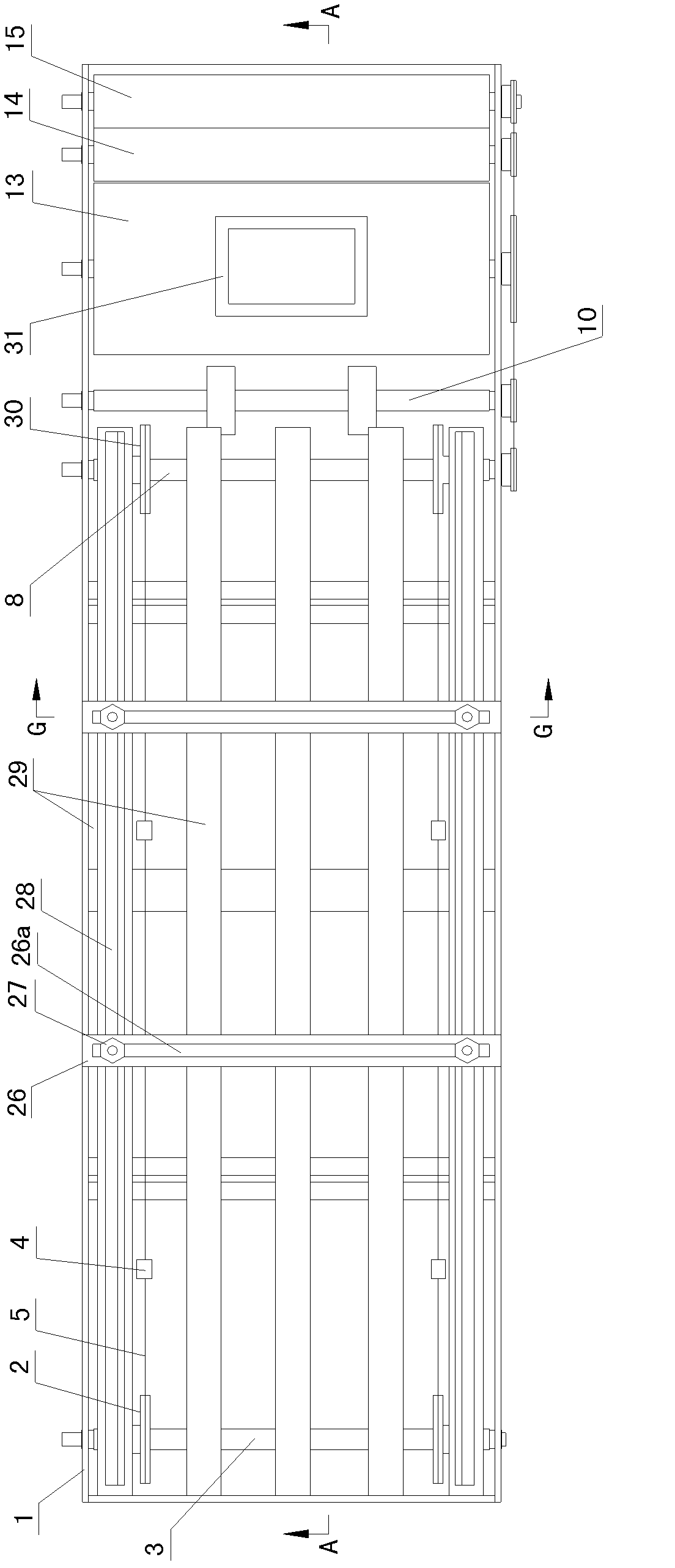

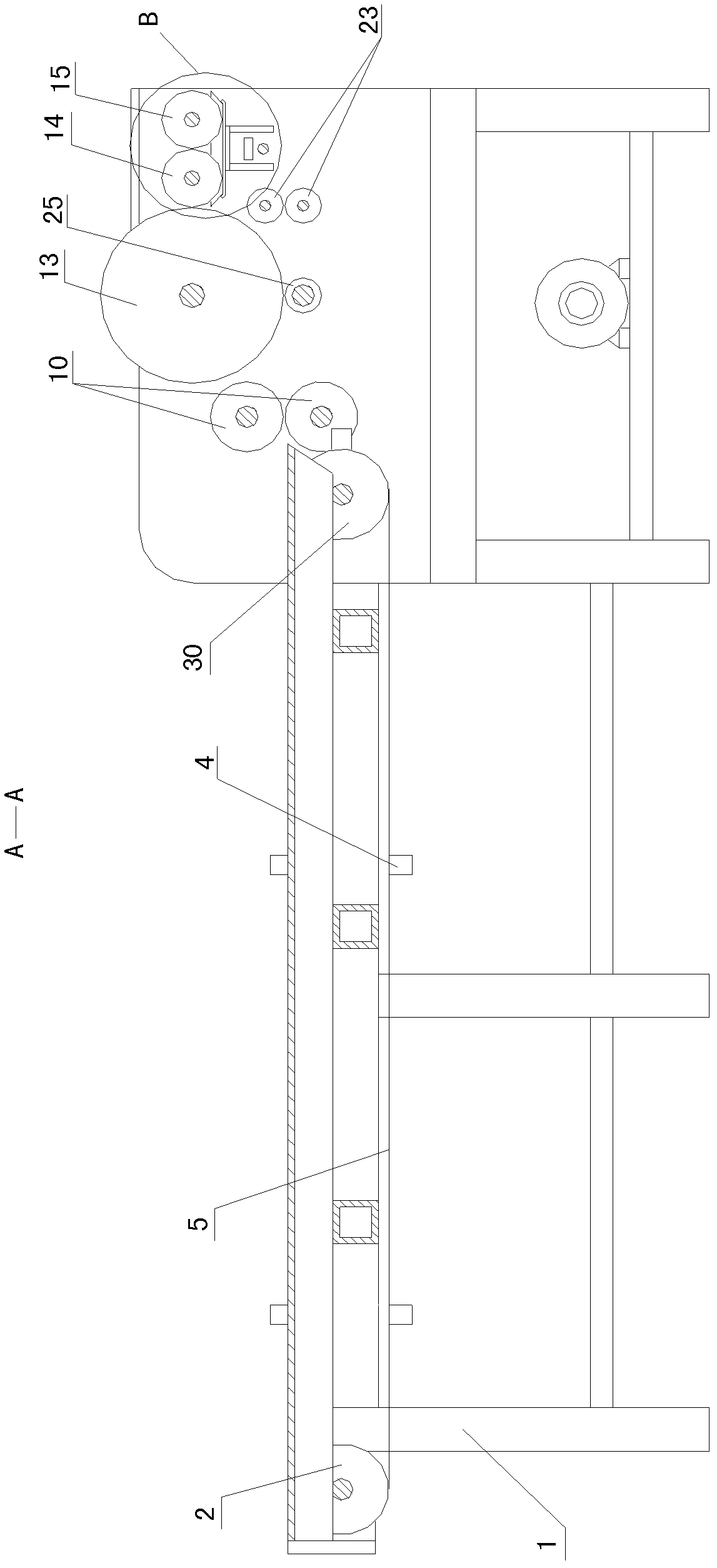

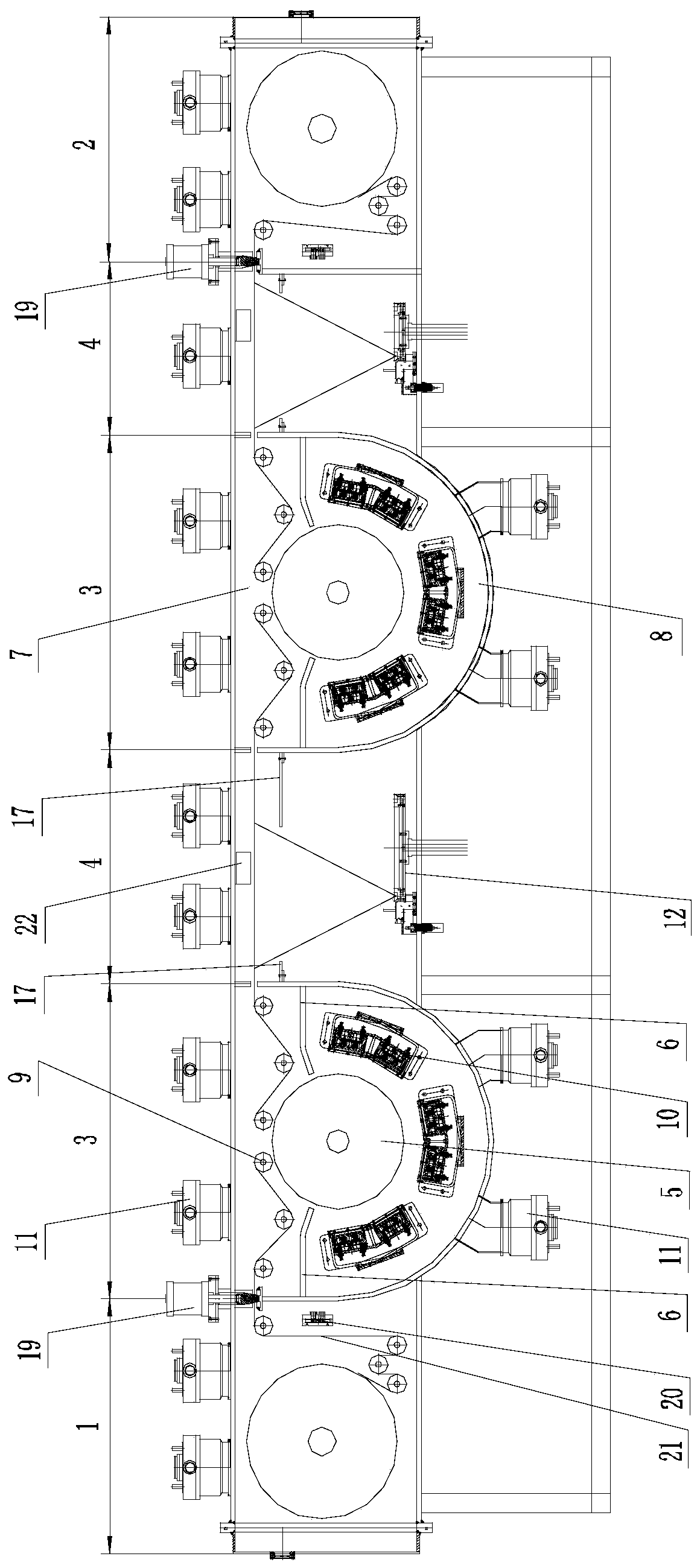

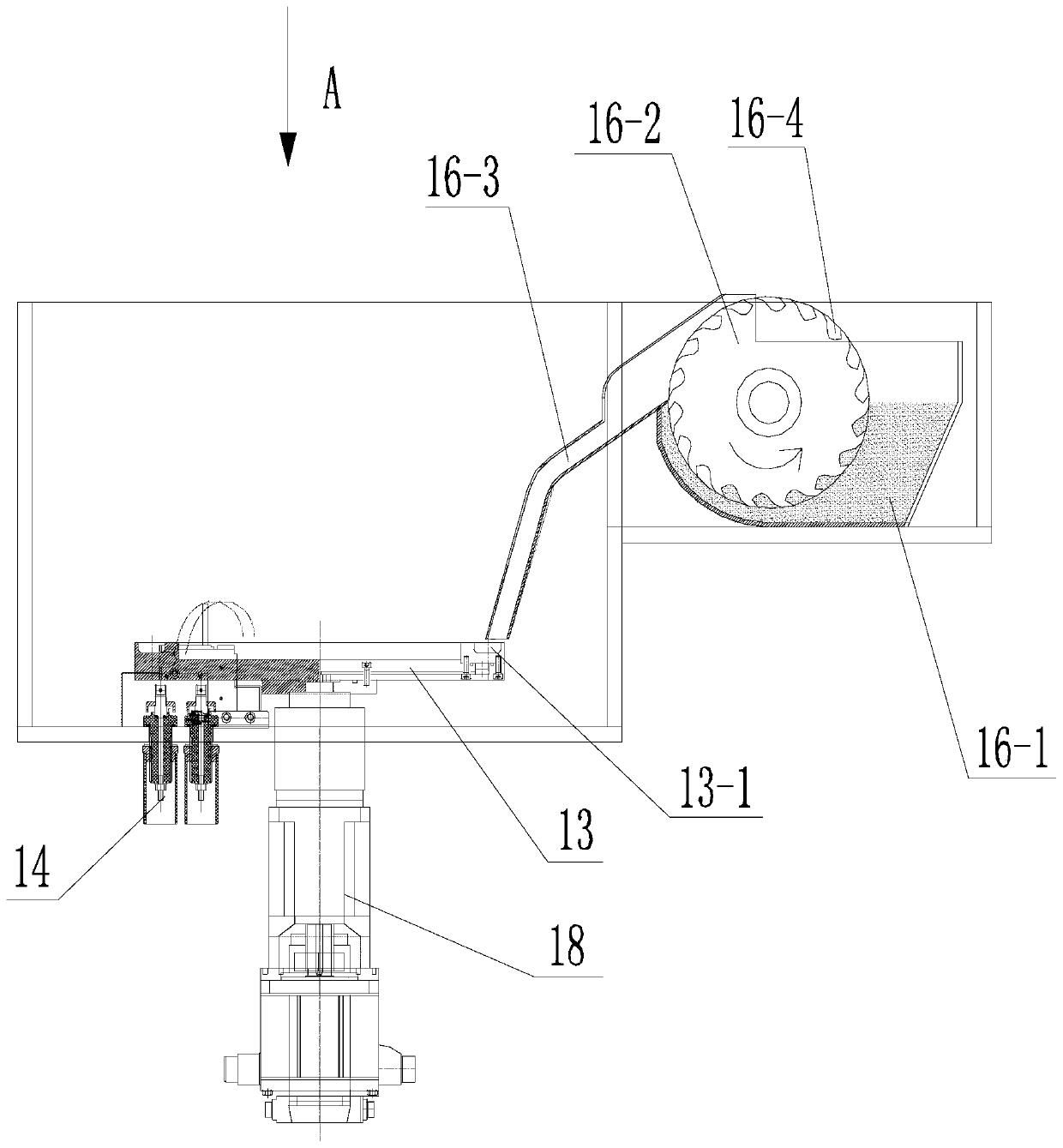

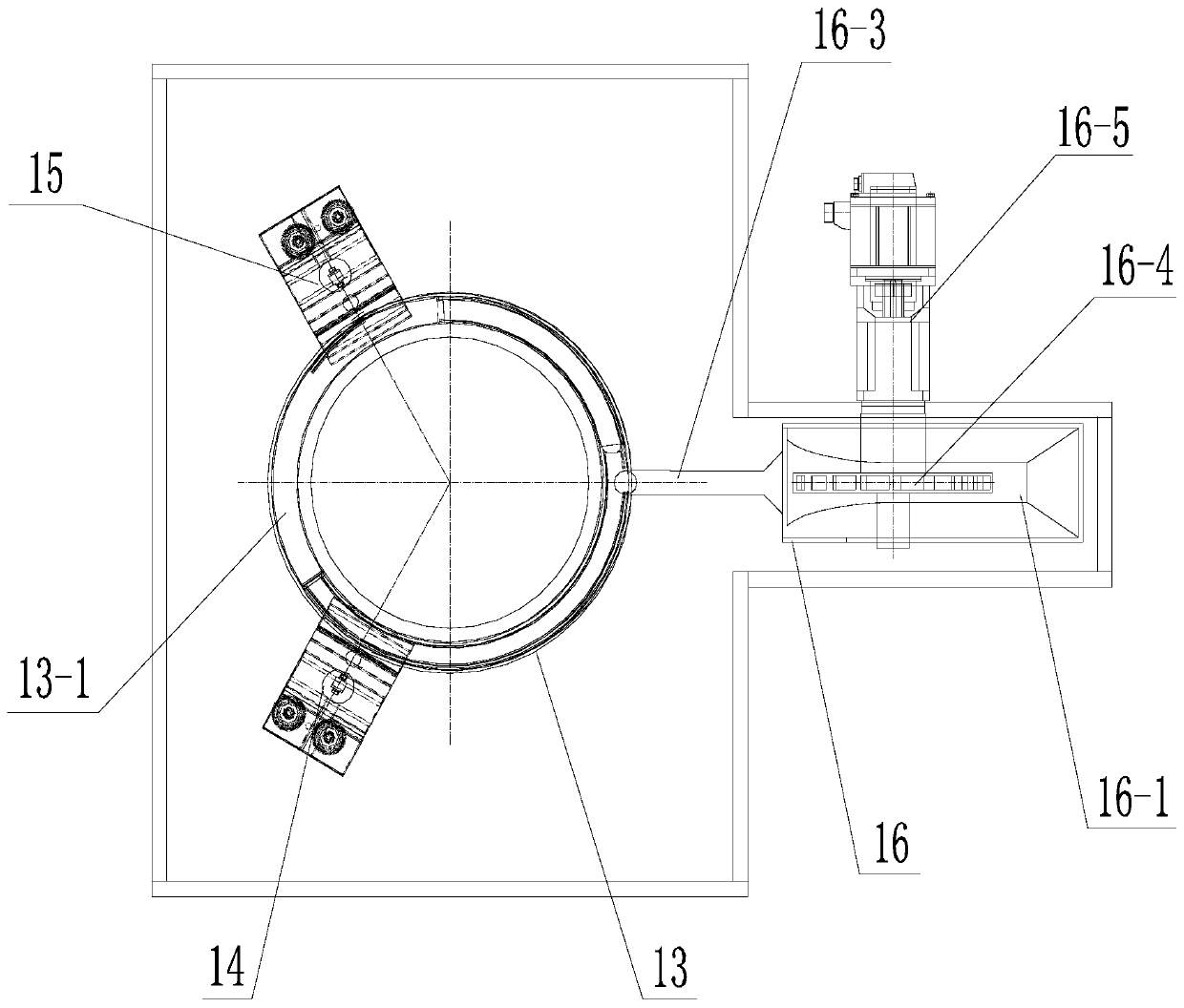

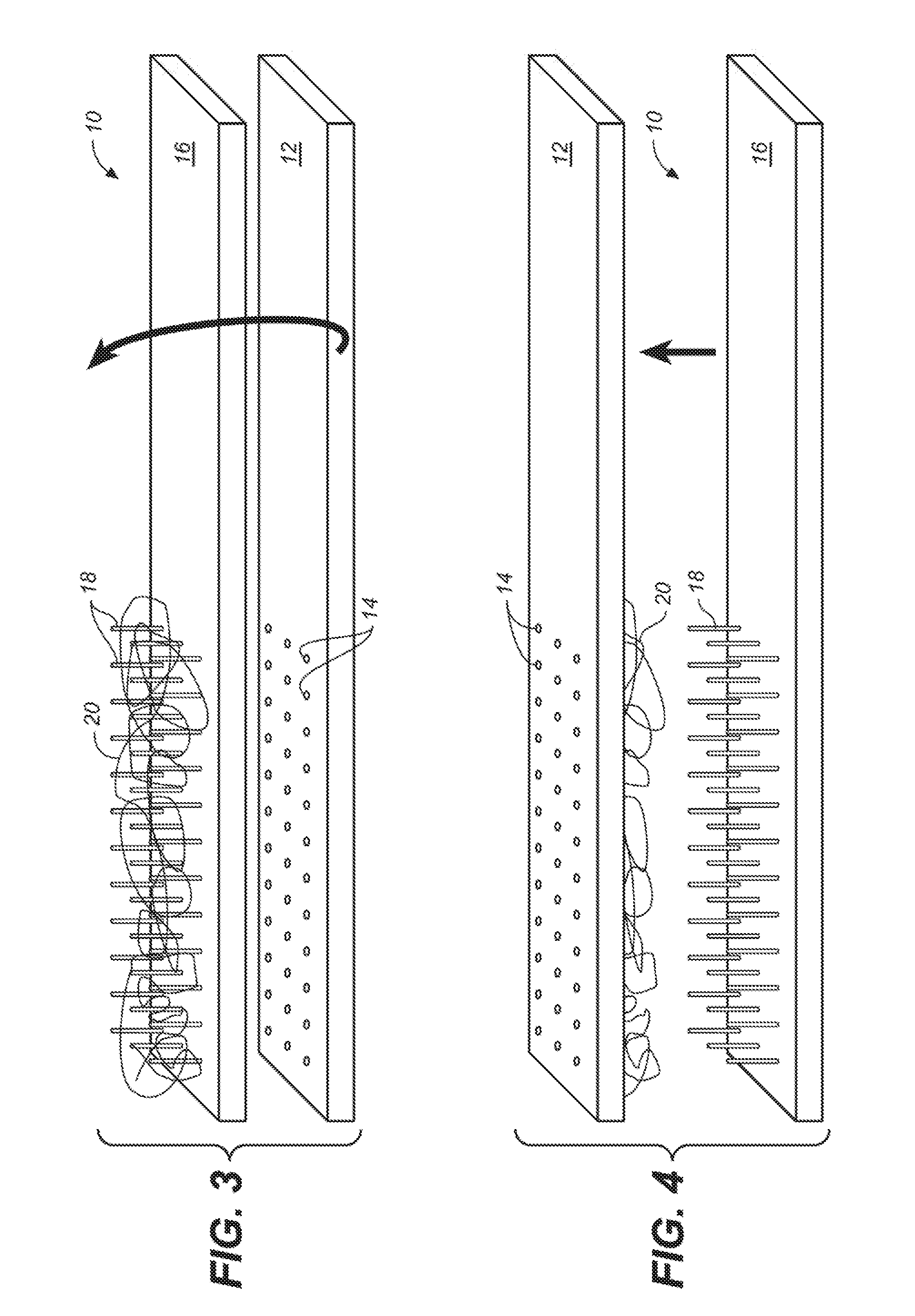

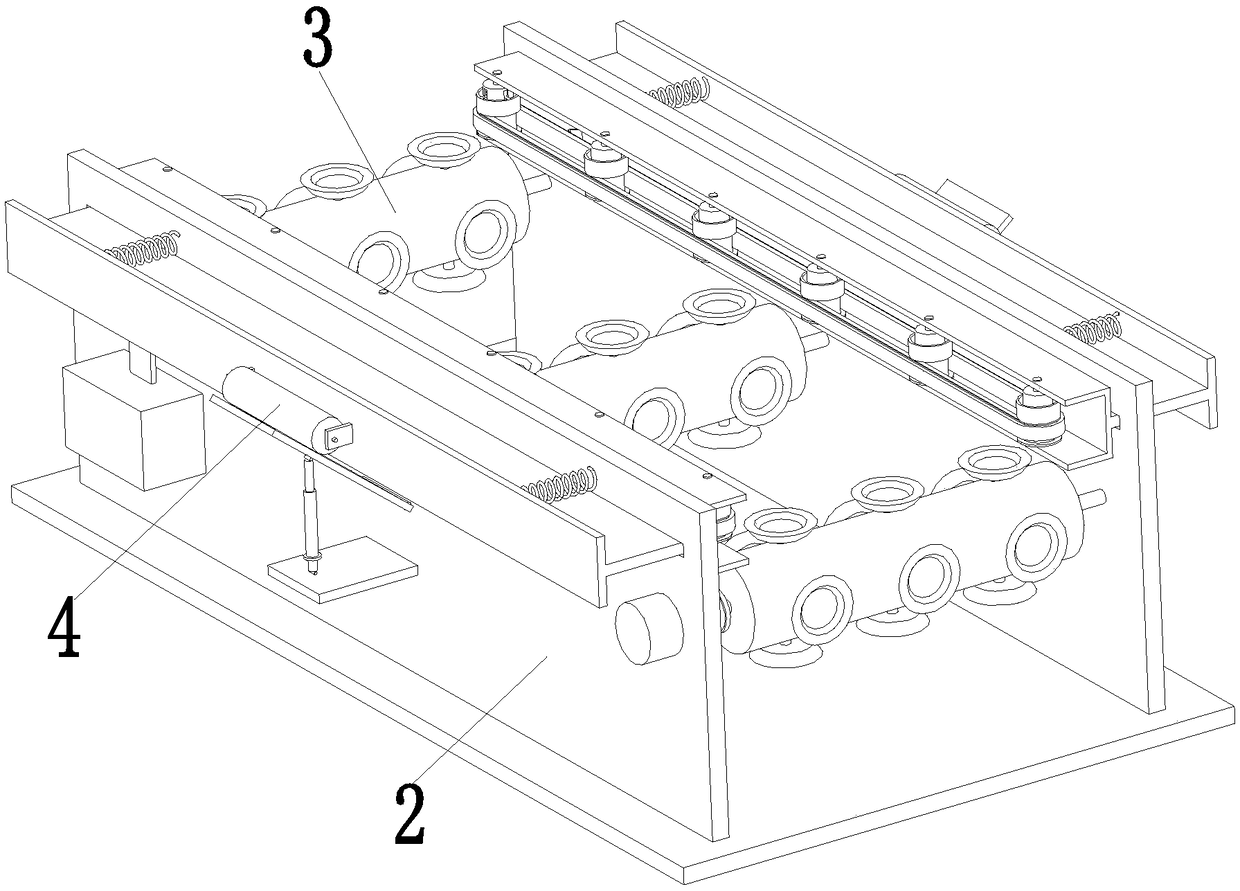

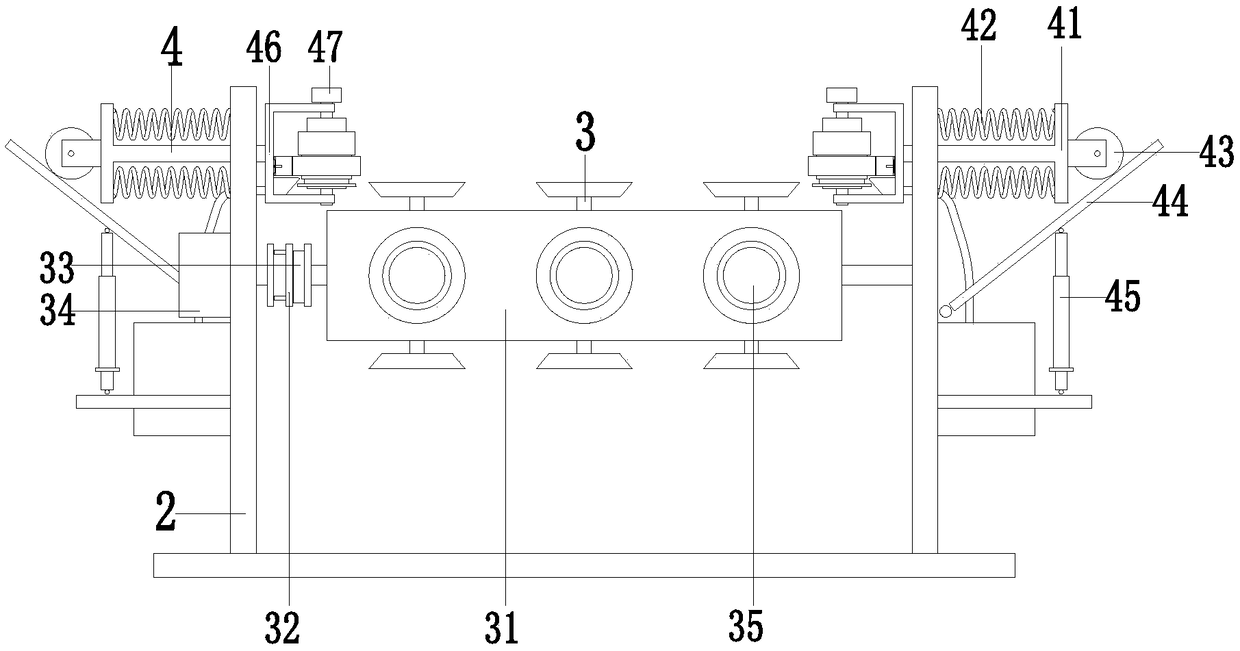

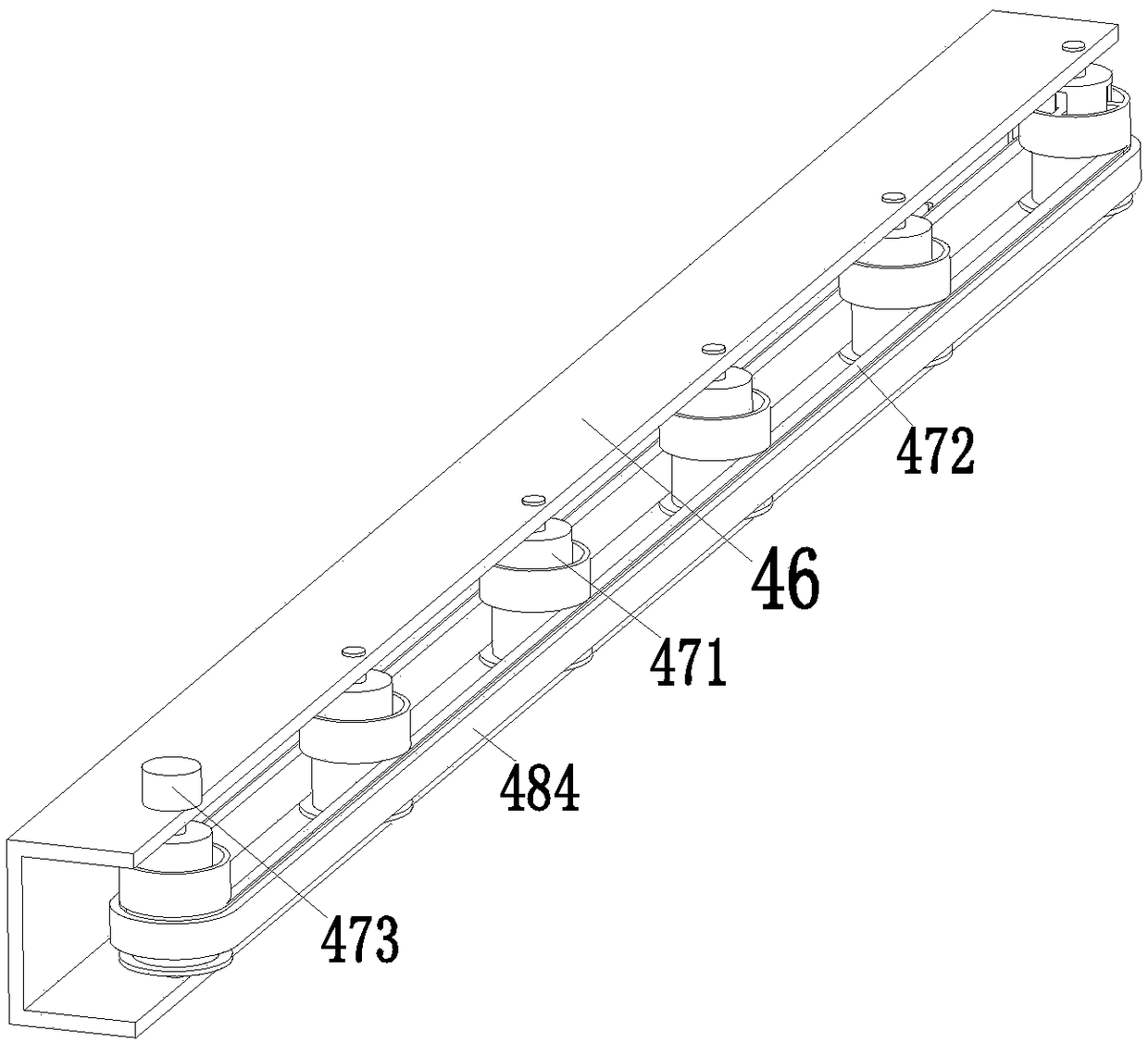

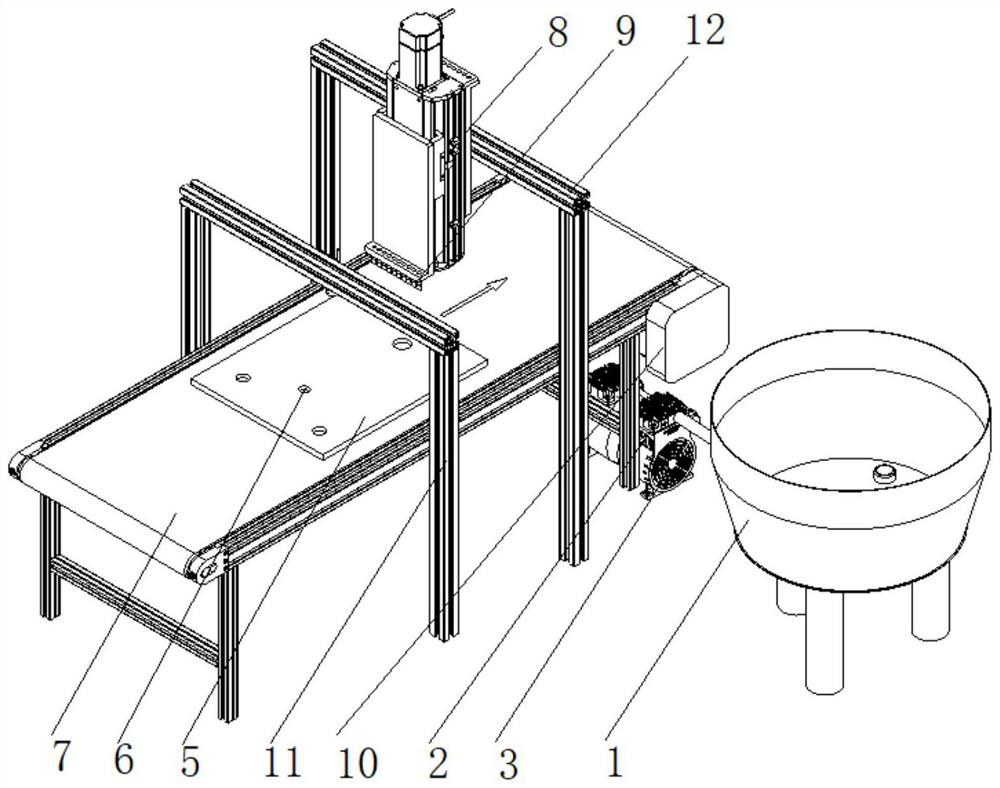

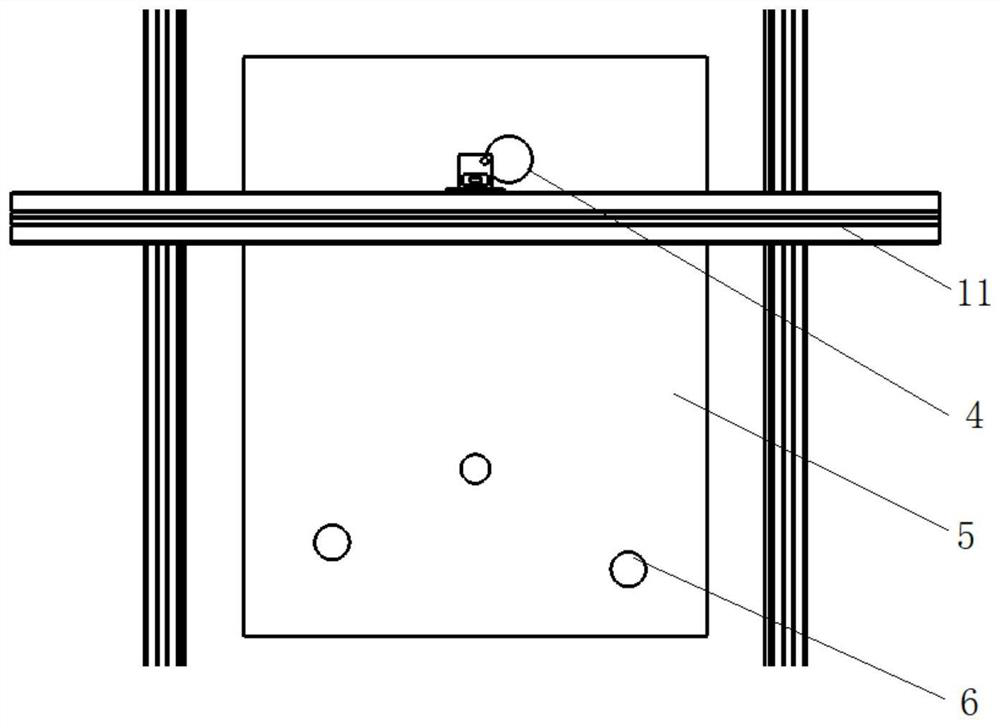

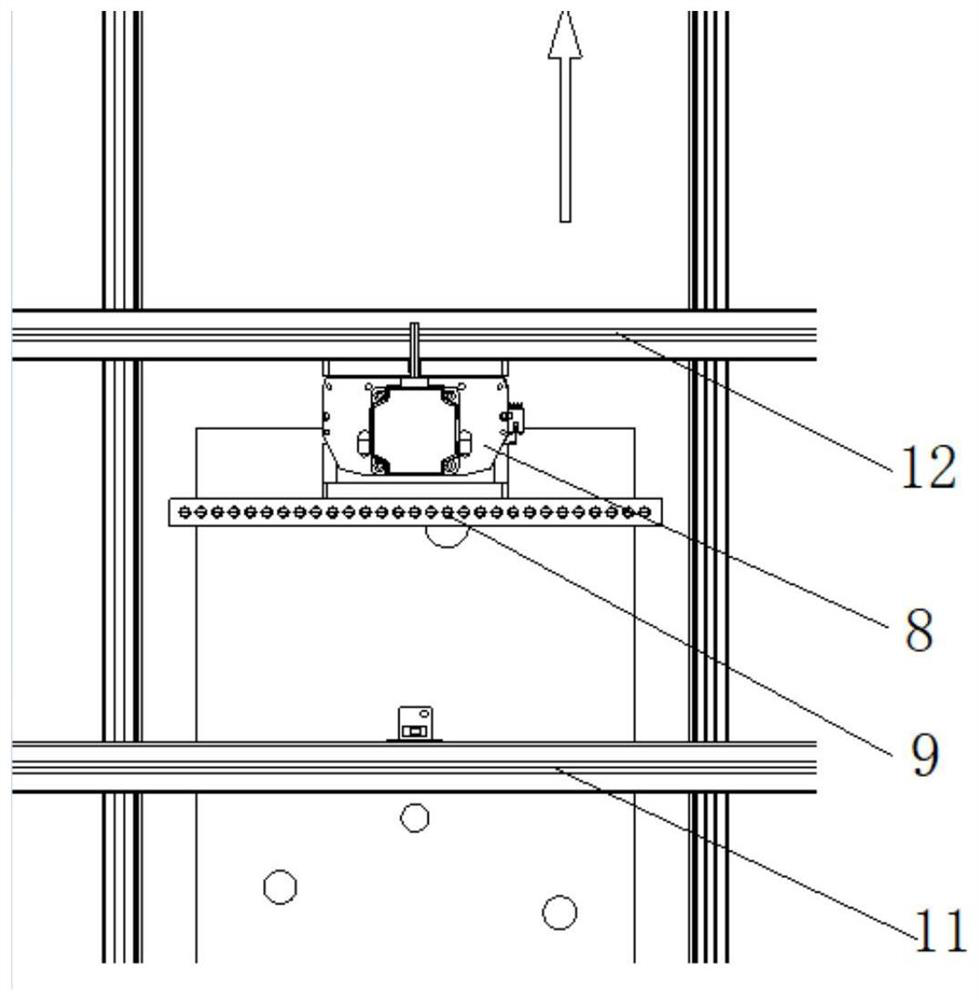

Semi-automatic window patching machine

InactiveCN102555293AImprove processing efficiencyReduce labor intensityContainer making machineryDrive shaftPolyvinyl chloride

Disclosed is a semi-automatic window patching machine. A framework is connected at one end of a worktable, a glue distributing strip is attached onto a glue distributing roll mounted on the framework, a laminating roll is disposed on the lower side of the glue distributing roll, a glue supply mechanism is arranged on the framework, a feeding mechanism arranged at the front of the glue distributing roll is provided with a driving shaft and a driven shaft, the driving shaft and the driven shaft are mounted on the worktable, two driving sprockets are respectively mounted at two ends of the driving shaft, two driven sprockets are respectively mounted at two ends of the driven shaft, a conveying chain is mounted on the driving sprockets and the driven sprockets, and a plurality of shifting claws are fixed onto the conveying chain. The glue distributing roll, the feeding mechanism and the glue supply mechanism run, sheets of packing boxes are placed on the worktable, glue can be accurately coated at edges of windows of the packing boxes by the aid of the glue distributing strip when the sheets of the packing boxes are pushed by the shifting claws to pass through the glue distributing roll and the laminating roll, and after the packing boxes are outputted, PVC (polyvinyl chloride) plates or films of the PVC plates can be manually, quickly and accurately attached onto the windows of the packing boxes. The semi-automatic window patching machine is reliable in structure and performance and low in cost.

