Patents

Literature

44results about How to "Clear production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inorganic heat-insulating fireproof plate and manufacturing method thereof

The invention discloses an inorganic heat-insulating fireproof plate and a manufacturing method thereof. The inorganic heat-insulating fireproof plate mainly is prepared by mixing the following components in percentage by weight: 10 to 20 percent of expanded vitrified ball, 8 to 15 percent of bauxite cement, 15 to 25 percent of ordinary Portland cement, 10 to 18 percent of hemihydrate gypsum, 0.2 to 0.5 percent of macromolecular polymer rubber powder, 0.05 to 0.1 percent of polypropylene fiber, 0.05 to 0.1 percent of organic silicon water repellent, 0.25 to 0.5 percent of cellulose ether and 45 to 60 percent of water. The heat-insulating fireproof plate product has excellent heat-insulating property, high strength and high dimensional stability.

Owner:DONGGUAN HENGHE ENERGY SAVING TECH

Processing method of organic liquid fertilizer

The invention discloses a processing method of an organic liquid fertilizer, which comprises the following steps: using soybean curb residues and bean curb wastewater as raw materials; taking beer yeast, Bacillus subtilis and lactic acid bacteria as composite strains; and putting the composite strains into a fermentation tank for fermentation in a sterile environment to prepare into the organic liquid fertilizer. In the processing method, the processing technology is simple, and the purpose of changing waste into value can be reached.

Owner:石河子市郁茏生物科技有限公司

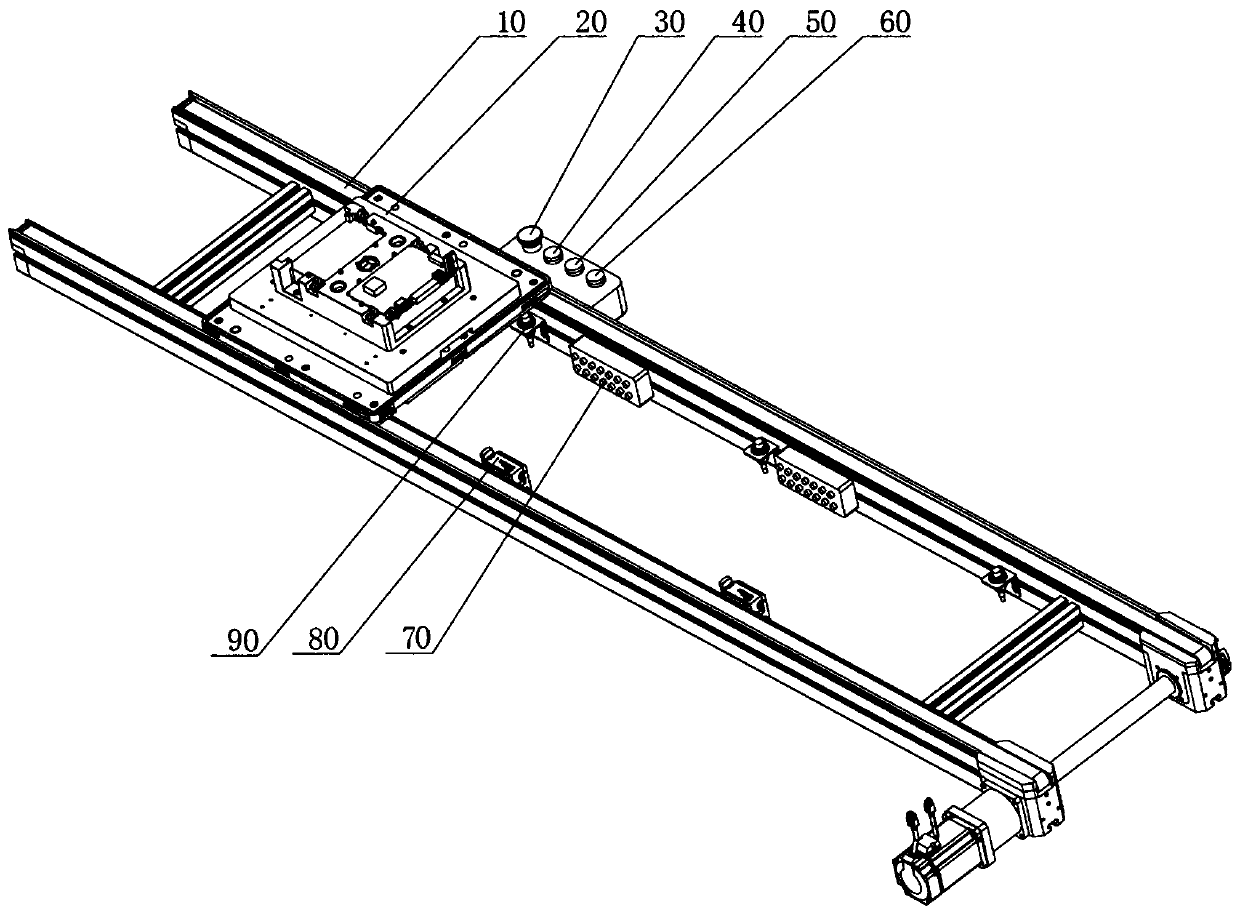

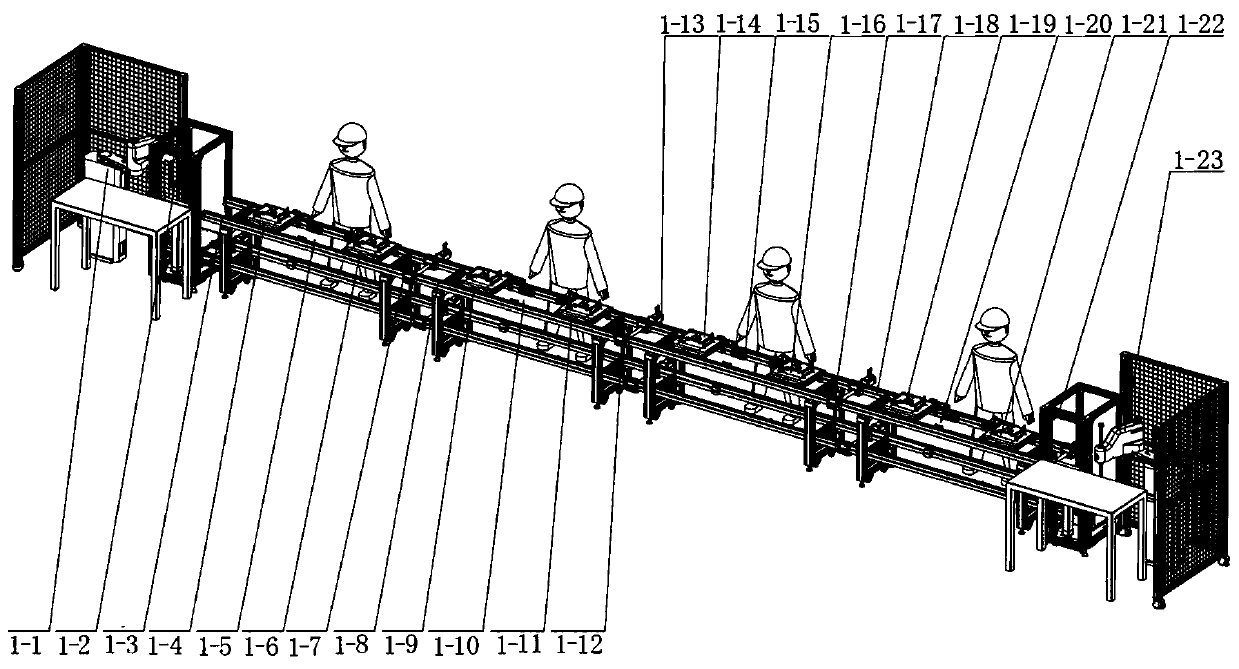

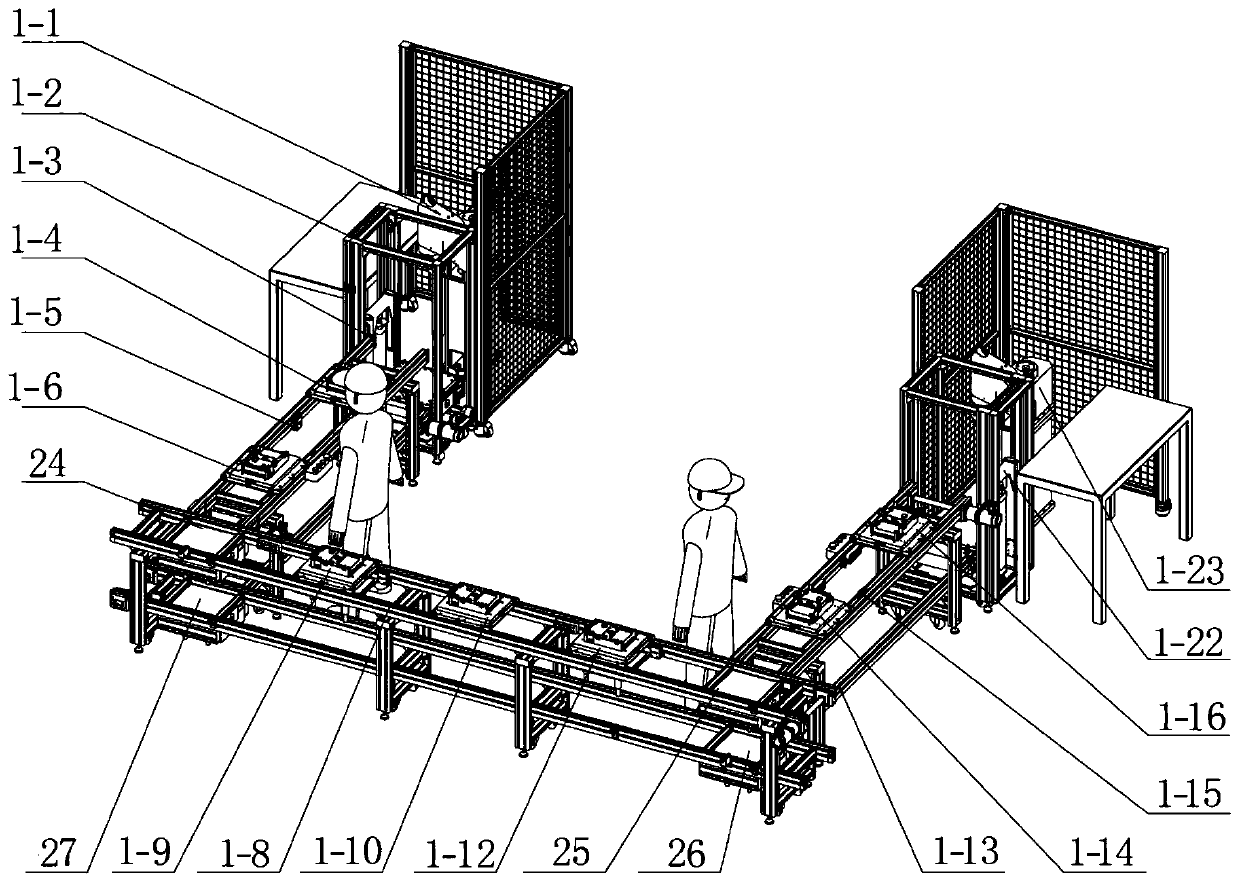

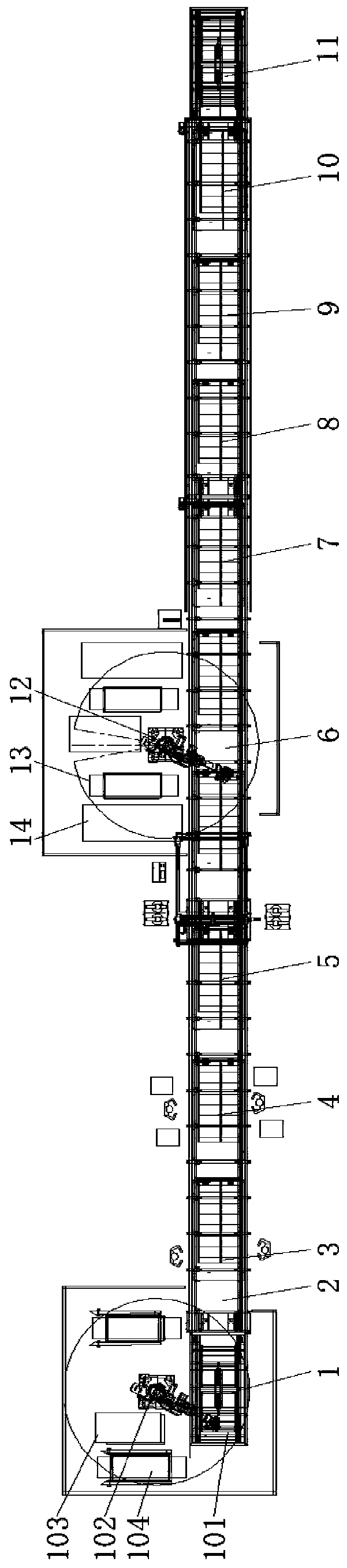

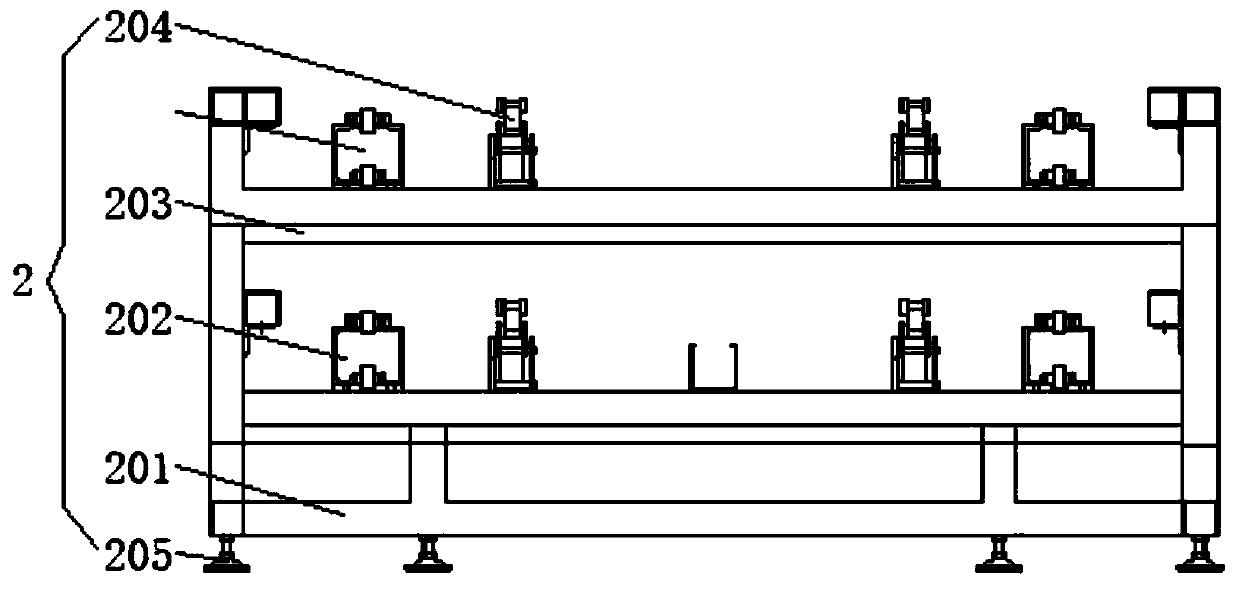

Automatic feeding and blanking production line and control method thereof

The invention discloses an automatic feeding and blanking production line and a control method thereof. The automatic feeding and blanking production line contains two structure modes, namely, a U-shaped line layout and a line type line layout. A production line body is formed by basic units and meets the requirement of a modular assembly technology; each basic unit is divided into an upper layerand a lower layer, so that modular splicing can be realized, and multiple layout forms are realized; and in addition, a tray backflow function can be realized. The production line is further providedwith a tray and tool conveying mechanism for supporting quick changeover, a tray conveying control system, a single-station manual / automatic real-time switching control system, a production line conveyor line body transfer real-time control mechanism, a production line work-in-process temporary storage station design, and flexible and changeable production line arrangement forms. On the basis of the idea of lean production, the problems of high stock level, circulation difficulty, high manufacturing cost, low product quality, waste in space, time, manpower and tool, and the like existing actually are solved.

