Gas diffusion layer and preparation method

A technology of gas diffusion layer and microporous layer, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems affecting the performance of the gas diffusion layer and the inability of the carbon fiber substrate to have conductivity, so as to save production time and improve the service life , the effect of not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

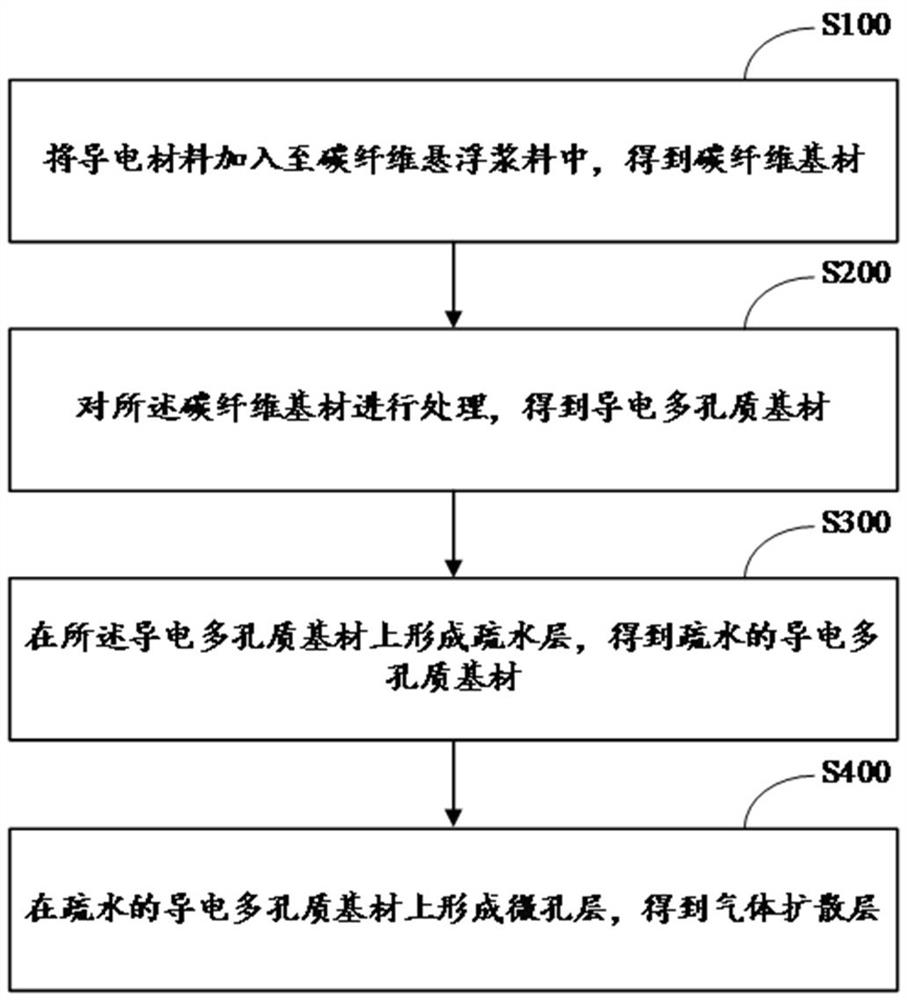

[0059] Such as figure 1 As shown, this embodiment provides a method for preparing a gas diffusion layer, which specifically includes the following steps:

[0060] S100, adding the conductive material into the carbon fiber suspension slurry to obtain a carbon fiber base material.