Owner:丁长生 +1

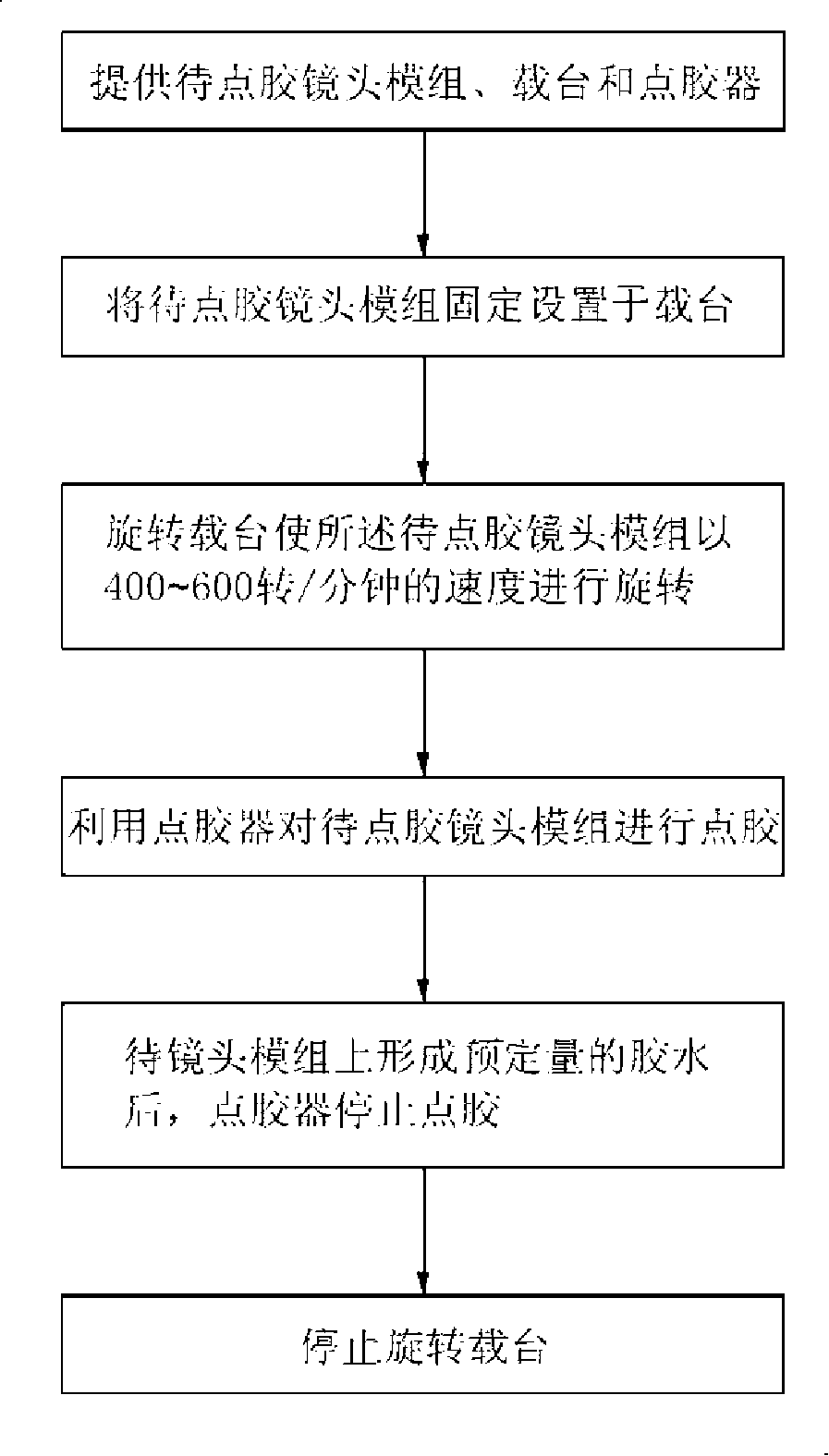

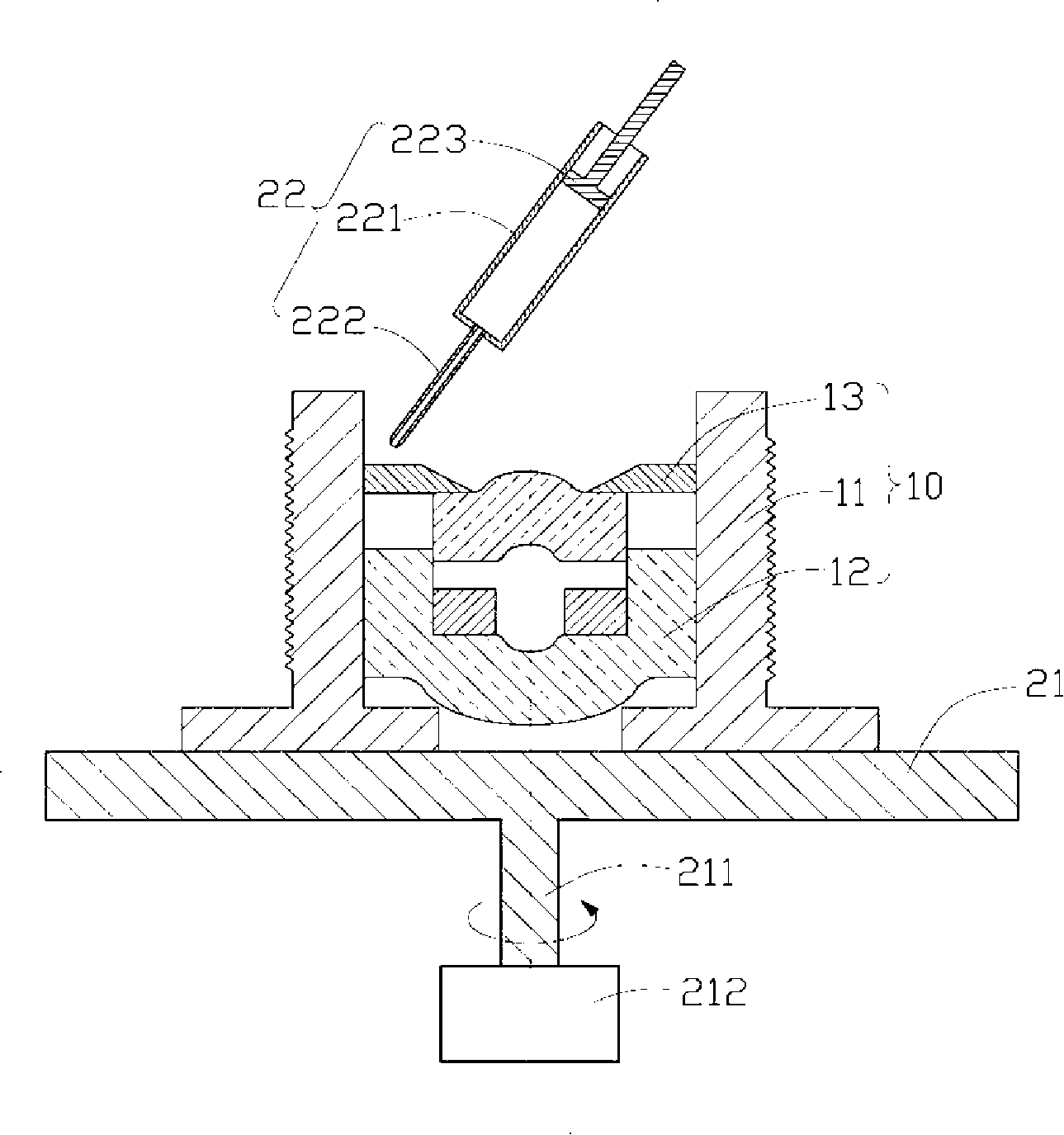

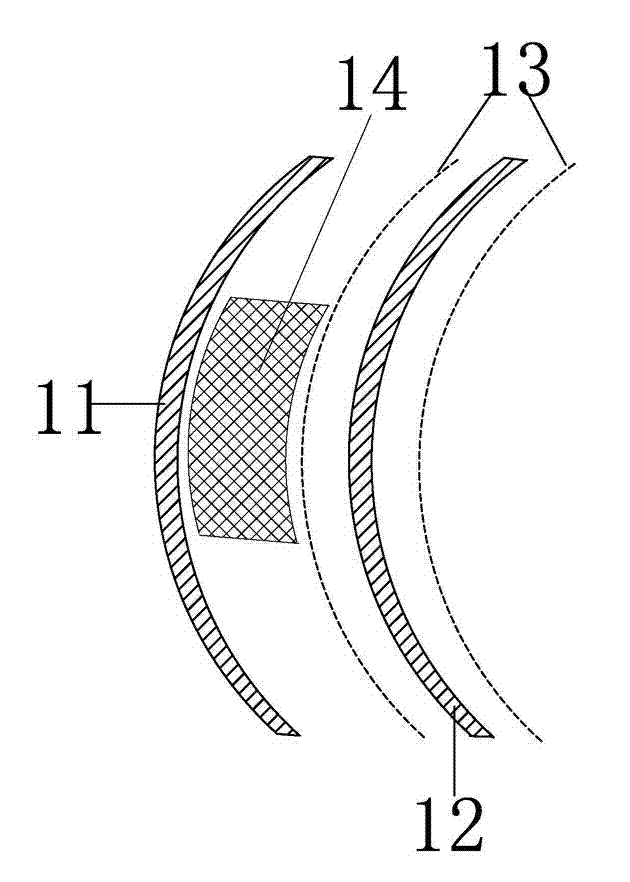

Method for spotting glue for lens module

The invention provides a dispensing method for a lens module group. The invention comprises the steps that a lens module group for dispensing, a stage and a dispensing device are provided; the lens module group for dispensing is fixed and mounted on the stage; the stage is revolved so that the lens module group for dispensing rotates with the speed of 400 to 600 rounds per minute; the dispensing device is used for the dispensing of the lens module group; after the predetermined amount of glue is formed on the lens module group, the dispensing device stops dispensing; the revolution of the stage is stopped. In the technology scheme, the stage rotates continuously with the speed of 400 to 600 rounds per minute, so that the glue is coated on the inner wall of the drawtube and the periphery of the spacing ring exactly due to the great centrifugal force, and the overflow of the glue is prevented. Even the dispensing pinhead has a certain distance with the inner wall of the drawtube during the dispensing process, the glue can be coated by spin on the inner wall of the drawtube and the periphery of the spacing ring exactly due to the centrifugal force, which ensures the dispensing quality of the lens module group.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

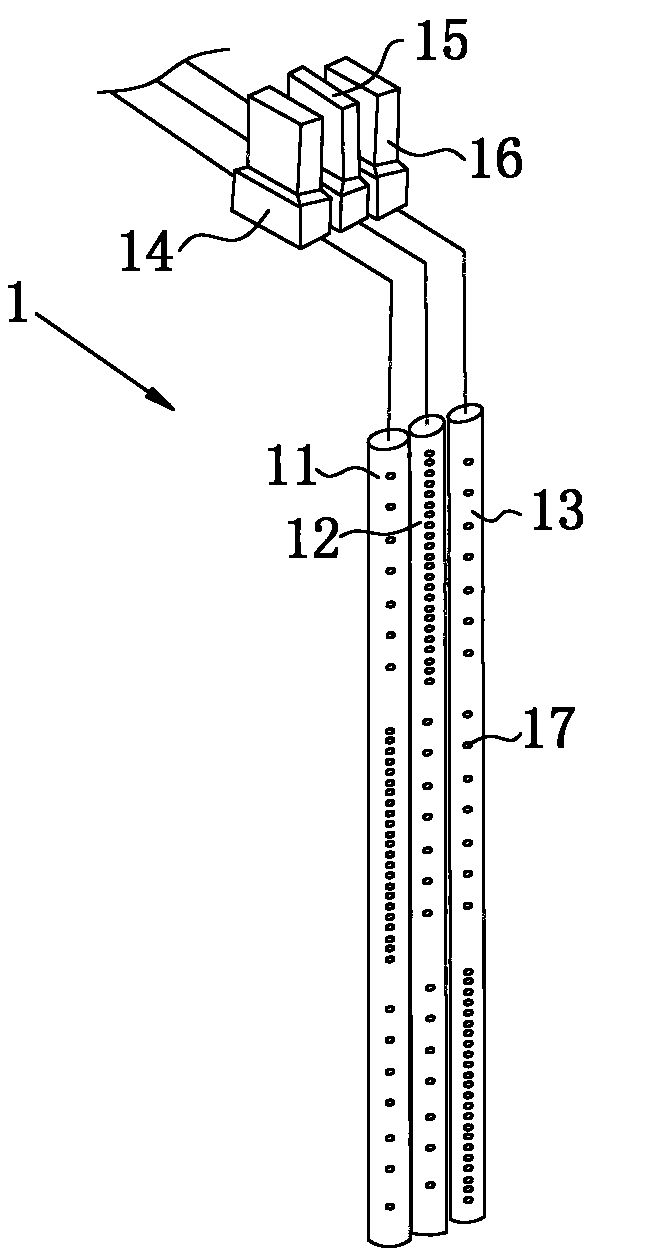

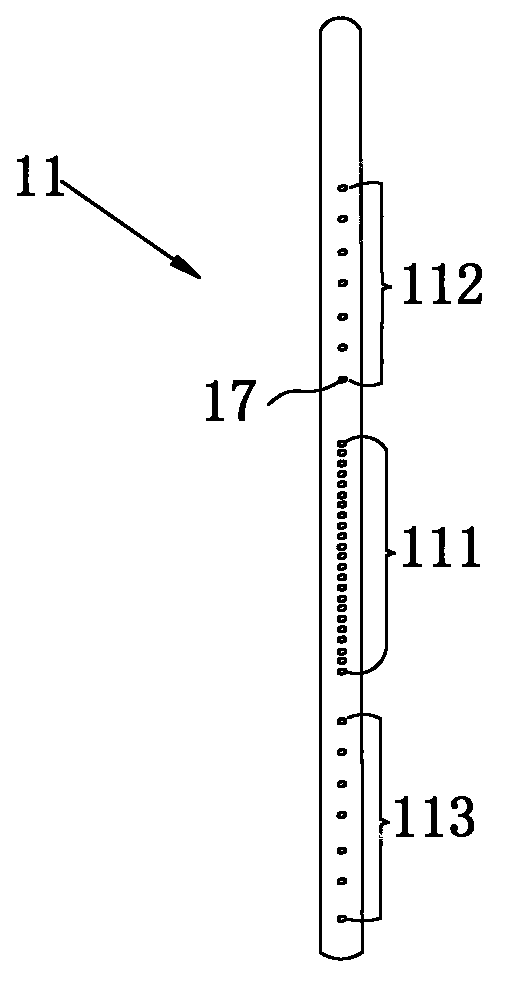

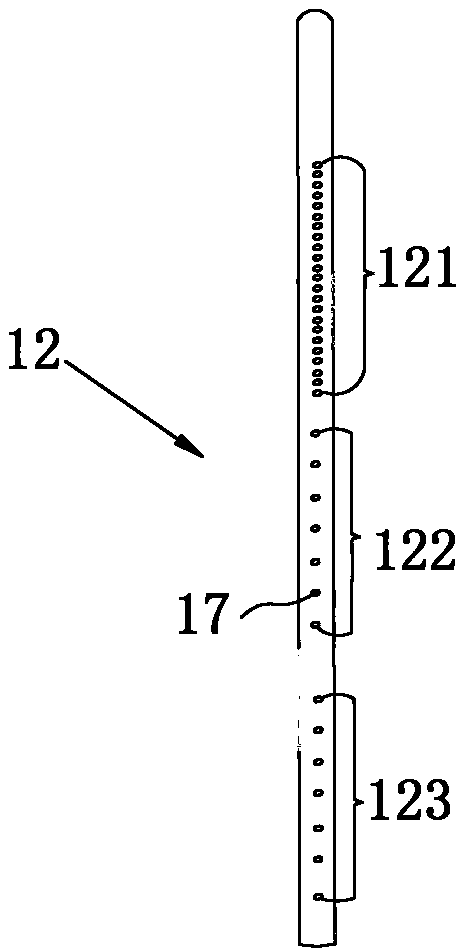

Adjustable gas distribution system and magnetron sputtering coating device comprising same

ActiveCN103014642AFlow adjustableAccurate coatingVacuum evaporation coatingSputtering coatingTarget surfaceThermodynamics

The invention discloses an adjustable gas distribution system and a magnetron sputtering coating device comprising the adjustable gas distribution system. The adjustable gas distribution system comprises at least two parallel gas distribution pipes; a flowmeter is arranged on each gas distribution pipe; blowing parts are arranged on two adjacent gas distribution pipes in a staggered manner and comprise a plurality of air holes which are of the same specification and formed uniformly; each air hole is formed in the radial direction of one gas distribution pipe; and the air holes are arranged in the axial directions of the gas distribution pipes in sequence. The gas distribution system is provided with at least two gas distribution pipes, and the blowing parts are on two adjacent gas distribution pipes in a staggered manner, so that gas blown out by the gas distribution system can reach a target surface uniformly, and then a film is ensured uniformity; the flowmeters are arranged on the gas distribution pipes, so that the flow rate of gas can be adjusted in real time, namely, the flow rate of gas can be adjusted accurately according to the distance between the target surface and the surface of an object to be coated, and different coating thicknesses; and the flow rates of gas blown out from all the gas distribution pipes can be the same, so that the purposes of controlling in real time and coating accurately can be achieved.

Owner:GUANGDONG ZHICHENG CHAMPION GROUP

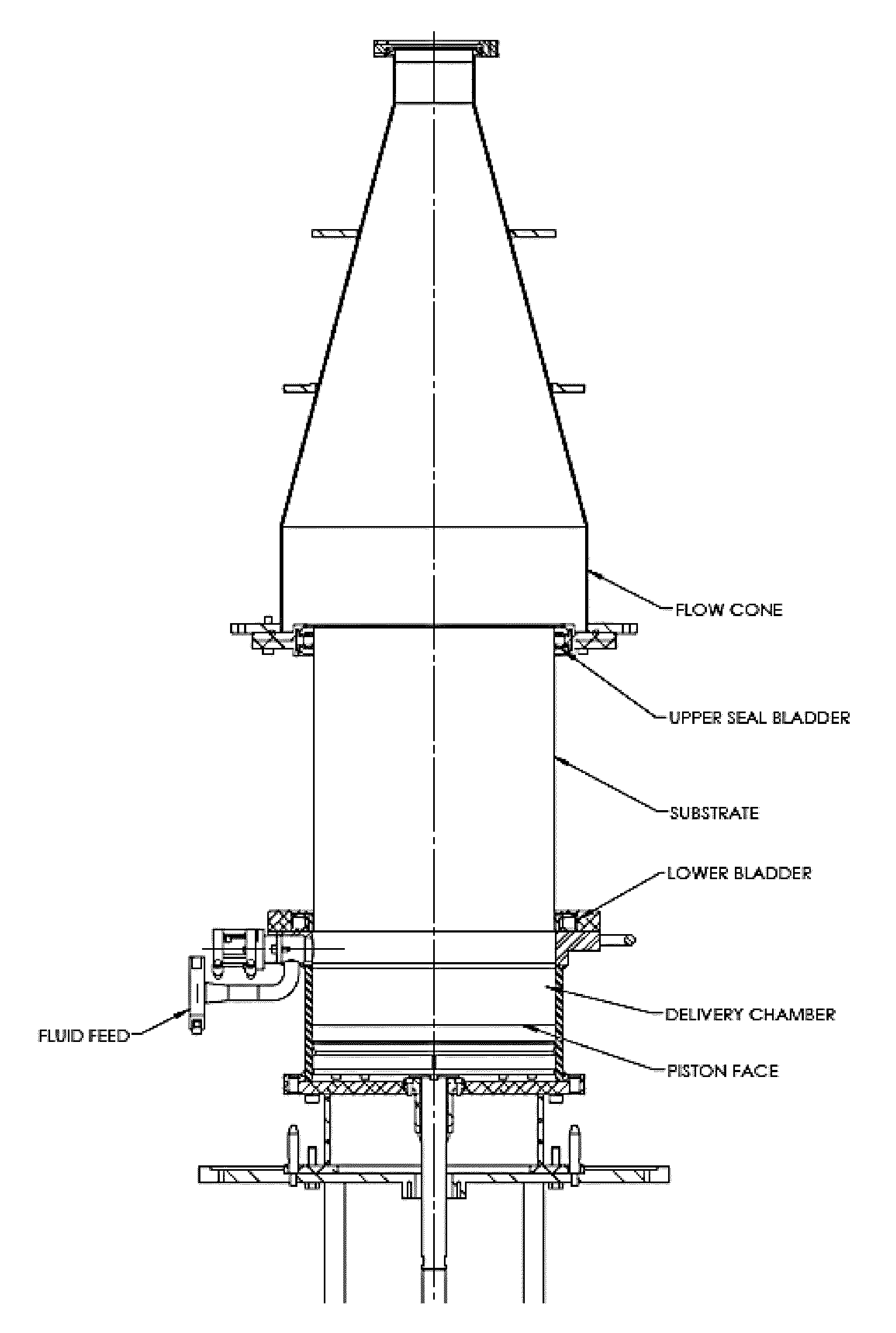

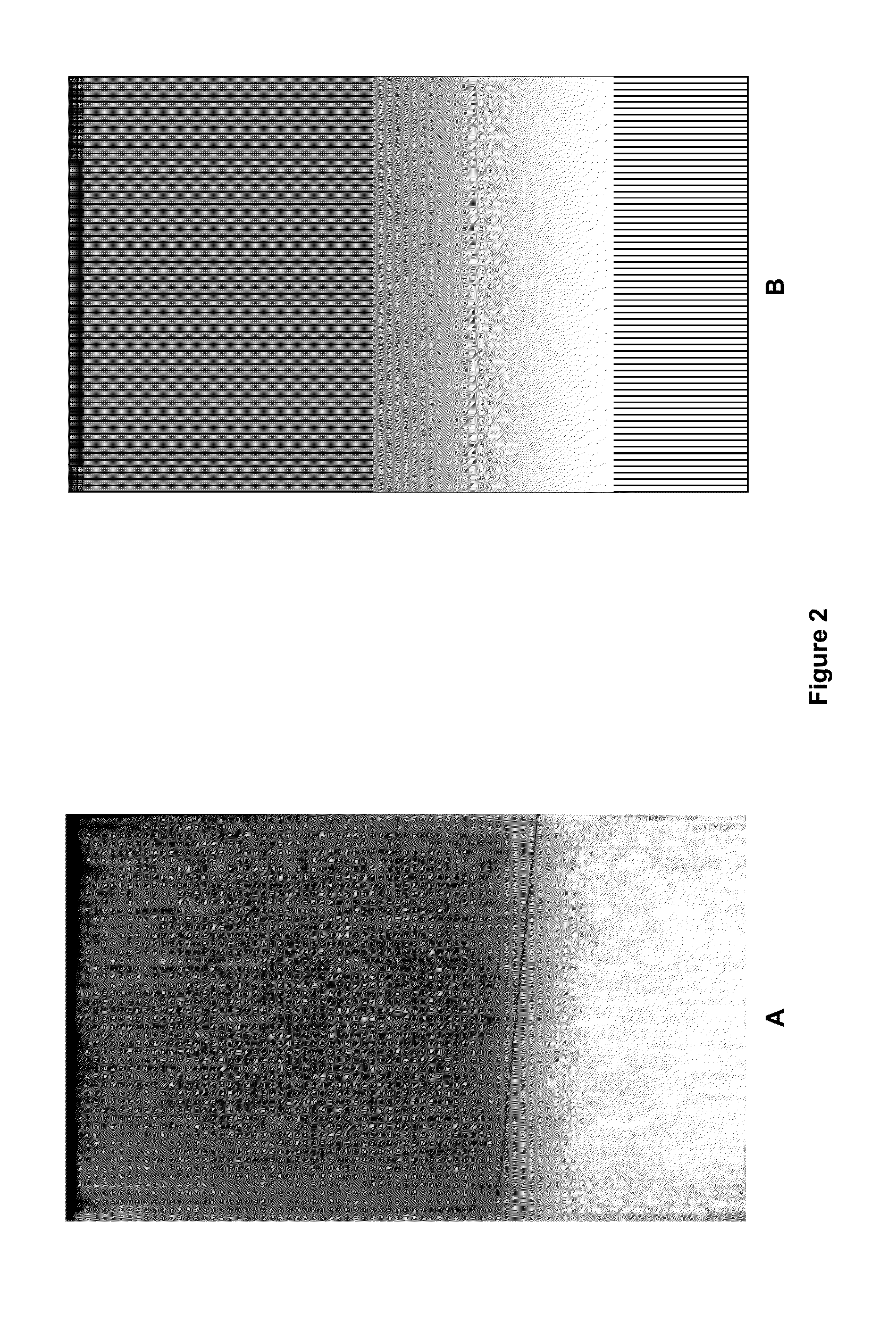

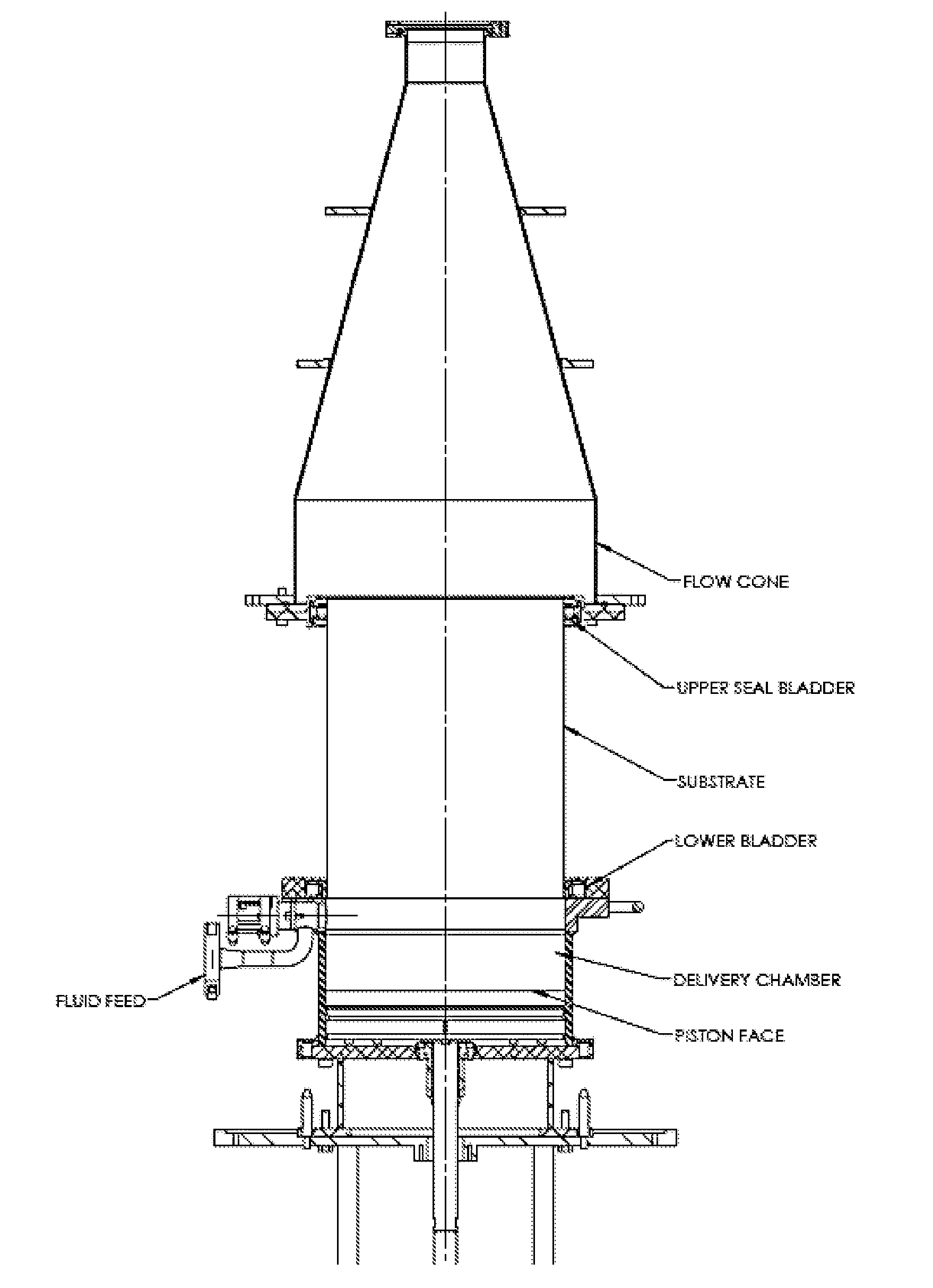

Method of coating a substrate with a catalyst component

ActiveUS9138735B2Accurate coatingEasy to controlExhaust apparatusDispersed particle separationEngineeringPartial filling

A method of coating a substrate with a liquid comprising a catalyst component, the method comprising:(a) holding the substrate vertically, thereby defining upper and lower ends thereof, wherein the vertical substrate comprises a plurality of channels that are open at said upper and lower ends;(b) continuously introducing the liquid into the substrate by pushing or injecting the liquid through the open ends of the channels at the lower end of the substrate with a piston; and(c) after the lower end of the substrate has been partly filled with the liquid in step (b), applying a vacuum to the open ends of the channels at the upper end of the substrate while continuing to introduce the liquid into the substrate.