Owner:西安精雕精密机械工程有限公司

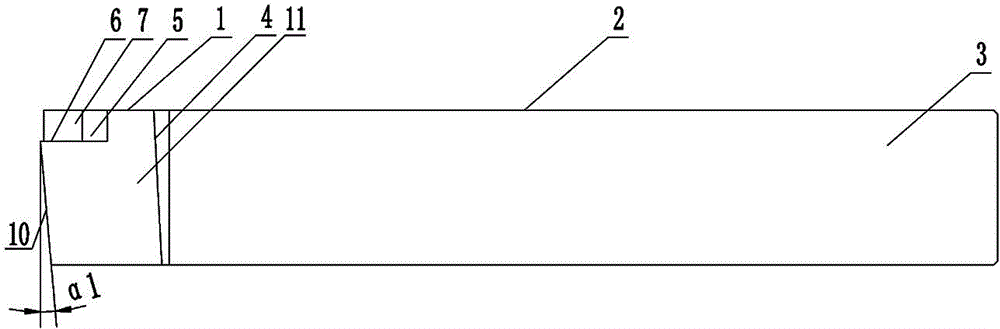

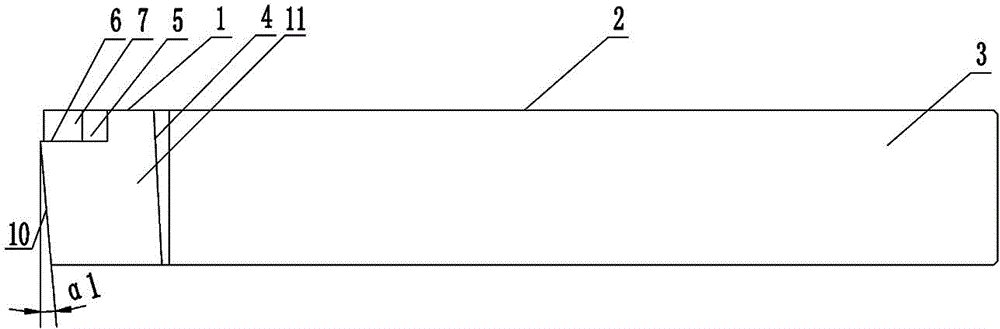

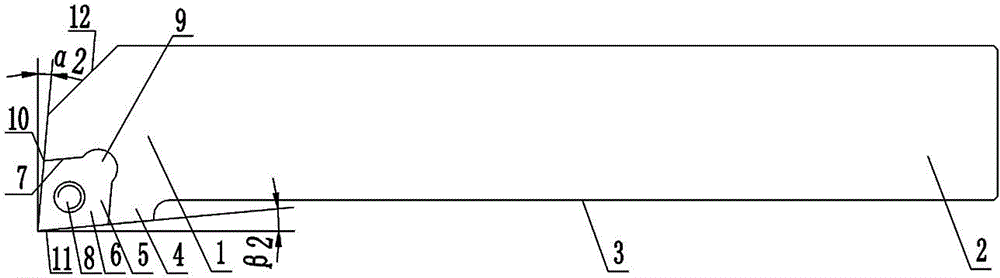

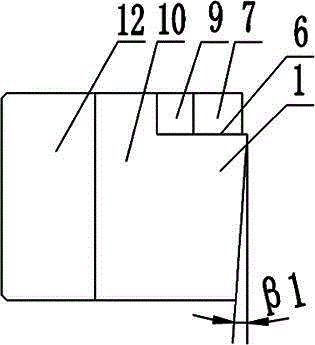

Numerical control cutting process of steel tube arch bridge pipe joint steel plate intersecting line

The invention relates to a numerical control cutting process of a steel tube arch bridge pipe joint steel plate intersecting line. The numerical control cutting process comprises a numerical control flame cutting machine and comprises the following steps that (1) a curve graph of the steel tube arch bridge pipe joint steel plate intersecting line is drawn through a geometric method and led into the numerical control flame cutting machine; (2) an angle turning device is installed at the numerical control flame cutting machine, and steering cutting of the numerical control flame cutting machine in four directions can be realized through the angle turning device; and (3) curve cutting of a required process groove containing welding is carried out on a steel plate so as to obtain parts which meet a requirement on an arch rib abutting joint curve. The numerical control cutting process has the advantages that firstly, the steel plate is formed by adopting numerical control cutting for one time, so that a production organization is smoother; secondly, raw materials are saved; thirdly, operating time that a welder carries out the welding is reduced; fourthly, a welded joint is uniform and attractive in appearance, fifthly, an integrated one-time cutting process is adopted, a working procedure is less, a cutting surface and a line are smooth and continuous, and quality is high, sixthly, the quality of a cut curve and a flame cutting surface are both improved, seventhly, the operating time that the welder carries out the welding is reduced, eighthly, production efficiency is high, and ninthly, working efficiency is improved.

Owner:中铁宝桥(宝鸡)路桥建设有限公司

Steel-concrete combined beam and construction method thereof

InactiveCN101798856ATaking into account the structureTaking into account the construction speedLoad-supporting elementsBuilding material handlingPull forceReinforced concrete

The invention discloses a steel-concrete combined beam, comprising a reinforced concrete part for resisting pressure and a steel component part for resisting pulling force, wherein the reinforced concrete part is a reverse U-shaped section; reinforced bars extend out a certain distance from two ends of the beam for connection; and the steel component part is positioned on the bottom of the combined beam, and forms a whole with the reinforced concrete part through weld joint connection or bolt connection. The combined beam can improve the seismic resistance of the structure, increase the structure ductility, and accelerate the construction progress, thus being a steel-reinforced concrete combined beam with relatively lower engineering cost and convenient construction.

