Patents

Literature

138results about How to "Reduce padding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

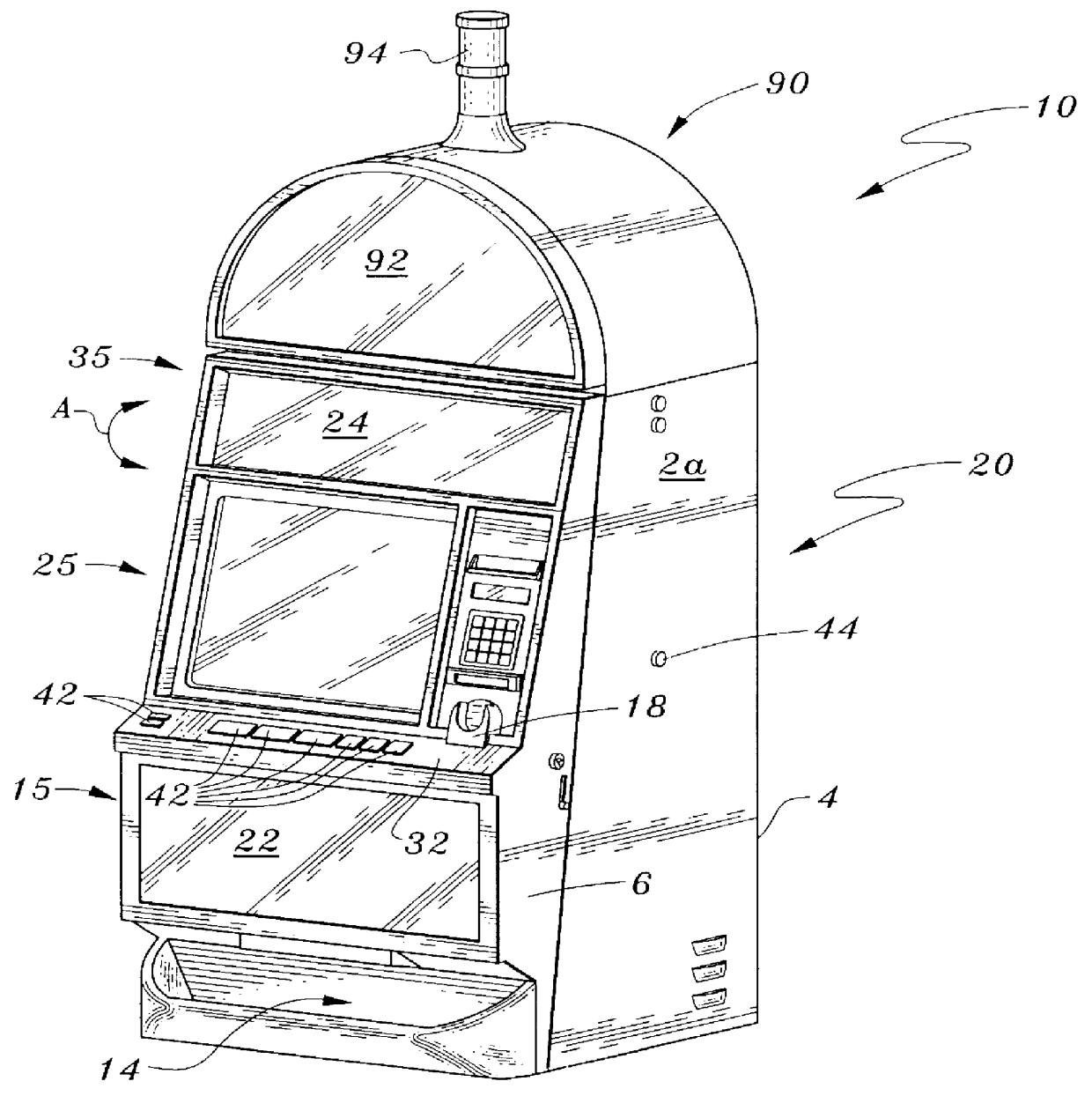

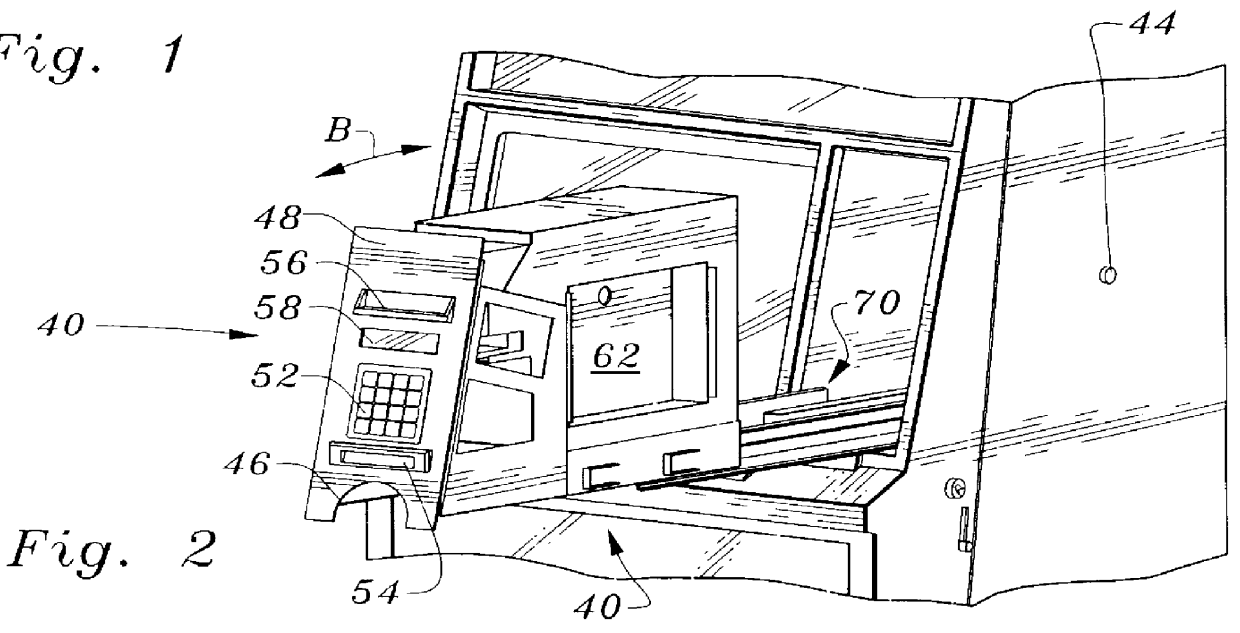

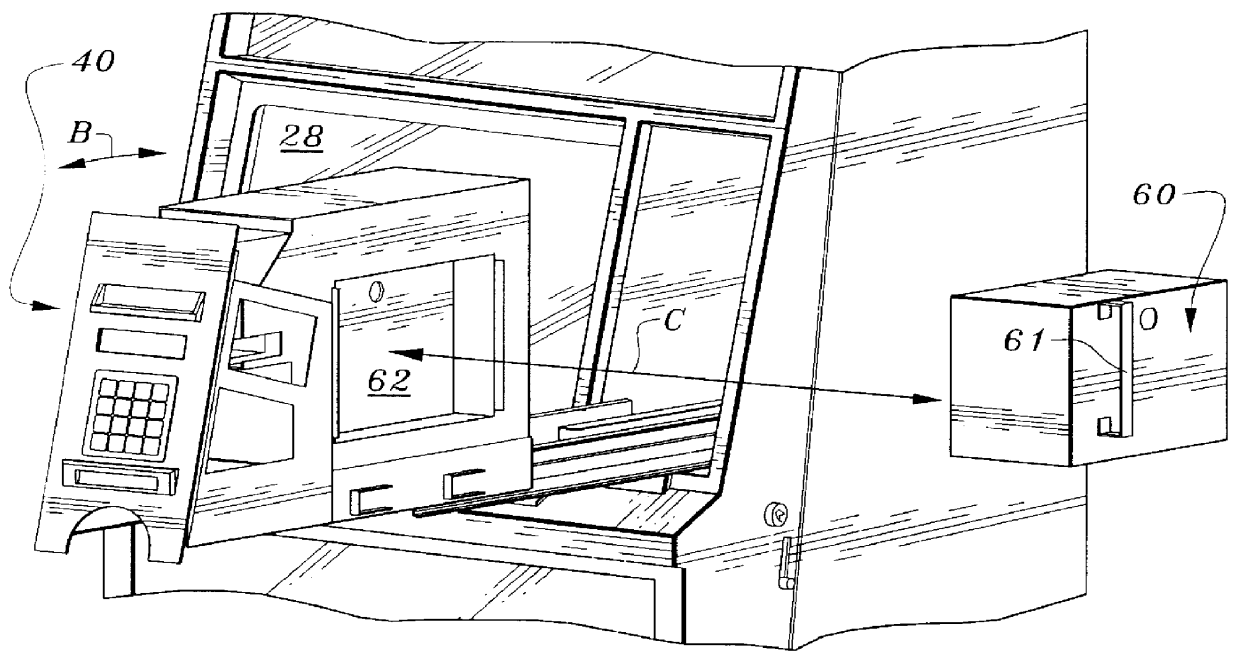

Gaming machine currency apparatus and method therefore

InactiveUS6068101ADurable and reliable useReduce maintenanceApparatus for meter-controlled dispensingVideo gamesEngineeringMechanical engineering

A gaming machine and method including a housing having a door which exposes a currency mechanism along a medial portion thereof and located between a side wall and a monitor. This strategic location of the currency mechanism allows clearance for an underlying coin hopper so as to minimize the need for an external currency mechanism and to provide access to the coin hopper in a much more maintenance friendly manner for tending to the coin hopper and currency mechanisms, e.g. for filling, etc.

Owner:CASINO DATA SYST

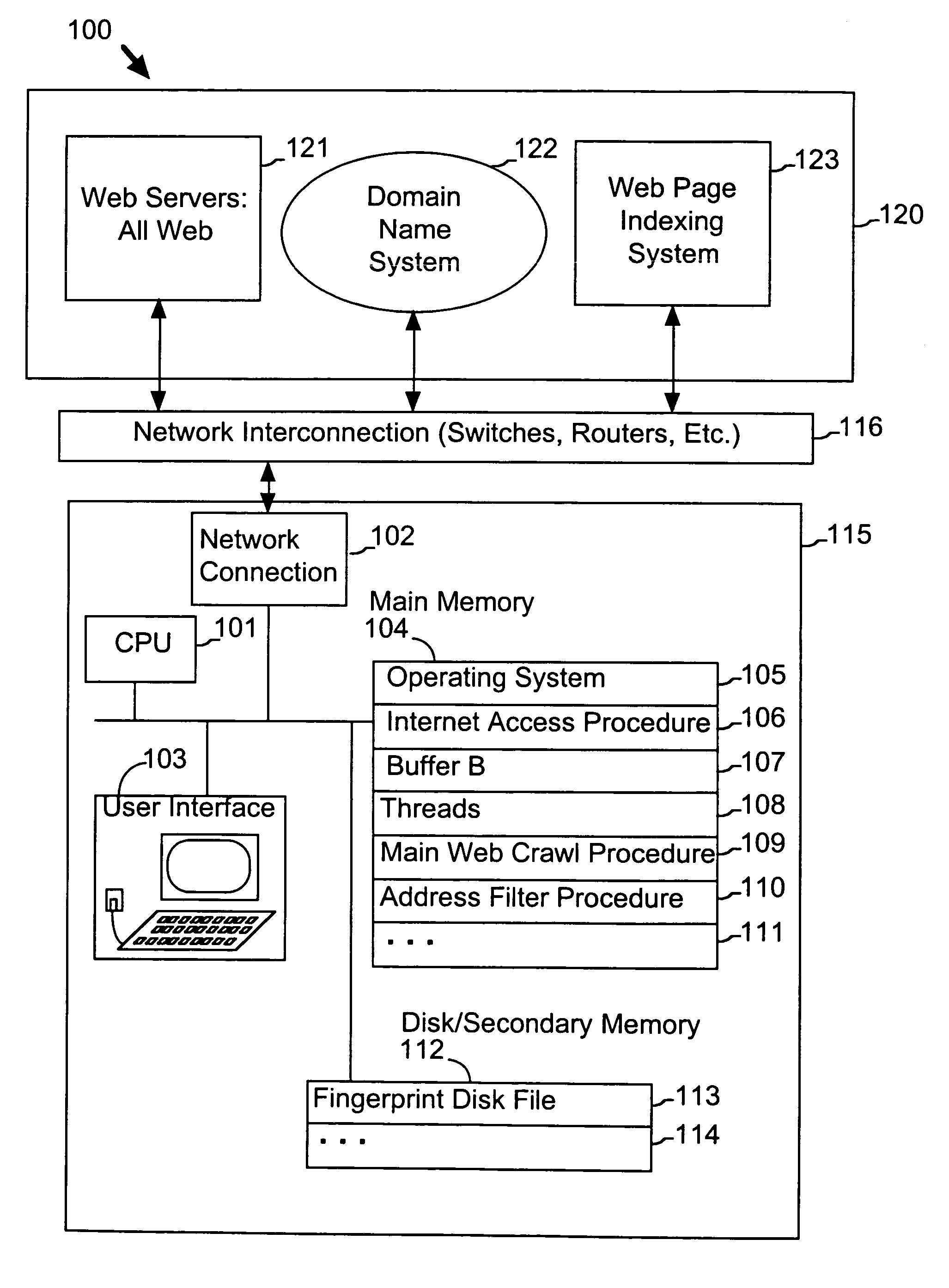

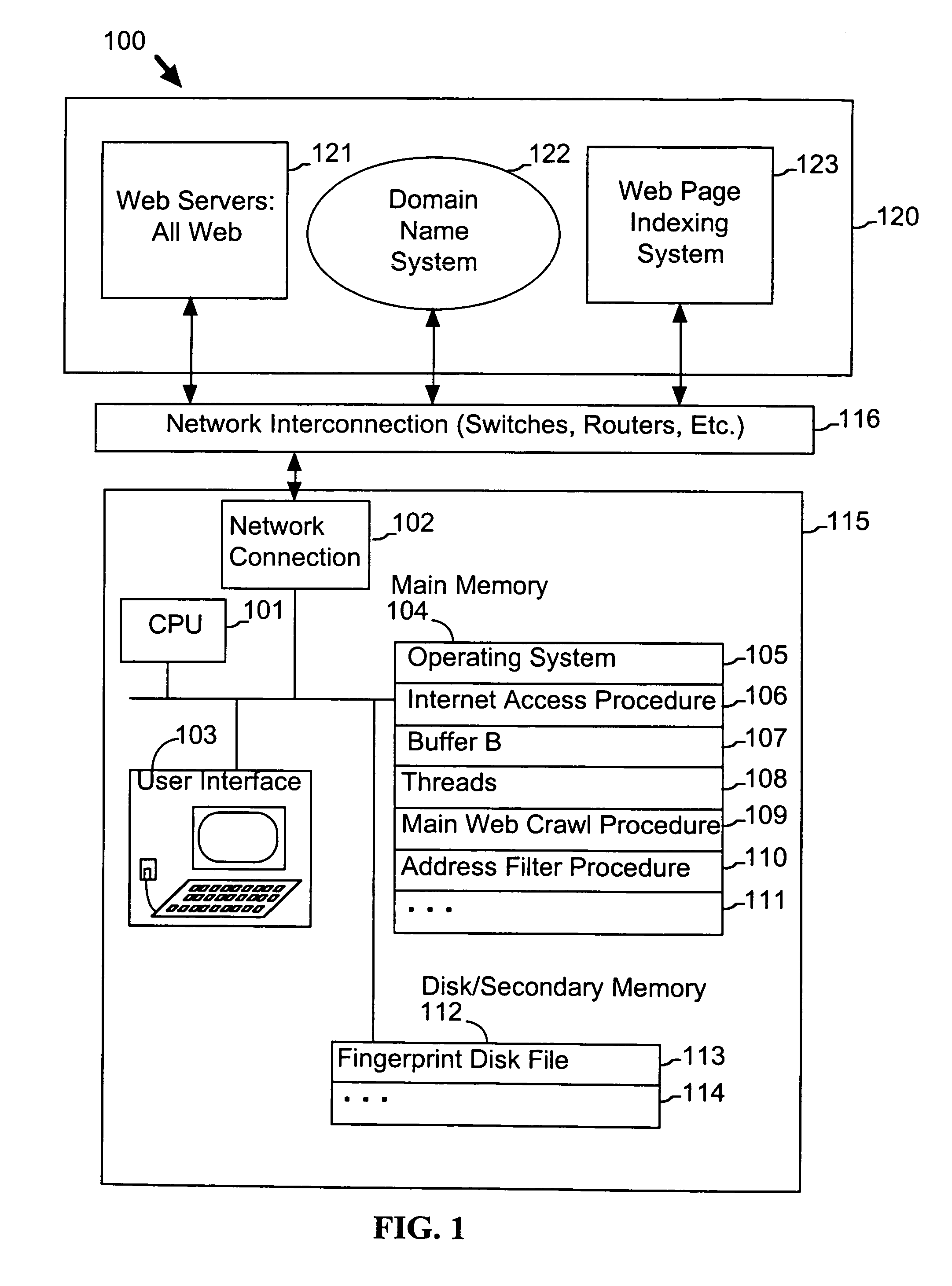

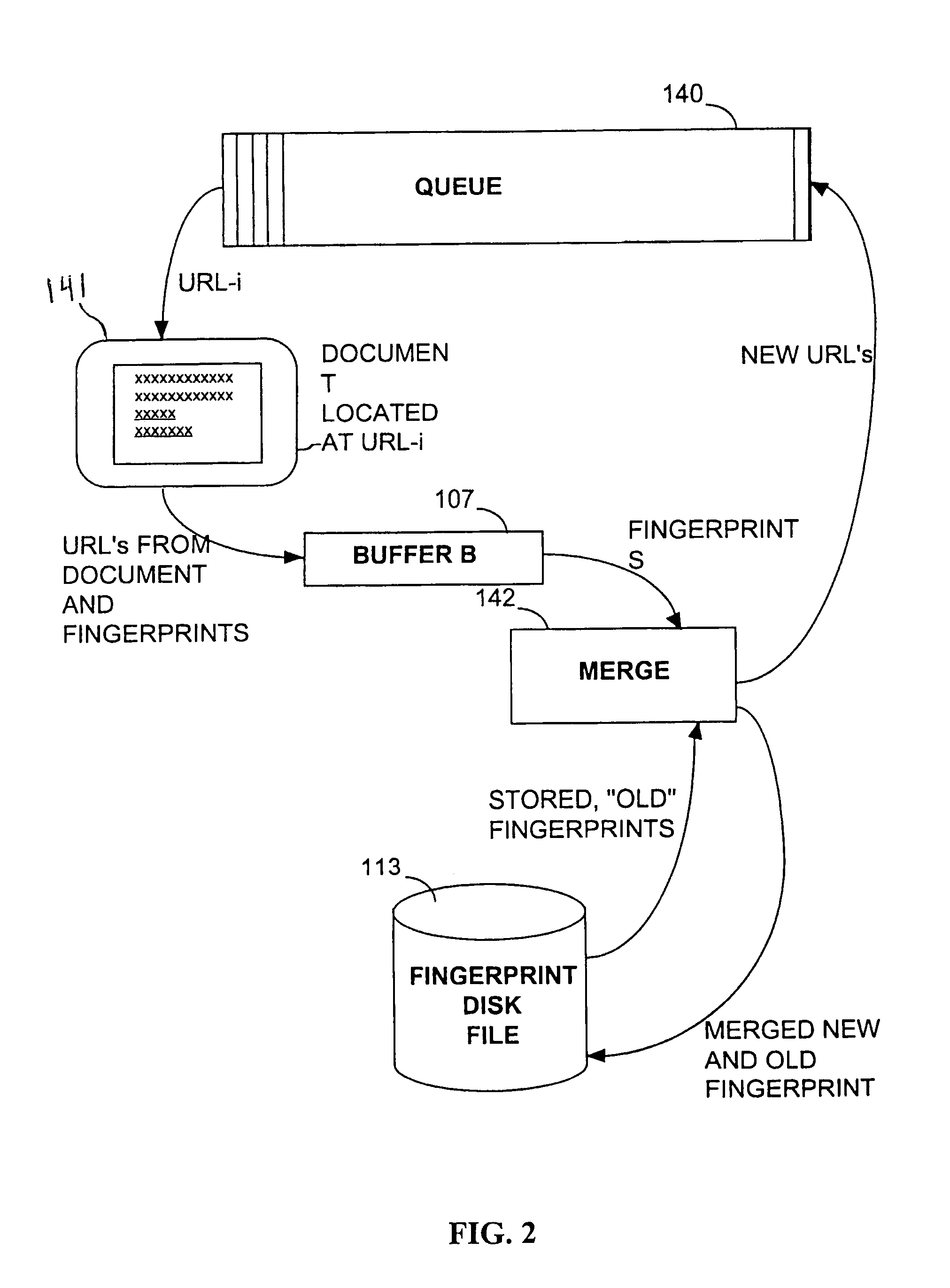

System and method for efficient filtering of data set addresses in a web crawler

InactiveUS6952730B1Reduce frequencyEfficient in operationWeb data indexingMultiple digital computer combinationsSparse fileDocument preparation

A web crawler stores fixed length representations of document addresses in a buffer and a disk file, and optionally in a cache. When the web crawler downloads a document from a host computer, it identifies URL's (document addresses) in the downloaded document. Each identified URL is converted into a fixed size numerical representation. The numerical representation may optionally be systematically compared to the contents of a cache containing web sites which are likely to be found during the web crawl, for example previously visited web sites. The numerical representation is then systematically compared to numerical representations in the buffer, which stores numerical representations of recently-identified URL's. If the representation is not found in the buffer, it is stored in the buffer. When the buffer is full, it is ordered and then merged with numerical representations stored, in order, in the disk file. In addition, the document corresponding to each representation not found in the disk file during the merge is scheduled for downloading. The disk file may be a sparse file, indexed to correspond to the numerical representations of the URL's, so that only a relatively small fraction of the disk file must be searched and re-written in order to merge each numerical representation in the buffer.

Owner:META PLATFORMS INC

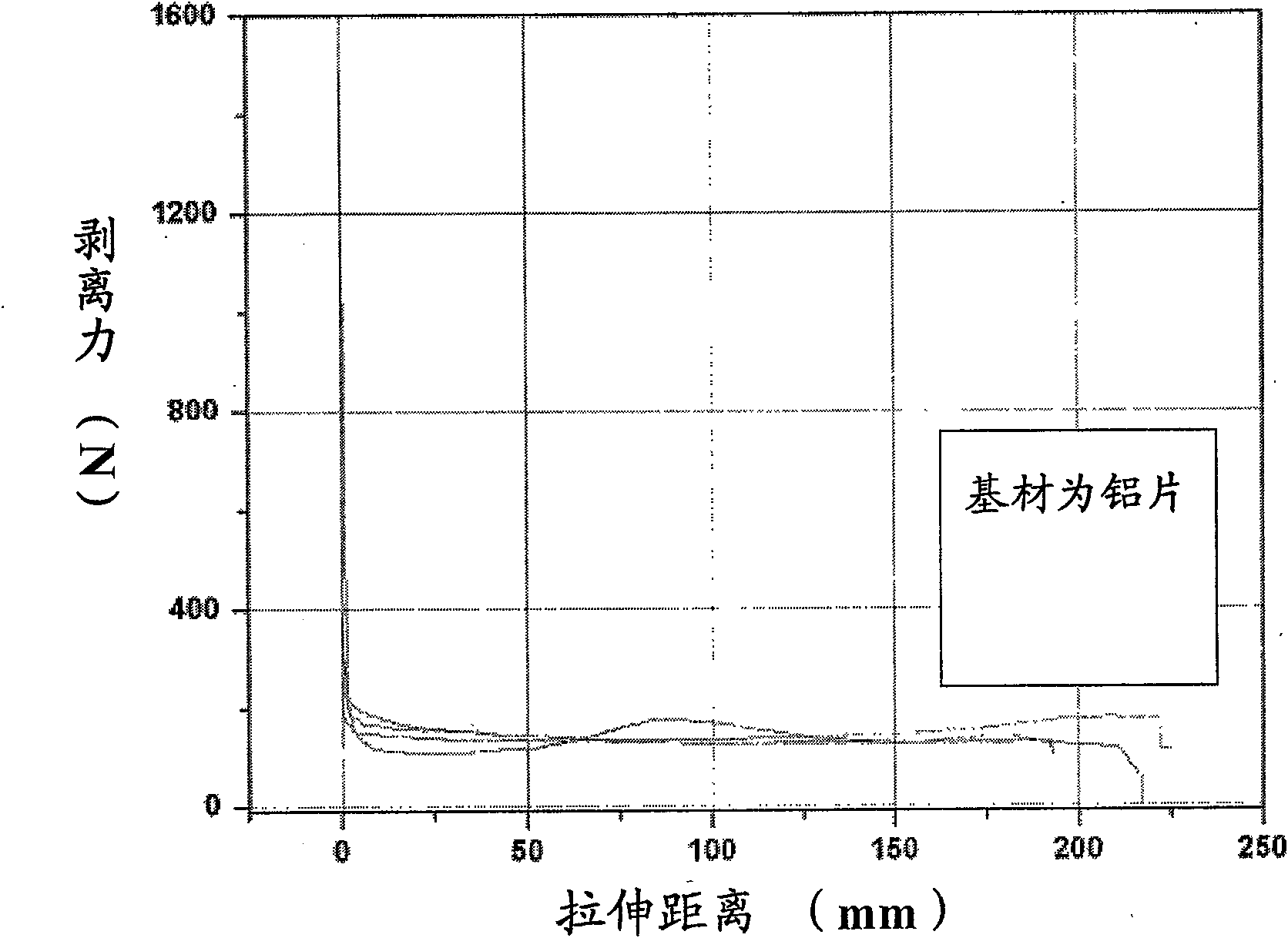

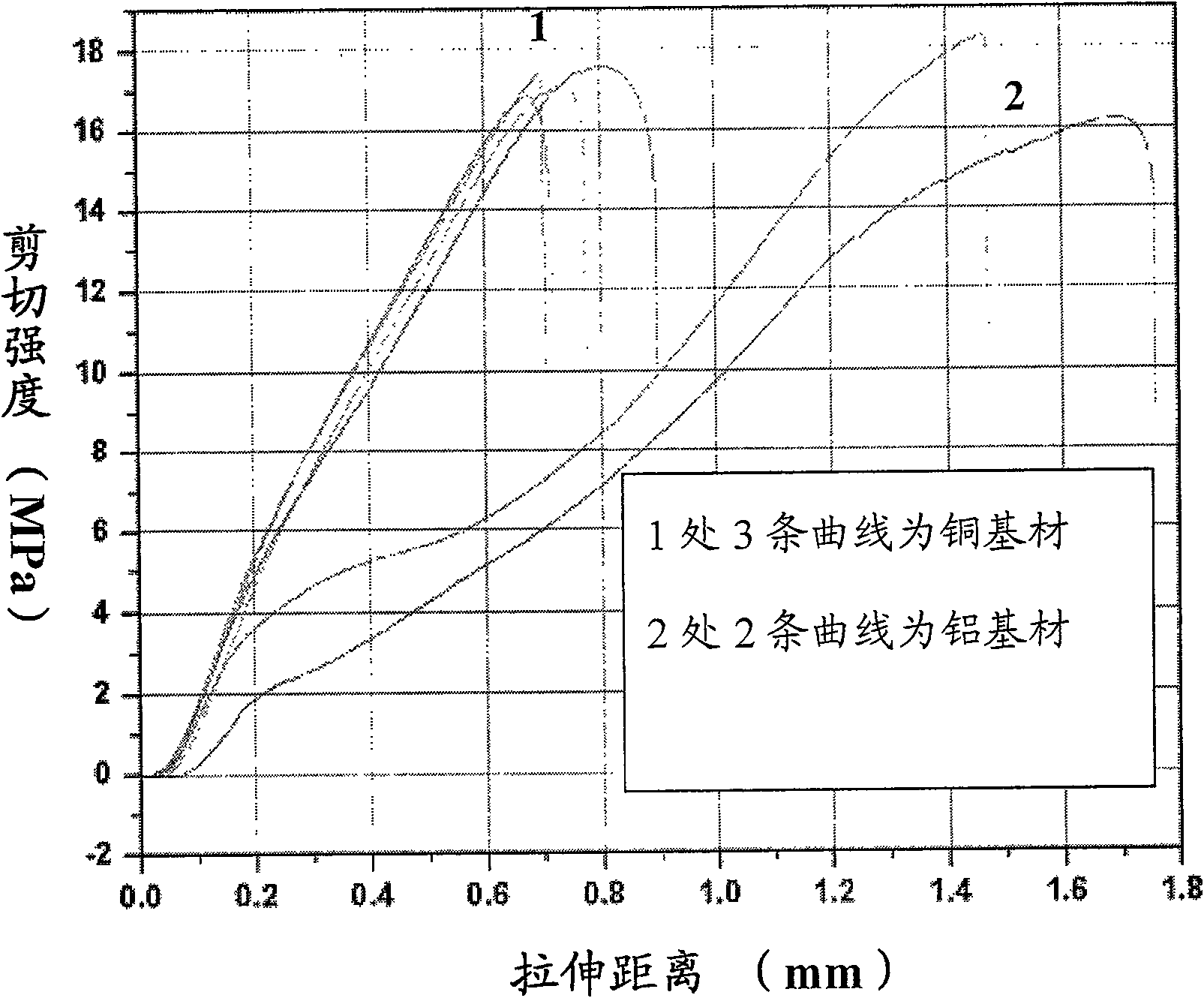

Heat-conducting polymer material and its prepn

InactiveCN1388202AImprove conduction characteristicsReduce paddingHeat-exchange elementsPolyolefinPolymer science

The heat-conducting polymer material includes polyolefin, heat-conducting assistant, environmental stress crack resisting assistant and impact resisting modifier. It is prepared through addition of crosslinking agent into heat-conducting assistant for surface treatment, or high temperature sintering and surface treatment of heat-conducting assistant after or without puffing treatment; mixing polyolefin with antioxidant; mixing all the material; fusion and extrusion in a double-screw extruder; cooling, drawing and slicing. The material of the present invention has excellent mechanical property, high conductivity and good welding property.

