Method for manufacturing super capacitor

A technology for supercapacitors and manufacturing methods, which is applied in the manufacture of hybrid/electric double-layer capacitors, etc., which can solve the problems of poor product quality of supercapacitors, inconsistent coating thickness of electrode slurry, etc. Consistent, easy viscosity control results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

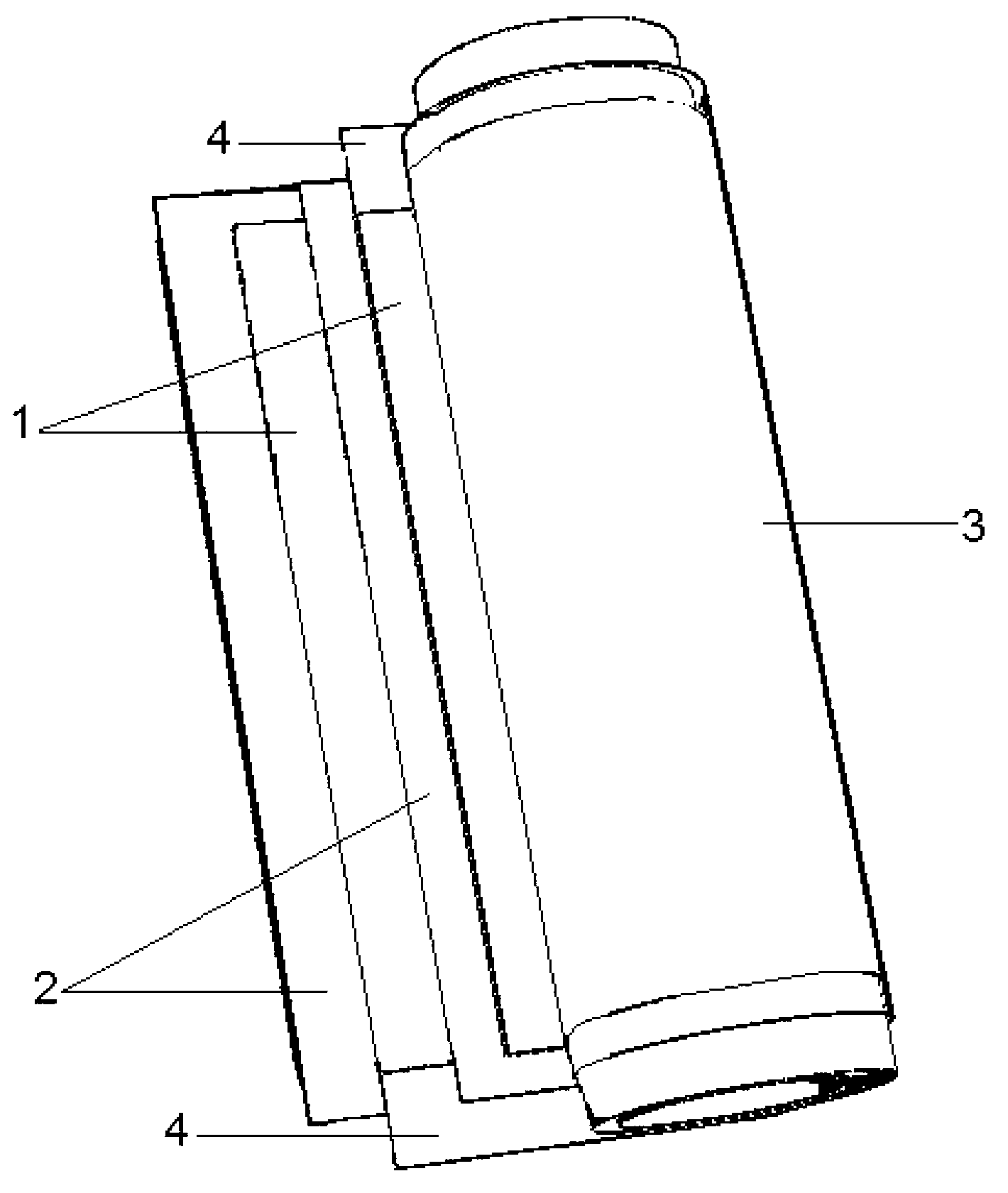

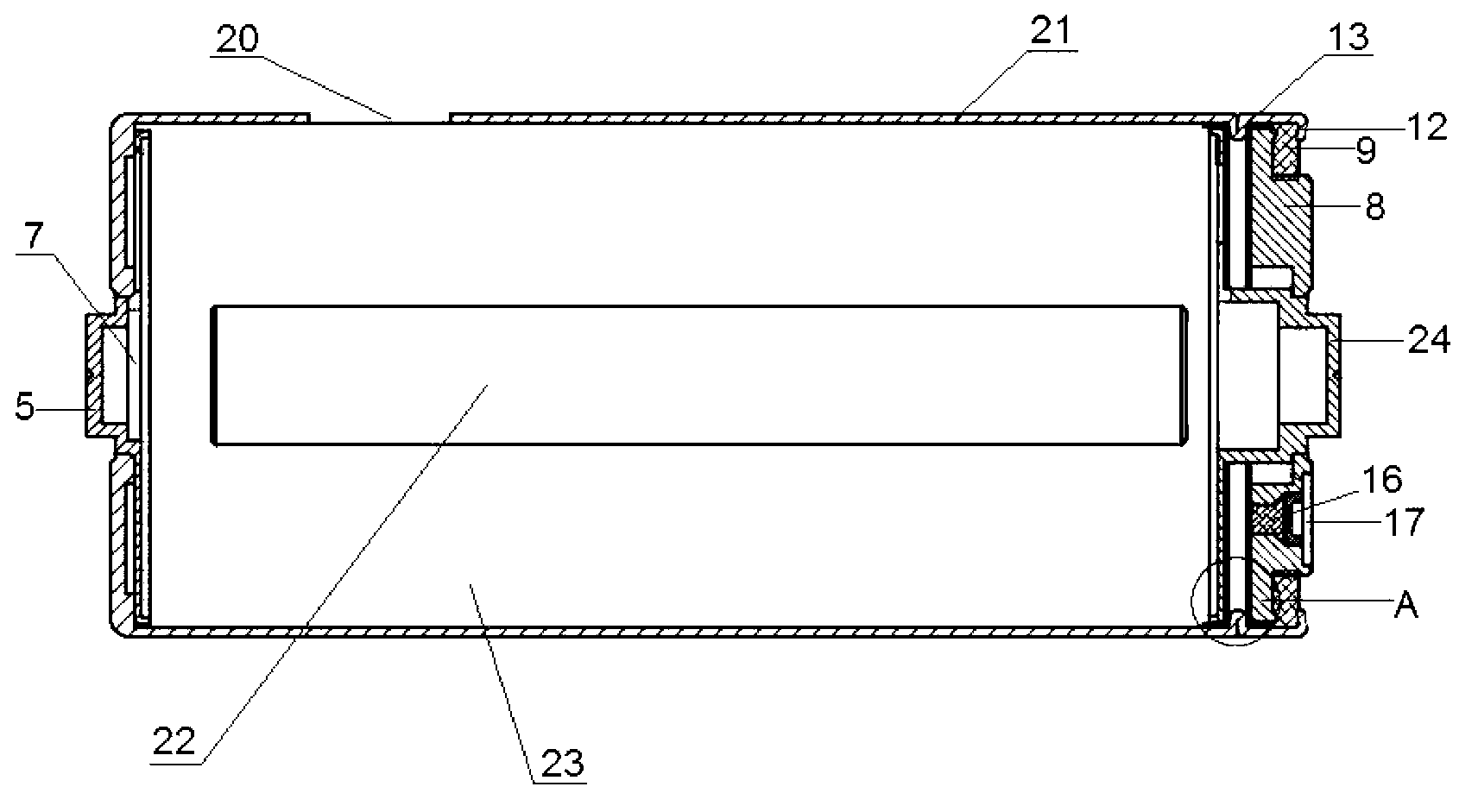

[0051] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

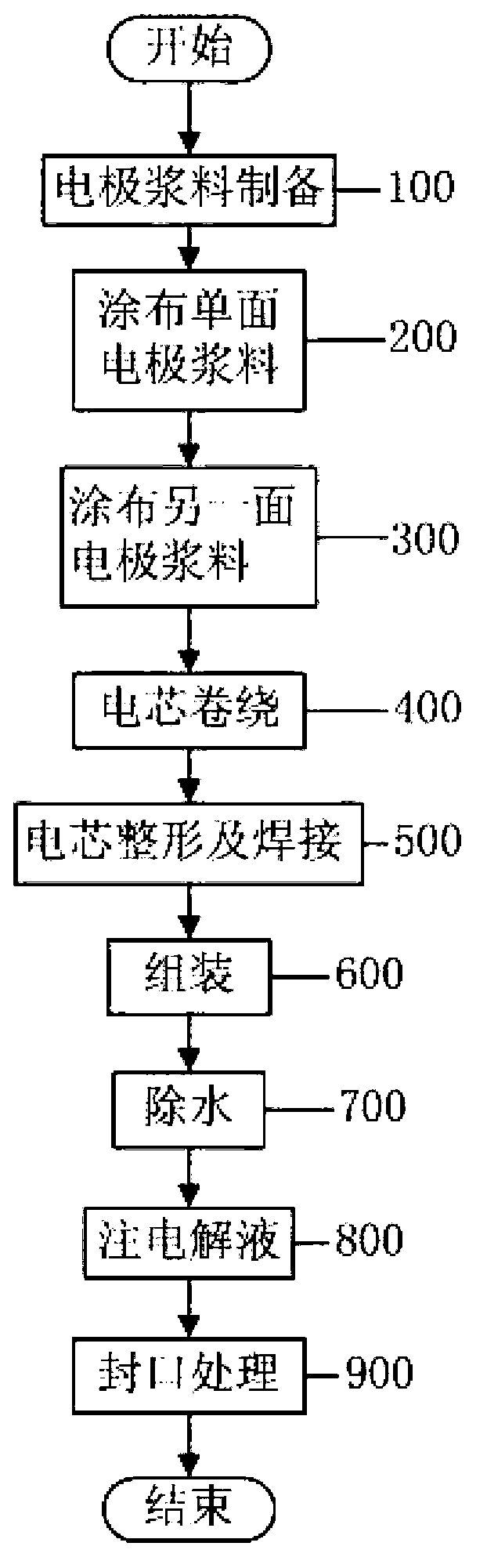

[0052] like figure 1 The illustrated embodiment is a method of manufacturing a supercapacitor, comprising the steps of:

[0053] Step 100, electrode slurry preparation:

[0054] According to the ratio of deionized water to polyurethane mass ratio of 20:1, put deionized water and polyurethane into a mixer and stir for 35 minutes to obtain a water-emulsion adhesive;

[0055] According to the mass ratio of activated carbon powder and polyurethane in the binder of 15:1, put activated carbon powder into the kneader and stir for 30 minutes to obtain a dough-like electrode slurry pre-finished product;

[0056] The electrode slurry pre-finished product is put into the stirring tank of mixer, according to the mass ratio of deionized water and the polyurethane in the binder is the ratio of 70: 1, adds deionized water again in stirring tank; 200pa to 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com