Owner:JOHNSON MATTHEY PLC

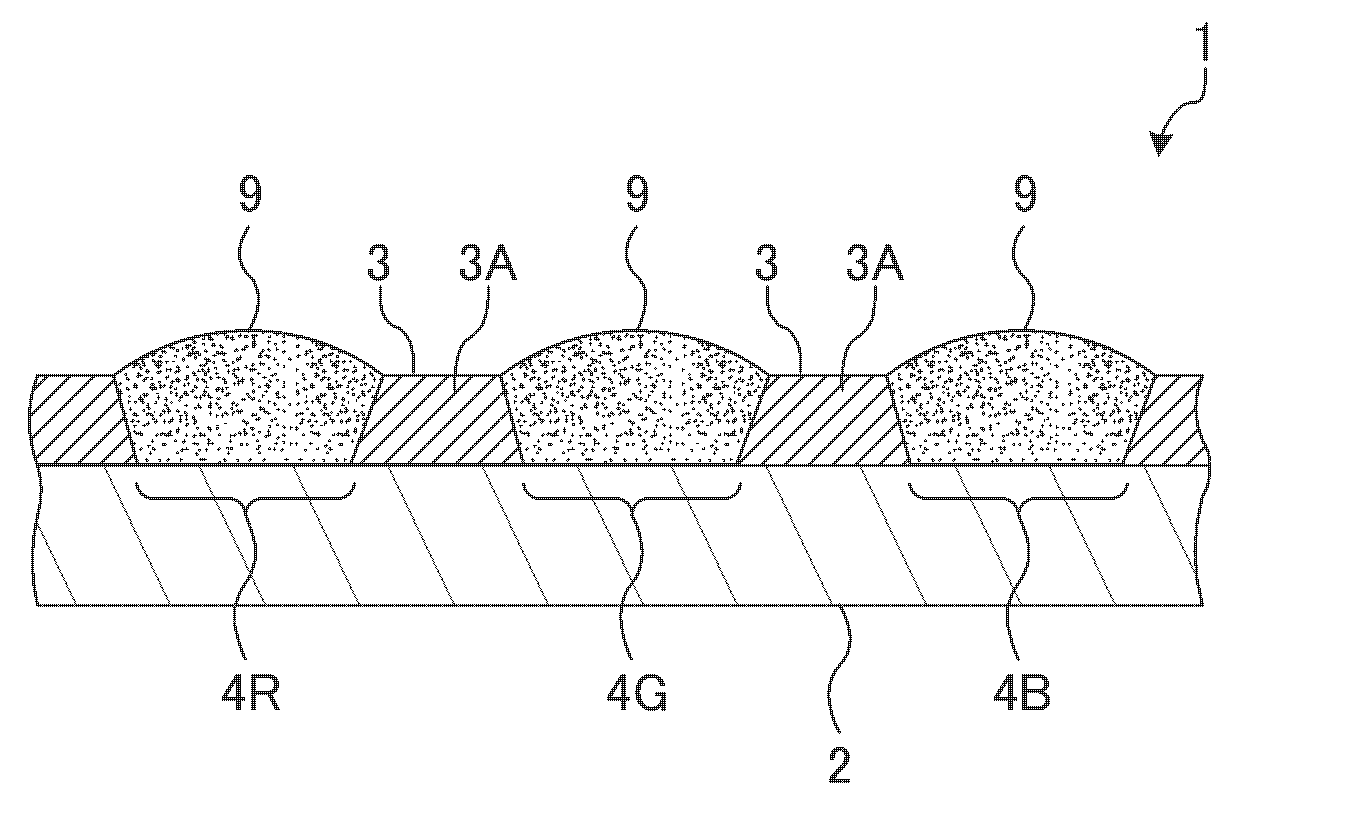

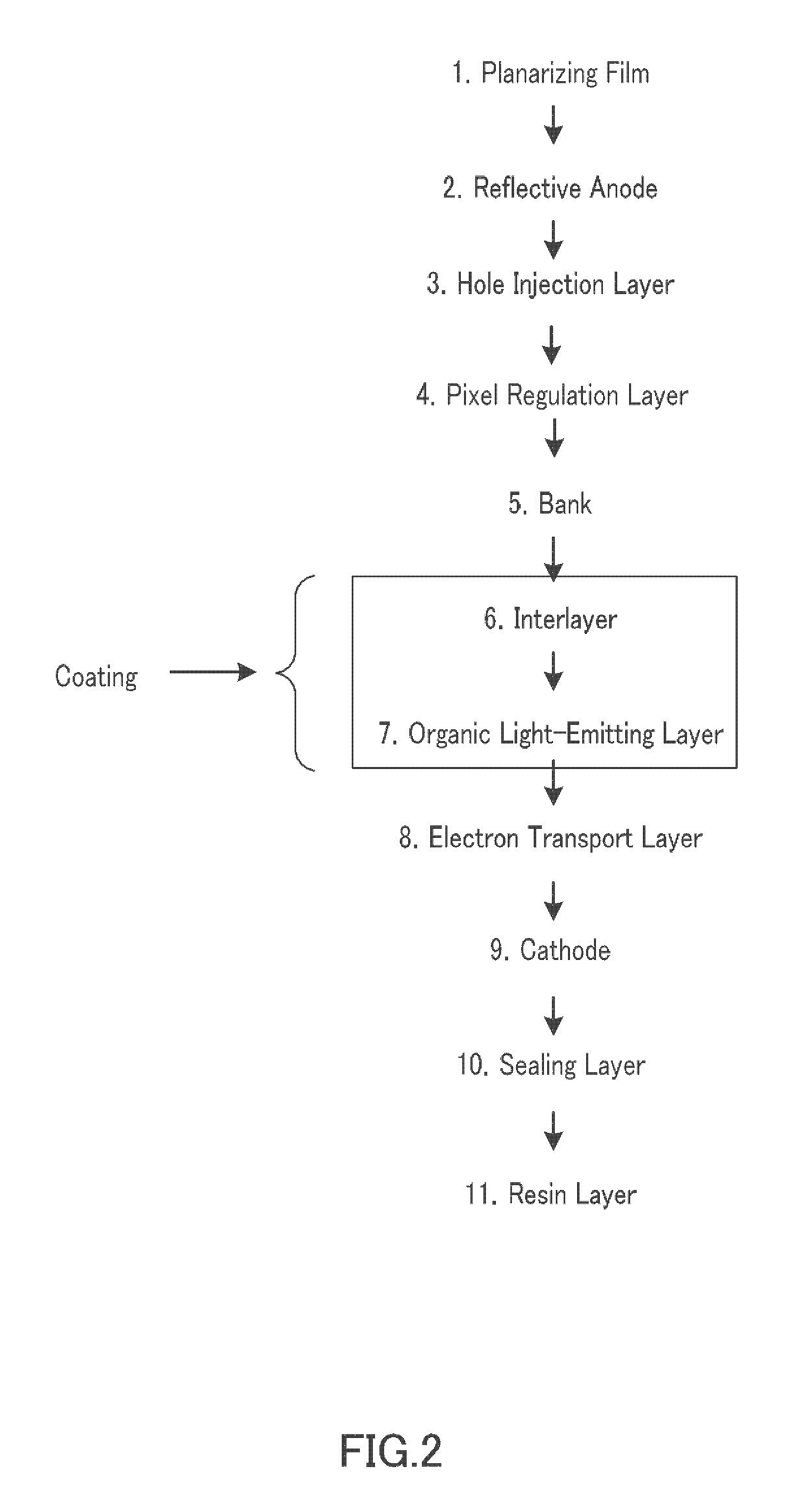

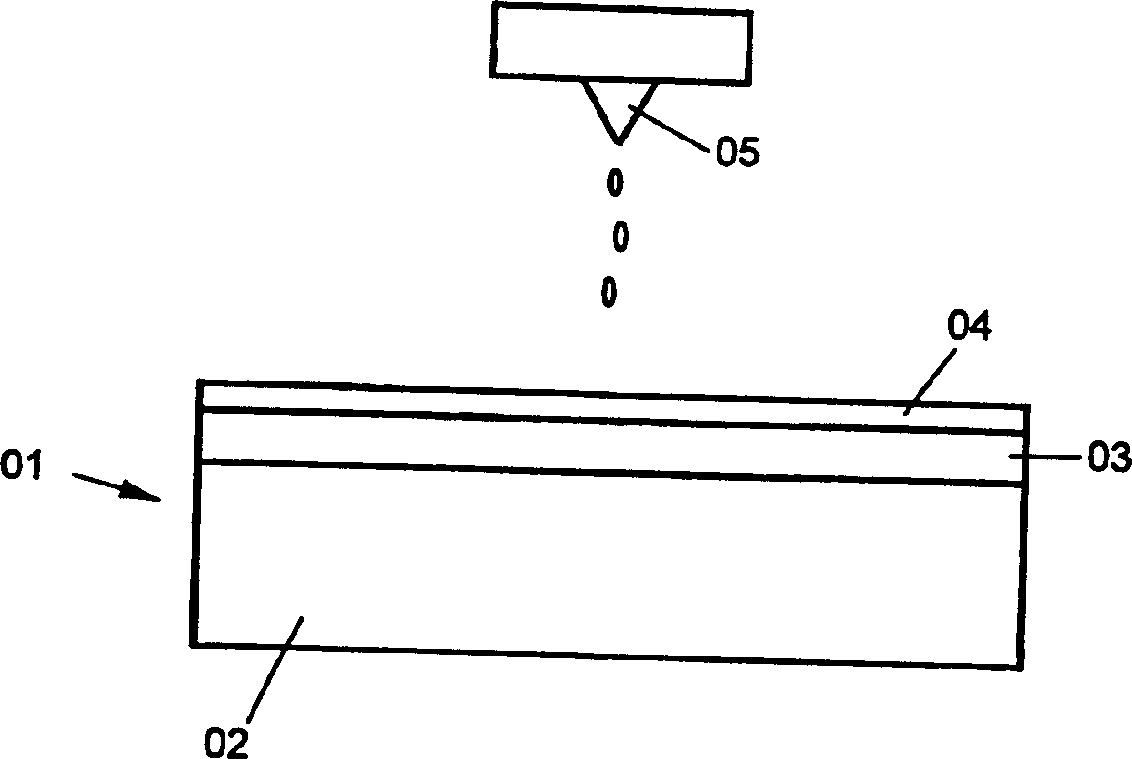

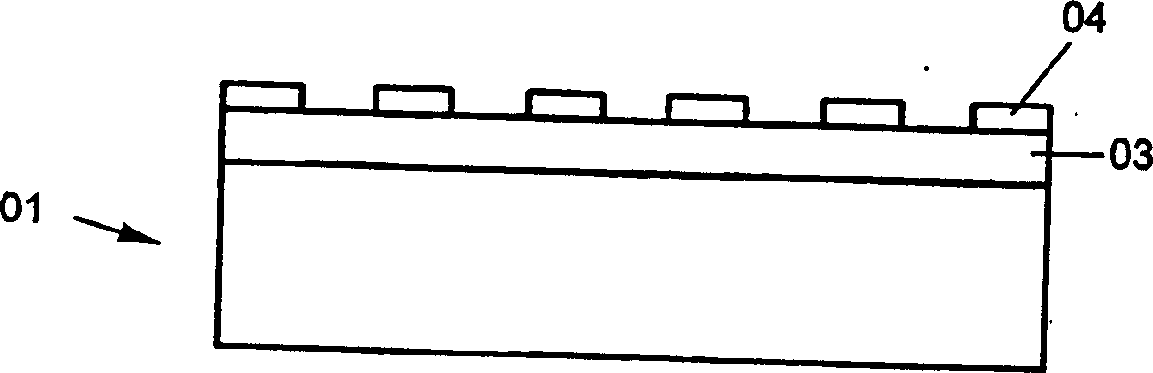

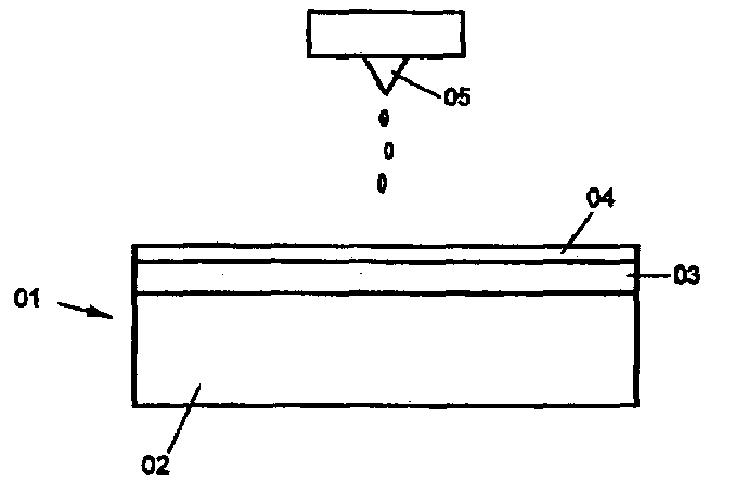

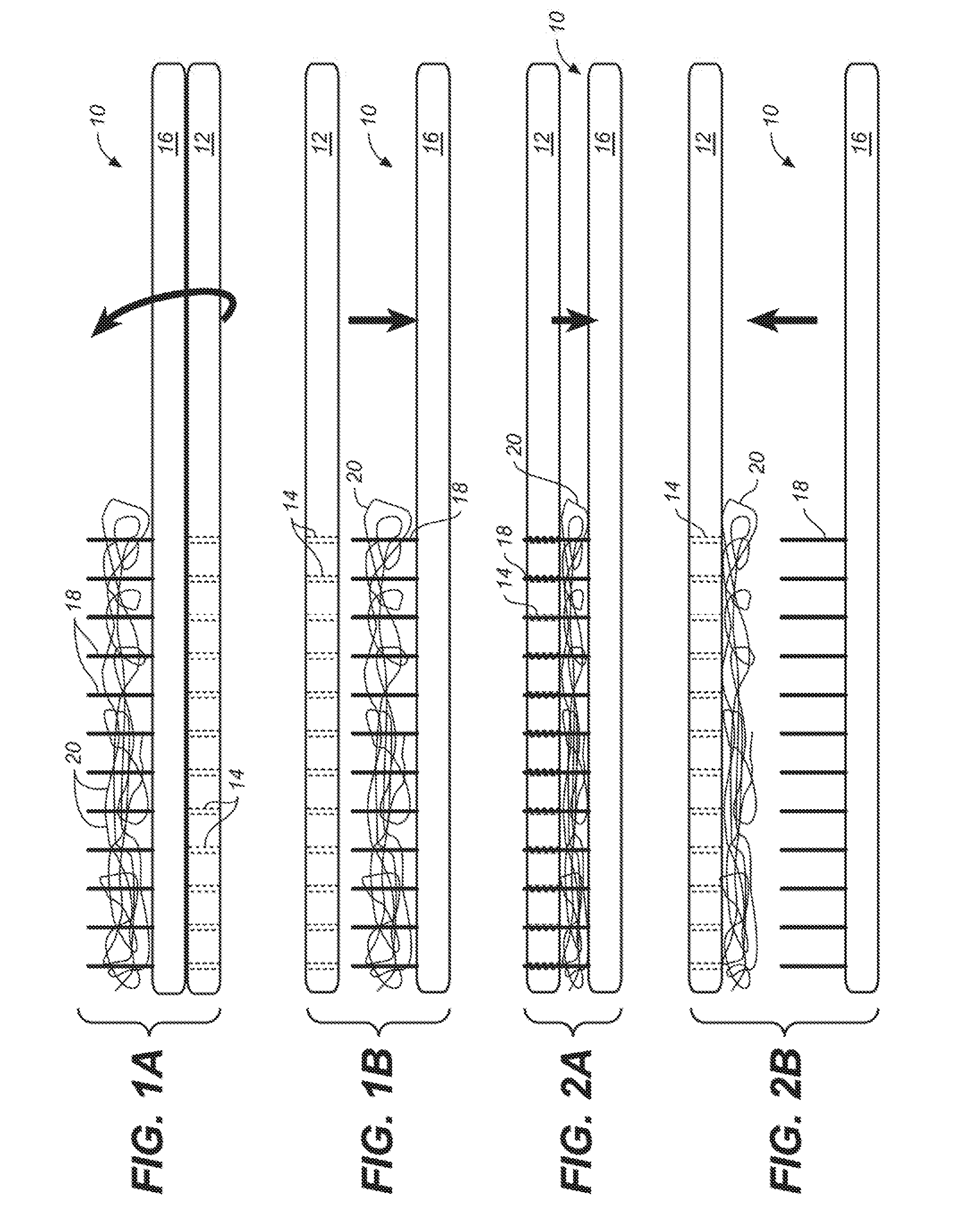

Coating method and manufacturing method of organic el display

ActiveUS20110300289A1Accurate timingPrecise applicationSolid-state devicesChemical vapor deposition coatingDisplay deviceEngineering

A coating method in which ink droplets containing functional material are ejected through nozzles on a substrate having a plurality of pixel regions and lyophobic portions adjacent to the respective pixel regions, to form a functional layer in each of the pixel regions includes: landing an ink droplet on a first pixel region and on a first lyophobic portion adjacent to the first pixel region; measuring a deviation of a landing position of the ink droplet on the first lyophobic portion from a set ink landing position; and ejecting an ink droplet on a second pixel region of the substrate while correcting the timing of ink ejection through the nozzles based on the deviation.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Method for inserting images on printing plates

InactiveCN1422212AAccurate coatingIncrease job securityPlate printingFoil printingEngineeringSilicon

The invention concerns a method for inserting images on printing plates, wherein a printing plate is prepared with an ink-accepting layer and an ink-repelling layer applied thereon. According to the invention, a developing fluid is sprayed on the ink-repelling layer by an ink-jet printing group in accordance with an image to be printed, by means of which the ink-repelling layer is etched or dissolved in the sprayed areas for swelling or adhesion promotion is eliminated. The etched or dissolved areas of the ink-repelling layer are removed. A waterless printing plate having an ink-repelling layer made of silicon is especially used.

