Preparation method for high-nickel ternary material of lithium ion battery

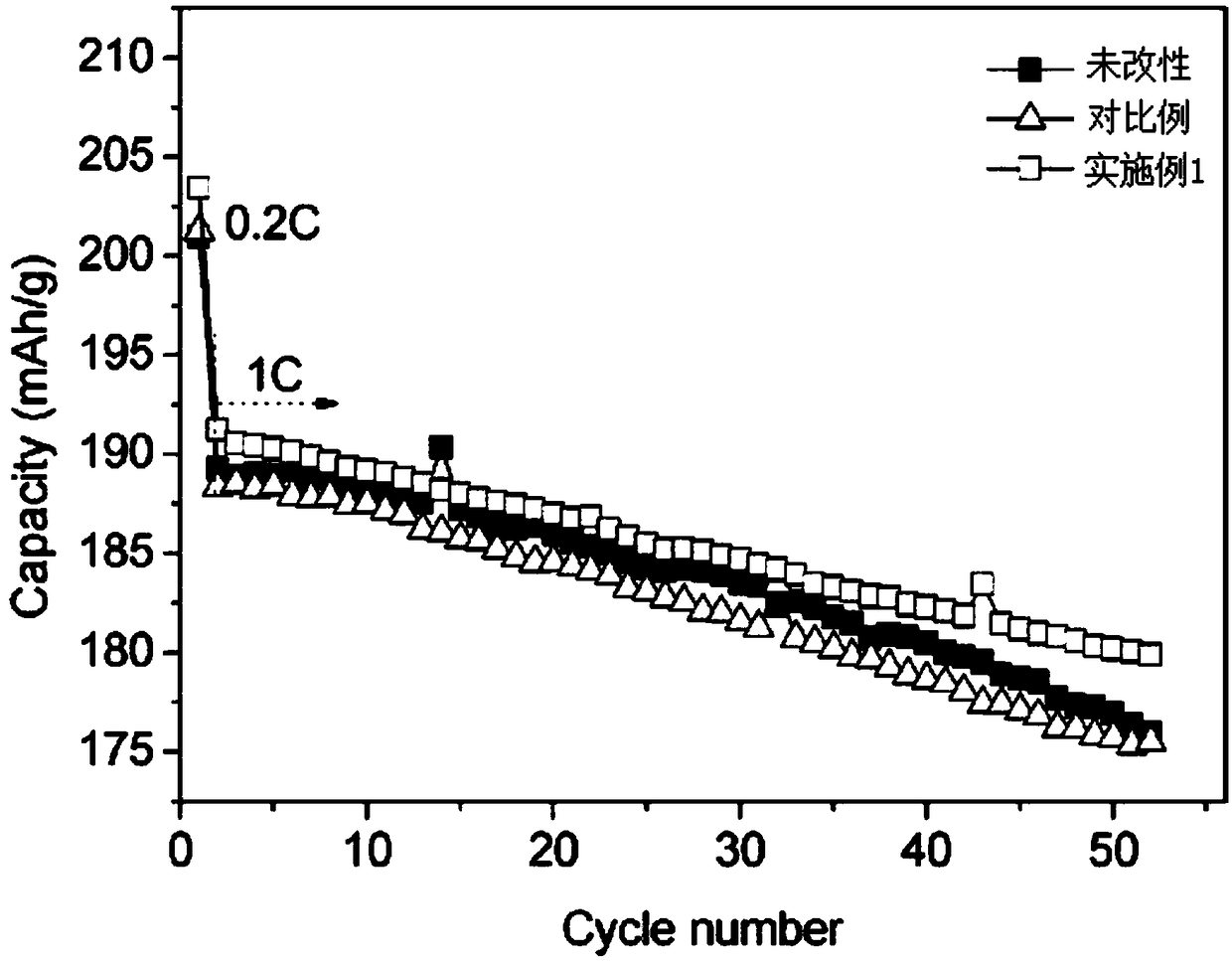

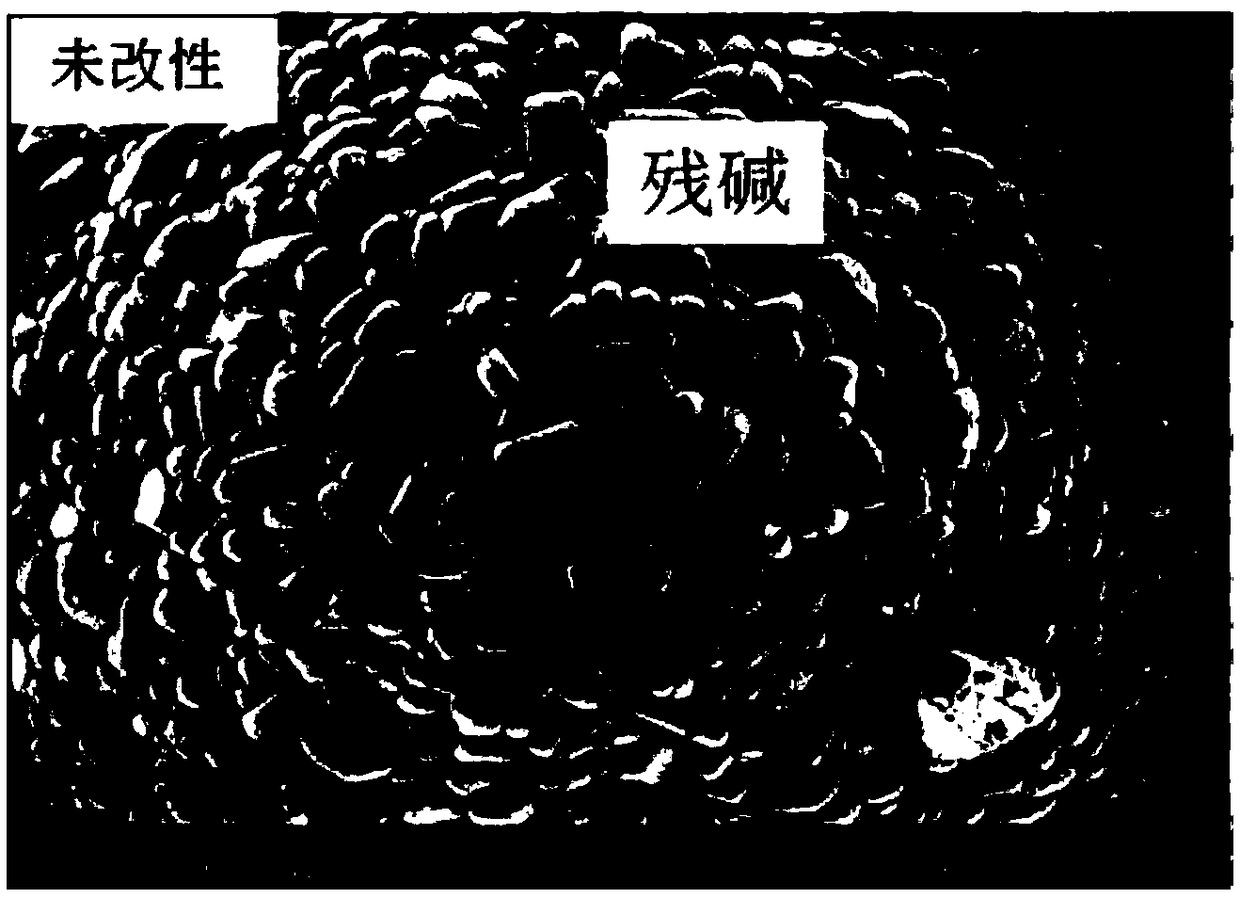

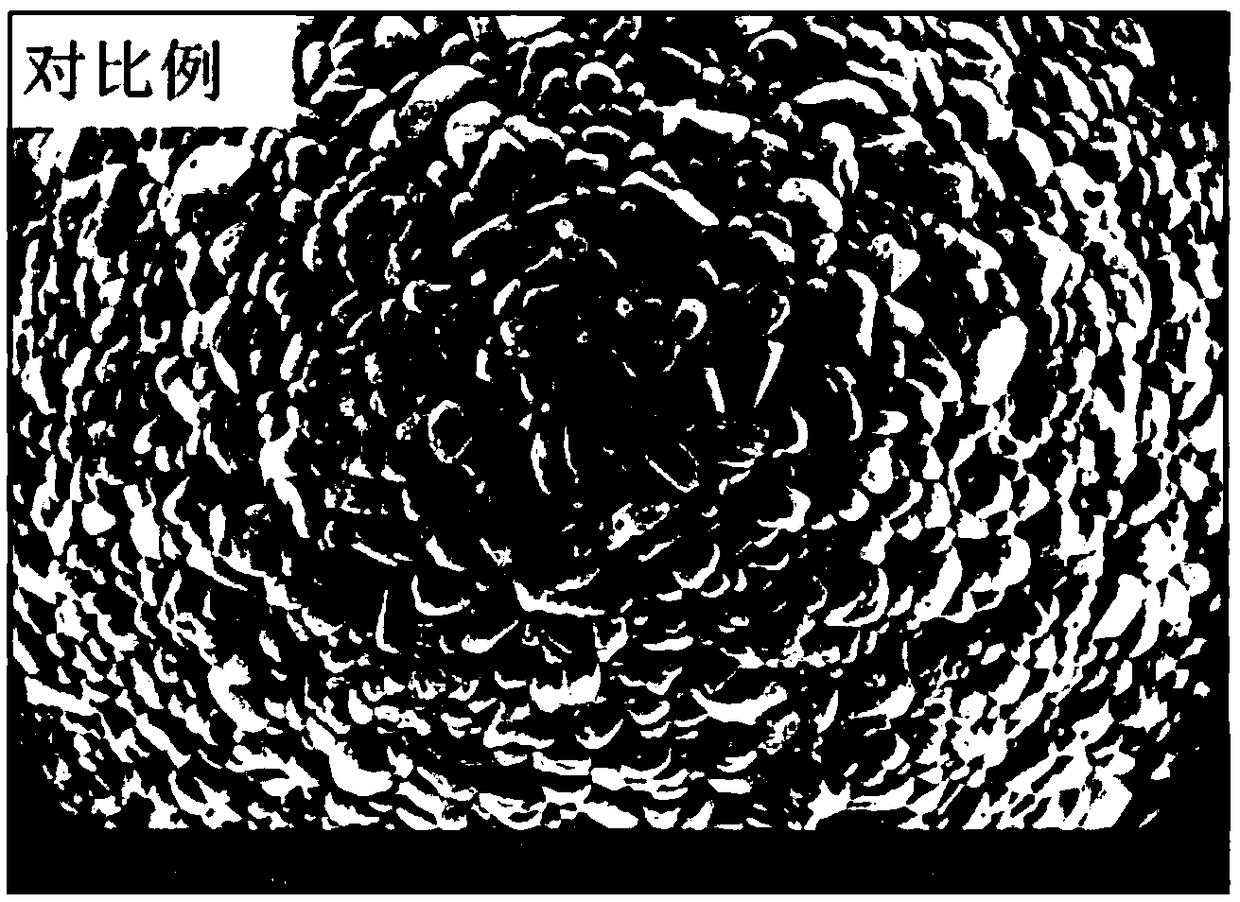

A technology of high-nickel ternary materials and lithium-ion batteries, applied in nanotechnology for materials and surface science, electrical components, battery electrodes, etc., can solve poor processing performance and storage performance, poor cycle stability, high-nickel materials The problem of high residual alkali on the surface can achieve the effects of reducing adverse effects, easy industrialization, and excellent modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) The high-nickel ternary hydroxide precursor Ni with a D50 of 10um prepared by the continuous co-precipitation method 0.85 co 0.1 mn 0.05 (OH) 2 LiNi is obtained by mixing and sintering with fine powder lithium hydroxide with a D50 of 7um at 770°C 0.85 co 0.1 mn 0.05 o 2 material, then for LiNi 0.85 co 0.1 mn 0.05 o 2 The material is crushed and classified, and divided into large-size high-nickel ternary material and small-size high-nickel ternary material. The D50 difference between the large-size high-nickel ternary material and the small-size high-nickel ternary material is 10-11um;

