High-strength and high-conductivity heat-resistant copper-chromium alloy material and preparation process thereof

An alloy material and a preparation process technology, which are applied in the field of high-strength, high-conductivity and heat-resistant copper-chromium alloy materials and the preparation process thereof, can solve the problems of high price of Ag, deteriorated electrical conductivity, unstable composition, etc., and achieve less harsh preparation conditions. , easy to promote industrialization, the effect of reasonable component formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

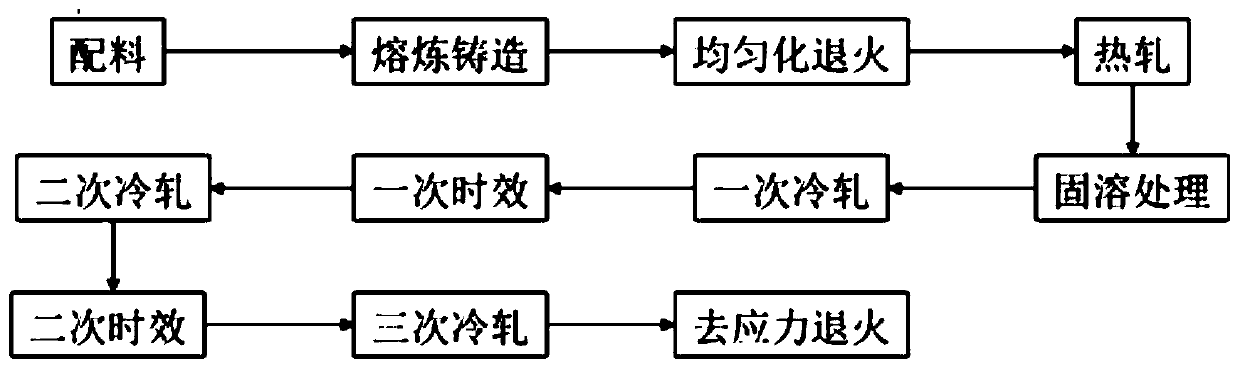

Method used

Image

Examples

Embodiment 1

[0061] This example provides a high-strength, high-conductivity, heat-resistant copper-chromium alloy material, including the following components in mass percentage:

[0062] Cr 0.1wt%, Ca 0.02wt%, Sr 0.001wt%, Ce 0.001wt%, Yb 0.001wt%, and the balance is Cu.

Embodiment 2

[0064] This example provides a high-strength, high-conductivity, heat-resistant copper-chromium alloy material, including the following components in mass percentage:

[0065] Cr 1.0wt%, Ca0.05wt%, Sr 0.2wt%, Ce 0.2wt%, Yb 0.2wt%, and the balance is Cu.

Embodiment 3

[0067] This example provides a high-strength, high-conductivity, heat-resistant copper-chromium alloy material, including the following components in mass percentage:

[0068] Cr 0.5wt%, Ca 0.06wt%, Sr 0.1wt%, Ce 0.1wt%, Yb 0.1wt%, and the balance is Cu.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com