Patents

Literature

65results about How to "Preparation conditions are not harsh" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Room-temperature curing epoxy structural adhesive composition and preparation method thereof

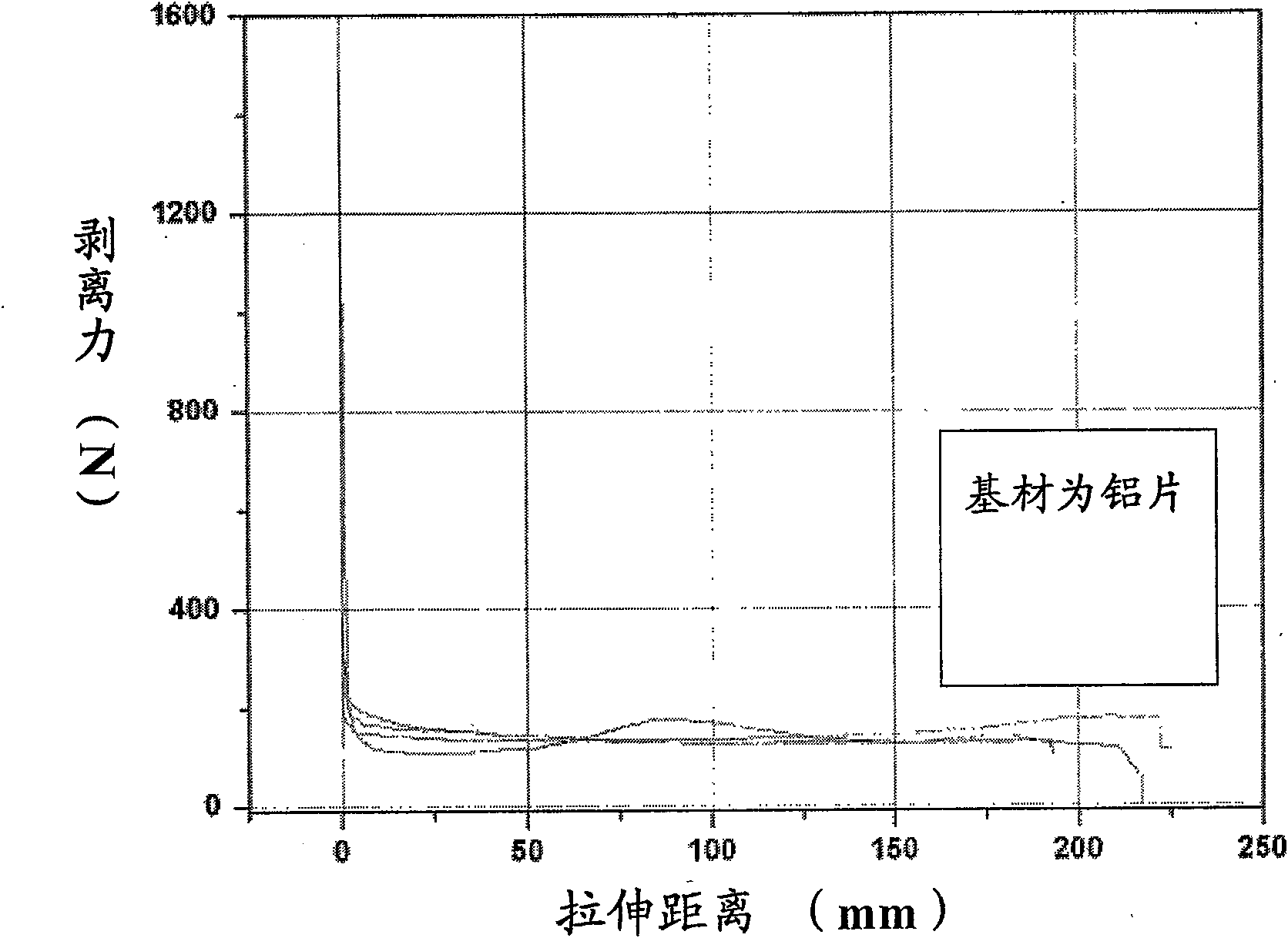

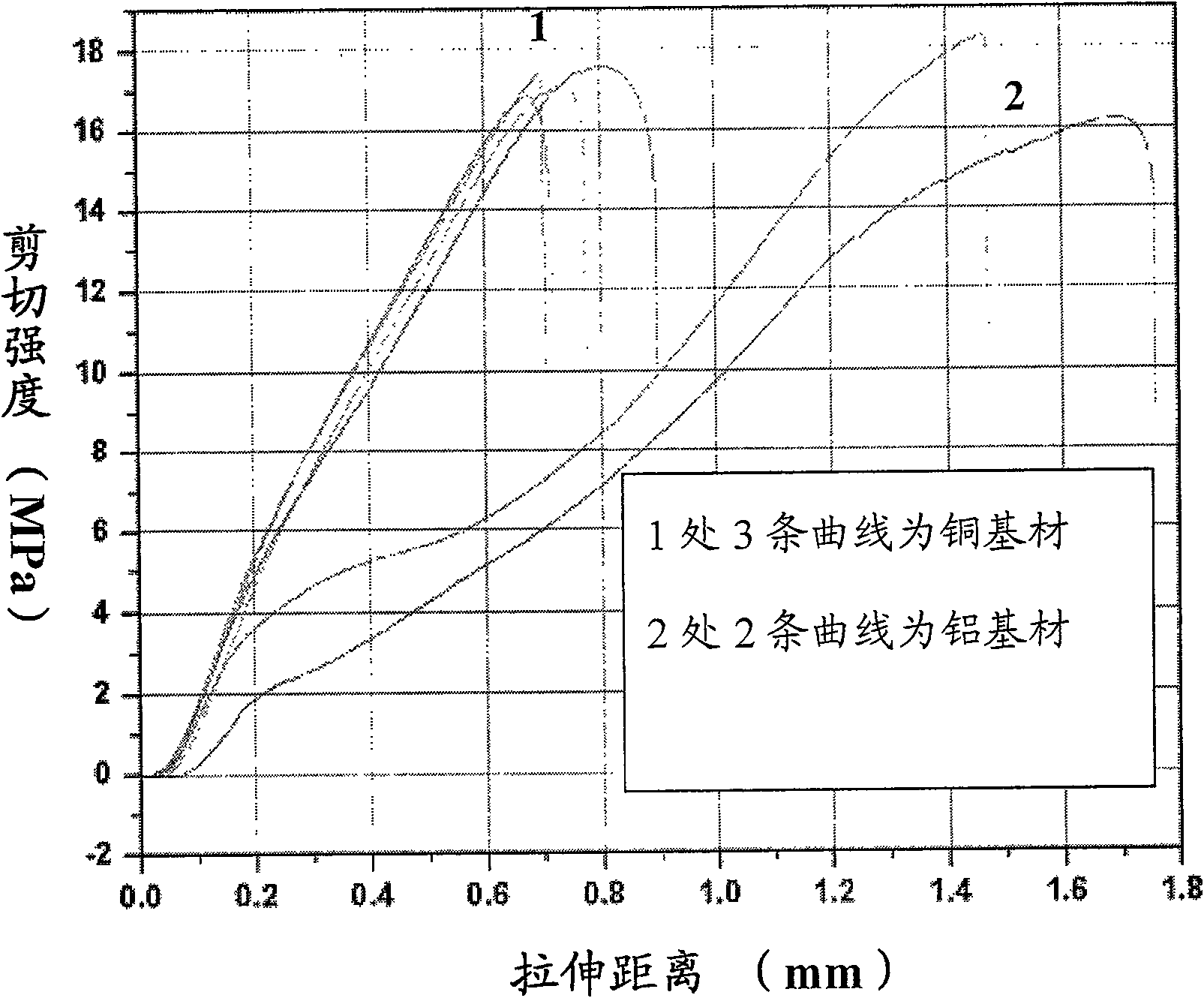

InactiveCN101818037AIncreased shear strengthHigh T-peel strengthEpoxy resin adhesivesNitrile rubberAdhesive

The invention relates to a room-temperature curing epoxy structural adhesive composition, which comprises a component A and a component B, wherein the component A comprises bisphenol A epoxy resin, toughness modified bisphenol A epoxy resin, silane coupling agent, thixotropic agent and colorant; and the component B comprises polyamide, polyether amine, a filler and a curing accelerator; the toughness modified bisphenol A epoxy resin is liquid nitrile rubber-modified bisphenol A epoxy resin and / or polymer-toughened bisphenol A epoxy resin with a nuclear shell structure; meanwhile, the invention also provides a method for preparing the room-temperature curing epoxy structural adhesive compositiion. The structural adhesive of the invention has the advantages of good toughness, strong high-temperature strength, short curing time, simple preparation method, and the like.

Owner:HENKELCHINAINVESTMENT

Method for preparing supported catalyst for preparing cyclopentanone with furfural through hydrogenation

ActiveCN103111299AHigh catalytic efficiencyReduce usageMetal/metal-oxides/metal-hydroxide catalystsPreparation from heterocyclic compoundsCatalytic effectAdipic acid

The invention discloses a method for preparing a supported catalyst for preparing cyclopentanone with furfural through hydrogenation. An activated carbon nano tube is adopted as a carrier, and loading metal comprises Ni, Cu, Co and Mg. The method for preparing the catalyst adopts a double dropwise adding and coprecipitation method, thus preparing the catalyst with high capacity and improving the catalytic effect of the catalyst; the preparation condition for the catalyst is easy to realize; and the range of raw materials for preparation is wide, precursors of all components are general and the raw materials for preparation can be selected flexibly according to market price. The catalyst prepared by the method has higher catalytic activity, the furfural conversion efficiency is above 96.6%, and the cyclopentanone selectivity is above 95.4%, so that the catalyst can be used for preparing the cyclpentanone with the furfural as a raw material, the problem that cyclopentanone self polymerization is easy to occur so as to generate a material with high boiling point in the process of generation of cyclopentanone by taking adipic acid as a raw material is solved, and the product yield is improved.

Owner:SOUTHEAST UNIV

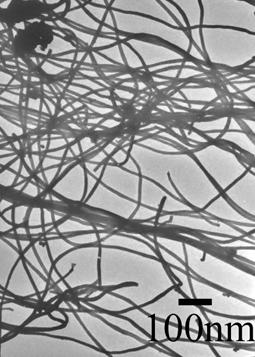

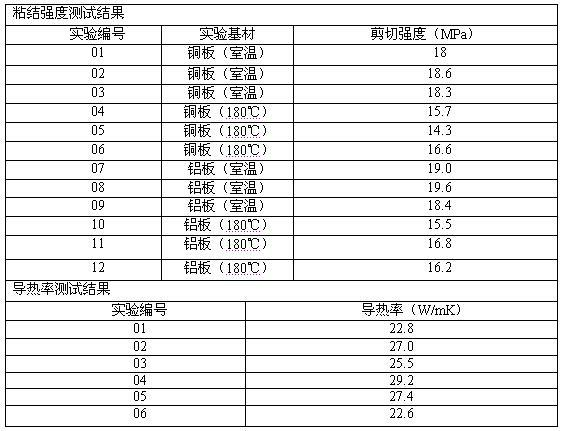

High-temperature resistant one-component isotropic conductive adhesive and preparation method thereof

InactiveCN101555393AEasy to prepareImprove controllabilityNon-macromolecular adhesive additivesEpoxy resin adhesivesGas phaseIsotropic conductive adhesives

The invention provides a high-temperature resistant one-component isotropic conductive adhesive and a preparation method thereof. The one-component isotropic conductive adhesive capable of resisting the high temperature of 180 DEG C for a long time is prepared by adding silver nano-wire as the conductive filler to an epoxy resin matrix and adding core-shell structure toughening epoxy resin and poly-functional epoxy resin as modifiers. The conductive adhesive comprises the following components by the mass percentage: 10% to 15% of matrix epoxy resin, 62% to 65% of silver nano-wire, 3.5% to 5.5% of poly-functional epoxy resin, 6% to 10% of core-shell structure toughening epoxy resin, 0.4% to 0.6% of gas-phase silicon dioxide, 0.6% to 1.0% of toughening diluting agent, 0.3% to 0.4% of coupling agent, 9% to 15% of curing agent and 0.1% to 0.2% of curing accelerator. The invention has the advantages of simple preparation method, good controllability, high material availability and mild preparation condition.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

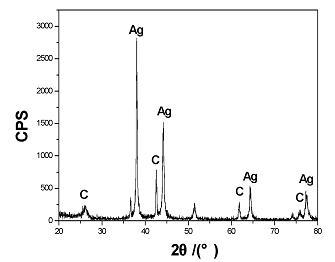

Silver-plated carbon nanotube heat-conducting adhesive and preparation method thereof

InactiveCN102191003AImprove corrosion resistanceLow priceNon-macromolecular adhesive additivesEpoxy resin adhesivesSilver plateNanowire

The invention relates to a heat-conducting adhesive, particularly a silver-plated carbon nanotube heat-conducting adhesive and a preparation method thereof. One-dimensional silver-plated carbon nanotubes are used as a heat-conducting filler of the heat-conducting adhesive to fully take the advantage of the fiber structure of the nanowire, so that a heat-conducting network can be well formed in the resin matrix of the heat-conducting adhesive. The composite heat-conducting adhesive has the advantages of low price, simple technique and simple formation process, can well satisfy the requirements for electronic and electric materials; and the excellent corrosion resistance of the silver-plated carbon nanotubes can greatly enhance the ageing resistance of the electric-conducting adhesive.

