Jacquard nap strip weaving and knitting composite fabric with flame-retardant fabric layer

A technology of flame retardant fabrics and composite fabrics, applied in the field of textile fabrics and fabrics, can solve the problems of lack of comfort and free movement, poor sense of hierarchy, and inability to satisfy people, achieve great comfort and free movement, and enhance sense of hierarchy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

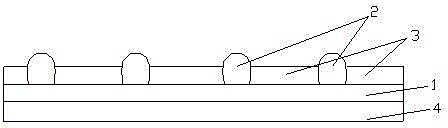

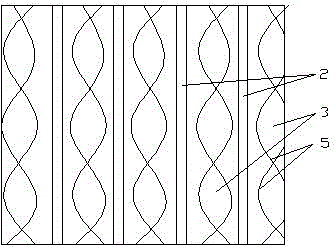

[0011] See figure 1 with figure 2 , The present invention relates to a jacquard pile top woven knitted composite fabric with a flame-retardant fabric layer, comprising a fabric body 1, the upper surface of the fabric body 1 is provided with a jacquard strip 2 and a pile strip 3, and the lower surface is provided with pile Layer 4. The jacquard strips 2 and the pile strips 3 are arranged at intervals. The jacquard strip 2, the pile strip 3 and the pile layer 4 are all fixed to the fabric body 1. The upper surface of the pile strip 3 is provided with a decoration 5, and the decoration 5 is fixed on the pile strip 3. figure 2 The decoration 5 in the embodiment is a bright line.

[0012] The fabric body 1 is made of fabric, the fabric is interwoven with warp threads and weft threads, one of the warp threads and the weft threads is an elastic covering yarn, and the elastic covering yarn is made of spandex yarn and It is composed of multiple nylon low-elastic yarns wrapped on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com