Owner:杭州华电华源环境工程有限公司

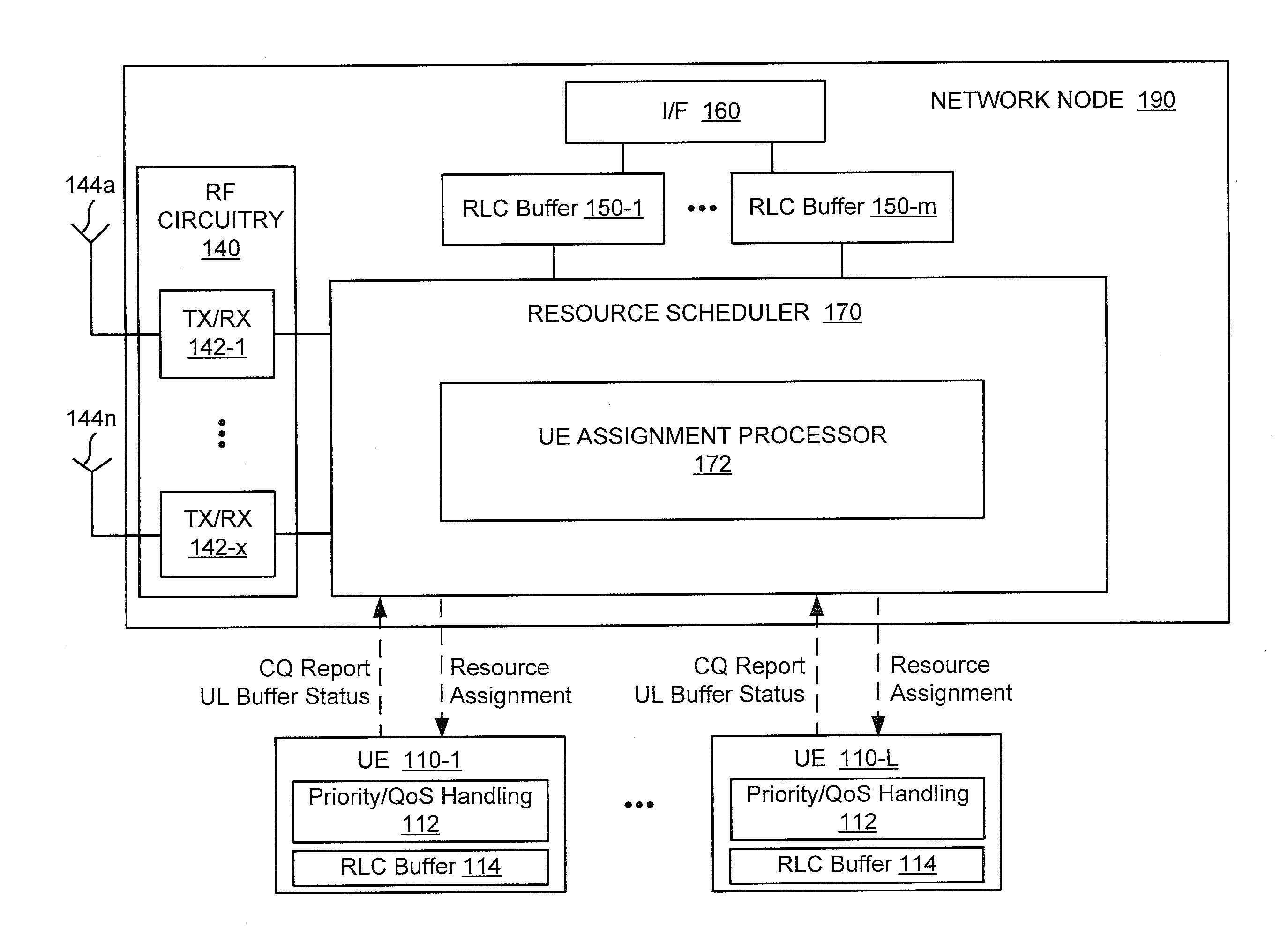

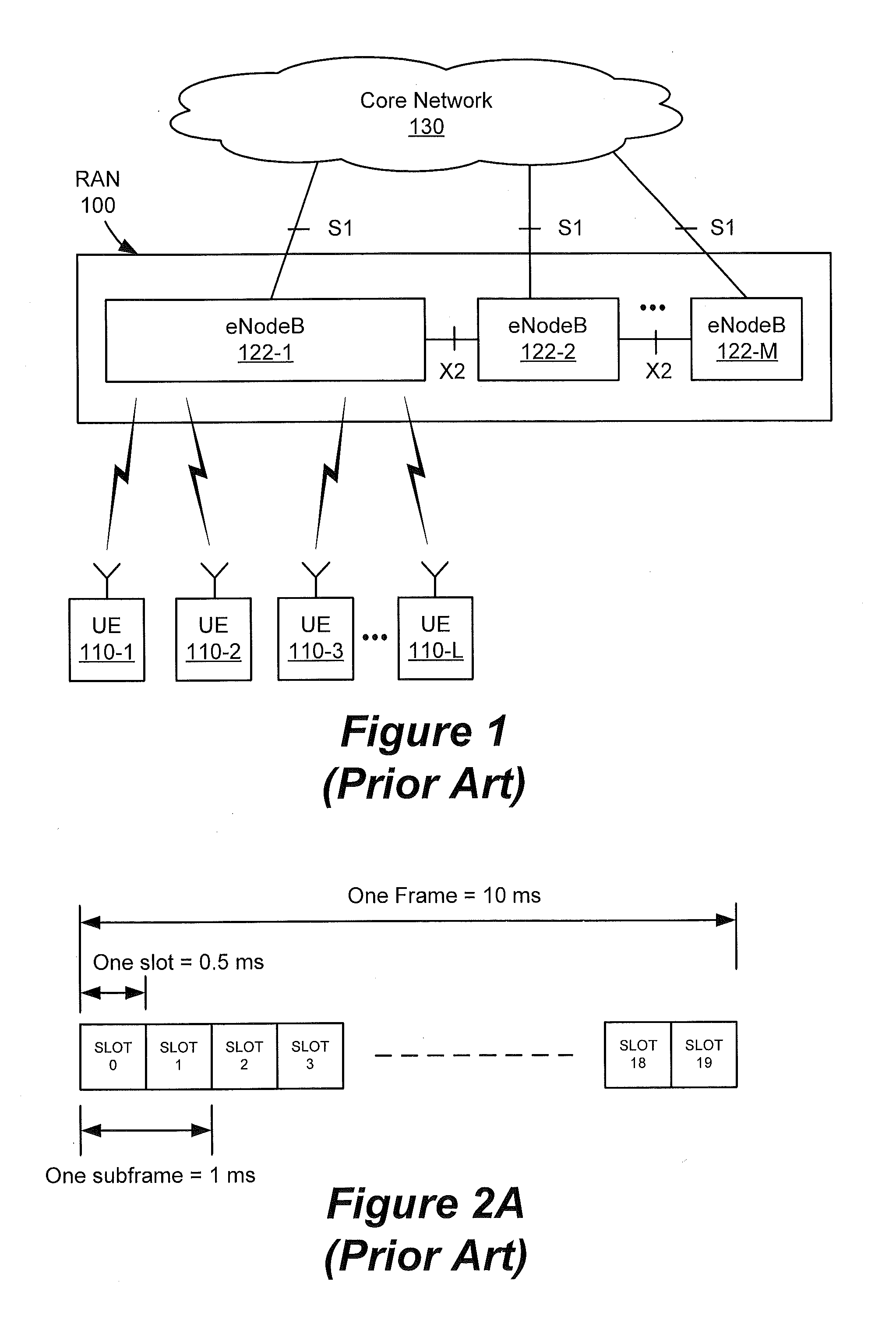

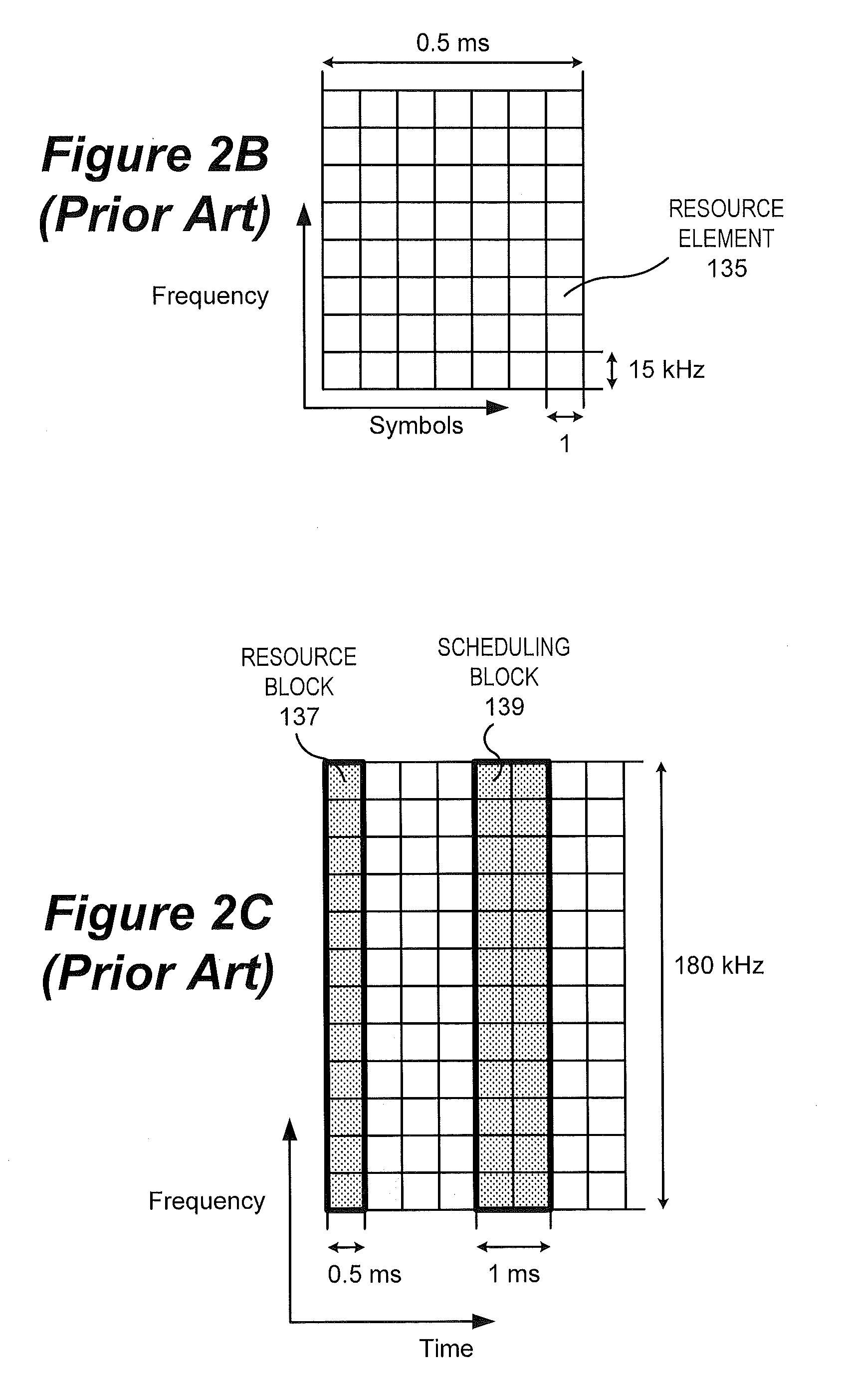

Methods and Apparatus for Link Adaptation for Single User and Multi-User Mimo

InactiveUS20130170469A1Lowering MCS levelReduce paddingNetwork traffic/resource managementInter user/terminal allocationCommunications systemSize ratio

Methods of performing link adaptation in a wireless communication system for simultaneous transmission of codewords include selecting initial modulation and coding scheme (MCS) levels for the codewords, estimating a size ratio of the codewords, determining a number of scheduling blocks (SB) for the codewords with the initial MCS levels, and determining revised MCS levels for the codewords in response to the determined number of SBs. Transport block sizes are computed for the codewords, and it is determined if there is a need to increase the number of scheduling blocks in at least one of the codewords. If there is a need to increase the number of scheduling blocks in a codeword, scheduling blocks are added to the codeword, and the transport block size for the codeword is recomputed. The codewords are then simultaneously transmitted over different multiple input-multiple output (MIMO) communication channels using the same time and frequency resources.

Owner:TELEFON AB LM ERICSSON (PUBL)

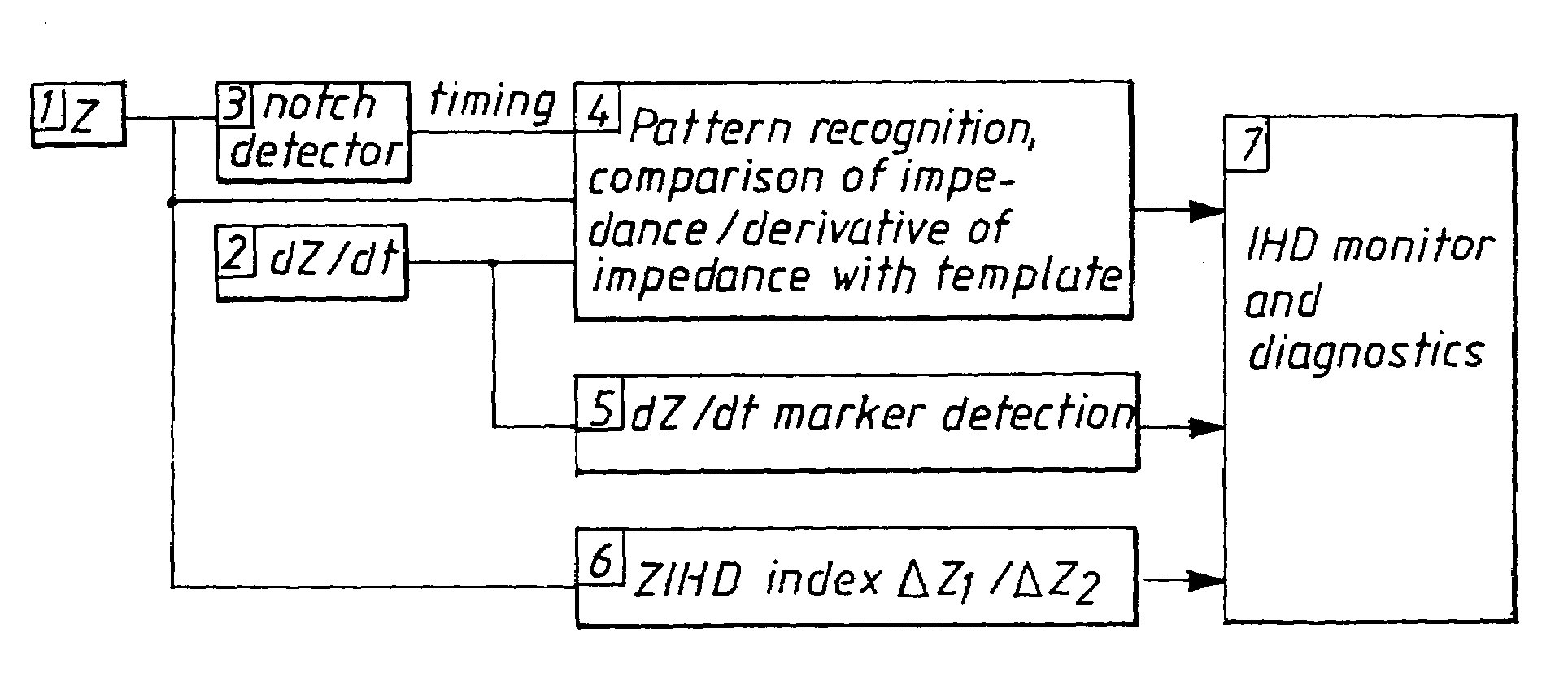

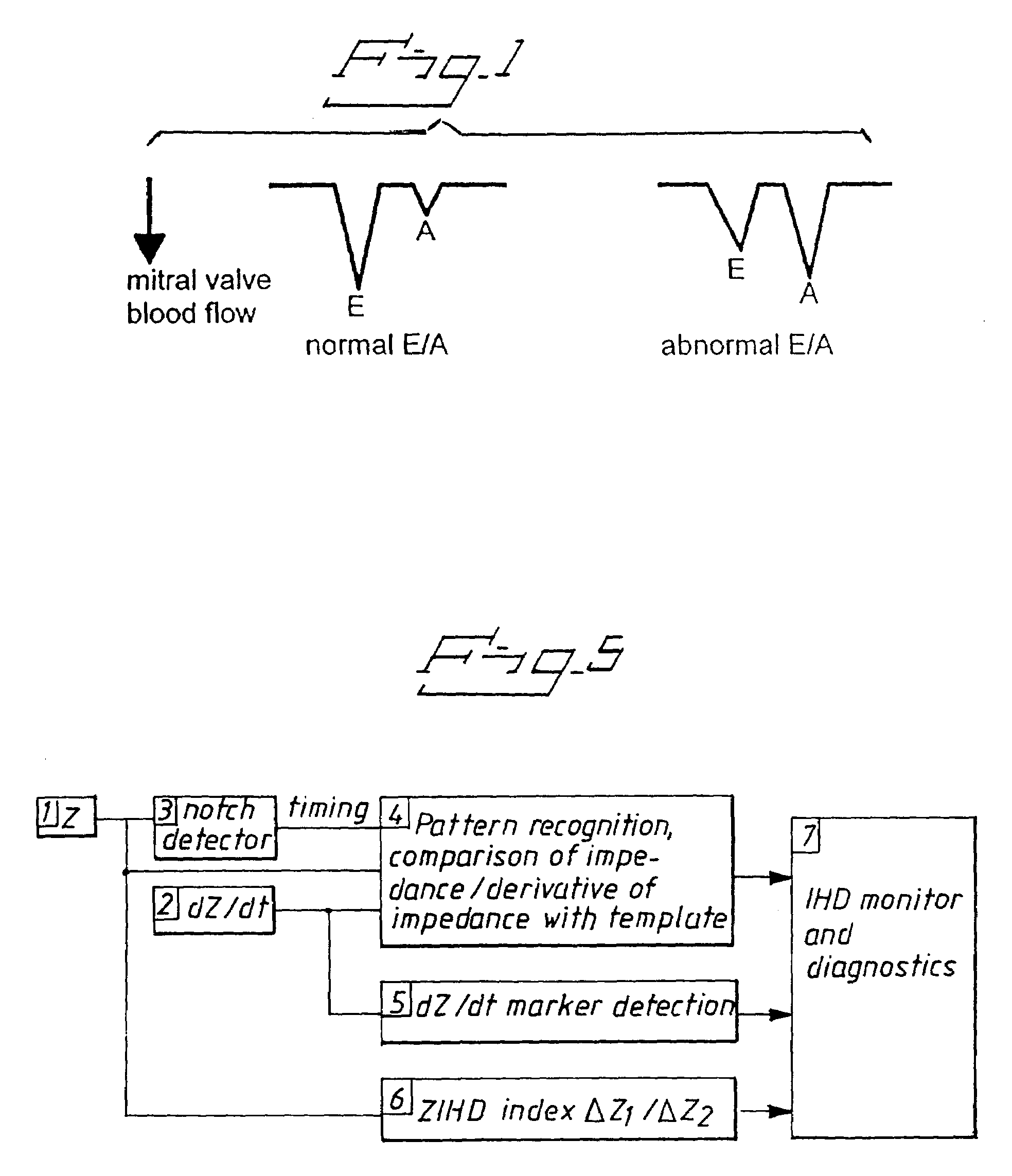

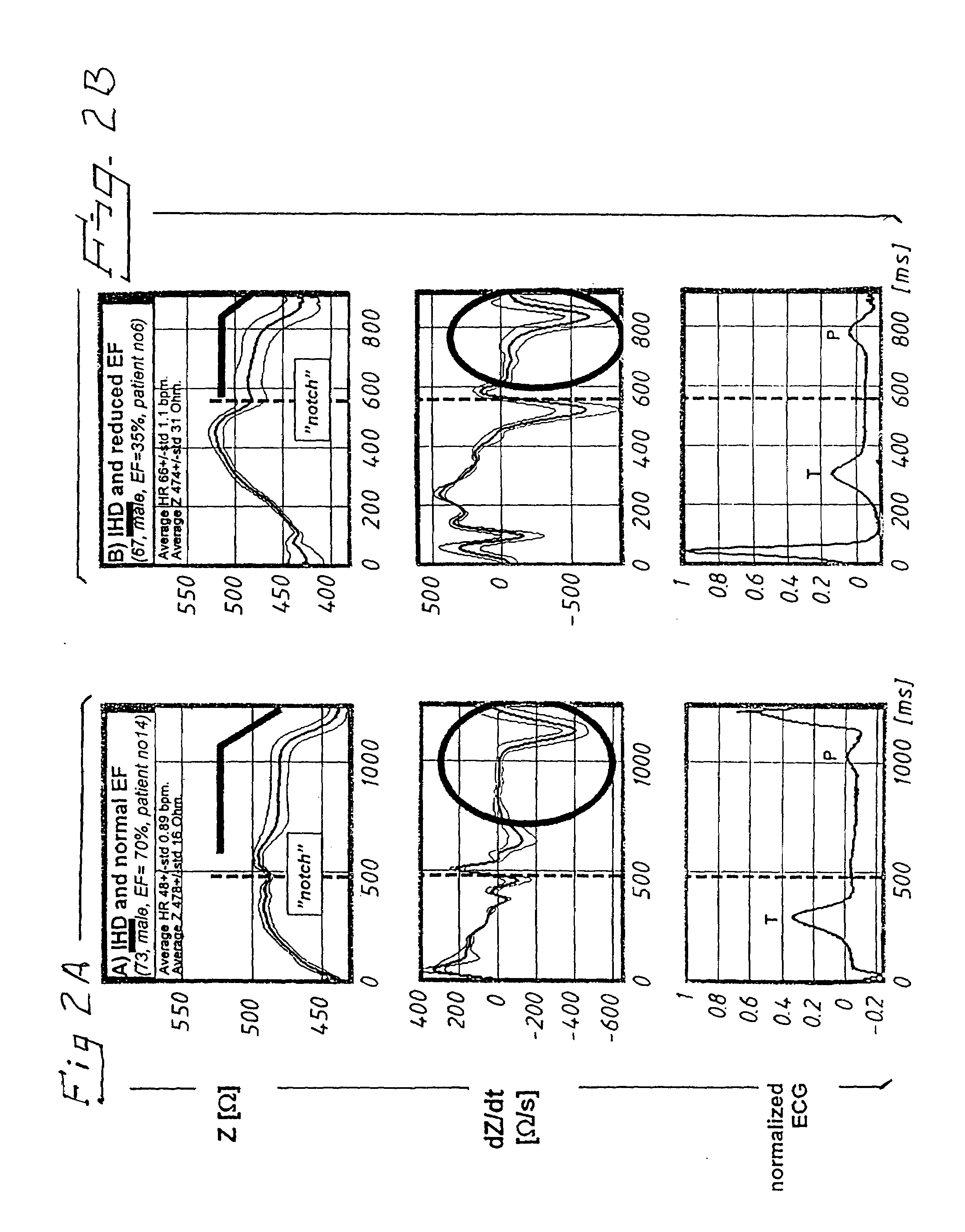

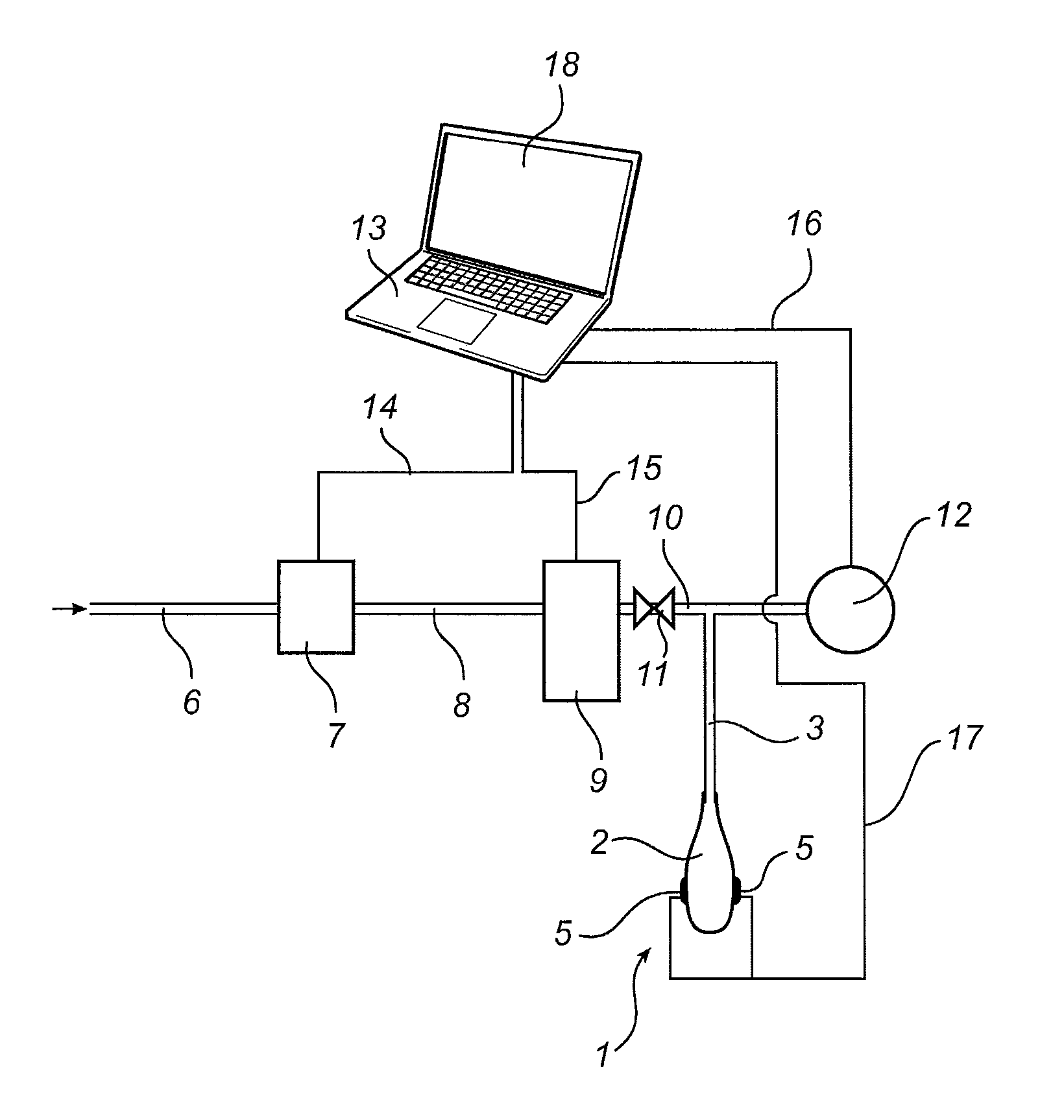

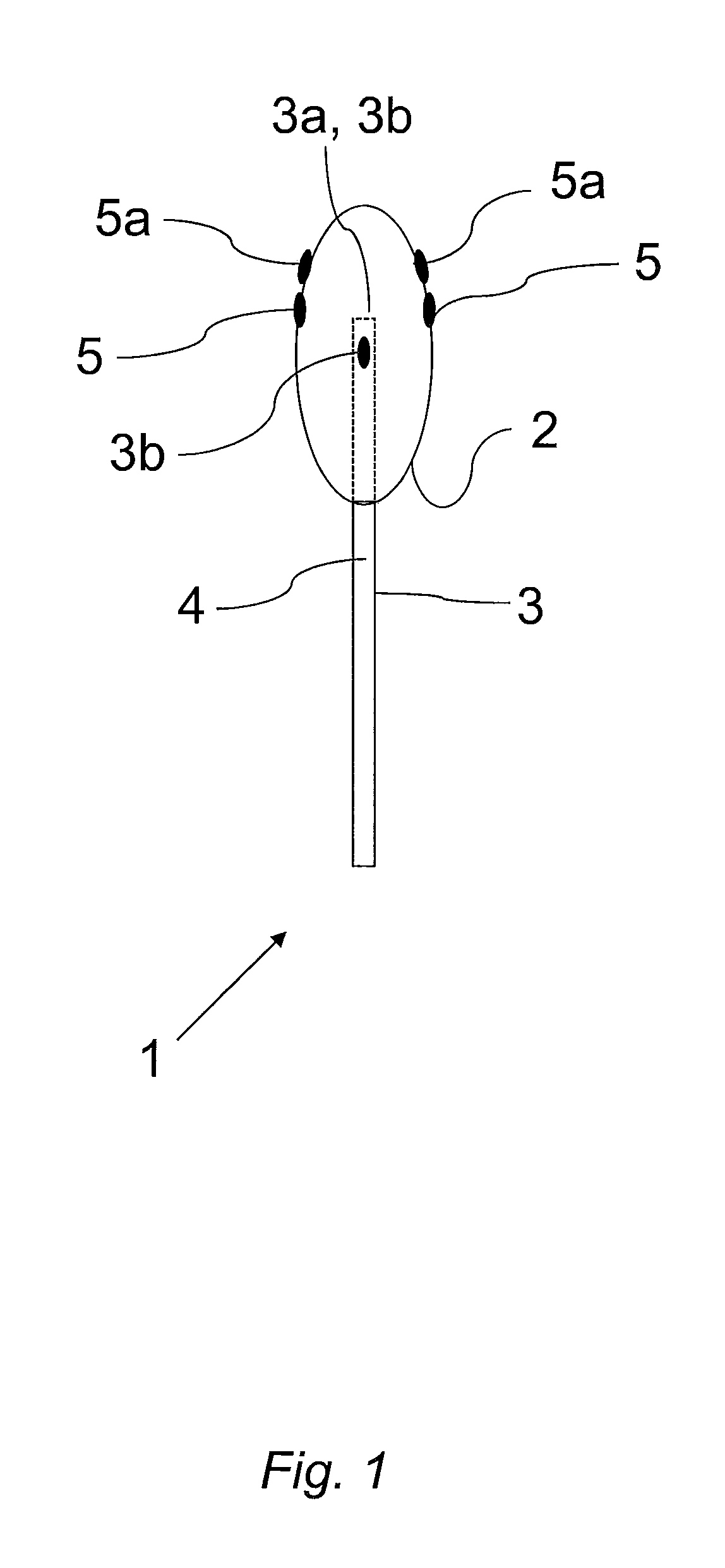

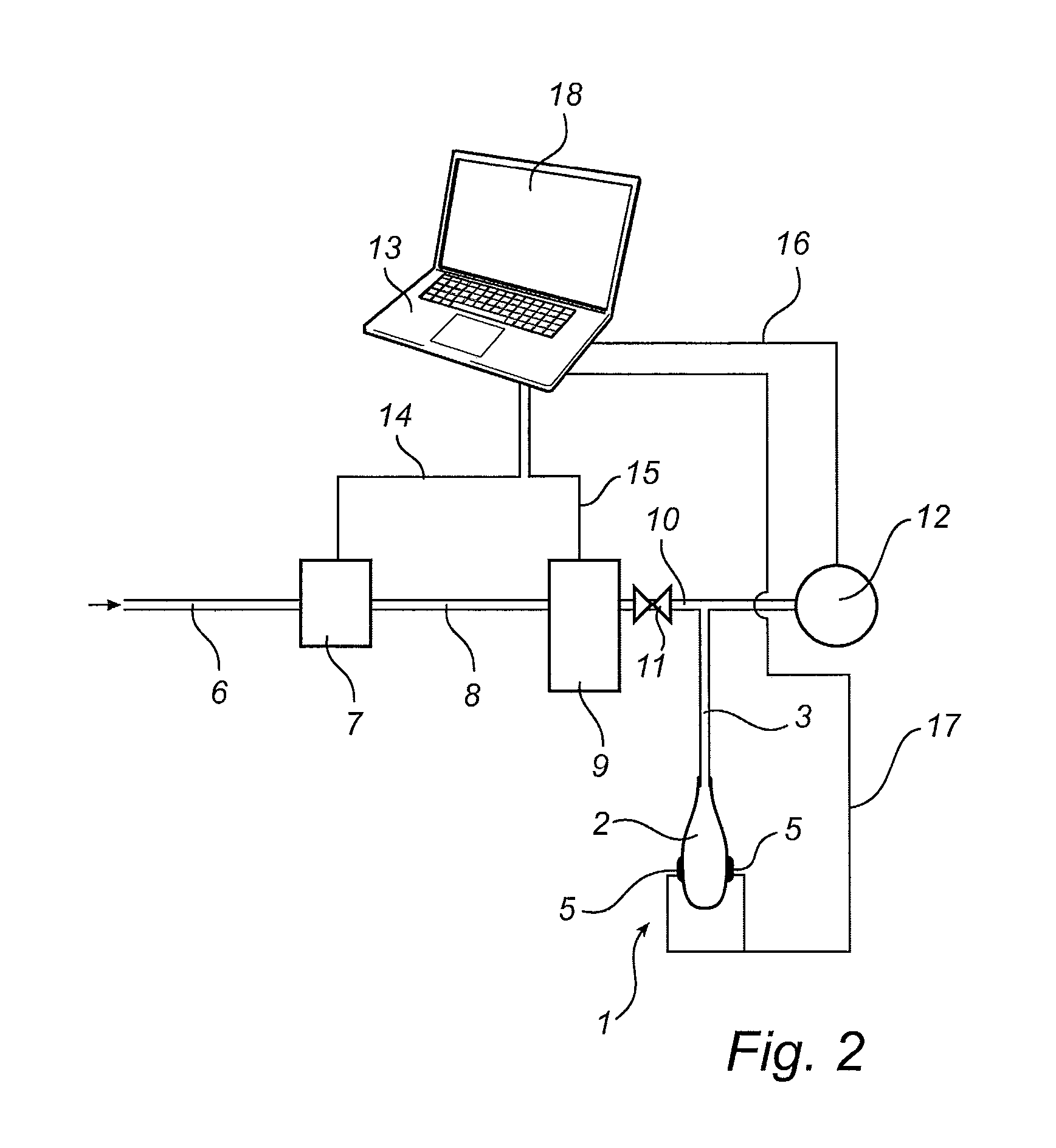

Monitor for early detection of ischemic heart disease

InactiveUS7190996B2Reliability in detection can be still improvedImprove reliabilitySurgeryCatheterIschemic diseaseIschemic Heart Diseases

A monitor for early detection of an ischemic heart disease of a patient has an impedance measurement unit including an electrode arrangement for measuring an intracardiac impedance and generating a corresponding impedance signal, a notch detector connected to the impedance measurement unit for detecting the occurrence of a notch in the impedance signal coincident with the entry of blood into the ventricle, and a pattern recognition unit which compares the measured post-notch impedance curve with a stored predetermined reference impedance curve template to detect an ischemic heart disease from the result of the comparison.