Owner:CHANGZHOU HE RUN NEW MATERIAL TECH

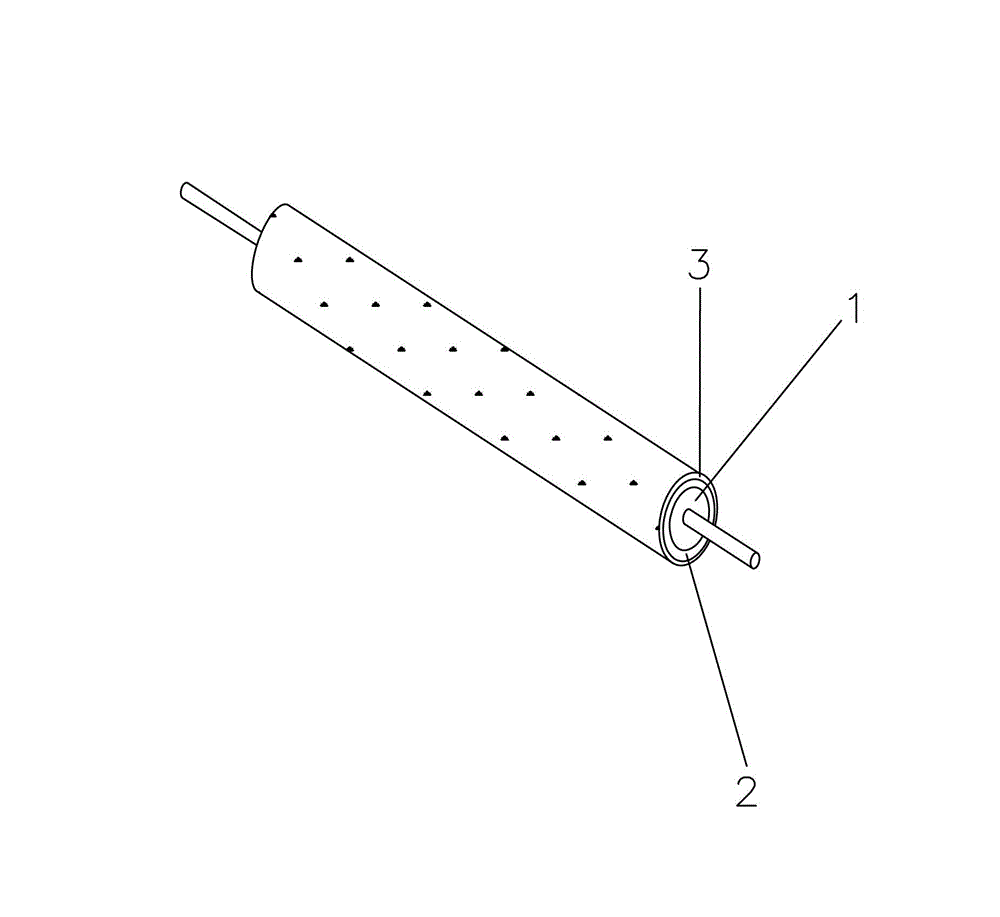

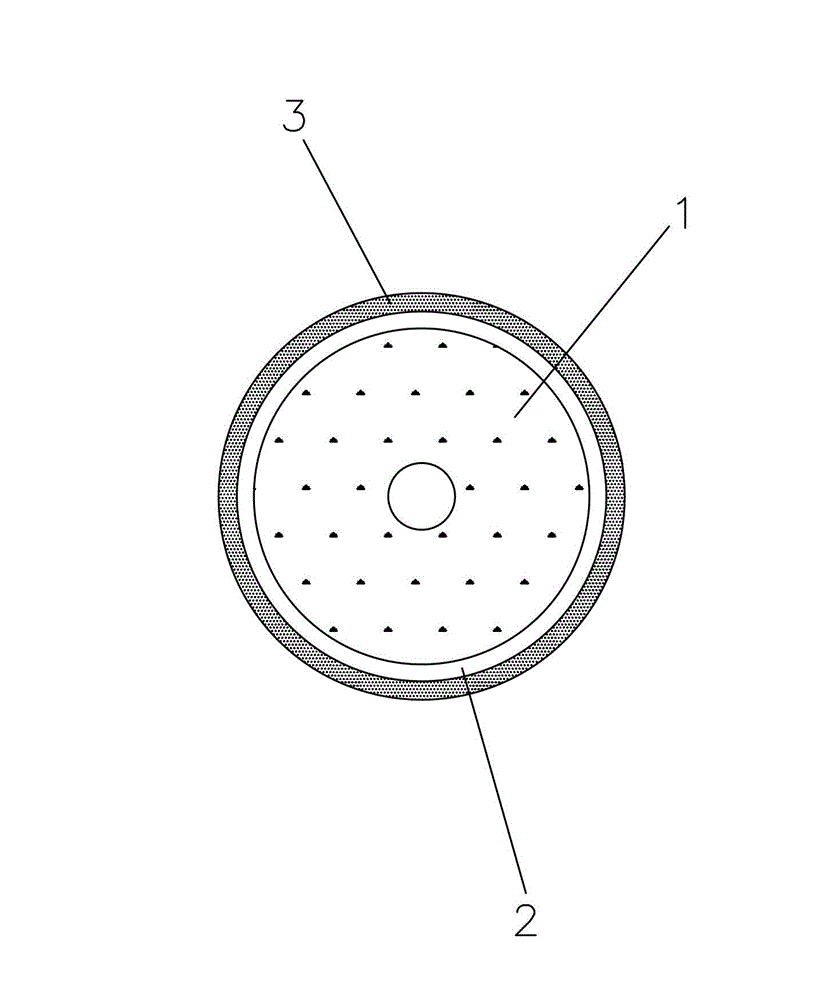

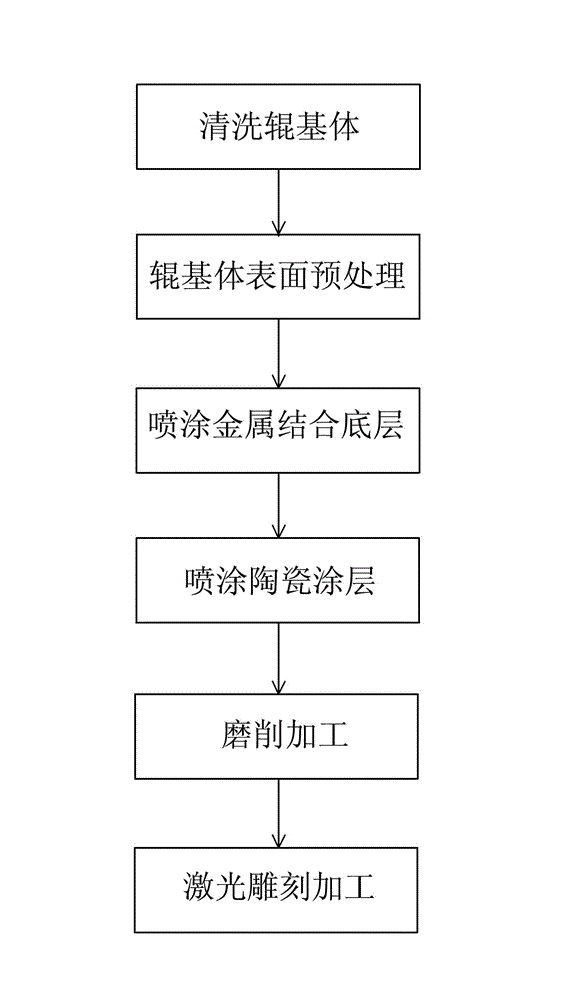

Laser engraved ceramic coating anilox roller and production method thereof

InactiveCN104002552AImprove printing accuracyHigh densityCeramic layered productsPrinting press partsCeramic coatingSpray coating

The invention discloses a laser engraved ceramic coating anilox roller and a production method thereof. The laser engraved ceramic coating anilox roller comprises a roller body, a transition layer and a working layer; the transition layer is a metal combined bottom layer, and the working layer is a ceramic coating layer; the transition layer is fixed onto the roller surface of the roller body, and the ceramic coating layer is fixed to the transition layer. The production method includes the steps of roller body cleaning, roller body surface pretreatment, metal combined bottom layer spray coating, ceramic working layer spray coating, spray coated ceramic working layer abrasive machining and ceramic working layer laser engraving machining. The laser engraved ceramic coating anilox roller has the advantages of long service life and high printing accuracy. The production method is fewer in process steps and not demanding in production conditions, can ensure the technical effect of the ceramic anilox roller, and is applicable to industrial batch production.

Owner:SUZHOU ZHISHUN SURFACE TECH

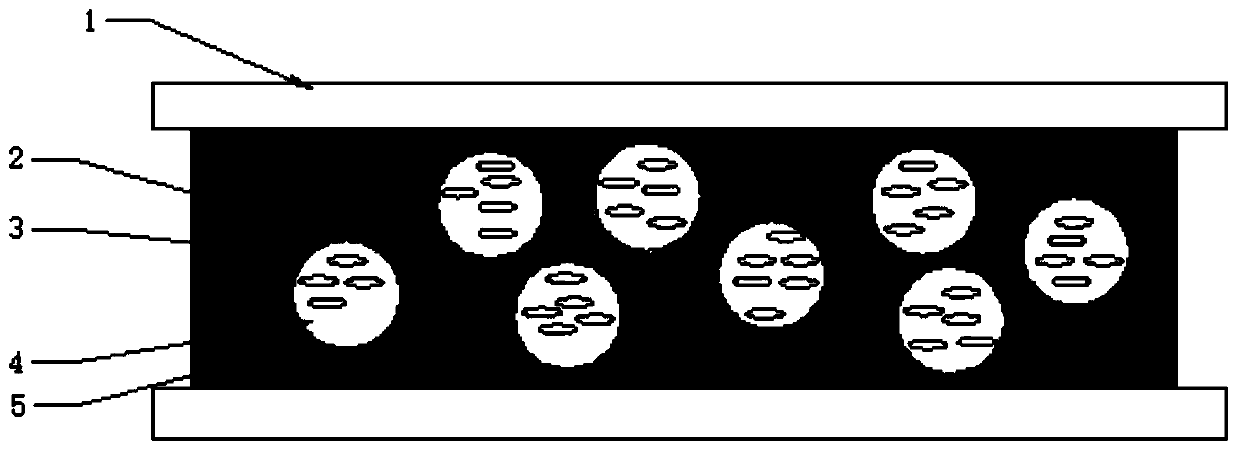

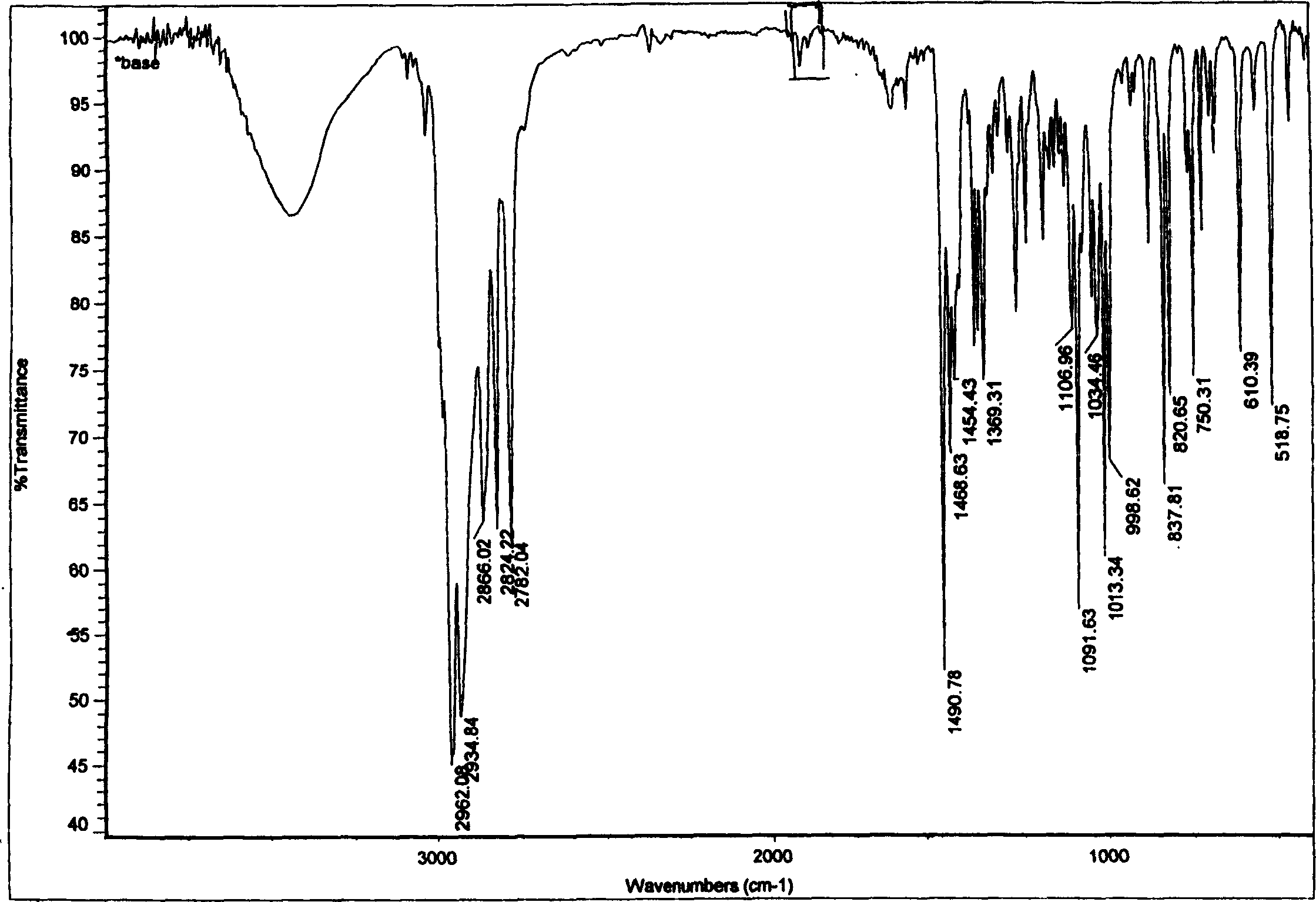

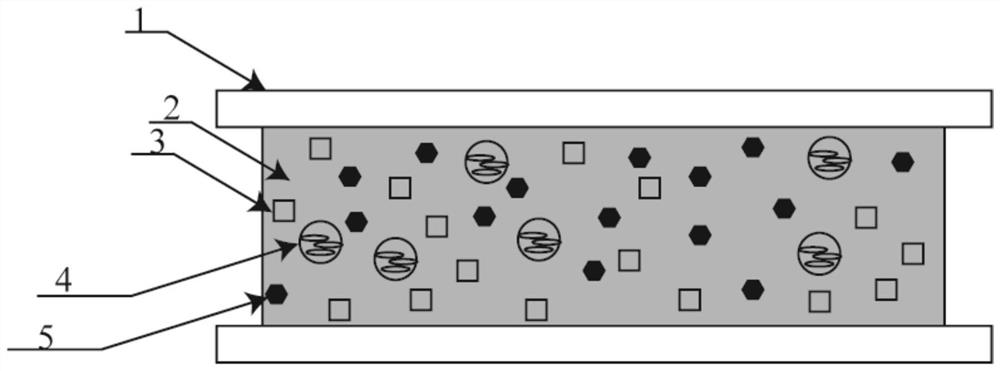

Semiconductor quantum dot doped polymer dispersed liquid crystal containing Ag nanoparticles

ActiveCN110932083ASimple preparation processLow costMaterial nanotechnologyActive medium materialRandom laserNanoparticle

The invention relates to semiconductor quantum dot doped polymer dispersed liquid crystal containing Ag nanoparticles and a preparation method thereof. The semiconductor quantum dot doped polymer dispersed liquid crystal containing the Ag nanoparticles is prepared from the following components in parts by mass: 1 to 5 parts of semiconductor quantum dots, 20 to 74 parts of a photosensitive polymer,20 to 78 parts of nematic liquid crystal, 1-5 parts of a photoinitiator, and 0.5 to 1.5 parts of Ag nano particles. The invention also relates to an application of the semiconductor quantum dot dopedpolymer dispersed liquid crystal containing the Ag nanoparticles in a random laser. The semiconductor quantum dot doped polymer dispersed liquid crystal containing the Ag nanoparticles has the advantages that the raw materials are simple and easy to obtain;, and the cost is low; the obtained random laser has the advantages of short preparation period, simple preparation process, easy regulation and control of emission wavelength, low production cost, higher intensity of emitted light, low threshold value and the like; and the semiconductor quantum dot doped polymer dispersed liquid crystal containing the Ag nanoparticles has a wide commercial application prospect.

Owner:WUYI UNIV

Hemostat and preparation method thereof

InactiveCN101757614BHigh affinityExcellent process stepsAnthropod material medical ingredientsPeptide/protein ingredientsWound healingSide effect

The invention discloses a hemostat and a preparation method thereof. A finished product liquor per 1000 g comprises 10-16 g of termite fungus garden composition powder, 4-6 g of collagen, 0.02-0.04 g of ternary acid, 7-9 g of bactericidal agent and the balance of water. The invention has the advantages that the termite fungus garden composition powder containing rich nutrient contents is utilizedin the prescription, the functions of detumescence, convergence and hemostasis are achieved, meanwhile the weak body is tonified without any side effect; the collagen has very strong affinity with different cells, and also has ideal affinity with growth factors which play a key role in the process of wound healing, after blood coagulation, the collagen can also prevent bleeding again through stimulating the regeneration and the repair of tissues. The hemostat is not fastidious about the using object, has fast hemostasis effect, excellent functions of anti-inflammatory, detumescence and acesodyne without toxic or side effect, or untoward reaction of stimulations. The preparation method has less technical steps and non-rigorous preparation condition, and can be suitable for the industrial mass production.

