Method for spotting glue for lens module

A lens module and glue dispensing technology, which is applied in installation, optics, instruments, etc., can solve problems such as poor glue dispensing, easy flow of glue, and affecting the optical and mechanical properties of the lens module.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation of the technical solution will be further described in detail below in conjunction with the accompanying drawings.

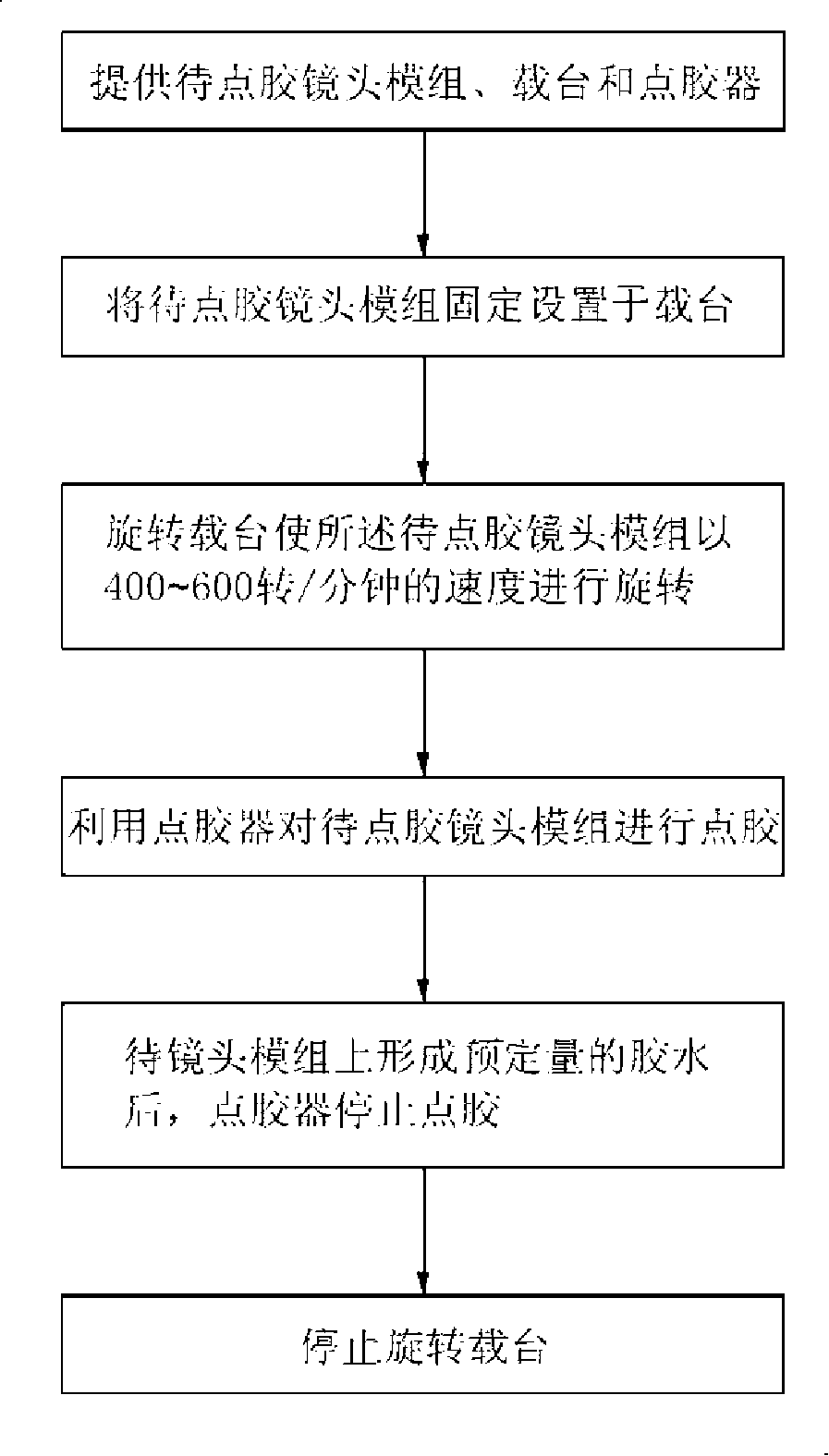

[0017] see figure 1 , the lens module dispensing method includes the steps of: providing a lens module to be dispensed, a carrier and a glue dispenser; fixing the lens module to be dispensed on the carrier; rotating the carrier to make the lens to be dispensed The module rotates at a speed of 400-600 rpm; use the dispenser to dispense glue on the dispensing lens module; after a predetermined amount of glue is formed on the lens module, the dispenser stops dispensing; stop rotating reprint table. The lens module dispensing method of this embodiment will be described step by step below.