Owner:ST JUDE MEDICAL

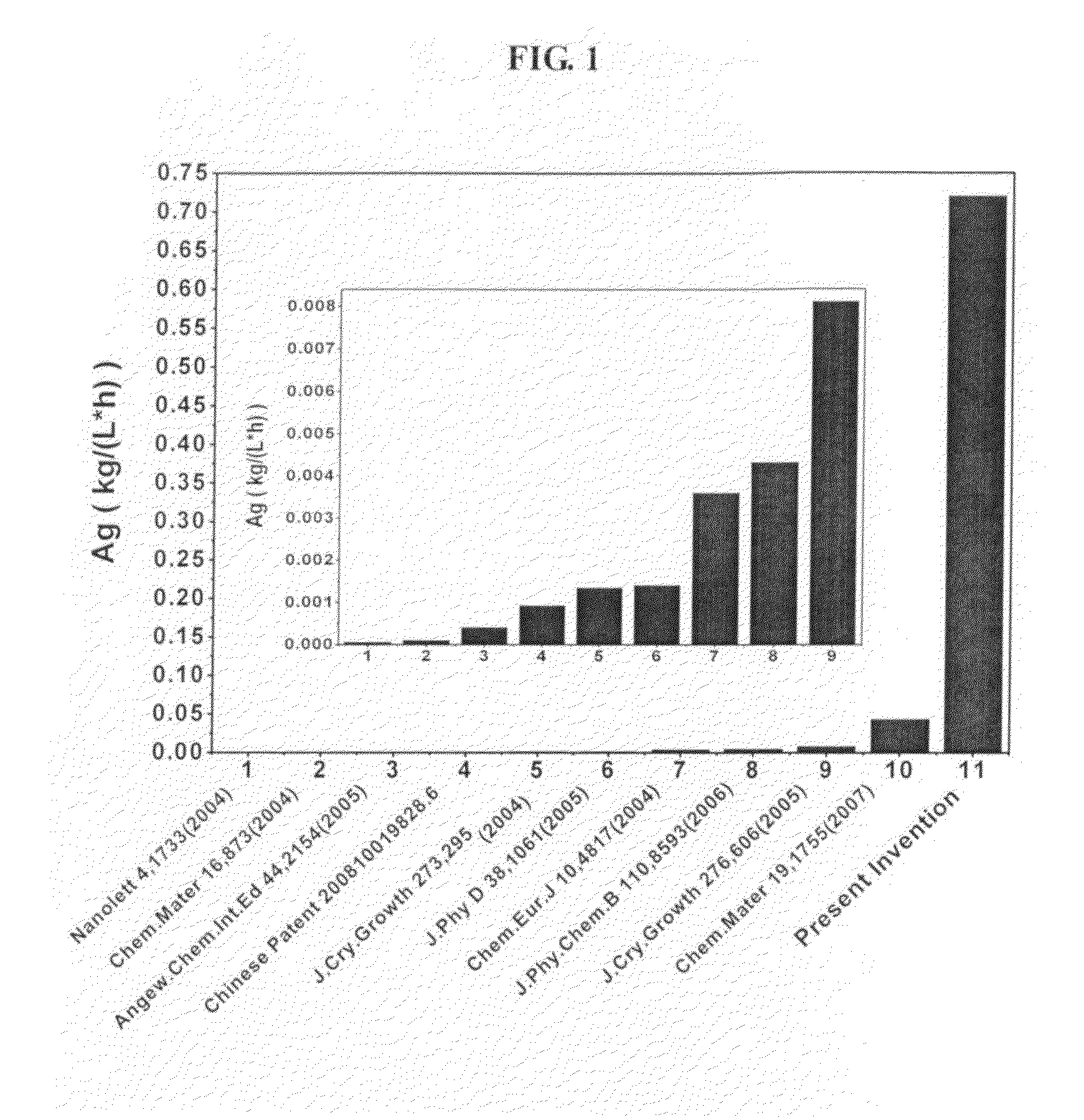

Particulate nanoparticles and nanowires of silver and method for large scale producing the same

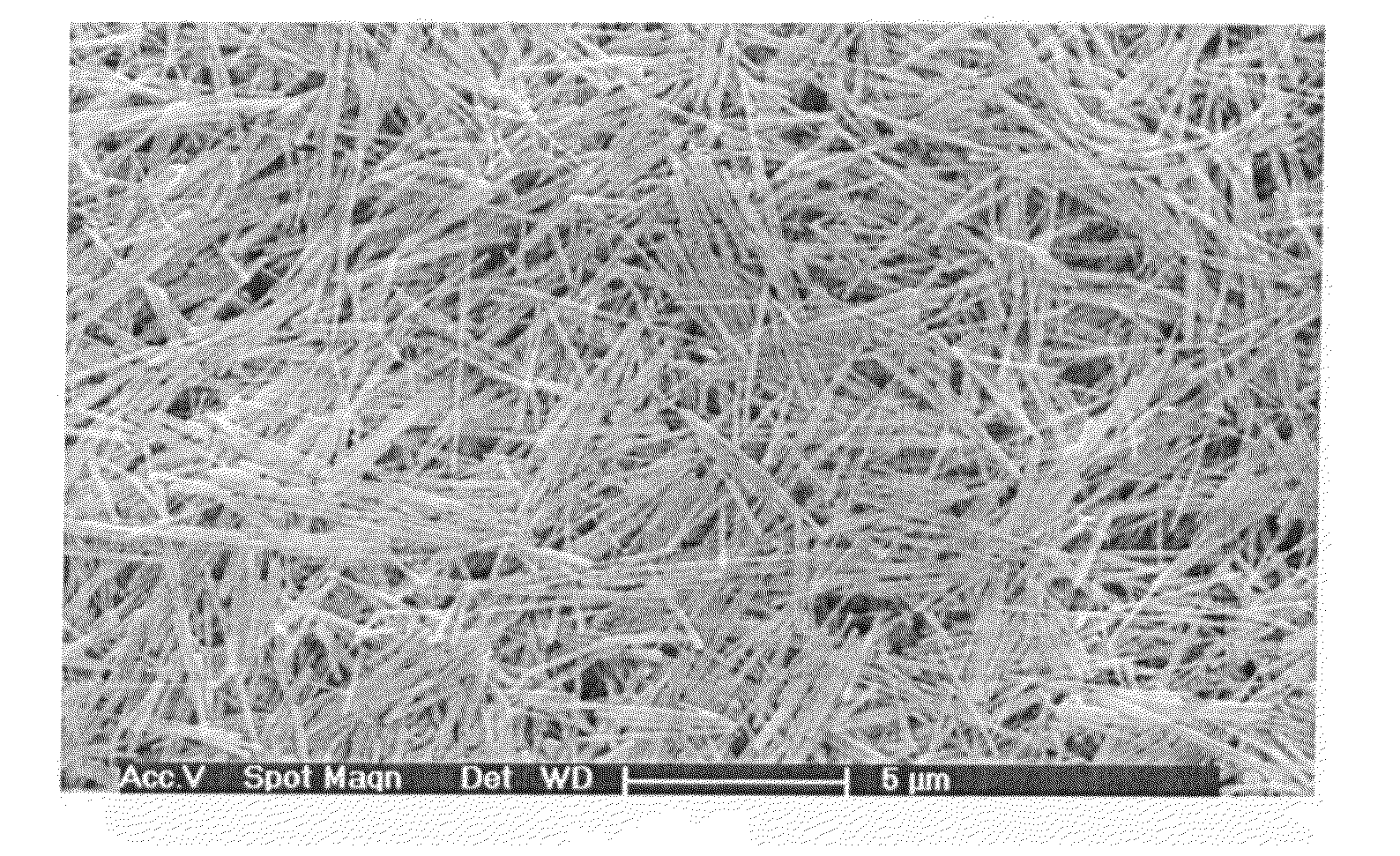

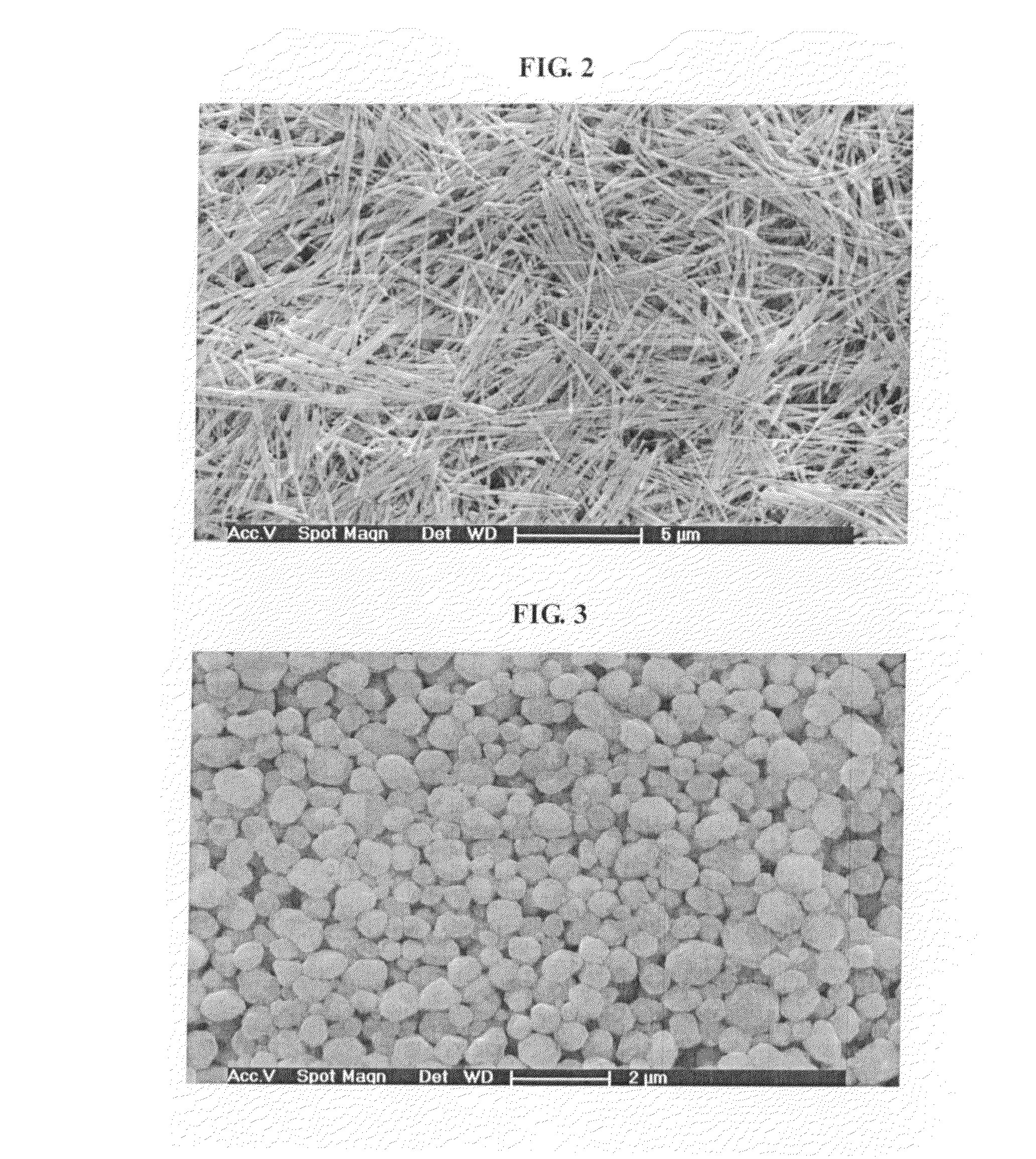

ActiveUS20100148132A1Good dispersionLow filling concentrationMaterial nanotechnologyPolycrystalline material growthParticulatesMean diameter

Disclosed is a method suitable for large-scale producing silver nanostructures including nanoparticles and nanowires with high crystallization and purity in a short period of time. In this method, silver particles with mean diameter less than 200 nm and silver nanowires with length in micrometers are produced through a microwave-assisted wet chemistry method. Tens to hundreds grams of silver nanoparticles and nanowires are obtained in minutes by microwave irradiation treatment to a precursor pre-made by highly concentrated silver salt solution and other additives. These silver nanoparticles and nanowires have good dispersibility and are ideal for forming conductive adhesives.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

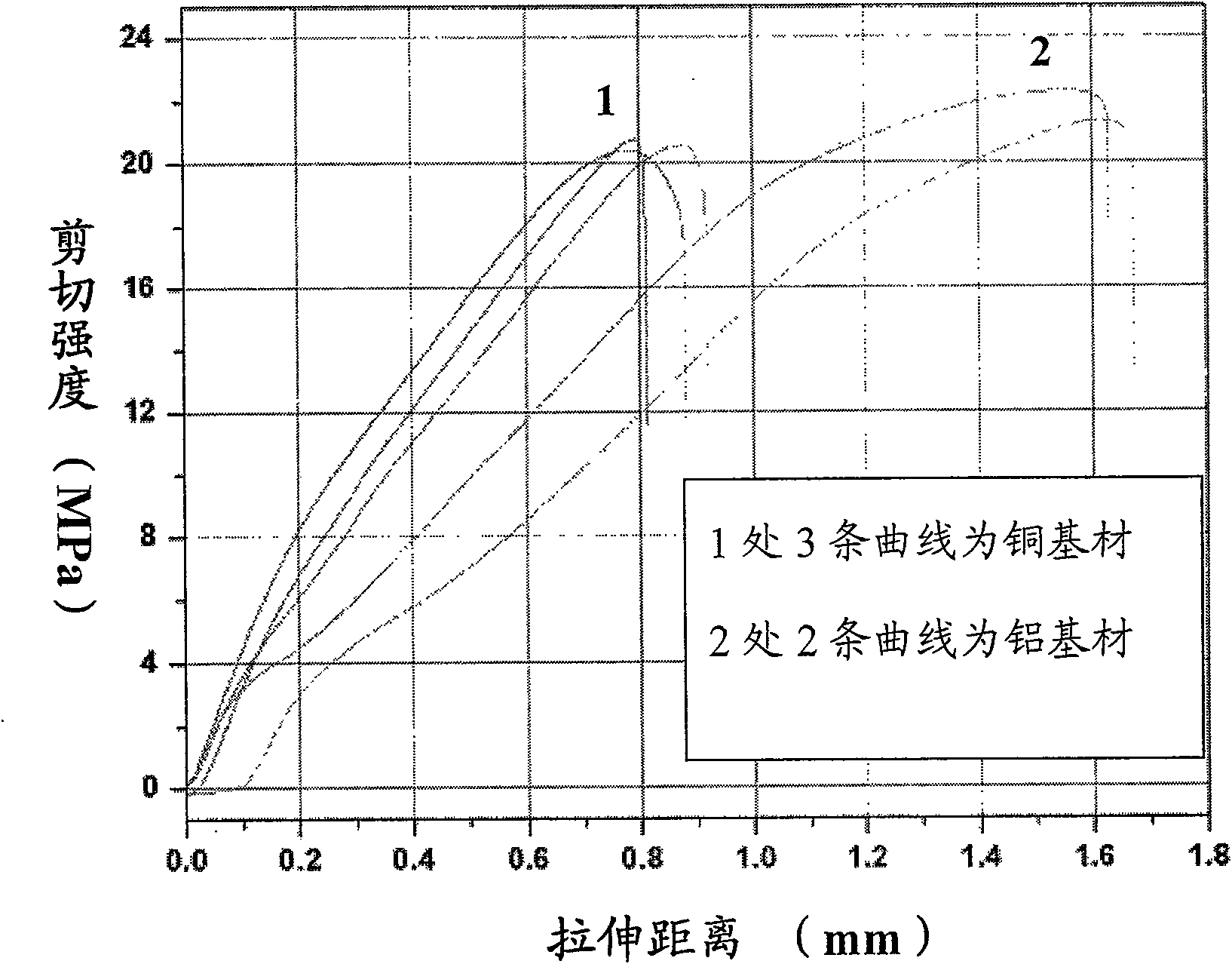

High-temperature resistant one-component isotropic conductive adhesive and preparation method thereof

InactiveCN101555393AEasy to prepareImprove controllabilityNon-macromolecular adhesive additivesEpoxy resin adhesivesGas phaseIsotropic conductive adhesives

The invention provides a high-temperature resistant one-component isotropic conductive adhesive and a preparation method thereof. The one-component isotropic conductive adhesive capable of resisting the high temperature of 180 DEG C for a long time is prepared by adding silver nano-wire as the conductive filler to an epoxy resin matrix and adding core-shell structure toughening epoxy resin and poly-functional epoxy resin as modifiers. The conductive adhesive comprises the following components by the mass percentage: 10% to 15% of matrix epoxy resin, 62% to 65% of silver nano-wire, 3.5% to 5.5% of poly-functional epoxy resin, 6% to 10% of core-shell structure toughening epoxy resin, 0.4% to 0.6% of gas-phase silicon dioxide, 0.6% to 1.0% of toughening diluting agent, 0.3% to 0.4% of coupling agent, 9% to 15% of curing agent and 0.1% to 0.2% of curing accelerator. The invention has the advantages of simple preparation method, good controllability, high material availability and mild preparation condition.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

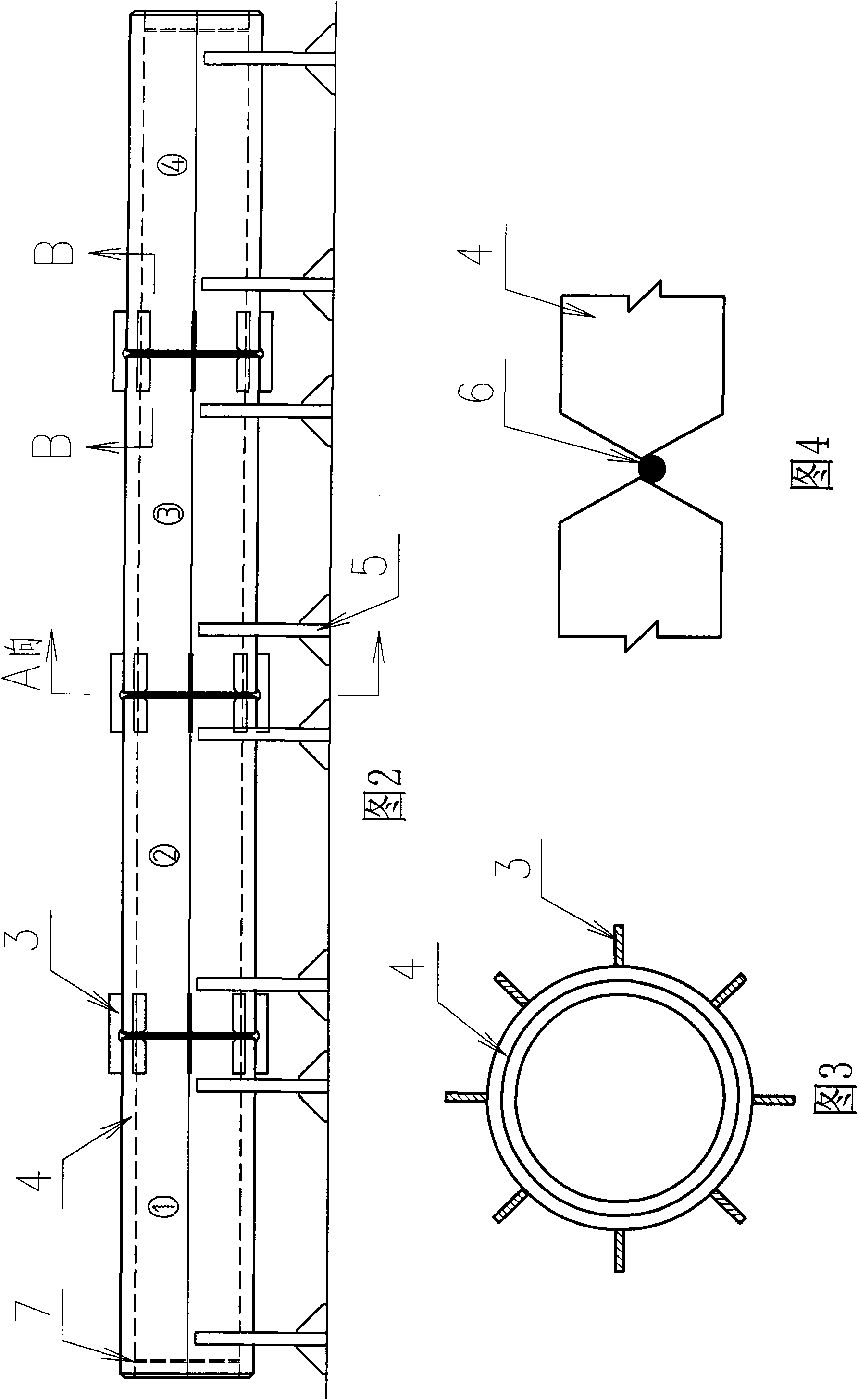

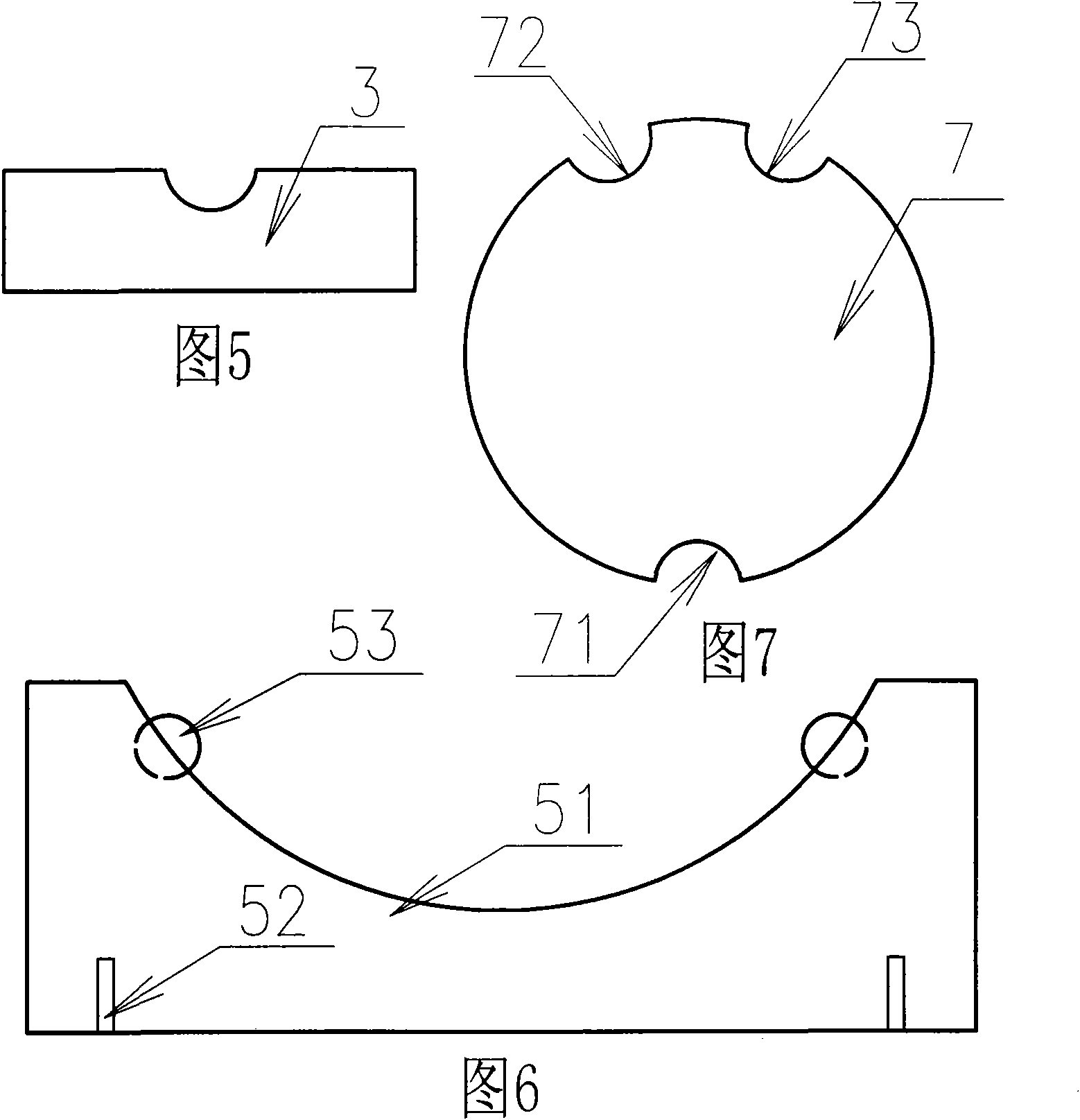

Manufacturing method for ultra-long and ultra-thick circular plate

ActiveCN101579700AImprove mechanical propertiesReduce stressWelding/cutting auxillary devicesArc welding apparatusChemical industryButt welding

A manufacturing method for ultra-long and ultra-thick circular plate is suitable for the steel circular plate which has a length more than 10 meters and has a thickness more than 100 millimeters. The method comprises the following steps: forging a plurality of segments of ultra-thick cylinders; carrying out mechanical processing to make the inner diameter, the wall thickness and the surface roughness accord with the requirements; and processing bevels at two ends. The invention is characterized in that the plurality of segments after procession are placed on a rolling jig bed 5; an interface part is fixed with a fixing plate; then the butt welding is performed after the bevels are added with ceramic gaskets 6; the long cylinder is prepared; the cutting is performed; and the ultra-long ultra-thick circular plate with the required dimension is manufactured. The invention has the advantageous of capability of manufacturing the ultra-long and ultra-thick circular plate with the length of more than 10 meters and the thickness of more than 100 millimeters, having high mechanical property of the manufactured plate, and having simple and convenient manufacturing method, easy operation and reduced manufacturing cost. The manufacturing method for ultra-long and ultra-thick circular plate can be widely used in the watercraft manufacturing industry and other mechanical chemical industry.

Owner:QINGDAO BEIHAI SHIPBUILDING HEAVY IND CO LTD

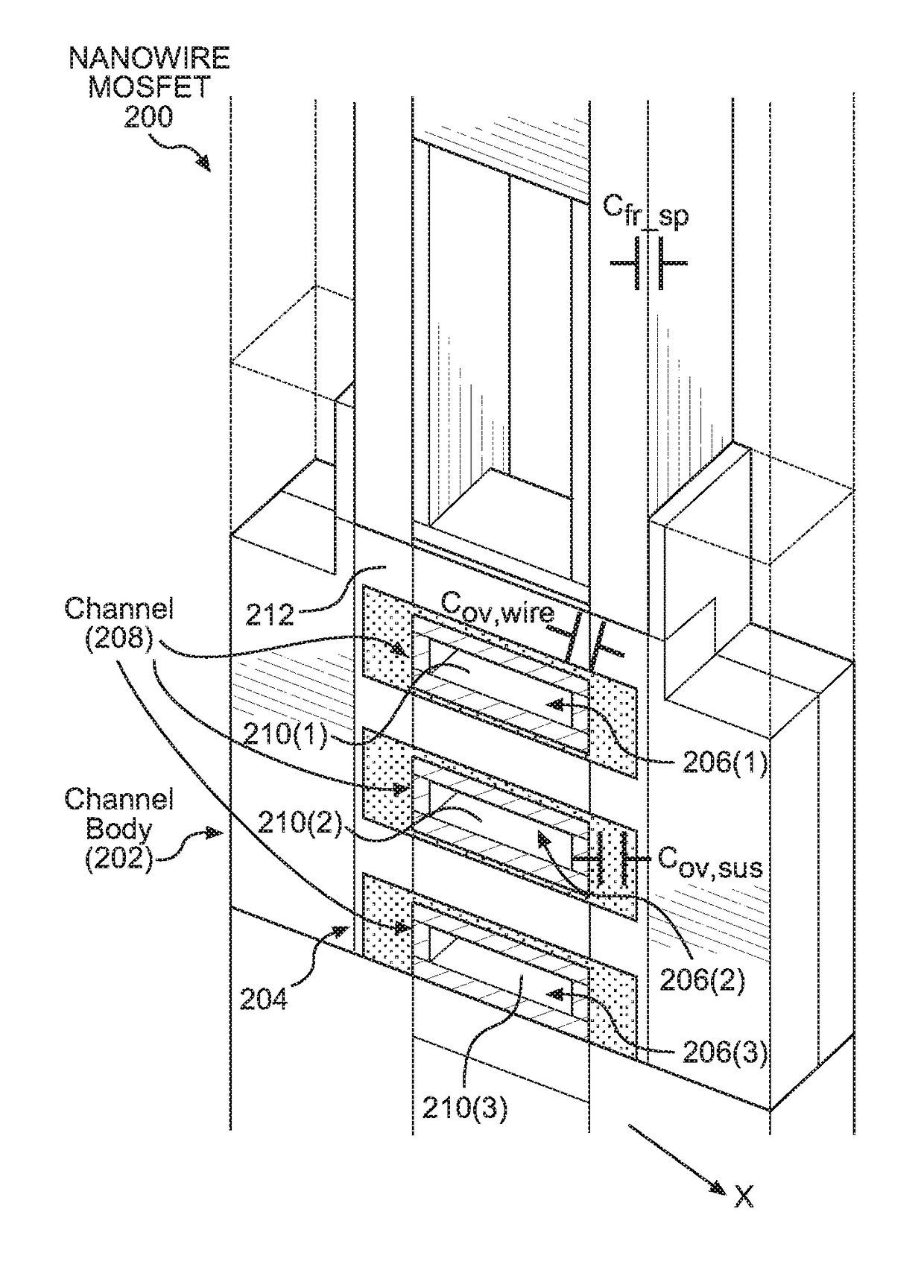

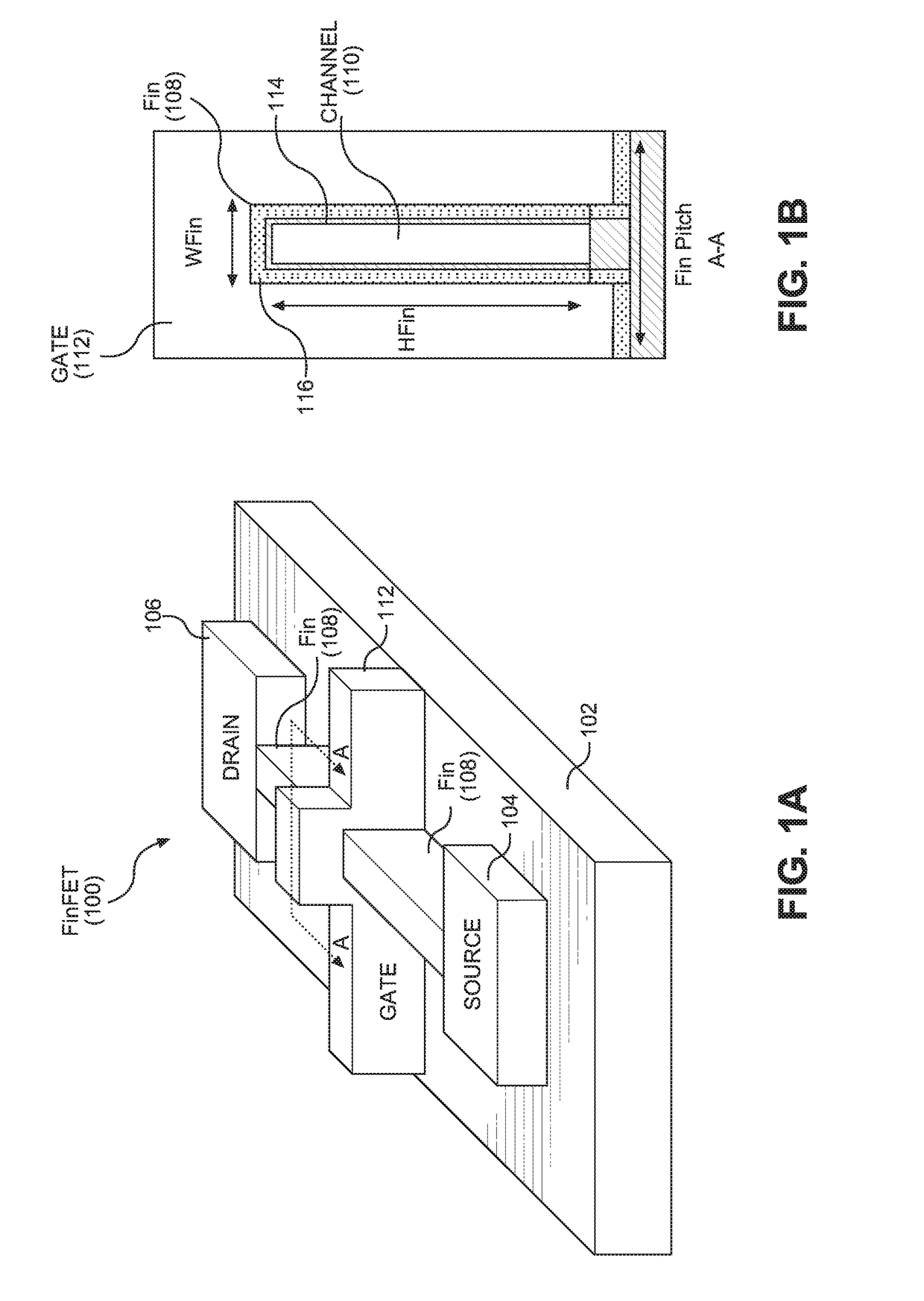

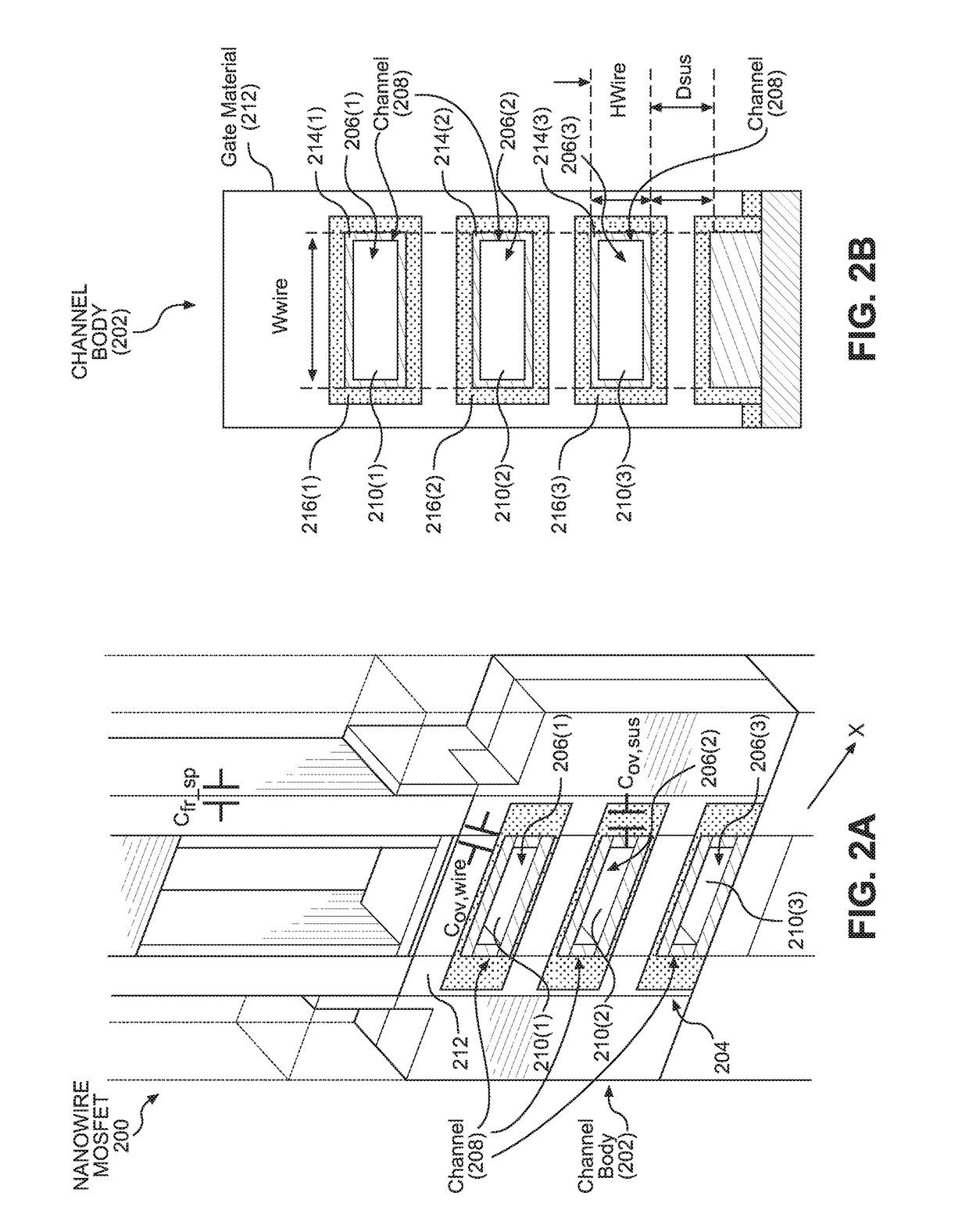

NANOWIRE METAL-OXIDE SEMICONDUCTOR (MOS) FIELD-EFFECT TRANSISTORS (FETs) (MOSFETs) EMPLOYING A NANOWIRE CHANNEL STRUCTURE EMPLOYING RECESSED CONDUCTIVE STRUCTURES FOR CONDUCTIVELY COUPLING NANOWIRE STRUCTURES

InactiveUS20170207313A1Increase widthIncrease channel current densitySemiconductor devicesMOSFETNanowire

Nanowire metal-oxide semiconductor (MOS) Field-Effect Transistors (FETs) (MOSFETs) employing a nanowire channel structure employing recessed conductive structures for conductively coupling nanowire structures are disclosed. Conductive structures are disposed between adjacent nanowire structures to conductively couple nanowire structures. Providing conductive structures in the nanowire channel structure increases the average cross-sectional area of nanowire structures, as compared to a similar nanowire channel structure not employing conductive structures, thus increasing effective channel width and drive strength for a given channel structure height. The precision of a gate material filling process is also eased, because gate material does not have to be disposed in areas between adjacent nanowire structures occupied by conductive structures. The conductive structure width can also be recessed with regard to width of nanowire structures in the nanowire channel structure to allow for a thicker metal gate to lower the gate resistance, while providing excellent electrostatic gate control of the channel.