Owner:苏州汇涵医用科技发展有限公司

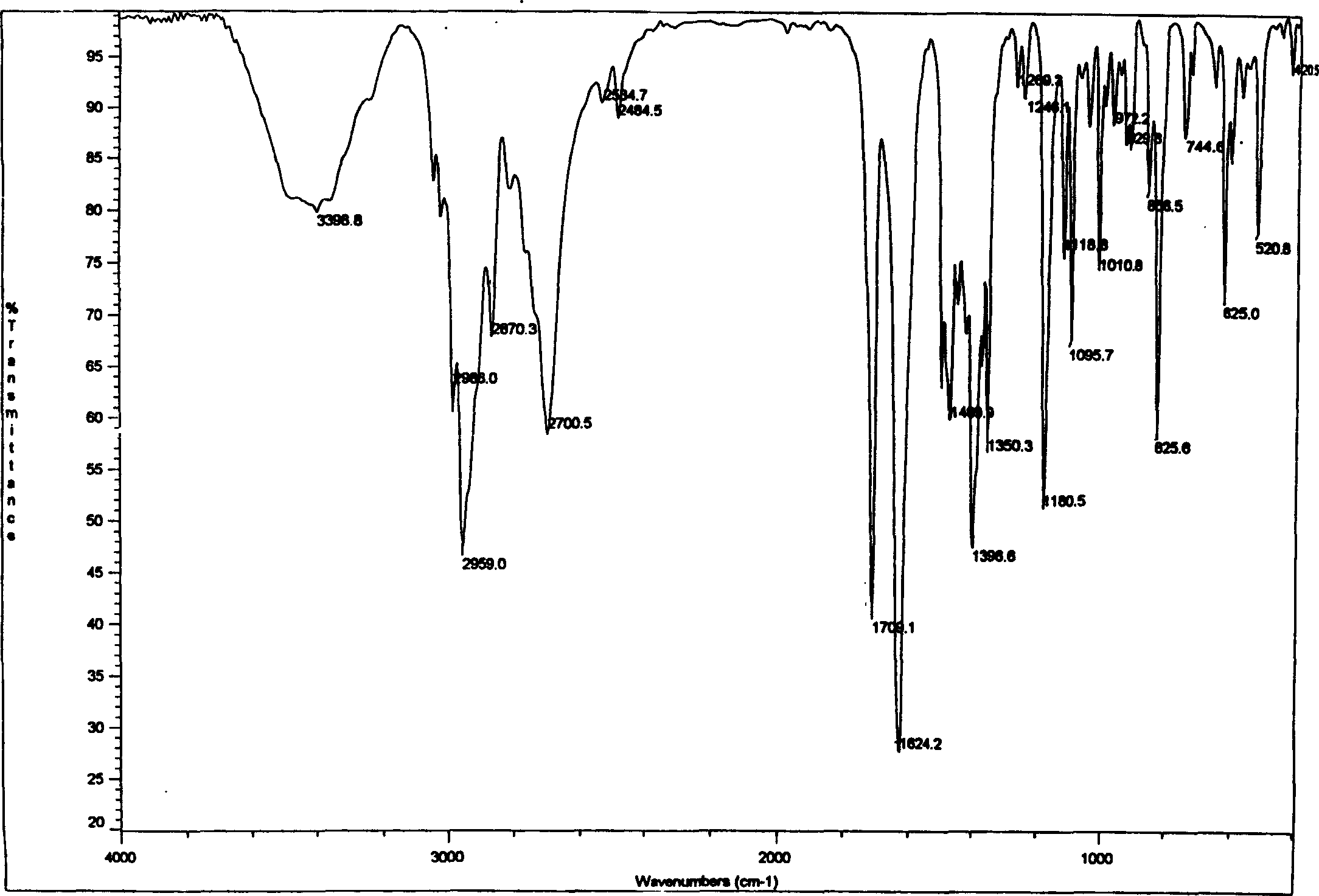

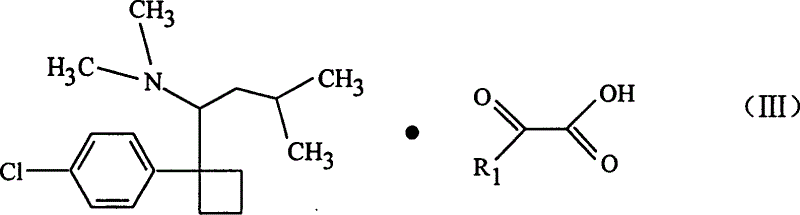

Sibutramine aliphatic salt of organic acid, its preparation process and use

The present invention relates to aromatic organic salt of Sibutramine and its preparation process. The hydrochloride of Sibutramine as initial material is added into water solution of caustic alkali and reacted for some time before ethyl ether extraction and drying to concentrate to obtain white solid free Sibutramine alkali. Organic solution of free Sibutramine alkali and organic solution of ketoacetic acid or similar organic fatty acid are then mixed at room temperature via stirring to react and separate white crystal, which is filtered and dried to obtain the aromatic organic salt of Sibutramine. The salt has excellent diabetes and obesity preventing and treating effect.

Owner:苏州市玮琪生物科技有限公司

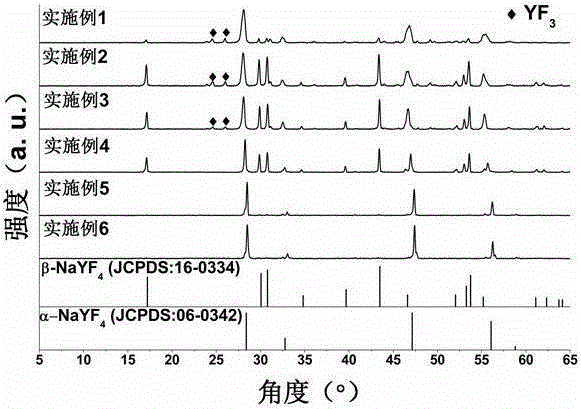

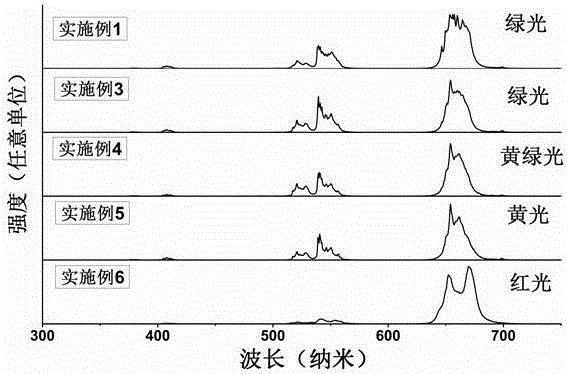

Preparation method for Er<3+>-Yb<3+>-co-doped NaYF4 fluorescent powder

ActiveCN105112056ASimple preparation processDon't need protectionLuminescent compositionsAcetic acidAlcohol

Owner:FUZHOU UNIV

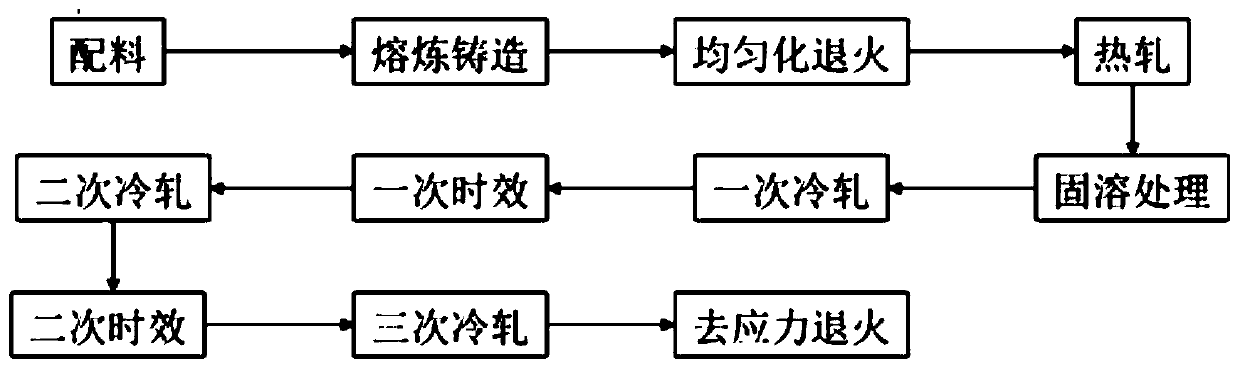

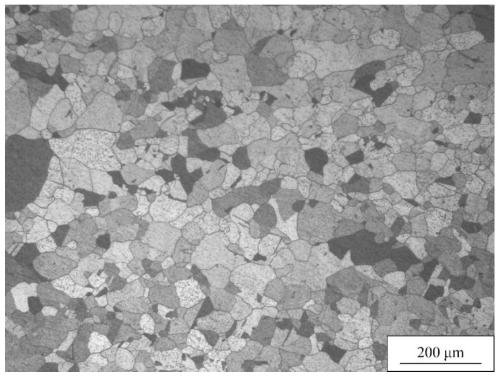

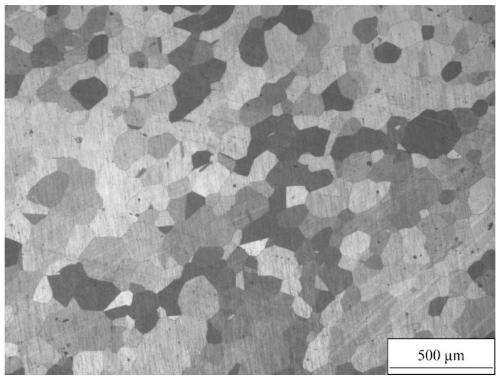

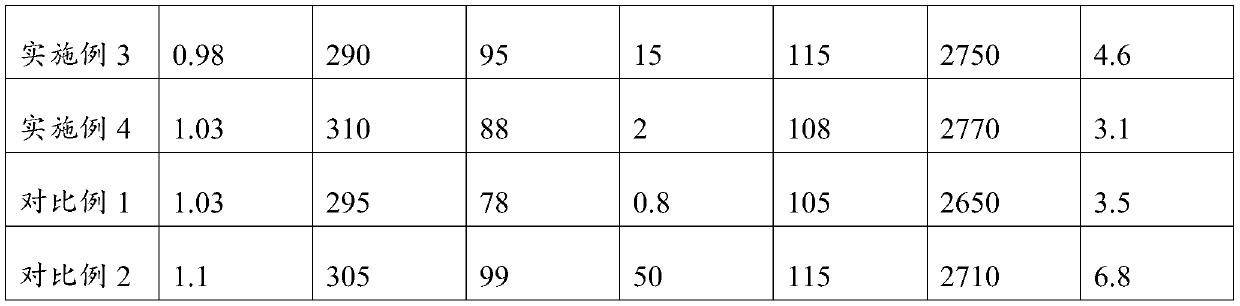

High-strength and high-conductivity heat-resistant copper-chromium alloy material and preparation process thereof

The embodiment of the invention provides a high-strength and high-conductivity heat-resistant copper-chromium alloy material and a preparation process thereof. The alloy material is reasonable in formula of components; the electric conductivity of the obtained copper-chromium alloy material can reach 82-98% IACS, the yield strength is 400-540 MPa, the strength of extension is 450-550 MPa, the ductility is 5-20%, and the material can resist heat greater than 550 DEG C; the problems of copper-chromium alloy materials in the prior art are solved; and raw materials of components are easy to obtain, no noble metal is included, and the cost is relatively low. The preparation process has no harsh preparation condition, is low in requirement for equipment, and is easy to industrially popularize.

Owner:CENT SOUTH UNIV

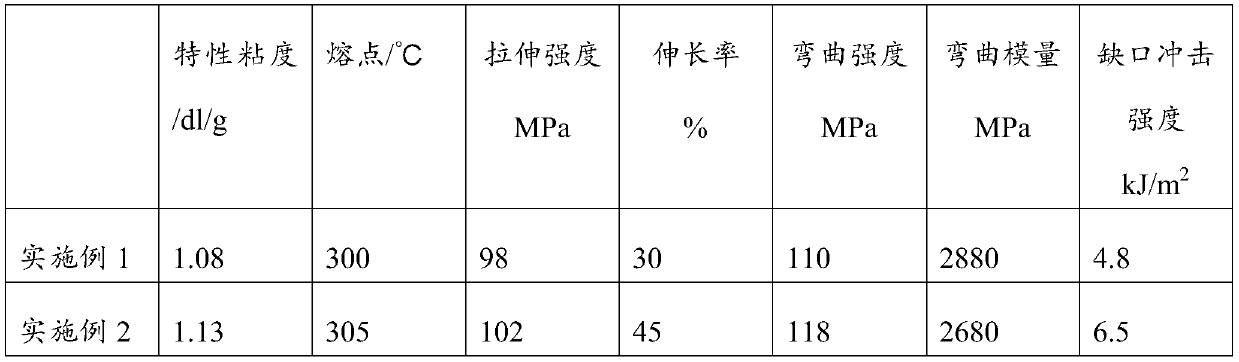

Preparation method of semi-aromatic polyamide

The invention provides a preparation method of semi-aromatic polyamide. The preparation method comprises the following steps: adding an aqueous solution of dibasic acid, diamine and fatty alcohol intoa reaction kettle to prepare a semi-aromatic nylon salt, evaporating the alcohol to remove the alcohol, and carrying out polymerizing to obtain the semi-aromatic polyamide. According to the preparation method, based on the characteristic that the long-carbon-chain semi-aromatic nylon salt has low solubility in water or alcohol but good solubility in a mixed solution of alcohol and water, dibasicacid and diamine are used as raw materials, the long-carbon-chain semi-aromatic nylon salt is prepared in the aqueous solution of fatty alcohol, then a distillation temperature is controlled, the fatty alcohol is removed through evaporation before a polymerization reaction temperature is reached, and heating is continued and polymerization is performed to obtain the semi-aromatic polyamide, thereby avoiding proportion imbalance caused by the volatile loss of diamine in a high-temperature environment.

Owner:JIANGMEN DENGZHONGTAI ENG PLASTICS CO LTD

Preparation method for titanium coating or titanium alloy coating

InactiveCN102943229ASimple preparation processPreparation conditions are not harshMolten spray coatingTitanium coatingTitanium alloy

The invention belongs to the technical field of preparation for a titanium coating, and relates to a preparation method for a titanium coating or a titanium alloy coating. The preparation method comprises the following specific steps of: (1) granulating titanium hydride to prepare a titanium hydride powder having a grain diameter ranging from -100 meshes to +400 meshes, wherein the titanium hydride powder ia taken as a raw material, or the mixed powder of the titanium hydride powder and titanium or titanium alloy is used as a raw material, the mass of the titanium hydride powder occupies more than 60% of mass of the mixed powder, and the grain diameter of the mixed powder ranges form -100 meshes to + 400 meshes; and (2) spraying the raw material in the step (1) on a matrix to obtain the titanium coating or the titanium alloy coating. The method can be performed in an atmospheric environment; and moreover, large-area spray of the titanium coating or the titanium alloy coating can be realized.

Owner:HUNAN METALLURGY MATERIAL RES INST

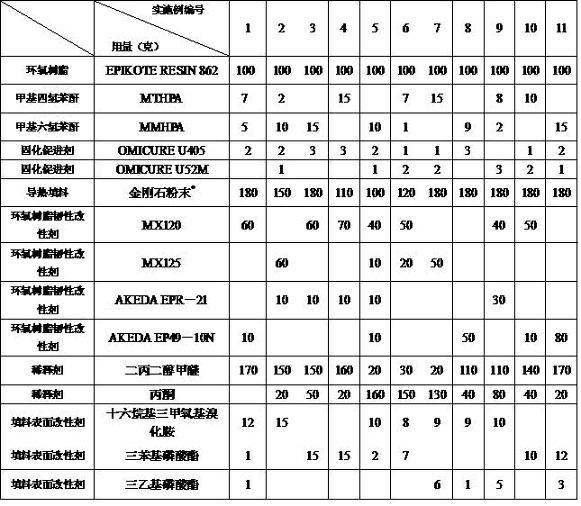

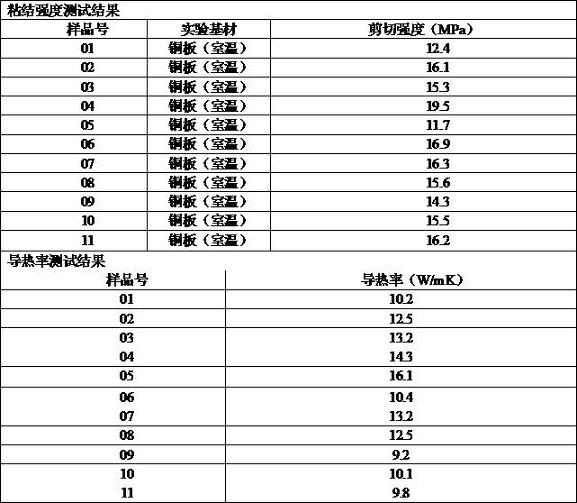

Diamond-filled isotropical high-performance heat-conductive adhesive and preparation method thereof

InactiveCN102079958AImprove thermal conductivityHigh bonding strengthNon-macromolecular adhesive additivesEpoxy resin adhesivesMaterials preparationEpoxy

The invention belongs to the technical field of material preparation, in particular relates to a diamond-filled isotropical high-performance heat-conductive adhesive and a preparation method thereof. The preparation method comprises the following steps of: firstly, mixing epoxy resins with an epoxy toughness modifier by mechanical stirring for 20 minutes at the rate of 1,500 r / min; secondly, adding a heat-conductive diamond filler into the obtained product under the stirring state, adding a modifier and a diluent on the filler surface, and continuously stirring for 15 minutes after the addition process is over; thirdly, adding a curing agent and a curing accelerator into the mixture after uniform mixing, performing mechanical stirring for 5 minutes, and transferring the mixture into a high-speed shear mixing machine for mixing for 30 seconds at the rate of 2,000 r / min; and fourthly, obtaining uniformly mixed jelly, namely the heat-conductive adhesive, after performing repeated mixing for three times in the high-speed shear mixing machine. The heat-conductive adhesive prepared by the method provided by the invention has higher heat conductivity of 10-16w / (m.k), and the shear strength of the adhesive can be improved.