Owner:HUNAN UNIV

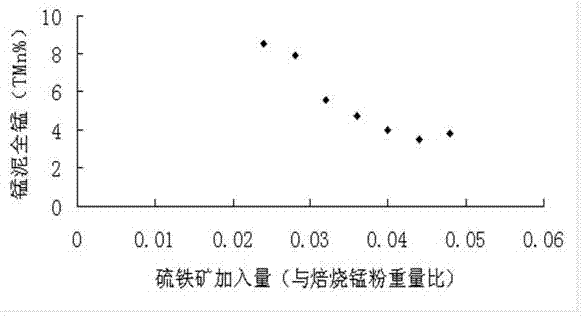

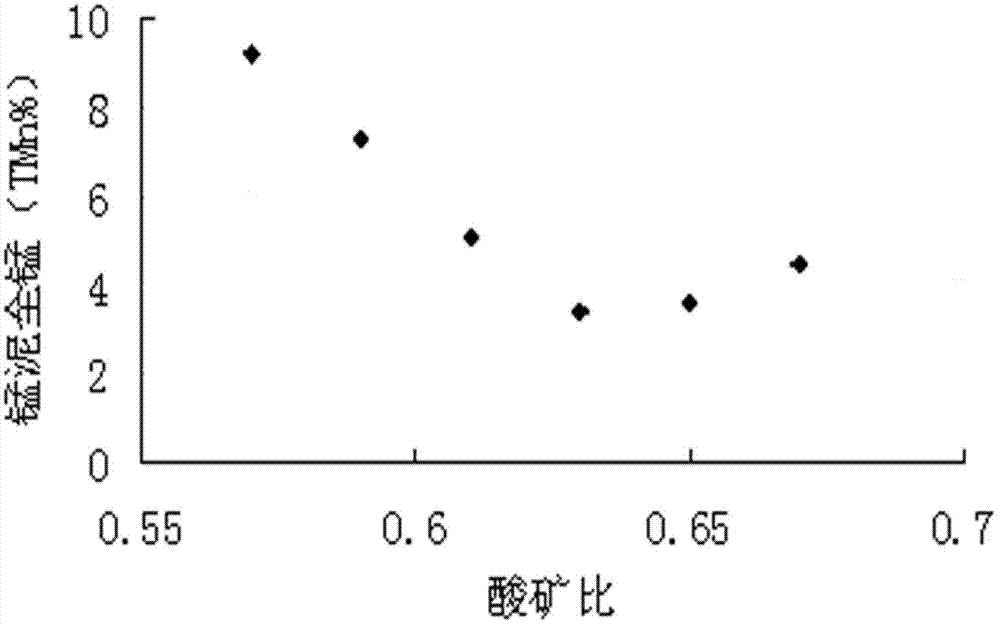

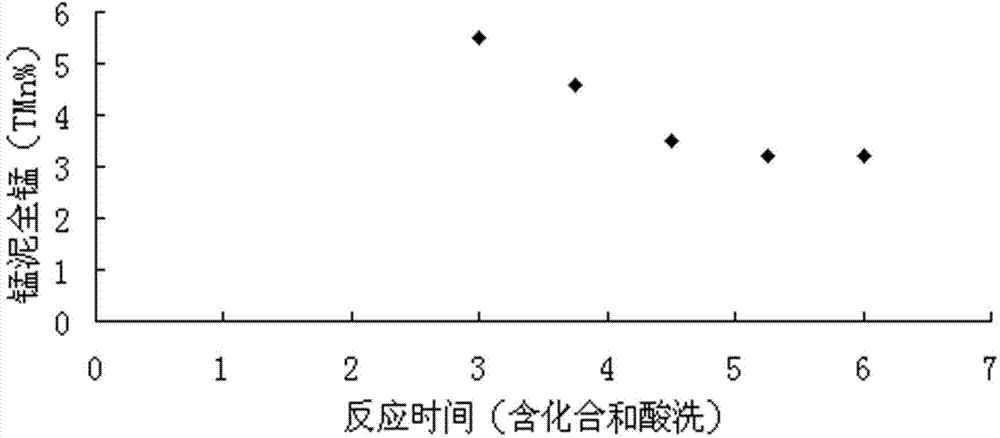

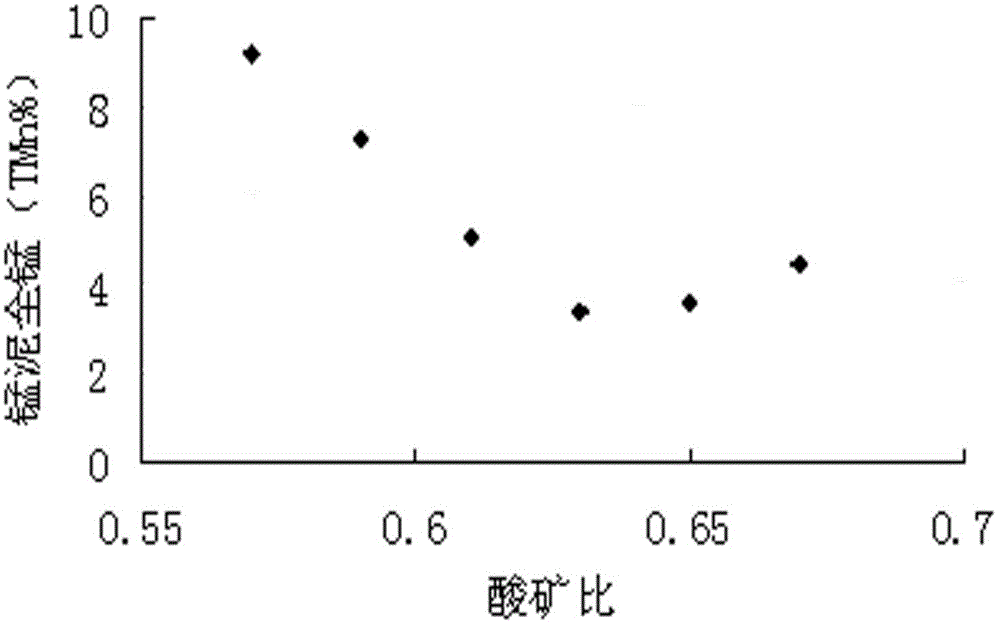

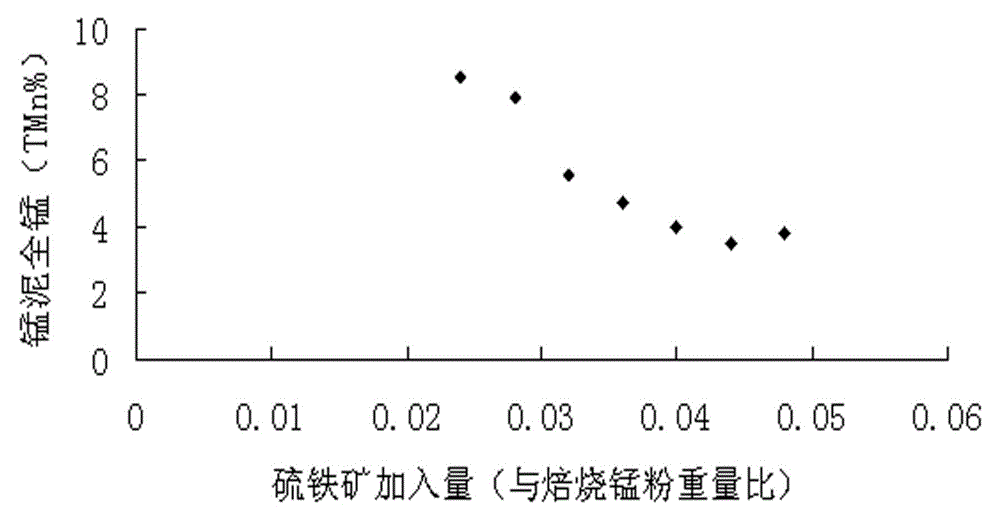

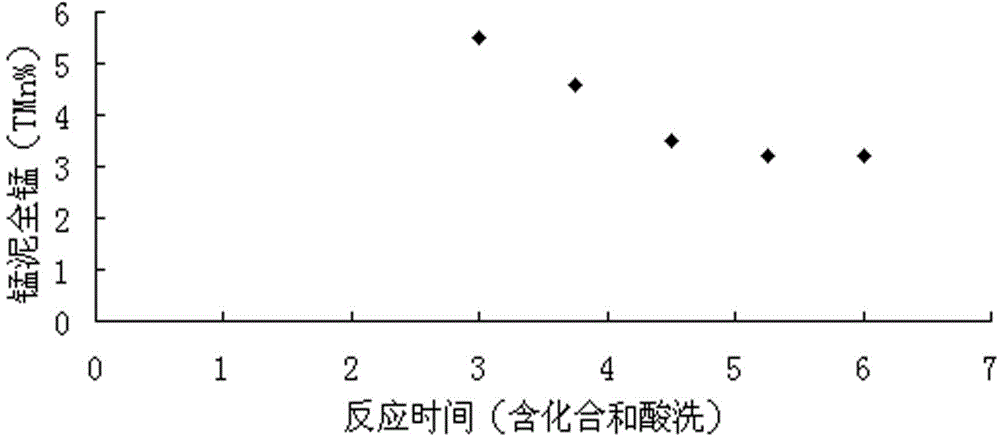

Novel process for producing manganese sulfate by combination of pyrogenic process and wet process

The invention discloses a novel process for producing manganese sulfate by combination of a pyrogenic process and a wet process. The novel process comprises the steps: (1), roasting with anthracite culm to obtain roasted manganese powder; (2), mixing the roasted manganese powder with a secondary solution and / or water for pulping, adding sulfuric acid, adding iron pyrite, performing a thermal reaction, filtering to obtain primary slag and a primary liquid; (3), pulping the primary slag by using water and / or third solution, adding sulfuric acid, adding iron pyrite, performing a thermal reaction, filtering to obtain secondary slag and a secondary liquid, rinsing and filtering the secondary slag to obtain third slag and a third liquid, discharging the third slag; and (4), removing iron from the primary liquid, removing heavy metals, standing, heating and concentrating and crystallizing, dewatering and drying to obtain the manganese sulfate. The novel process has the beneficial effects that (1), the content of full manganese in the manganese slag reaches below 4 percent, the content of tetravalent manganese slag reaches below 0.6 percent, the metal recovery rate reaches above 82 percent, and the mine consumption cost is low; and (2), the main content of a manganese sulfate product reaches above 98.5 percent, the content of a water insoluble is within 0.02 percent, the content of impurities is within 0.3 percent, and the content of heavy metal elements is within 6 ppm.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

Printing ink used for clothes printing and preparation method thereof

The invention discloses a printing ink used for clothes printing and a preparation method thereof, which relate to the field of printing ink. The printing ink comprises the following raw materials inparts by weight: 25-35 parts of alkyd resin, 15-25 parts of polyamide resin, 8-15 parts of hydroxypropyl methyl cellulose, 7-12 parts of fluororesin, 8-20 parts of butyl acetate, 4-10 parts of flaxseed oil, 3-8 parts of mineral oil, 2-5 parts of 2-ethyl aluminum hexahydric, 3-6 parts of barium sulfate, 3-6 parts of nano alumina, 2-5 parts of modified nano titanium dioxide, 1.5-3.2 parts of a pigment, 1.8-3.6 parts of a surfactant, 0.8-3.2 parts of a lubricant, 1.5-3.5 parts of a stabilizing agent, and 1.4-3.5 parts of an adhesion promoter. The printing ink has the advantages that viscosity ishigh, shedding from an applying surface is difficulty carried out, the lubricity is good, uniform spraying is easily realized, the surface of the sprayed patterns is smooth, the beauty is high, the practical and effective performance is long, the process flow is clear, and the preparation is easy to operate.

Owner:合肥佳洋电子科技有限公司

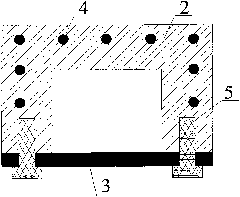

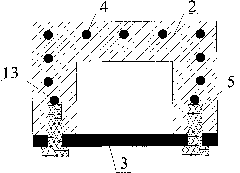

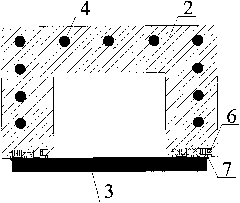

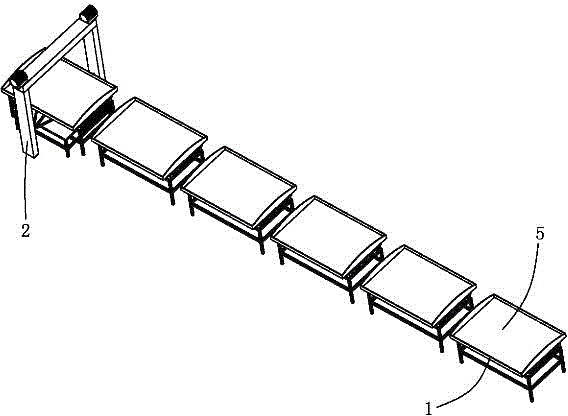

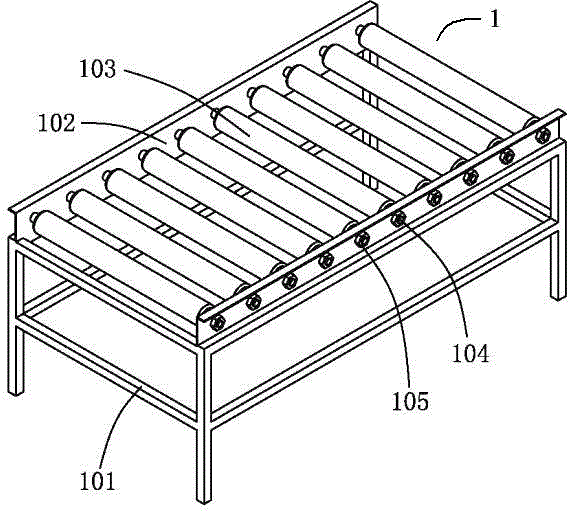

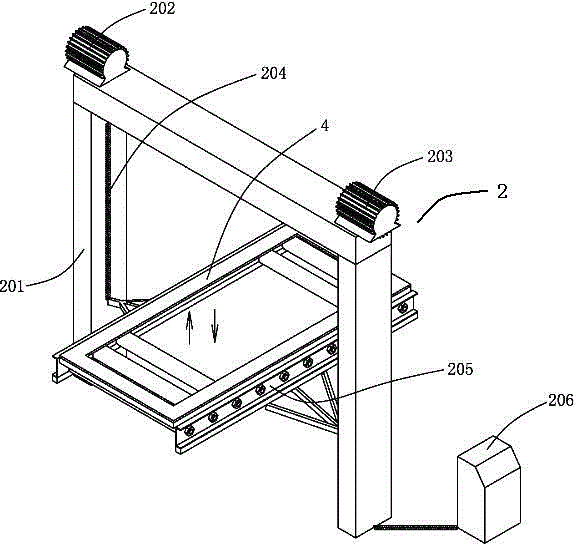

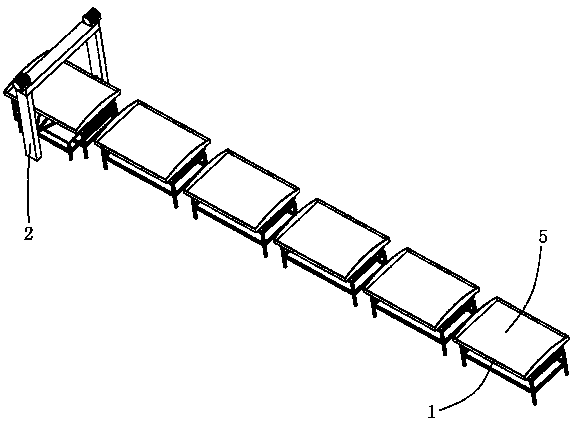

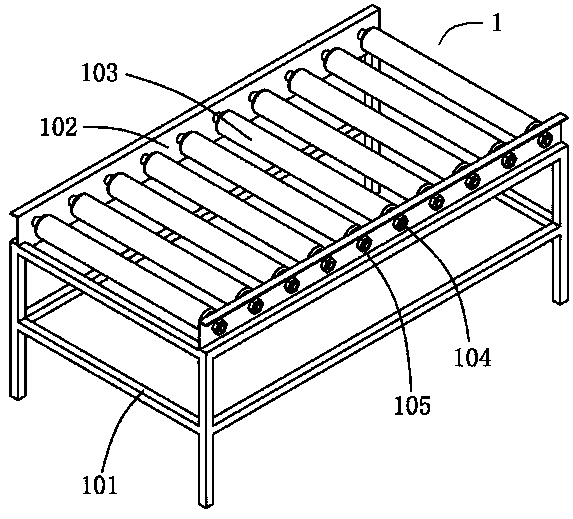

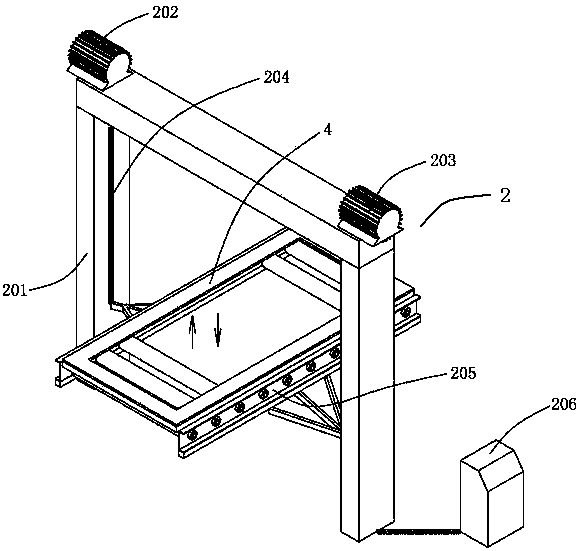

Flexible production line for medium and large vehicle air conditioners

ActiveCN103143933AReduce labor intensityClear production processAssembly machinesProduction lineAutomobile air conditioning

The invention relates to a flexible production line for medium and large vehicle air conditioners. The flexible production line comprises unpowered roller workbenches, a lifting platform, rotating roller transitional workbenches and transitional plates. The production line can be designed in a through type or a bending shape according to sites, then a corresponding number of unpowered roller workbenches and rotating roller transitional workbenches are arranged according to the specific production process, each roller workbench represents one process, each roller workbench is provided with one transitional plate, components of the medium and large vehicle air conditioners are borne by the transitional plates to be assembled in the processes one by one, and the assembling processes are basically completed when the components are transferred to the lifting platform. The flexible production line disclosed by the invention has the beneficial effects that the production processes are clear, the components are moved, people do not need to move, the labor intensity of workers is reduced, and the investment of corresponding devices and tools is reduced; and the adopted devices are suitable for assembly line work, the production efficiency is improved, different products are better in consistency, and the flexible production line is suitable for the multi-species and small-batch production of medium and large vehicle air conditioners.

Owner:XIAMEN SONGZHI AUTOMOBILE AIR CONDITIONER

External application Chinese medicament for spondylosis

InactiveCN101618171AClear production processAnthropod material medical ingredientsHydroxy compound active ingredientsMyrrhPeppermints

The invention discloses an external application Chinese medicament for spondylosis, which is prepared from the following 14 kinds of Chinese medicinal raw materials: kudzuvine root, clematis root, incised notopterygium rhizome, largeleaf gentian root, earthworm, safflower, zedoary, swordlike atractylodes rhizome, szechuan lovage rhizome, costustoot, frankincense, myrrh, peppermint and borneol. The external application Chinese medicament has functions of activating blood circulation to dissipate blood stasis, clearing and activating the channels and collaterals, diminishing inflammation and relieving pain, and has the obvious therapeutic effect on the spondylosis.

Owner:BEIJING ZHONGKE RENHE SCI & TECH

Novel high-efficiency electrolysis water hydrogen production graphite-based electrode plate

InactiveCN109183066AWide variety of sourcesClear production processElectrodesElectrolysisCarbonization

The invention provides a novel high-efficiency electrolysis water hydrogen production graphite-based electrode plate. The graphite-based electrode plate is characterized in that the electrode plate isa graphite-based plate material, and when the electrode plate is used as a cathode and an anode at the same time for electrolysis water hydrogen production, the hydrogen production efficiency is 1 to3 times that of a stainless steel material. A manufacturing process of the graphite-based plate material includes crushing, resin impregnation, solidification, milling, graphitization, kneading, molding, carbonization and cutting. The electrode plate material is wide in source, the manufacturing technique is clear, cost is low, and the hydrogen production efficiency is high.

