Adjustable gas distribution system and magnetron sputtering coating device comprising same

A gas distribution system and magnetron sputtering technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problems of decreased application effect, high production cost, difficult operation and maintenance, etc. To achieve the effect of convenient operation and maintenance, low production cost and uniform film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

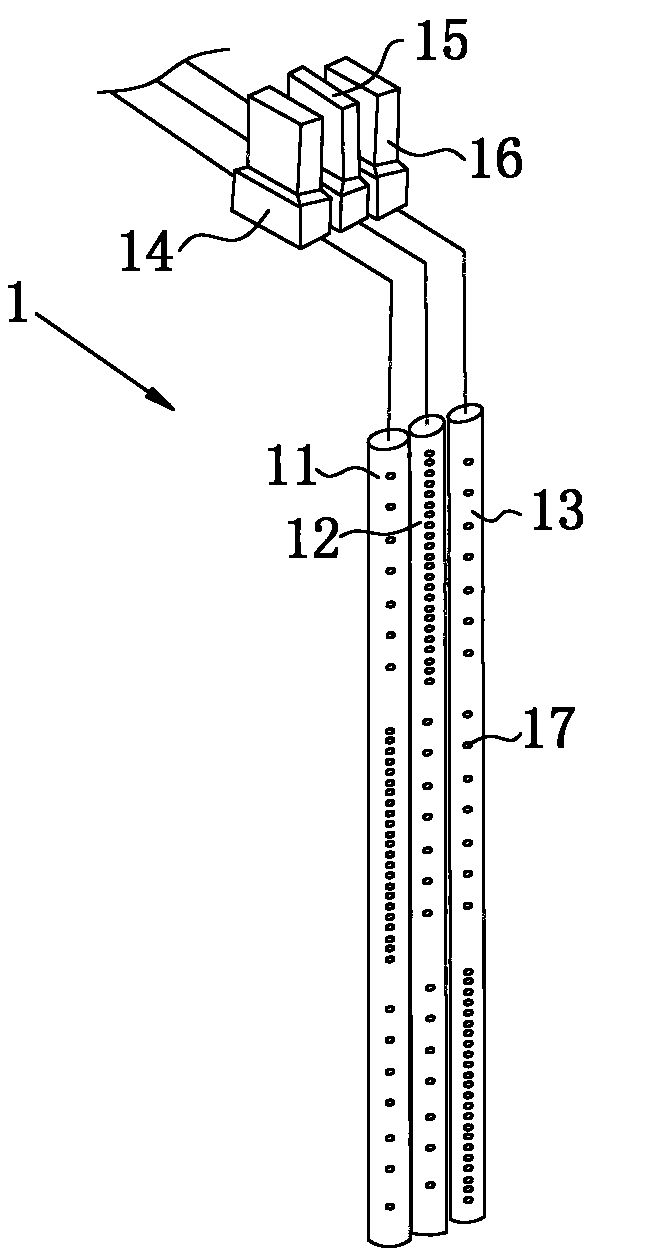

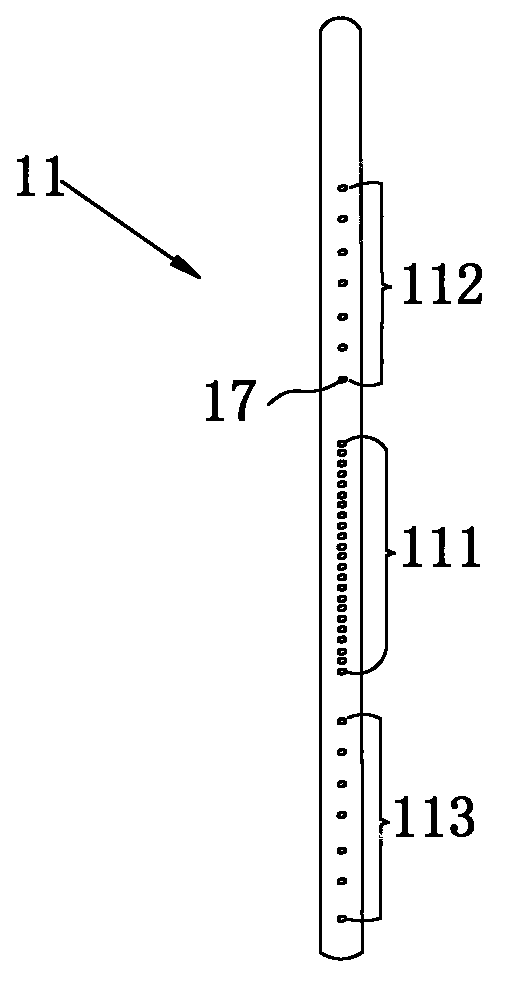

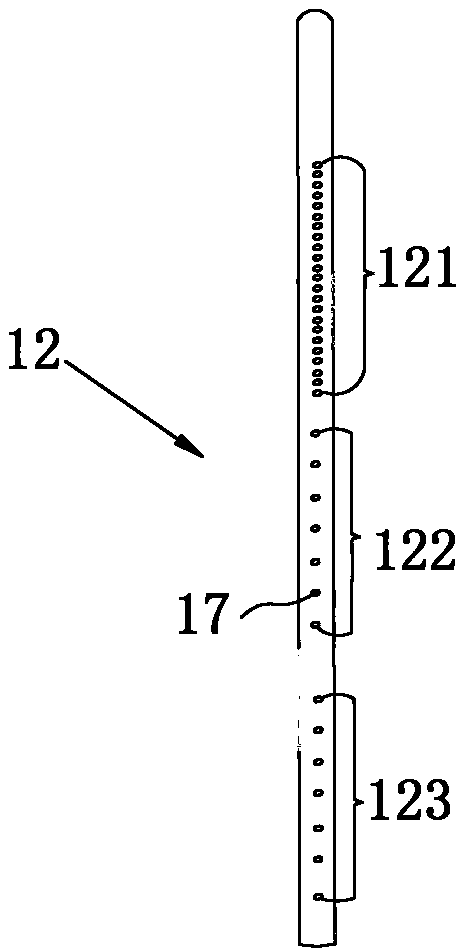

[0063] Such as figure 1 As shown, the adjustable air distribution system described in this embodiment includes three air distribution pipes arranged in parallel, which are respectively the first air distribution pipe 11, the second air distribution pipe 12 and the third air distribution pipe 13. In the first air distribution pipe 11 The first flow meter 14 for controlling its gas flow is arranged on the top, the second flow meter 15 for controlling its gas flow is arranged on the second gas distribution pipe 12, and the second flow meter 15 for controlling its gas flow is arranged on the third air distribution pipe 13 The third flow meter 16.

[0064] The first air distribution pipe 11 , the second air distribution pipe 12 and the third air distribution pipe 13 are provided with air blowing sections matching the length of the target surface of the magnetron sputtering target, and the blowing sections of the three air distribution pipes have the same length.

[0065] Such as ...

Embodiment 2

[0078] Such as Figure 6 As shown, the adjustable air distribution system described in this embodiment includes four air distribution pipes arranged in parallel, namely the first air distribution pipe 41, the second air distribution pipe 42, the third air distribution pipe 43 and the fourth air distribution pipe 44 , a first flow meter 45 for controlling its gas flow is arranged on the first air distribution pipe 41, a second flow meter 46 for controlling its gas flow is arranged on the second air distribution pipe 42, and a third air distribution pipe 43 A third flowmeter 47 for controlling the gas flow is provided, and a fourth flowmeter 48 for controlling the gas flow is arranged on the fourth air distribution pipe 44 .

[0079] The first gas distribution pipe 41, the second gas distribution pipe 42, the 3rd gas distribution pipe 43 and the 4th gas distribution pipe 44 are provided with an air blowing section matching the length of the target surface of the magnetron sputteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com