Owner:CHANGZHOU HE RUN NEW MATERIAL TECH +1

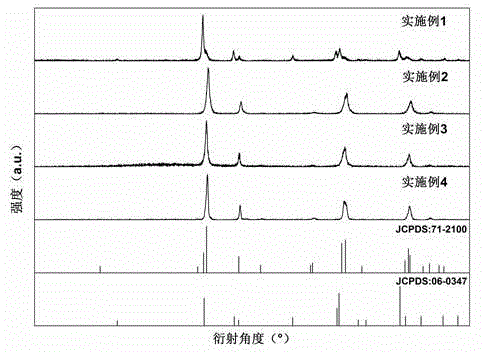

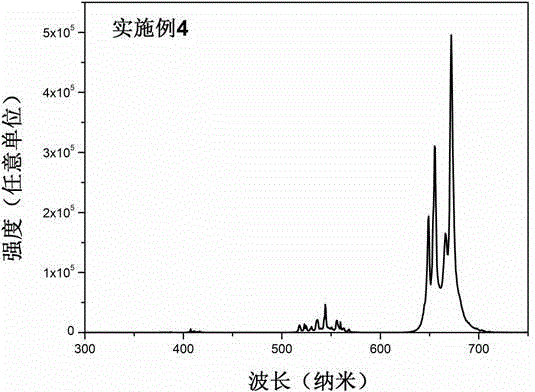

Preparation method of Er<3+> and Yb<3+> co-doped YOF red up-conversion fluorescent material

ActiveCN104830344AThe synthesis process is simpleQuality improvementLuminescent compositionsPerfluoroacetic AcidPhysical chemistry

The invention provides a preparation method of an Er<3+> and Yb<3+> co-doped YOF red up-conversion fluorescent material. The preparation method is low in heat treatment temperature, relatively wide in temperature adjusting range and simple in process. The preparation method specifically comprises the following steps: mixing yttrium nitrate, ytterbium nitrate and erbium nitrate according to a general formula mixing ratio; taking isopropanol, ethanol and water as a solvent, adding trifluoroacetic acid into the solvent, and stirring uniformly to obtain a transparent sol A; drying the transparent sol A to obtain a colloidal substance for heat treatment; heating from room temperature to 350-600DEG C, keeping the temperature for a certain period of time, cooling to the room temperature along with a furnace, and grinding to obtain Er<3+> and Yb<3+> co-doped YOF powder; or coating the transparent sol A on a glass or silicon chip substrate by virtue of a rotary coating method, drying in the air for 15-30 minutes at room temperature, then drying in a drying box at 100DEG C, then putting into a high-temperature furnace to perform annealing treatment, heating to 350-600DEG C according to a heating rate of 1-10DEG C / min, and performing heat preservation and cooling to obtain an Er<3+> and Yb<3+> co-doped YOF fluorescent thin film.

Owner:FUZHOU UNIV

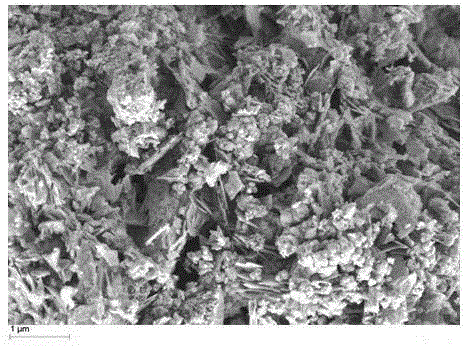

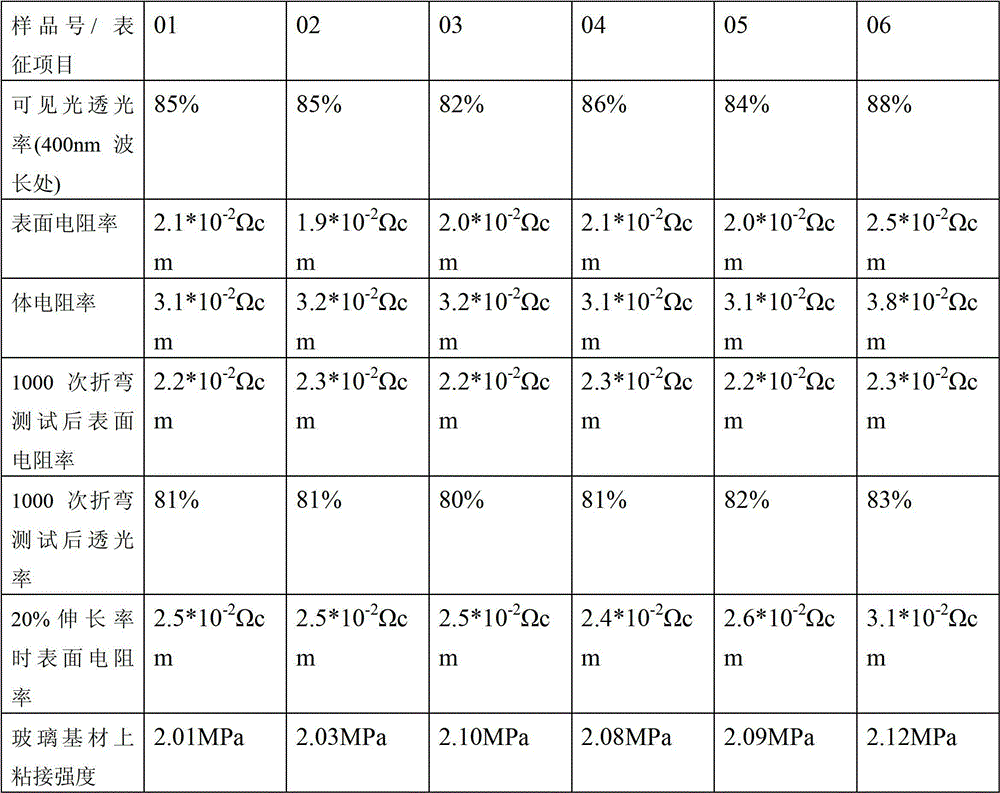

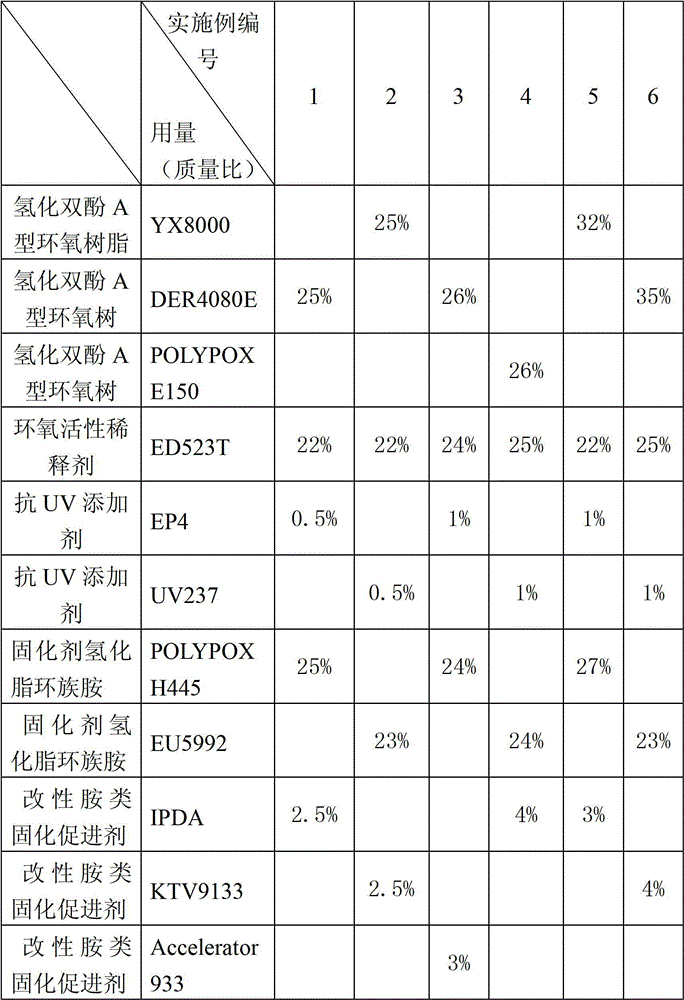

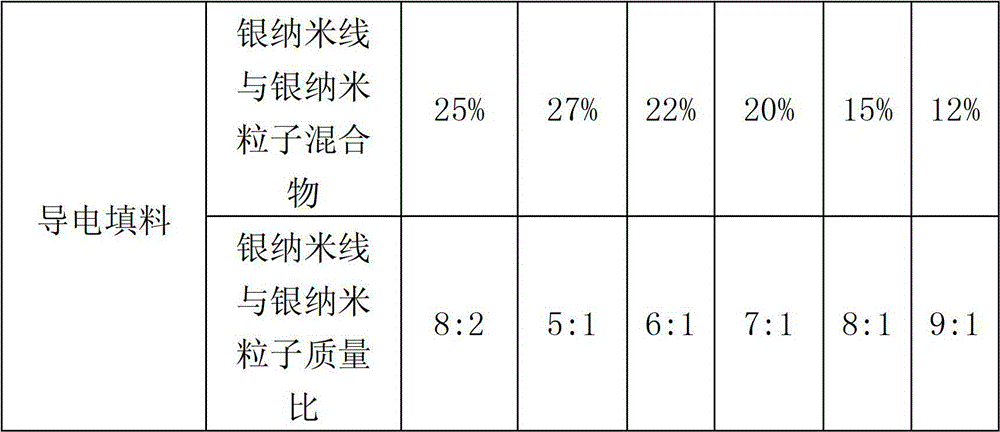

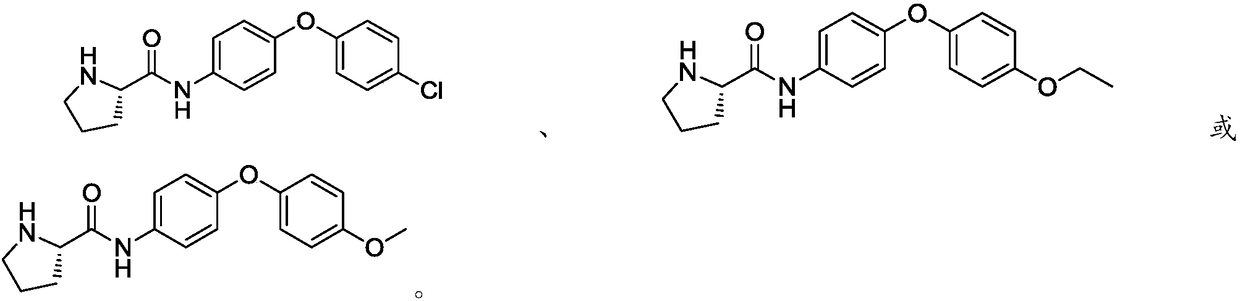

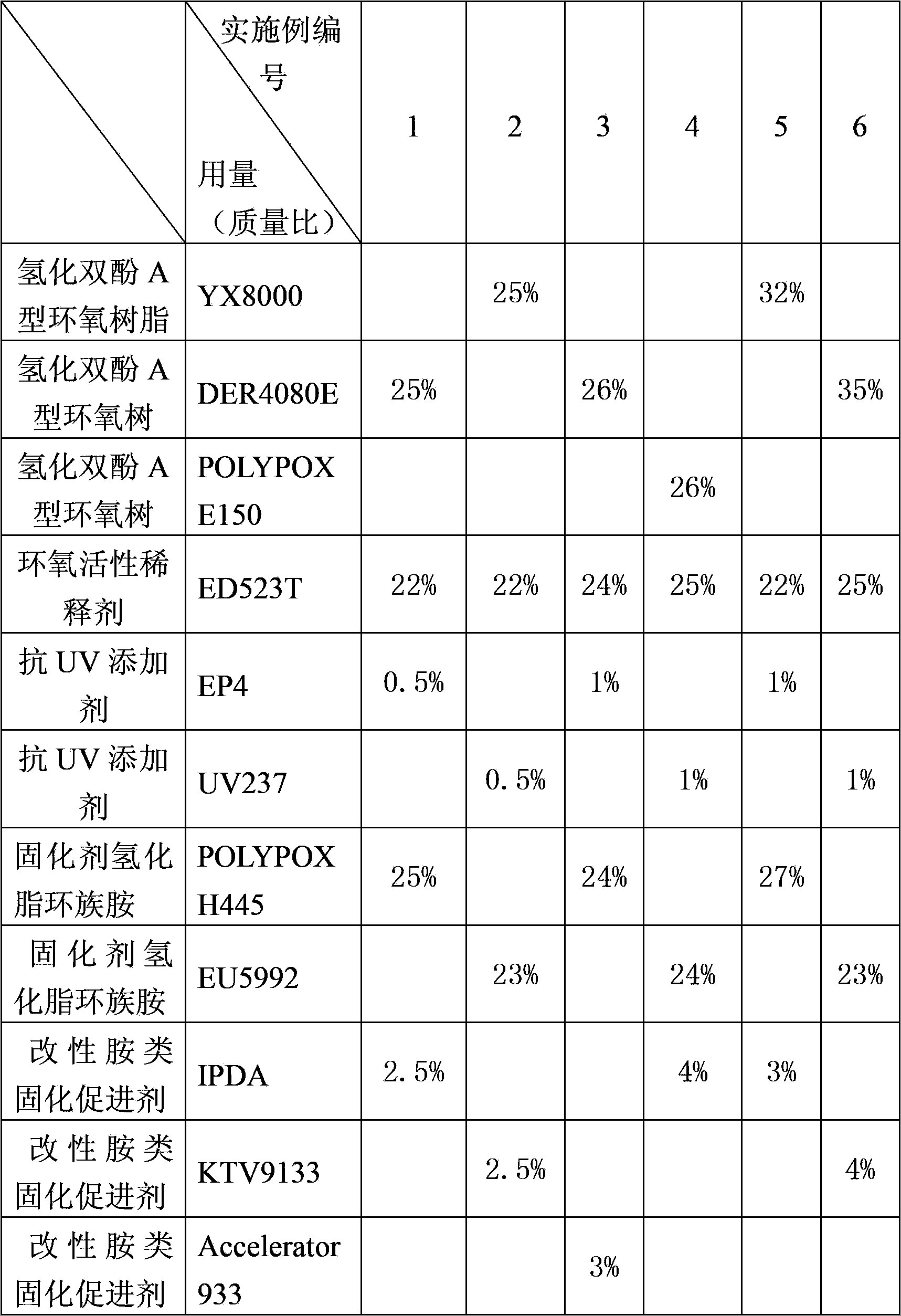

Novel transparent conductive film and preparation method thereof

ActiveCN102863913AImprove toughnessHigh elongationNon-macromolecular adhesive additivesFilm/foil adhesivesSurface resistivityUltraviolet

The invention aims to solve the technical problems of overcoming the defects of high resistivity, low ductility and poor adhesion between a conductive layer and a basal body of the transparent conductive film in the prior art and provide a novel transparent conductive film and a preparation method thereof. The novel transparent conductive film comprises the following components in percentage by mass: 25-35 percent of hydrogenated bisphenol A epoxy resin, 22-25 percent of epoxy resin active diluting agent, 0.5-1.5 percent of anti-ultraviolet (UV) additive, 20-30 percent of hydrogenated alicyclic amine, 2.5-4 percent of modified amine type curing promoter and 12-27 percent of conductive filler. The transparent conductive film is low in both surface resistivity and size resistivity, can be made into thin films of different thickness, and has the advantages of high transparency, high conductivity, high adhesion strength and the like; and the preparation method has the advantages of simple preparation method, readily available raw materials and non-severe preparation conditions.