Owner:KOENIG & BAUER AG

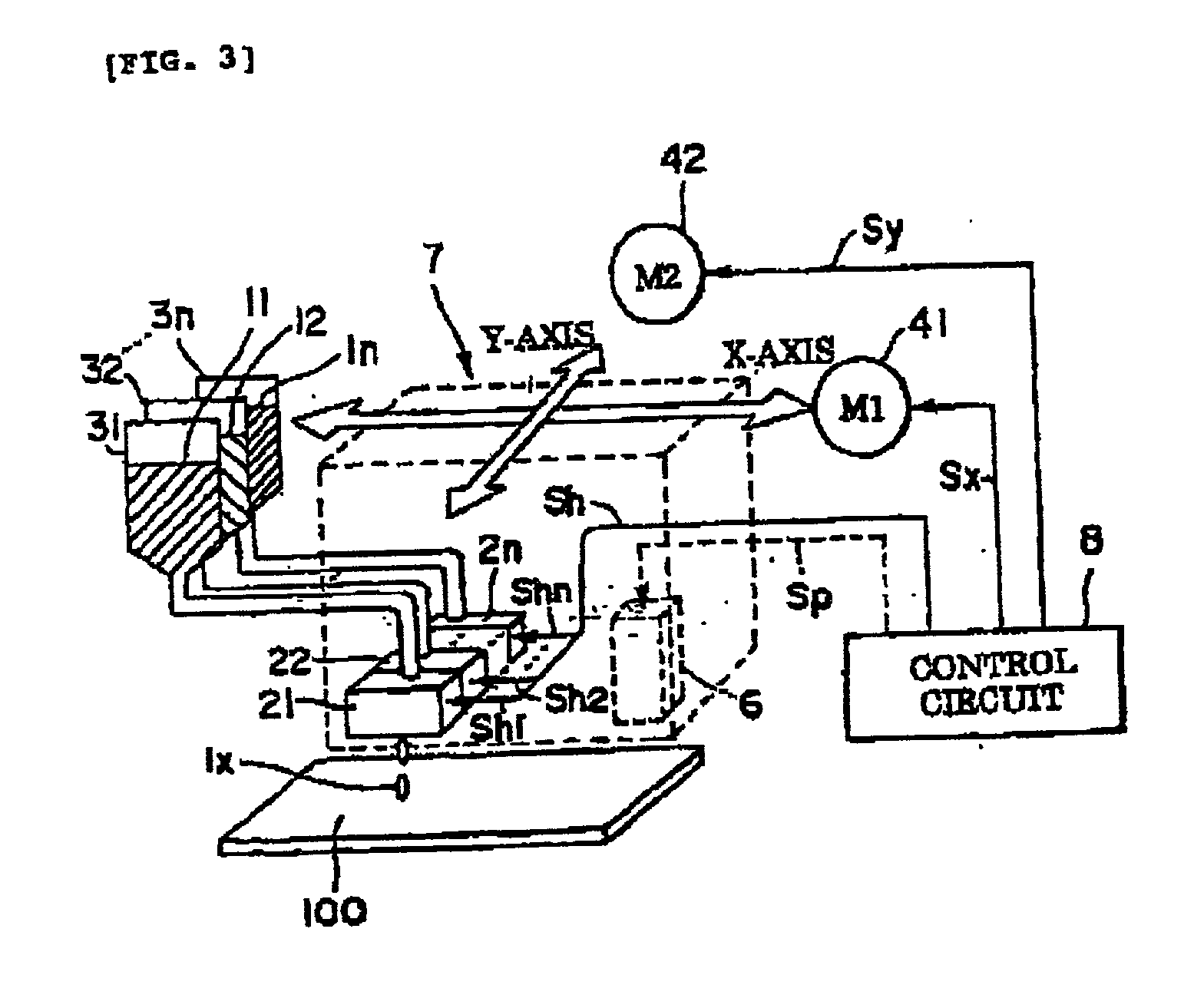

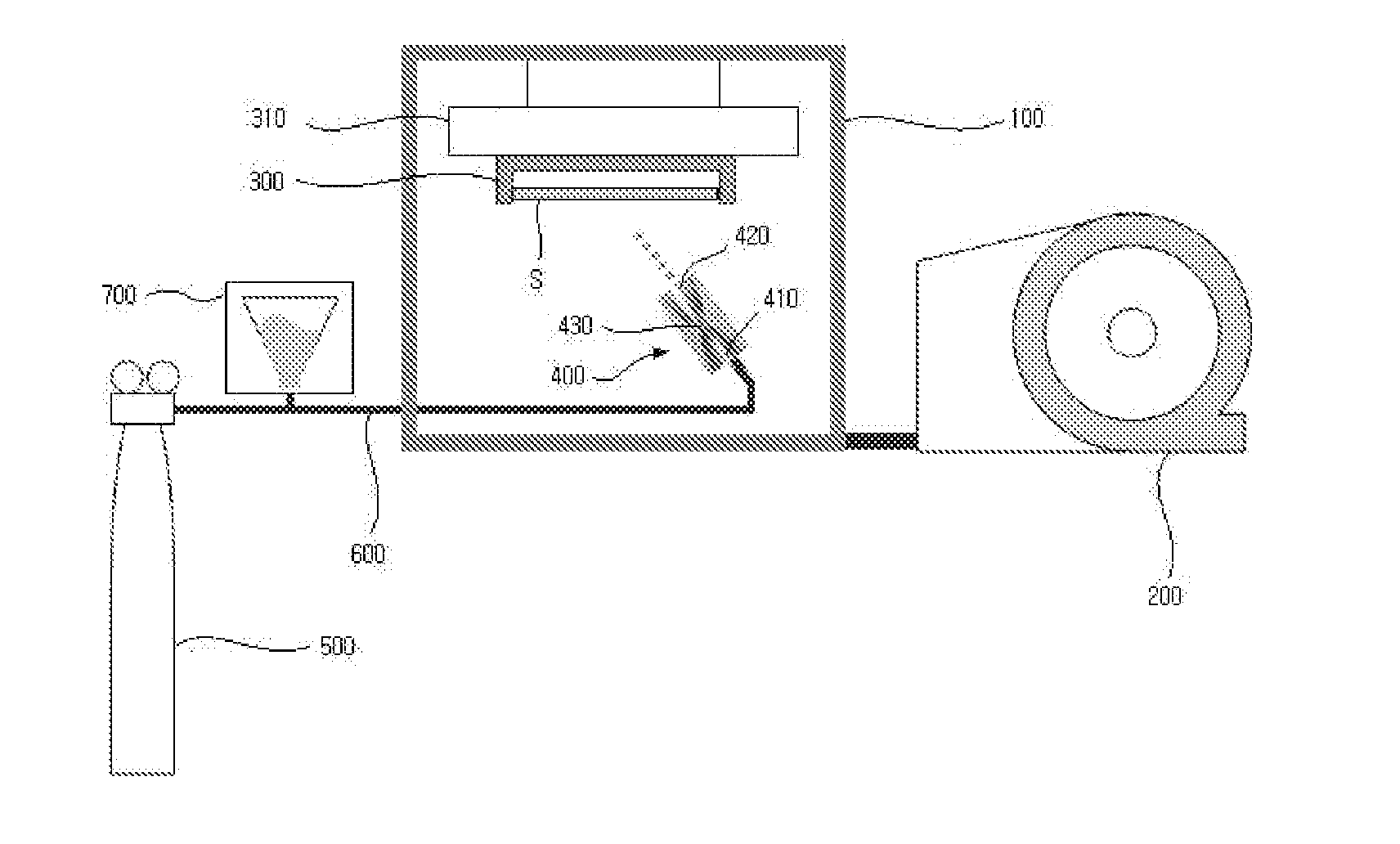

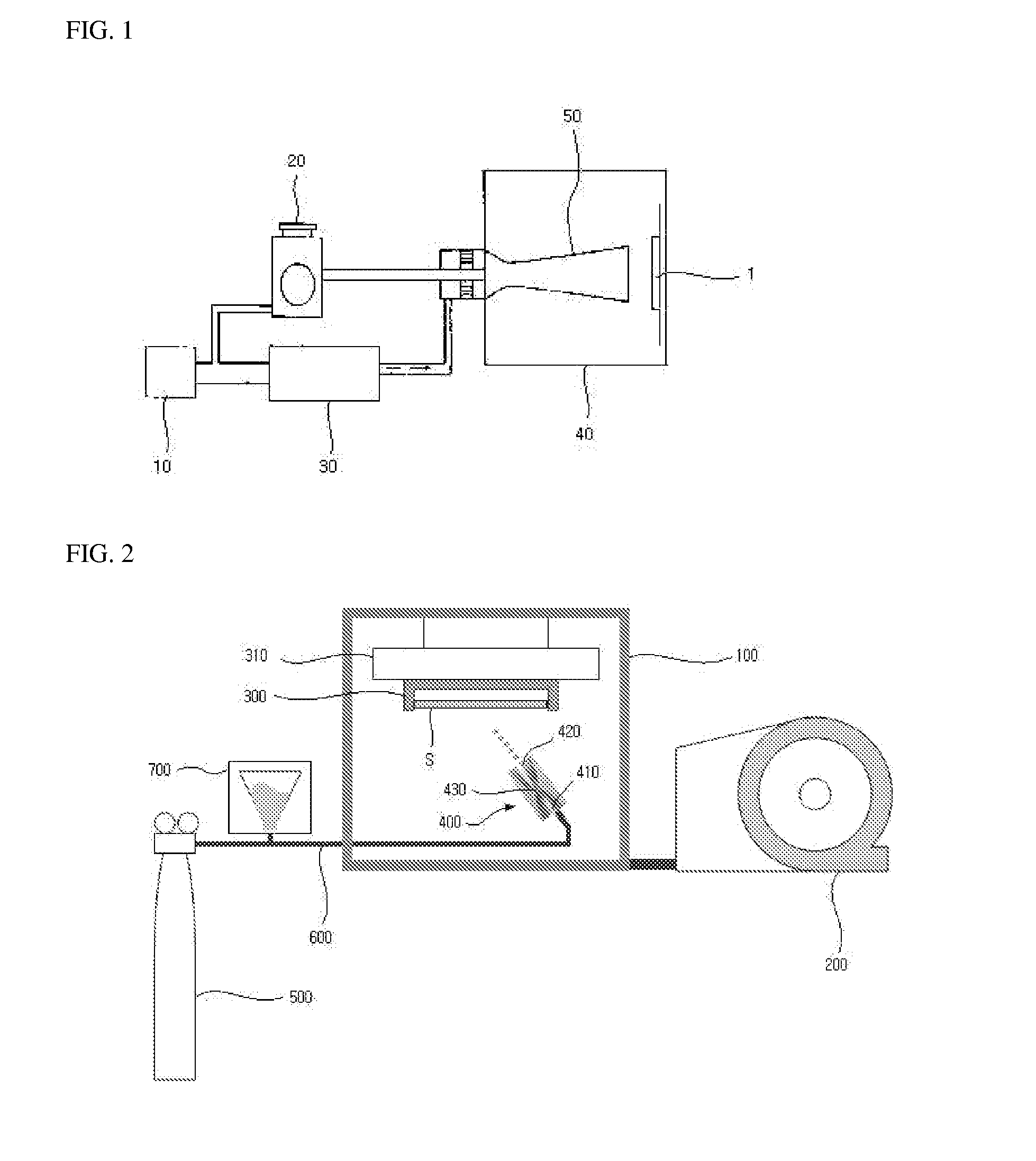

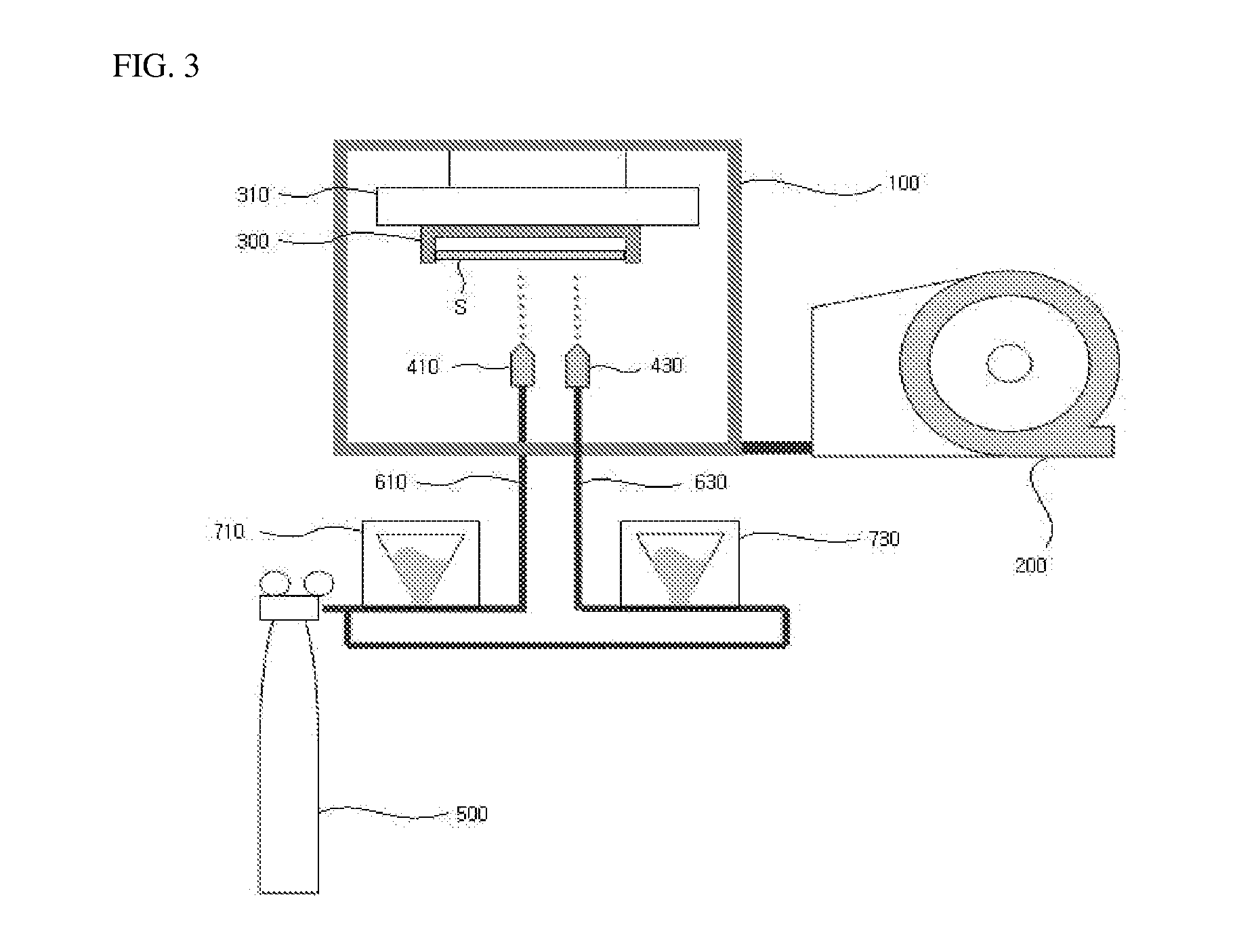

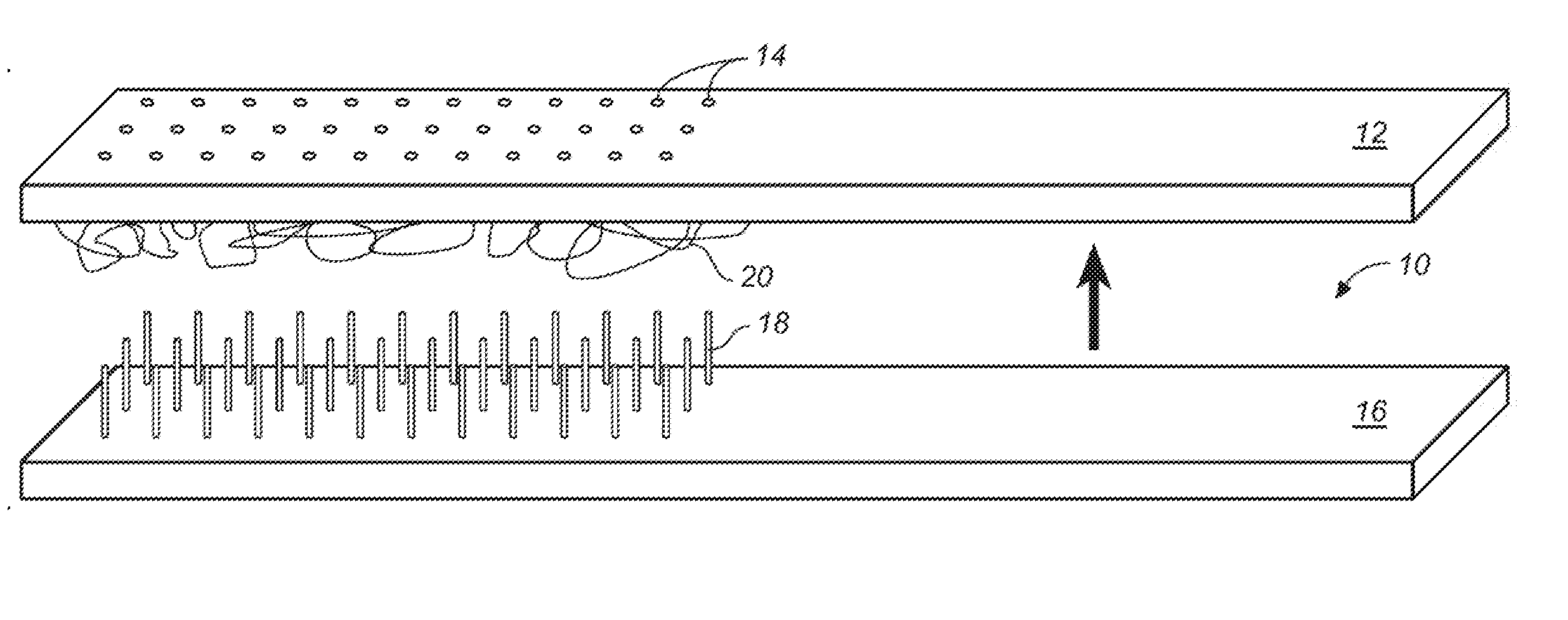

Method and apparatus for coating powder material on substrate

InactiveUS20090214772A1Reduce resistanceStoring evenlyLiquid surface applicatorsVacuum evaporation coatingHeat resistanceRoom temperature

An apparatus and method for coating a powder material on a substrate is disclosed, to enable various materials such as metal or ceramic powder to be coated on a substrate made of a material having low heat-resistance, the method including supplying a predetermined powder; carrying the supplied powder to a predetermined spraying nozzle by injecting a gas at a room temperature; and spraying the powder carried under conditions of the room temperature and vacuum state on the substrate through spraying nozzle, wherein the grain size of predetermined powder is in a range between about 0.1 to about 10 μm, and the powder is sprayed on the substrate at a velocity of about 500 to about 1200 m / sec.

Owner:SEOUL NAT UNIV R&DB FOUND

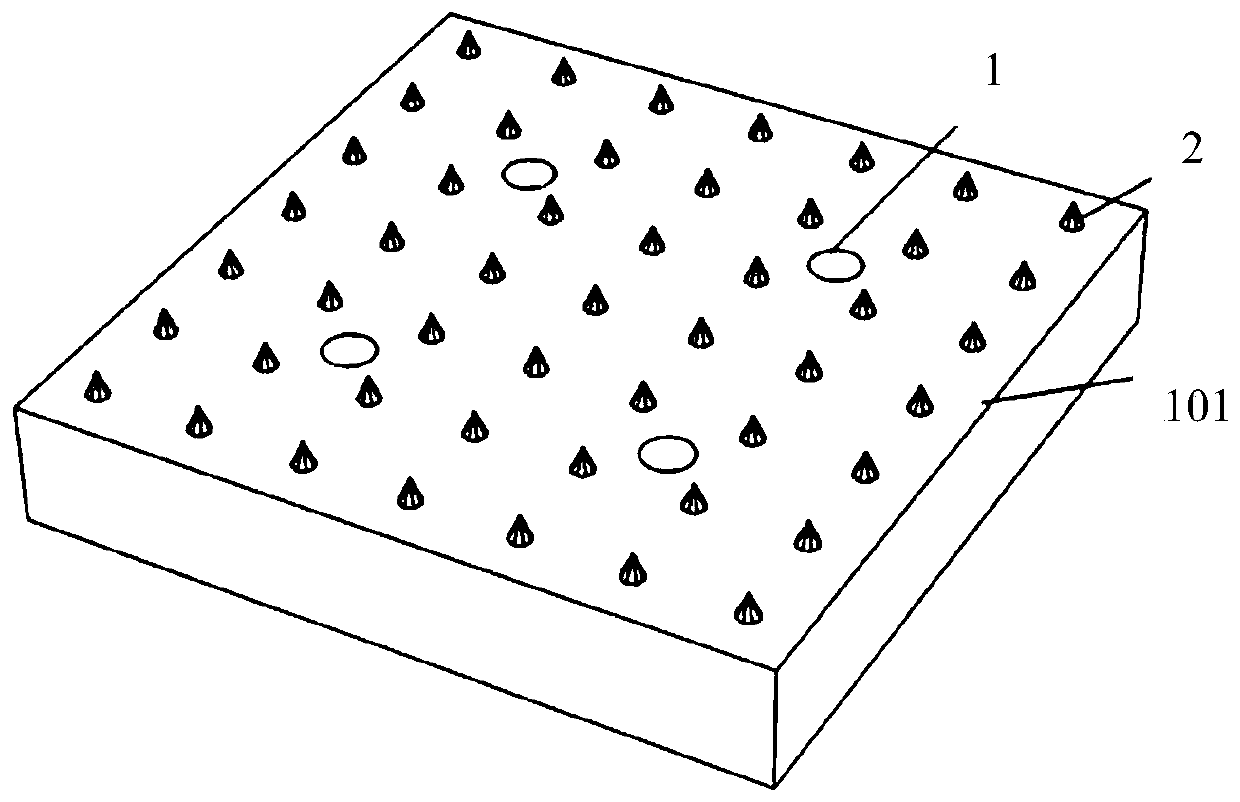

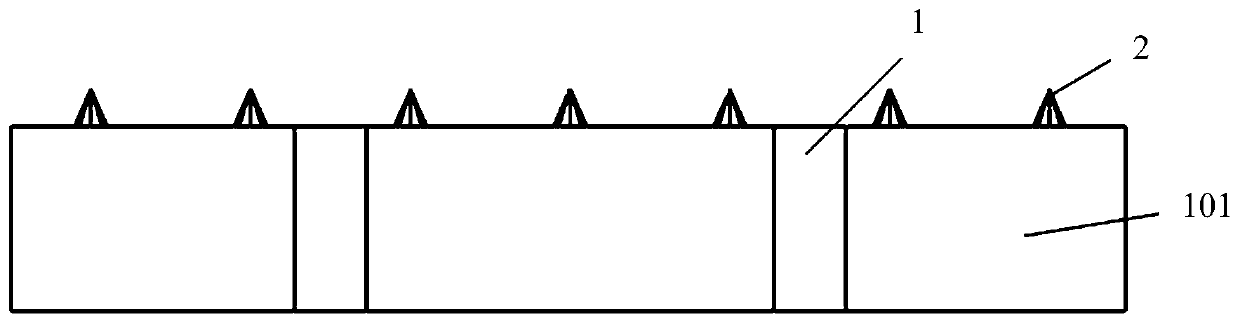

Monocrystalline silicon high-throughput microneedle structure

PendingCN109893753AImprove structural strengthReduce processing costsMedical devicesHoneycombOptoelectronics

The invention relates to a monocrystalline silicon high-throughput microneedle structure. The structure comprises a monocrystalline silicon substrate, monocrystalline silicon microneedle body arrays and one or more throughput holes, wherein the monocrystalline silicon microneedle body arrays are uniformly distributed on the upper surface of the monocrystalline silicon substrate, the one or more throughput holes penetrate through the monocrystalline silicon substrate, the one or more throughput holes and the monocrystalline silicon microneedle body arrays do not interfere each other, microneedle bodies in the monocrystalline silicon microneedle body arrays are solid bodies, axes of the solid bodies are perpendicular to the surface of the monocrystalline silicon substrate, the solid bodies are in a shape of cone or polygonal pyramid, and the monocrystalline silicon microneedle body arrays are arranged in one of honeycomb shape, square shape and triangular shape. The microneedle structurehas the advantages of high structural strength, low processing cost, high finished product rate and good consistency, multiple through holes are distributed around microneedles to continuously provide liquid medicines for subcutaneous permeation, and the microneedle structure has the advantages of no needle breakage and high throughput.

