Oleophylic ceramsite adopting oil-based drilling cutting residues obtained after thermal decomposition and preparation method of oleophylic ceramsite

An oil-based drill cuttings and thermal analysis technology, applied in ceramic products, applications, household appliances, etc., can solve the problems of not having lipophilic properties, increasing the strength of ceramsite, and restricting the production of raw materials, so as to achieve easy backwash regeneration, enhanced Oil removal performance, effect of saving clay or shale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An oil-friendly ceramsite using thermal desorption of oil-based drilling cuttings residues, which is mainly composed of oil-based drilling cuttings thermal desorption residues, bauxite, potassium feldspar, and bentonite, and the raw materials are calculated in parts by mass: oil content 0.3 % oil-based drilling cuttings thermal analysis residue 60 parts, low-grade bauxite 20 parts, potassium feldspar 15 parts, bentonite 5 parts.

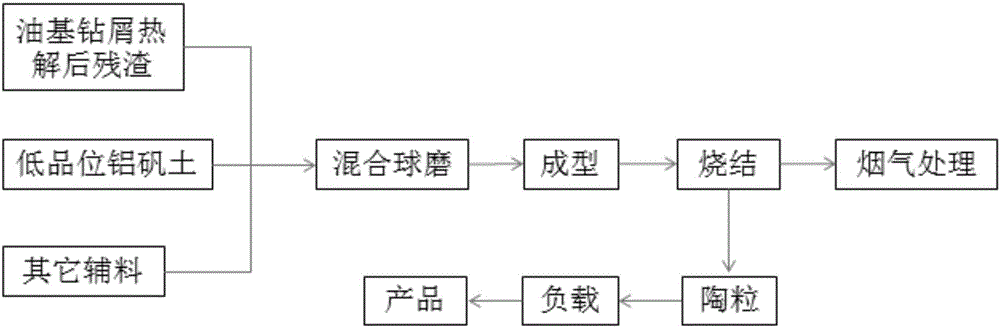

[0036] The above-mentioned preparation method of oil-friendly ceramsite utilizing thermal analysis of oil-based drilling cuttings residues comprises the following steps:

[0037](1) Mix and ball mill base drilling cuttings thermal analysis residue, low-grade bauxite, potassium feldspar, and bentonite at a weight ratio of 60:20:15:5, and pass the milled material through a 200-mesh screen;

[0038] (2) The material after ball milling and sieving is put into a ball forming machine and rolled into shape, and according to the size of the material p...

Embodiment 2

[0043] An oleophilic ceramsite using thermal analysis of oil-based drilling cuttings residues, which is mainly composed of oil-based drilling cuttings thermal analysis residues, bauxite, potassium feldspar, bentonite, and glass powder, and the raw materials are calculated as follows in parts by mass: 45 parts of thermal analysis residue of oil-based drilling cuttings with an oil content of 0.2%, 35 parts of low-grade bauxite, 10 parts of potassium feldspar, and 10 parts of bentonite; glass powder is added in the form of additives, and the amount of glass powder added accounts for 15% of the total weight.

[0044] The above-mentioned preparation method of oil-friendly ceramsite utilizing thermal analysis of oil-based drilling cuttings residues comprises the following steps:

[0045] (1) Base drill cuttings thermal analysis residue, low-grade bauxite, potassium feldspar, and bentonite are mixed in a weight ratio of 45:35:10:10, and 15% of the total mass of the mixture is added t...

Embodiment 3

[0051] An oleophilic ceramsite using thermal analysis of oil-based drilling cuttings residues, which is mainly composed of oil-based drilling cuttings thermal analysis residues, bauxite, potassium feldspar, bentonite, and glass powder, and the raw materials are calculated as follows in parts by mass: 30 parts of thermal analysis residue of oil-based drilling cuttings with an oil content of 0.05%, 40 parts of low-grade bauxite, 20 parts of potassium feldspar, and 10 parts of bentonite; glass powder is added in the form of additives, and the amount of glass powder added accounts for other raw materials 20% of the total weight.

[0052] The above-mentioned preparation method of oil-friendly ceramsite utilizing thermal analysis of oil-based drilling cuttings residues comprises the following steps:

[0053] (1) Oil-based drilling cuttings thermal analysis residue, low-grade bauxite, potassium feldspar, and bentonite are mixed in a weight ratio of 30:40:20:10, and 20% of the total m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com