Owner:常州凯得新材料科技有限公司

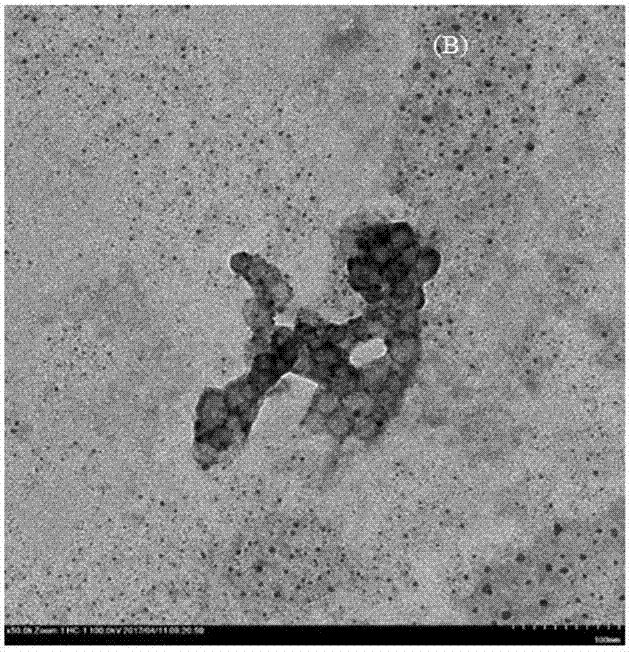

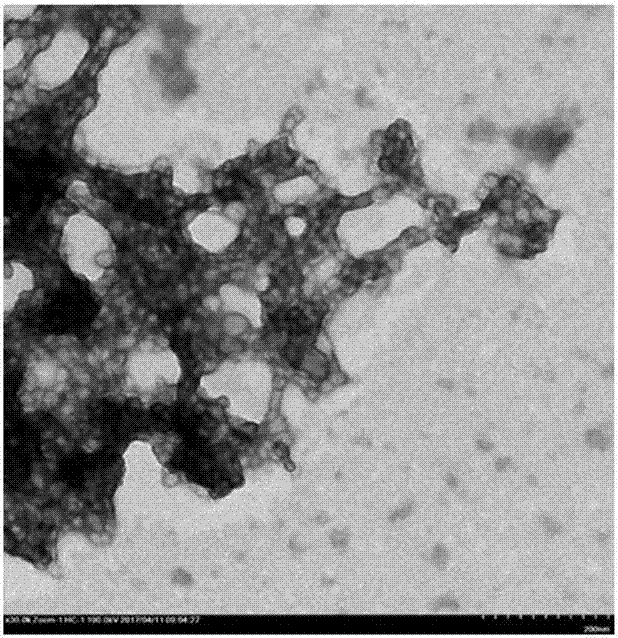

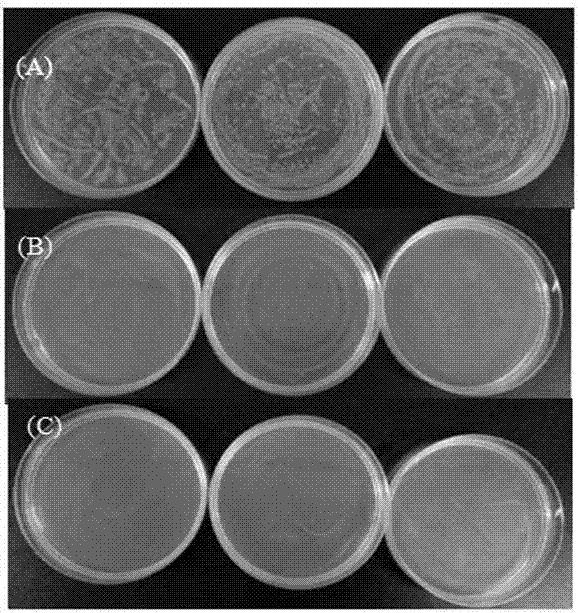

Antibacterial crosslinked nanoparticles and preparation method thereof

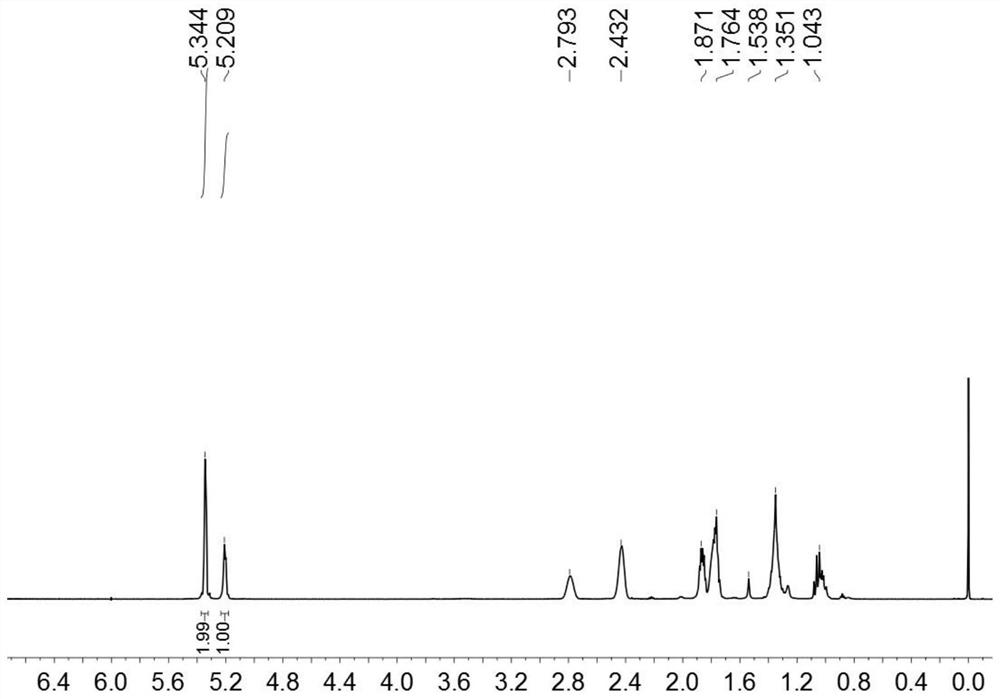

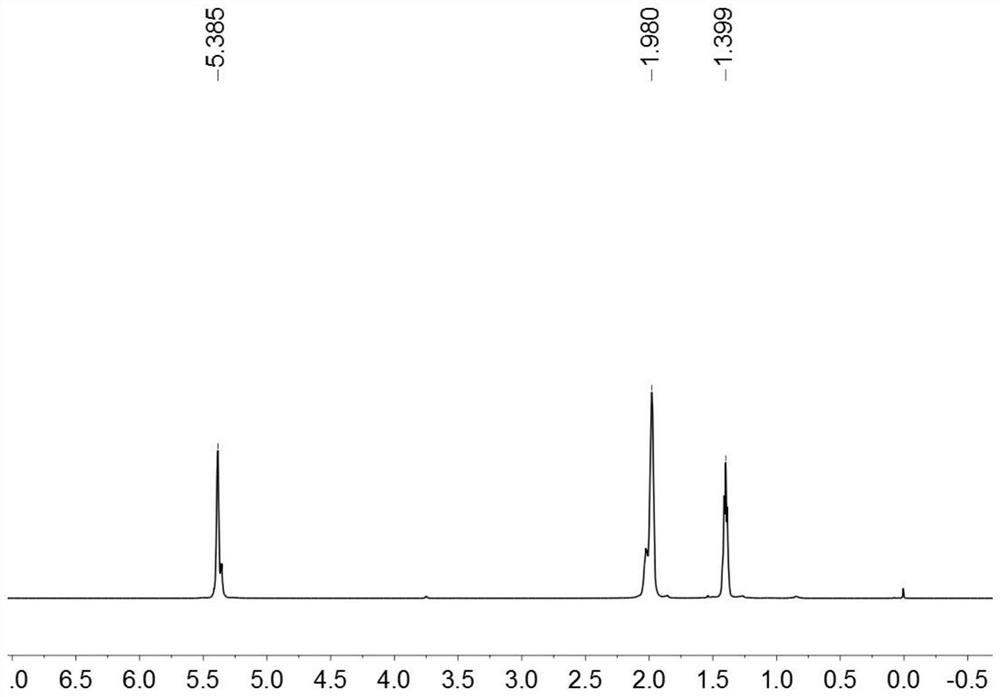

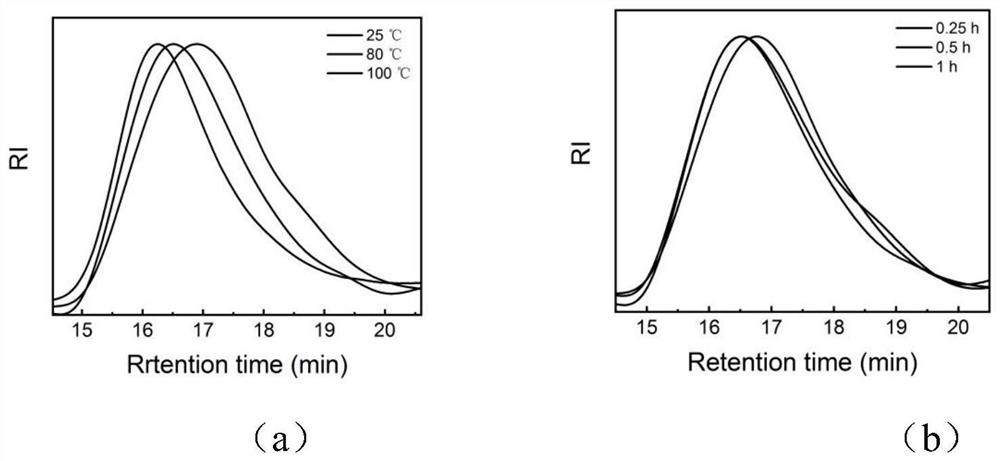

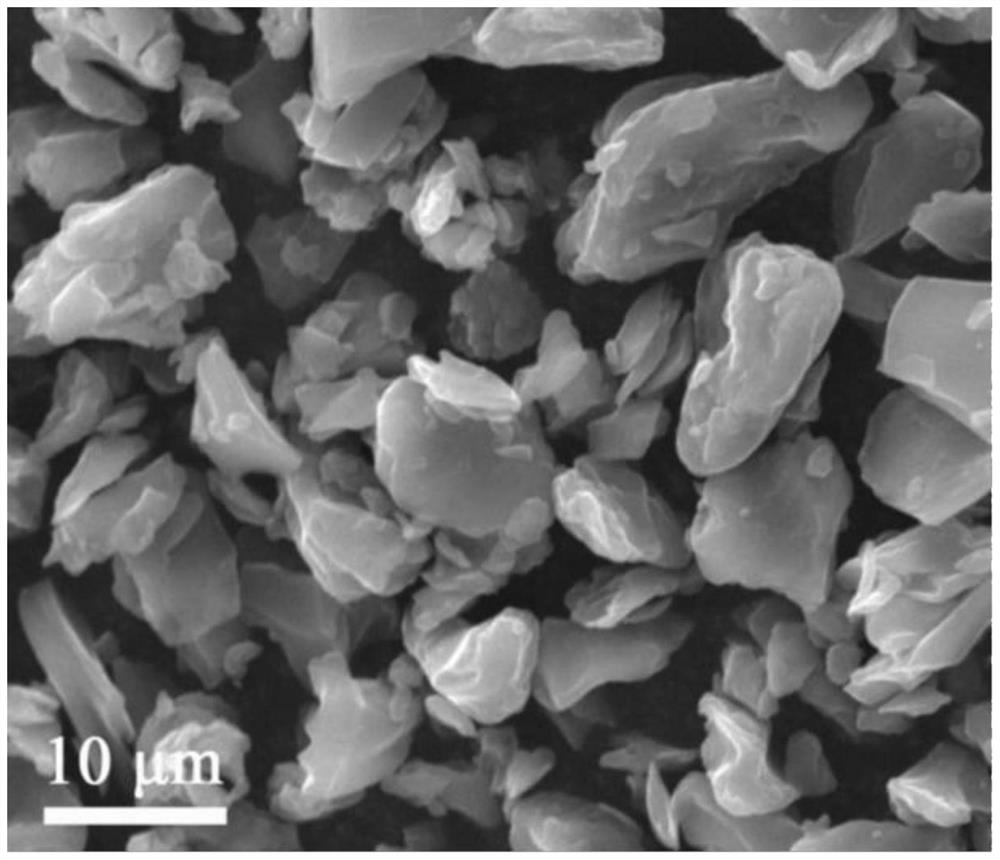

ActiveCN107325209AWith functionalization reactionWide range of monomersBiocideDisinfectantsEscherichia coliGlycol methacrylate

The invention relates to antibacterial crosslinked nanoparticles and a preparation method thereof. The method comprises the steps of firstly, adopting solution polymerization to synthesize poly [2-(N,N-dimethyl amino)ethyl methacrylate] (PDMAEMA) under the regulation of a reversible addition fragmentation chain transfer (RAFT) agent-CPND; then, under the acidic condition, taking the PDMAEMA as a macromolecule RAFT agent, and adding oil-soluble monomer methyl methacrylate (MMA) and a crosslinking agent-ethylene glycol dimethacrylate (EGDMA) in a semi-continuous charging way to prepare crosslinked nano emulsion for soap-free antibacterial particles. After that, the nanoparticles are enabled to be subjected to quaternization, and the good antibacterial property of the nanoparticles is verified by taking gram-negative bacteria escherichia coli as an experimental strain and using a spread-plate method.

Owner:SUZHOU UNIV

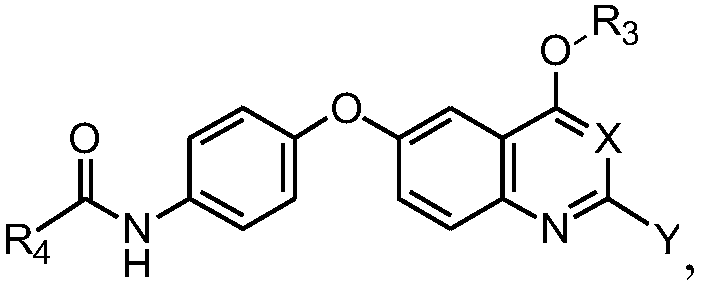

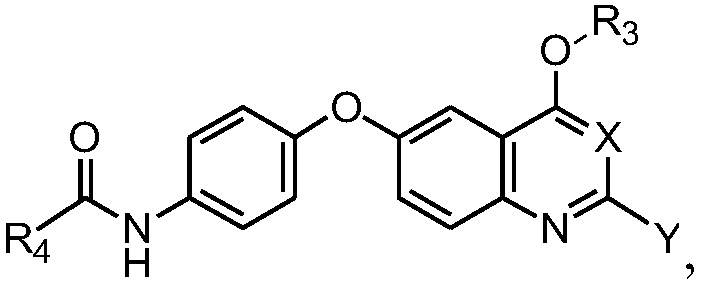

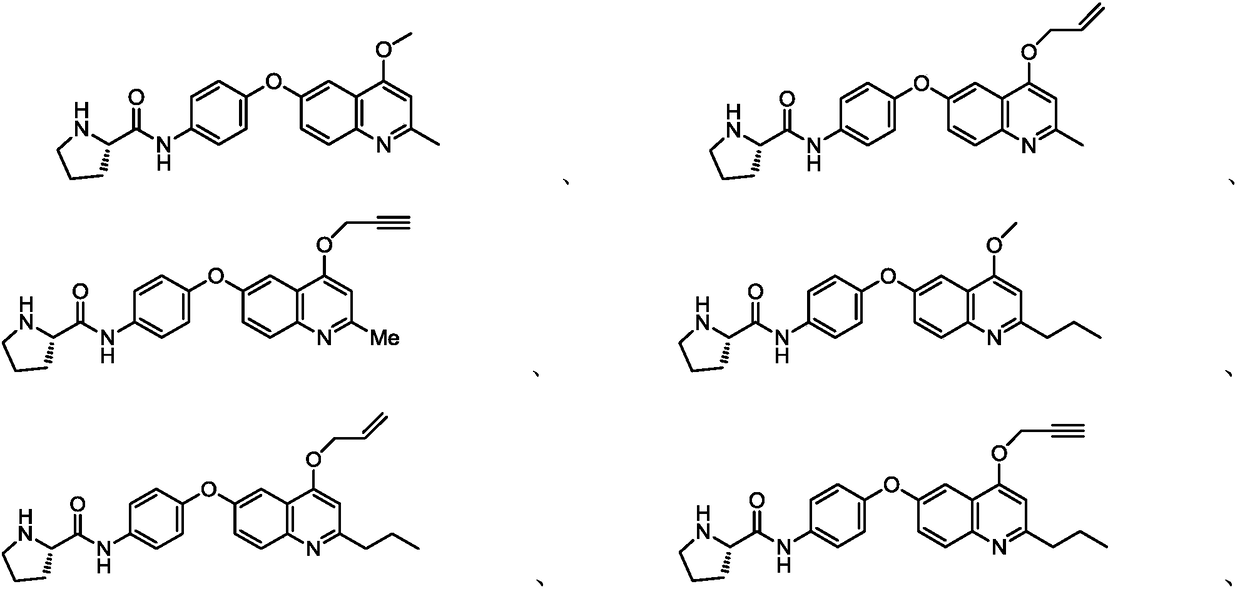

Quinoline or quinazoline compound as well as preparation method and application thereof

