Wax mold preparation method for investment casting precision casting

An investment precision casting and wax mold technology, which is applied in the field of aluminum alloy precision casting, can solve the problems affecting the dimensional accuracy and surface quality of castings, the dimensional accuracy of wax molds cannot be stably controlled, and the cooling shrinkage of wax molds is large, so as to improve dimensional stability Sex and production efficiency, high promotion and application value, and high mold precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

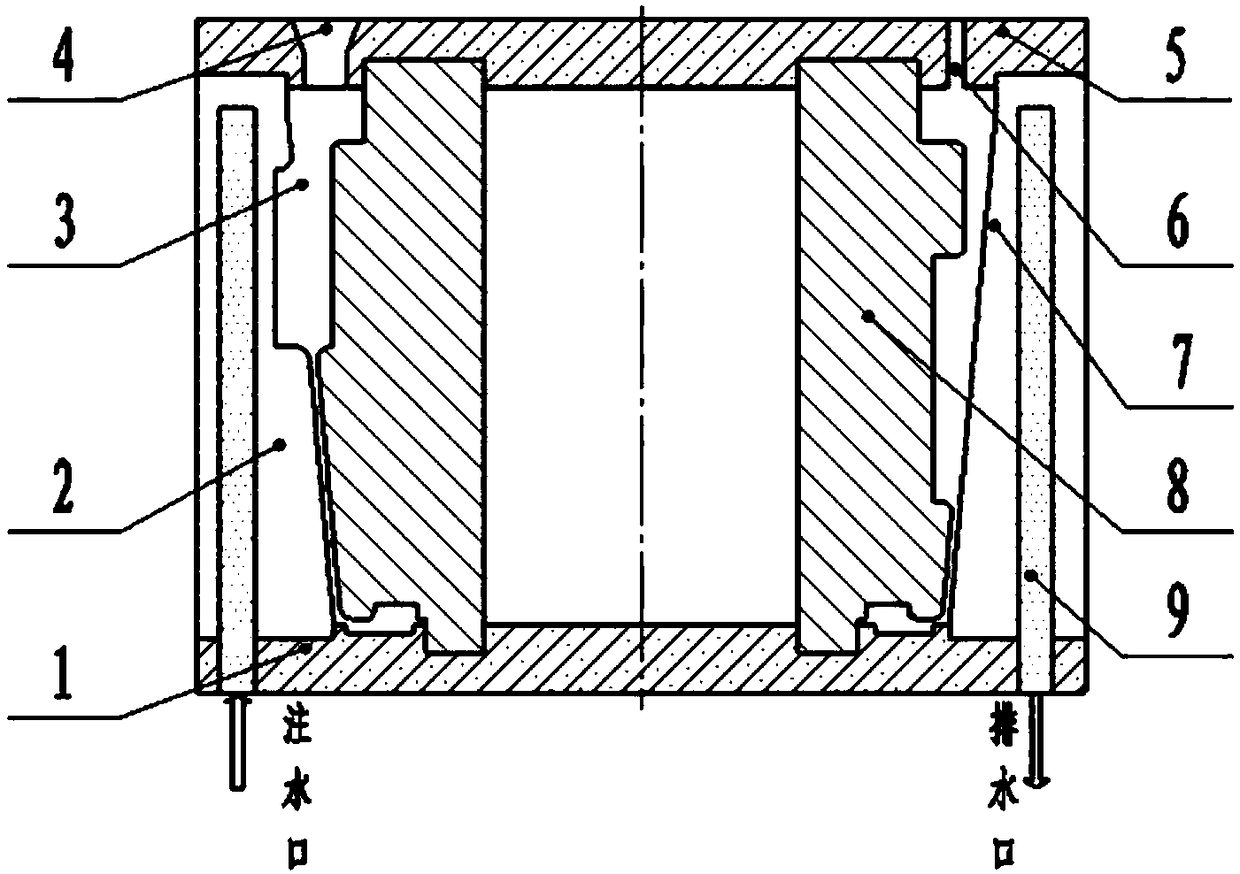

[0023] Embodiment 1: as figure 1 and figure 2 As shown, this embodiment provides a mold for wax pattern forming of investment precision casting, including a mold consisting of an upper cover plate 5, a lower bottom plate 1, a left outer mold 2, a right outer mold 7 and a core mold 8. Cavity 3, the mandrel is fixed through the grooves set on the upper cover and the lower bottom plate, the wax injection hole 4 and the exhaust hole 5 are opened on the upper cover and communicated with the cavity, the left outer mold and the right outer mold are connected by bolts It is integrated, and its matching clearance is ≤0.15mm, which can be selected but not limited to 0.15mm, 0.10mm, 0.05mm, etc.

[0024] Wherein, the diameter of the wax injection hole is φ10-15mm, and the mouth is provided with a taper of 5-8°. The diameter of the wax injection hole can be selected but not limited to φ10mm, φ11mm, φ12mm, φ13mm, φ14mm or φ15mm, and the taper can be selected but not limited to 5°, 6°, 7...

Embodiment 2

[0035] Embodiment 2: This embodiment takes a thin-walled aluminum alloy cabin casting as the application object. The specific outline dimensions: height 345mm, large end circle Φ135mm, small end circle Φ132mm, main body wall thickness 8.0mm, typical thin-walled cabin casting structure , the thin wall accounts for more than 85%, and the inner cavity contains 8 longitudinal ribs with a width of 6mm, 4 small circular bosses of Φ20mm, and 1 square boss of 50mm×50mm.

[0036] The operation steps of wax mold forming of aluminum alloy cabin body components are carried out as follows:

[0037] (1) Clean the mold with industrial alcohol on the wax pressing platform first, and brush lubricating oil on the inner cavity of the mold with a brush, then place the core mold in the corresponding groove of the lower bottom plate, cover the upper cover plate, and lock it with bolts For the left and right outer molds of the mold, ensure that the matching gap is ≤0.15mm. Finally, insert a thermoco...

Embodiment 3

[0042]Embodiment 3: This embodiment takes a thin-walled aluminum alloy cabin casting as the application object. The specific outline dimensions: height 435mm, large end circle Φ245mm, small end circle Φ230mm, main body wall thickness 3.5mm, typical thin-walled cabin casting structure , the thin wall accounts for more than 75%, and the inner cavity contains 4 longitudinal ribs with a width of 10mm, 10 small circular bosses of Φ25mm, and 4 circular bosses of Φ78mm.

[0043] The operation steps of wax mold forming of aluminum alloy cabin body components are carried out as follows:

[0044] (1) Clean the mold with industrial alcohol on the wax pressing platform first, and brush lubricating oil on the inner cavity of the mold with a brush, then place the core mold in the corresponding groove of the lower bottom plate, cover the upper cover plate, and lock it with bolts For the left and right outer molds of the mold, ensure that the matching gap is ≤0.15mm. Finally, insert a thermoc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com