Owner:安徽锦美碳材科技发展有限公司

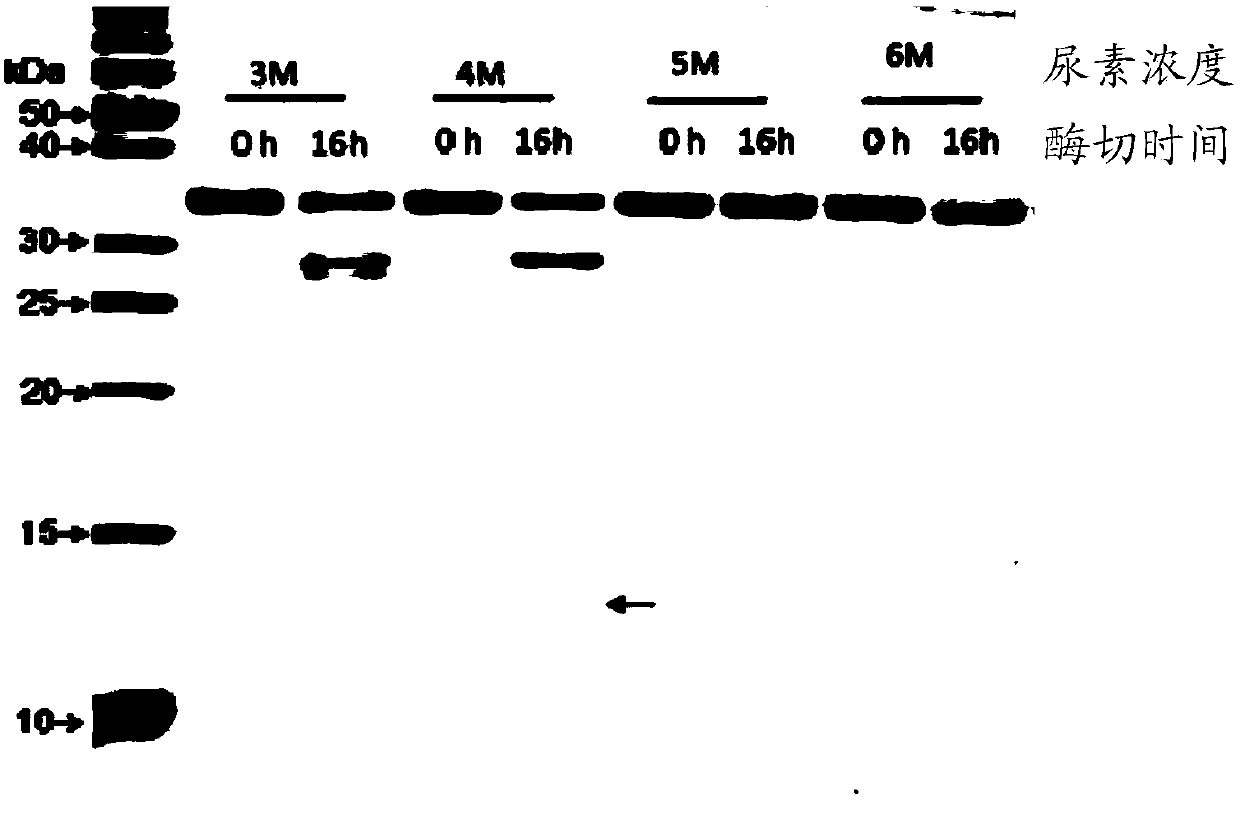

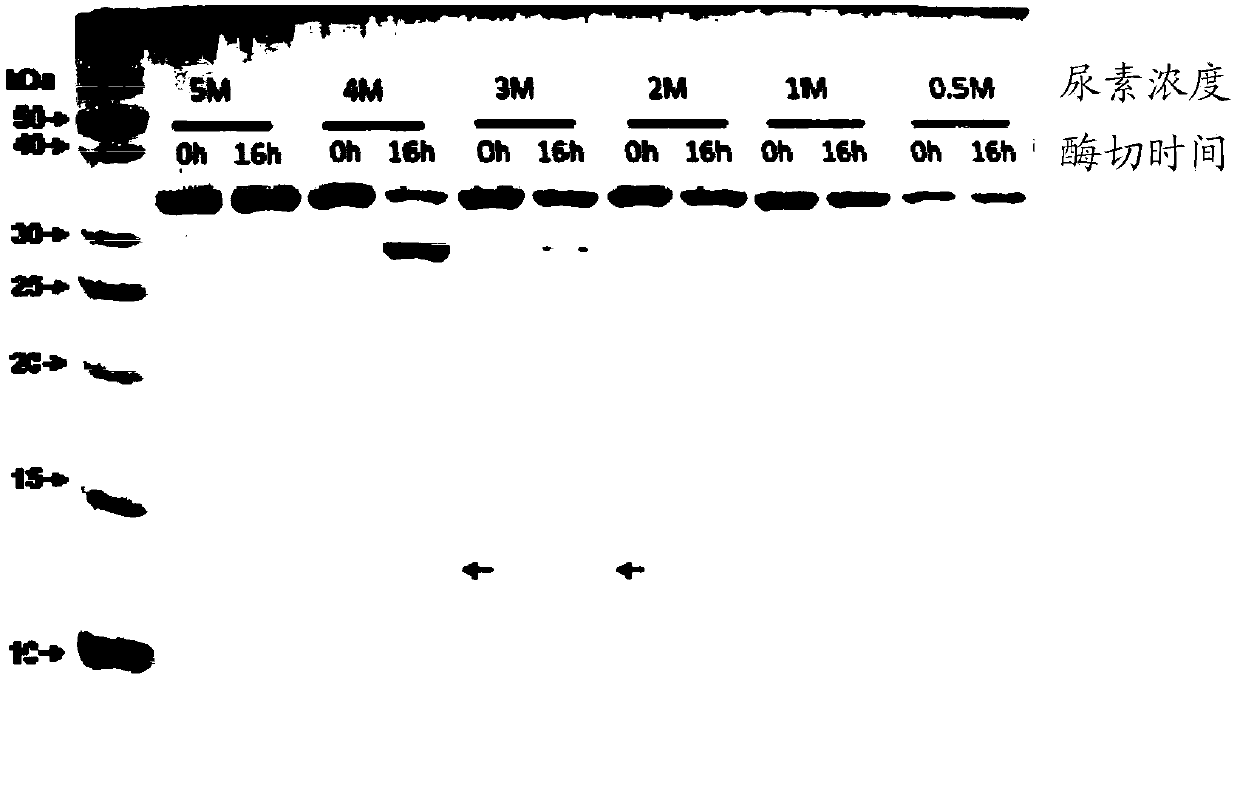

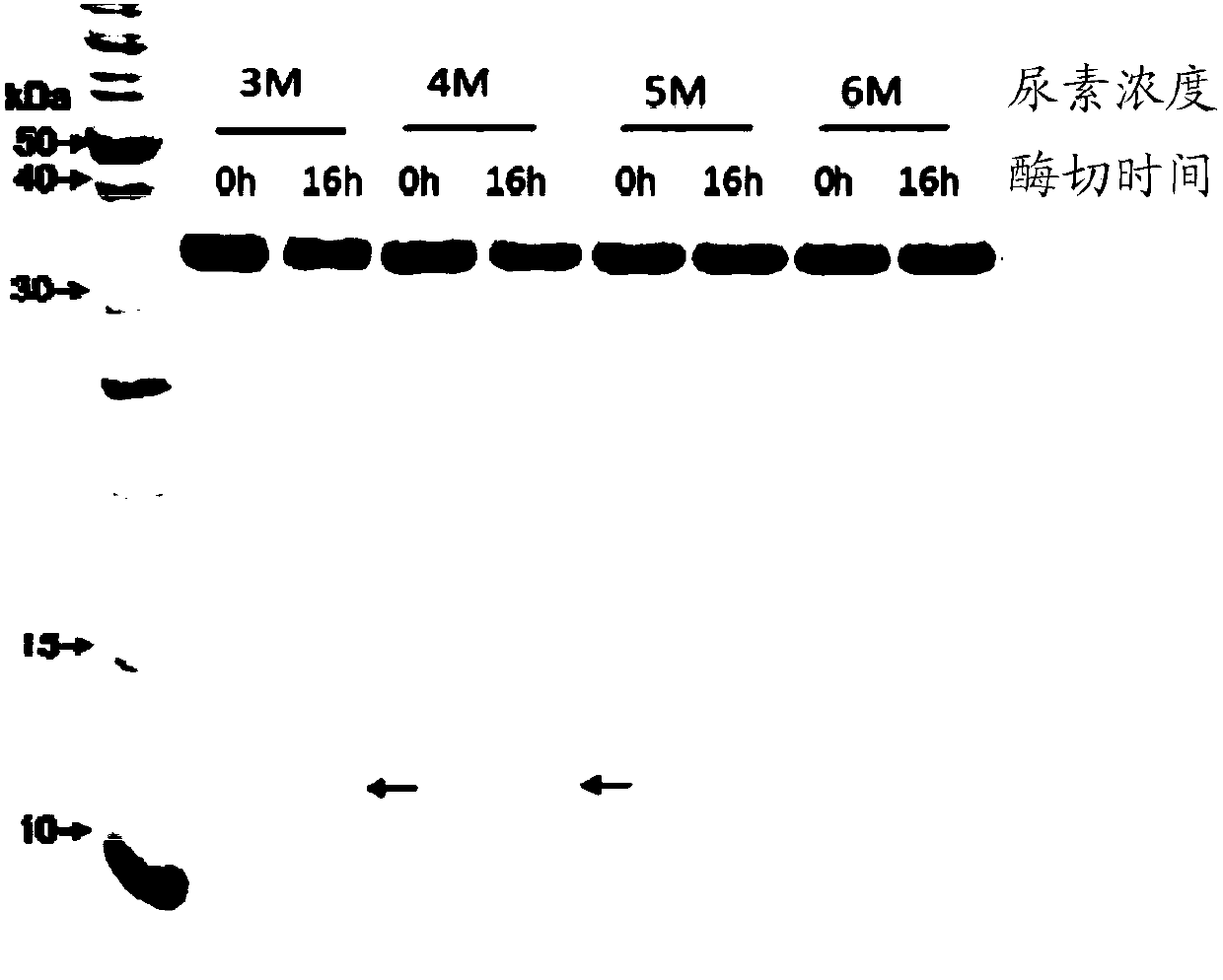

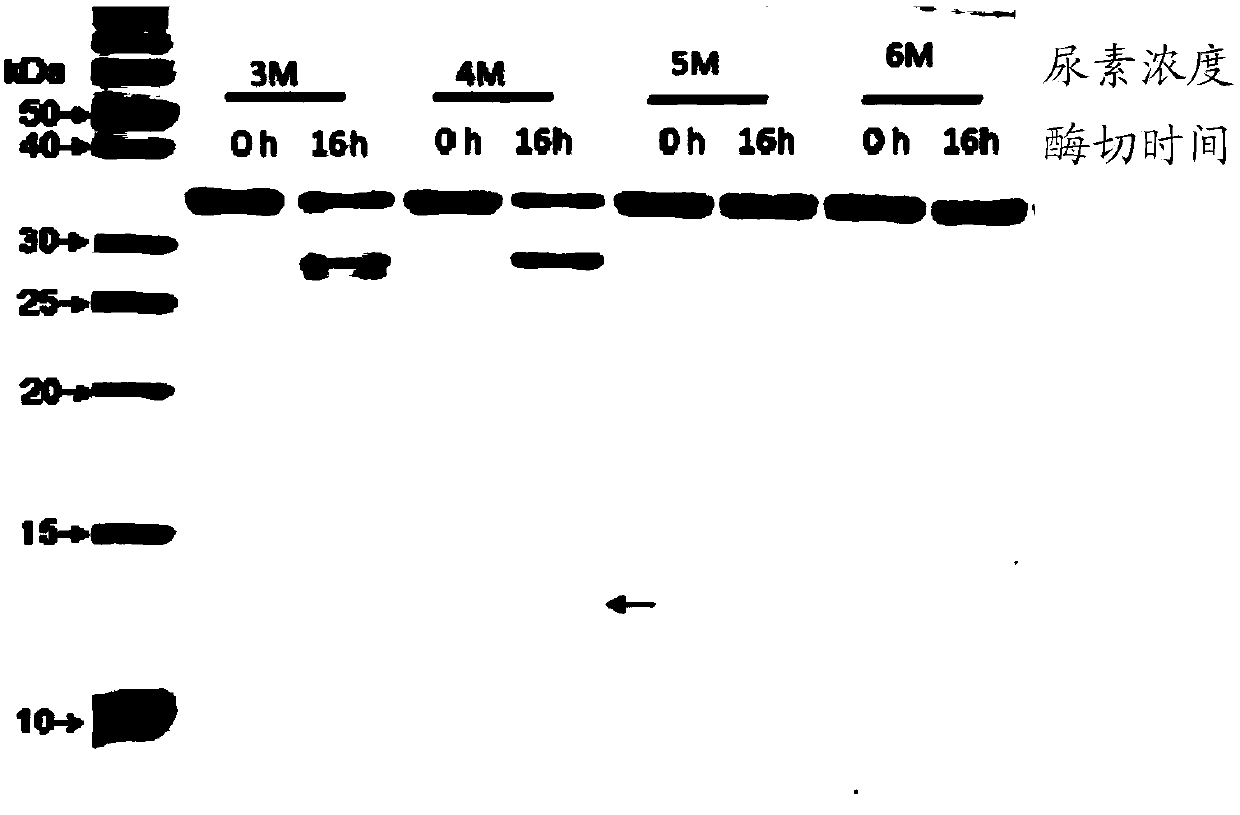

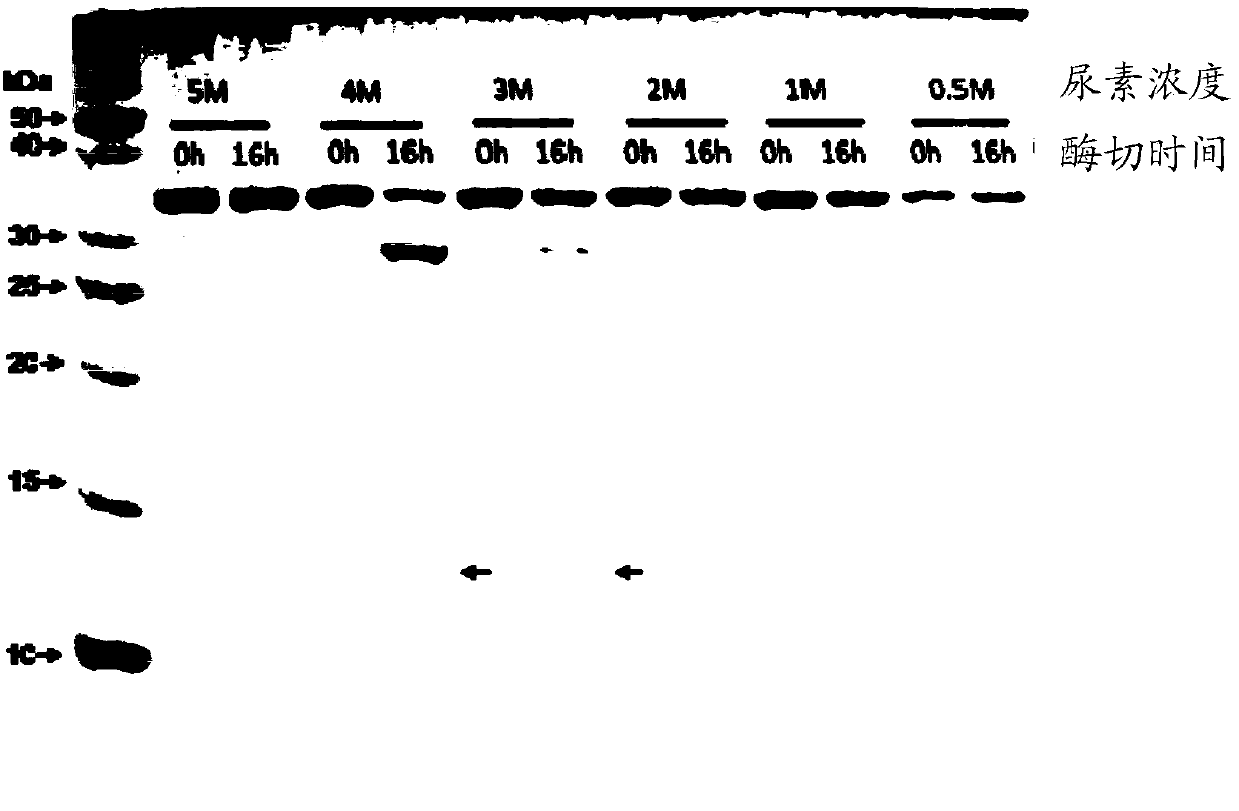

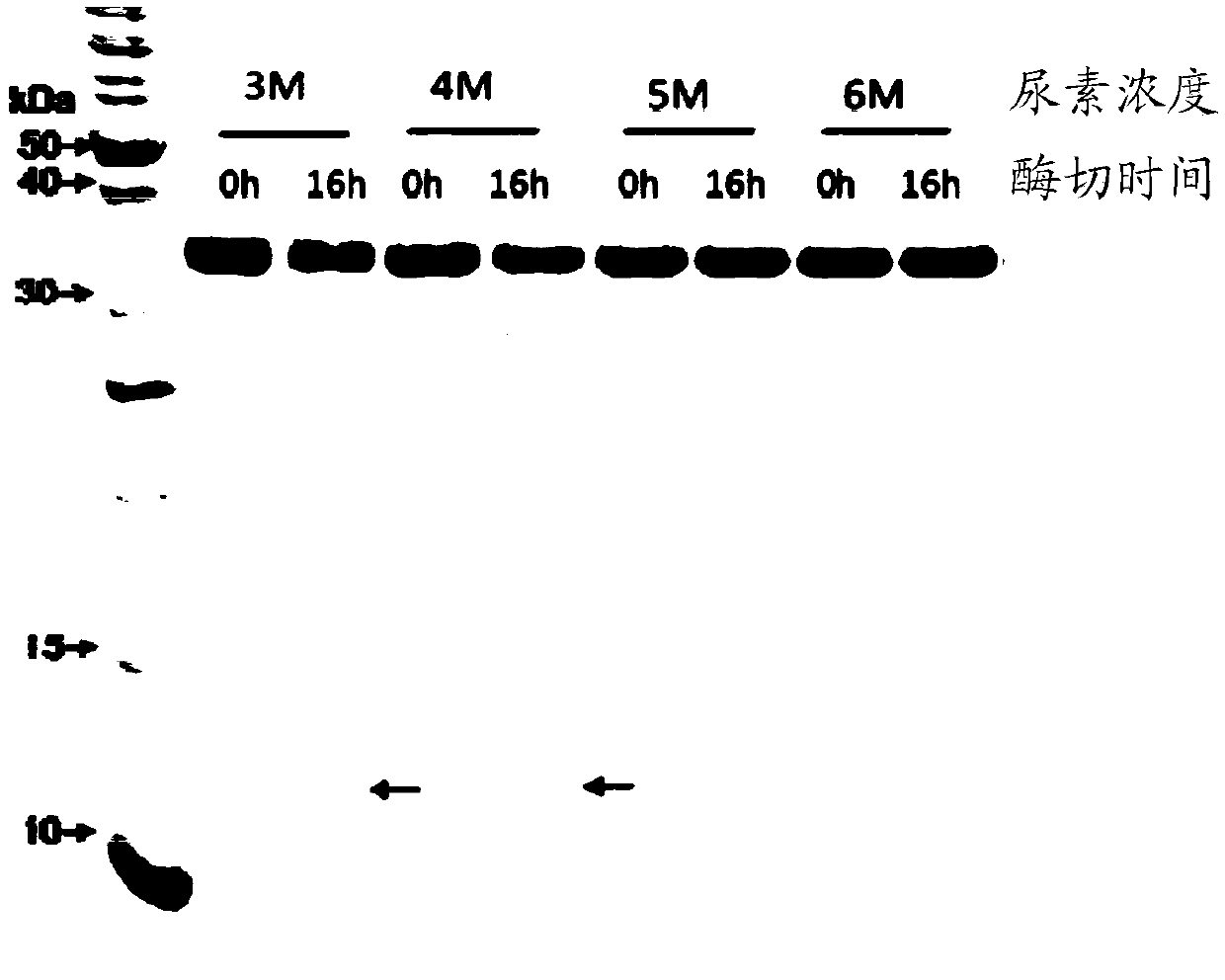

TEV protease variant, fusion protein, preparation method and uses thereof

ActiveCN111019926AUnique access to performanceHigh activityAntibody mimetics/scaffoldsCorticotropinBiochemistryProtease

The invention provides a TEV protease variant, a fusion protein, a preparation method and uses thereof, particularly a screened TEV protease variant with unique properties, and a fusion protein. According to the invention, polypeptides can be rapidly and efficiently prepared through TEV protease variant and polypeptide fusion expression so as to solve the problems existing in the current polypeptide recombinant production process.

Owner:SHANGRAO CONCORD PHARMA CO LTD

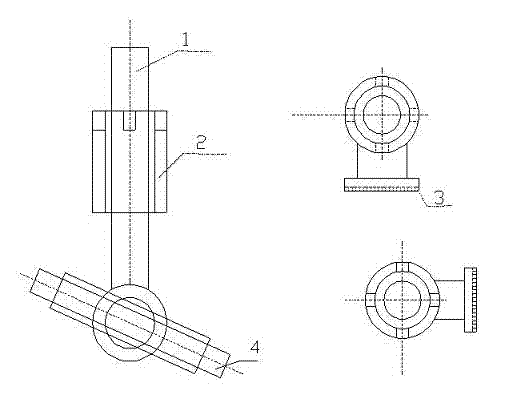

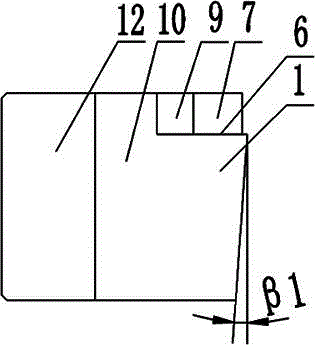

Multi-azimuth feed cutter bar manufacturing process capable of avoiding machining interference

InactiveCN104972150AClear production processReduce manufacturing costTurning machine accessoriesQuenchingMaterial consumption

The invention discloses a multi-azimuth feed cutter bar manufacturing process capable of avoiding machining interference. The process comprises the steps of A, material preparation; B, shape turning; C, surface finish turning; D, milling of the front surface (11) of a cutter handle (2); E, plane abrasion of the outer surface of a cutter bar; F, finish milling of a rhombus cutter blade groove (5), a receding hole groove (9), a fixing screw hole (8), a left end face (10), the front surface (11) and an inclined tangent plane (12) on a vertical machining center; G, deburring; H, protective quenching; I, surface crocus