ActiveCN109134434AEasy to prepareRaw materials are easy to getOrganic active ingredientsOrganic chemistryQuinolineEnergy supply

The invention relates to quinoline or quinazoline compound as well as a preparation process and application thereof. The structural formula is shown in the description. The quinoline or quinazoline compound can inhibit the activity of PFKFB3 in tumor cells, effectively block activation of key enzymes during a glycolysis process, and inhibit energy supply for tumor cells.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

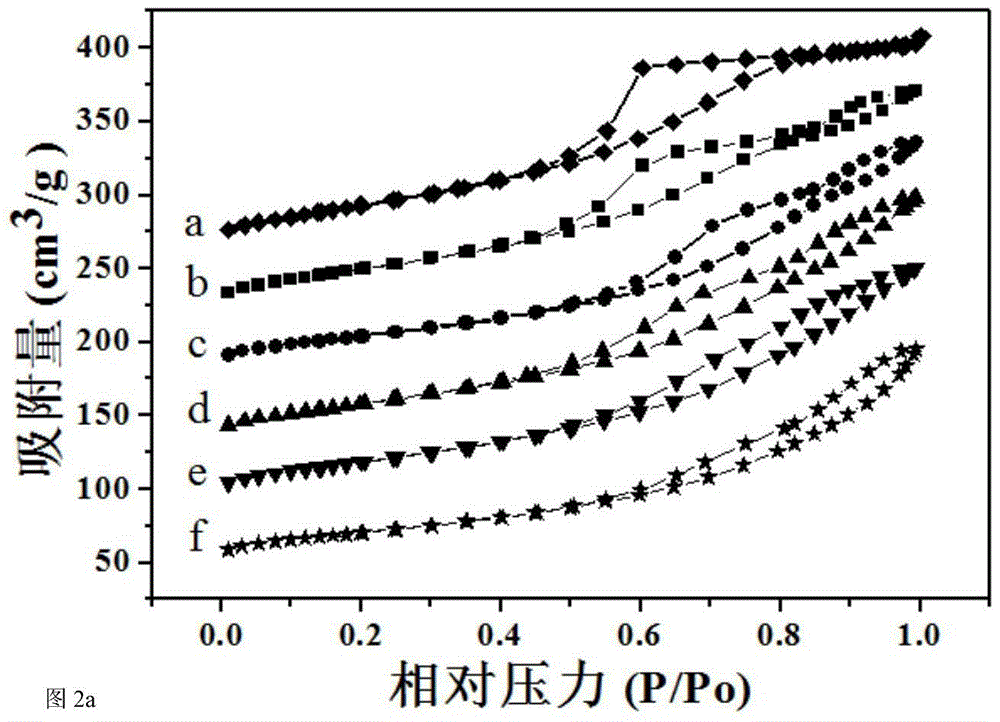

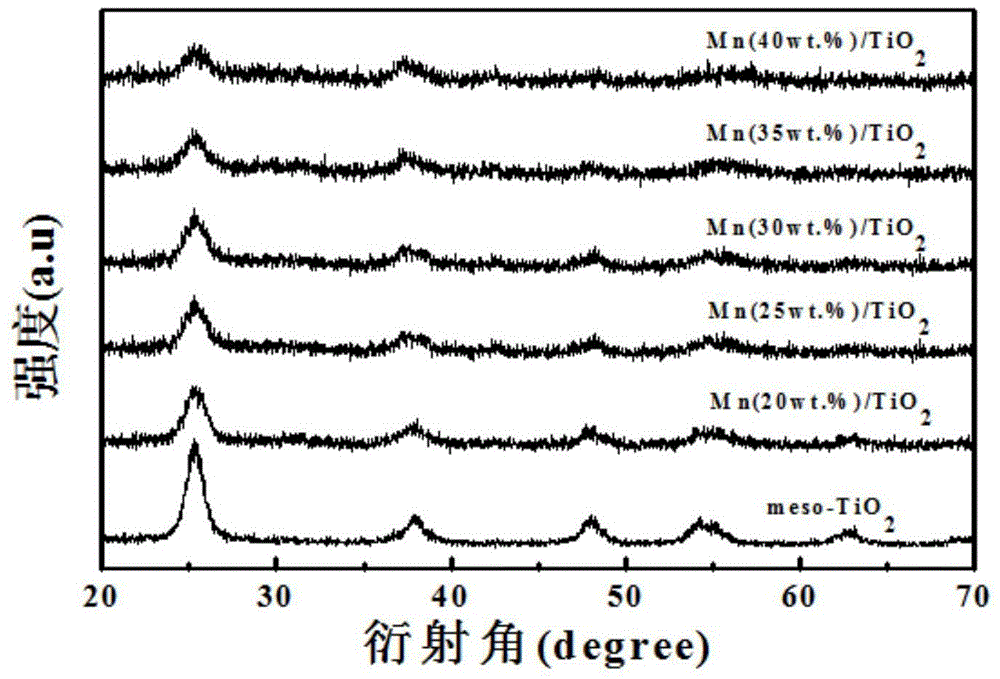

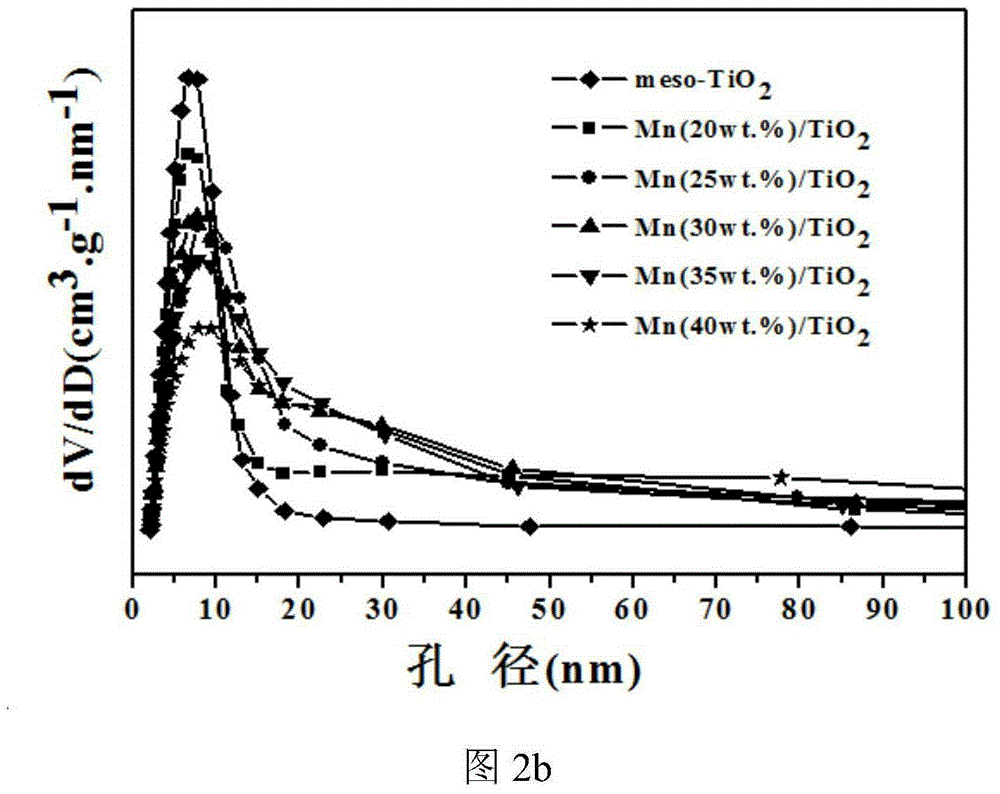

Manganese oxide/titanium dioxide catalyst for FCC (catalytic cracking) regenerated flue gas denitrification, preparation method therefore and applications

InactiveCN105126826AGood dispersionImprove denitrification efficiencyMaterial nanotechnologyDispersed particle separationManganese oxideAmmonium sulfate

The invention provides a manganese oxide / titanium dioxide catalyst for FCC (catalytic cracking) regenerated flue gas denitrification, a preparation method therefore and applications. The manganese oxide / titanium dioxide catalyst is prepared through a hydrothermal method: a solution containing a titanium source and a solution containing a manganese source, pore-enlarging agents and ammonium sulfate optionally are mixed, a hydrothermal reaction is carried out, the reaction products are subjected to solid-liquid separation, the obtained solid is washed, dried and baked, and the manganese oxide / titanium dioxide catalyst is obtained. The manganese oxide / titanium dioxide catalyst is a nano-level load-type oxide catalyst, the dispersibility of active components is good, the preparation method is simple, the active temperature window is wide (at a temperature of 150-350 DEG C, the denitration efficiency is more than 90%), and the low temperature activity is good (at a temperature of 150 DEG C, the denitration efficiency reaches 98%). In addition, the provided catalyst has advantages of large comparison area, high thermal stability, high N2 selectivity and the like, and has good application prospects.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Catalyst for synthesizing 2,3,6-trimethylphenol and preparation method thereof

InactiveCN102974354BExtended service lifeReduce usageOrganic chemistryOrganic compound preparationMetacresolAlkali metal oxide

The invention discloses a method for preparing 2,3,6-trimethylphenol, and the 2,3,6-trimethylphenol is an important intermediate of vitamin E. The method comprises the following steps of: enabling a mixture of metacresol, methanol and water to pass a fixed bed reactor containing an o-position methylation catalyst in a liquid space velocity of 0.4-10 h<-1>, and preparing the 2,3,6-trimethylphenol by carrying out a gas solid phase catalytic reaction under a temperature of 280-450 DEG C and a pressure of 0-10 MPa, wherein the o-position methylation catalyst consists of iron oxide, silicon dioxide and alkali metal oxide, and in the oxides, the metal ion molar ratio of iron, silicon, aluminum and alkali metal is equal to 100:(0.1-10):(0.2-5):(0-1). According to a catalyst for synthesizing the 2,3,6-trimethylphenol and a preparation method thereof, the conversion rate of the metacresol for compounding the 2,3,6-trimethylphenol is 100%, the yield of the 2,3,6-trimethylphenol is above 99.9%, and the service life of the catalyst is longer than 3000 hours.

Owner:SOUTHEAST UNIV

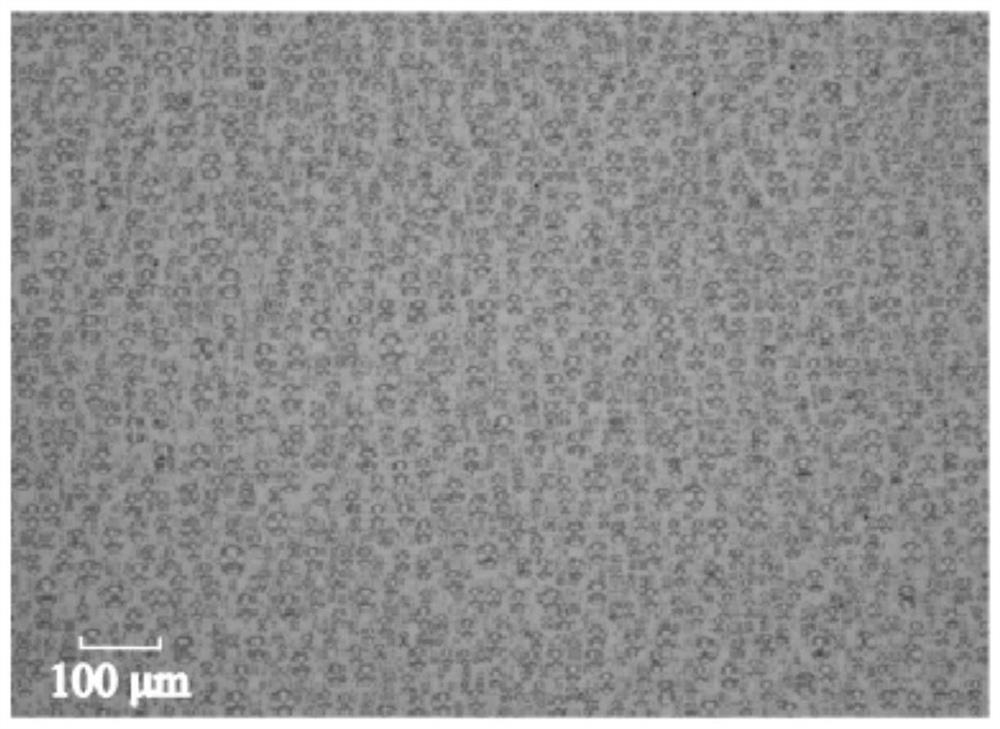

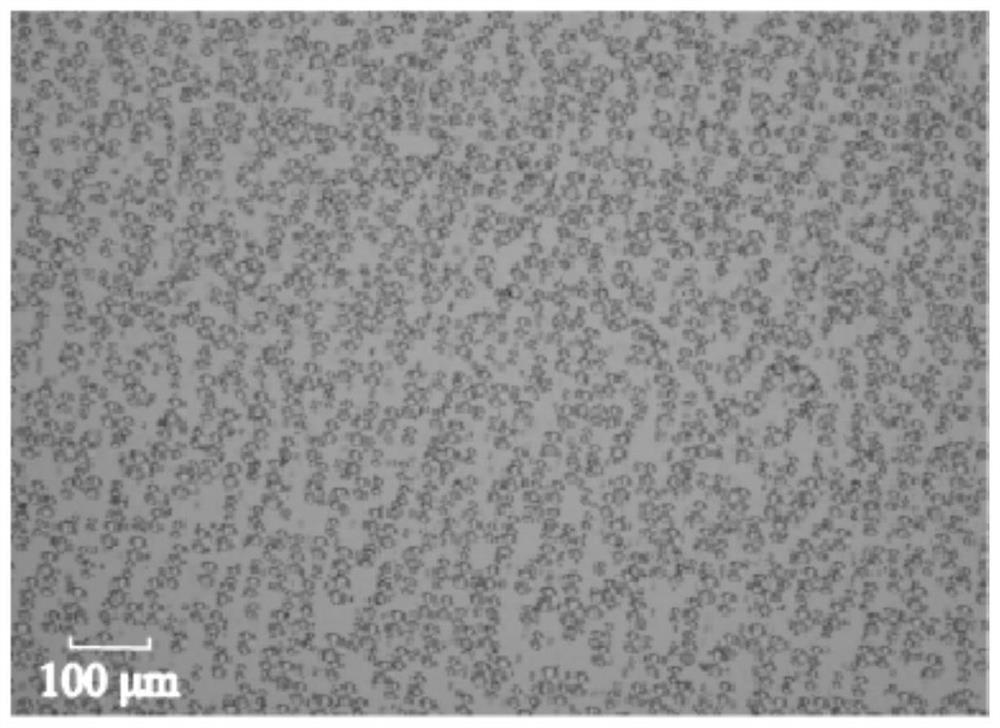

Polymer dispersed liquid crystal and preparation method and application

ActiveCN111995836ALow costPreparation conditions are not harshLiquid crystal compositionsLaser detailsLiquid crystallineRandom laser

The invention relates to a polymer dispersed liquid crystal which is prepared from the following components in parts by mass: 0.5-1.5 parts of nano-silver loaded graphene, 1-5 parts of semiconductor quantum dots, 20-74 parts of a photosensitive polymer, 20-78 parts of nematic liquid crystal, and 1-5 parts of a photoinitiator, wherein the silver content of the nano-silver loaded graphene is less than or equal to 45wt%, the average transverse size is more than or equal to 5 [mu]m, and the average longitudinal size is 0.8-1.2 [mu]m. The invention also relates to a preparation method of the polymer dispersed liquid crystal and application of the polymer dispersed liquid crystal in a random laser. The polymer dispersed liquid crystal disclosed by the invention has the characteristics of simpleand easily available raw materials and low cost, and the obtained random laser has the advantages of short preparation period, simple preparation process, easy regulation and control of emission wavelength, low production cost, higher intensity of emitted light, low threshold value and the like, and has a wide commercial application prospect.