Owner:QUALCOMM INC

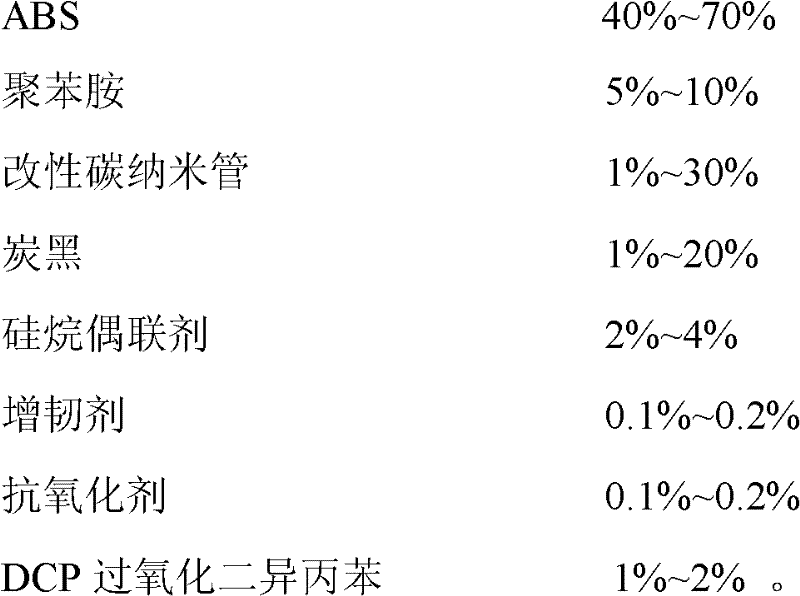

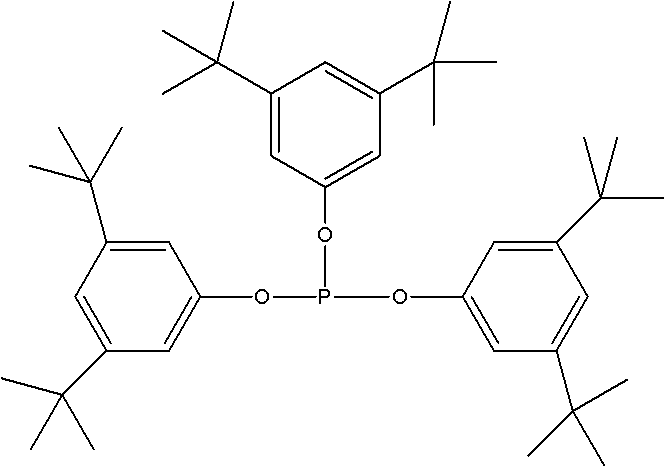

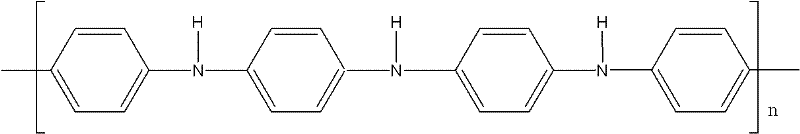

A new type of antistatic ABS resin material and preparation method thereof

ActiveCN102268171AImprove mechanical propertiesImprove chemical performanceOther chemical processesModified carbonOmega

The invention discloses a novel antistatic ABS (Acrylonitrile Butadiene Styrene) resin material and a preparation method thereof. The antistatic ABS resin material comprises the following components in percentage by weight: 40-70 percent of ABS, 5-10 percent of polyaniline, 1-30 percent of modified carbon nanotube, 1-20 percent of carbon black, 2-4 percent of silane coupling agent, 0.1-0.2 percent of toughener, 0.1-0.2 percent of anti-oxidant and 1-2 percent of DCP (Dicumyl Peroxide). The antistatic ABS resin material has the advantages of permanent antistatic property, good effect, high mechanical property, high processability, good application prospect and good comprehensive performance; the surface resistance of the ABS resin can be lowered to 105 omega.centimeter or lower; a permanentantistatic material can be obtained; the used raw materials do not have toxic or side effects; and the method is safe to operate, and has a simple and practical process.

Owner:5ELEM HI TECH CORP

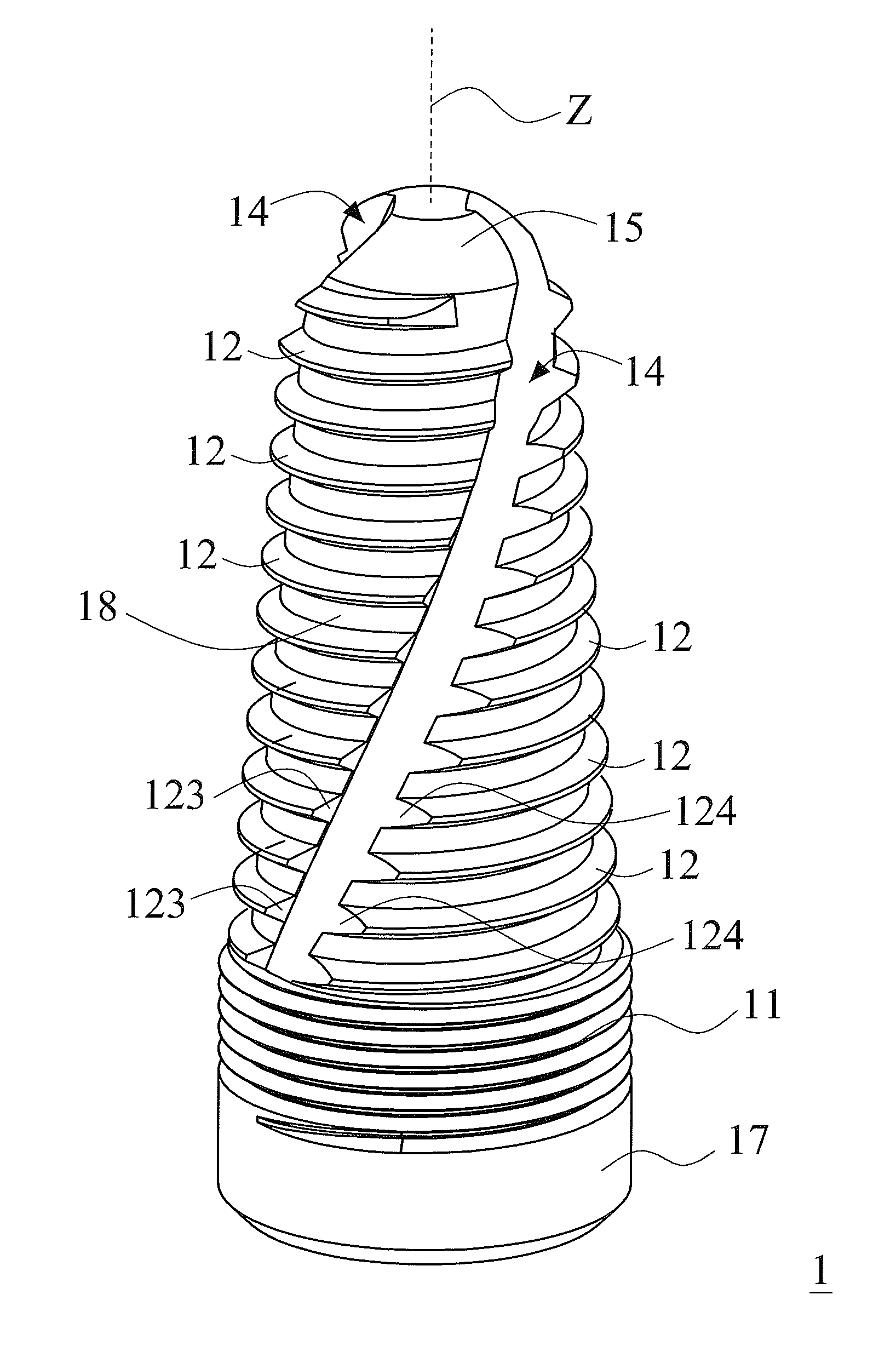

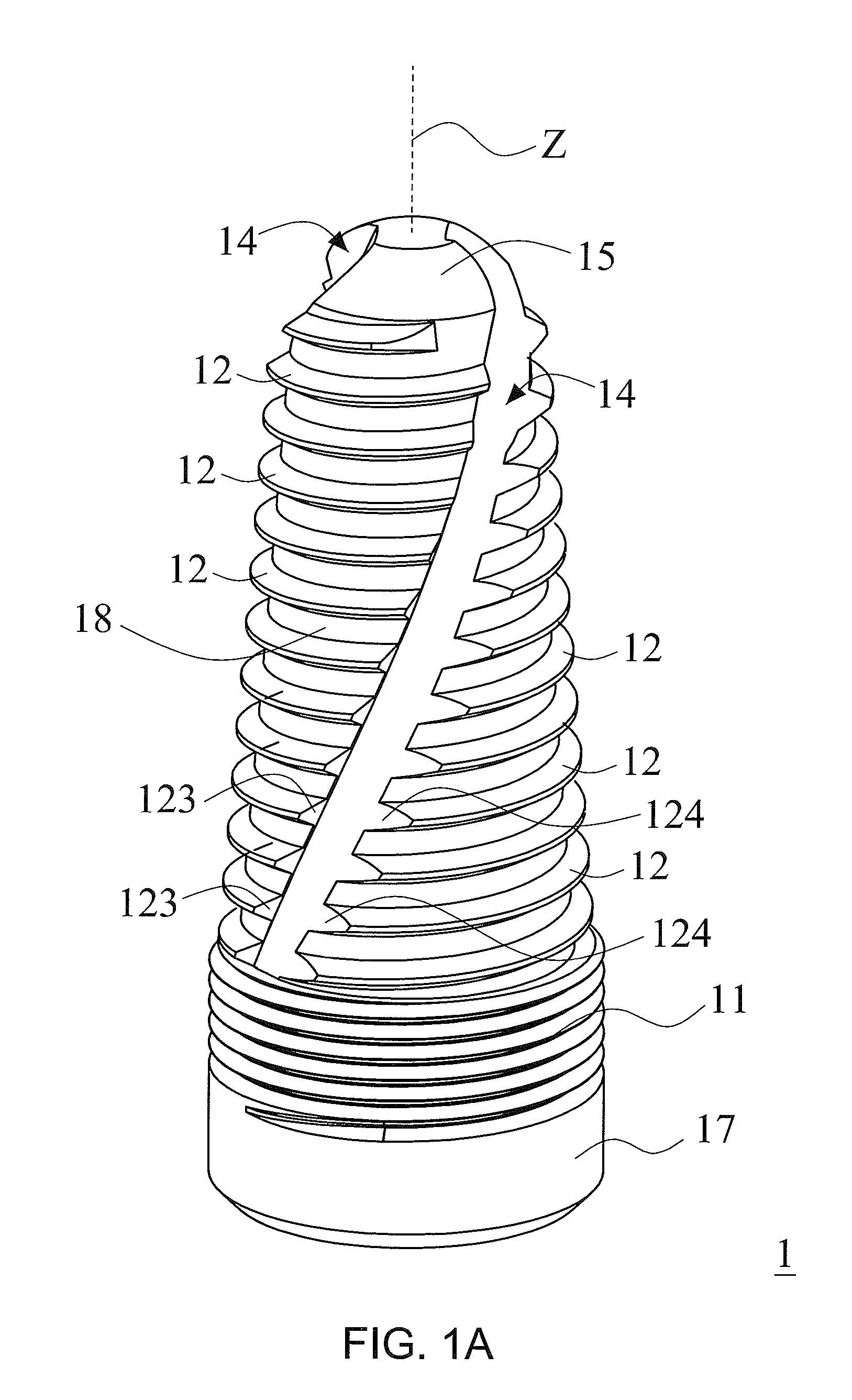

Dental Implant

InactiveUS20150297321A1Relief the painSpeed wound healingDental implantsDental implantBiomedical engineering

The present invention provides a dental implant, includes a body portion, a first thread portion, a head portion, a plurality of second thread portions and a plurality of trenches. The body portion defines a drilling axial direction in a longitudinal direction thereof. The first thread portion is arranged on one end of the body portion in the drilling axial direction. The head portion is arranged on another end of the body portion in the drilling axial direction. The second thread portions have a pitch larger than that of the first thread portion, and formed on radial sides of the body portion. The second thread portions are arranged at different positions in the drilling axial direction. Each second thread portion has a cutting face and a cumulative face at two ends of the dental implant in a rotative direction P. The trench is formed at a radial side of the head portion and the body portion, and passes through the cutting faces and the cumulative faces from the head portion to the first thread portion.

Owner:CHEN LEON

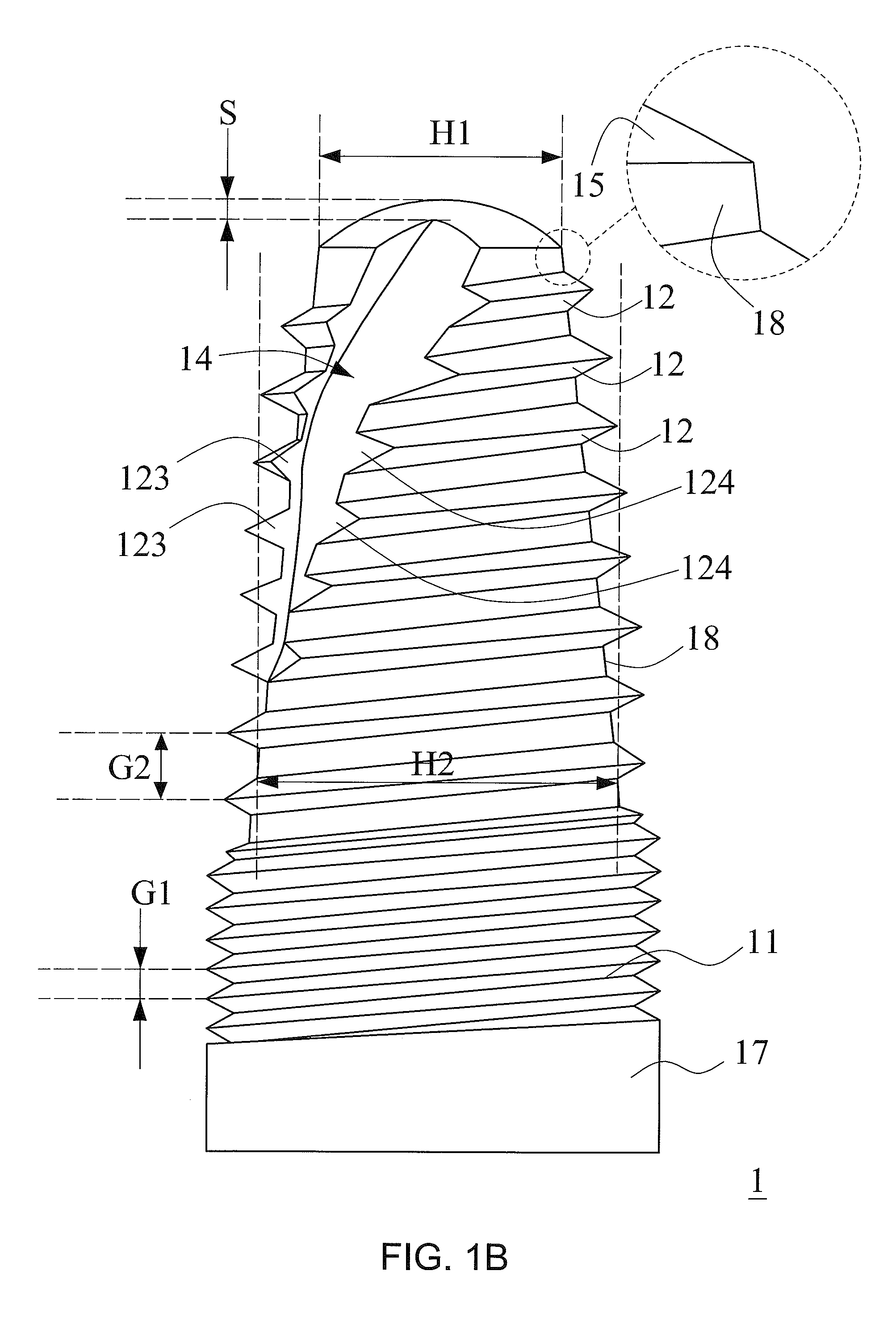

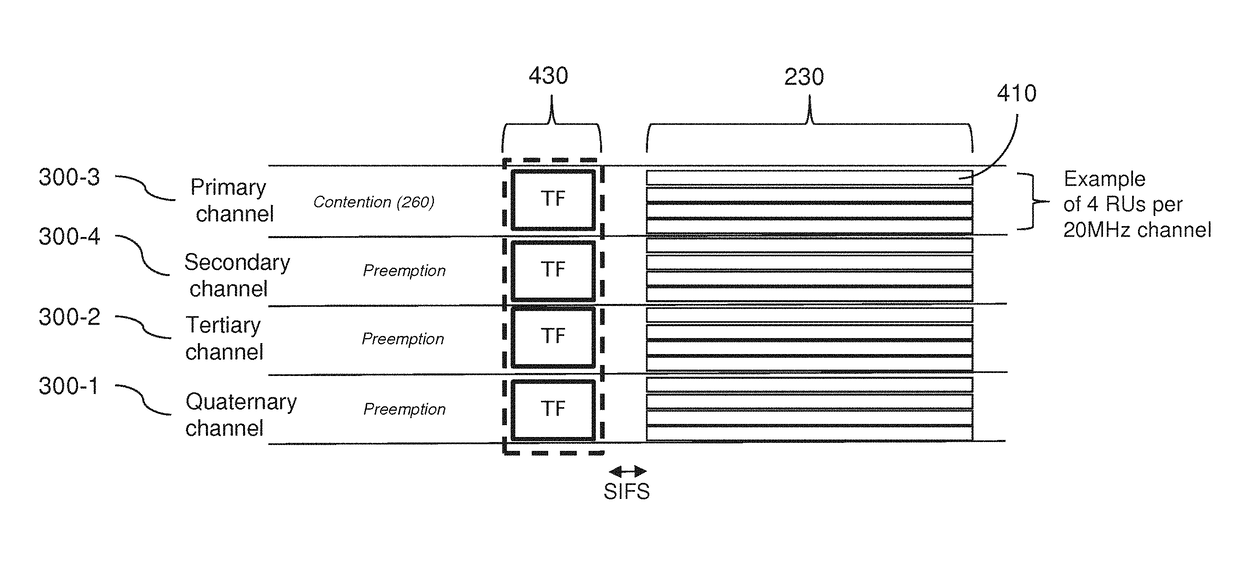

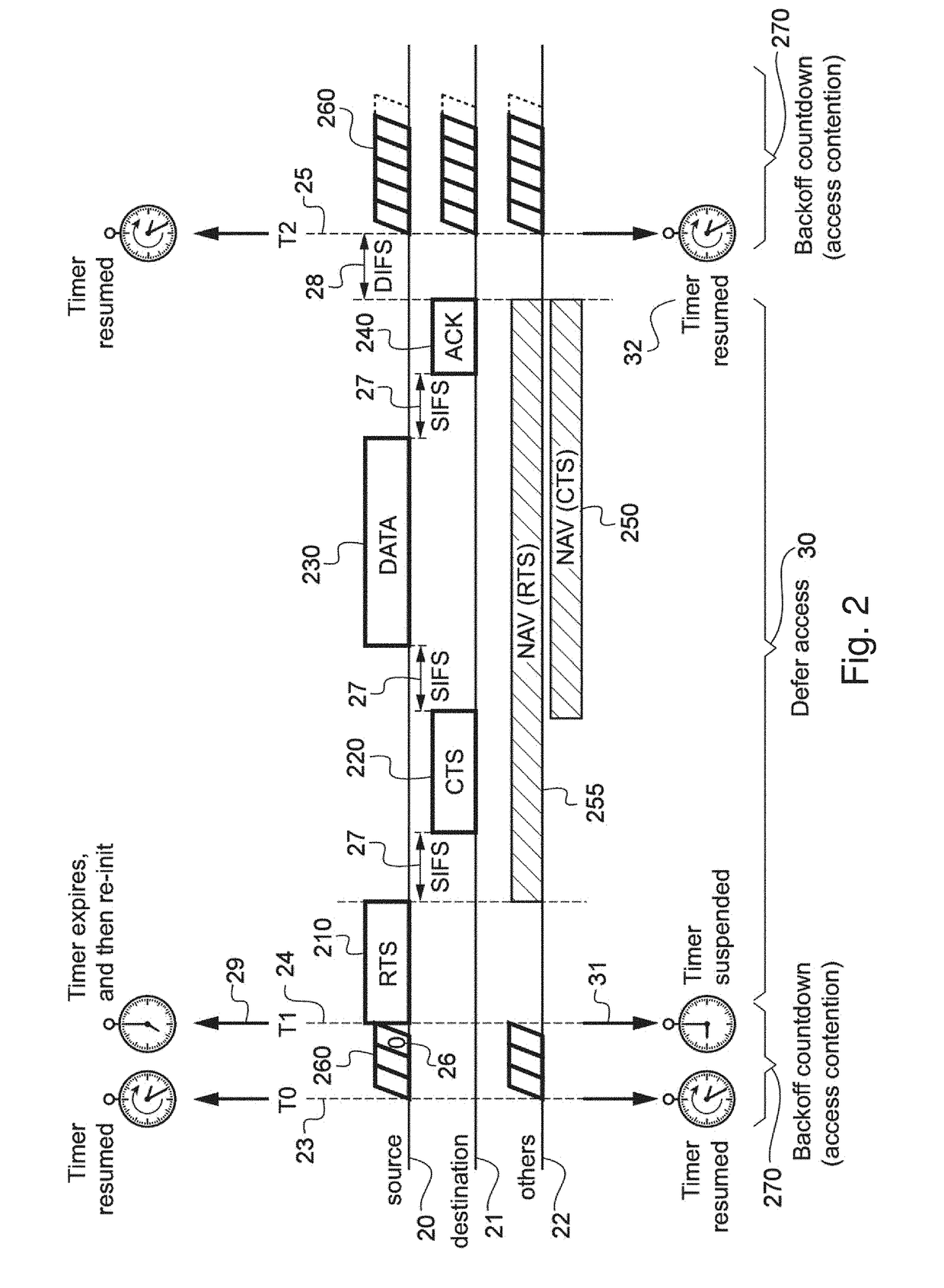

Trigger frames adapted to packet-based policies in an 802.11 network

ActiveUS20180213566A1Reduce paddingImprove transmission robustnessNetwork traffic/resource managementNetwork topologiesNetsniff-ngReal-time computing

Owner:CANON KK

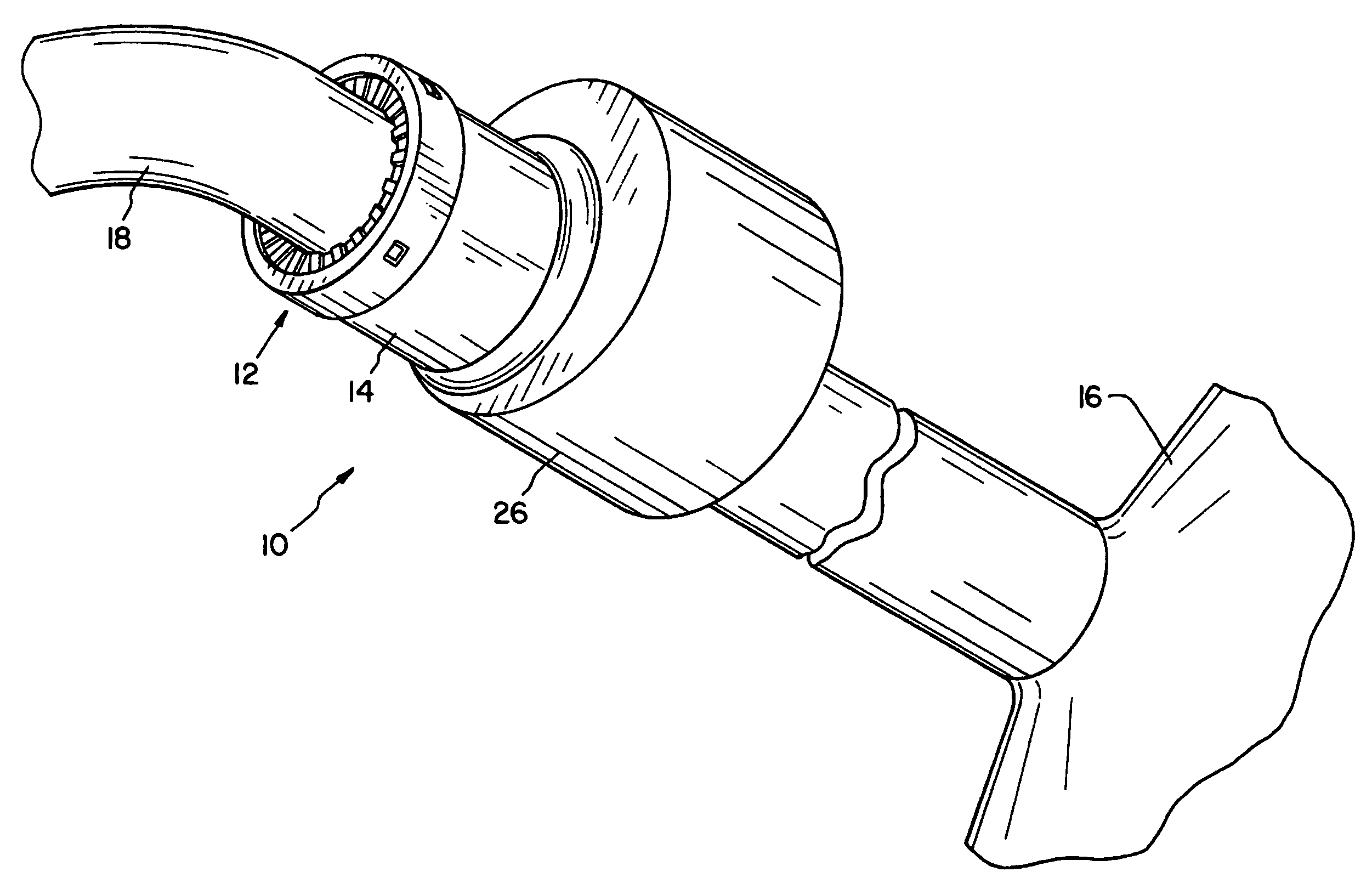

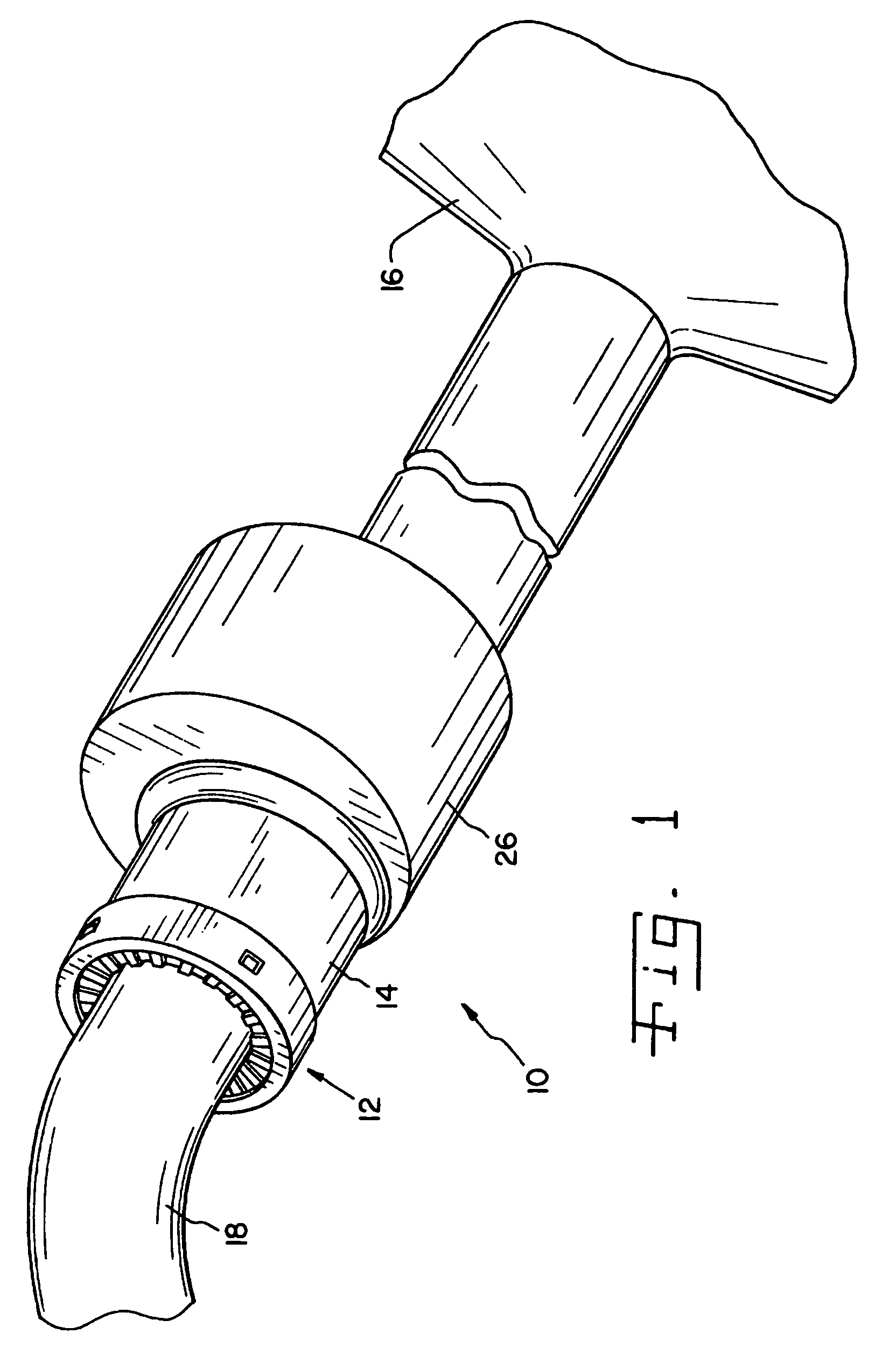

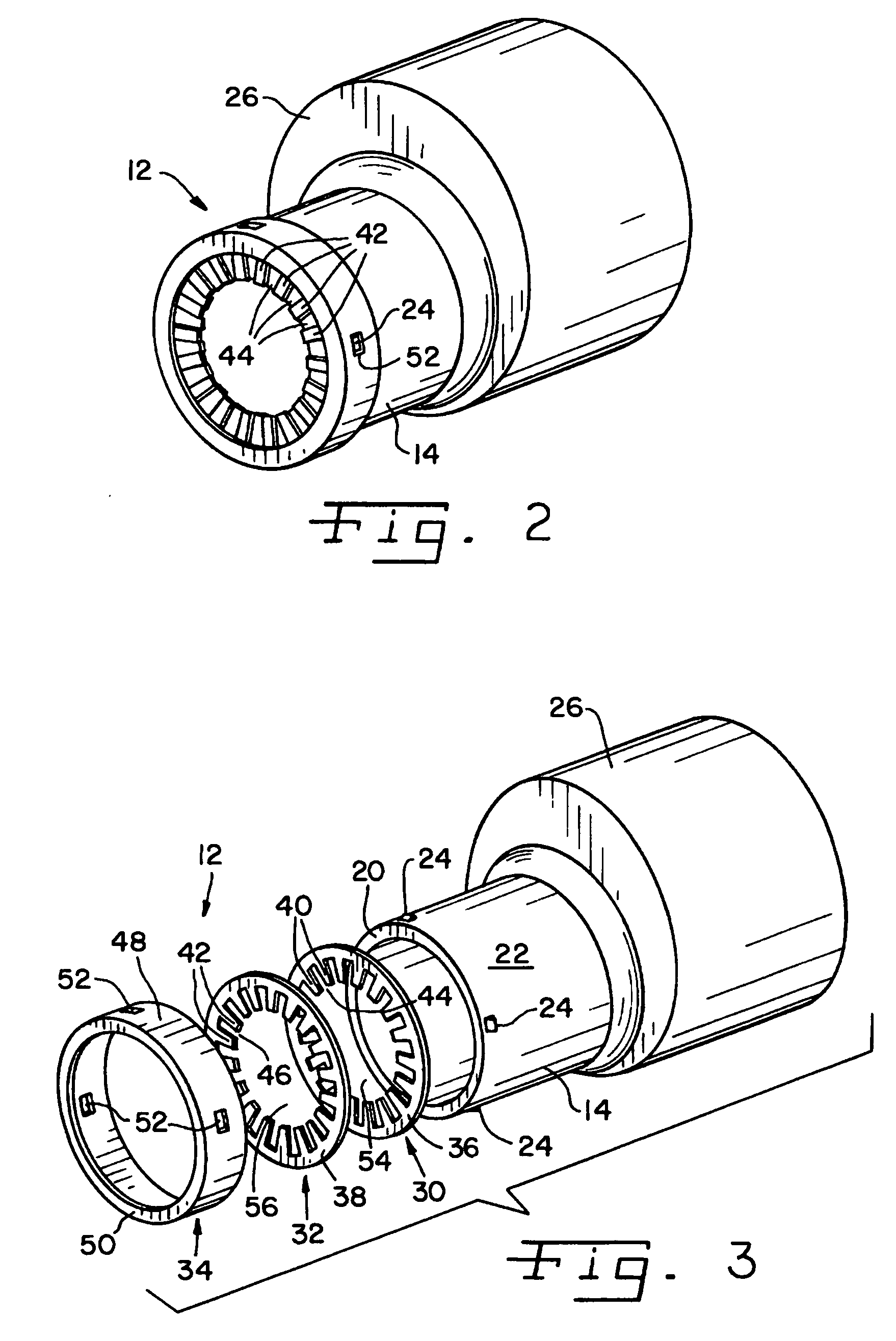

Seal assembly for fuel fill pipes

ActiveUS20070023102A1Reduce paddingDecrease air entrainment with the fuel during refuelingSolid materialClosures to prevent refillingNozzleEngineering

