Device and method for manufacturing lithium ion battery winding spacing

A lithium-ion battery and gap technology, applied in the direction of secondary batteries, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as battery deformation, achieve the effect of releasing internal stress, solving deformation, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

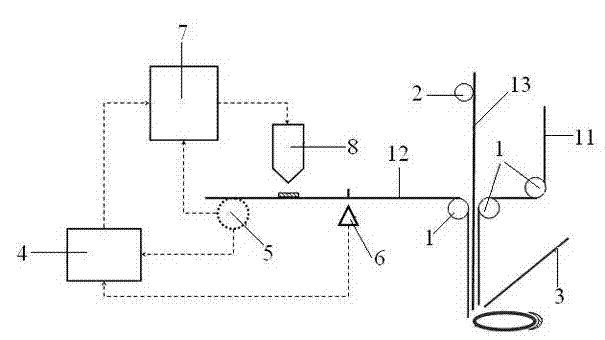

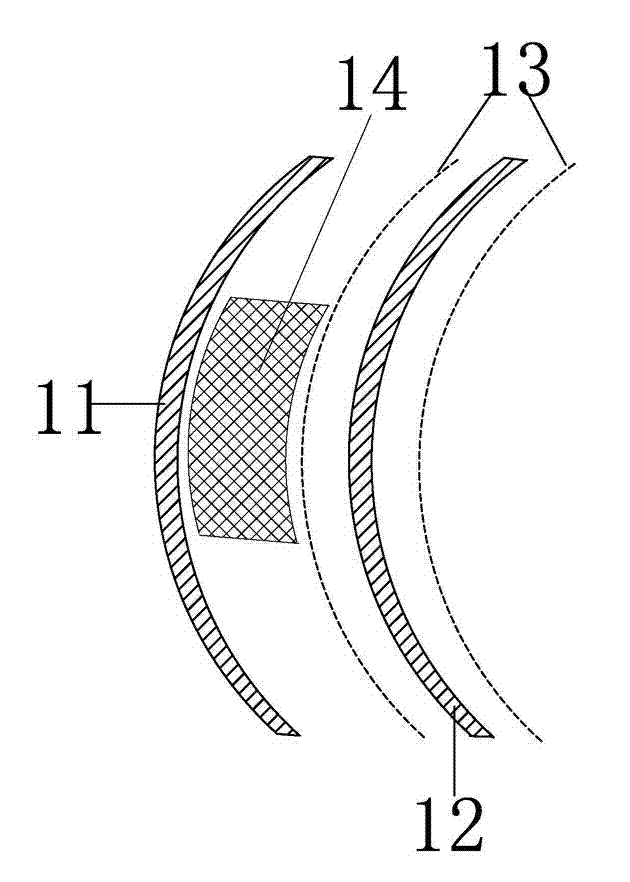

[0028] Example 1: see figure 2 The device for manufacturing the winding gap of lithium-ion batteries provided in this embodiment includes a pole piece driving wheel 1, a diaphragm driving wheel 2 and a winding machine 3, and also includes a PLC controller 4, an encoder 5, a sensor 6 and a coating machine 7. The PLC controller 4 is electrically connected to the encoder 5, the sensor 6 and the coating machine 7 respectively, and the encoder 5 is respectively connected to the pole piece driving wheel 1, the diaphragm driving wheel 2, the winding machine 3 and the coating machine 7, and the coating The coating machine 7 is provided with a coating head 8 and a control system. Among them, the encoder 5 is a high-precision encoder 5 .

[0029] Wherein, the coating head 8 is located directly above the pole piece before winding. The coating material is contained in the coating machine 7 . The coating is ethylene carbonate or dry ice. Among them, ethylene carbonate itself is a comp...

Embodiment 2

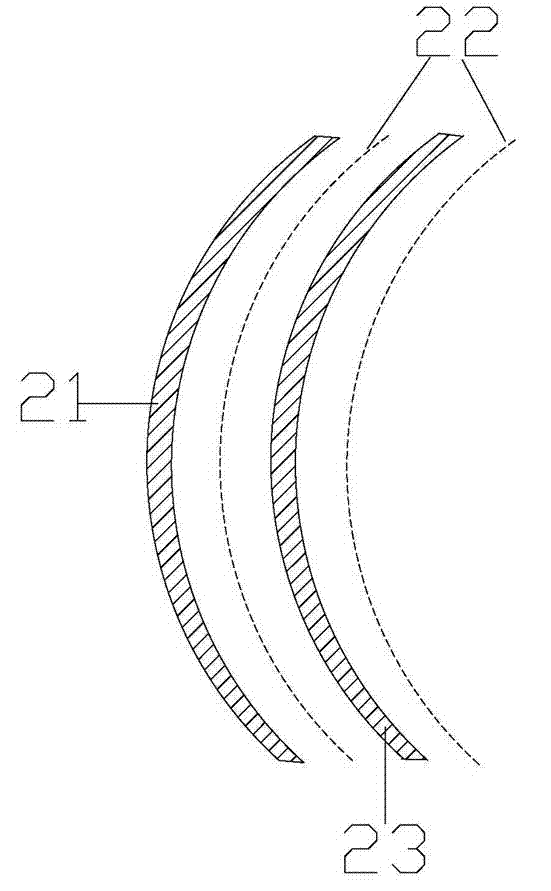

[0030] Example 2: see image 3 The device for manufacturing the winding gap of lithium-ion batteries provided in this embodiment includes a pole piece driving wheel 1, a diaphragm driving wheel 2 and a winding machine 3, and also includes a PLC controller 4, an encoder 5, a sensor 6 and a coating machine 7. The PLC controller 4 is electrically connected to the encoder 5, the sensor 6 and the coating machine 7 respectively, and the encoder 5 is respectively connected to the pole piece driving wheel 1, the diaphragm driving wheel 2, the winding machine 3 and the coating machine 7, and the coating The coating machine 7 is provided with a coating head 8 and a control system. Among them, the encoder 5 is a high-precision encoder 5 .

[0031] Wherein, the coating head 8 is located at the side of the corner of the pole piece during winding. The coating material is contained in the coating machine 7 . The coating is ethylene carbonate or dry ice.

[0032] The invention also provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com