Owner:WUYI UNIV

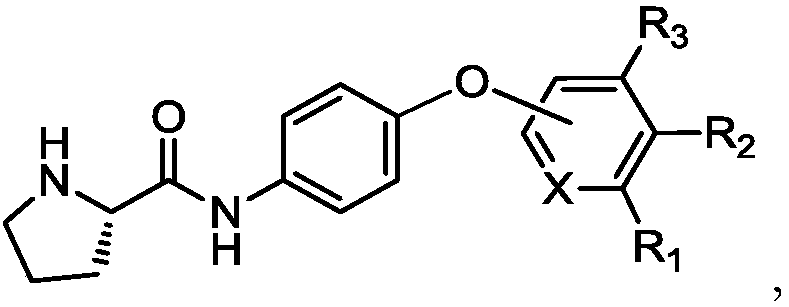

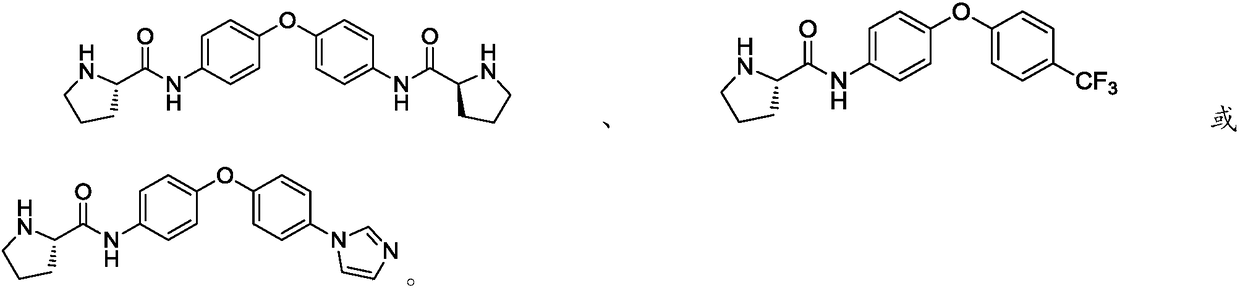

Diaryl ether compound, preparation method and application thereof

ActiveCN109134336AEasy to prepareRaw materials are easy to getOrganic chemistryAntineoplastic agentsArylBiological activation

The invention relates to a diaryl ether compound , a preparation method and application thereof, wherein the diaryl ether compound has the following structural formula: (the formula is shown in the description), wherein, -X- is CH- or -N-; =R1,-R2,-R3 are independently selected from one kind of H-,-F,-Cl,-Br, alkoxy, aryl, aryloxy, N, N-Dialkylamino, N-Alkyl-N-Acylamino, pyridyl, imidazolyl, pyrazolyl, furyl, pyrrolyl, morpholinyl, N-Alkyl piperazinyl, piperidinyl and tetrahydropyrrolyl. The diaryl ether compound has the advantage of inhibiting the activity of a PFKFB3 in the tumor cells, effectively blocking the activation of the key enzyme during the glycolysis process, thereby blocking energy supply from the energy source of the tumor cells, and providing a new medicament for the effective treatment of the tumor diseases.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Novel transparent conductive film and preparation method thereof

ActiveCN102863913BLower surface resistivityLower volume resistivityNon-macromolecular adhesive additivesFilm/foil adhesivesSurface resistivityUltraviolet

Owner:常州凯得新材料科技有限公司

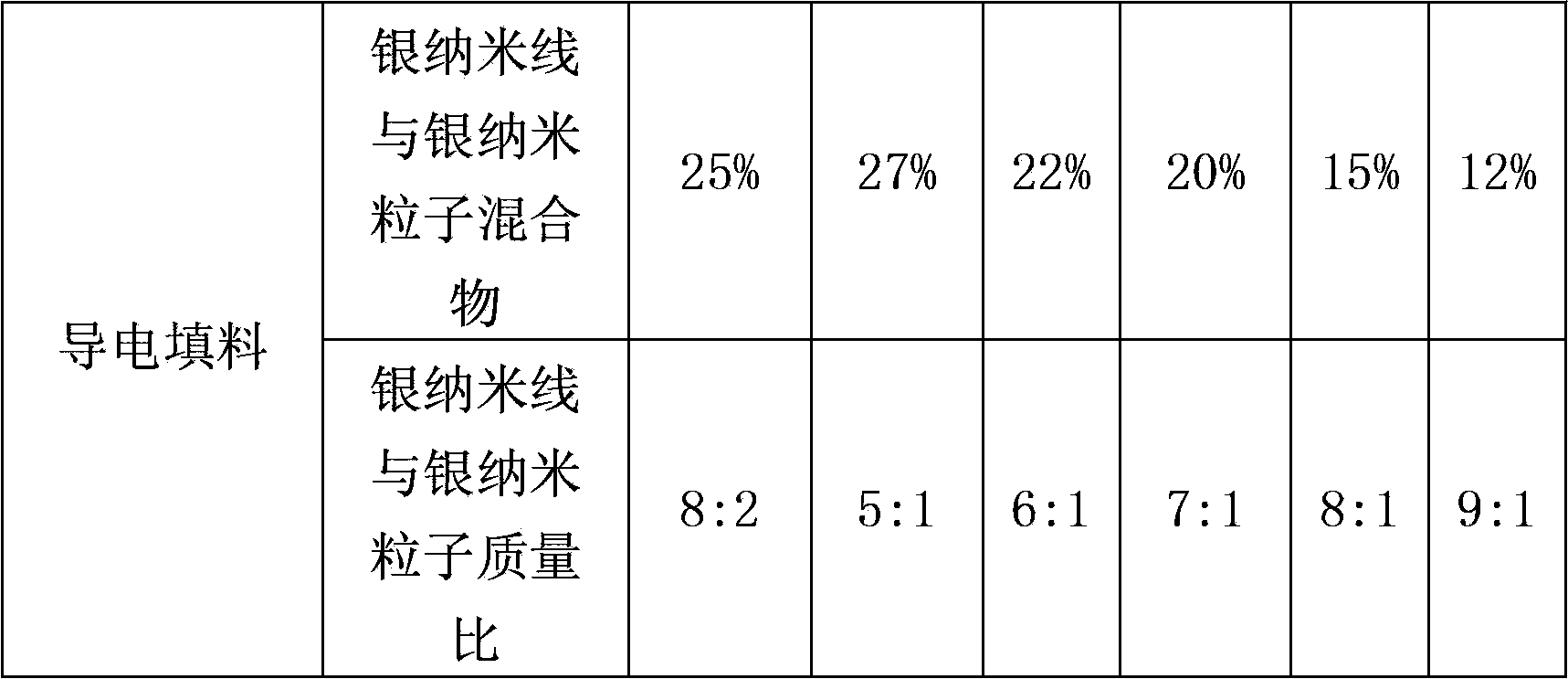

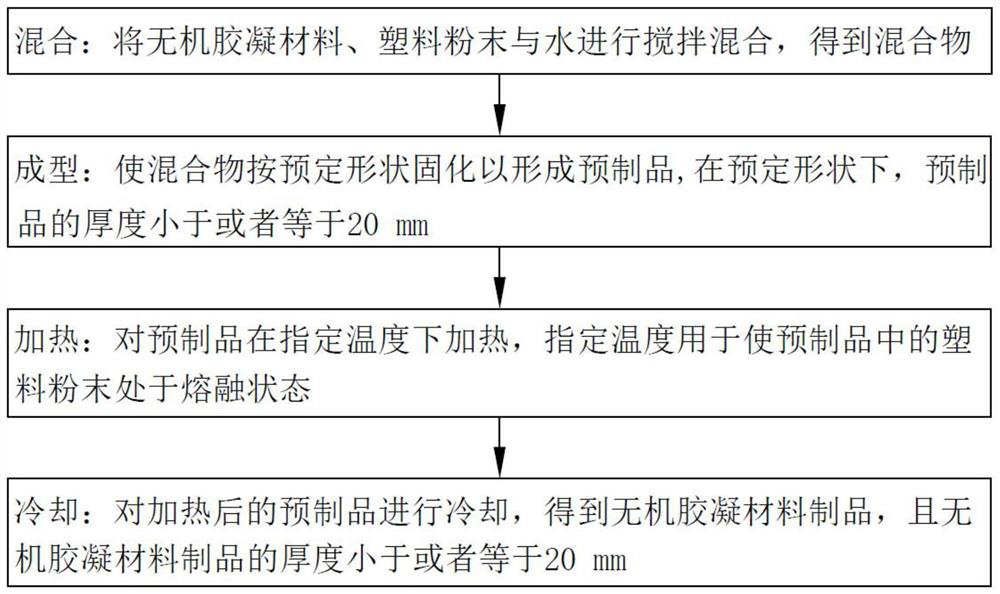

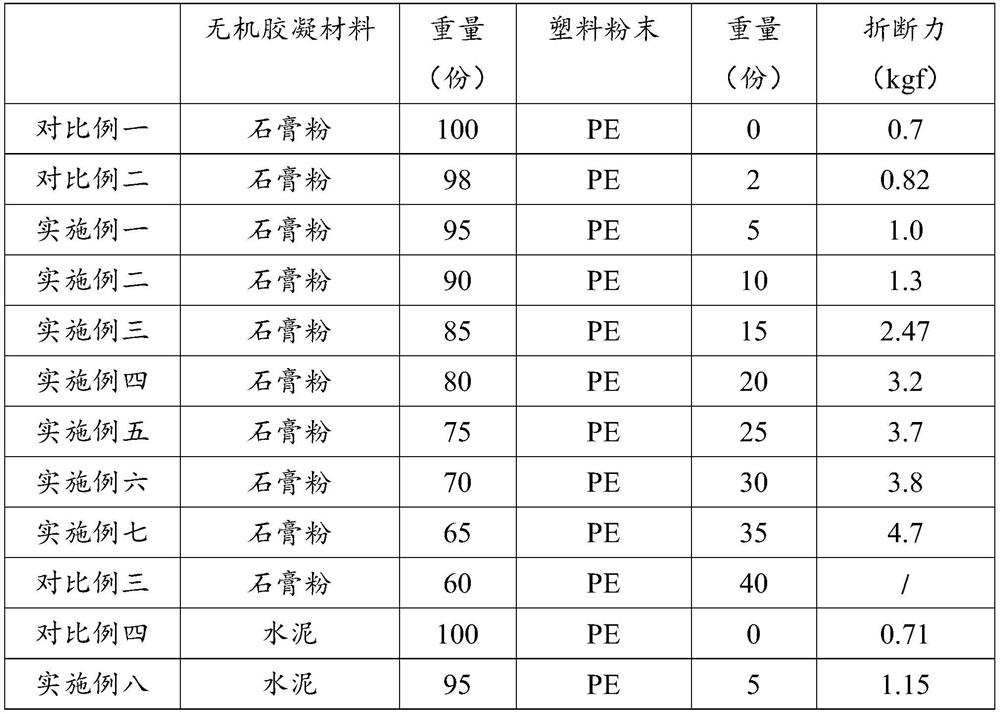

Inorganic cementing material product and preparation method thereof

PendingCN114591053AImprove toughnessSolve Thickness ProblemsSolid waste managementMolten stateCeramic materials

The invention relates to the technical field of inorganic cementing material products, in particular to an inorganic cementing material product and a preparation method thereof. The inorganic cementing material product comprises the following components in parts by weight: 65-90 parts of an inorganic cementing material and 10-35 parts of plastic powder, the preparation method of the inorganic cementing material product comprises the following steps: stirring and mixing an inorganic cementing material, plastic powder and water to obtain a mixture; the mixture is cured and formed according to a preset shape to form a prefabricated product, and the thickness of the prefabricated product is smaller than or equal to 20 mm under the preset shape; heating the prefabricated product at a specified temperature, wherein the specified temperature is used for enabling the plastic powder in the prefabricated product to be in a molten state; and cooling the heated prefabricated product to obtain the inorganic cementing material product with the thickness of less than or equal to 20mm. According to the inorganic cementing material product and the preparation method thereof, the low cost can be ensured, the preparation conditions are not harsh, and the thinner inorganic cementing material product with good toughness can be prepared.

Owner:广东景龙建设集团有限公司

Binuclear vanadium catalyst as well as preparation method and application thereof

The invention discloses a binuclear vanadium catalyst. The structural general formula of the catalyst is described in the descriptions of the invention. In the structural general formula, the structural formula of Linker is one of the following formulas described in the descriptions of the invention; R1, R2, R3, R4, R5, R '1, R' 2, R '3, R' 4 and R '5 are one or more of hydrogen atoms, alkyl groups, fluorine atoms, bromine atoms and chlorine atoms. The binuclear vanadium catalyst comprises electron withdrawing groups which can be used for ring-opening metathesis polymerization reaction of monomers with weak catalytic reaction capacity and other cycloolefin monomers; the number of polar groups can be effectively adjusted, the topological structure of a polymer can be effectively controlled,and a new strategy is provided for synthesizing functionalized polyolefin.