Owner:ILLINOIS TOOL WORKS INC

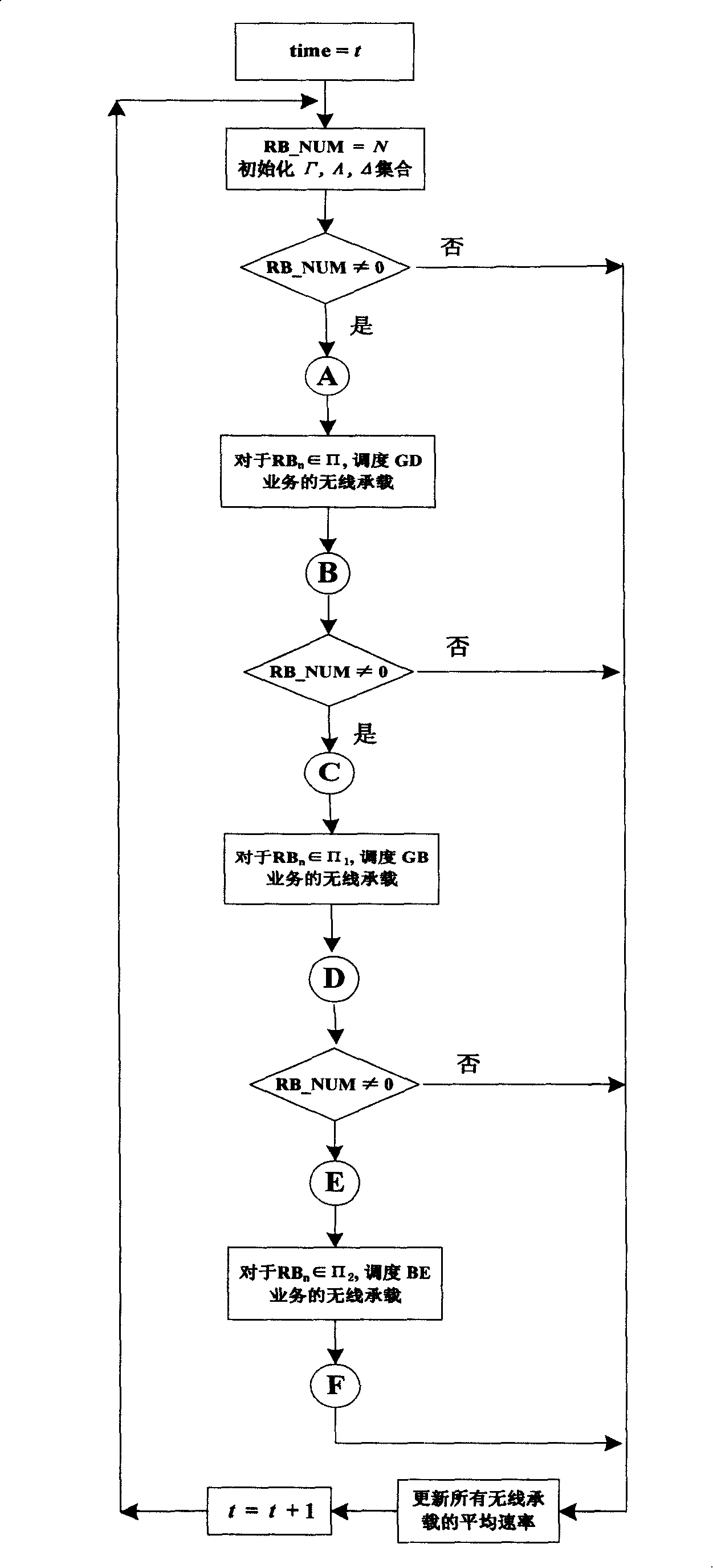

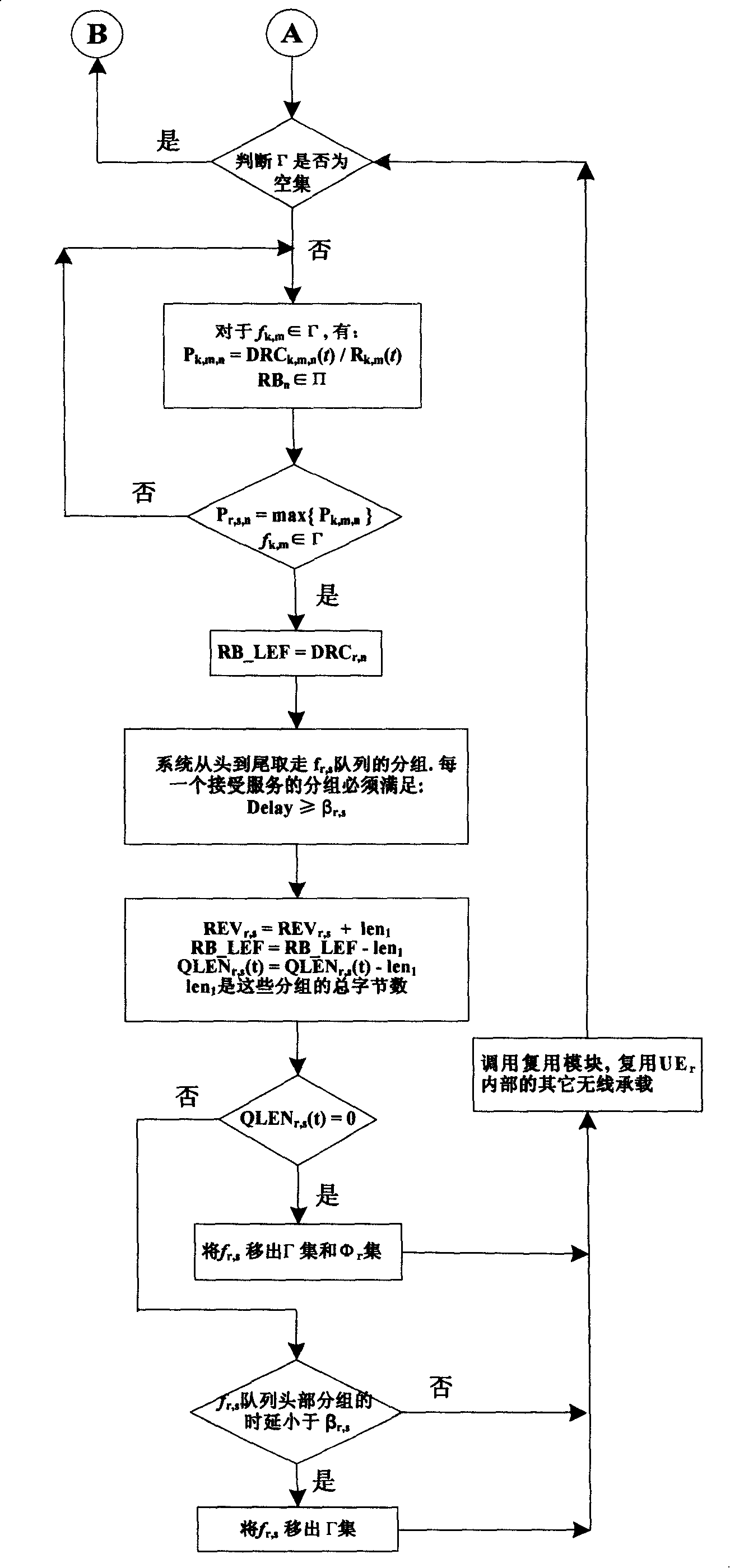

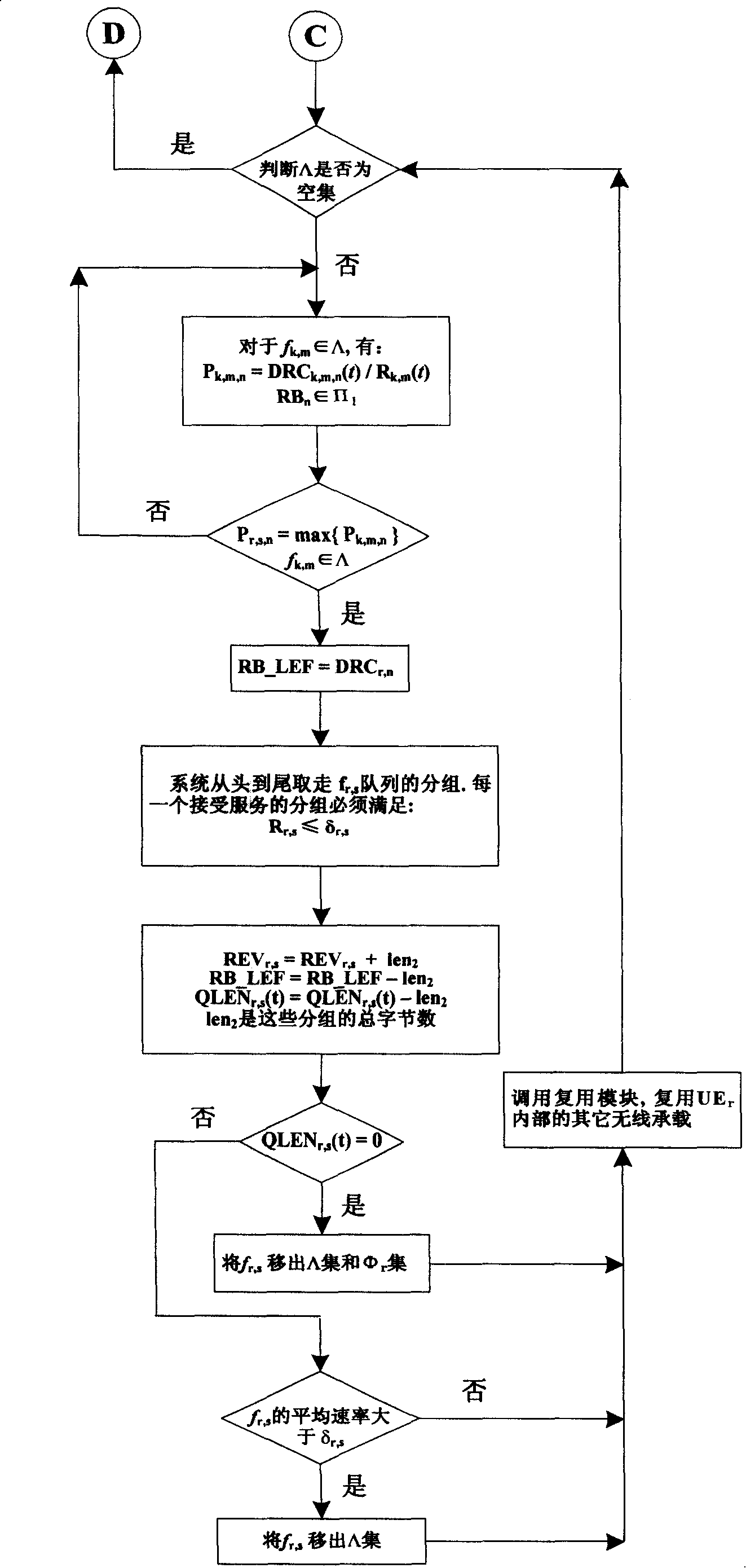

Scheduling method of multi service multiplexing supporting medium access control lay

InactiveCN101232705AReduce paddingGuaranteed minimum QOS requirementsRadio/inductive link selection arrangementsRadio transmission for post communicationResource blockFair scheduling

The invention relates to a multi-service integration dispatching method that supports the medium access control layer. The order of priority for system dispatching radio bearer services in each dispatching time unit TTI is as follows: a delay-constrained (GD) service, a minimum guaranteed bandwidth (GB) service and a best effort (BE) service; in the course of dispatching, if resource blocks are not used up when the resource blocks are dispatched to a certain radio bearer, the rest of the resource blocks will be dispatched to other radio bearers in the same UE as the radio bearer; if the rest of the number of resource blocks is zero, the average speed of all radio bearers will be renewed and next dispatching time unit will be entered. The invention avoids the problem that a service of high priority occupies resources of a service of low priority and ensures minimum QOS requirements of two services using definite proportional fair scheduling algorithm specific to GD and GB services.

Owner:SHANGHAI RES CENT FOR WIRELESS COMM

Thermal-conductivity nano-composite material and preparation method thereof

The invention relates to a thermal-conductivity nano-composite material and a preparation method thereof. The thermal-conductivity nano-composite material comprises the following components by weight percentage: 10-80% of polyolefin, 2-15% of nano-material, 5-50% of thermal conductivity additive, 3-10% of environmental stress resistant cracking additive, 4-19% of impact resistant modifier additive, 0.1-0.5% of antioxidant, a coupling agent of 0.4-3% of the total amount of the nano-material and the thermal conductivity additive, and a wetting agent of 1-6% of the total amount of the nano-material and the thermal conductivity additive. The preparation method comprises the following steps that: firstly, the nano-material, the polyolefin, the impact resistant modifier additive, the coupling agent, and the wetting agent are melted and co-blended according to a certain ratio to be made into masterbatches; secondly, the polyolefin, the masterbatches, the thermal conductivity additive, the environmental stress resistant cracking additive, the impact resistant modifier additive, the antioxidant, the coupling agent and the wetting agent are melted and co-blended according to a certain ratio to be extruded and dried; and thirdly, the materials are melted and co-blended to be extruded and dried to obtain a product. The materials provided by the invention have excellent thermal conductivity and good mechanical properties, and are widely used in heat exchange equipment in various industries.

Owner:HANGZHOU RUNPAQ ENVIRONMENT EQUIP

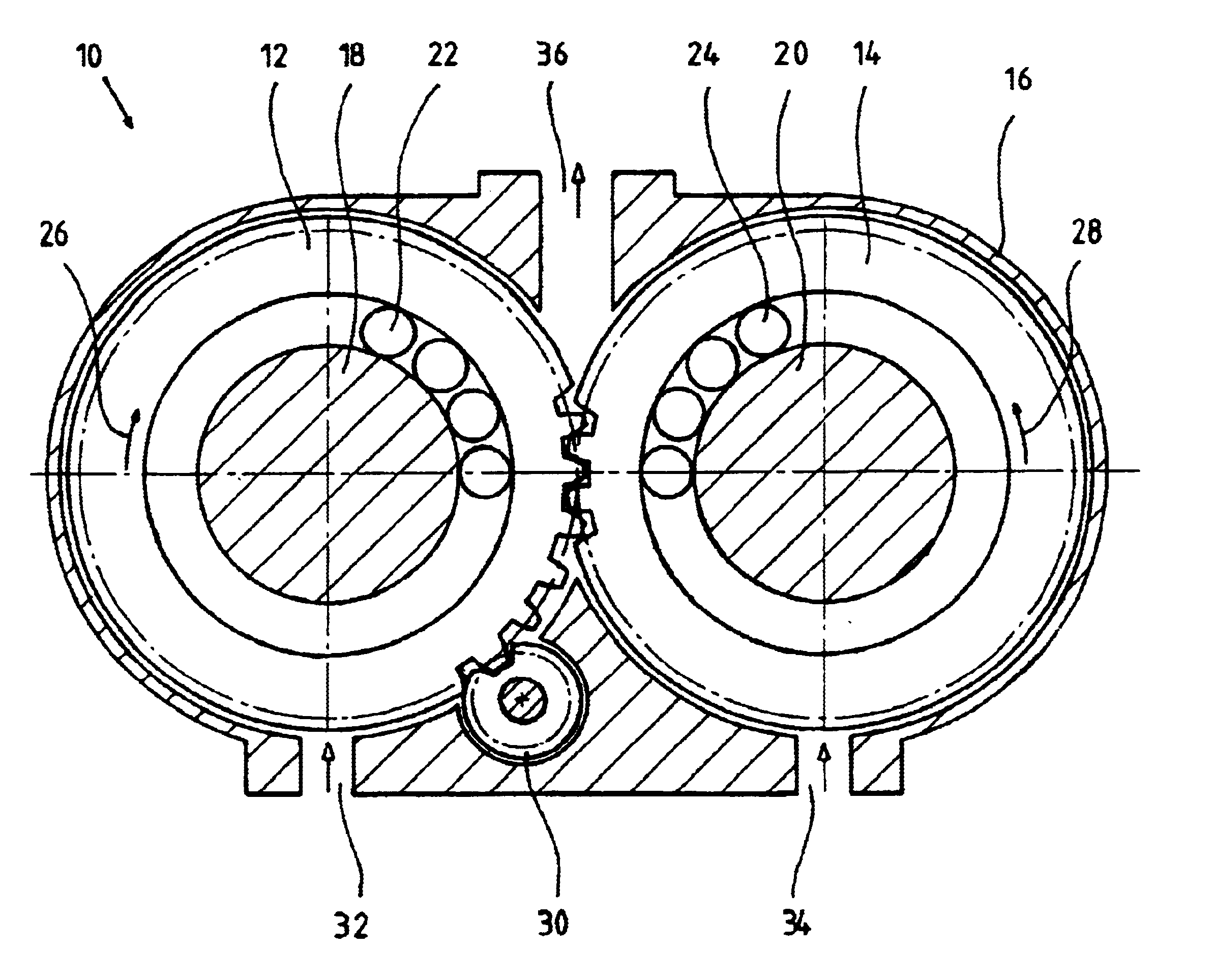

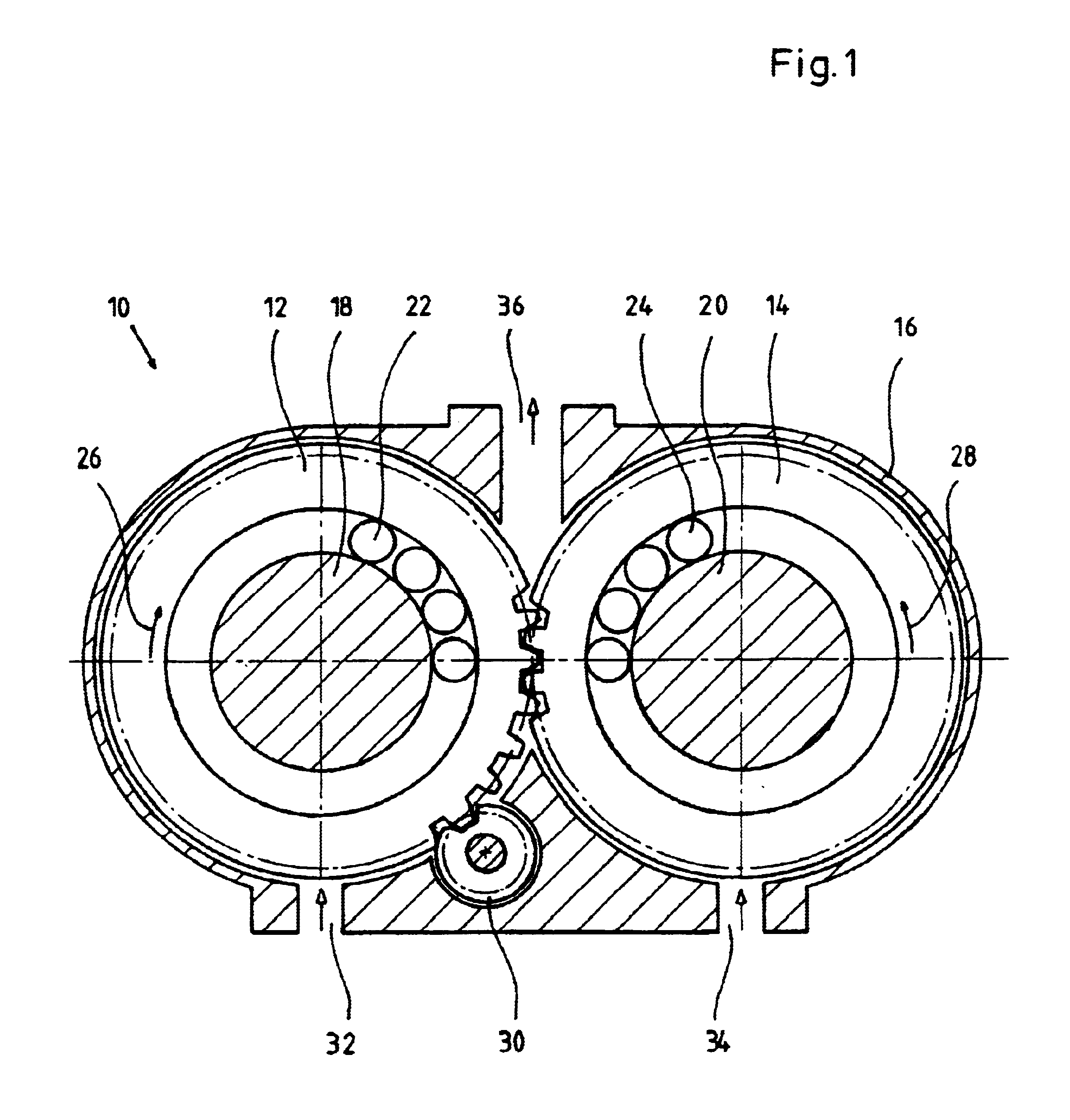

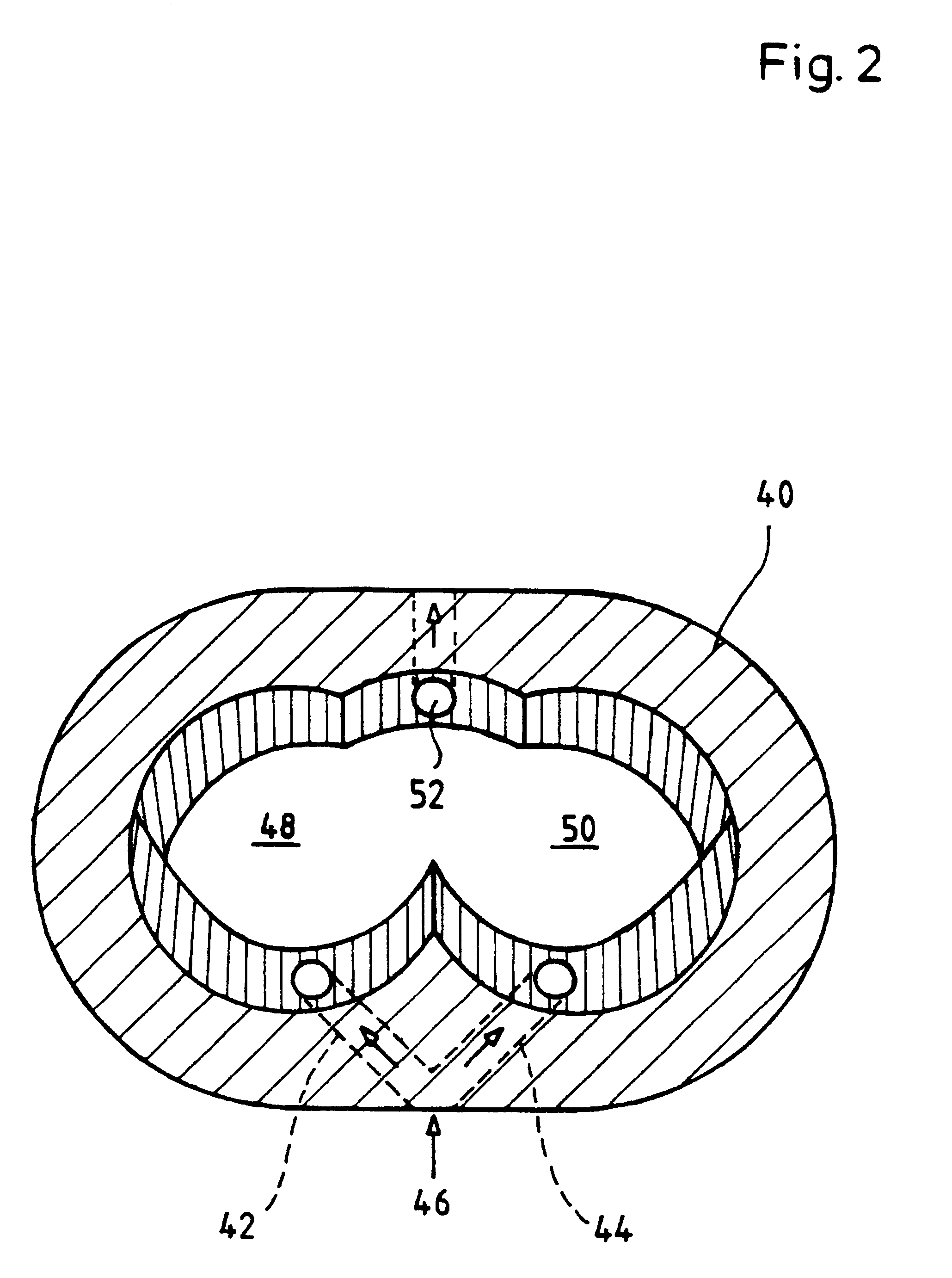

Rotary displacement machine having at least two annular displacement gears and supply channels

InactiveUS6705847B1Save materialReduce weightOscillating piston enginesEngine of counter-engagement typeControl theory

A rotary displacement machine has a housing and at least two annular displacement gears arranged in the housing and supported rotatably on a stationary axle, receptively. The at least two annular displacement gears have external teeth for conveying a fluid. At least two supply channels are provided in the housing and have a supply mouth, respectively, opening toward the annular displacement gears for supplying a fluid to the annular displacement gears. The supply mouth is configured such that, upon operation of the rotary, displacement machine, a fluid exiting from the supply mouth reaches either only the teeth of a single one of the annular displacement gears or only the teeth of the annular displacement gears rotating in the same direction.