[0018] The first step is to provide a lens module to be dispensed, a carrier and a dispenser.

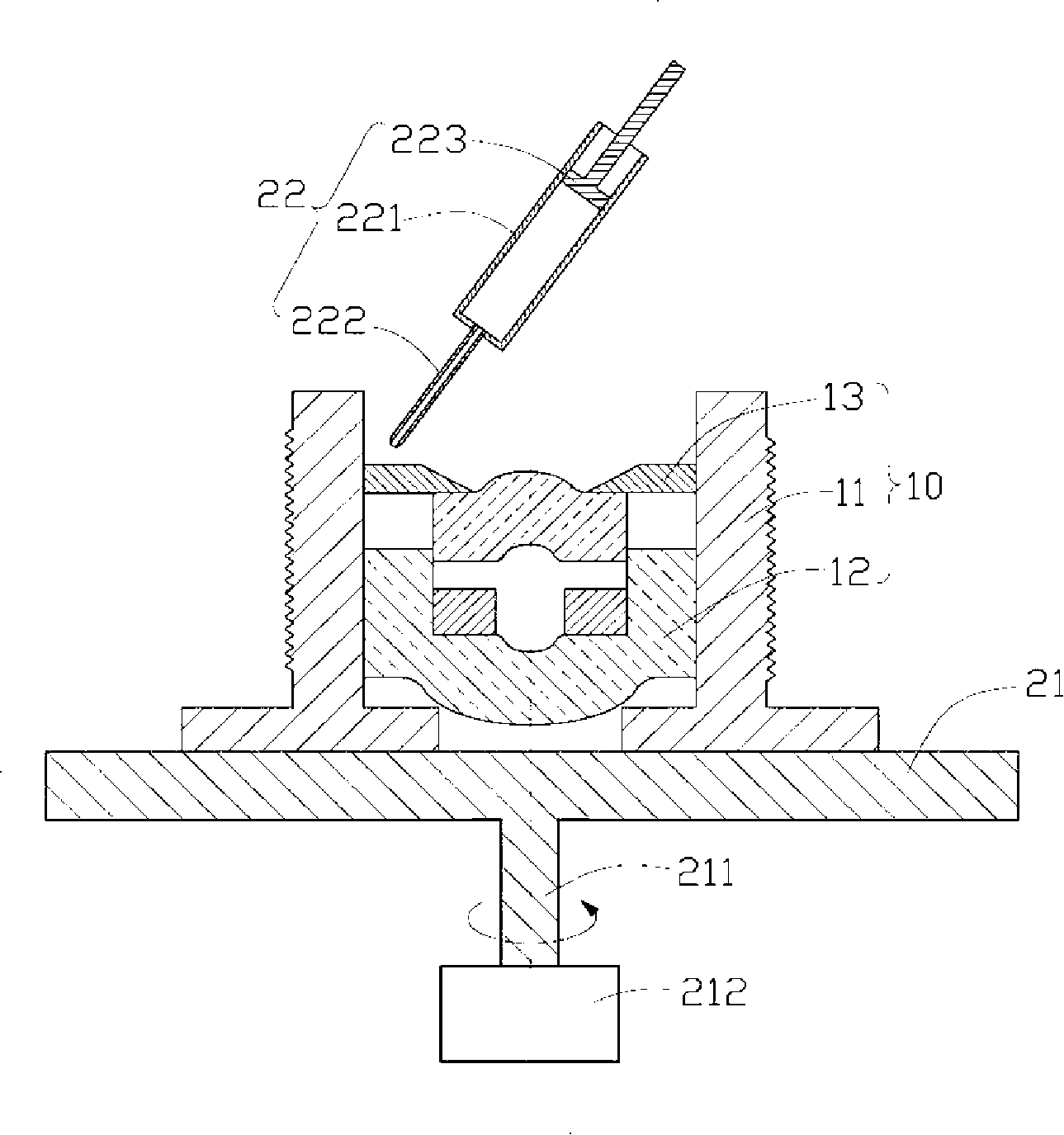

[0019] see figure 2 , the lens module 10 to be glued includes a lens barrel 11 , a lens group 12 , and a spacer ring 13 . The lens group 12 and the spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com