Owner:苏州泽矽能电子科技有限公司

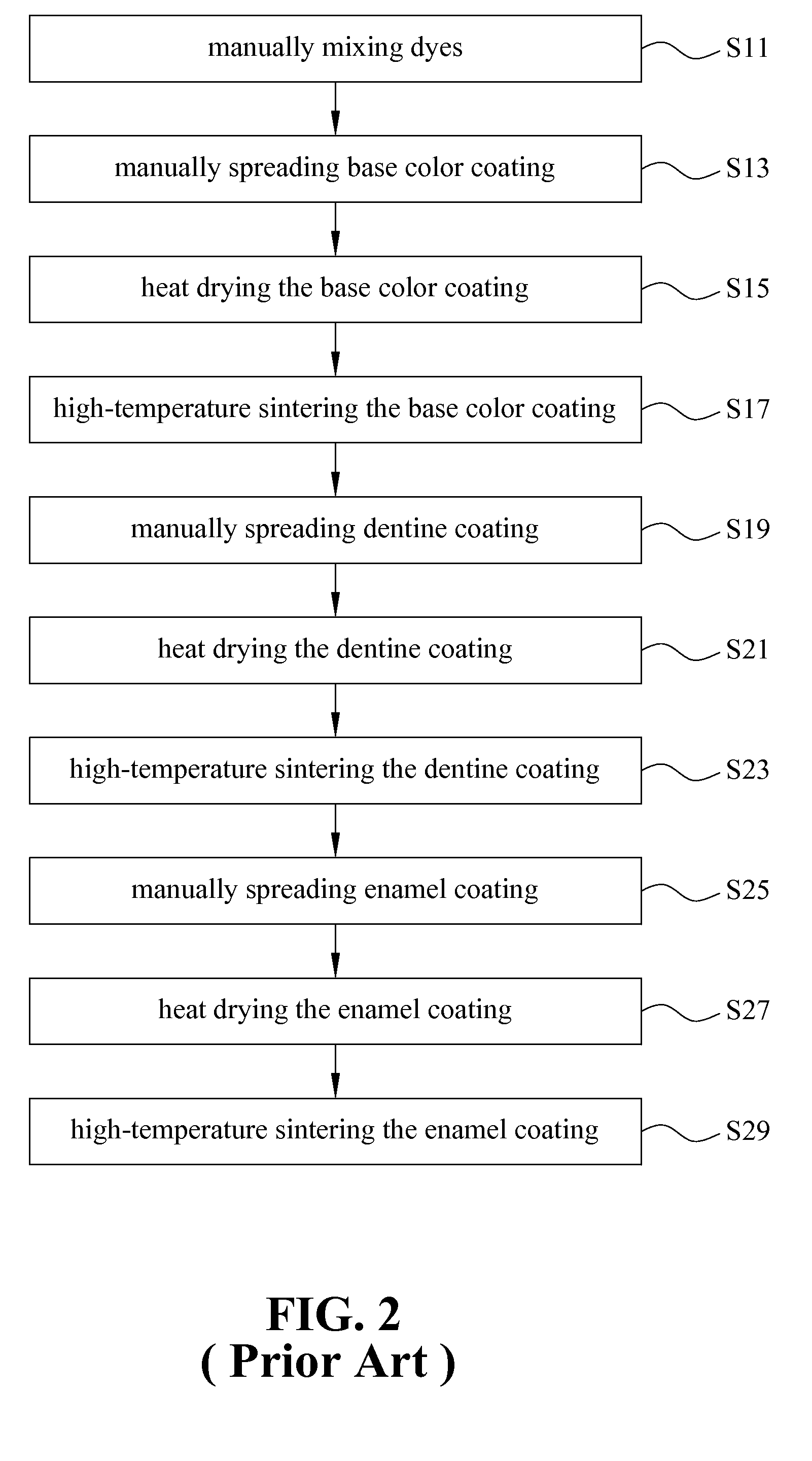

Computerized Method For Coloring Porcelain Tooth

InactiveUS20110256507A1Accurate coatingOvercome disadvantagesMechanical/radiation/invasive therapiesGum massageComputer-aidedComputer aid

A computerized method for coloring a porcelain tooth includes a color difference comparison step, a first computer aided process, and a second computer aided process, for precisely controlling the color of the porcelain tooth. Each parameter is obtained from data comparison. The first computer aided process forms a first layer on the surface of the porcelain tooth and then and the second computer aided process forms a second layer on the first layer by way of computer aided manufacturing (CAM) according to the color difference comparison step. Because of CAM, the method does not require an experienced operator. Therefore, it may reduce labor cost, human error, and ceramic powder consumption. The method may thus save cost, improve production efficiency, and shorten delivery time of the porcelain tooth product.

Owner:A&E BIO CERAMIC

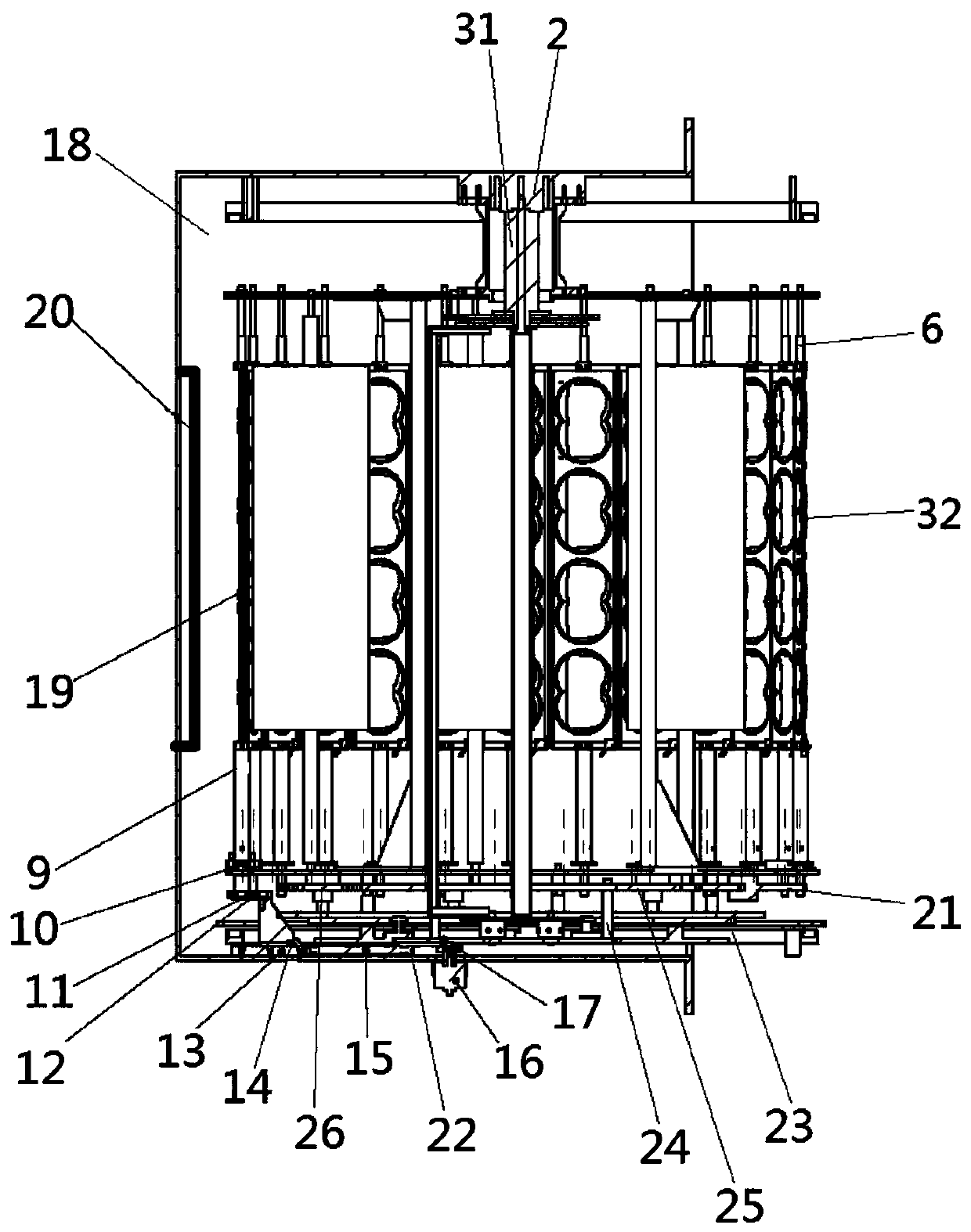

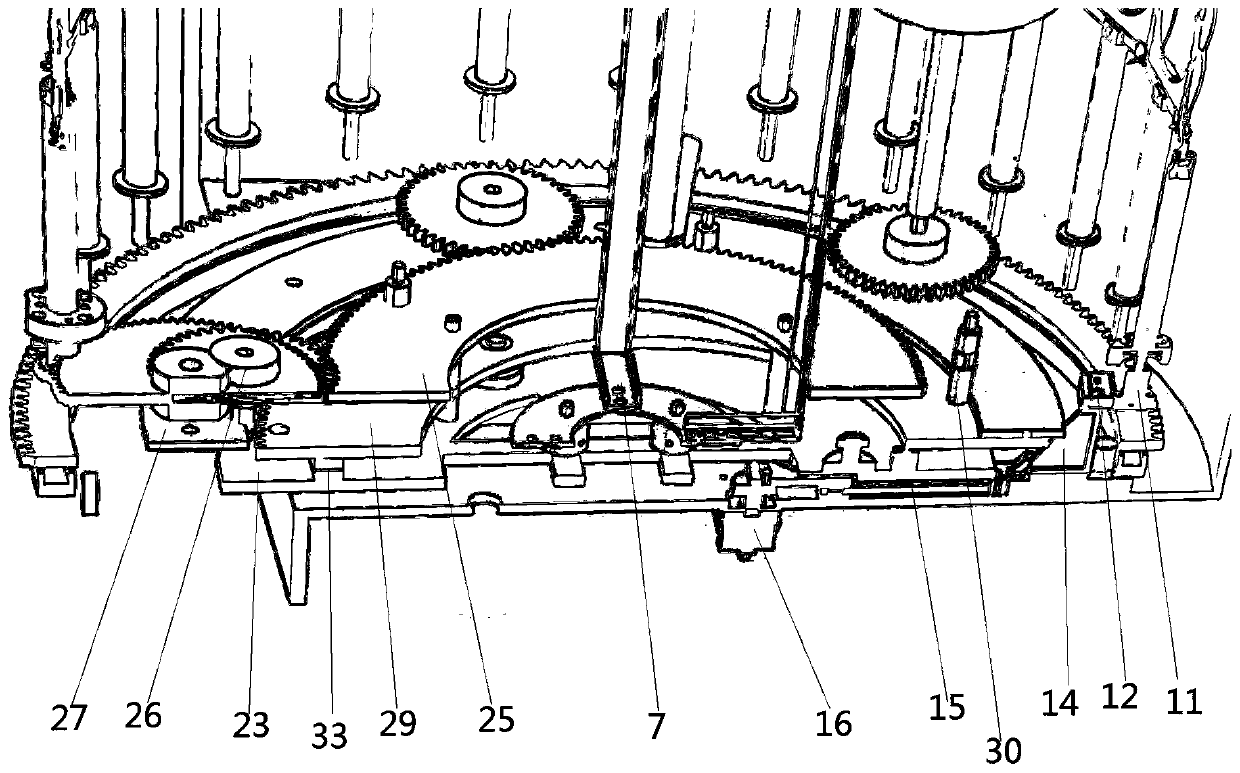

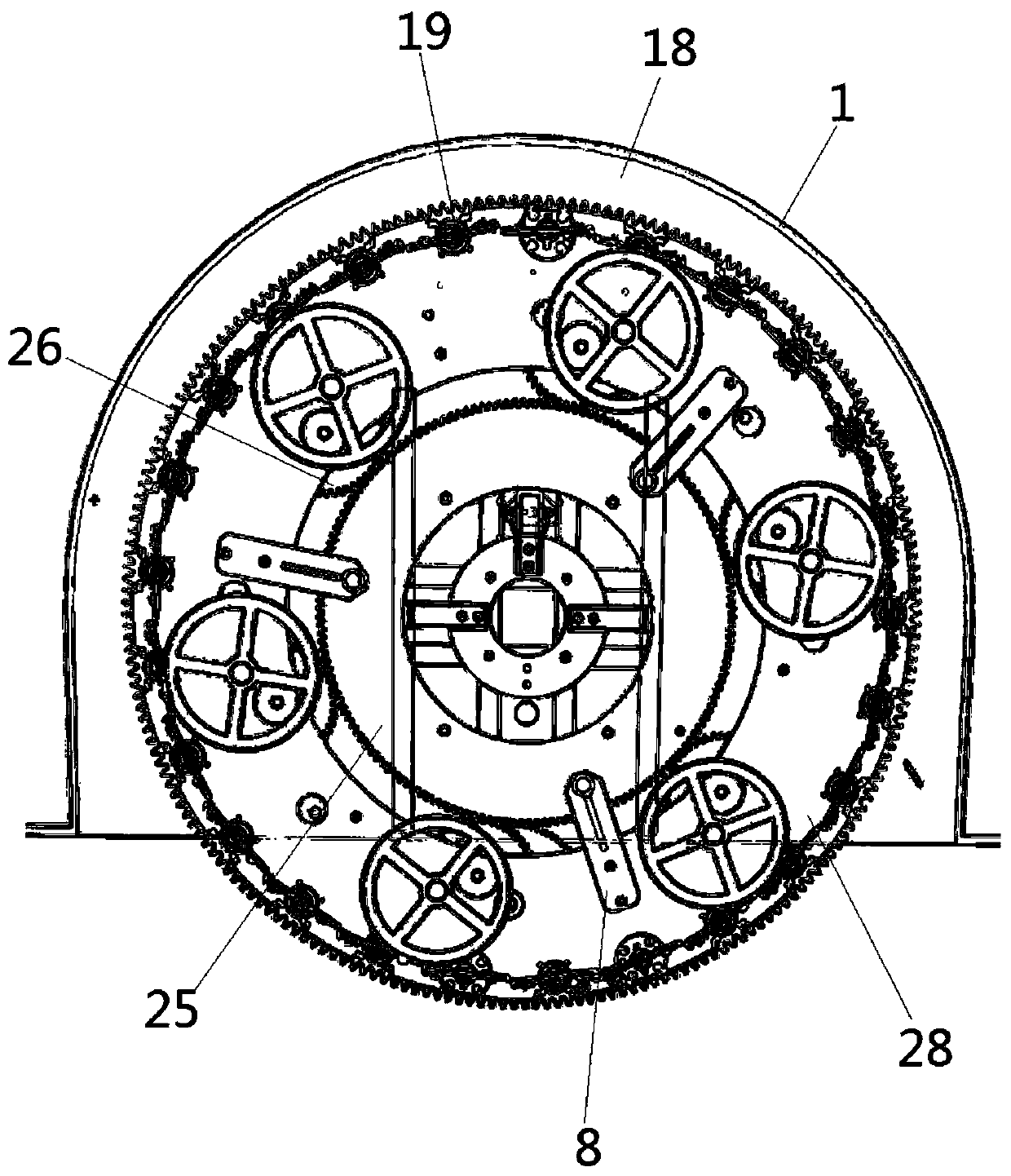

Revolution-rotation coating equipment for vacuum coating

PendingCN110172677ASave time and energyImprove efficiencyVacuum evaporation coatingSputtering coatingElectric energyFixed frame

The invention relates to revolution-rotation coating equipment for vacuum coating. A coating furnace chamber is arranged in a furnace body; a revolution plate rotating mechanism and a rotation gear mechanism are arranged in the coating furnace chamber; and a target material is connected to one side of the inner wall. According to the revolution-rotation coating equipment for vacuum coating provided by the invention, the revolution plate rotating mechanism adopts a planetary gear mechanism to drive a hanging frame tray so as to realize the revolution of an AR fixed frame assembly, and the rotation gear mechanism enables a rack and a rotation gear to mesh through a crank and rocker mechanism, so that a rotation lower shaft rotates to drive a hanging tool to turn over at 180 degrees and coaton the reverse side, and the aim of accurately turning over the hanging tool is achieved through a rotation positioner; and since the crank and rocker mechanism is controlled through a rotary cylinder, uniform coating can be selectively carried out, automatic turnover can be realized within one same furnace batch, the consumption of time and electric energy required for opening, turning over, vacuumizing and heating is avoided, the time and the electric energy are effectively saved, the double-faced coating efficiency is improved, and the uniformity and the consistency of double-faced coatingare effectively ensured.

Owner:佛山王氏航空光学科技有限公司

Winding type optical coating device and method based on magnetron sputtering and electron gun evaporation

InactiveCN111378951AGuaranteed compactnessImprove bindingVacuum evaporation coatingSputtering coatingSputteringOptical coating

The invention discloses a winding type optical coating device and method based on magnetron sputtering and electron gun evaporation. The device comprises a plurality of vacuum chambers which are linearly connected, wherein two vacuum chambers positioned at two ends are an unwinding chamber and a winding chamber respectively; at least one magnetron sputtering coating chamber and at least one electron gun evaporation coating chamber are arranged between the unwinding chamber and the winding chamber; and when a plurality of magnetron sputtering coating chambers and / or electron gun evaporation coating chambers are arranged, the magnetron sputtering coating chambers and the electron gun evaporation coating chambers are alternately arranged. The method comprises the following steps of alternately performing magnetron sputtering coating treatment and electron gun evaporation coating treatment on a base material, and coating a silicon oxide optical film or a silicon oxide / titanium oxide optical film. According to the winding type optical coating device and method disclosed by the invention, the magnetron sputtering coating and electron gun evaporation coating are combined, so that high binding force is formed between the film and a workpiece or the base material while the structural compactness of the film can be guaranteed, the coating effect of the workpiece or the base material is effectively improved, and the optical performance of the coated product is improved.

Owner:ZHAOQING KERUN VACUUM EQUIP

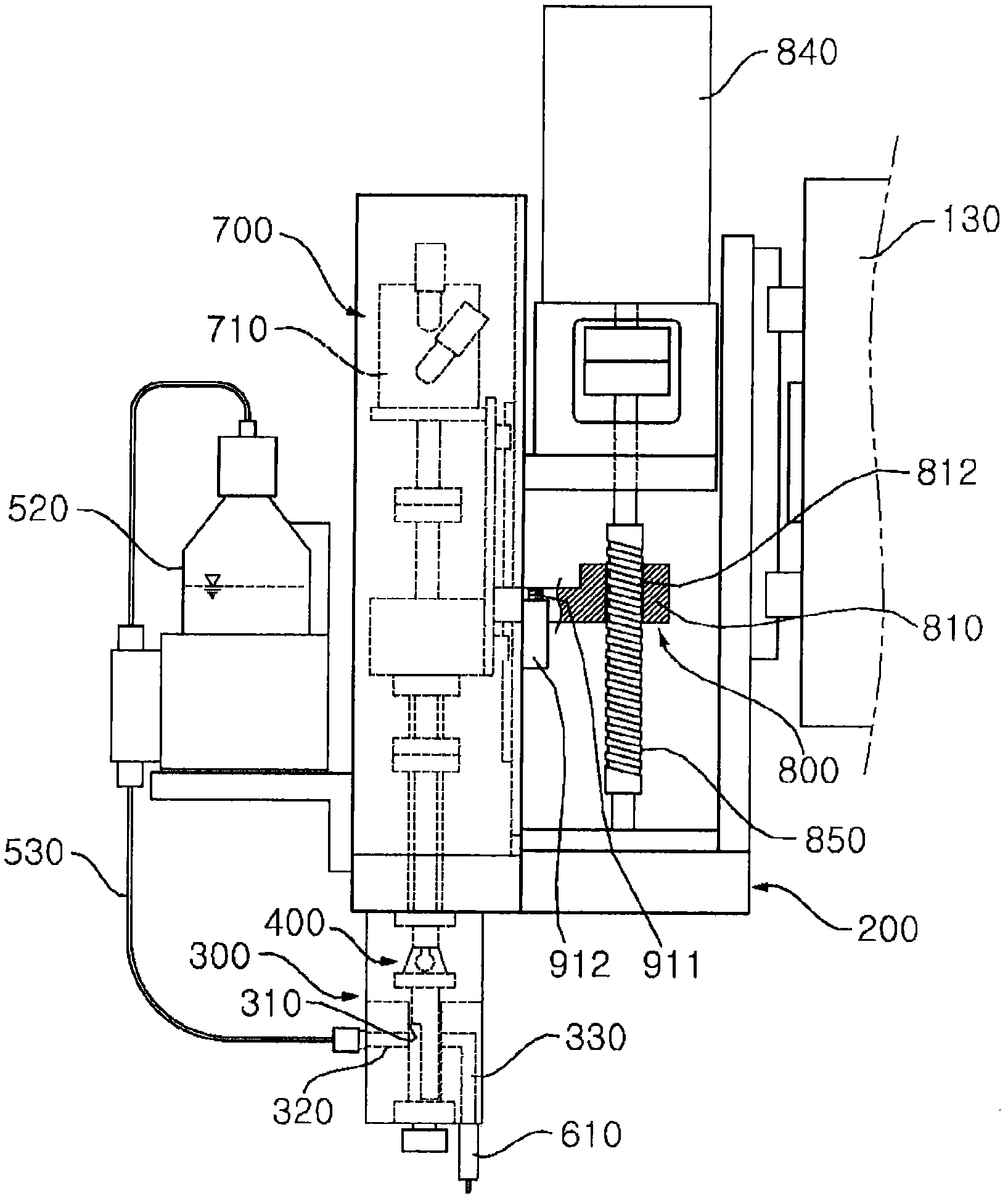

Method of coating a substrate with a catalyst component

ActiveUS20140356530A1Excellent profile control controlExcellent control control over dose lengthExhaust apparatusDispersed particle separationEngineeringPartial filling

A method of coating a substrate with a liquid comprising a catalyst component, which substrate comprises a plurality of channels, wherein the method comprises:(a) holding the substrate vertically;(b) introducing the liquid into the substrate through the open ends of the channels at a lower end of the substrate; and(c) after the lower end of the substrate has been part-filled with the liquid, applying a vacuum to the open ends of the channels at the upper end of the substrate while introducing the liquid into the substrate.

