Method for determining amount of wear, method for manufacturing sliding contact, and sliding contact

A sliding contact and manufacturing method technology, applied in sliding contact bearings, measuring devices, testing wear resistance, etc., can solve the problems of low accuracy, low precision, time-consuming solid lubricating coating, etc., to achieve reliability and service life The effect of improving and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

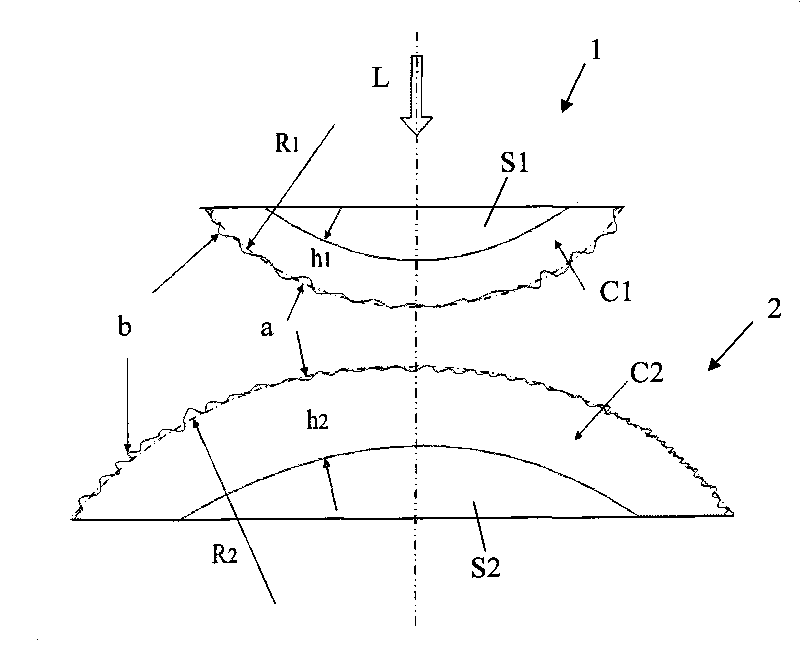

[0037] figure 1 shows the sliding contacts (counter ligands) 1 and 2 with solid lubricant coatings in non-coordinated contact with each other, which slide relative to each other. Sliding contact 1 has a base S1 and a solid lubricating coating C1 formed on the base, and sliding contact 2 has a base S2 and a solid lubricating coating C2 formed on the base.

[0038] However, only one of the sliding contacts 1 and 2 may have only the solid lubricating coating.

[0039] The material of the substrate S1 has a modulus of elasticity E 1s and Poisson's ratio v 1s , the material of the substrate S2 has an elastic modulus E 2s and Poisson's ratio v 2s .

[0040] The solid lubricating coating C1 has an outer surface curvature radius R1 and a thickness h1, and a material elastic modulus E 1c and Poisson's ratio v 1c ; The solid lubricating coating C2 has an outer surface curvature radius R2 and a thickness h2, and a material elastic modulus E 2c and Poisson's ratio v 2c . The mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com