Semi-automatic window patching machine

A semi-automatic and window sticking machine technology, which is applied in the direction of container manufacturing machinery, paper/cardboard containers, containers, etc., can solve the problems of high price, high cost, complex structure, etc., to improve processing efficiency, reduce labor intensity, and reliable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described below in conjunction with embodiment and accompanying drawing.

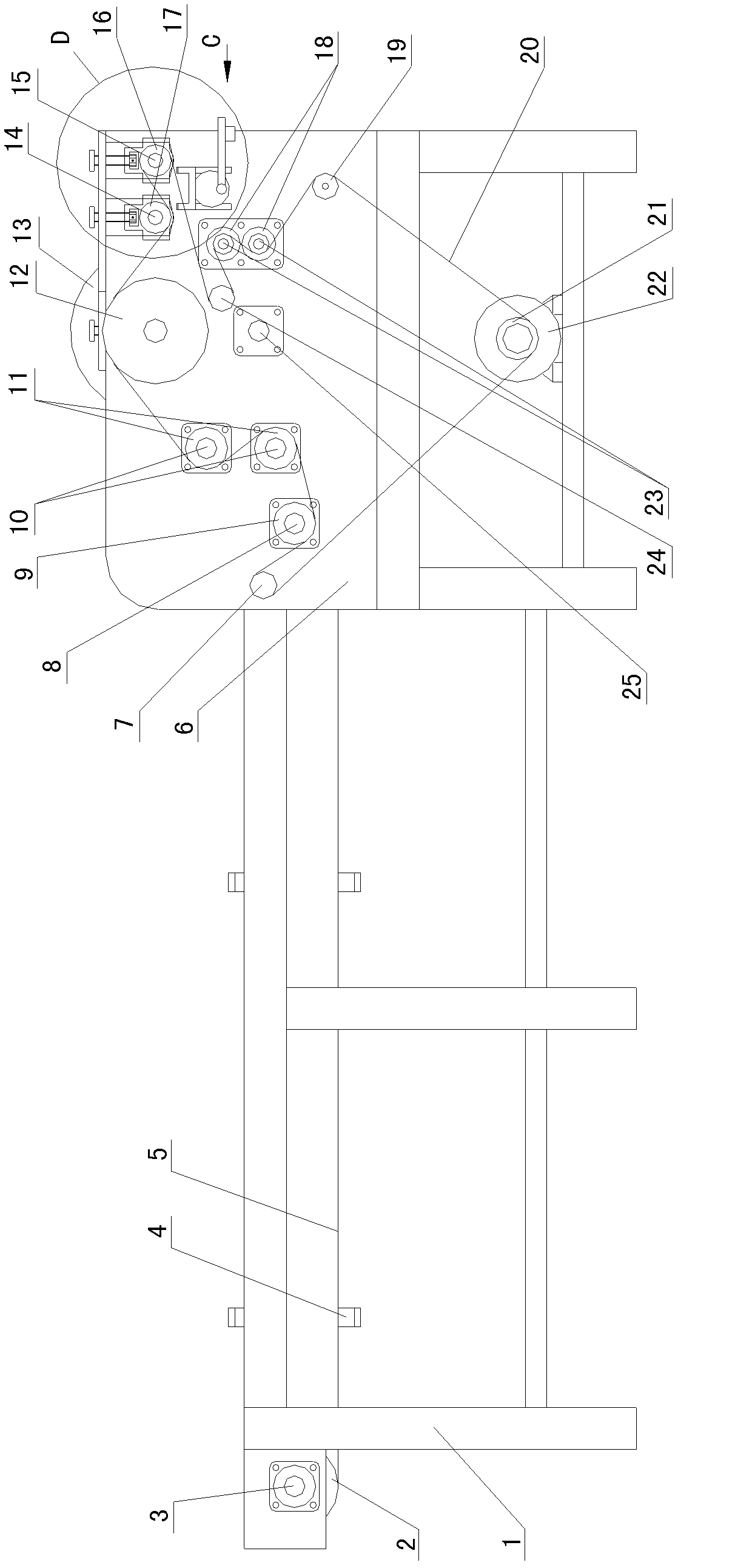