Owner:JOHNSON MATTHEY PLC

Magnetically induced hair brush cleaner system and method of using same

InactiveUS20160309887A1Reduce usageImproved ability to completely removeBrushesHair combsBristleEngineering

A method of magnetically induced removal of hair from a brush, wherein the method is comprised of the steps of applying a ferrofluid composition onto a portion of a user's hair; brushing the ferrofluid composition coated hair with a hair brush having a plurality of bristles; placing a magnetized hair brush base having a plurality of openings over the bristles such that the plurality of openings aligns with and interacts with the plurality of bristles such that substantially any of the user's hair that is located within the bristles is attracted towards the magnetized hair brush base; and removing the user's hair from the bristles.

Owner:ANNEM VIDHYASAI

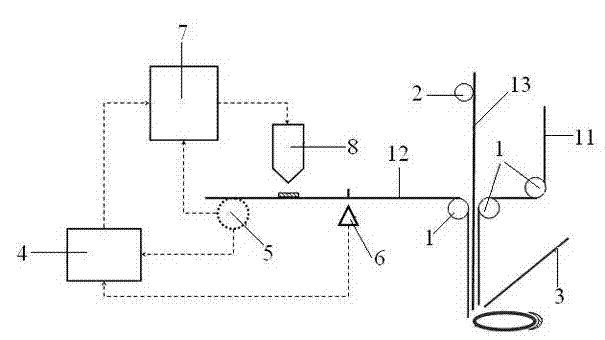

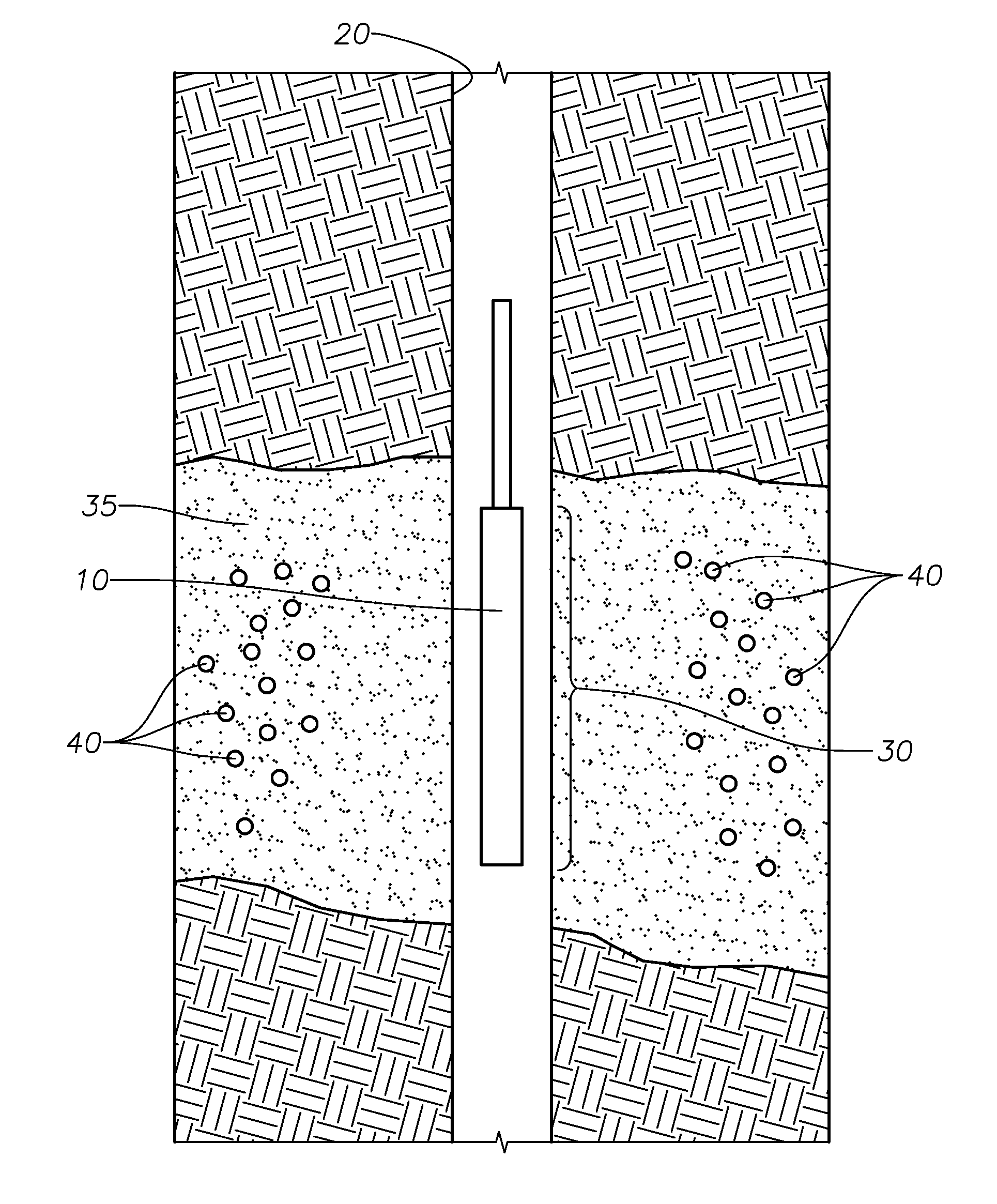

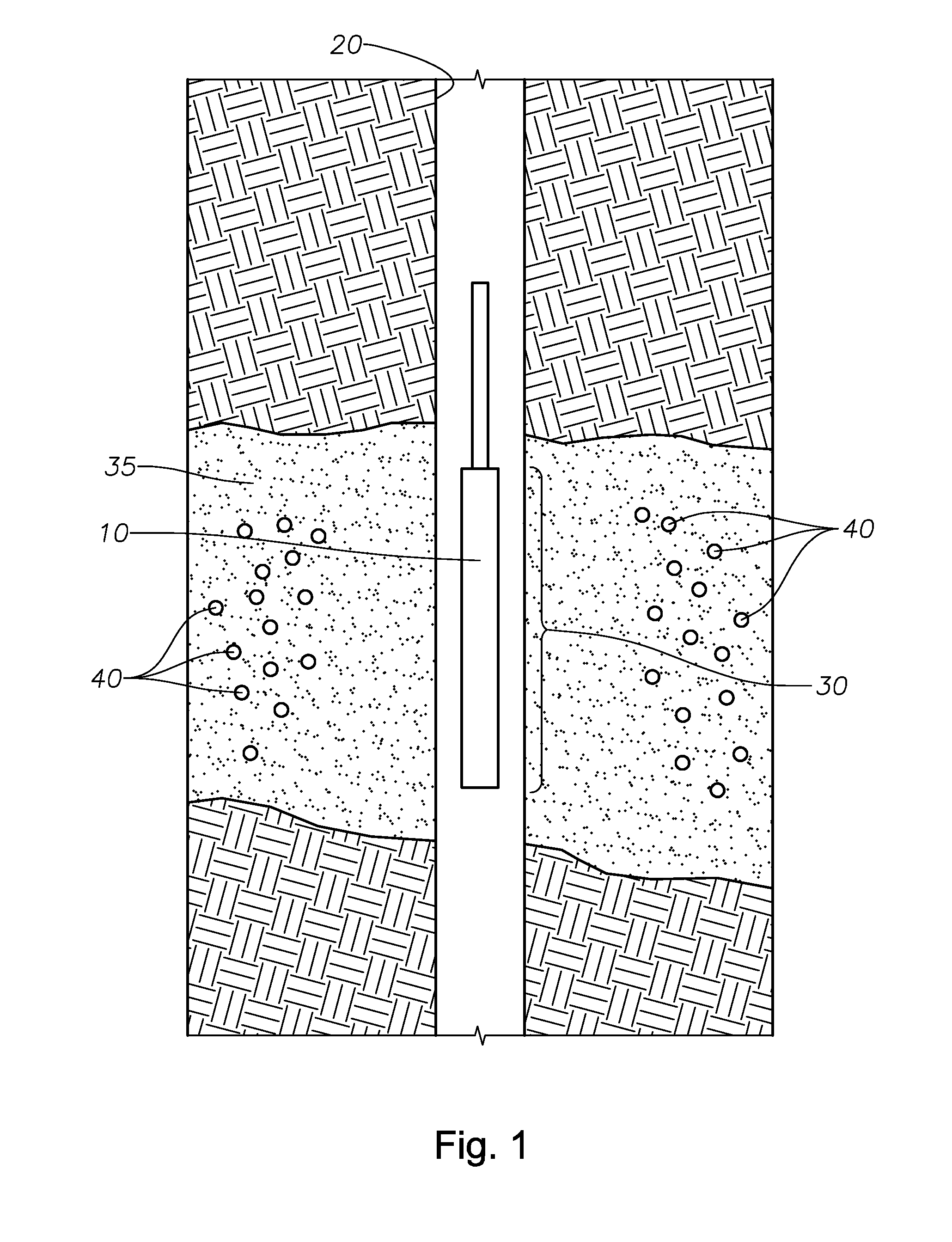

Device and method for manufacturing lithium ion battery winding spacing

ActiveCN102903960AControl positionControl shapeFinal product manufactureSecondary cellsWinding machineDrive wheel

The invention belongs to the technical field of lithium ion battery manufacture, and in particular relates to a device for manufacturing lithium ion battery winding spacing. The device comprises pole piece driving wheels, a diaphragm driving wheel, a winding machine, a PLC controller, an encoder, a transducer and a coating machine. The PLC controller is electrically connected with the encoder, the transducer and the coating machine respectively; the encoder is connected with the pole piece driving wheels, the diaphragm driving wheel, the winding machine and the coating machine; and the coating machine is provided with a coating head and a control system. Compared with the prior art, the encoder and the transducer are used to collect data of transport speed and displacement of the pole pieces, and feedback the data to the PLC controller; and the PLC controller controls the coating machine to coat corners of the pole pieces, so as to achieve precise coating on the pole pieces, and obtain a coating layer with precisely controlled position, shape, size and thickness. In addition, the device can conduct automatic coating on the pole pieces to greatly improve production efficiency.

Owner:DONGGUAN AMPEREX TECH +1

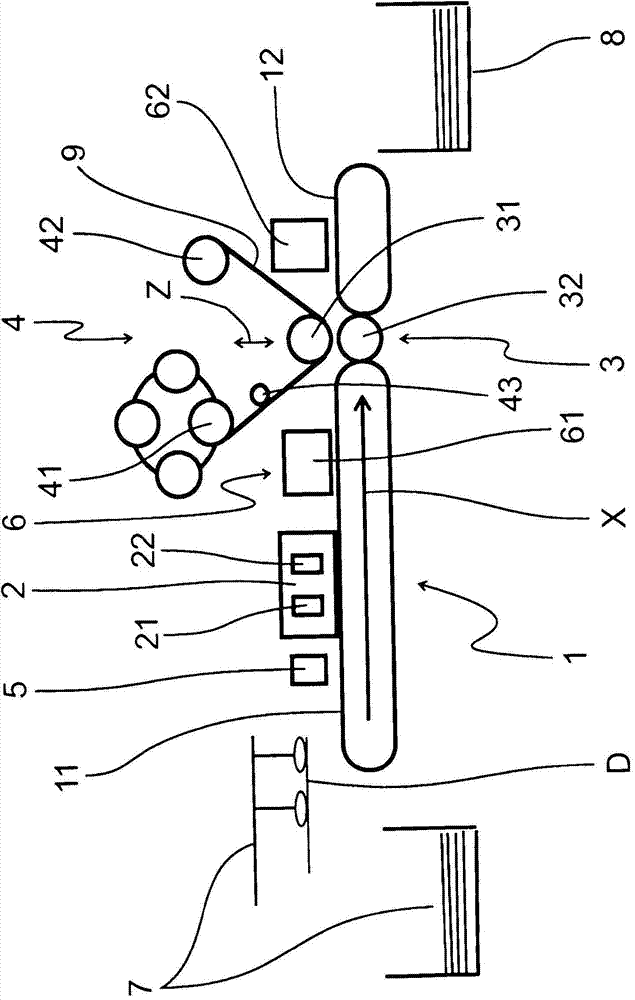

Foil stamping method and corresponding device

InactiveCN103946034AEasy to pressPrecise coatingTransfer printingDecorative surface effectsAdhesiveFoil stamping

The invention relates to a foil stamping method according to which a surface of a printing product (D) is provided with an adhesive layer in places intended to be imprinted prior to a transfer film (9), which consists of a carrier film and a transfer layer adhering thereto by means of a release layer, being placed onto the printing product (D) under the effect of pressure, the transfer layer sticking to the printing product (D) in places intended to be imprinted. Prior to foil printing, an applicable adhesive is applied to the printing product (D), instead of or in addition to the adhesive layer, in the places intended to be semi-embossed and the pressure acts evenly across the entire surface of the printing product (D), namely also on the raised places resulting from semi-embossing and the remaining surroundings during foil printing. The invention further relates to a foil stamping device for transferring a transfer layer which adheres to a carrier film onto the printing product (D) in places intended to be imprinted, said foil stamping device comprising a conveying system (1) for the printing product (D), adhesive application means (2), arranged on the conveying system (1), which provides a surface of the printing product (D) with an adhesive layer in places intended to be imprinted, a foil transfer means (3) having a transfer roller (31) and a foil feeding means (4) associated with the foil transfer means (3), the outer surface of the transfer roller (31) being covered with an elastic cover of a small thickness.

Owner:彼得巴特

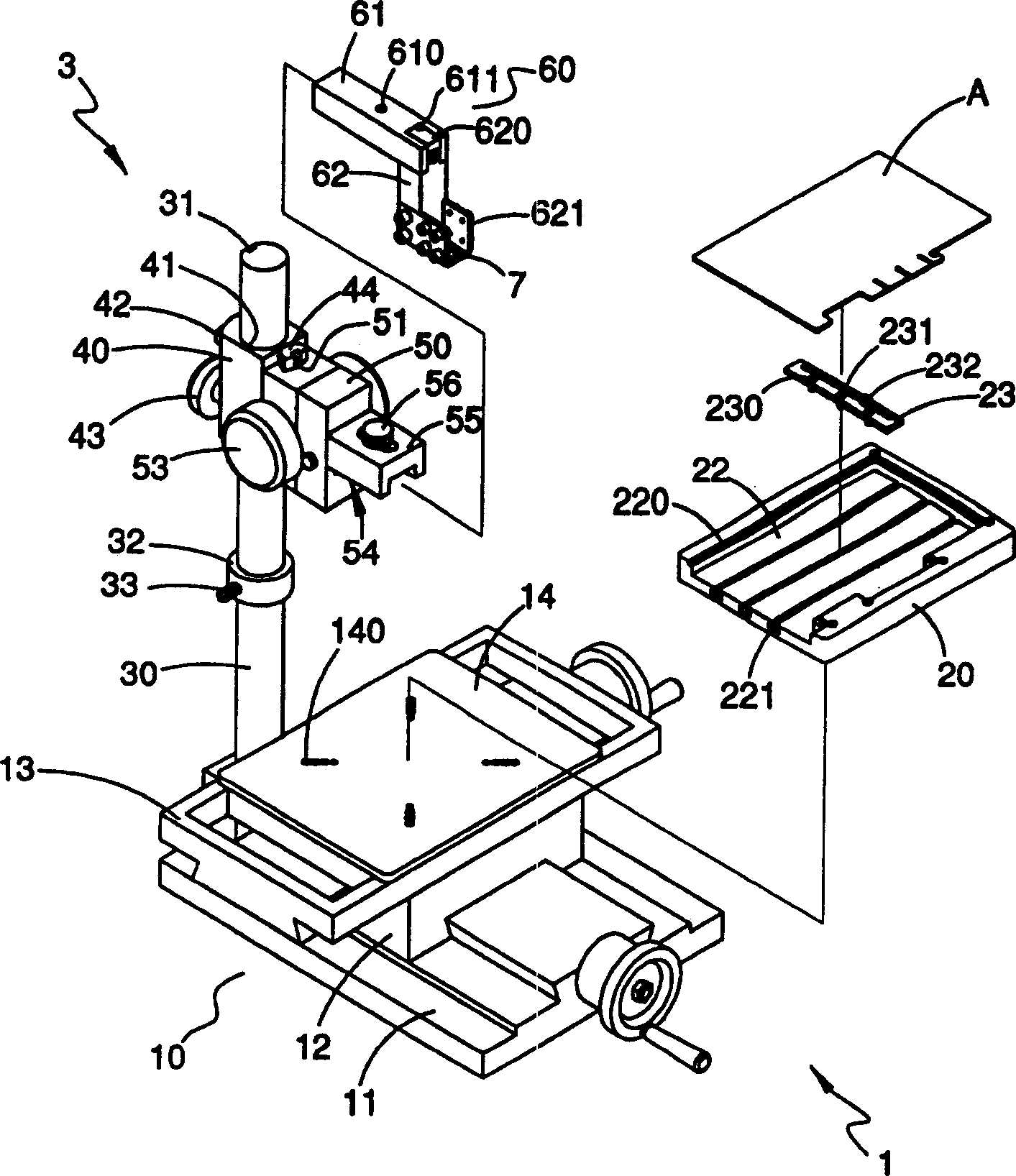

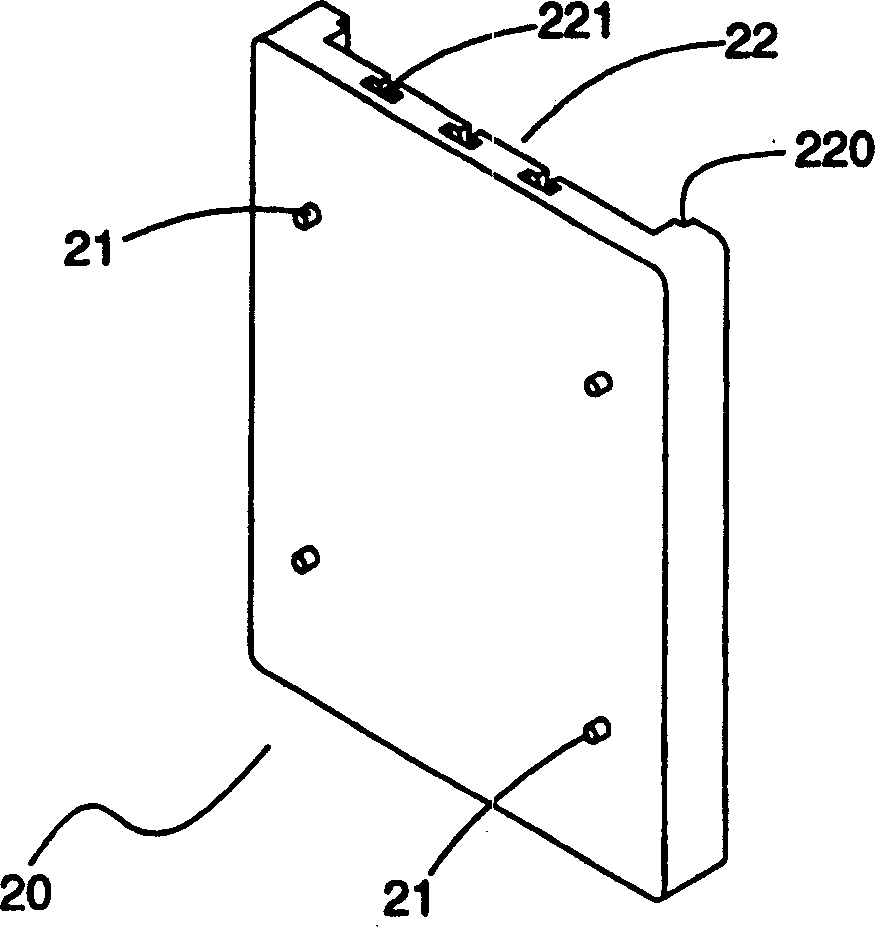

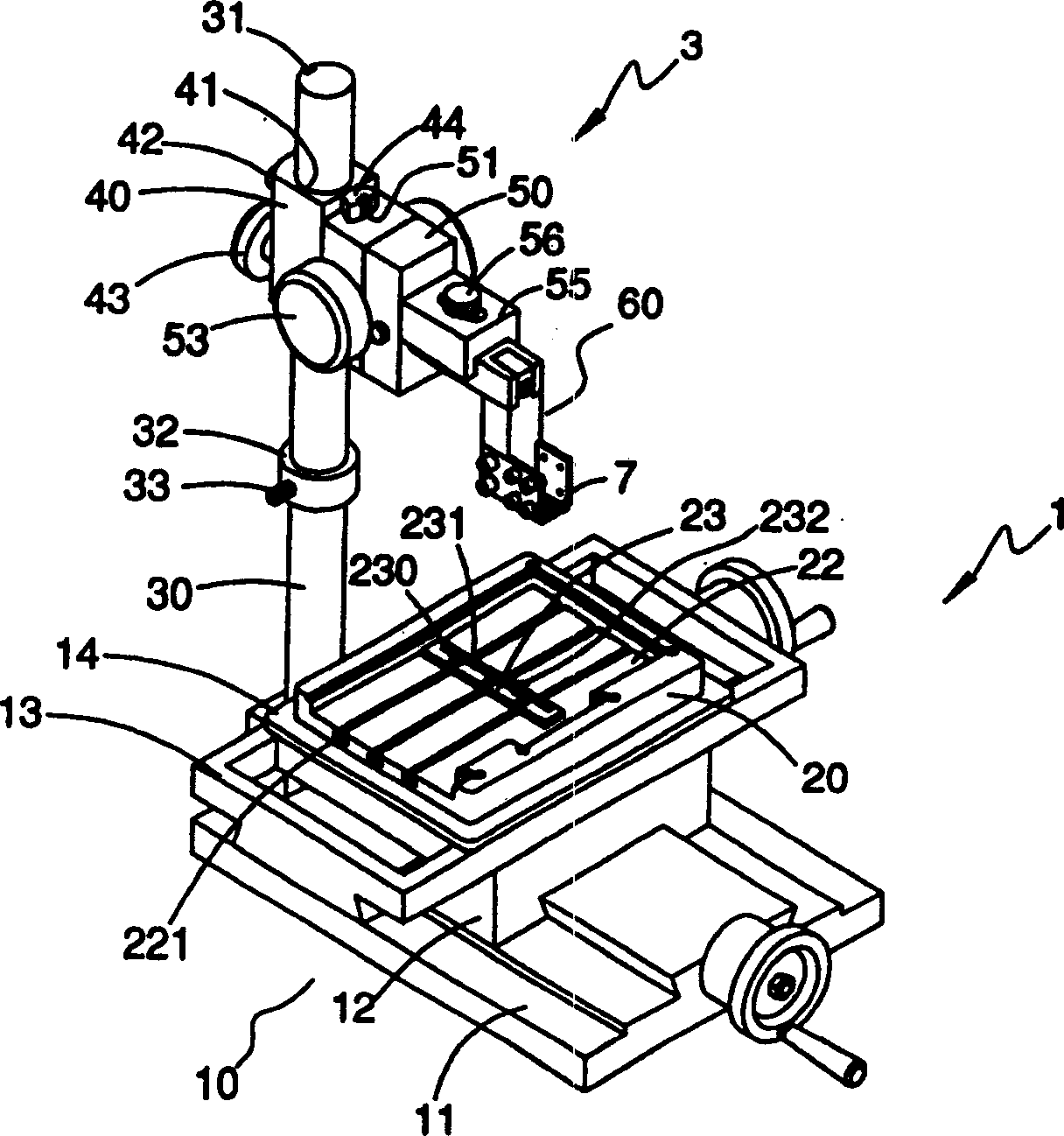

Tin cream coating assistant apparatus

InactiveCN1585592AAccurate coatingAccurate and stable pressurePrinted circuit assemblingEngineeringMobile device

The invention consists of a mobile device, a lifting and lowering device and a tin transplanting device. The mobile device can provide two dimensional spaces for holding a work piece or adjusting the work piece and the lifting and lowering device can control the height of the tin transplanting device. So the tin transplanting board on the tin transplanting device can be precisely and stably pressed on the working area of the work piece. Further more it makes tin past to be precisely paint on each SMT welding spot.

