Coating head unit

A technology of coating heads and liquid crystals, applied in coatings, devices for coating liquid on surfaces, optics, etc., can solve problems such as processing errors of moving components and changes in assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

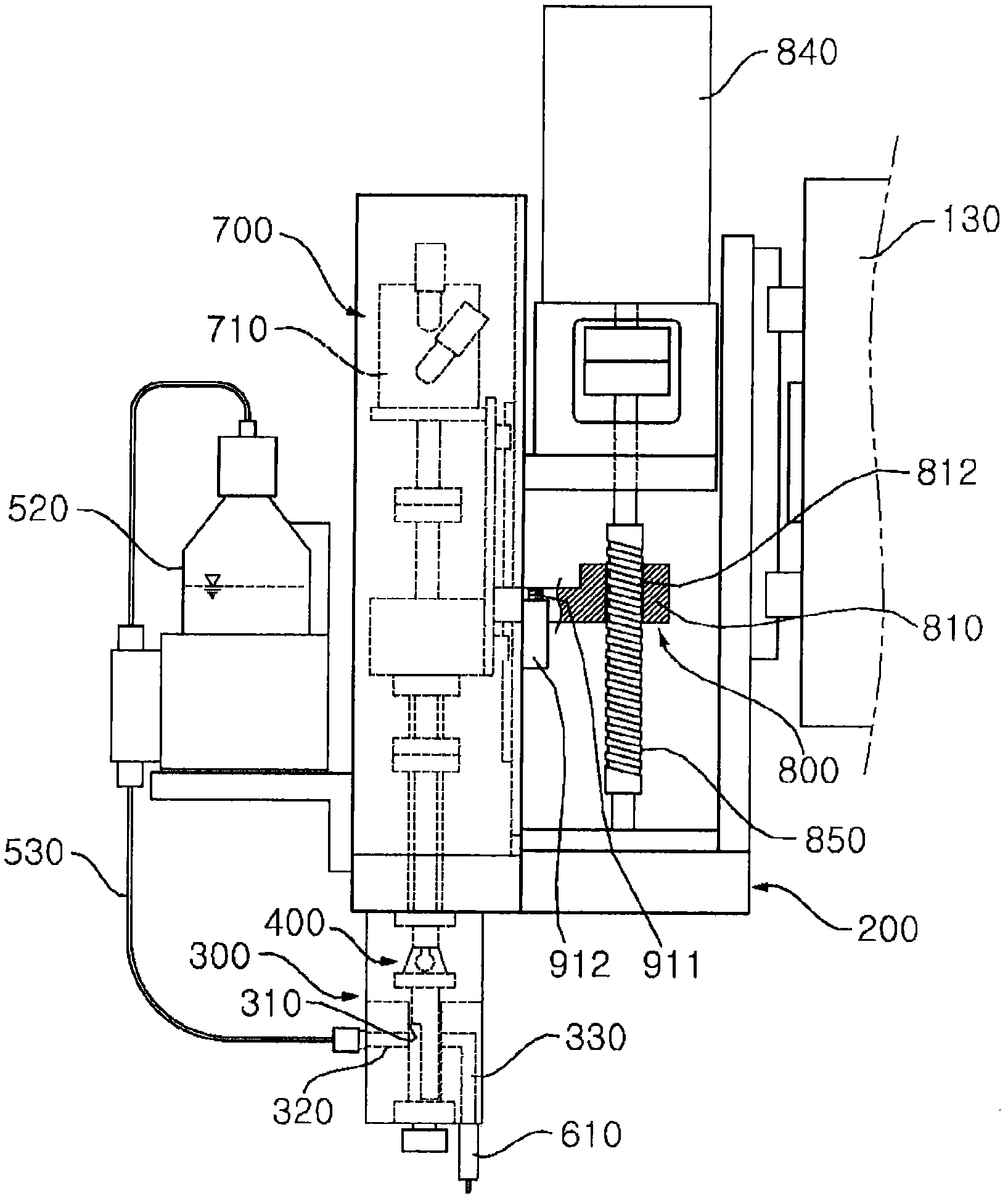

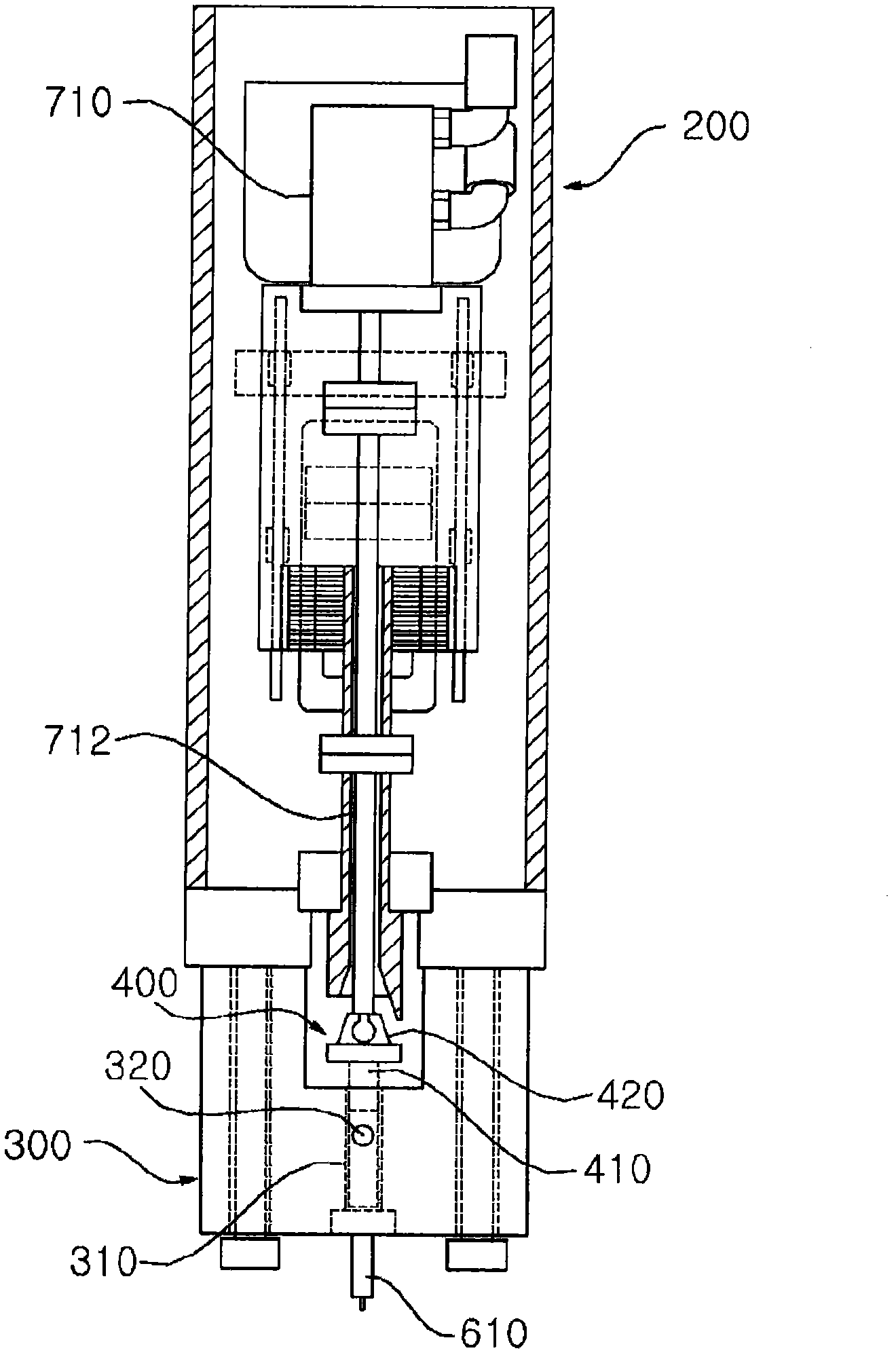

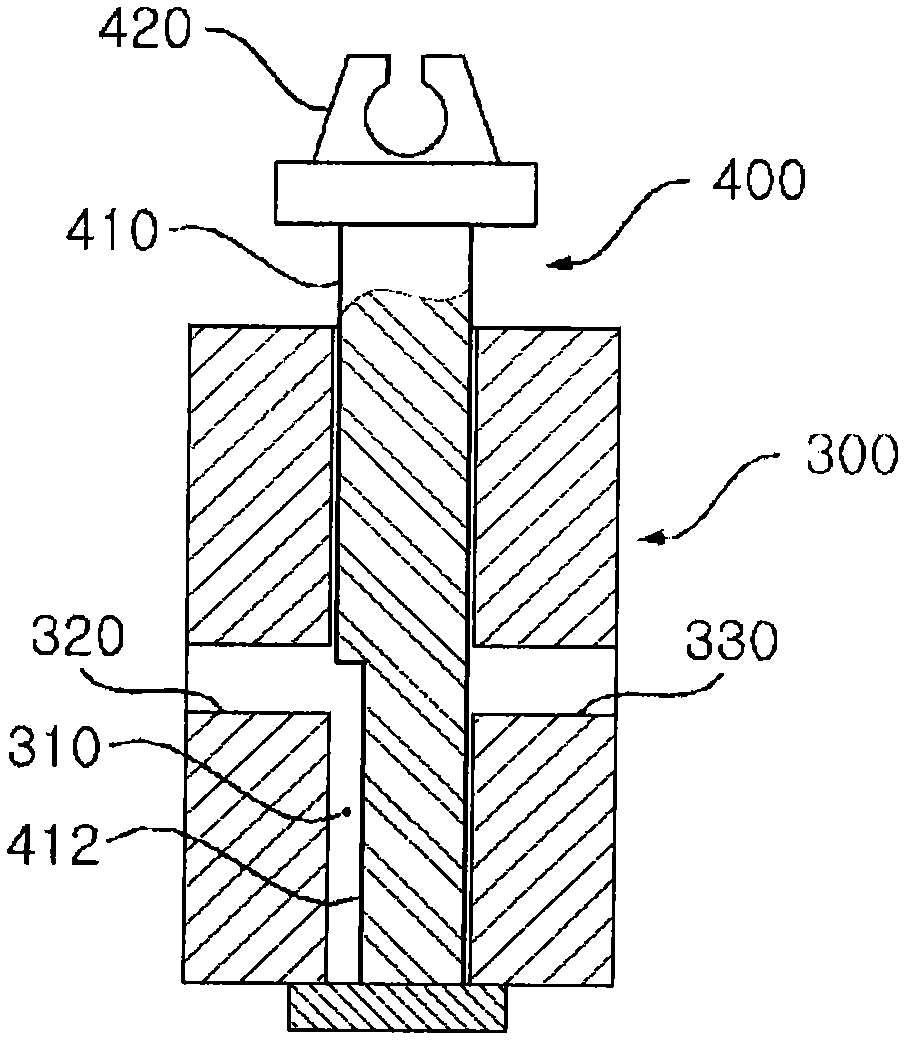

[0029] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0030] At least one coating head unit according to the invention is arranged in the LC coater. The coating head unit applies liquid crystal to the glass panel while moving relative to the glass panel. The coating head unit according to the present invention coats liquid crystals using a volume control method in which liquid crystals are discharged from the receiving space when the volume of the liquid crystal receiving space is reduced by movement of the moving member. The coating head unit of the present invention is characterized by displacement measuring means for measuring the displacement between before and after the movement of the moving member. In the present invention, two methods for measuring the displacement of the moving member will be disclosed. The first method of measurement is to indirectly measure the displacement of the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com