Owner:SAGAWE JOHANN +1

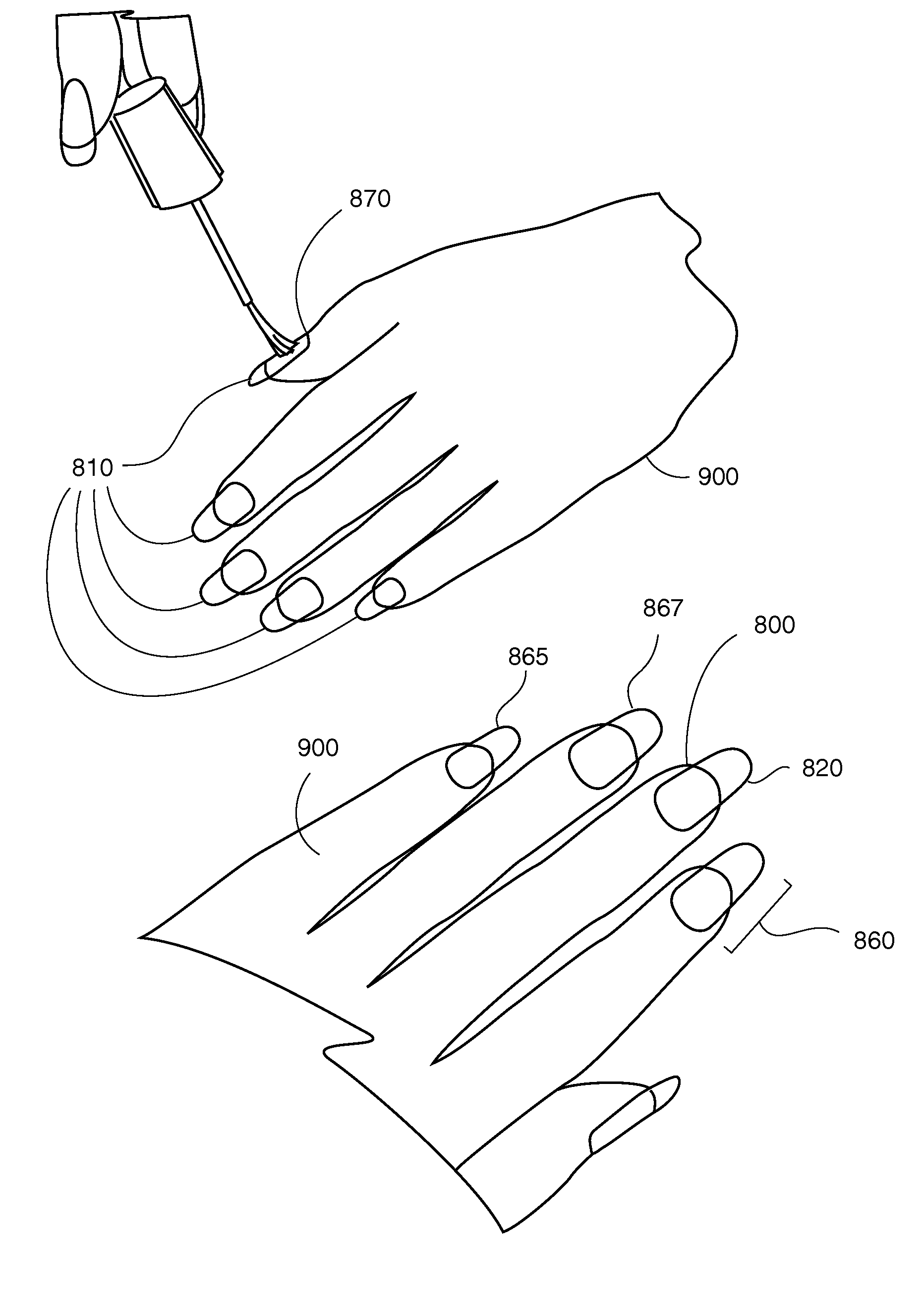

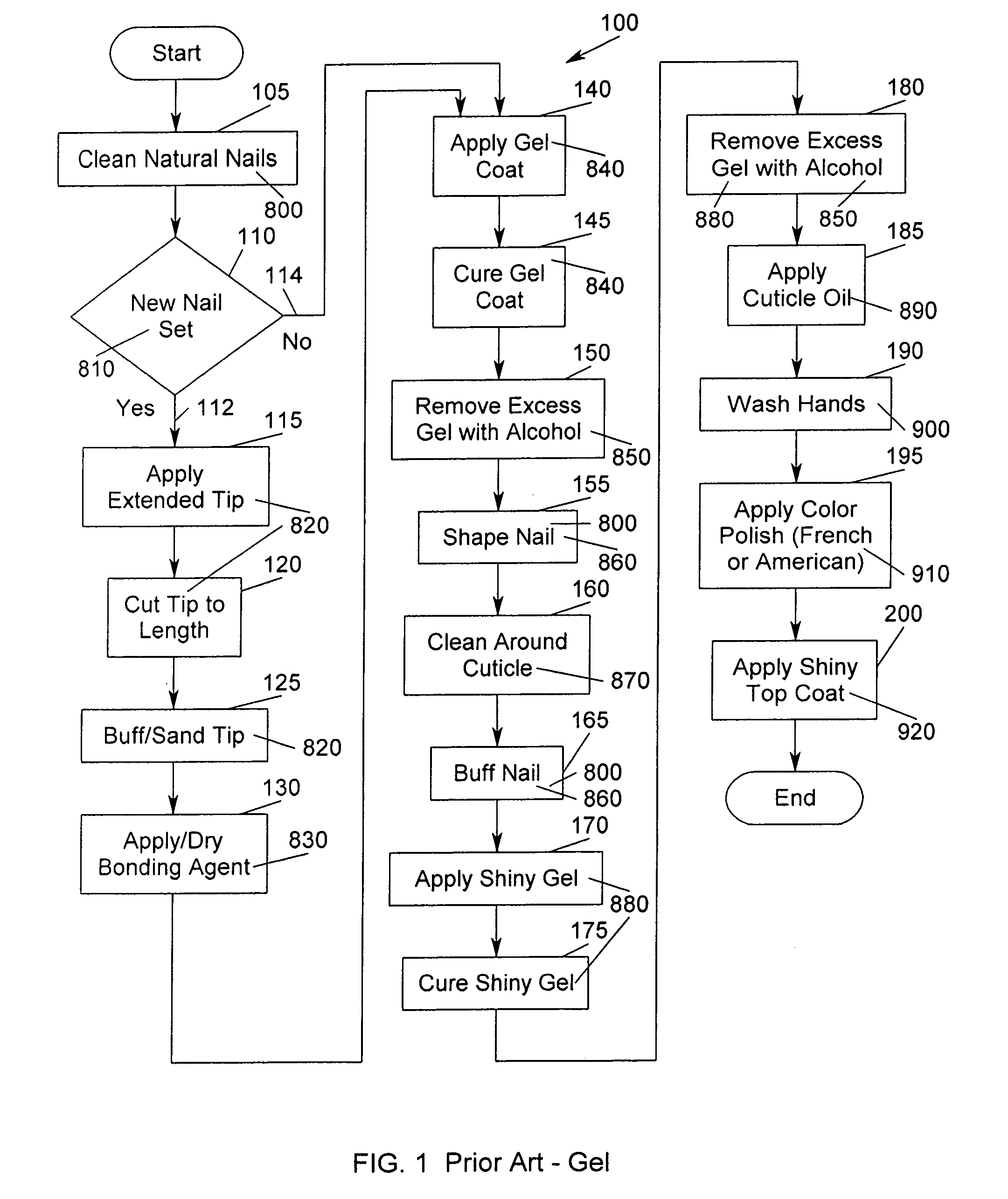

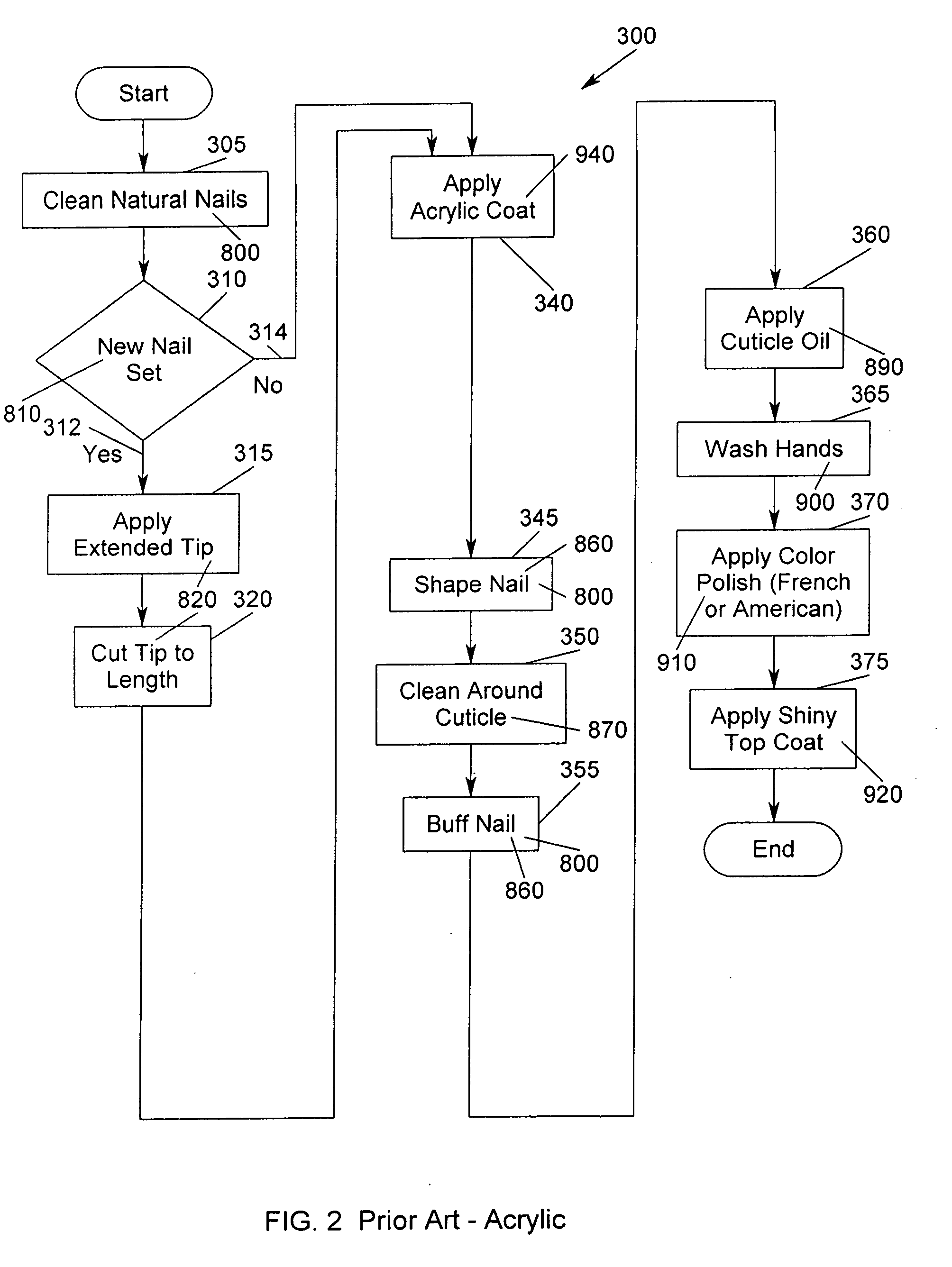

Durable nail coating composition and method of use thereof

InactiveUS20080159973A1Avoid breakingEasy to prepareCosmetic preparationsToilet preparationsAcrylic polymerChemistry

A durable nail coating composition comprising a one-to-one mixture of acrylic polymeric coatings, wherein the durable nail coating composition is applied to the portion of the nail extending forward of the fingertip. The durable nail coating composition is applied via a process that includes selectively installing a new nail set of tips to the natural nail, sizing the tips and selectively applying coatings that include the one-to-one mixture of acrylic polymers. Further, the durable nail coating is applied to a front portion of the nail to provide increased protection from damage with a gel coating subsequently coating the entire nail with or without added tips.

Owner:DOAN QUANG V

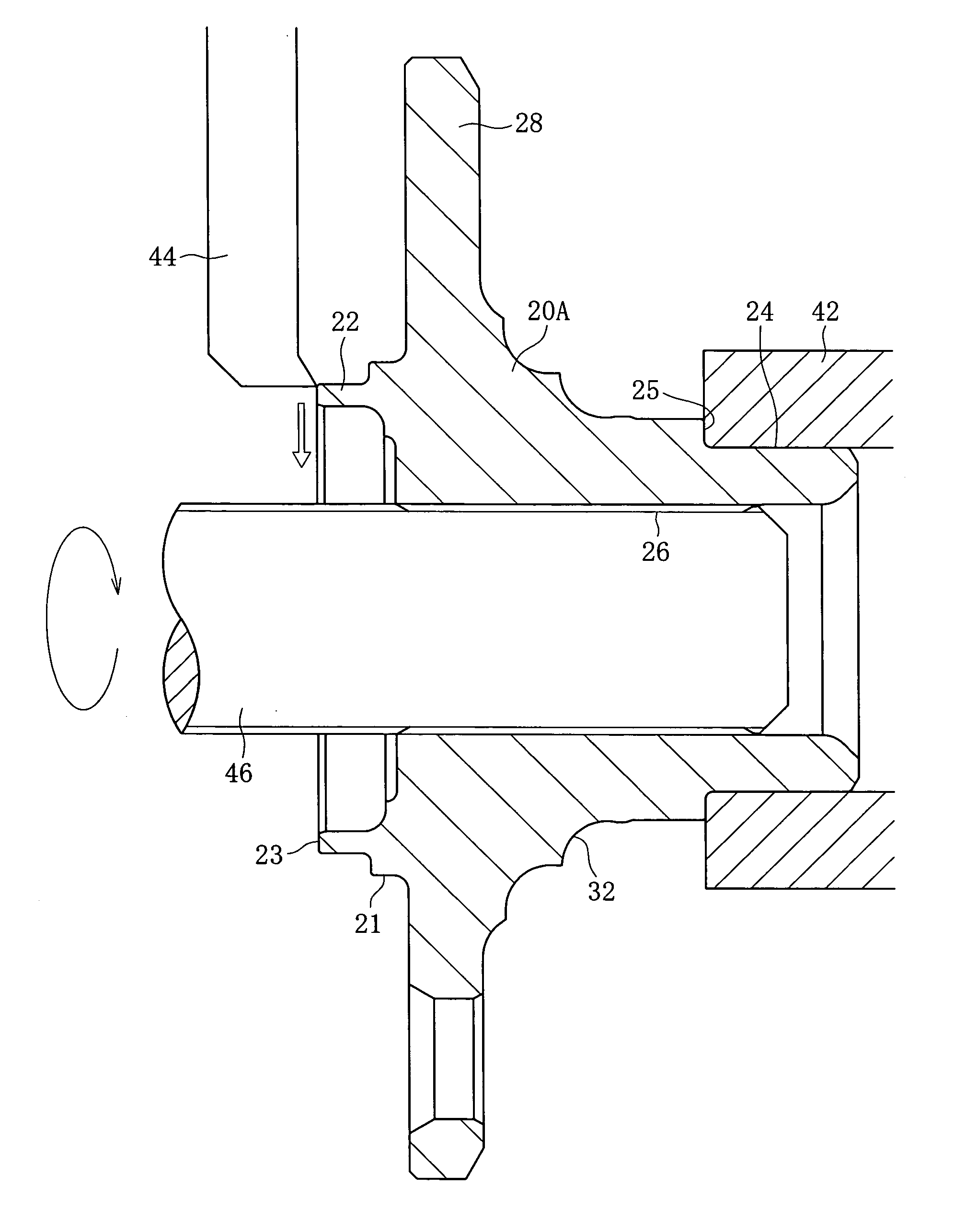

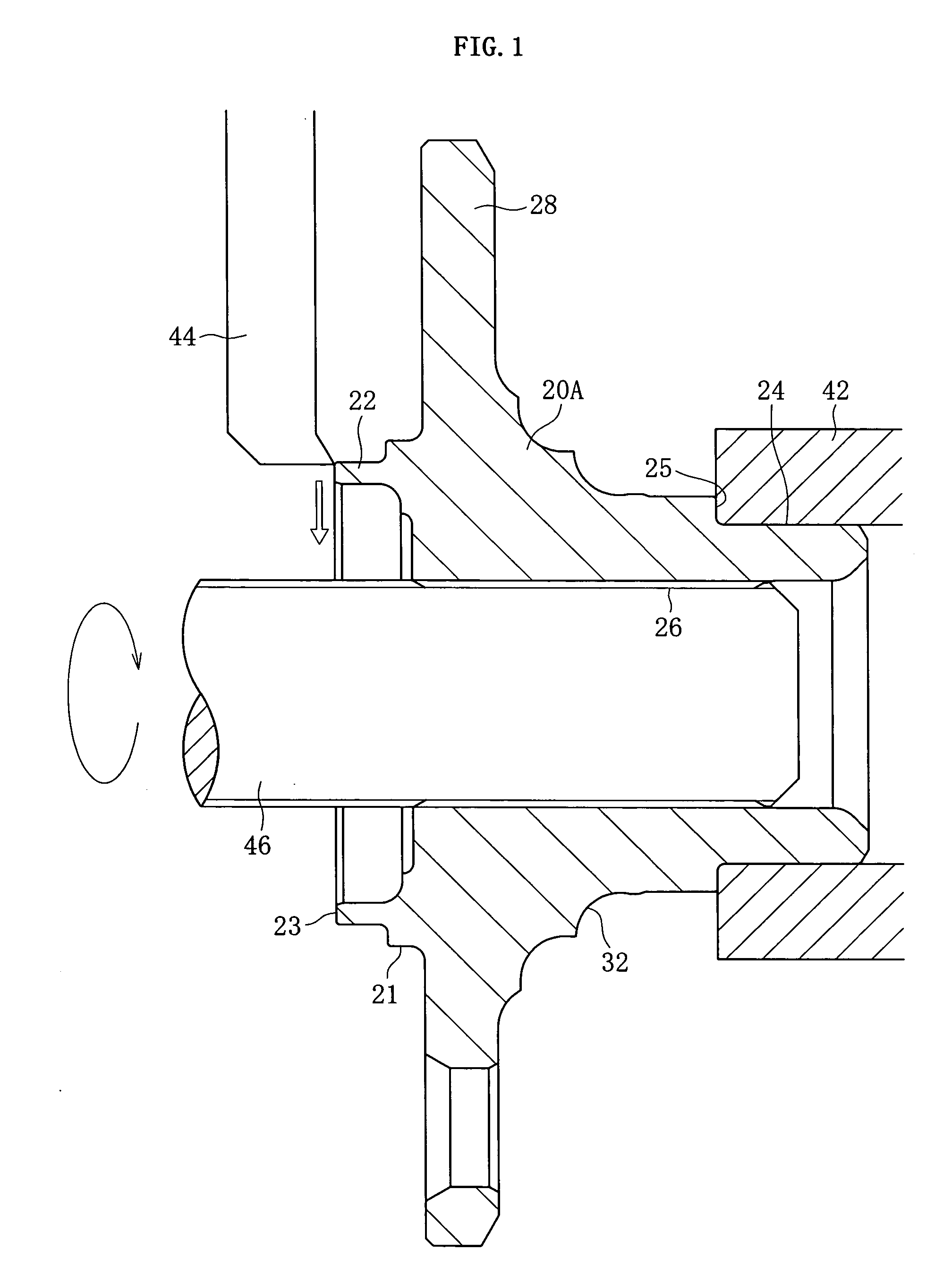

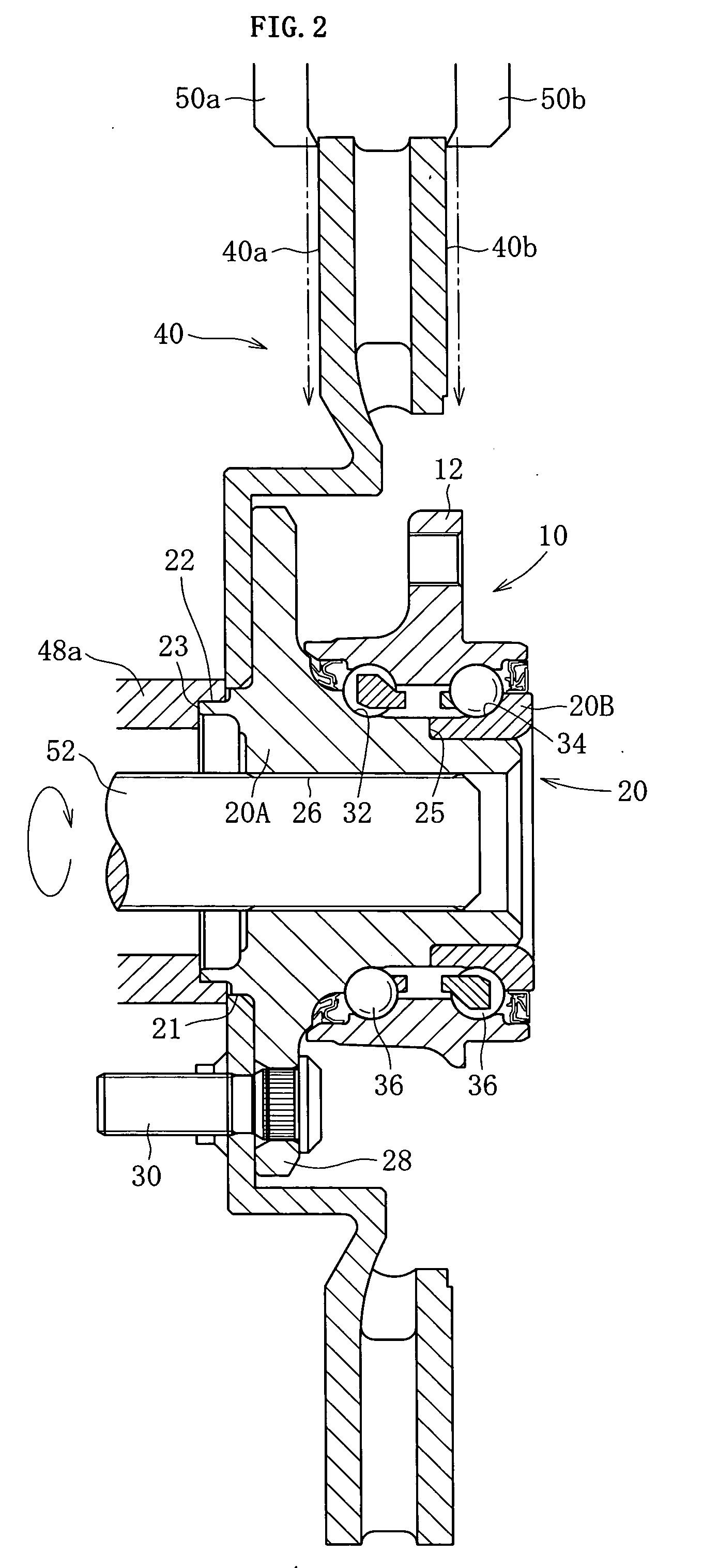

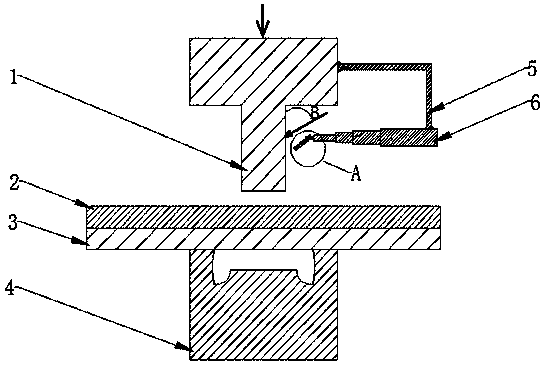

Processing method for brake rotor-equipped wheel bearing devices

ActiveUS20070033787A1Reduce paddingImprove accuracyTurning machine accessoriesHubsBrakeClassical mechanics

An outer member 10 and an inner member 20 constituting a wheel bearing device are assembled and the brake rotor 40 is fixed to the hub ring 20A of the inner member. In this state, the pad slide surfaces 40a and 40b of the brake rotor 40 are lathed with the reference provided by a wheel pilot end surface 23. Alternatively, the wheel pilot end surface 23 of the hub ring 20A by chucking the knuckle pilot 16 of the outer member 10 with the wheel bearing device put in its assembled state, and the pad slide surfaces 40a and 40b of the brake rotor 40 are lathed with the reference provided by the wheel pilot end surface 23.

Owner:NTN CORP

Method of making tissue sheets with textured woven fabrics having highlighted design elements

InactiveUS20060157210A1Enhances roll bulkIncrease in sizeNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringPulp and paper industry

A method of making tissue sheets is disclosed in which three-dimensional woven papermaking fabrics, such as throughdrying fabrics, are provided with woven highlight areas, particularly woven highlight areas containing design elements which make the design elements more visible in the resulting tissue product.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Polyamide-polyhenylene ether resin composition

The present invention can provide a resin composition characterized by comprising (A) a polyamide, (B) a polyphenylene ether, (C) an elastomer, and (D) a phosphorus compound selected from among phosphoric acids, phosphorous acids, hypophosphorous acids, metal phosphates, metal phosphites, metal hypophosphites, and phosphoric esters, wherein the resin composition contains 1 to 35 ppm of phosphorus element based on 100% by mass of the sum of the components (A) to (D), and can provide a molding composed of the resin composition. The resin composition can be used in a wide range of fields such as electrical / electronic parts, OA parts, vehicle parts and mechanical parts. In particular, the resin composition can be suitably used for exterior parts of automobiles or the like where large moldings are required.

Owner:ASAHI KASEI CHEM CORP

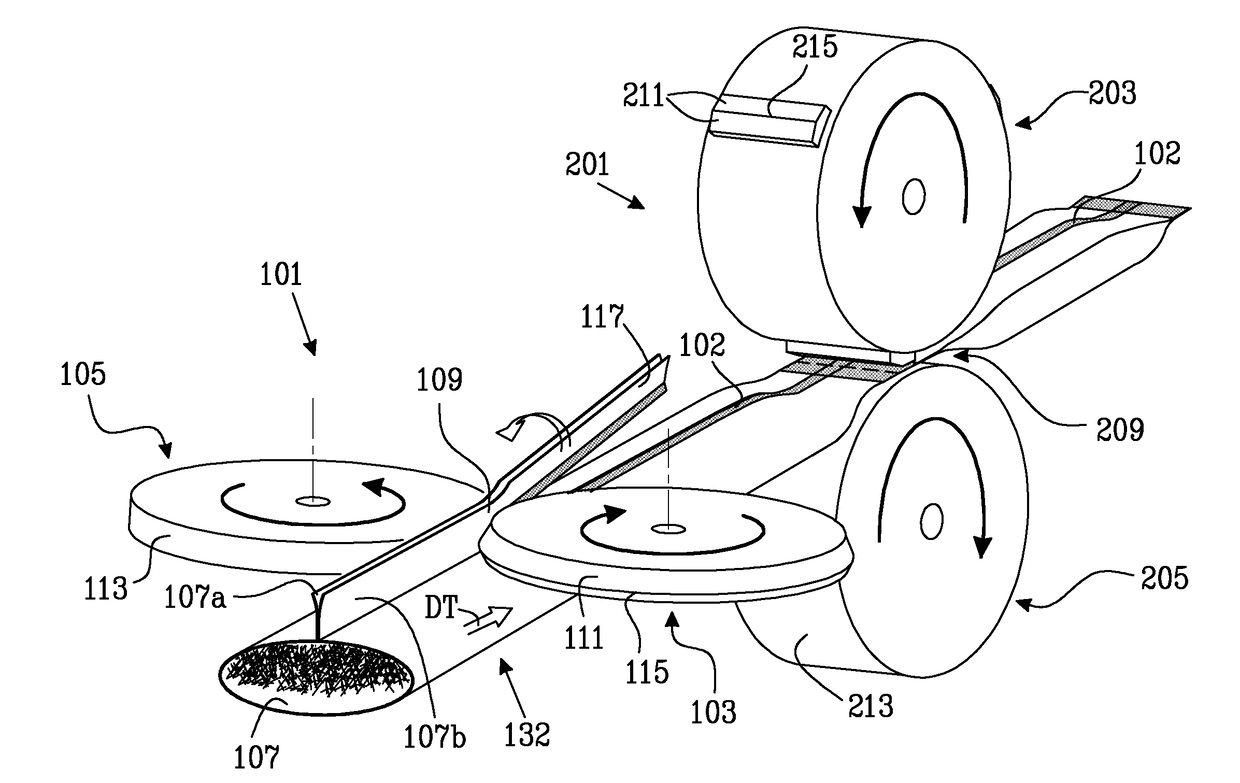

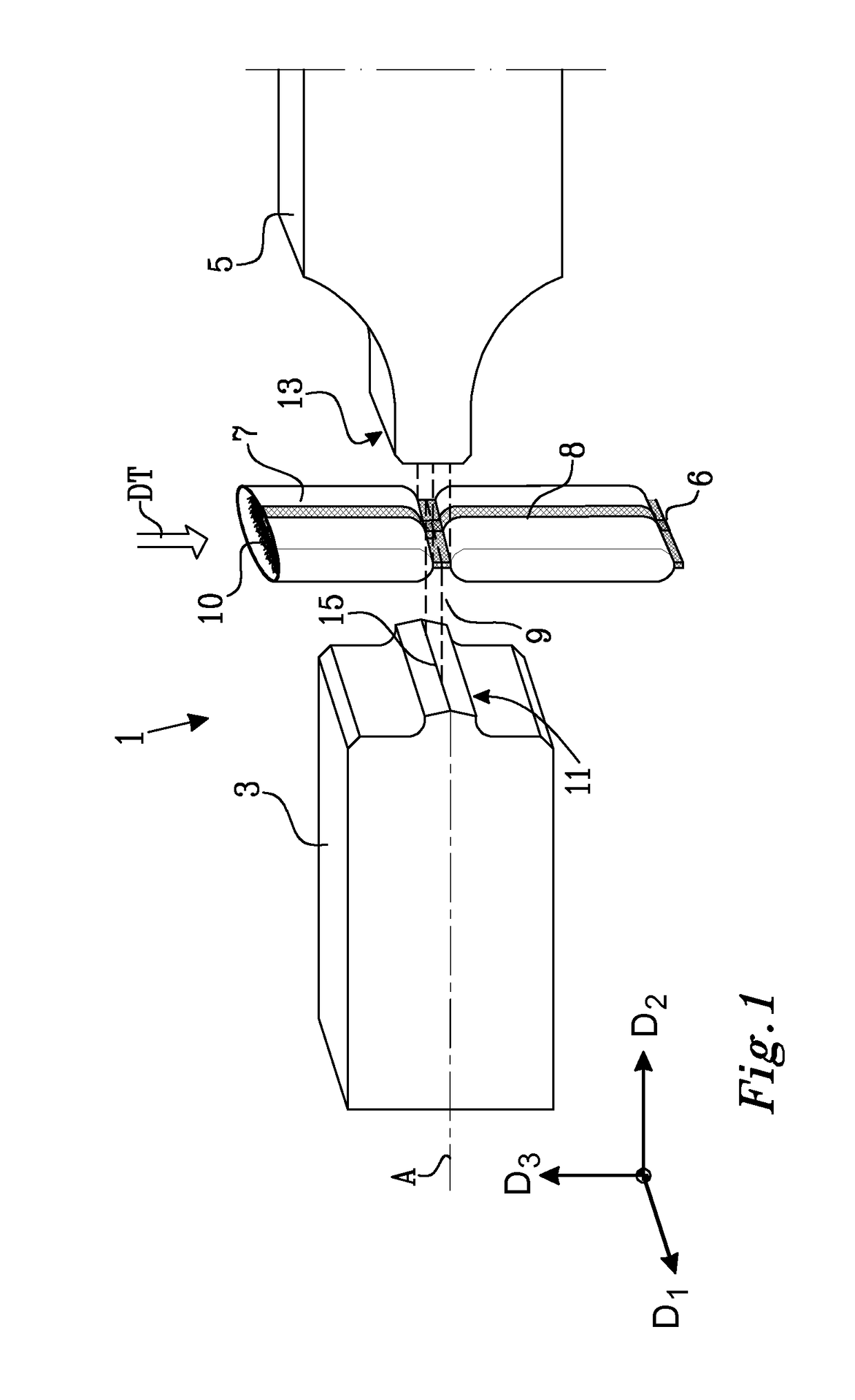

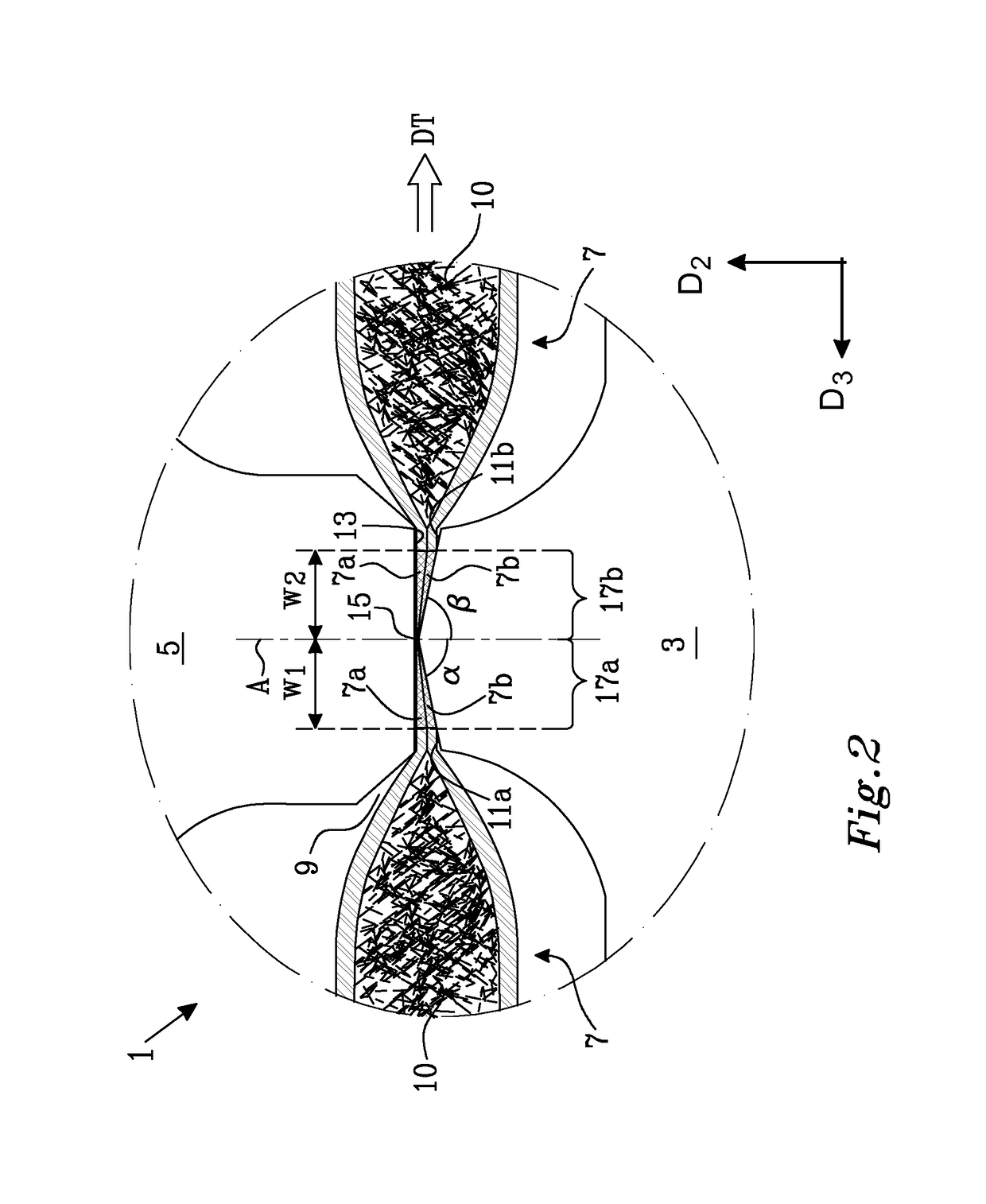

An oral pouched snuff product

ActiveUS20180255826A1Stay hydratedQuantity minimizationTobacco treatmentTobacco devicesFilling materialsEngineering

The present disclosure relates to an oral pouched snuff product comprising a filling material and a saliva-permeable pouch enclosing the filling material, the oral pouched snuff product having a longitudinal direction and a transverse direction perpendicular to said longitudinal direction, the saliva-permeable pouch comprising a first elongated seal and a second elongated seal, each of said first and second elongated seals having a seal length extending along the transverse direction of the product and a seal width extending along the longitudinal direction of the product, wherein the seal width of said at least one elongated seal being equal to or less than 2 mm, such as within the range of from 0.1 mm to 2 mm or from 0.1 mm to 1 mm or from 0.1 mm to 0.5 mm. There is also provided a container having a base and a detachable lid together providing an interior container space in which a plurality of these oral pouched snuff products is contained.

