Numerical control cutting process of steel tube arch bridge pipe joint steel plate intersecting line

A steel pipe arch bridge and cutting process technology, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of rough cutting surface, low cutting precision of pipe joint processing, and uneven curve transition, so as to reduce steel plate and The use of welding consumables, the production process is clear, and the effect of smooth curve transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

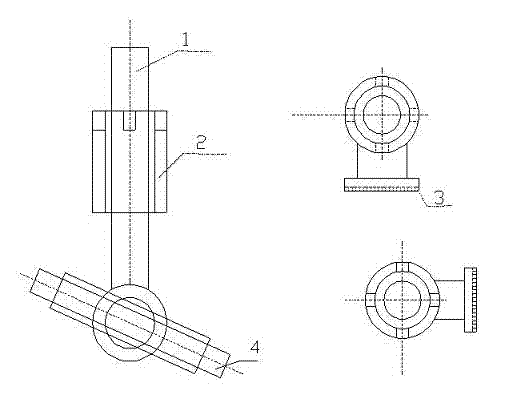

[0010] Embodiment 1: with reference to attached figure 1 and 2 . This process is a flame cutting method (a numerical control cutting method of intersecting line of steel pipe arch bridge tube section steel plate), including CNC flame cutting machine, that is, in WD-105 CNC flame cutting machine, (1) drawing steel pipe arch bridge by geometric method The curve diagram of the intersecting line of the pipe section steel plate is imported into the CNC flame cutting machine. (2) The CNC flame cutting machine is equipped with a corner device ( figure 2 Middle 2-steering device), this corner device can enable the CNC flame cutting machine to realize the turning and cutting in four directions, (3) carry out the curve cutting of the steel plate including the process groove required for welding, and then get the butt curve that can meet the requirements of the arch rib parts required.

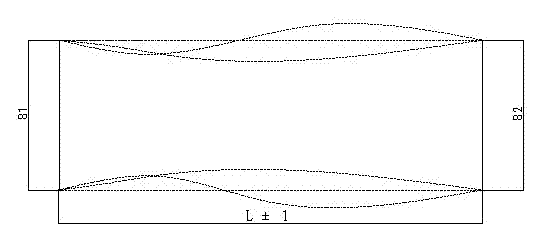

[0011] 1. Determine method: Using the WD-105 CNC flame cutting machine, the curve diagram of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com