paper sanding; and J, bed welding of a hard alloy layer on the groove wall. The multi-azimuth feed cutter bar manufacturing process capable of avoiding machining interference has the beneficial effects that the manufacturing cost is low; the machining range of a cutter is enlarged; the structure is reasonable and reliable; a cutter blade is replaced easily and quickly; material consumption is reduced.

Owner:CHENGDU LIXIN SCI & TECH

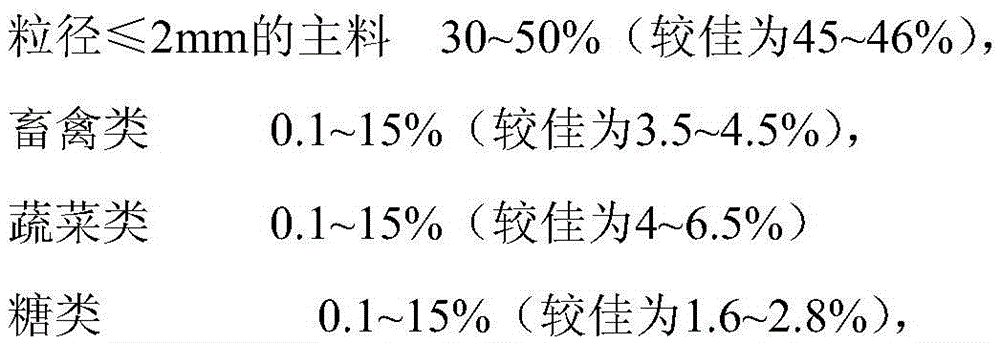

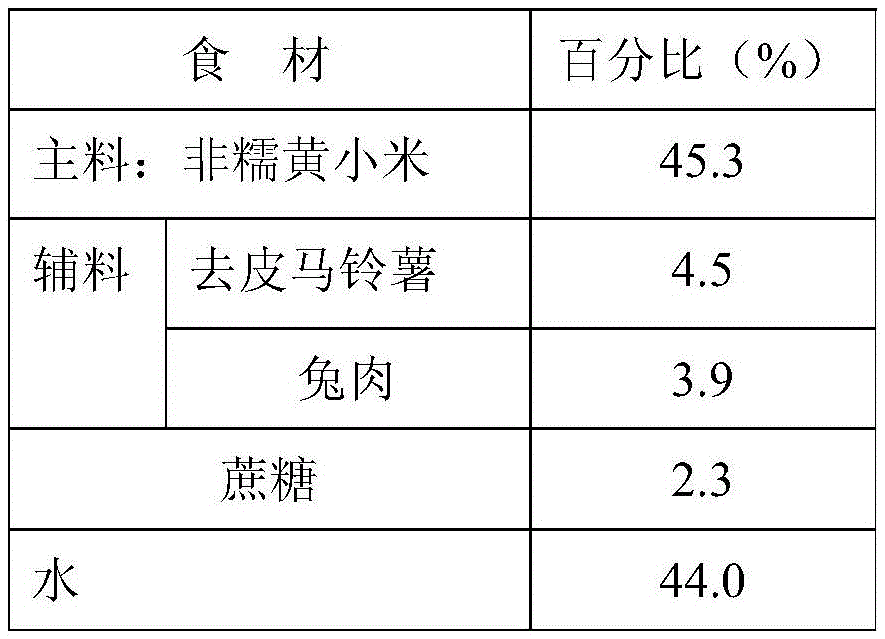

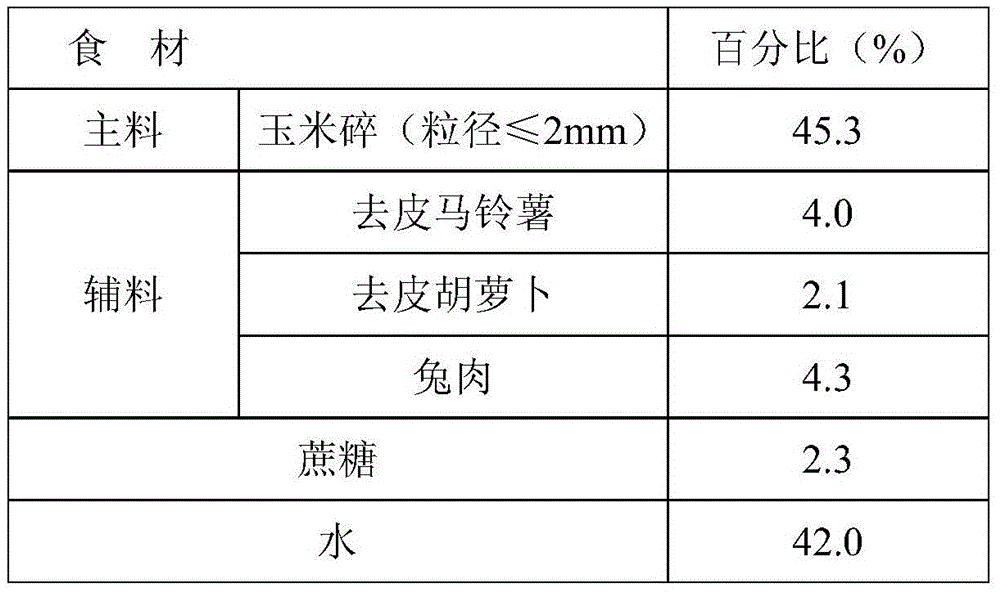

Food material-based cordyceps militaris mycelium solid culture method and solid culture medium utilized in solid culture method

ActiveCN105543111AGood loose air permeabilityHigh specific surface areaFungiMicroorganism based processesLivestockFungal mycelium

The invention discloses a cordyceps militaris mycelium solid culture medium. The solid culture medium comprises the following components in percentage by weight: 30%-50% of main materials with the particle sizes less than or equal to 2mm, 0.1%-15% of livestock, 0.1%-15% of vegetables, 0.1%-15% of saccharides and the balance of water, wherein the main materials are non-glutinous cereals or beans, the livestock and the vegetables are auxiliary materials, and the saccharides are monosaccharides or disaccharides. The invention further simultaneously discloses a preparation method of the cordyceps militaris mycelium solid culture medium and a food material-based cordyceps militaris mycelium solid culture method utilizing the solid culture medium. By taking the food materials as the main materials and the auxiliary materials, the solid culture medium has relatively large specific surface area and good loosening breathability, and good nutritional conditions and physical space can be provided for the growth of cordyceps militaris mycelia.