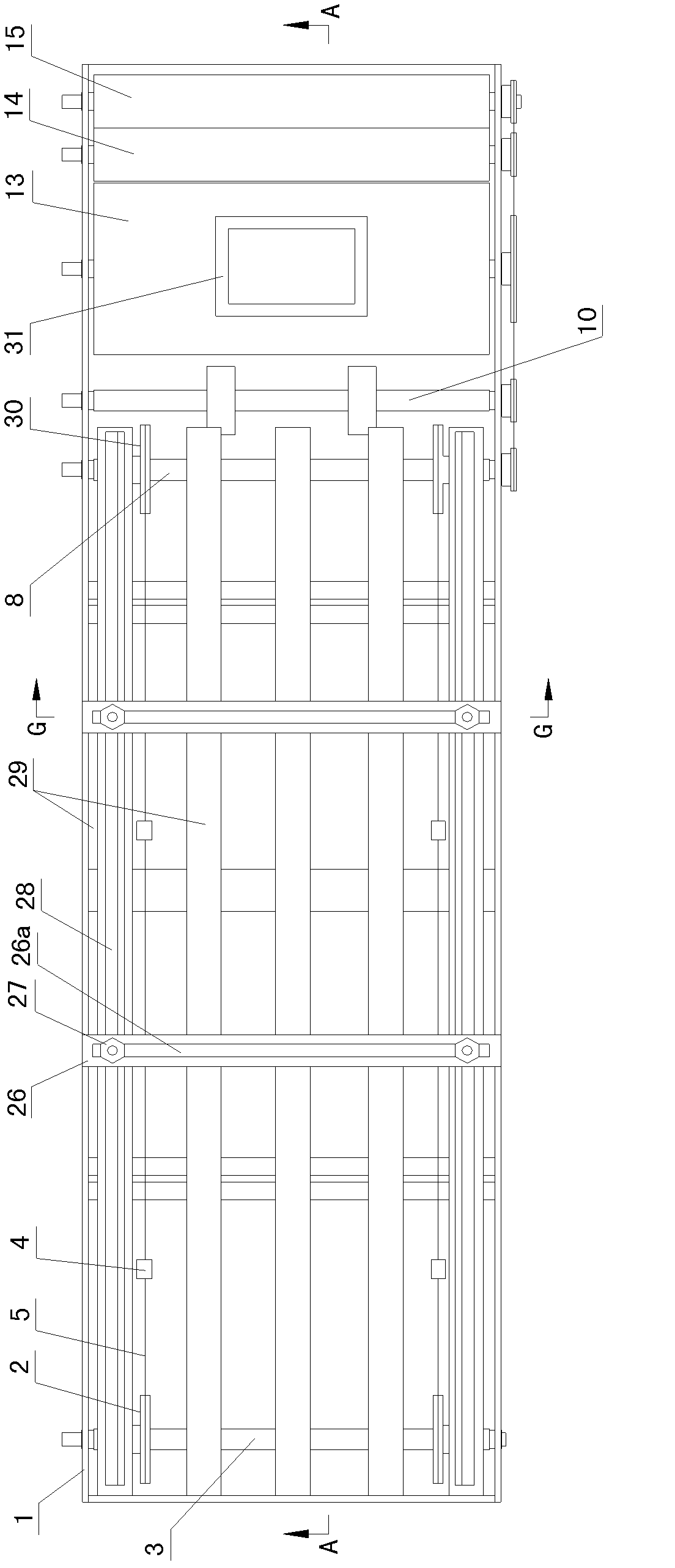

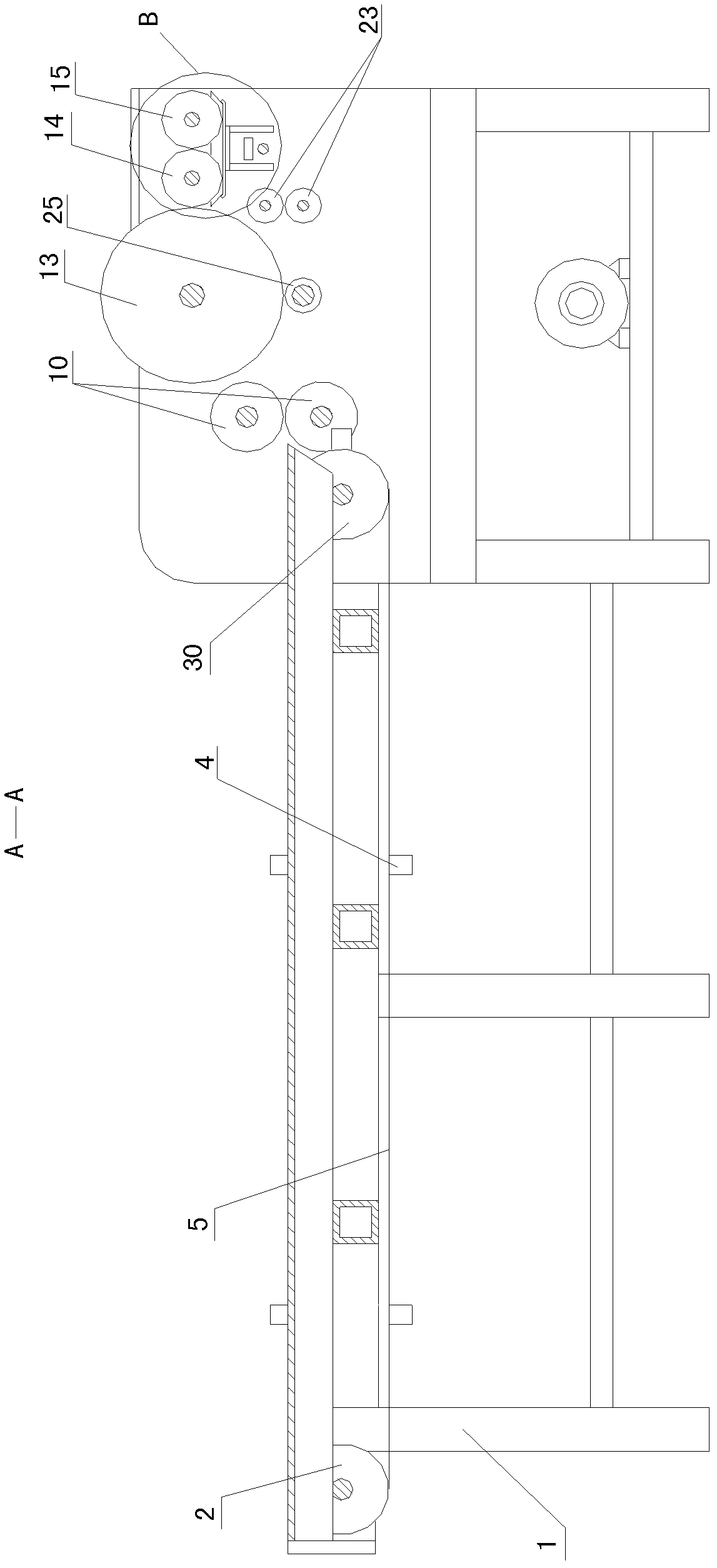

[0017] see figure 1 , figure 2 , image 3

[0018] The semi-automatic window sticking machine provided by the present invention has a workbench 1, one end of the workbench 1 is connected with a frame 6, and the cloth rubber roller 13 mounted on the frame 6 is attached with a cloth with the same shape as the edge of the skylight of the corresponding packaging box. Adhesive strip 31, the below of cloth rubber roller 13 establishes rolling roller 25. The feeding mechanism has a driving shaft 8 and a driven shaft 3, and the driving shaft 8 and the driven shaft 3 are installed on the workbench 1. A driving sprocket 30 is respectively installed at both ends of the driving shaft 8, and a driving sprocket 30 is respectively installed at both ends of the driven shaft 3. A driven sprocket 2 is housed, and a conveying chain 5 is housed on the driving sprocket 30 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com