Owner:SWEDISH MATCH NORTH EURO

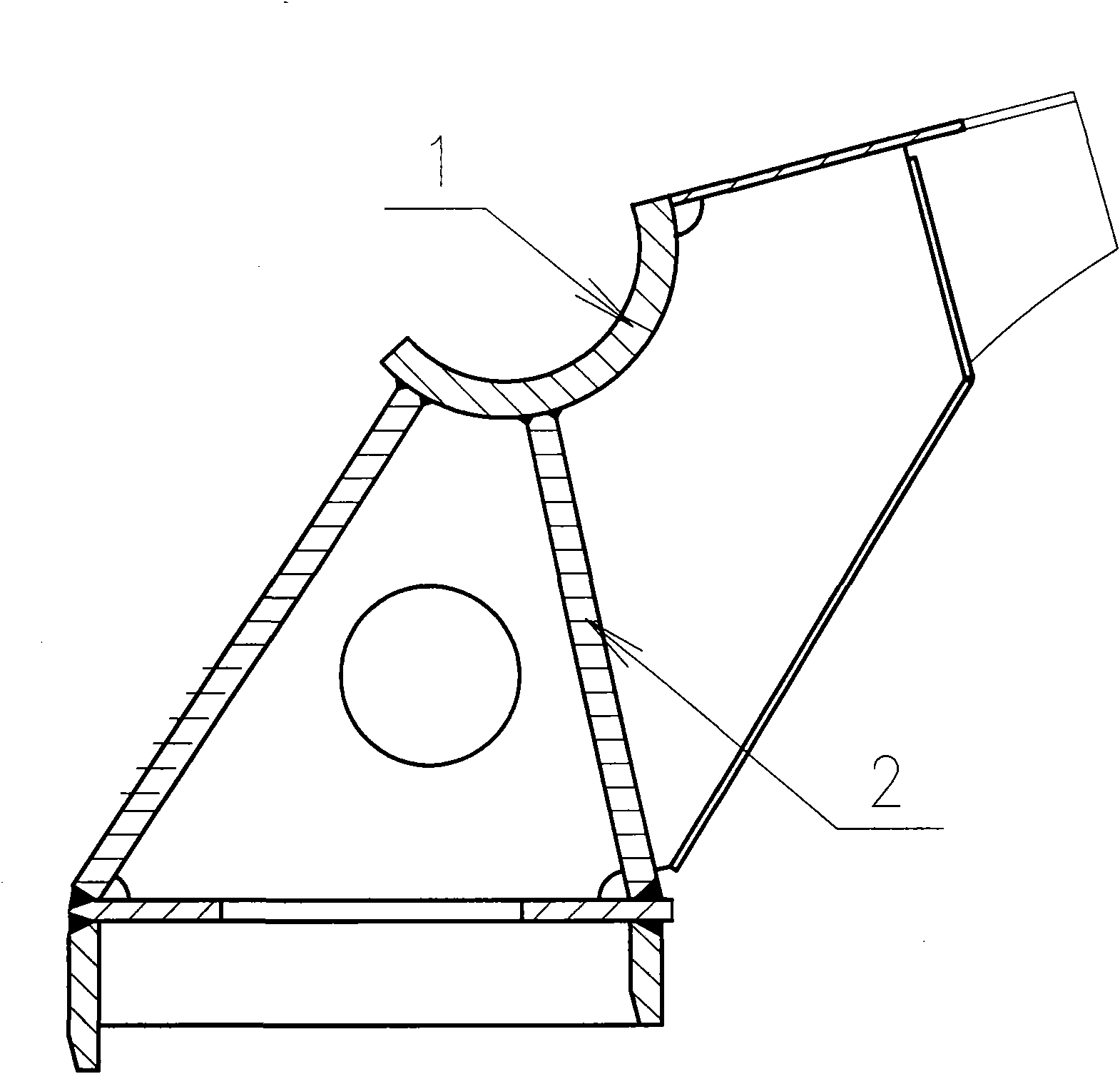

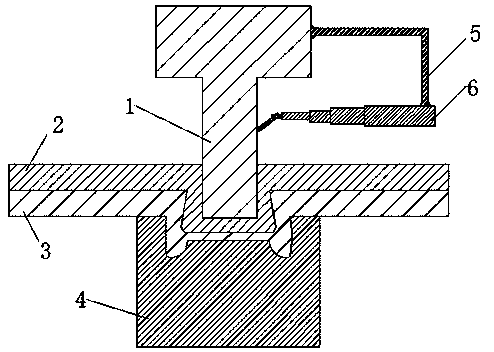

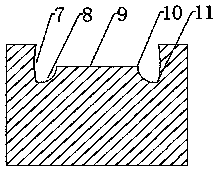

Ultrasonic-assisted impressing connecting device and method

ActiveCN107695215AReduced downforceReduce resistanceNon-electric welding apparatusUltrasonic assistedMaterial Crack

The invention relates to an ultrasonic-assisted impressing connecting device and method and belongs to the technical field of impressing connecting. The ultrasonic-assisted impressing connecting device comprises a punch pin, a lower riveting die, a curved frame, a telescopic rod and an ultrasonic generator. The upper end of the punch pin is connected with an external impressing system. One end ofthe curved frame is welded to the sidewall of the punch pin, and the other end of the curved frame is welded to the tail end of the telescopic rod. Two ribbed plates are welded to the top end of the telescopic rod. The two ribbed plates are both provided with corresponding threaded through holes. The ultrasonic generator is mounted at the top end of the telescopic rod. By adopting the ultrasonic-assisted impressing connecting device, the problems that a difficult-to-deform material cracks, is difficult to deform, has gaps and poor in metallurgical bonding during impressing connecting are solved; the problems that light beam reflection and plasma shielding effects during aluminum laser welding through an aluminum alloy welding method, and the defects of cracks, pores welding joints softenedand the like occur easily are solved; the hold-down resistance borne by the punch pin is reduced by applying ultrasonic vibration. Mechanical-metallurgical combined connection is realized. The mechanical properties of joints are improved.

Owner:KUNMING UNIV OF SCI & TECH

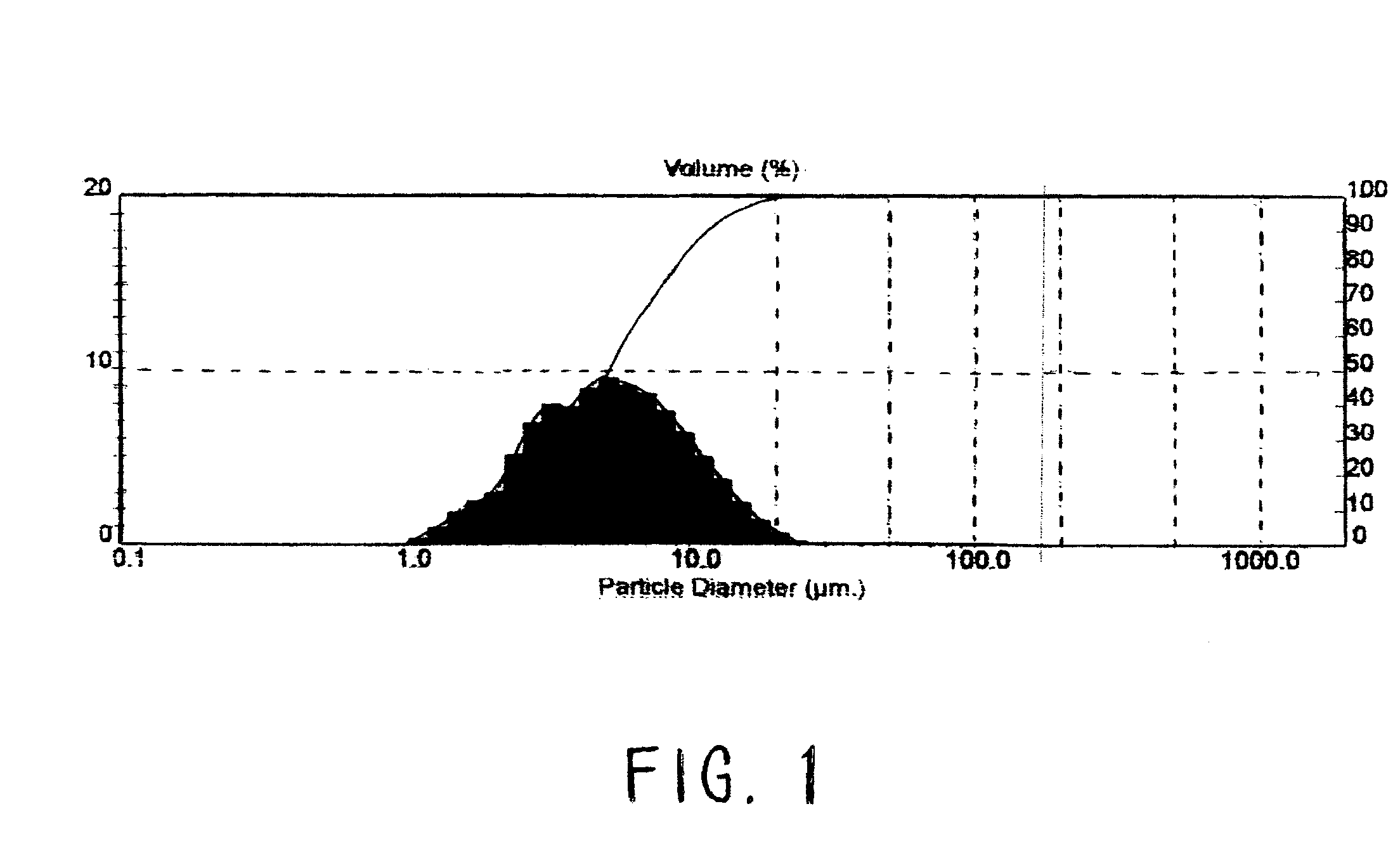

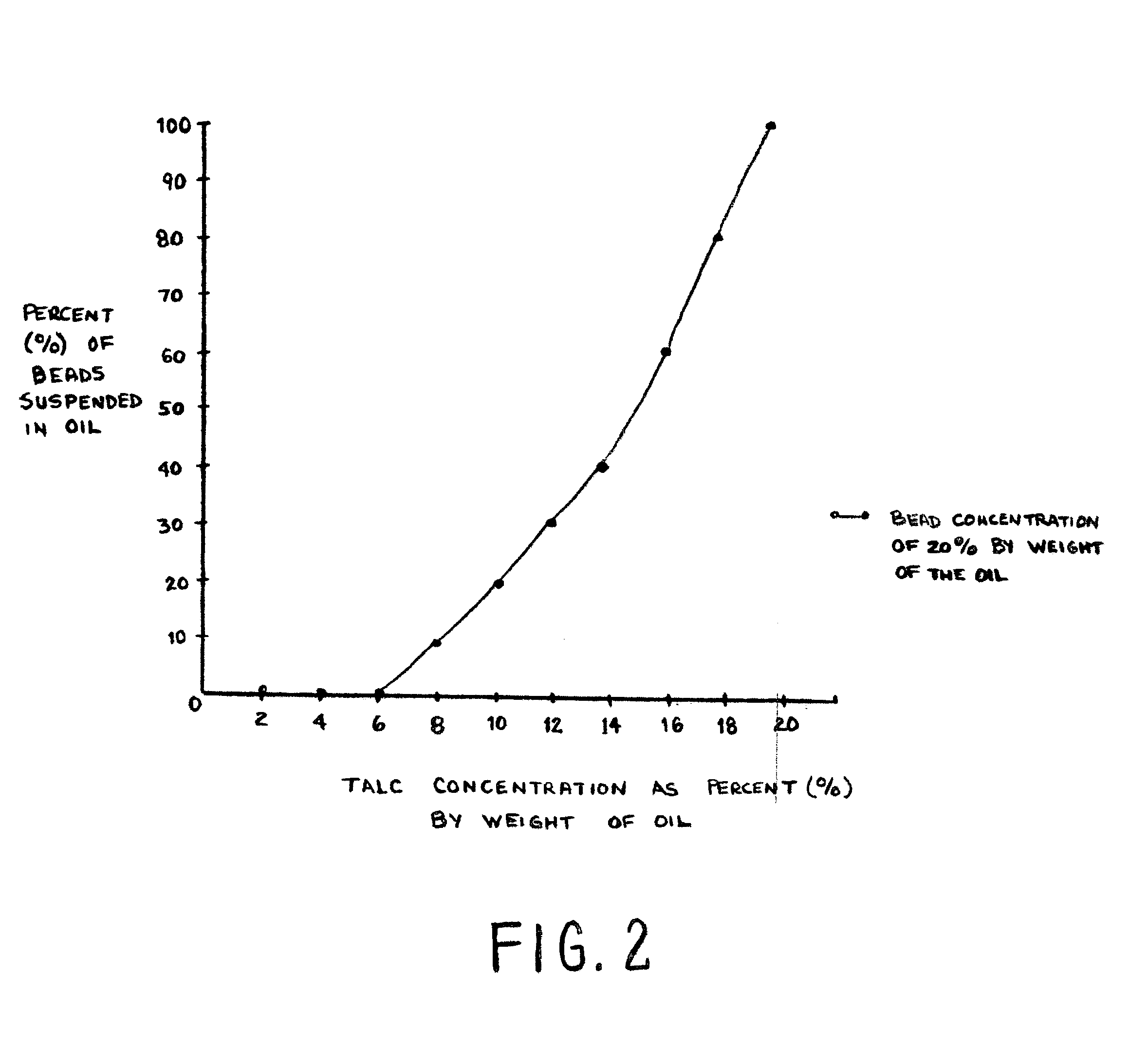

Drilling fluid additive system containing graphite and carrier

InactiveUS20040138067A1Superior pore throat sealerLowers HTHP/dynamic filtrateFlushingDrilling compositionPolypropylene glycolGraphite

A drilling fluid additive system is provided wherein the system is manufactured by a method comprised of admixing graphite with at least one carrier such as a polypropylene glycol or oil to create a suspended mixture, and allowing the surface of the graphite to be pre-wet with the carrier prior to adding the mixture to a drilling fluid; and then further admixing hydrophilic clay, a pH controller, a fluid loss controller, and at least one dispersant to said drilling fluid additive system.

Owner:MI

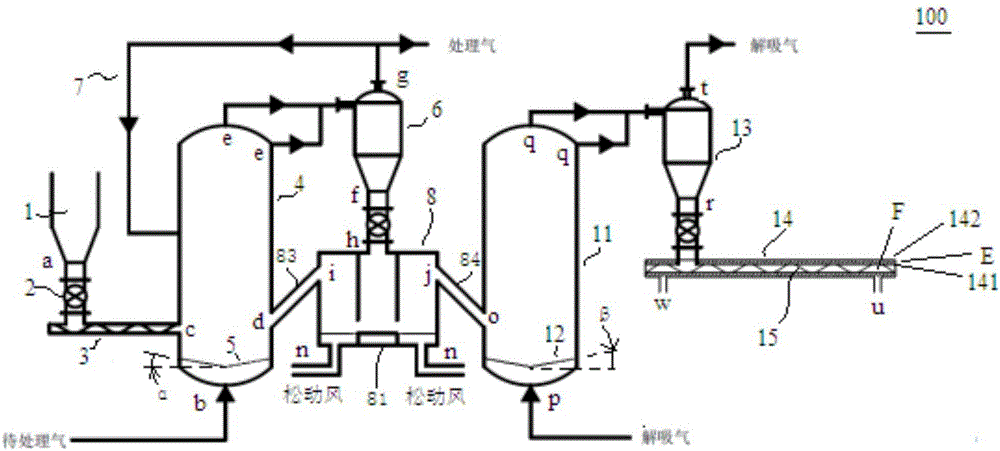

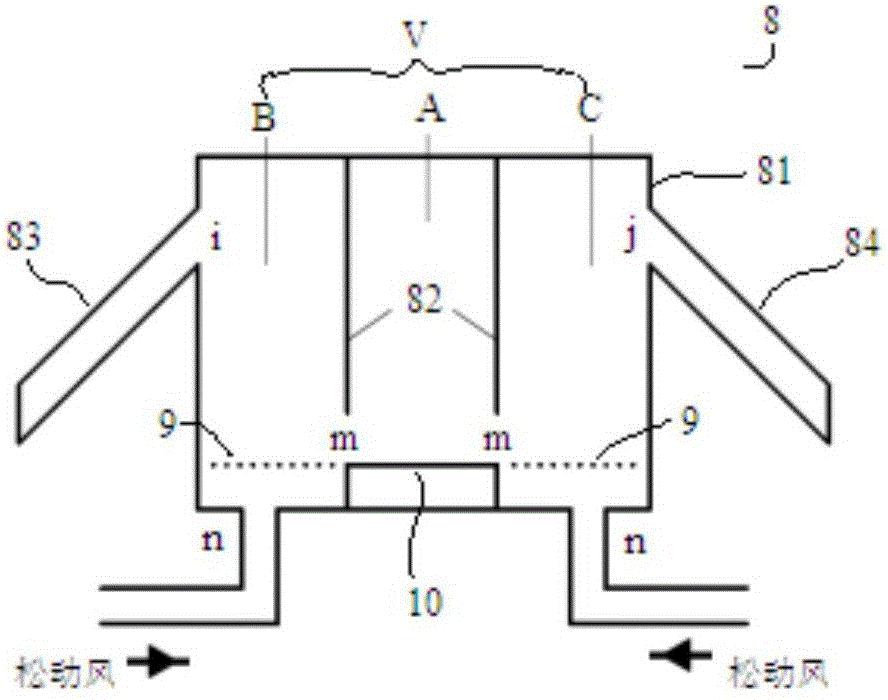

Fluidized bed gas adsorption-desorption system and treatment method thereof

ActiveCN105903314AHigh gas velocityReduce labor intensityDispersed particle separationGas solidFluidized bed

The invention discloses a fluidized bed gas adsorption-desorption system and a treatment method thereof. The system includes an adsorption fluidized bed, a regeneration fluidized bed, an adsorption side gas-solid separator, a desorption side gas-solid separator and a feed divider. The adsorption fluidized bed has an adsorbent inlet, a to-be-treated gas inlet, a first returned material inlet and a first mixture outlet. The adsorption side gas-solid separator is connected to the first mixture outlet. The regeneration fluidized bed has a second returned material inlet, a desorption gas inlet, and a second mixture outlet. The desorption side gas-solid separator is connected to the second mixture outlet. The feed divider has a feed inlet, an adsorption side divided material outlet and a desorption side divided material outlet, the feed inlet is connected to an adsorption side solid-discharge port of the adsorption side gas-solid separator, the adsorption side divided material outlet is connected to the first returned material inlet, and the desorption side divided material outlet is connected to the second returned material inlet. The system provided by the invention is easy to operate, the system treatment ability is enhanced, and the adsorption efficiency, adsorption economical efficiency and operation continuity are improved.

Owner:SHENWU TECH GRP CO LTD

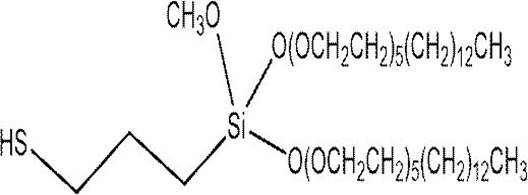

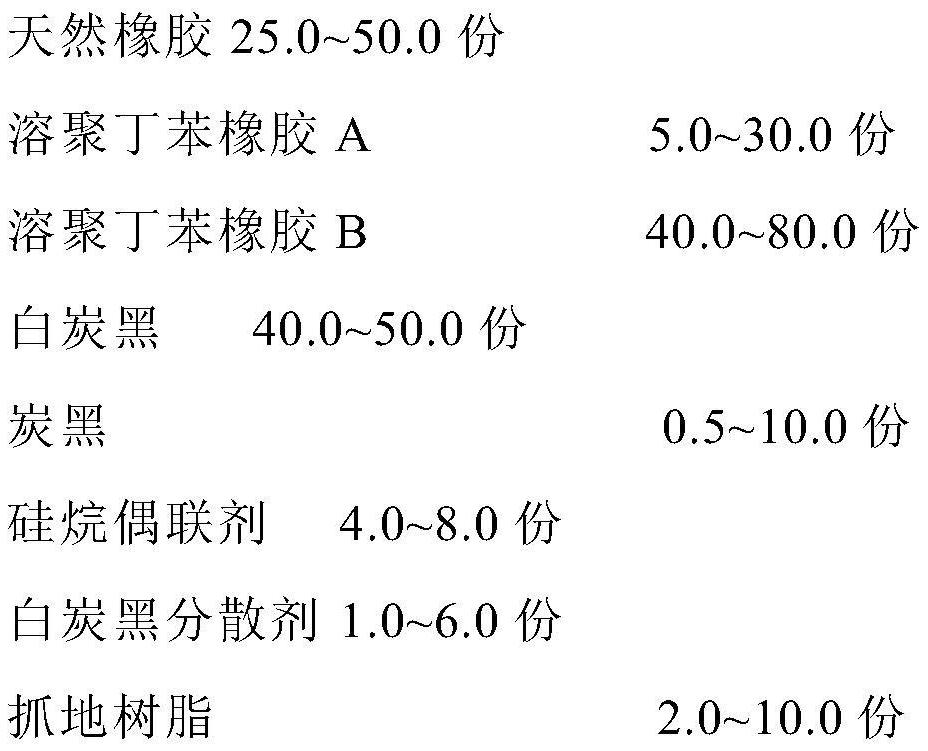

A kind of low filling high performance tire tread compound and tire

ActiveCN109251379BHigh strengthImprove thermal stabilitySpecial tyresRolling resistance optimizationRubber materialPolymer science

The invention belongs to the field of manufacturing of rubber tires, and relates to a low-filling high-performance tire tread rubber material and a tire, wherein the tire tread rubber material is formed by mixing the following raw materials by weight: 25.0-50.0 parts of natural rubber, 5.0-30.0 parts of a solution polymerized styrene-butadiene rubber A, 40.0-80.0 parts of a solution polymerized styrene-butadiene rubber B, 40.0-50.0 parts of white carbon black, 0.5-10.0 parts of carbon black, 4.0-10.0 parts of a silane coupling agent, 1.0-6.0 parts of a white carbon black dispersing agent, 2.0-10.0 parts of a road-holding resin, and 0.5-3.0 parts of an anti-reversion agent. According to the present invention, the tire tread rubber material uses a large amount of the natural rubber, is lessfilled with the filler, such that the high tensile strength and the high elongation at break can be achieved, the requirements of low rolling resistance and high wet gripping of the tire can be met, and the rolling resistance and the wet road-holding ability can meet the Class B stipulated by the EU Tire Labeling Regulation.

Owner:ZHONGCE RUBBER GRP CO LTD

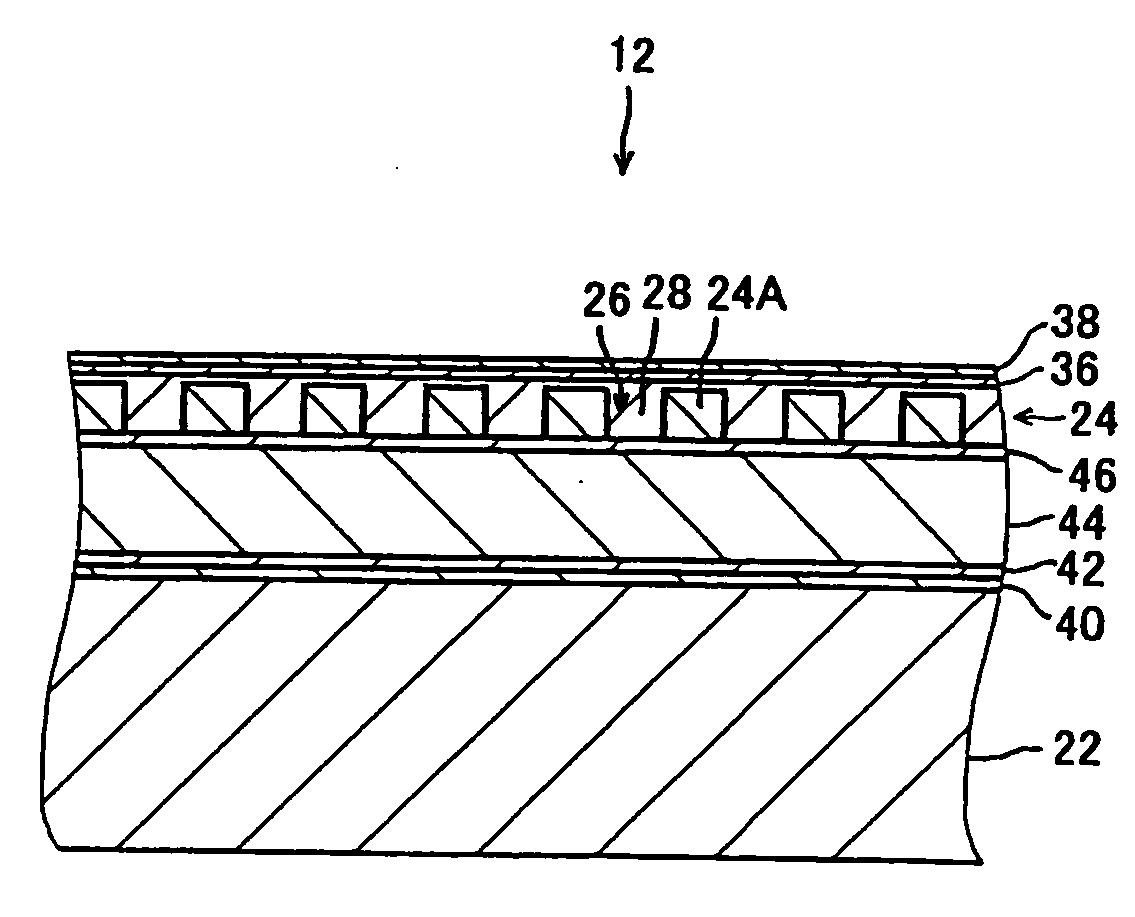

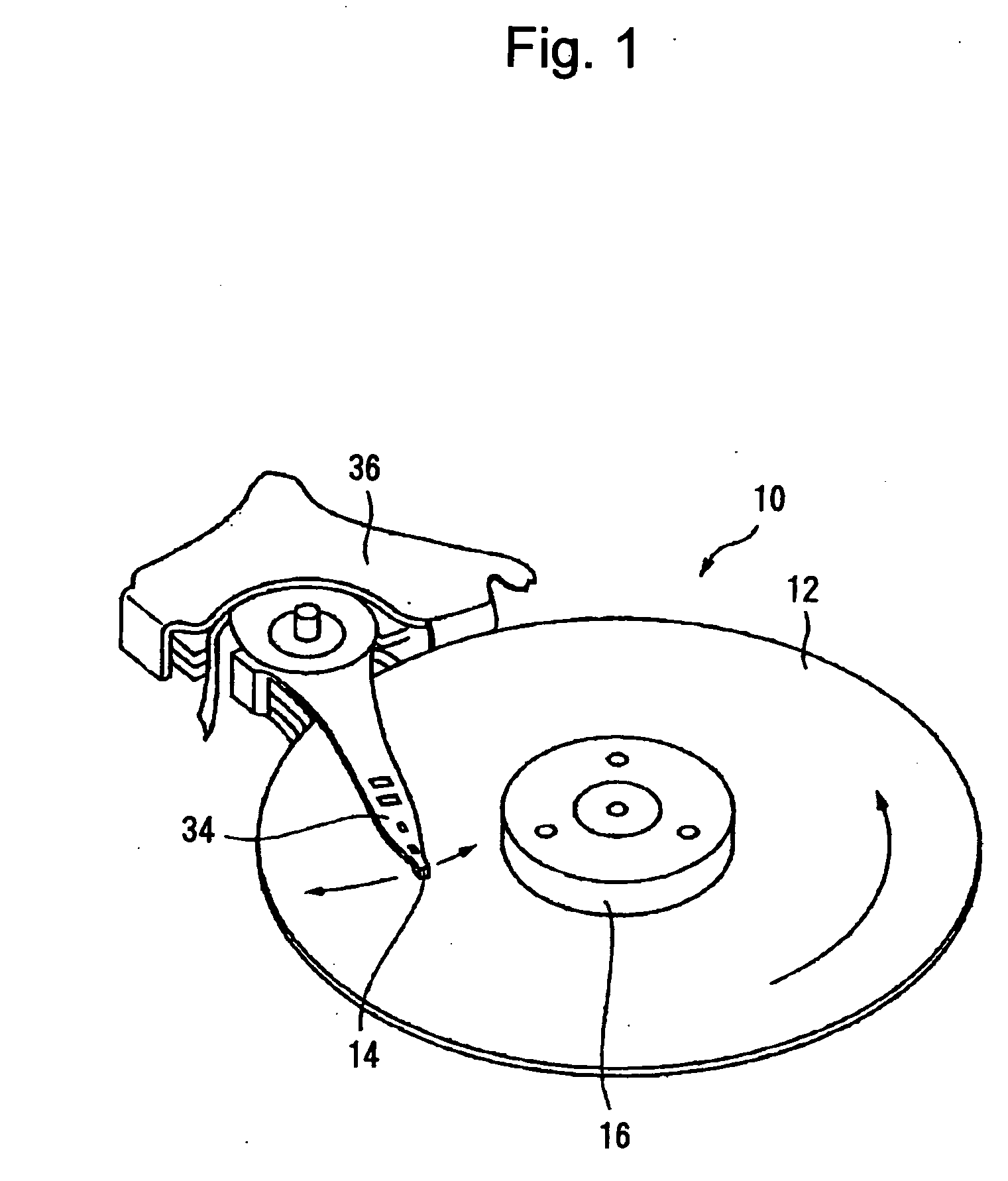

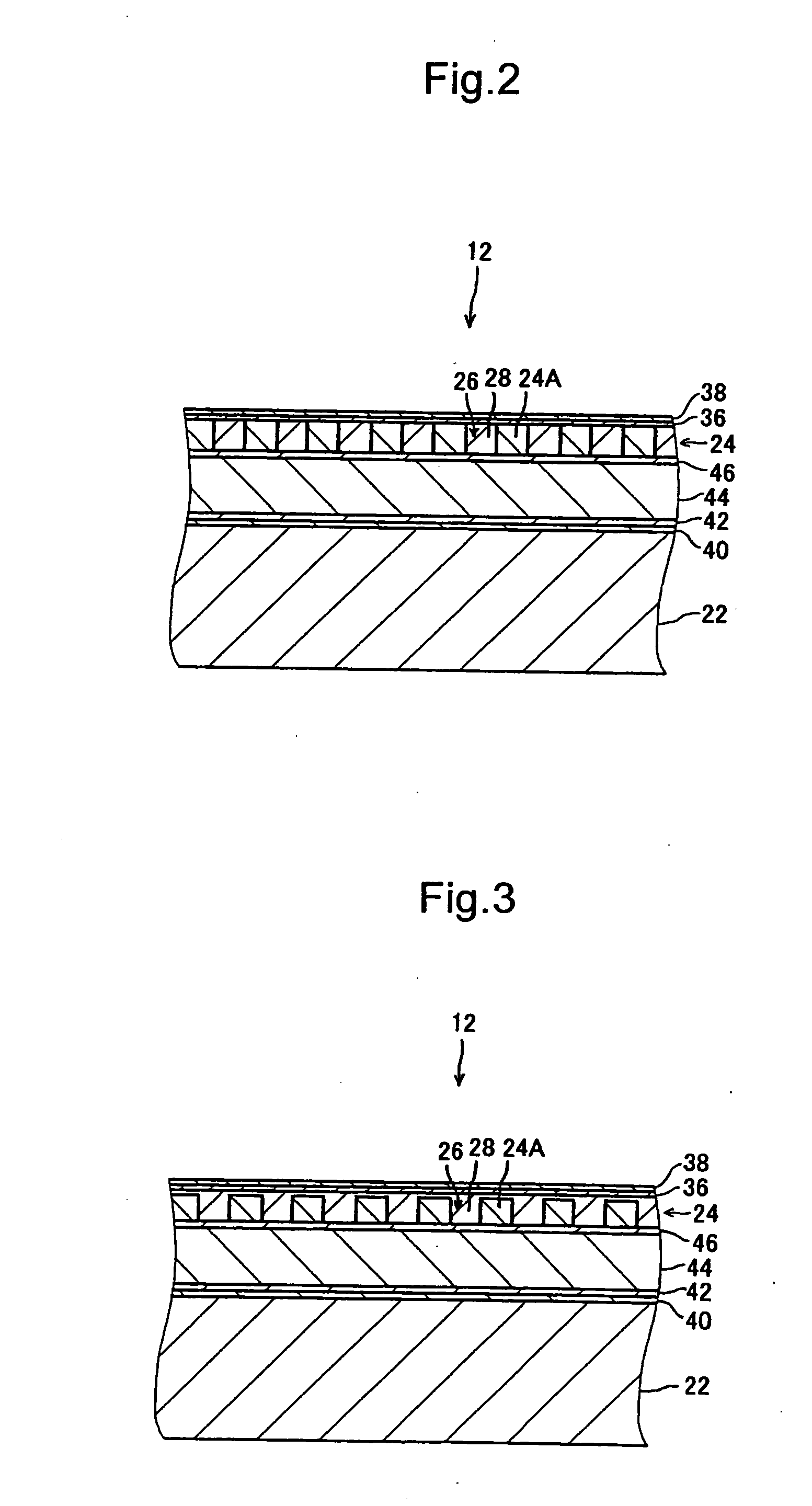

Magnetic recording medium and magnetic recording/reproducing device

InactiveUS20060188751A1Favorable recording/reproducing characteristicImprove reliabilityDifferent record carrier formsRecord information storageFilling materialsEngineering

A magnetic recording medium is provided that includes a recording layer having recording elements formed as convex portions and a filling material filled within the concave portions between the recording elements. The medium is highly reliable and has a surface less liable to damages when a magnetic head contacts the surface, so that good recording / reproducing characteristics are ensured. The magnetic recording medium includes a recording layer formed in a predetermined concavo-convex pattern over a substrate and having recording elements formed as convex portions in the concavo-convex pattern and a filling material filled within the concave portions between the recording elements. The filling material is substantially composed of Si and O, and the ratio of the number of O atoms to the number of Si atoms is equal to or more than 1.5 and less than 2.