Owner:ZHEJIANG UNIV

Wallboard production line

InactiveCN110815535ASave spaceIncrease incomeCeramic shaping plantsManufacturing lineIndustrial engineering

The invention relates to the technical field of wallboard production, in particular to a wallboard production line which comprises a product off-line station, a line body, a cleaning station, a ceramic tile placing station, a gluing station, a substrate placing station, a pressing plate placing and inspection station, a curing station and a lifting platform II. The line body is placed at the tailend of the product off-line station. The cleaning station, the ceramic tile placing station, the gluing station, the substrate placing station, the pressing plate placing and inspection station and the curing station are fixedly connected to the top of the line body, and the ceramic tile placing station is located at the tail end of the cleaning station. According to the wallboard production line,feeding, conveying, tool cleaning, manual ceramic tile placing, gluing, substrate pasting by a robot, pressing plate placing and curing drying are orderly combined, the production process is clear, the automation degree is high, the occupied workshop space is small, the pollution source is few, the power consumption is low, the cost is low, the maintenance is easy, the robot is adopted for substrate placing, positioning is accurate, the production efficiency is improved, and therefore the enterprise income is improved.

Owner:中山新硕智能科技有限公司

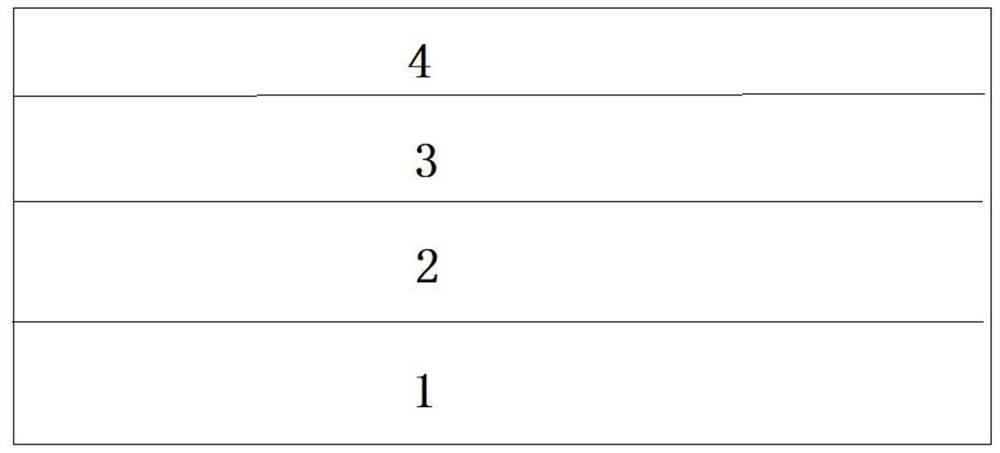

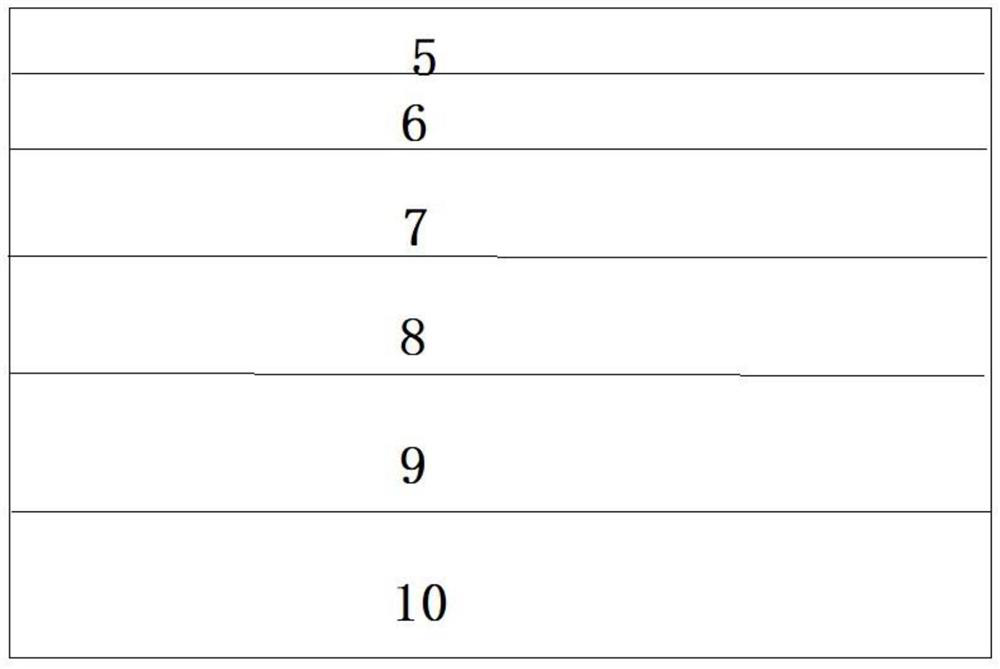

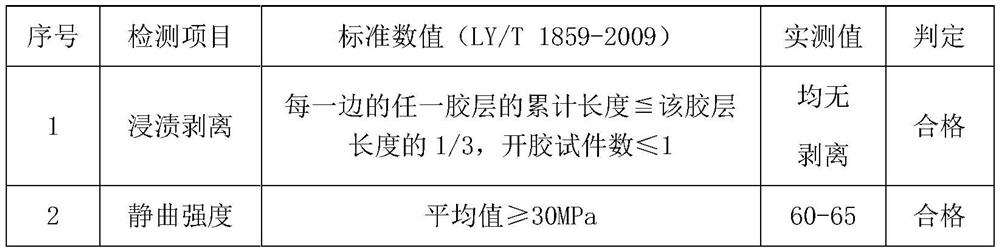

Archaized solid wood composite floor and production process thereof

PendingCN111749425ANo pollution in the processSave resourcesNatural patternsWood veneer joiningSolid woodAdhesive

The invention belongs to the technical field of building materials, and relates to an archaized solid wood floor, in particular to an archaized solid wood composite floor. A crisscross multilayer board base material layer is taken as a main body, the surface of the multilayer board base material layer is coated with adhesive to form a bonding layer, a surface layer is attached, a special archaizedprocessing layer is further arranged on the surface layer, and the uppermost layer is a UV paint layer. The special archaized layer is located between the surface layer and the surface UV paint layer, the thickness of the special archaized layer is between 0.1 mm and 1 mm, and the special archaized layer comprises a hand scraping archaized layer, a wire drawing process layer, a sawtooth grain treatment layer, a color coating process layer, a sand mark treatment layer and a color wiping treatment layer from top to bottom. The present invention also discloses a production process. According tothe archaized solid wood composite floor, the natural texture and the natural color of the wood are retained, the production process is simple, no distortion is lost in the texture pattern, the floorhas good visual characteristics through post-processing, and has relatively high paint adhesion and the like, and the physical and mechanical properties of the produced archaized floor meet the requirements of various indexes.

Owner:圣象地板(句容)有限公司

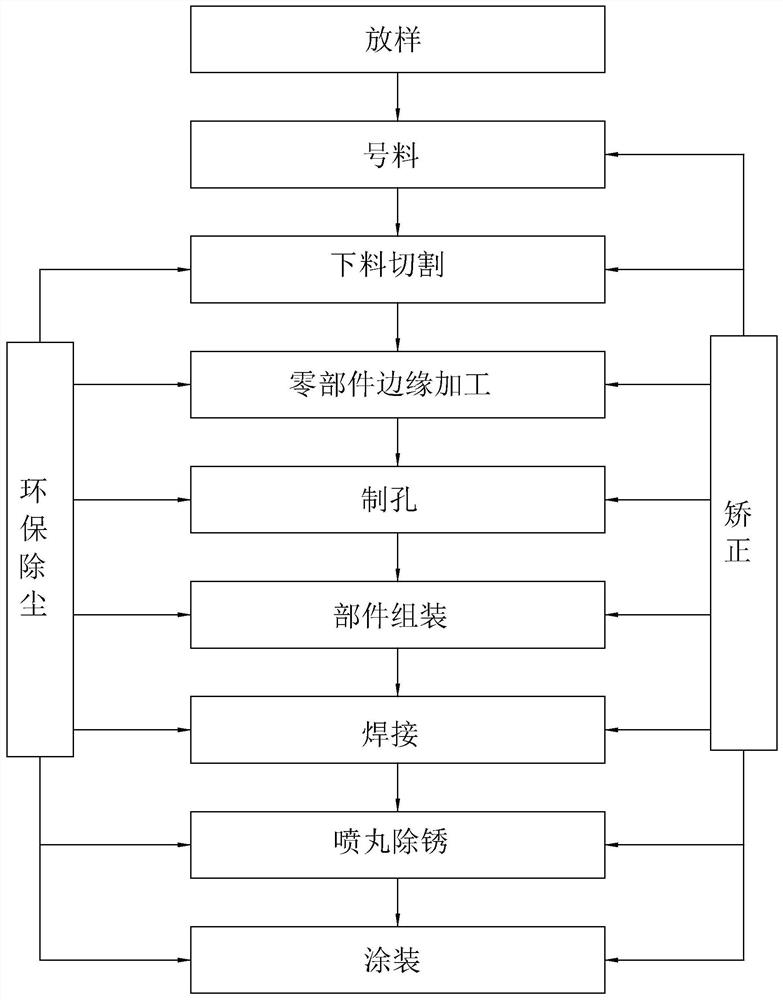

Fabricated steel structure manufacturing and machining process

PendingCN112264767AThe production process is clearImprove production qualityPeeningMachining process

The invention relates to a fabricated steel structure manufacturing and machining process. The process comprises the following steps: a, lofting; b, marking off; c, blanking and cutting; d, machiningof the edges of parts; e, drilling; f, correcting; g, component assembling; h, welding and re-correcting; i, shot peening; and j, coating. The process has the effects that the product quality of produced steel structures is improved, and environmental pollution in the production process is reduced.

Owner:河北远大钢构科技有限公司

Thick-wall copper pipe production process

The present invention discloses a thick-wall copper pipe production process, which comprises: 1, forging and stamping, wherein a furnace temperature is increased to 850-900 DEG C, a cooper ingot is forged and stamped, and thermal insulation is performed for 2-7 h; 2, reverse extrusion, wherein the copper ingot is subjected to position limitation by using an outer mold, the cooper rod is subjected to reverse extrusion through an inner mold to form a cooper pipe having the bottom, and the extruded cooper pipe is cooled to achieve a room temperature; and 3, cold extrusion, wherein the cooper pipe is subjected to cold extrusion to stretch so as to achieve the required size, and thermal insulation is performed for 3-4 h. According to the present invention, the manufacturing process is clear, the temperature and other parameters are reasonably controlled so as to produce the thick-wall cooper pipe meeting requirements by using the simple and conventional production process, and the quality is good.

Owner:常州市武进长虹结晶器有限公司

Method for screening protease variant, and protease variant obtained by method

ActiveCN111019925AEfficient cuttingUnique access to performanceCorticotropinFusion with protease siteGeneticsBiochemistry

Owner:SHANGRAO CONCORD PHARMA CO LTD

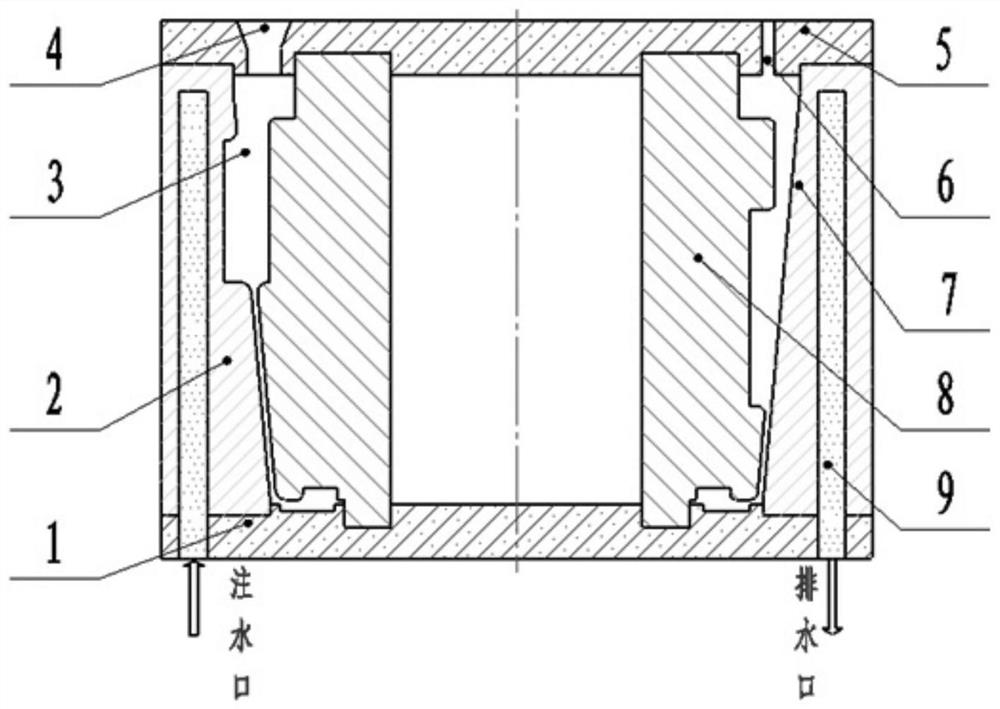

Wax mold preparation method for investment casting precision casting

ActiveCN109093069ARapid coolingGood dimensional stabilityFoundry moulding apparatusMaterials preparationWax

