High-nickel positive electrode material, preparation method thereof and application of high-nickel positive electrode material in lithium ion battery

A positive electrode material, high nickel technology, applied in the field of high nickel positive electrode material and its preparation, can solve the problem of high material cost, and achieve the effects of low cost, high compaction density and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a high-nickel positive electrode material, and the preparation method of the high-nickel positive electrode material includes the following steps:

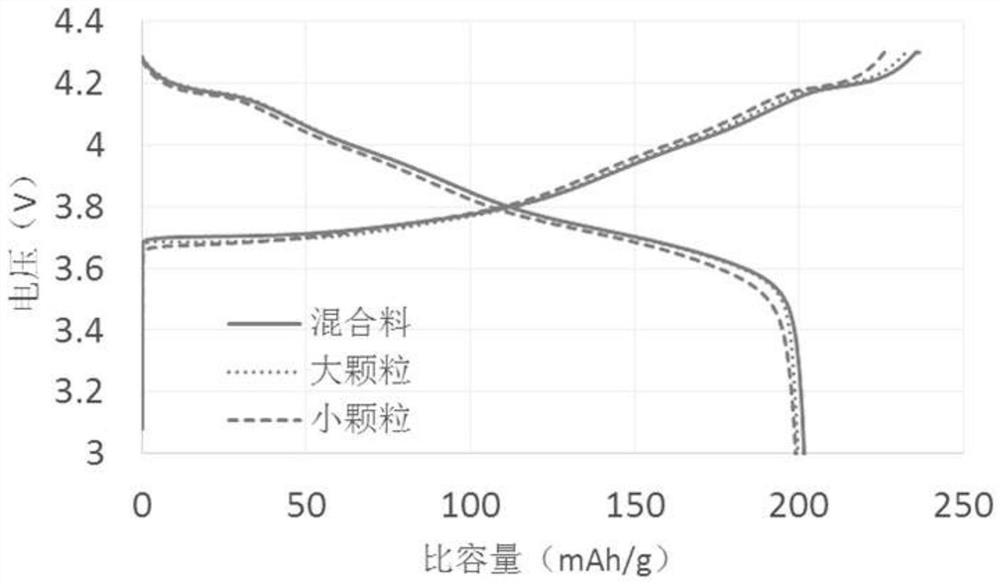

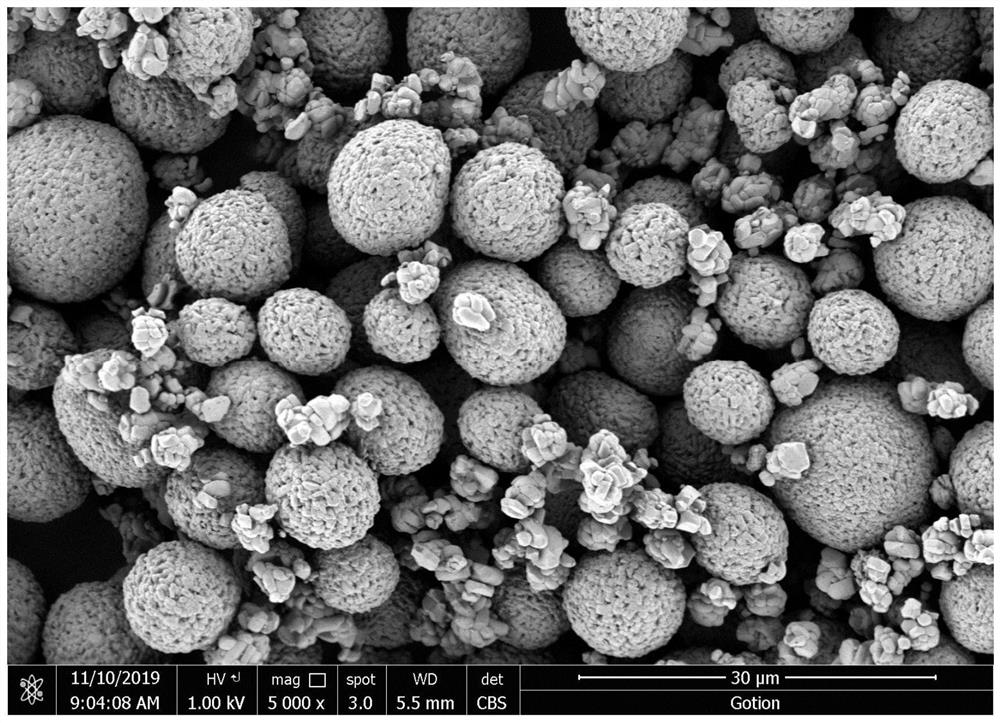

[0048] The high-nickel hydroxide precursor Ni with D50 of 10 μm and (D90-D10) / D50=0.8 0.85 co 0.1 mn 0.045 Zr 0.005 (OH) 2 Mix it with micronized lithium hydroxide with a D50 of 7 μm at a molar ratio of 1:1.03, and sinter at 770°C for 12 hours to obtain LiNi 0.85 co 0.1 mn 0.045 Zr 0.005 o 2 Material;

[0049] Will LiNi 0.85 co 0.1 mn 0.045 Zr 0.005 o 2 The material is mechanically crushed and sieved, and the particle size of the sintered material is controlled to be consistent with the high-nickel hydroxide precursor; the sieved material is washed with water, the water-material ratio is 1:1, and the washing time is 10 minutes. The material is vacuum-dried after centrifugal dehydration, and the moisture content after drying is 400ppm. The dried material is dry-coated with nano-ZrO 2...

Embodiment 2

[0056] This embodiment provides a high-nickel positive electrode material, and the preparation method of the high-nickel positive electrode material includes the following steps:

[0057] The high-nickel hydroxide precursor Ni with D50 of 15 μm and (D90-D10) / D50=0.8 0.85 co 0.1 mn 0.045 Zr 0.005 (OH) 2 LiNi is obtained by mixing with fine powder lithium hydroxide with a D50 of 7 μm at a molar ratio of 1:1.03 and sintering at 770 °C for 12 hours. 0.85 co 0.1 mn 0.045 Zr 0.005 o 2 Material;

[0058] Will LiNi 0.85 co 0.1 mn 0.045 Zr 0.005 o 2 The material is mechanically crushed and sieved, and the particle size of the crushed and sieved material is consistent with that of the precursor; the sieved material is washed with water, the water-material ratio is 2:1, and the washing time is 5 minutes. Vacuum drying is carried out after centrifugal dehydration, and the moisture content after drying is 500ppm, and the dried material is dry-coated with nano-ZrO 2 , nano-...

Embodiment 3

[0063] This embodiment provides a high-nickel positive electrode material, and the preparation method of the high-nickel positive electrode material includes the following steps:

[0064] The high-nickel hydroxide precursor Ni with D50 of 10 μm and (D90-D10) / D50=0.8 0.9 co 0.05 mn 0.045 Zr 0.005 (OH) 2 Mix with micronized lithium hydroxide with a D50 of 7 μm at a molar ratio of 1:1.03, and mix and sinter at 730°C for 12 hours to obtain LiNi 0.9 co 0.05 mn 0.045 Zr 0.005 o 2 Material;

[0065] Will LiNi 0.9 co 0.05 mn 0.045 Zr 0.005 o 2 The material is crushed and sieved, and the particle size of the sintered material is controlled to be consistent with the high-nickel hydroxide precursor; the sieved material is washed with water, the water-material ratio is 1:2, and the washing time is 1min. Vacuum drying is carried out after centrifugal dehydration, and the moisture content after drying is 300ppm, and the dried material is dry-coated with nano-ZrO 2 , nano-Zr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com