Owner:ASUSTEK COMPUTER INC

High-nickel positive electrode material, preparation method thereof and application of high-nickel positive electrode material in lithium ion battery

PendingCN111883768ALow costIncrease compaction densitySecondary cellsPositive electrodesPhysical chemistryLithium-ion battery

The invention provides a high-nickel positive electrode material, a preparation method thereof and an application of a high-nickel positive electrode material in a lithium ion battery. The high-nickelpositive electrode material comprises a large-size high-nickel positive electrode material and a small-size high-nickel positive electrode material, wherein the large-size high-nickel positive electrode material accounts for 50-90% of the total mass of the high-nickel positive electrode material. By controlling the particle size and particle size distribution of a high-nickel hydroxide precursor,two high-nickel positive electrode materials with different particle sizes are obtained and then mixed according to a certain proportion to obtain a final material, the mixed material has higher compaction density, the volume energy density of a battery can be improved, and thus the cost of the battery is reduced. Besides, the selected small-size high-nickel hydroxide precursor does not contain Co element, and washing is not needed in the preparation process, so that the cost is very low.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

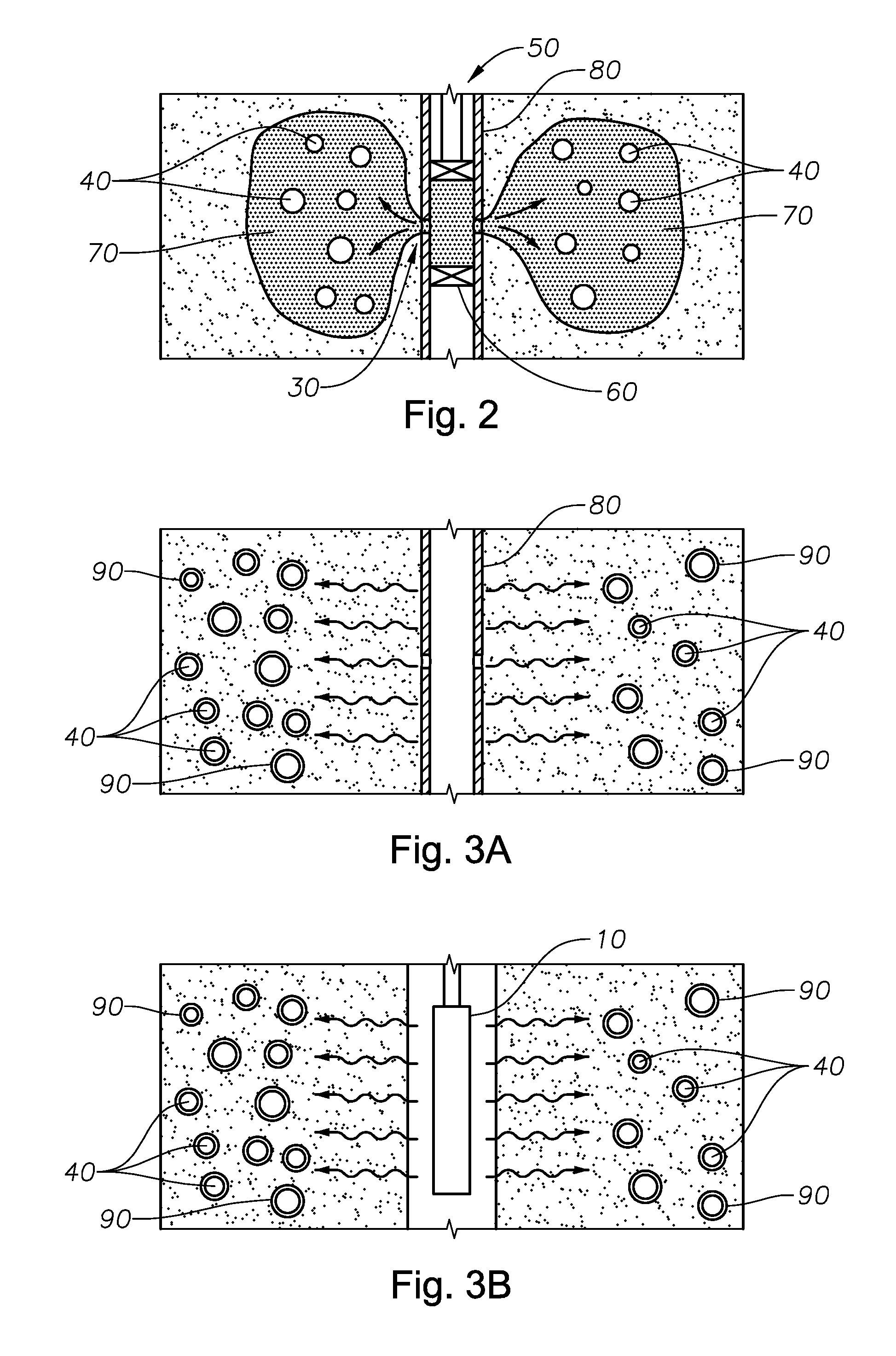

Sand production control through the use of magnetic forces

A process for controlling the production of loose sand particles within an underground formation through the use of magnetic forces is provided. The loose sand particles are magnetized and then subjected to a magnetic field of sufficient strength such that the operator can control the movement of the loose sand particles within the underground formation. In some instances, the present invention can provide an efficient process for keeping the loose sand particles within the formation, and thereby prolonging the useful life of the downhole equipment. In other instances, the present invention can provide an efficient process for sweeping the loose sand particles out of the underground formation in a controlled fashion. The present invention includes at least three embodiments for magnetizing the loose sand particles, including direct magnetization, contacting the sand particles with a magnetizing reagent, and contacting the sand particles with paramagnet nanoparticles.

Owner:SAUDI ARABIAN OIL CO

Single-surface galvanized steel plate surface protection process

ActiveCN108914030AEasy to moveUniform movementHot-dipping/immersion processesPolyurea/polyurethane coatingsSheet steelDust particles

The invention relates to a single-surface galvanized steel plate surface protection process. The single-surface galvanized steel plate surface protection process comprises the following specific steps: (1) steel is received and inspected; (2) dust particles on the surfaces of steel plates are cleaned through pretreatment to guarantee the surface cleanness of the steel plates; and the lower end surfaces and two sides of the steel plates are fixed through a fixing device 1; (3) degreasing treatment: a dipping method is used in degreasing; the temperature is controlled within 50-60 DEG C; and removed grease is prevented from attaching on the surfaces of the steel plates again; (4) hot galvanization is performed; and (5) drying is performed. The single-surface galvanized steel plate surface protection process solves the problems of need of manual movement of the steel plates, need of manual protection of galvanized end surfaces of the steel plates, nonuniform moving speed of the steel plates caused by manual control, incapability of guaranteeing the coating uniformity of acid-resistance substances, imprecise manual protection of the steel plates and incapability of guaranteeing no influence on the galvanized end surfaces of the steel plates by the acid-resistance substances due to wrong operation of the galvanized end surfaces of the steel plates.

Owner:山东亚洪新材料科技有限公司

Automatic hole filling mechanism for veneer

PendingCN112643823APrecise position controlPrecise size controlIrregularity removal devicesControl systemCoating system

The invention provides an automatic hole filling mechanism for a veneer. The automatic hole filling mechanism is composed of a veneer moving system, a glue discharging system, a hole positioning system, an automatic coating system and a control system, and the veneer moving system comprises a conveying belt and a conveying belt motor for driving the conveying belt; the hole positioning system comprises a camera fixing frame located above the conveying belt and a CCD camera installed on the camera fixing frame; the glue discharging system comprises a mixed glue storage barrel, a glue pump connecting pipe externally connected to the mixed glue storage barrel, and a glue discharging pump mounted at the other end of the glue pump connecting pipe; and the automatic coating system comprises a lifting mechanism fixing frame, a lifting device and a plurality of glue spraying heads, wherein the lifting device is installed on the lifting mechanism fixing frame, the multiple glue spraying heads are installed at the bottom of the lifting mechanism fixing frame and closely connected side by side, each glue spraying head is provided with a control valve, and the glue spraying heads are connected with glue outlets of the glue pump through hoses. According to the automatic hole filling mechanism, manual veneer cutting and hole filling are omitted, automatic hole filling of the veneer is achieved, and the veneer laying efficiency is greatly improved.

Owner:天津源启晟科技发展有限公司

Coating head unit

The present invention discloses a coating head unit used for coating liquid crystal onto a glass panel during the manufacturing process of LCDs. The coating head unit comprises a discharging means, a mobile member, a stationary member and a displacement measuring means. The discharging means comprises a liquid crystal receiving member. The liquid crystal receiving member comprises a liquid crystal discharging channel and a liquid crystal receiving space arranged in the liquid crystal discharging channel. The discharging means also comprises a mobile piece movably arranged in the liquid crystal receiving space. When the mobile piece is moved to reduce the volume of the receiving space, liquid crystal is discharged out of the receiving space through the liquid crystal discharging channel. The mobile member is moved along the movement direction of the mobile piece together with the mobile piece. The stationary member is stationary in the movement direction relative to the mobile piece. The displacement measuring means measures the displacement of the mobile member relative to the stationary member.

Owner:TOP ENG CO LTD

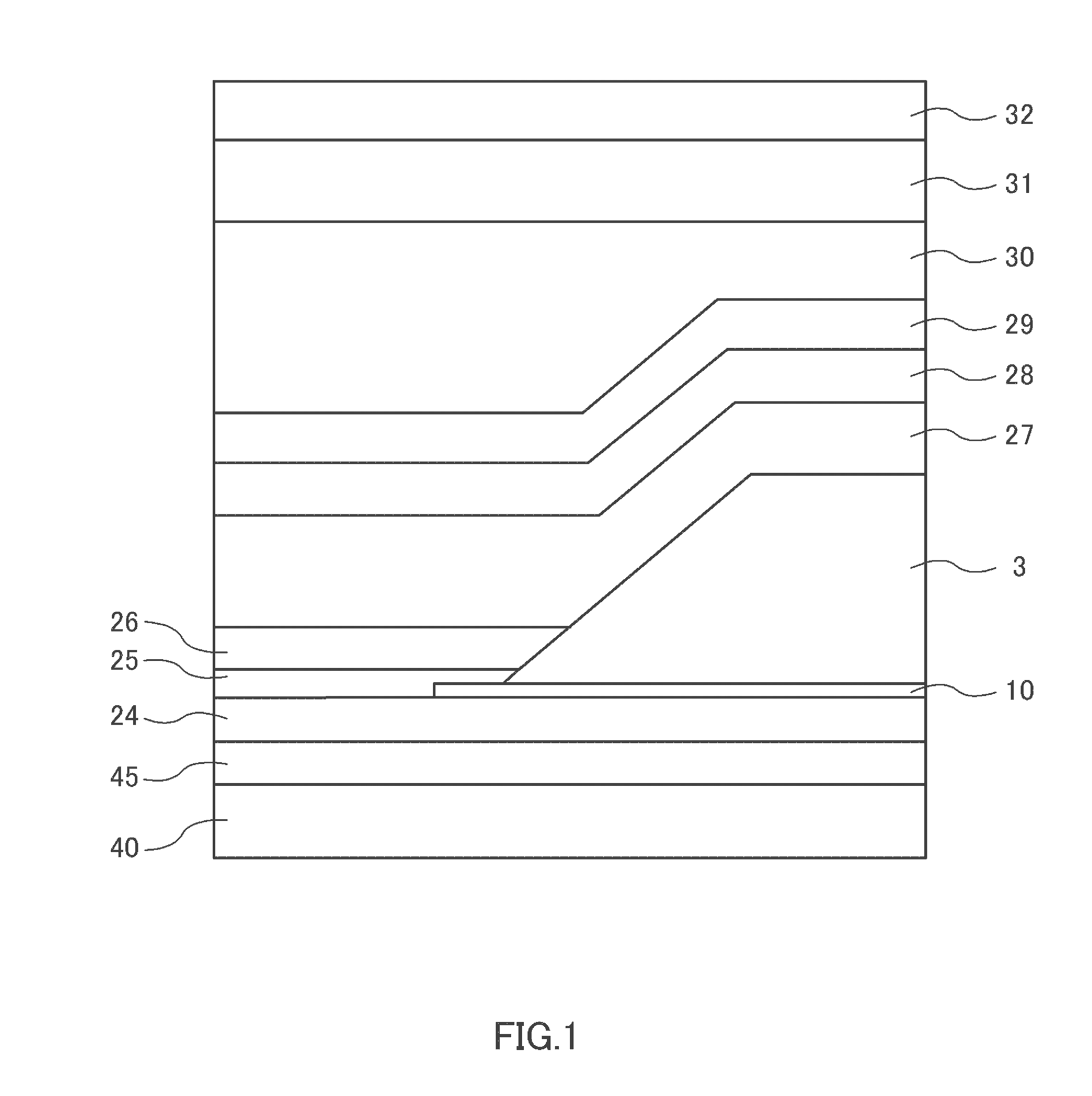

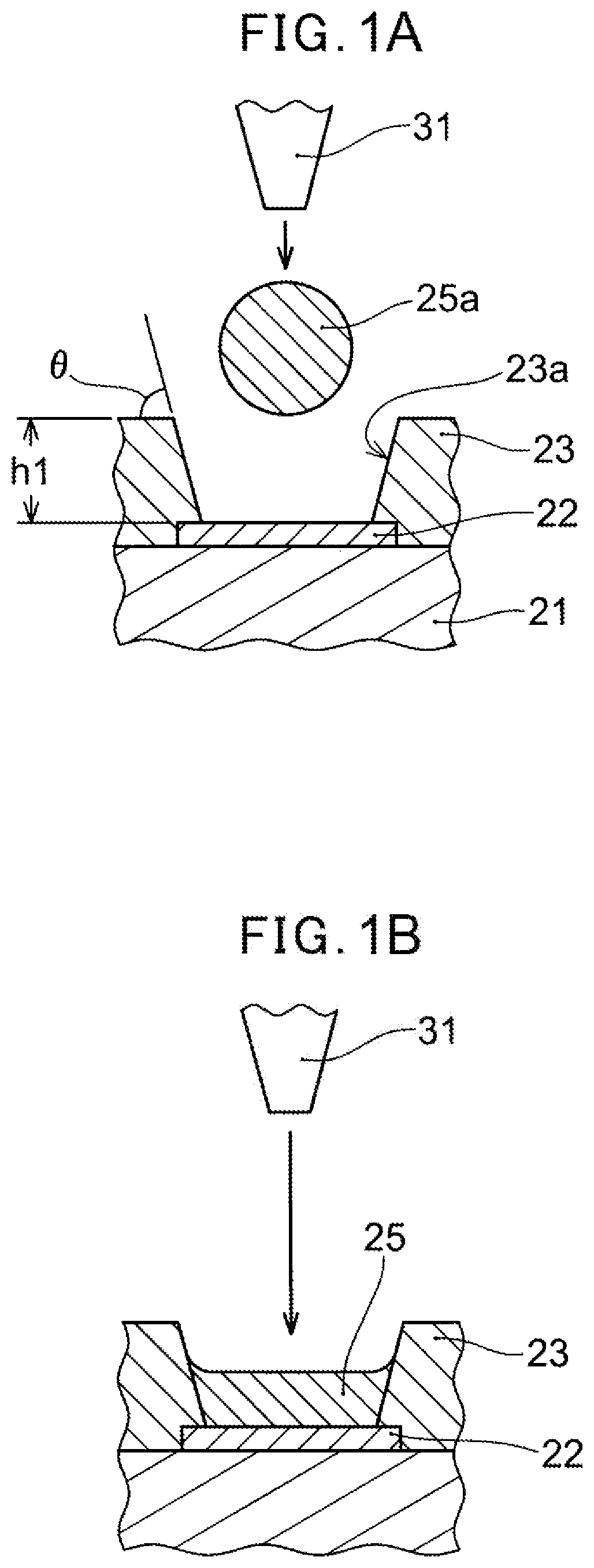

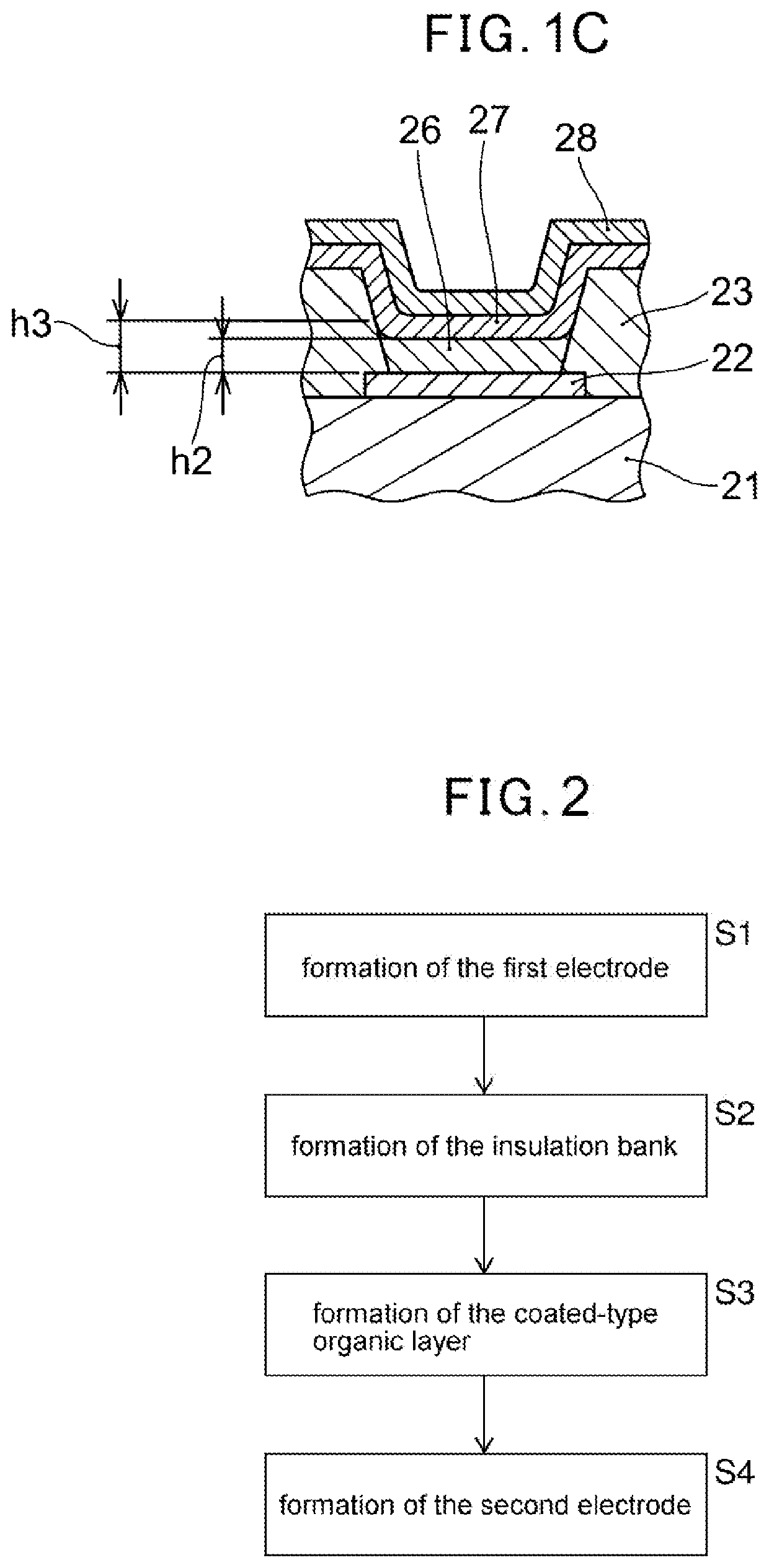

Organic el light-emitting element and manufacturing method thereof

ActiveUS20200220081A1Easy to manufactureLow costElectroluminescent light sourcesSolid-state devicesOligomerOrganic layer

An organic EL light-emitting element is provided in which, by means of an organic material that is oligomeric, an organic layer coated film 25 is formed in a high-definition pixel pattern in the openings 23a of insulation banks 23 that are formed to be hydrophilic; a manufacturing method of said organic EL light-emitting element is also provided. The coated film 25 is formed by dropwise injection of a liquid composition containing an organic material oligomer.

Owner:SAKAI DISPLAY PROD

Coating of a glass sleeve

InactiveUS20150136118A1Transmission loss be reduceImprove efficiencySolar heating energySolar heat devicesEngineeringCoating

A method of applying a coating to a glass sleeve with an inner surface and an outer surface, the glass sleeve configured as a part of a solar-receiver tube, is provided. Thereby, the coating is solely applied to one of the surfaces of the glass sleeve. A method of fixing such glass sleeve in an interior of a coating tank, such coating tank and a fixing arrangement for fixing such glass sleeve in an interior of a coating tank, is also provided.

Owner:SIEMENS CONCENTRATED SOLAR POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com