The invention discloses a wax mold preparation method for investment casting precision casting. The wax mold preparation method comprises the following steps that (1), mold closing is performed; (2),wax material preparation is carried out, wherein the wax material is added into a heat preservation furnace of a wax pressing machine; the temperature is raised to 90 DEG c to 100 DEG c, and after thewax material is completely melted, silicon carbide particles with the particle size of 6-14 [mu]m and the content of 3-5 wt% are added while the mixture is stirred, standing for 20-30 minutes is performed after the silicon carbide particles are completely added; cooling water with the temperature of 20-25 DEG c is injected into a cooling groove of the wax pressing machine for reducing the temperature of the wax to be 55-60 DEG c for later use; and (3), wax mold pressing is carried out, wherein a wax injection gun is used for injecting the wax material in the wax pressing machine into a mold cavity at the pressure of 0.3-0.5MPa, and when the wax is discharged from exhaust holes, wax injection is stopped; next, a mold water cooling system is started, and the flow is controlled to be 5-8 L / min; and when a temperature measurement thermocouple detects that the temperature of the wax is less than or equal to 35 DEG c, the mold is opened to take out the wax mold. According to the method, theeffect of enhancing the strength of the wax mold is achieved through the framework, the size contraction and deformation of the wax mold can be reduced effectively, the precision of the prepared waxmold can reach + / -0.5 mm, and the shrinkage rate is stabilized within 0.40%.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Large and medium-sized automobile air conditioner flexible production line

ActiveCN103143933BReduce labor intensityClear production processAssembly machinesProduction lineUltimate tensile strength

Owner:XIAMEN SONGZHI AUTOMOBILE AIR CONDITIONER

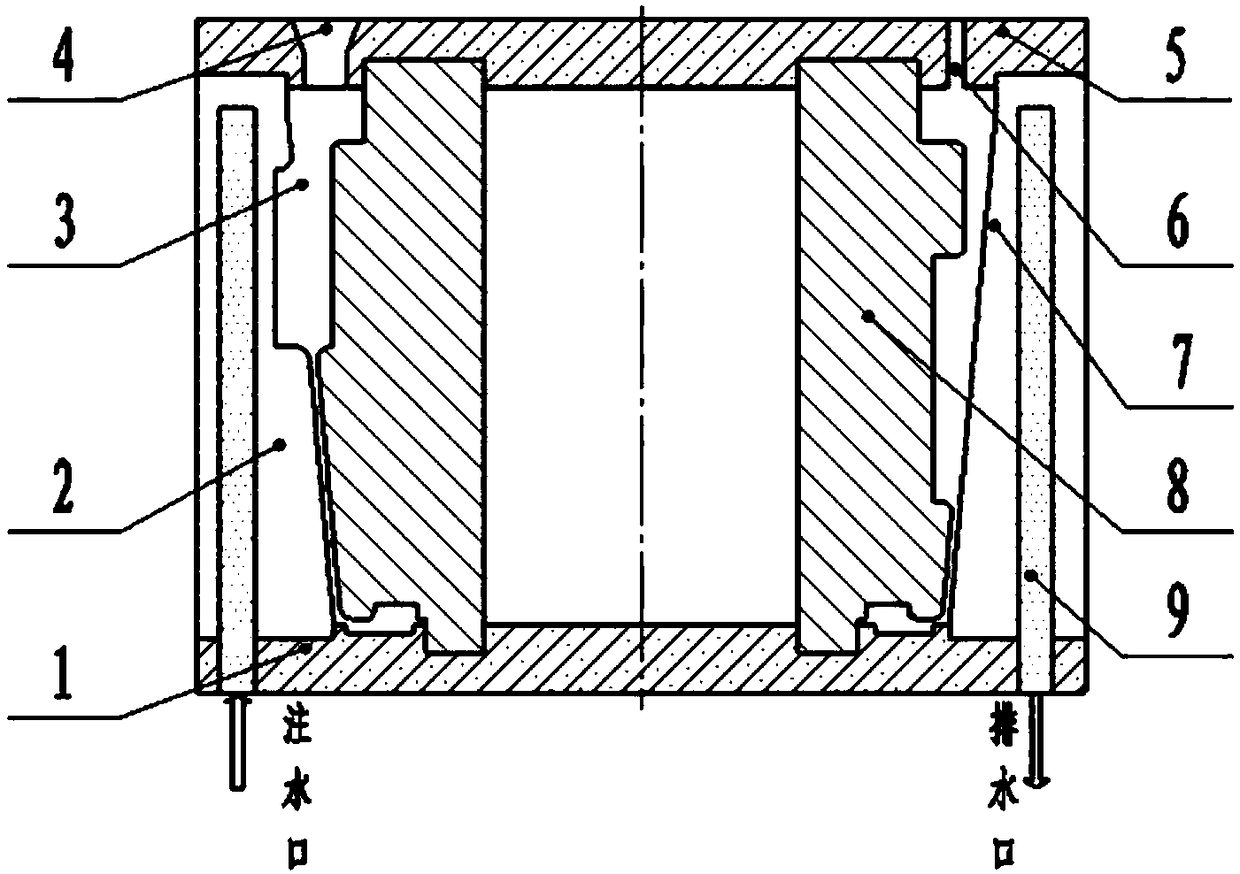

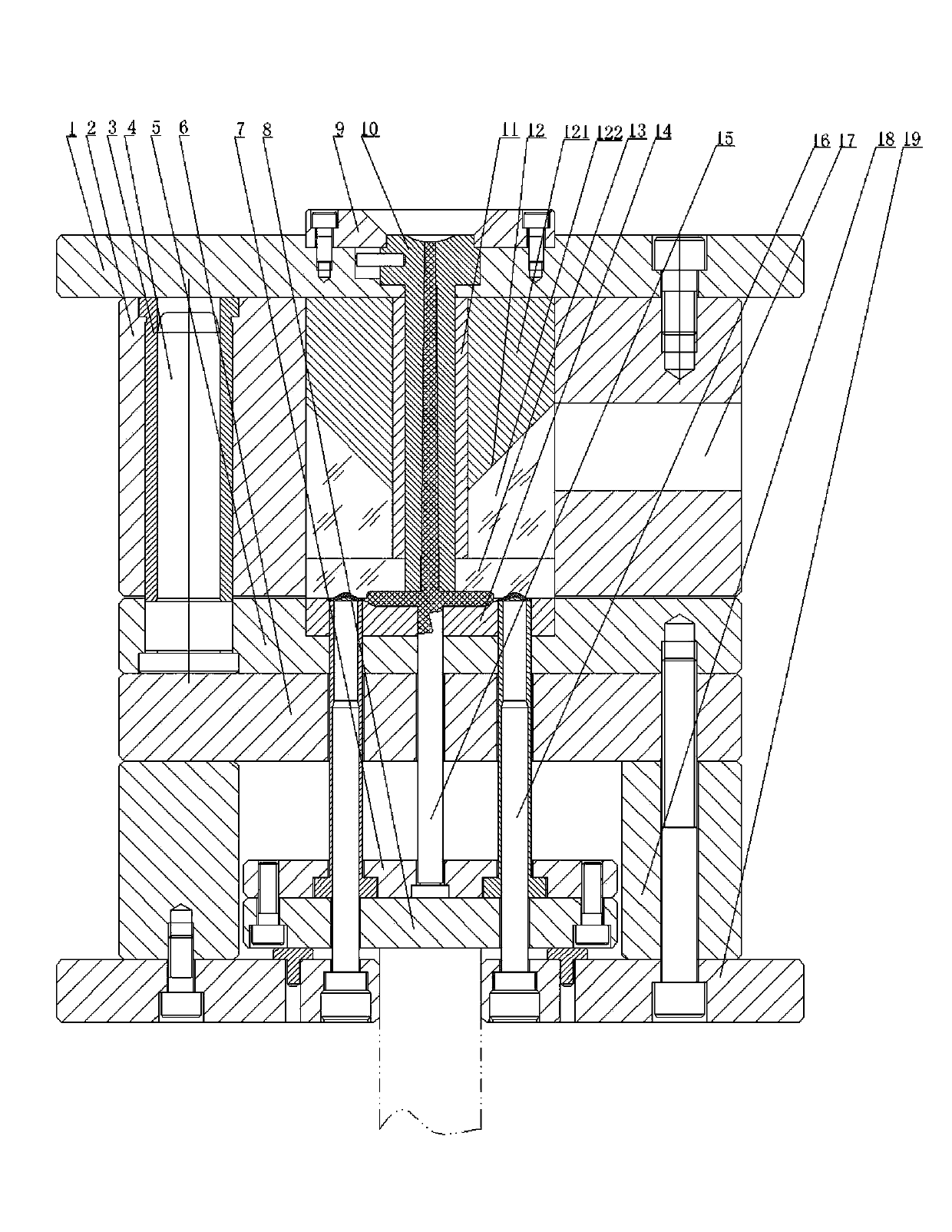

Visual injection molding mould

InactiveCN103991173ADetermining Injection Molding DefectsClarify the generation process of injection molding defectsInjection mouldingCushion

The invention relates to a visual injection molding mould which comprises a movable mold fixing plate and a fixed mold seat plate, wherein the movable mold fixing plate is connected with a fixed template; the fixed template is provided with a guide pillar sleeve; a casting sleeve is fixed by a locating ring on the movable mold fixing plate; the fixed mold seat plate is connected with a bracket; the bracket is provided with a movable mold base plate and a movable template; the movable template is provided with a guide pillar; a mold core is embedded in the movable template; the mold core is provided with a sprue puller and a mold core push pipe; the visual injection molding mould is characterized in that a bushing and a cushion block are arranged between the fixed template and the casting sleeve; the cushion block is formed by a 45-degree wedge-shaped upper cushion block and a 45-degree wedge-shaped lower cushion block; a mold cavity is formed between the mold core and the lower cushion block; the lower cushion block and the mold core are made from quartz glass; the fixed template is provided with a horizontal observation hole. According to the visual injection molding mould, the flow process of resin in the mold cavity can be directly observed by the horizontal reflection of the observation hole in the fixed template, so that computer aided engineering (CAE) numerical simulation results can be verified; furthermore, the production process of various injection molding defects can be figured out.

Owner:JIAXING UNIV

A new process for producing manganese sulfate by combined fire method and wet method

The invention discloses a novel process for producing manganese sulfate by combination of a pyrogenic process and a wet process. The novel process comprises the steps: (1), roasting with anthracite culm to obtain roasted manganese powder; (2), mixing the roasted manganese powder with a secondary solution and / or water for pulping, adding sulfuric acid, adding iron pyrite, performing a thermal reaction, filtering to obtain primary slag and a primary liquid; (3), pulping the primary slag by using water and / or third solution, adding sulfuric acid, adding iron pyrite, performing a thermal reaction, filtering to obtain secondary slag and a secondary liquid, rinsing and filtering the secondary slag to obtain third slag and a third liquid, discharging the third slag; and (4), removing iron from the primary liquid, removing heavy metals, standing, heating and concentrating and crystallizing, dewatering and drying to obtain the manganese sulfate. The novel process has the beneficial effects that (1), the content of full manganese in the manganese slag reaches below 4 percent, the content of tetravalent manganese slag reaches below 0.6 percent, the metal recovery rate reaches above 82 percent, and the mine consumption cost is low; and (2), the main content of a manganese sulfate product reaches above 98.5 percent, the content of a water insoluble is within 0.02 percent, the content of impurities is within 0.3 percent, and the content of heavy metal elements is within 6 ppm.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

Manufacturing process of large diameter copper tube

ActiveCN103567253BModerate hardnessNo crackingMetal-working apparatusFurnace temperatureThermal insulation

Owner:常州市武进长虹结晶器有限公司

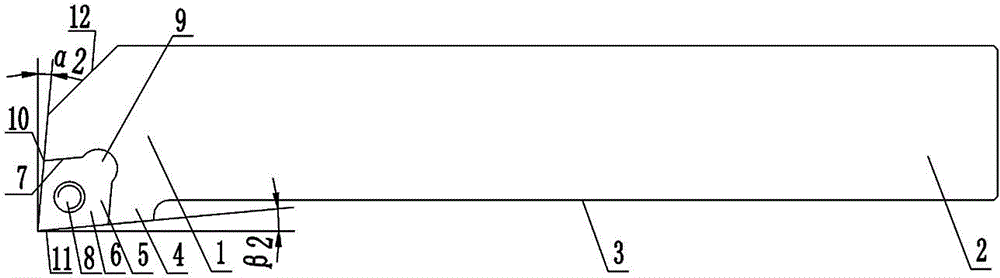

Mechanically-clamped type cutter bar capable of overcoming stress concentration and saving materials

InactiveCN104972152AClear production processReduce manufacturing costTool holdersStress concentrationMaterial consumption

The invention discloses a mechanically-clamped type cutter bar capable of overcoming stress concentration and saving materials. The mechanically-clamped type cutter bar capable of overcoming stress concentration and saving materials comprises a cutter bit (1) and a square cutter handle (2). A boss (4) is arranged on the cutter bit (1). A cutter blade groove (5) is formed in the upper surface of the cutter bit (1). A fixing screw hole (8) is formed in a groove bottom face (6). A receding hole groove (9) is formed in the intersection part of two connected groove walls (7). The mechanically-clamped type cutter bar capable of overcoming stress concentration and saving materials has the beneficial effects that the manufacturing cost is low; the machining range of a cutter is enlarged; the structure is reasonable and reliable; a cutter blade is replaced easily and rapidly; material consumption is reduced.