Owner:HEFEI UNIV OF TECH

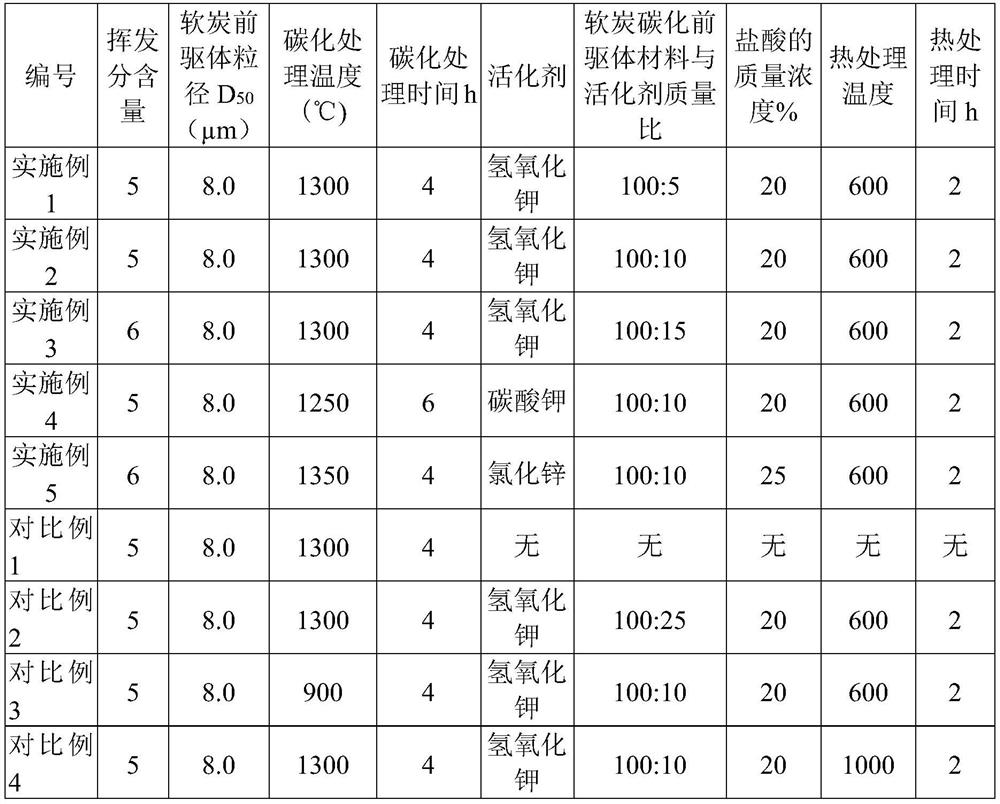

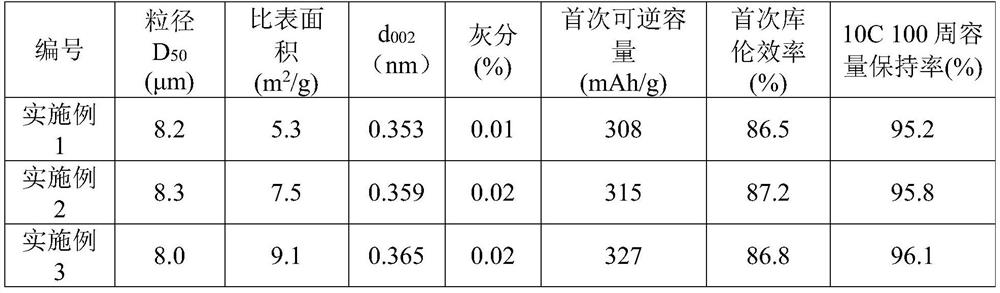

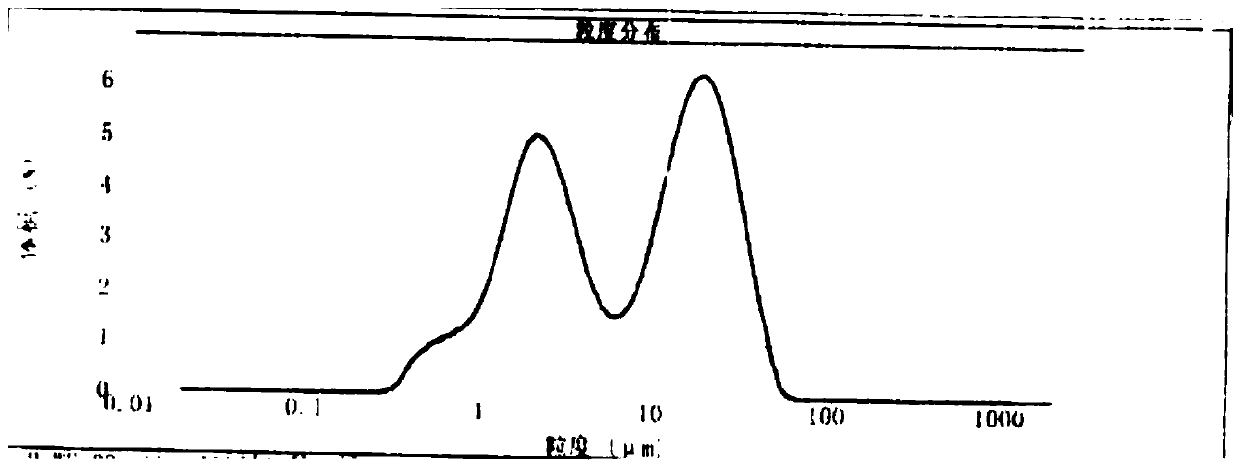

Modified soft carbon negative electrode material, lithium ion battery, negative electrode material and preparation method

PendingCN112551503ASimple preparation processUniform specific surface areaCell electrodesFinal product manufactureElectrical batteryLithium-ion battery

The invention discloses a modified soft carbon negative electrode material, a lithium ion battery, a negative electrode material and a preparation method. The preparation method of the modified soft carbon negative electrode material comprises the steps of sequentially carrying out activation treatment, washing, drying and heat treatment on a soft carbon carbonization precursor material, wherein the soft carbon carbonization precursor material is obtained by carbonizing a soft carbon precursor material at the temperature of 1250-1450 DEG C; the mass ratio of the soft carbon carbonization precursor material to an activating agent in the activating treatment process is 100: (3-15); the activating agent is an alkali metal-containing alkaline inorganic compound and / or chlorine-containing inorganic salt; and the temperature of the heat treatment is 500-700 DEG C. According to the modified soft carbon negative electrode material disclosed by the invention, the structure of the soft carbon isimproved, the amorphous degree of the soft carbon structure is improved, pore lithium storage sites of the soft carbon material are increased, lithium intercalation and deintercalation channels are increased, and the obtained modified soft carbon negative electrode material is high in initial reversible capacity, initial coulombic efficiency and capacity retention ratio after 100 cycles.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

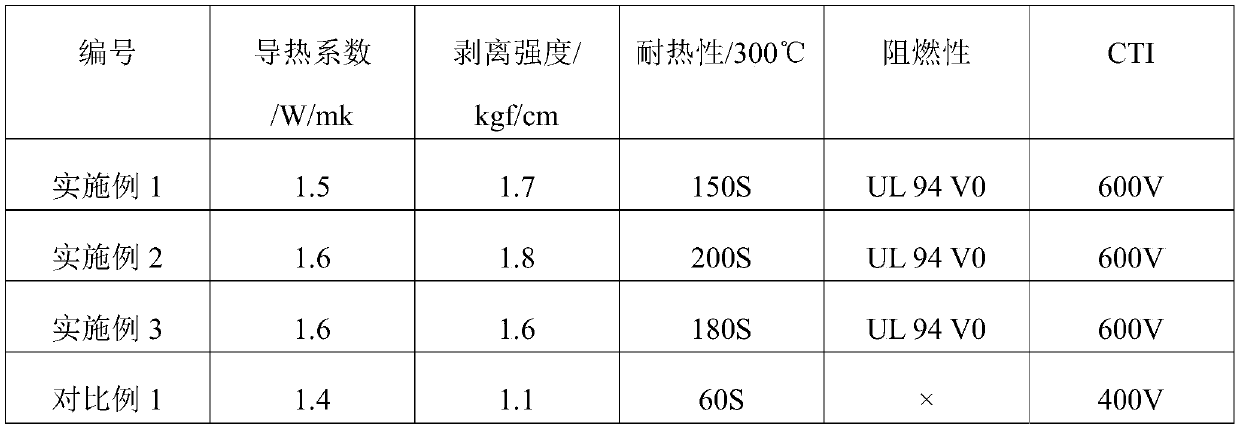

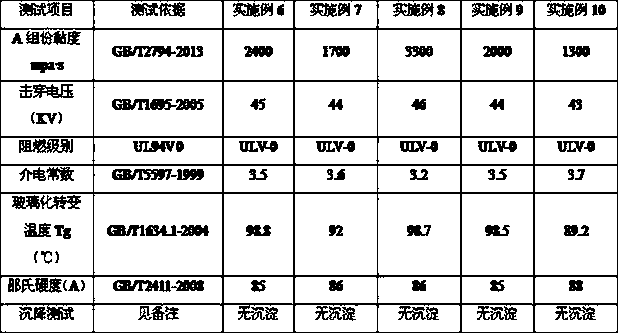

High-thermal-conductive epoxy resin composition and preparation method thereof

The embodiment of the invention provides a high-thermal-conductive epoxy resin composition and a preparation method thereof. According to the high-thermal-conductive epoxy resin composition provided by the embodiment of the invention, through epoxy resin, a filler, a fire retardant and a solvent in appropriate proportion, the epoxy resin composition with the thermal conductivity coefficient beinglarger than 1.5 W / mk and the CTI being up to 600 is prepared, the composition is not complex in component, simple in preparation process, not harsh in preparation condition and low in production cost,and the problems that in the prior art, a body-type thermally conductive and insulating polymer material is cumbersome in preparation process, large in difficulty and high in cost are solved.

Owner:JIANGXI PINSHENG ELECTRONICS CO LTD

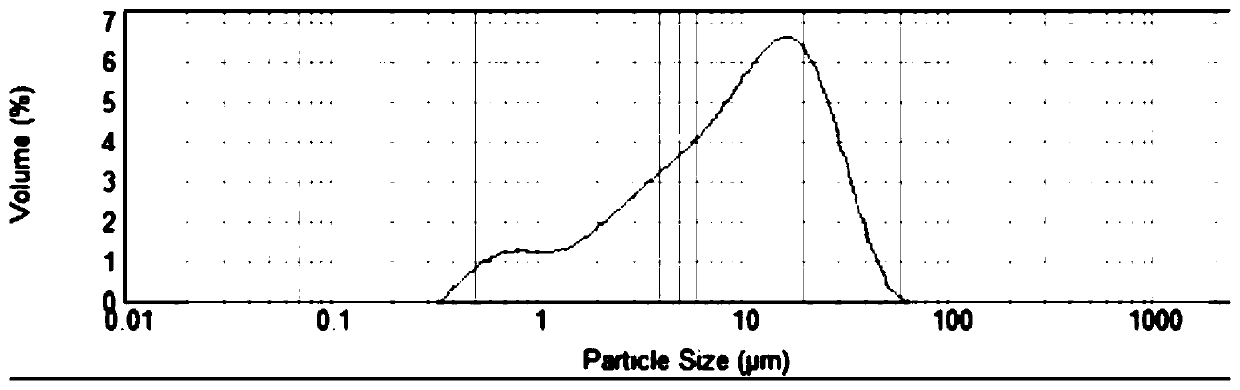

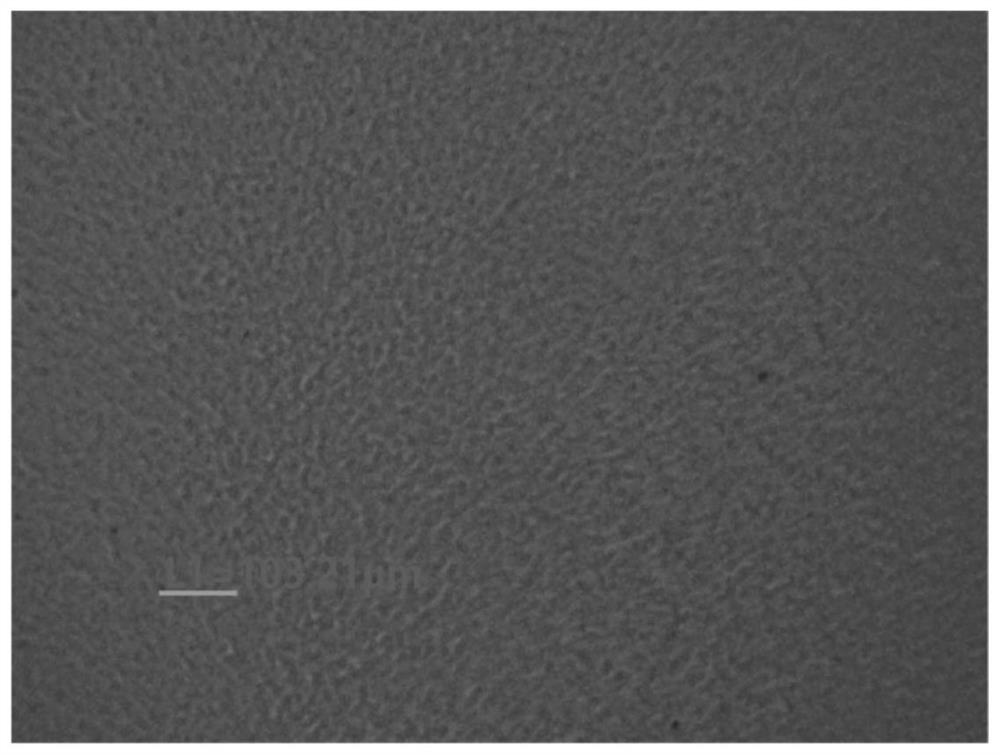

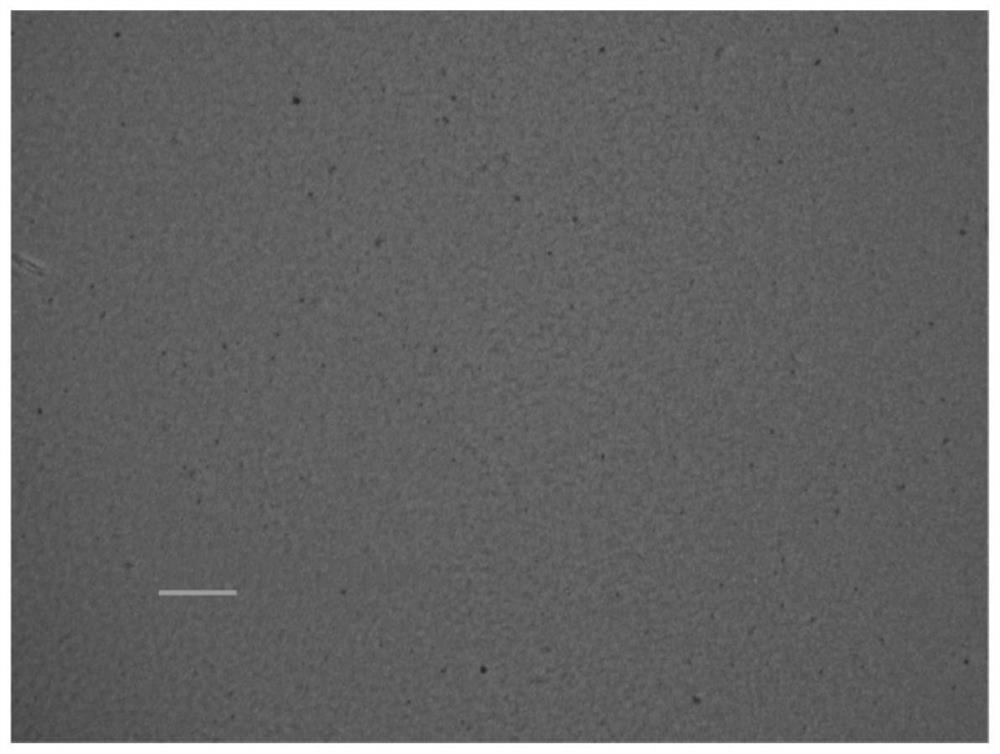

A kind of non-normal distribution aluminum hydroxide powder and its preparation method and application

ActiveCN107964380BReduce manufacturing costEasy to integrateMacromolecular adhesive additivesEpoxy resin adhesivesEpoxyAluminium hydroxide

Owner:SHIJIAZHUANG HUIDE TECH

Graphene and quantum dot co-doped polymer as well as preparation method and application thereof

The invention relates to a graphene and quantum dot co-doped polymer and a preparation method thereof. The graphene and quantum dot co-doped polymer is prepared from the following components: 1-3 parts of graphene; 5-15 parts of semiconductor quantum dots; 20-74 parts of a photosensitive polymer; and 1-5 parts of a photoinitiator. The invention also relates to a preparation method of the graphene and quantum dot co-doped polymer and application of the graphene and quantum dot co-doped polymer in a random laser. The graphene and quantum dot co-doped polymer disclosed by the invention is applied to a random laser and has relatively good light stability, and an emission wave band is easy to adjust; the laser emission threshold is low and the full width at half maximum is small; and the method has the advantages of simple synthesis process, short production period and low cost, and has wide commercialization prospects.

Owner:WUYI UNIV

A kind of preparation method of flake silver powder

ActiveCN110465671BGuaranteed purityGuaranteed electrical conductivityTransportation and packagingMetal-working apparatusBall millPowder

The embodiment of the present invention provides a preparation method of flaky silver powder. In this method, the silver powder is first dispersed and then coated, and then the coated silver powder particles are ball-milled, which effectively prevents the silver powder particles from agglomerating during the ball-milling process. Agglomeration and agglomeration, the prepared flake silver powder has a small particle size and a high tap density.

Owner:湖南中伟新银材料科技有限公司

A method for preparing a supported catalyst for furfural hydrogenation to cyclopentanone

ActiveCN103111299BHigh catalytic efficiencyReduce usageMetal/metal-oxides/metal-hydroxide catalystsPreparation from heterocyclic compoundsActivated carbonBoiling point

The invention discloses a method for preparing a supported catalyst for preparing cyclopentanone with furfural through hydrogenation. An activated carbon nano tube is adopted as a carrier, and loading metal comprises Ni, Cu, Co and Mg. The method for preparing the catalyst adopts a double dropwise adding and coprecipitation method, thus preparing the catalyst with high capacity and improving the catalytic effect of the catalyst; the preparation condition for the catalyst is easy to realize; and the range of raw materials for preparation is wide, precursors of all components are general and the raw materials for preparation can be selected flexibly according to market price. The catalyst prepared by the method has higher catalytic activity, the furfural conversion efficiency is above 96.6%, and the cyclopentanone selectivity is above 95.4%, so that the catalyst can be used for preparing the cyclpentanone with the furfural as a raw material, the problem that cyclopentanone self polymerization is easy to occur so as to generate a material with high boiling point in the process of generation of cyclopentanone by taking adipic acid as a raw material is solved, and the product yield is improved.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com