[0036] (2), the large size LiNi 0.85 co 0.1 mn 0.05 o 2 Materials and Small Size LiNi 0.85 co 0.1 mn 0.05 o 2 The materials are all stirred and washed, the ratio of water to material is 1:1, small size LiNi 0.85 co 0.1 mn 0.05 o 2 The washing time of the material is 10 minutes, and the large size LiNi 0.85 co 0.1mn 0.05 o 2 The washing time of the material is...

Embodiment 2

[0039] (1) The high-nickel ternary hydroxide precursor Ni with a D50 of 8um prepared by the continuous co-precipitation method 0.8 co 0.1 mn 0.1 (OH) 2 LiNi is obtained by mixing and sintering with fine powder lithium hydroxide with a D50 of 15um at 770°C 0.80 co 0.1 mn 0.1 o 2 material, then for LiNi 0.80 co 0.1 mn 0.1 o 2 The material is crushed and classified, and divided into large-size high-nickel ternary material and small-size high-nickel ternary material. The D50 difference between the large-size high-nickel ternary material and the small-size high-nickel ternary material is 5-6um;

[0040] (2), the large size LiNi 0.80 co 0.1 mn 0.1 o 2 Materials and Small Size LiNi 0.80 co 0.1 mn 0.1 o 2 The materials are all stirred and washed, the ratio of water to material is 2:1, small size LiNi 0.80 co 0.1 mn 0.1 o 2 The washing time of the material is 5 minutes, and the large size LiNi 0.80 co 0.1 mn 0.1 o 2 The washing time of the material is 12 minute...

Embodiment 3

[0043] (1) The high-nickel ternary hydroxide precursor Ni with a D50 of 15um prepared by the continuous co-precipitation method 0.9 co 0.06 mn 0.04 (OH) 2 LiNi is obtained by mixing and sintering with fine powder lithium hydroxide with a D50 of 6um at 770°C 0.9 co 0.06 mn 0.04 o 2 material, then for LiNi 0.9 co 0.06 mn 0.04 o 2 The material is crushed and classified into large-size high-nickel ternary material and small-size high-nickel ternary material. The D50 difference between the large-size high-nickel ternary material and the small-size high-nickel ternary material is 14-15um;

[0044] (2), the large size LiNi 0.9 co 0.06 mn 0.04 o 2 Materials and Small Size LiNi 0.9 co 0.06 mn 0.04 o 2 The materials are all stirred and washed, the ratio of water to material is 1.5:1, small size LiNi 0.9 co 0.06 mn 0.04 o 2 The washing time of the material is 12 minutes, and the large size LiNi 0.9 co 0.06 mn 0.04 o 2 The washing time of the material is 20 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com