Owner:CHENGDU LIXIN SCI & TECH

A kind of wax pattern preparation method for investment precision casting

ActiveCN109093069BRapid coolingGood dimensional stabilityFoundry moulding apparatusCarbide siliconWax

The invention discloses a wax mold preparation method for investment casting precision casting. The wax mold preparation method comprises the following steps that (1), mold closing is performed; (2),wax material preparation is carried out, wherein the wax material is added into a heat preservation furnace of a wax pressing machine; the temperature is raised to 90 DEG c to 100 DEG c, and after thewax material is completely melted, silicon carbide particles with the particle size of 6-14 [mu]m and the content of 3-5 wt% are added while the mixture is stirred, standing for 20-30 minutes is performed after the silicon carbide particles are completely added; cooling water with the temperature of 20-25 DEG c is injected into a cooling groove of the wax pressing machine for reducing the temperature of the wax to be 55-60 DEG c for later use; and (3), wax mold pressing is carried out, wherein a wax injection gun is used for injecting the wax material in the wax pressing machine into a mold cavity at the pressure of 0.3-0.5MPa, and when the wax is discharged from exhaust holes, wax injection is stopped; next, a mold water cooling system is started, and the flow is controlled to be 5-8 L / min; and when a temperature measurement thermocouple detects that the temperature of the wax is less than or equal to 35 DEG c, the mold is opened to take out the wax mold. According to the method, theeffect of enhancing the strength of the wax mold is achieved through the framework, the size contraction and deformation of the wax mold can be reduced effectively, the precision of the prepared waxmold can reach + / -0.5 mm, and the shrinkage rate is stabilized within 0.40%.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Method for manufacturing decorative paintings from sorghum stalk

InactiveCN108099479AImprove the three-dimensional effectEasy to makeSpecial artistic techniquesManufacturing technologyPlant stalk

The invention relates to a method for manufacturing decorative paintings from sorghum stalk, and belongs to the field of art craft manufacture. The technical scheme includes that the method comprisescutting portions from a second knot to a sixth knot of the sorghum stalk, removing knots of the sorghum stalk, cleaning the sorghum stalk, soaking the sorghum stalk for 12 hours to degrease the sorghum stalk, dyeing the cleaned sorghum stalk, then fishing out the sorghum stalk, airing the sorghum stalk at the room temperature of 20 DEG C, splitting the sorghum stalk by the aid of small sharp knives, scraping the sorghum stalk to obtain sheets and scraping inner flesh in the sorghum stalk; designing drafts and drawing backgrounds with watercolor pigment or traditional Chinese painting pigment;coating latex on the drafts, clinging the sheets according to the backgrounds drawn in the drafts, adhering dyed quartz sand onto plant backgrounds in the drafts and carrying out shiny treatment on adhered materials; carrying out mounting and framing. Compared with the prior art, the method has the advantages that the decorative paintings are good in stereoscopic impression as compared with existing plant stalk paintings, manufacturing procedures are simple, the method is easy to operate and includes definite manufacturing technologies, and the decorative paintings which are products are attractive in appearance.

Owner:曹进然

Production process for hydraulic suspension damper

ActiveCN107350753AClear production processClear craftElectrical resistance and conductancePunch press

The invention discloses a production process for a hydraulic suspension damper. The method comprises the following steps of 1, stamping, wherein roll materials are put into a stamping die, a hydraulic suspension is fixed on a fixing mechanism of a punching machine for position fixation, and a driving punch of a driving mechanism is utilized to conduct stamping on the hydraulic suspension; 2, trimming and polishing, wherein trimming treatment is conducted on the stamped hydraulic suspension, and then the surface of the hydraulic suspension is polished to be smooth; 3, aluminum casting, wherein the temperature of a resistance aluminum melting furnace is set to 600-800 DEG C, heating is conducted for 20-30 minutes at first, pure aluminum is added into the resistance aluminum melting furnace to be completely melted, the hydraulic suspension treated in the step 2 is placed into the stamping die, a hydraulic aluminum casting machine is turned on to conduct aluminum casting operation on the hydraulic suspension, and after the aluminum casting operation is finished, the aluminum-casted hydraulic suspension is detected. The production process is perfect, the production efficiency is high, the damping effect is good, and it is ensured that the hydraulic suspension damper is high in quality, stable in performance and long in service life.

Owner:浙江淅川减振器有限公司

A production process of a hydraulic suspension shock absorber

The invention discloses a production process for a hydraulic suspension damper. The method comprises the following steps of 1, stamping, wherein roll materials are put into a stamping die, a hydraulic suspension is fixed on a fixing mechanism of a punching machine for position fixation, and a driving punch of a driving mechanism is utilized to conduct stamping on the hydraulic suspension; 2, trimming and polishing, wherein trimming treatment is conducted on the stamped hydraulic suspension, and then the surface of the hydraulic suspension is polished to be smooth; 3, aluminum casting, wherein the temperature of a resistance aluminum melting furnace is set to 600-800 DEG C, heating is conducted for 20-30 minutes at first, pure aluminum is added into the resistance aluminum melting furnace to be completely melted, the hydraulic suspension treated in the step 2 is placed into the stamping die, a hydraulic aluminum casting machine is turned on to conduct aluminum casting operation on the hydraulic suspension, and after the aluminum casting operation is finished, the aluminum-casted hydraulic suspension is detected. The production process is perfect, the production efficiency is high, the damping effect is good, and it is ensured that the hydraulic suspension damper is high in quality, stable in performance and long in service life.

Owner:浙江淅川减振器有限公司

The Brewing Technology of Lotus Seed Glutinous Rice Wine

InactiveCN104312837BHigh utilization rate of lotus seed starchSimple production processAlcoholic beverage preparationHorticultureYeast

The invention discloses a brewing process of lotus seed-glutinous rice wine. The brewing process of the lotus seed-glutinous rice wine comprises the following steps: (1) fermenting glutinous rice as a raw material to prepare wine yeast; (2) feeding treated lotus seeds for further fermentation to prepare the lotus seed-glutinous rice wine. The glutinous rice is fermented by a conventional brewing process and the treated lotus seeds are fed for further fermentation, so that the glutinous rice is prepared into excellent wine yeast and the lotus seeds are fully utilized, therefore, a high lotus seed starch utilizing ratio is realized.

Owner:ZHEJIANG UNIV

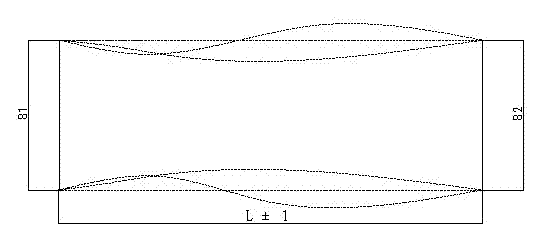

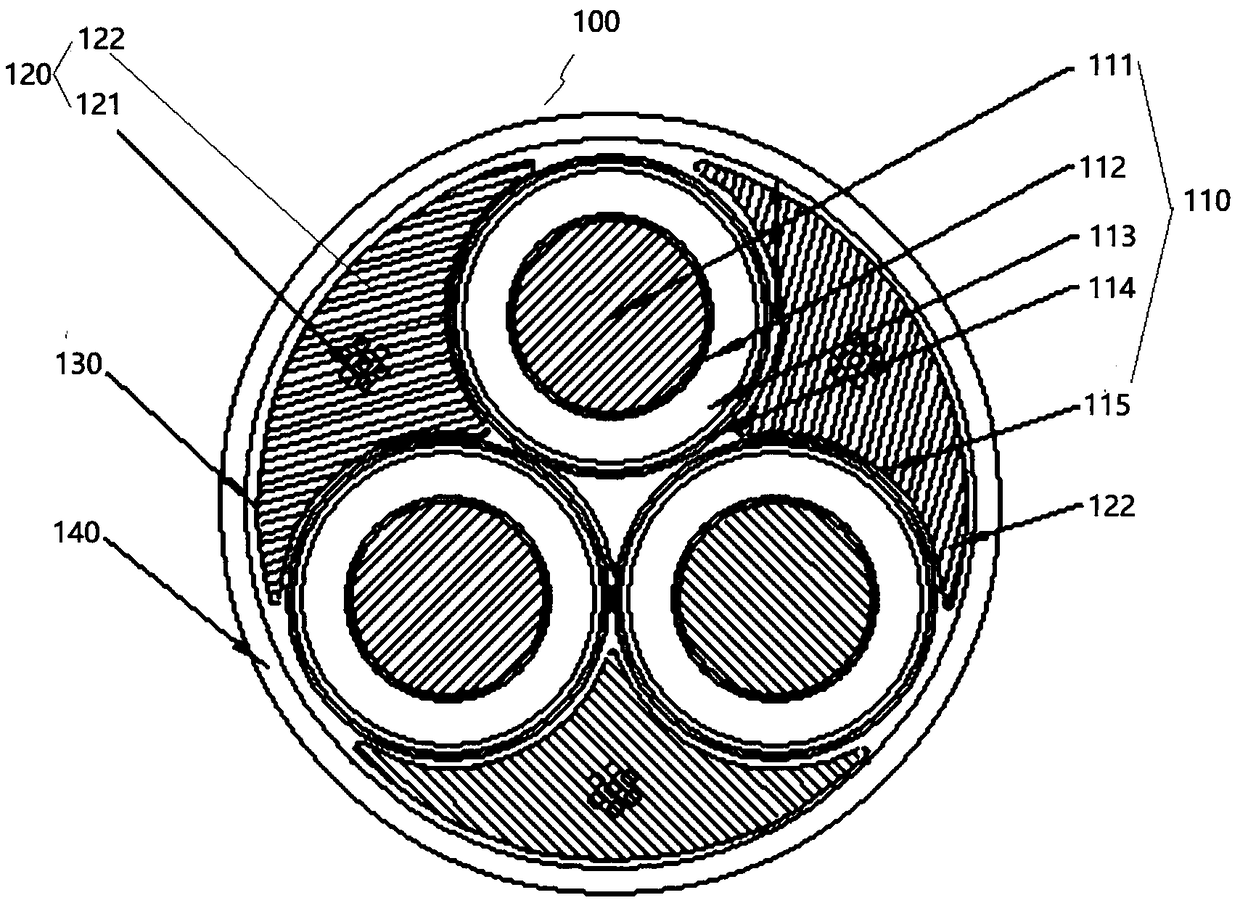

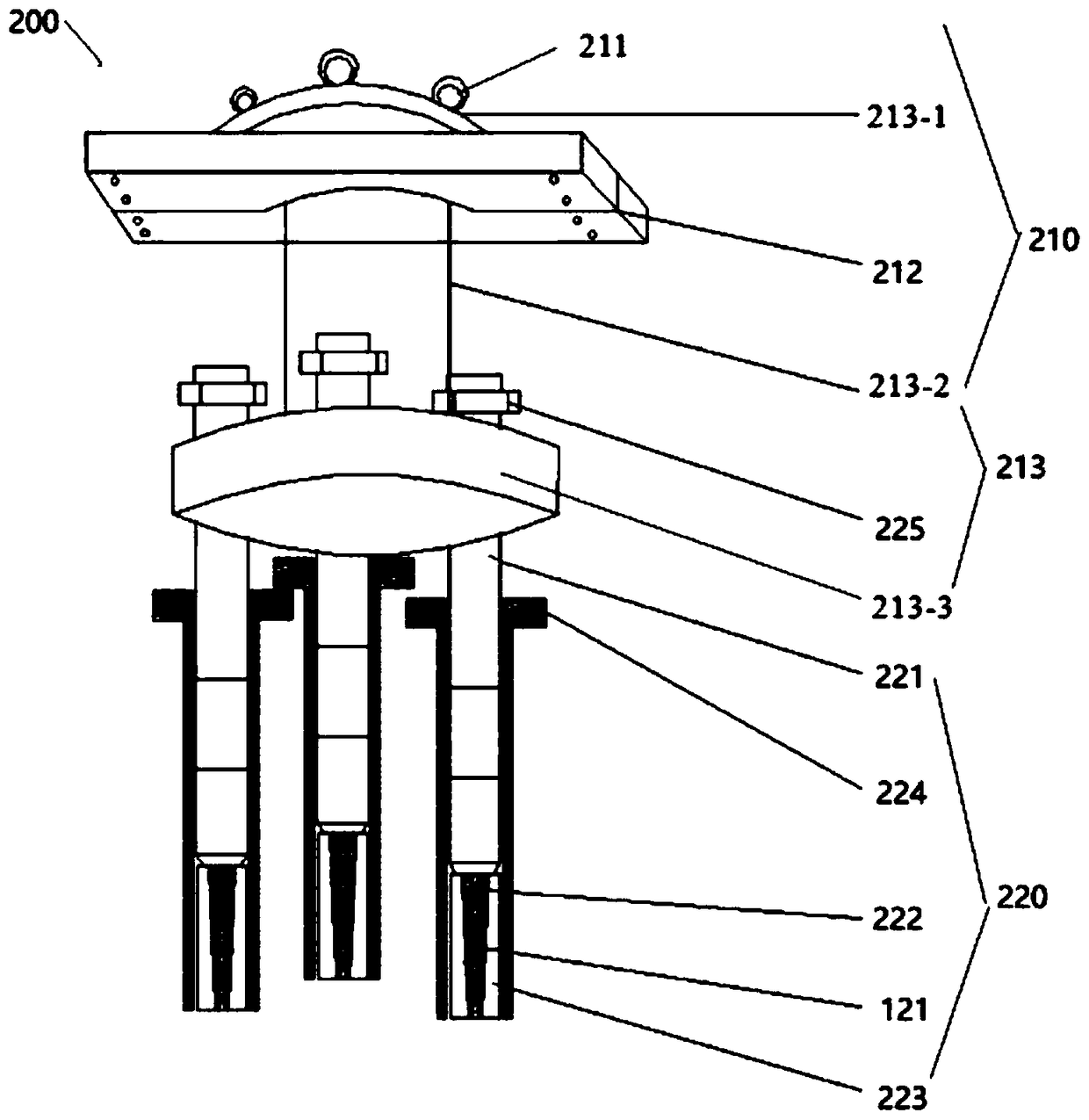

Medium-voltage hoisting cable for super high-rise building and production installation process thereof

ActiveCN109346237AImprove tensile propertiesReduce weightPower cables with screens/conductive layersInsulated cablesHigh riseMedium pressure

The invention discloses a medium-voltage hoisting cable for a super high-rise building and a production installation process thereof. The cable comprises three insulated wire cores, three filling strips, a reinforced layer and an outer sheath layer; the three insulated wire cores are pairwise tangent; an included angle of extension lines of circle centers of the adjacent insulated line cores is 120 degrees; each of the filling strips consists of a composite reinforced core located in the center and a filling body coated at the outside of the composite reinforced core; the composite reinforcedcores are located in the center of the filling body; the included angle of a center line of the three composite reinforced cores is 120 degrees; and a cross-section shape of the filling body is the same as that of a gap between two adjacent insulated line cores and the reinforced layer. According to the cable disclosed by the invention, the composite cores are adopted as bearing cores and are disposed in the filling strips, the tensile resistance of the cable can be greatly improved, the hoisting safety margin of the hoisting cable is improved, the cable weight is light, the periphery of the cable is fixed without a steel wire, and the construction difficulty is low.

Owner:FAR EAST CABLE +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com