Device for manufacturing full-automatic soft fixed abrasive particle air pressure grinding wheel

A technology of pneumatic grinding wheel and preparation device, which is applied in the direction of grinding device, grinding/polishing equipment, manufacturing tools, etc., which can solve the problems of non-consolidation, low efficiency, stable bonding performance, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

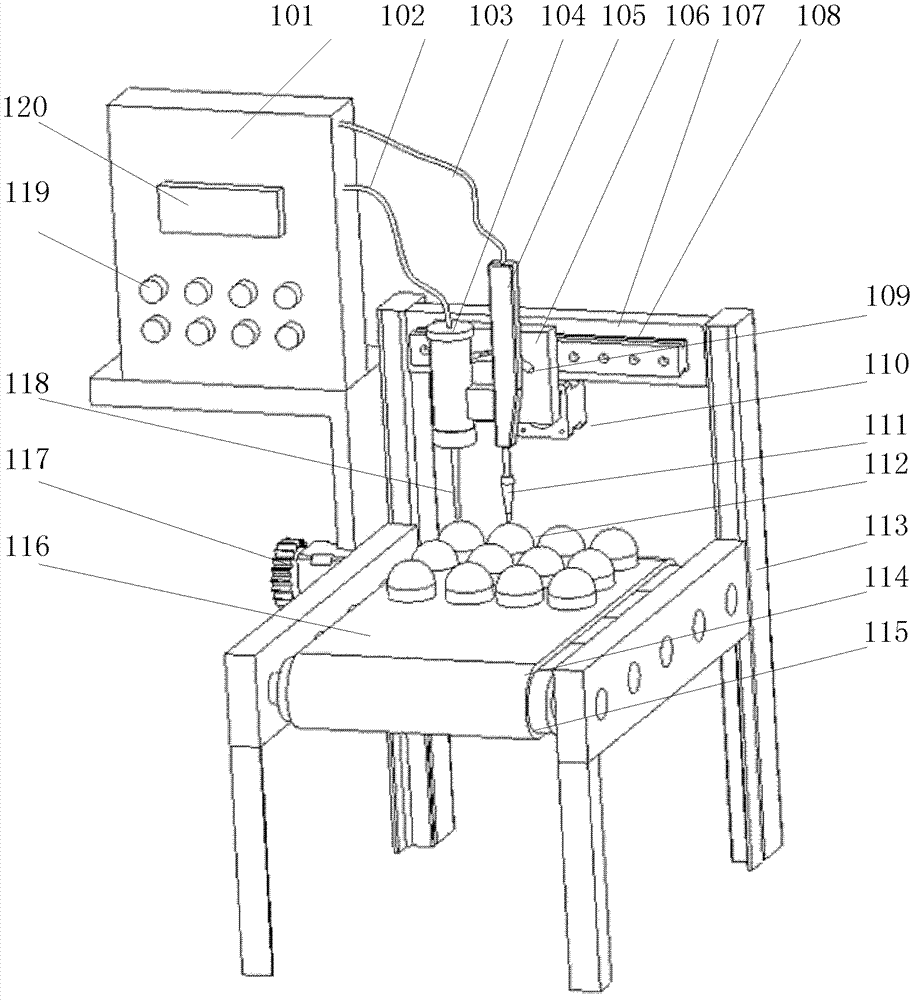

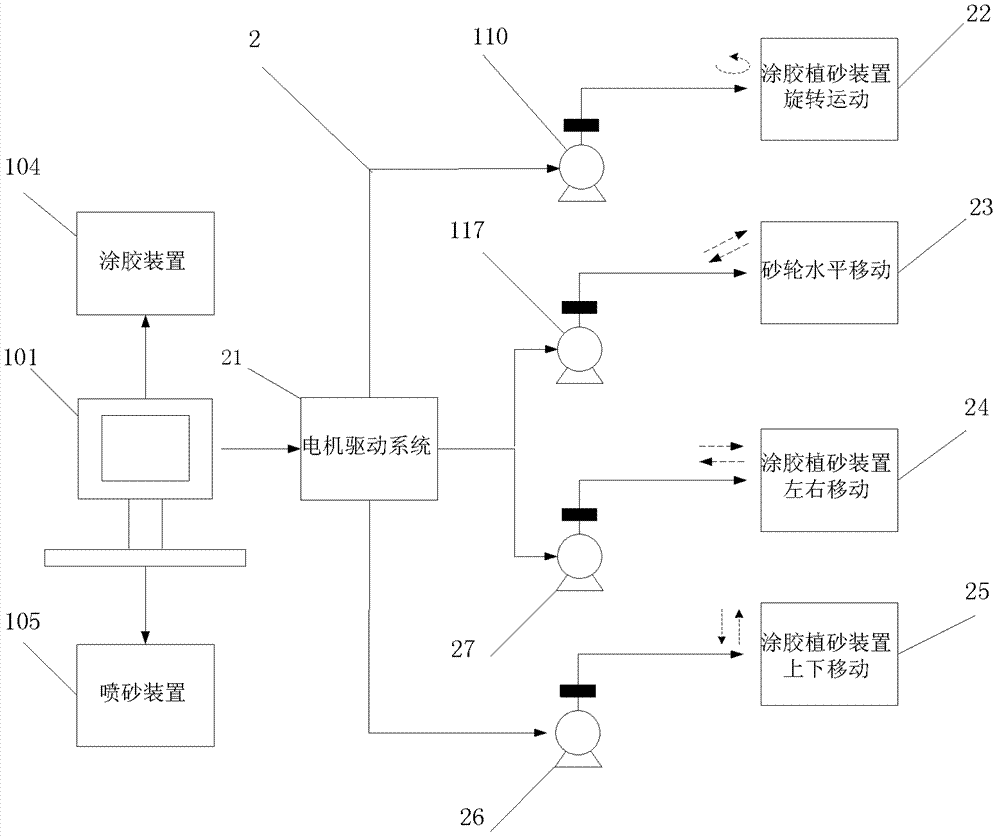

[0022] refer to figure 1 and figure 2 .

[0023] Fully automatic soft-consolidated abrasive pneumatic grinding wheel preparation device, including an abrasive solidification platform for placing a pneumatic grinding wheel support, the bottom of the abrasive solidification platform is supported by a four-corner bracket, and in the middle of the abrasive solidification platform The rollers are installed, and a rolling mechanism is formed by an annular tape between each roller, and its rotation is controlled by the first servo motor;

[0024] There are brackets on the left and right sides of the abrasive grain curing platform, guide rails are installed on the inside of the brackets, connecting rods are installed between the guide rails on both sides, and the up and down movement of the connecting rods in the guide rails Driven by the second servo motor; the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com