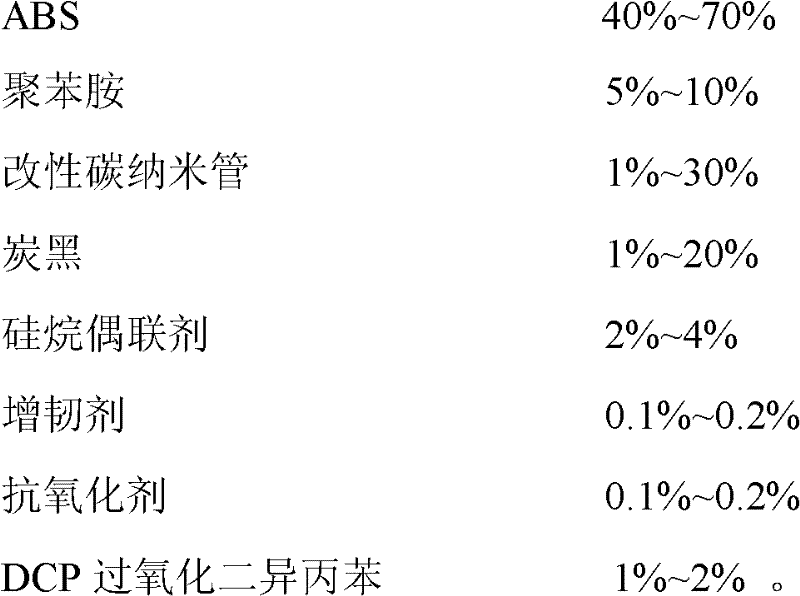

A new type of antistatic ABS resin material and preparation method thereof

An ABS resin, antistatic technology, applied in the field of new antistatic ABS resin material and its preparation, can solve the problems of difficult control of material resistivity, poor processing performance of composite materials, reduced mechanical properties of materials, etc., and achieve permanent antistatic properties. , The effect of good processability and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0031] (1) Pretreatment of raw materials: put carbon nanotubes (multi-walled carbon nanotubes, diameter 10-30nm, tube length 1-2μm, provided by Shenzhen Nanometer Port Co., Ltd.) in concentrated nitric acid with a volume ratio of 10:70 (analytical pure, Jiangxi Hongdu Biochemical Co., Ltd.) and concentrated sulfuric acid (analytical pure, Zhenjiang Yuanguang Chemical Co., Ltd.) mixed acid, ultrasonically oscillated for 4 to 5 hours, cooled, filtered, and the filtered filter cake was washed with distilled water to obtain Modified carbon nanotubes; raw material ABS resin (tensile strength is 40-60MPa, Charpy notched impact strength is 25-35kJ / m 2 Provided by Dow Chemical Company of the United States, brand name Caliber 201-10, melt index is 10g / 10min) dried at 80-90°C for 2-4h; carbon black (Cabot Company, BP800) was heated at 600-700°C for 1-2h , to remove surface organic matter, the carbon black has a specific surface area of 254m 2 / g, particle size 45μm;

[0032](2) Blen...

Embodiment 3~4

[0038] (1) Pretreatment of raw materials: put carbon nanotubes (multi-walled carbon nanotubes, 10-30nm in diameter, 1-2μm in length, provided by Shenzhen Nanometer Port Co., Ltd.) in concentrated nitric acid with a volume ratio of 20:60 (analytical pure, Jiangxi Hongdu Biochemical Co., Ltd.) and concentrated sulfuric acid (analytical pure, Zhenjiang Yuanguang Chemical Co., Ltd.) mixed acid, ultrasonically oscillated for 4 to 5 hours, cooled, filtered, and the filtered filter cake was washed with distilled water to obtain Modified carbon nanotubes; raw material ABS resin (tensile strength is 40-60MPa, Charpy notched impact strength is 25-35kJ / m 2 Provided by Dow Chemical Company of the United States, brand name Caliber 201-10, melt index is 10g / 10min) dried at 80-90°C for 2-4h; carbon black (Cabot Company, BP800) was heated at 600-700°C for 1-2h , to remove surface organic matter, the carbon black has a specific surface area of 254m 2 / g, particle size 45μm;

[0039] (2) Bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com