Single-surface galvanized steel plate surface protection process

A technology of galvanized steel sheet and steel sheet, applied in hot dip plating process, metal material coating process, coating and other directions, can solve the problems of low work efficiency, uneven moving speed of manual control steel sheet, high labor intensity, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

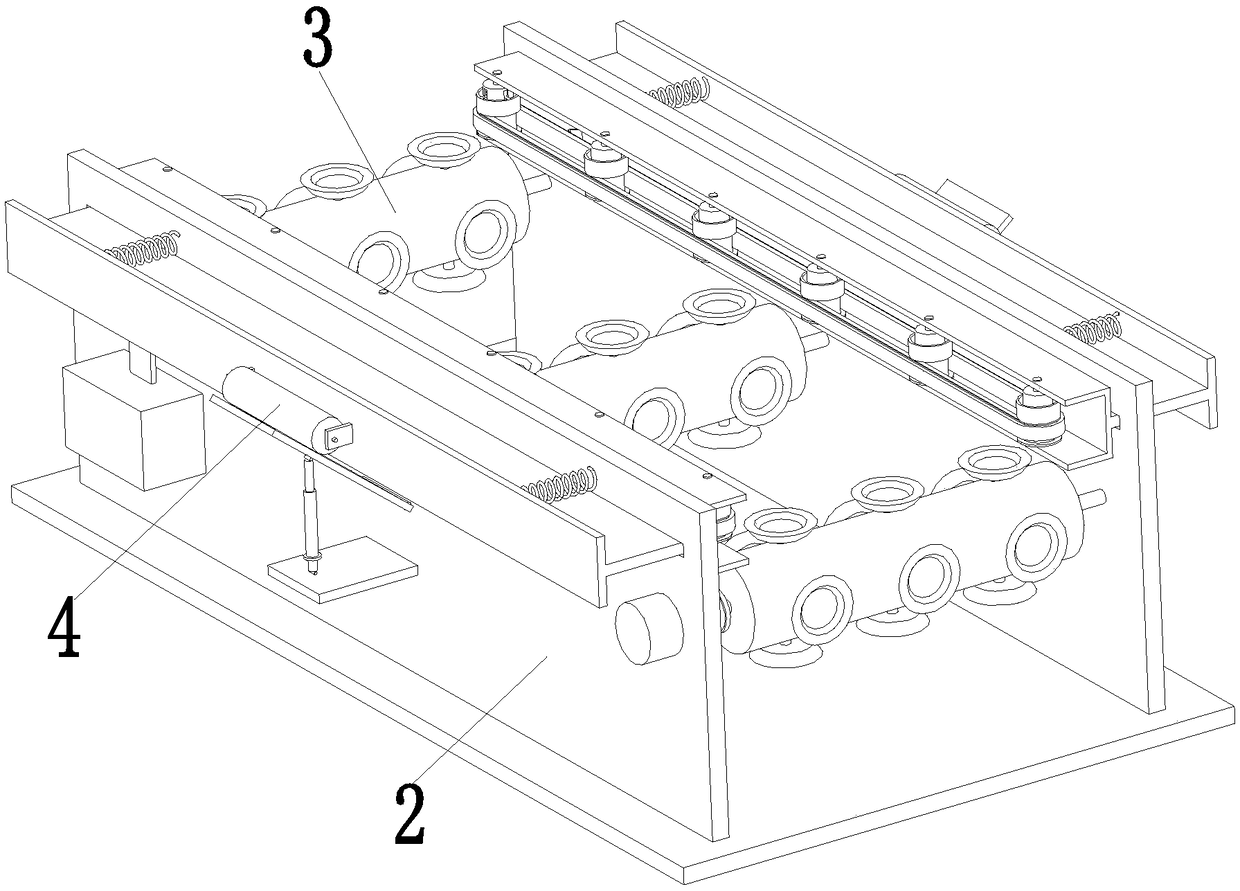

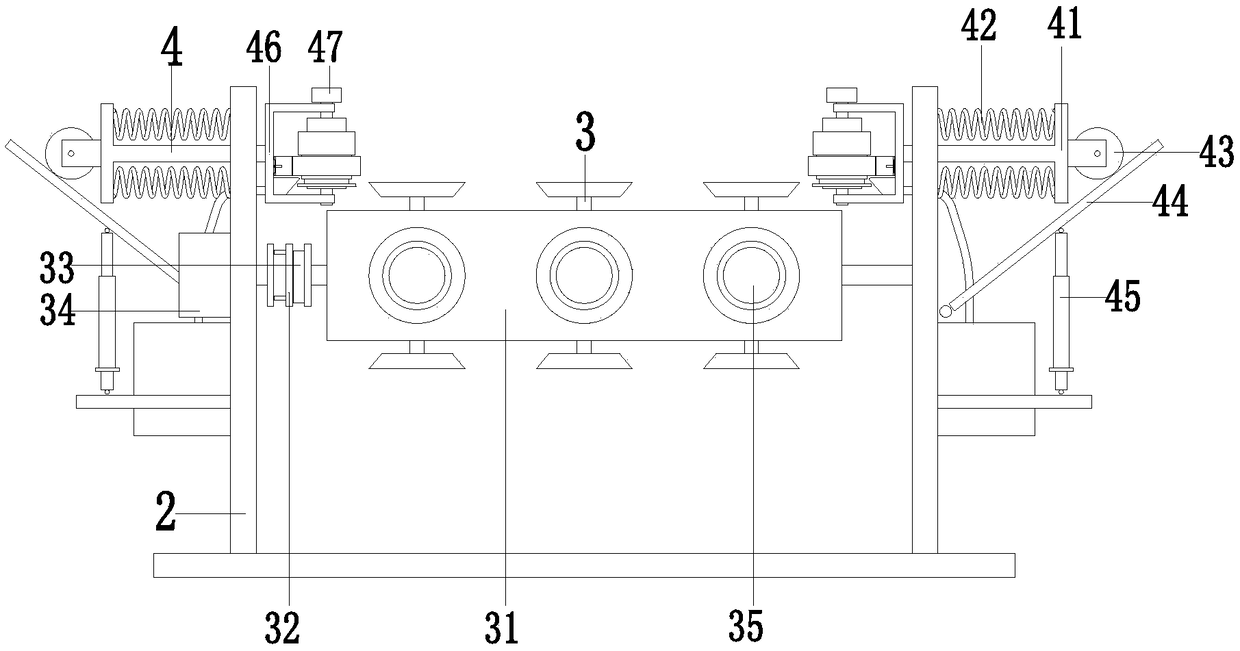

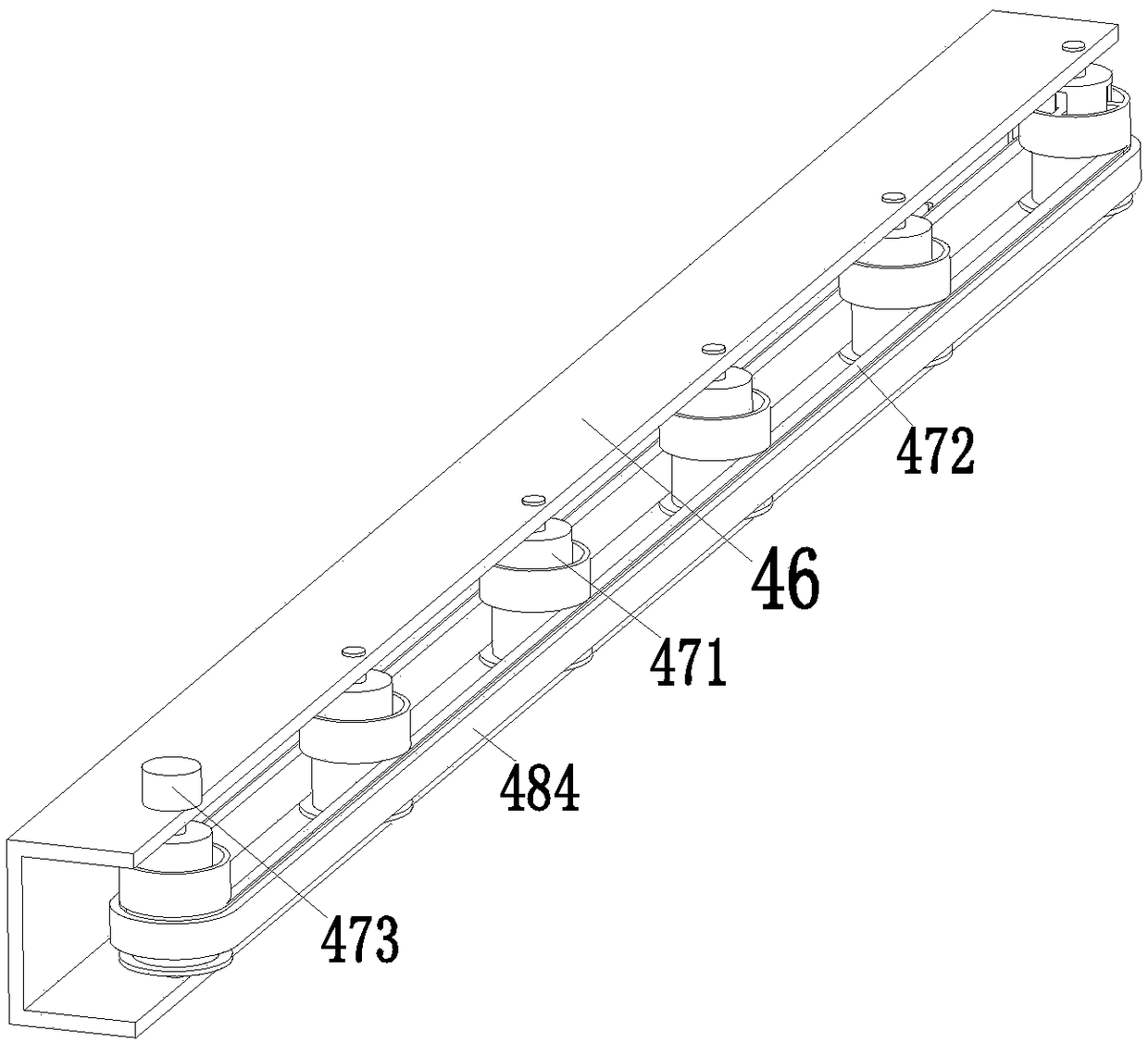

[0026] Such as Figure 1 to Figure 5As shown, a single-side galvanized steel surface protection process includes the following steps:

[0027] Step 1. Incoming inspection of steel products, check whether there are obvious defects on the surface of the steel products by visual inspection, and select steel products without obvious bending and dents;

[0028] Step 2. Clean the surface of the steel plate, use a fan to clean off the dust on the surface of the steel plate, and use a rag to wipe off the dust adhered to the surface of the steel plate;

[0029] Step 3, steel plate protection operation, place the steel plate on the fixing device, the fixing device fixes the lower end surface and both sides of the steel plate, the fixing device contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com