Portable nursing pad containing polylactic acid fiber and preparation method thereof

A polylactic acid fiber, portable technology, applied in the field of sanitary nursing pads, can solve the problems of waste of manpower, material and financial resources in the production process, long processing process of nursing pads, affecting product absorption, etc. The effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

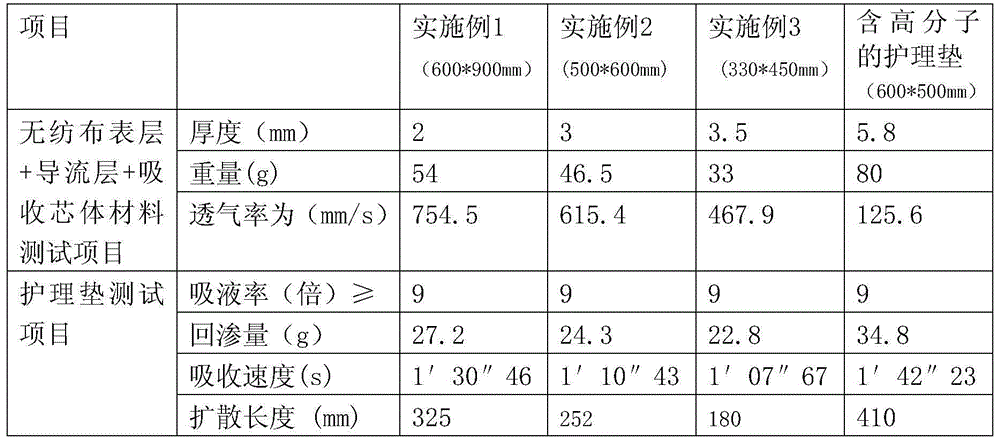

Examples

Embodiment 1

[0037] 1) Preparation of the surface layer: open the polylactic acid fiber with a linear density of 1.2D and a length of 38mm, and directly feed it into the first carding machine through the air-flow cotton box, and directly form a web after passing through the doffer and stripping roller to form the upper layer The surface layer in the combination, the grammage is 10g / m 2 .

[0038] 2) Preparation of the diversion moisture-absorbing layer: the water-repellent HDPE / PP bicomponent fiber with a linear density of 6D and a length of 76mm and the superabsorbent fiber with a linear density of 10D and a length of 76mm were developed according to a ratio of 95:5. After being loosely mixed, it is fed into the second carding machine through the air-flow cotton box, and is directly formed into a web after passing through the doffer and the stripping roller to form a diversion and moisture-absorbing layer in the upper layer combination, with a grammage of 20g / m 2 .

[0039] 3) Preparati...

Embodiment 2

[0043] 1) Preparation of the surface layer: open the polylactic acid fiber with a linear density of 1.2D and a length of 38mm, and directly feed it into the first carding machine through the air-flow cotton box, and directly form a web after passing through the doffer and stripping roller to form the upper layer The surface layer in the combination has a grammage of 15g / m 2 .

[0044] 2) Preparation of the diversion moisture-absorbing layer: the water-repellent HDPE / PP bi-component fiber with a linear density of 4D and a length of 65mm and the superabsorbent fiber with a linear density of 8D and a length of 76mm were developed according to a ratio of 93:7. After being loosely mixed, it is fed into the second carding machine through the air-flow cotton box, and is directly formed into a web after passing through the doffer and the stripping roller to form the diversion and moisture-absorbing layer in the upper layer combination, with a grammage of 30g / m 2 .

[0045] 3) Prepar...

Embodiment 3

[0049] 1) Preparation of the surface layer: open the polylactic acid fiber with a linear density of 1.2D and a length of 38mm, and directly feed it into the first carding machine through the air-flow cotton box, and directly form a web after passing through the doffer and stripping roller to form the upper layer The surface layer in the combination has a grammage of 20g / m 2 .

[0050] 2) Preparation of the diversion moisture-absorbing layer: the water-repellent PP / PET bicomponent fiber with a linear density of 3D and a length of 38 mm and the superabsorbent fiber with a linear density of 7D and a length of 51 mm were prepared according to a ratio of 90:10. After being loosely mixed, it is fed into the second carding machine through the air-flow cotton box, and is directly formed into a web after passing through the doffer and stripping rollers to form the diversion moisture-absorbing layer in the upper layer combination, and the diversion moisture-absorbing layer is obtained a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com