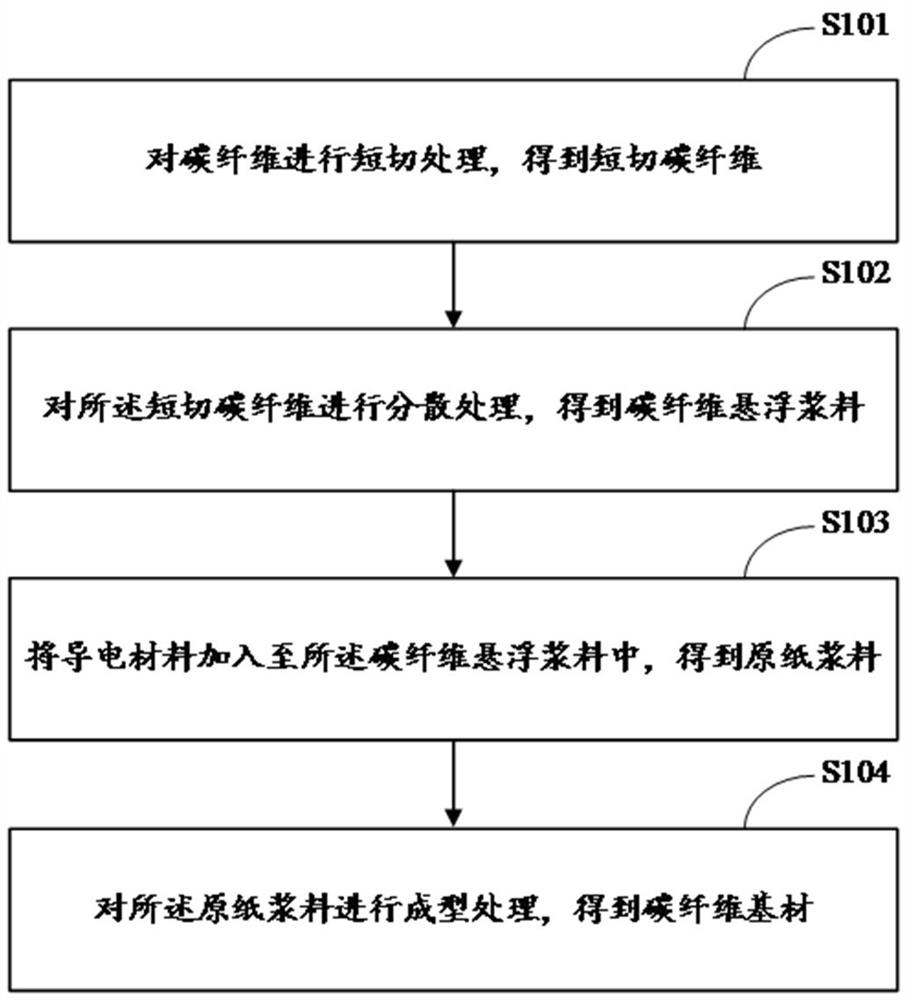

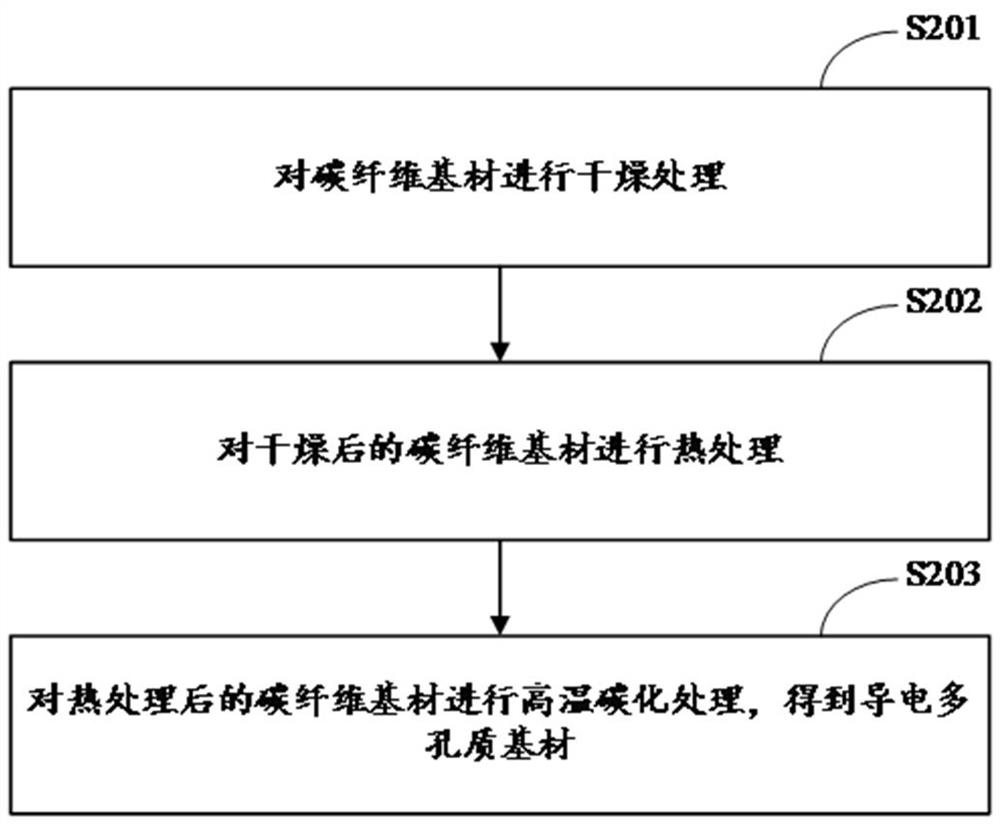

[0061] Such as figure 2 As shown, S100 specifically includes the following steps:

[0062] S101, chopping the carbon fibers to obtain chopped carbon fibers.

[0063] Specifically, the carbon fiber filaments are chopped by a chopping machine to obtain chopped carbon fibers.

[0064] Further, the length of the chopped carbon fiber is 3mm-10mm. Such an arrangement can avoid the high cost of producing chopped carbon fibers due to the length of the chopped carbon fibers being too short. At the same time, it can avoid the poor dispersion effect of the chopped carbon fiber caused by too long length of the chopped carbon fiber, thereby affecting the performance of the carbon fiber base material.

[0065...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com