Owner:TDK CORPARATION

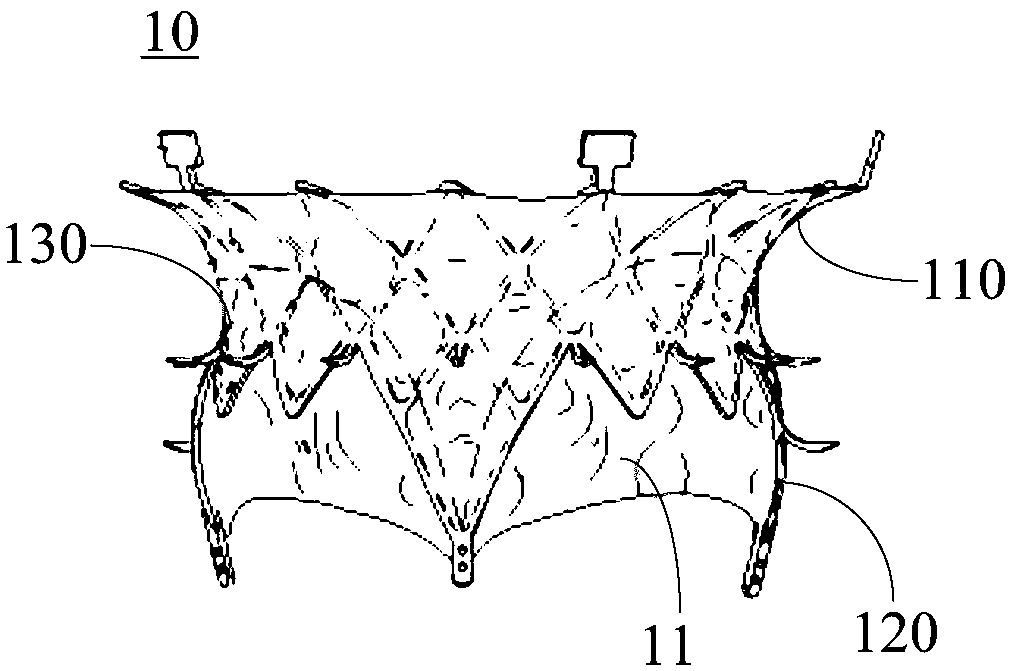

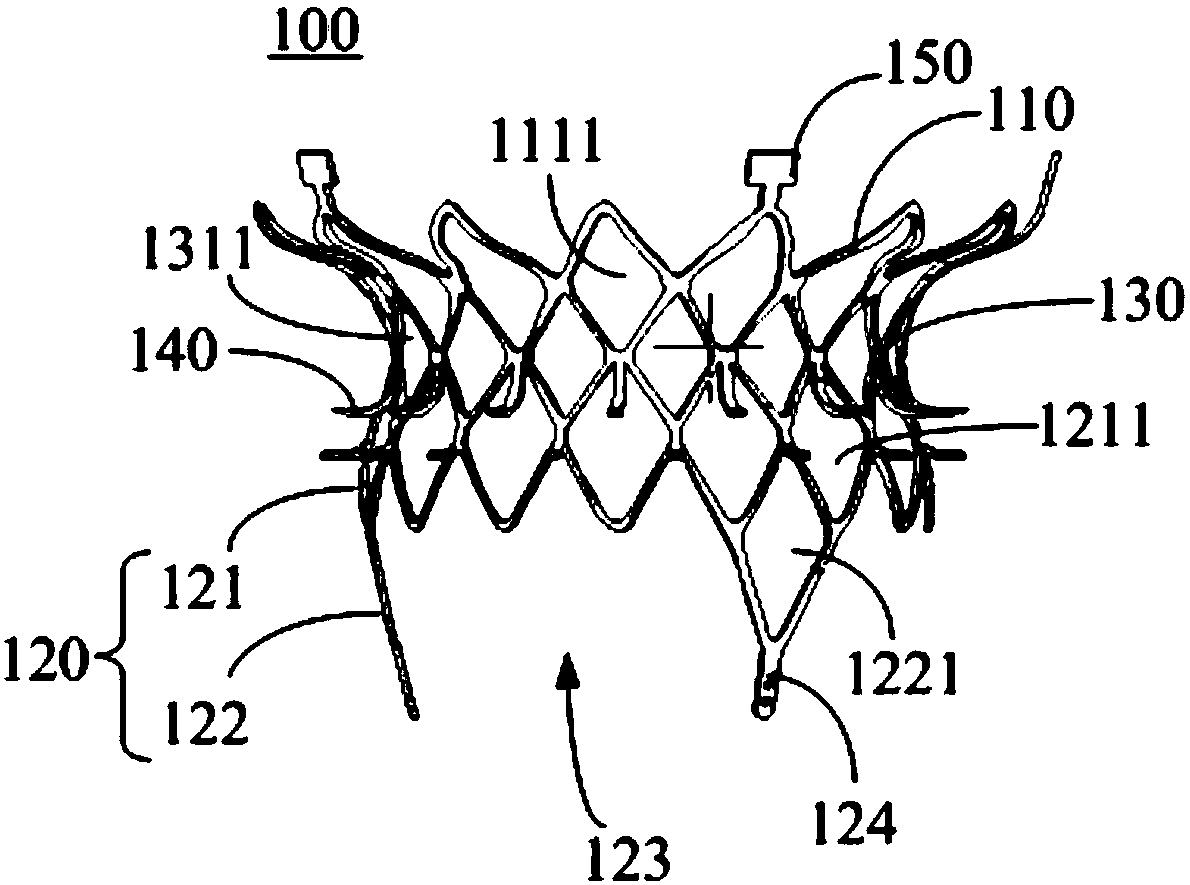

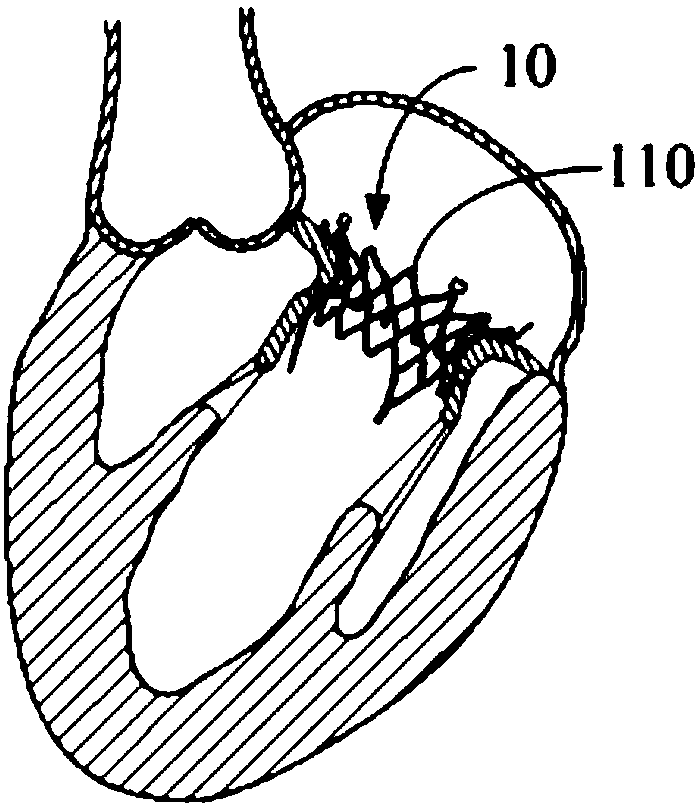

Cardiac valve prosthesis and bracket thereof

The invention relates to a cardiac valve prosthesis and a bracket thereof. The bracket comprises an inflow tract, an outflow tract and a transitional region located between the inflow tract and the outflow tract in the axis direction, wherein the outflow tract comprises a ring structure and at least two evagination structures formed through extending in the axis direction; the at least two evagination structures are respectively connected with one end away from the transitional region, of the ring structure; and a vacant region is restricted between every two adjacent evagination structures. The cardiac valve prosthesis and the bracket thereof disclosed by the invention can be suitable for various valve replacement surgeries at the same time, damage risk of the surgeries on patients and the surgery cost can be reduced, and the influence of the bracket on the cardiac function can be minimized.

Owner:SHANGHAI MICROPORT CARDIOFLOW MEDTECH CO LTD

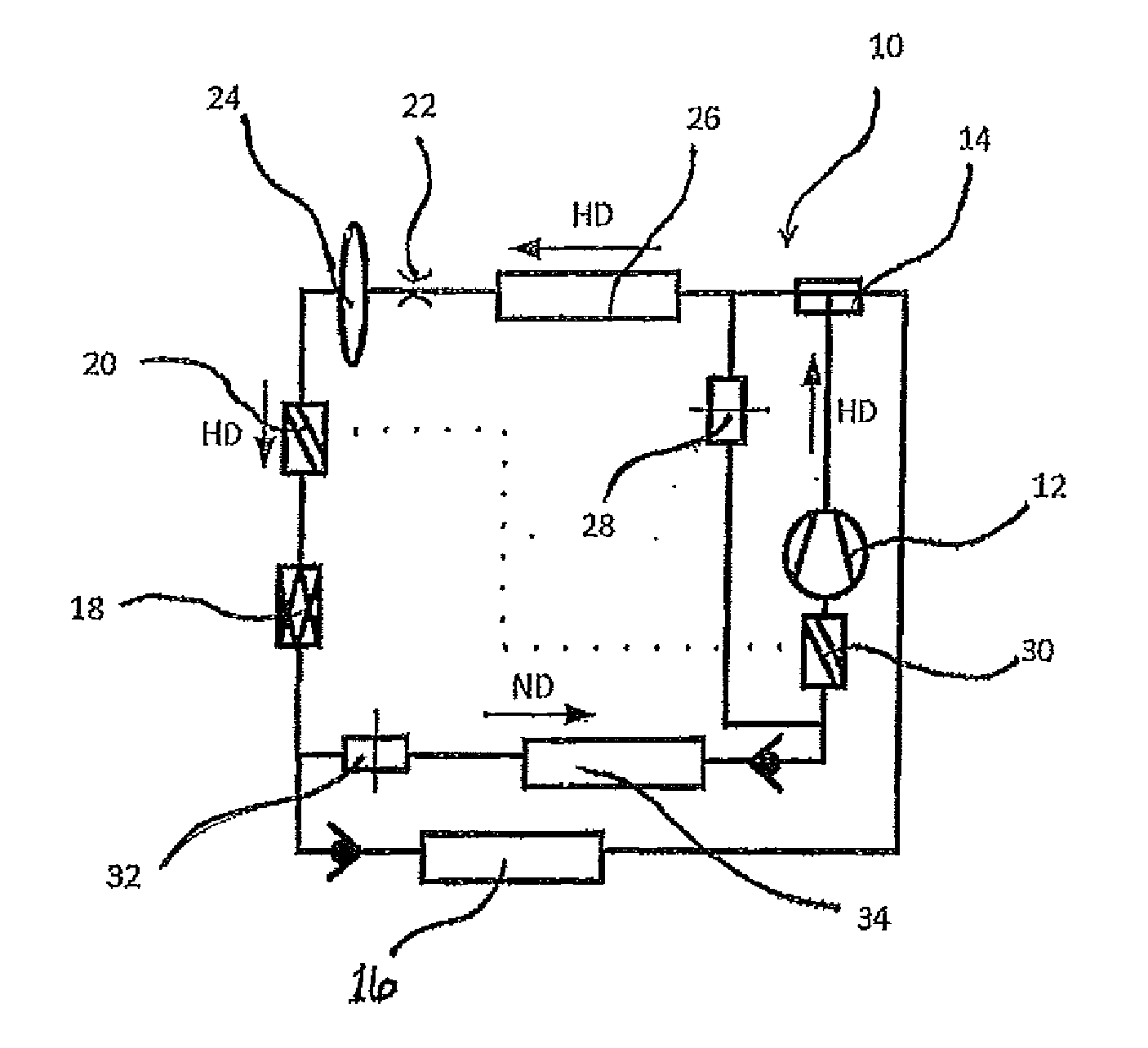

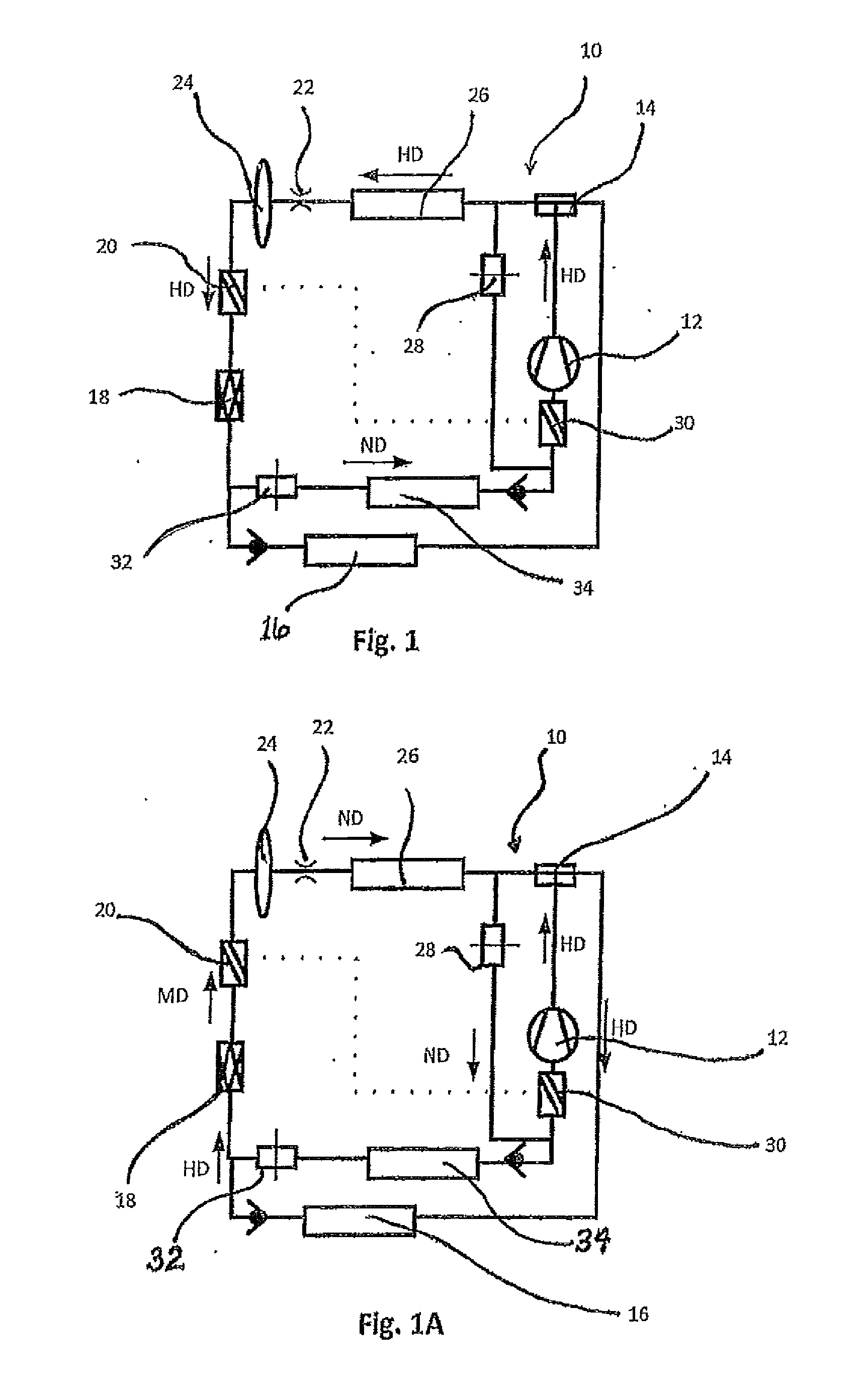

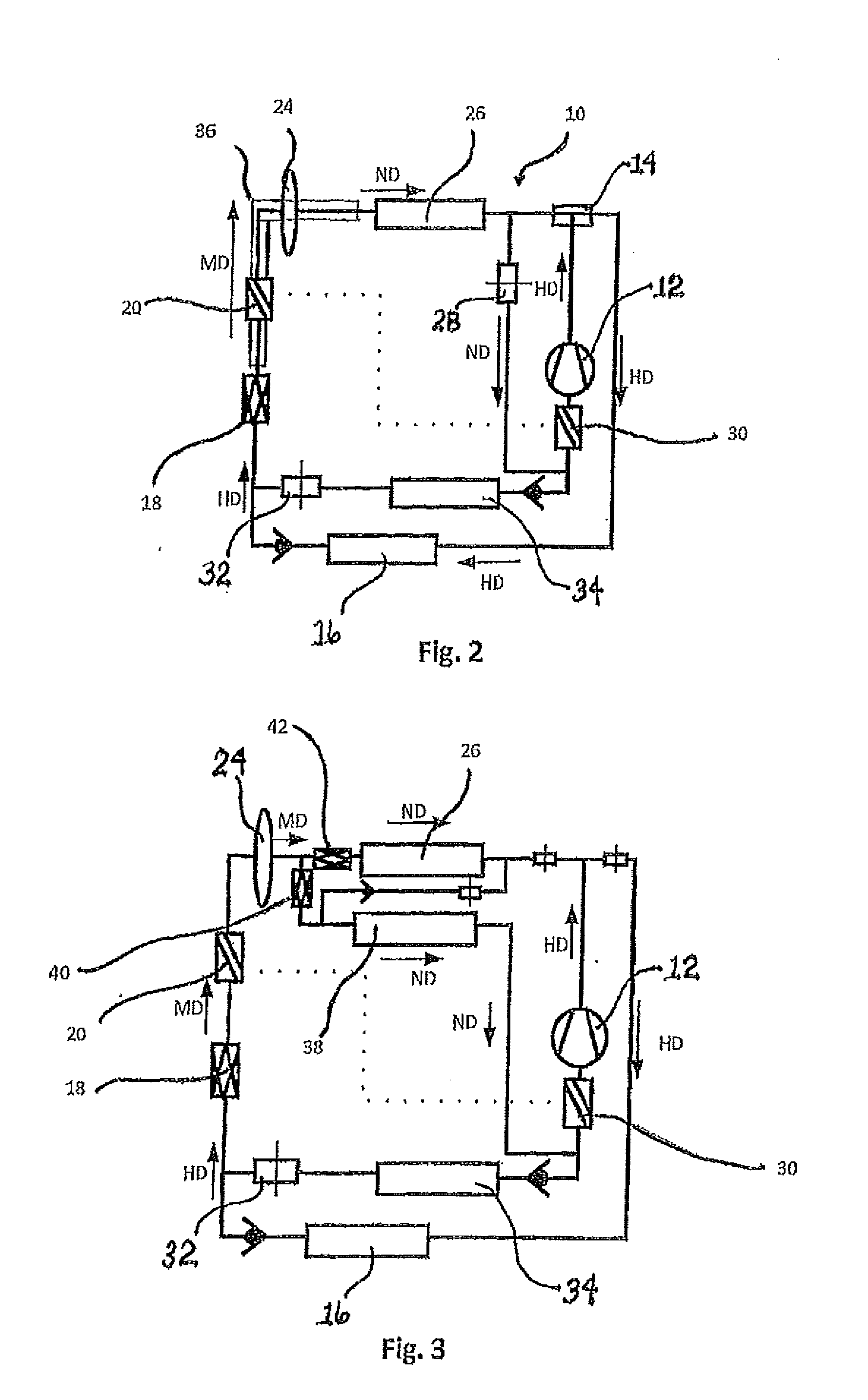

Refrigerant circuit

InactiveUS20130031922A1Reduce fillingReduce needMechanical apparatusHeat pumpsInterior spaceHigh-pressure area

The invention includes a refrigerant circuit for a cooling operation and a heat pump operation. The refrigerant circuit has a high pressure area and a low pressure area, including at least one heat source / heat sink, a compressor, an expansion device, at least one thermal interior space module, and an internal heat exchanger. The internal heat exchanger has a high pressure side part and a low pressure side part, wherein the high pressure side part is disposed between the expansion device and the heat source / heat sink. The invention also includes at least one metering device through which the high pressure side part of the internal heat exchanger is operable during the heat pump operation at a medium pressure level intermediate a pressure level in the high pressure area and a pressure level in the low pressure area of the refrigerant circuit.

Owner:HANON SYST

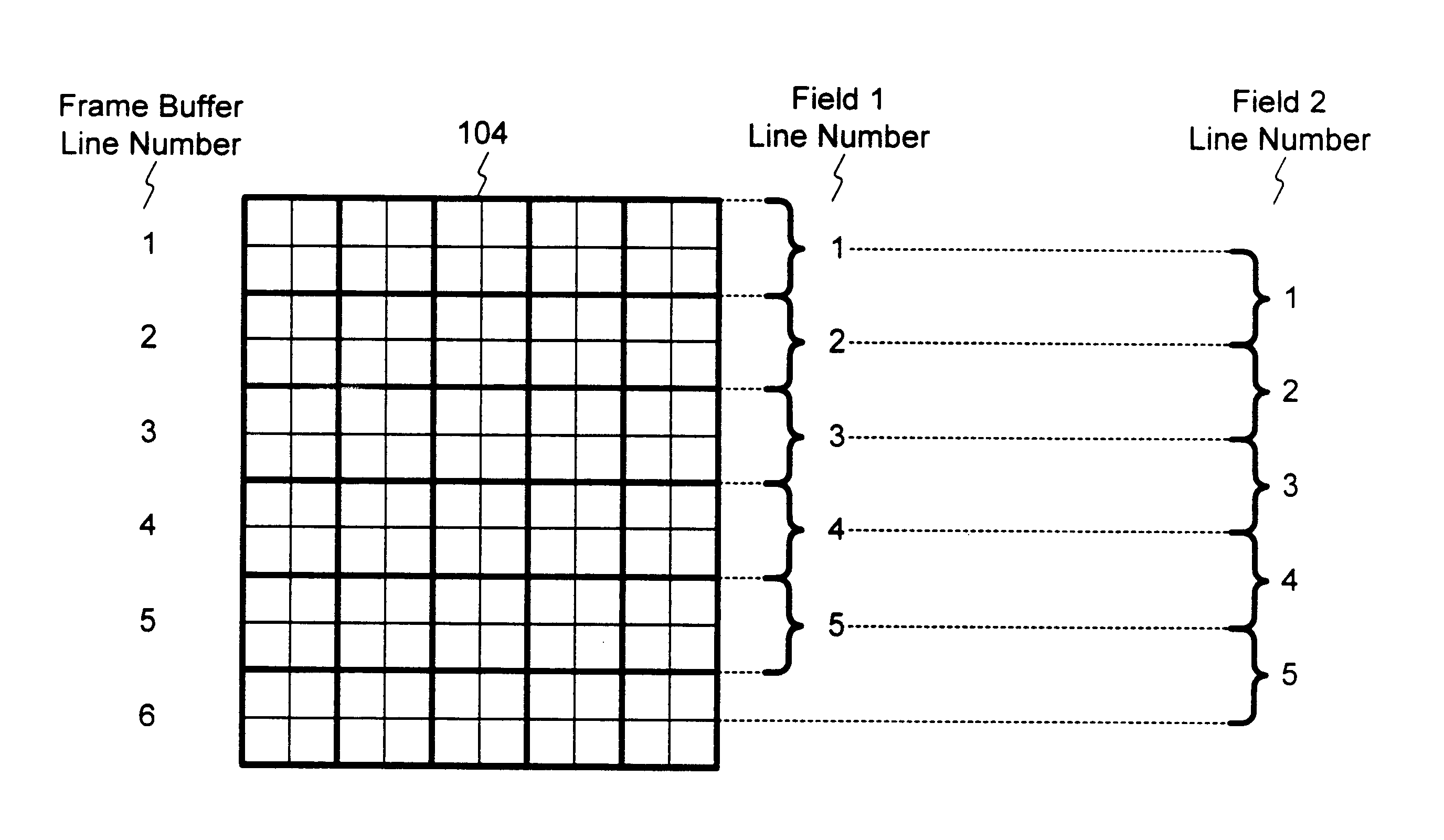

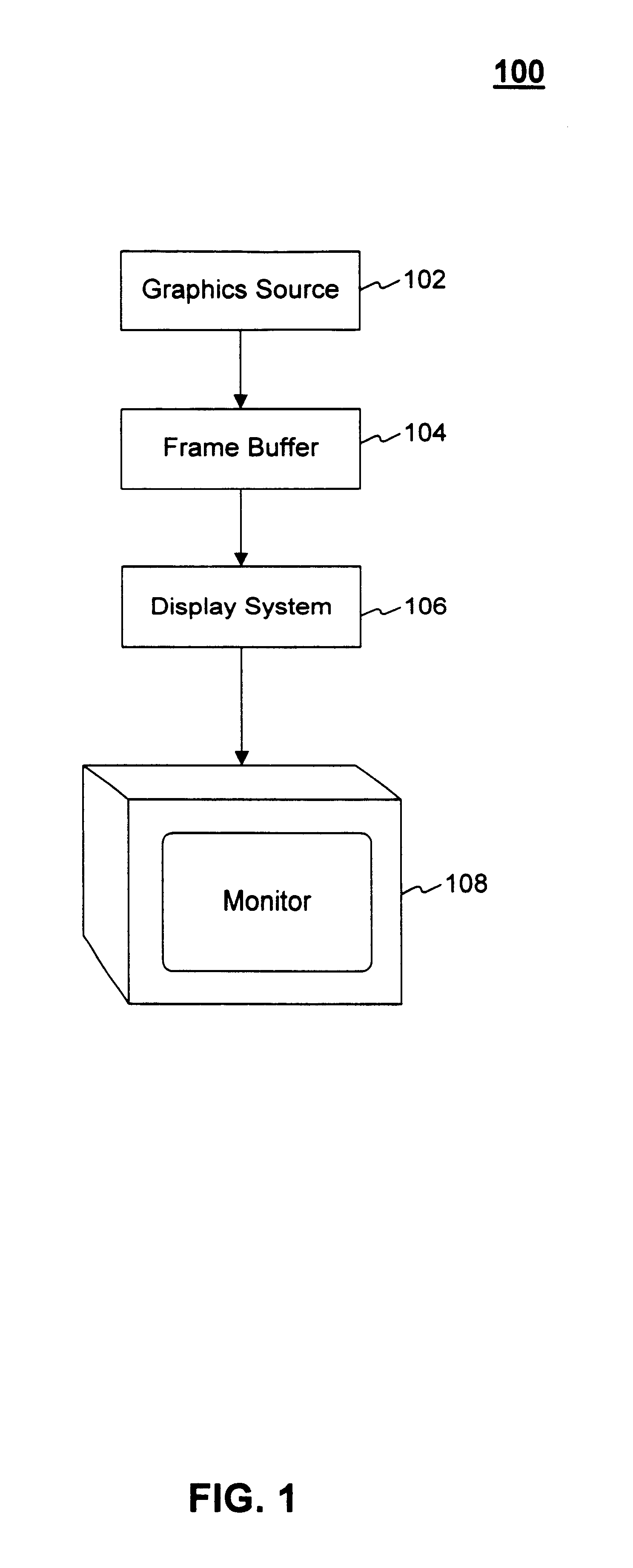

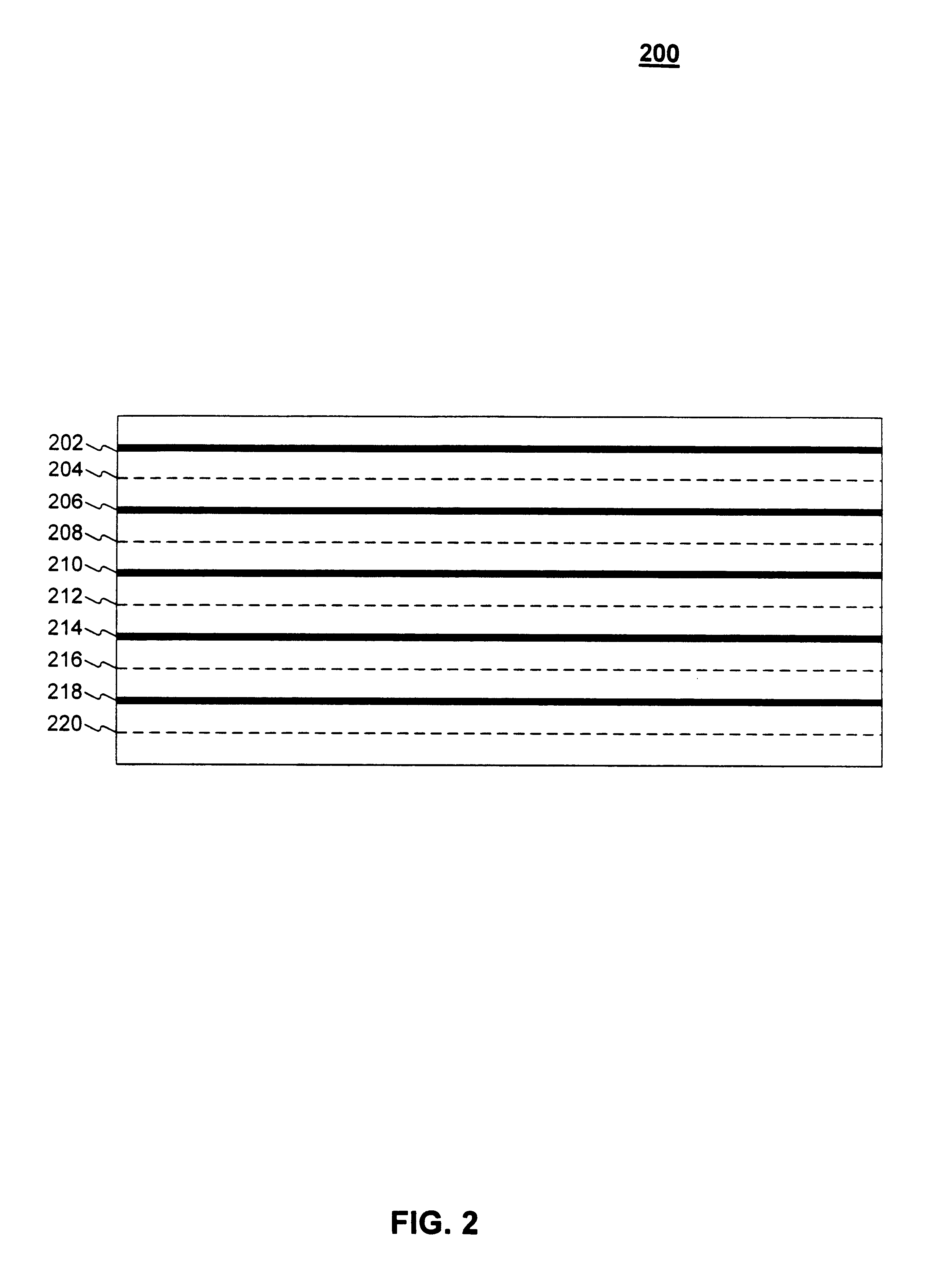

Reducing fill and improving quality of interlaced displays using multi-sampling

InactiveUS6870543B1Reduce fillImprove qualityTelevision with combined individual color signalPicture reproducers using cathode ray tubesDisplay deviceComputer program

The present invention provides a system, method and computer program product for reducing fill and improving quality of interlaced displays using multi-sampling. In an embodiment of the invention, a frame buffer for a interlaced display is filled. Initially, a first multi-sample of the first line of the first field is calculated. The bottom sub-pixels of the first multi-sample are the top sub-pixels of a multi-sample of the first line of the second field. The first multi-sample is written into the frame buffer. Then, a second multi-sample of the second line of the first field is calculated. The top sub-pixels of the second multi-sample are the bottom sub-pixels of a multi-sample of the first line of the second field. Also, the bottom sub-pixels of the second multi-sample are the top sub-pixels of the second line of the second field. The second multi-sample is written into the frame buffer. A multi-sample for each subsequent line of the first field is calculated in this manner and written into the frame buffer. Then, a last multi-sample consisting of the bottom sub-pixels of a full multi-sample of the last line of the second field is calculated. The last multi-sample is also written into the frame buffer.

Owner:MICROSOFT TECH LICENSING LLC

Pressure sensing system and method

ActiveUS20130158426A1Reduce riskEvaluating efficacyStrain gaugePerson identificationNasal cavityPressure sense

A device for detecting rhinitis in a human subject includes an inflatable member that, in a first state, is configured to be introducible into the nasal cavity of the human subject; an expansion member configured to expand the inflatable member to an expanded, second state within the nasal cavity such that the inflatable member abuts against the tissue of the nasal cavity, and a pressure sensing member configured to measure a pressure exerted on the inflatable member by the tissue of the nasal cavity. A system for detecting rhinitis and methods for analyzing tissue response pressure, detecting rhinitis, predicting the efficacy of a planned rhinitis treatment and evaluating the efficacy of a previous rhinitis treatment are provided.

Owner:CHORDATE MEDICAL AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com