Automatic speed adjusting device for small-size two-stroke gasoline engine

A gasoline engine, automatic speed regulation technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve problems such as product launch, and achieve the effect of increasing reliability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

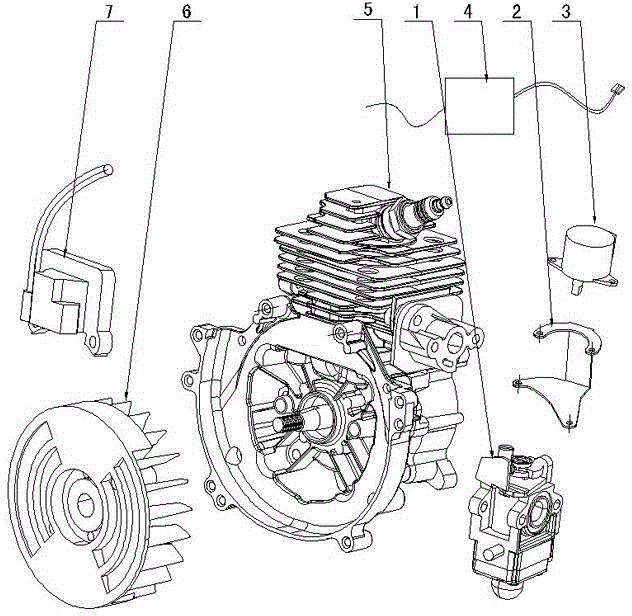

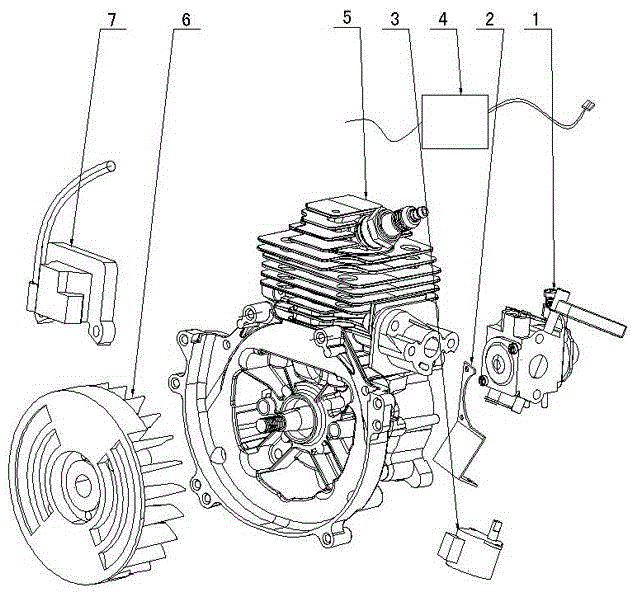

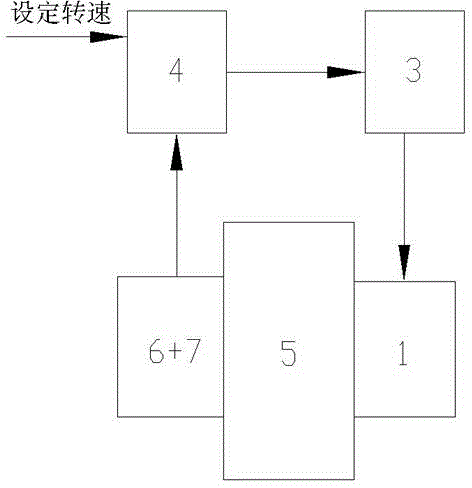

[0015] Figure 1 to Figure 3 Shown, for the present invention creates the concrete embodiment of a kind of small two-stroke gasoline engine automatic speed control device, it comprises carburetor 1, speed regulating motor 3, circuit controller 4, engine 5, flywheel and magneto 6, engine High voltage pack 7, speed regulating motor 3 are fixed on the carburetor 1 by mounting bracket 2, and the engine speed signal of the flywheel and magneto 6 that are installed on the crankshaft of engine 5 is transmitted to circuit controller 4, and circuit controller 4 and After the set speed is compared, the rotation signal of the speed regulating motor is output, so that the speed regulating motor 3 rotates forward or reversely, the throttle opening of carburetor 1 is opened or closed at a certain angle driven by speed regulating motor 3, and the throttle opening of carburetor 1 changes Control the engine 5 rotating speed, make the engine 5 rotating speed work at a constant speed under the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com