High-temperature resistant one-component isotropic conductive adhesive and preparation method thereof

An isotropic, conductive adhesive technology, used in conductive adhesives, adhesives, epoxy resins, etc., can solve problems such as poor high temperature resistance, and achieve high mechanical properties, good controllability, and easily available raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The composition and mass percentage of the conductive adhesive are as follows: epoxy resin EPON828 10.6%; silver nanowire 65%; AG-804.5%; MX1257%; TS-7200.6%; NC5130.7%; Methyltetrahydrophthalic anhydride 11%; 2-ethyl-4-methyl-imidazole 0.2%.

[0027] The preparation process and process are as follows:

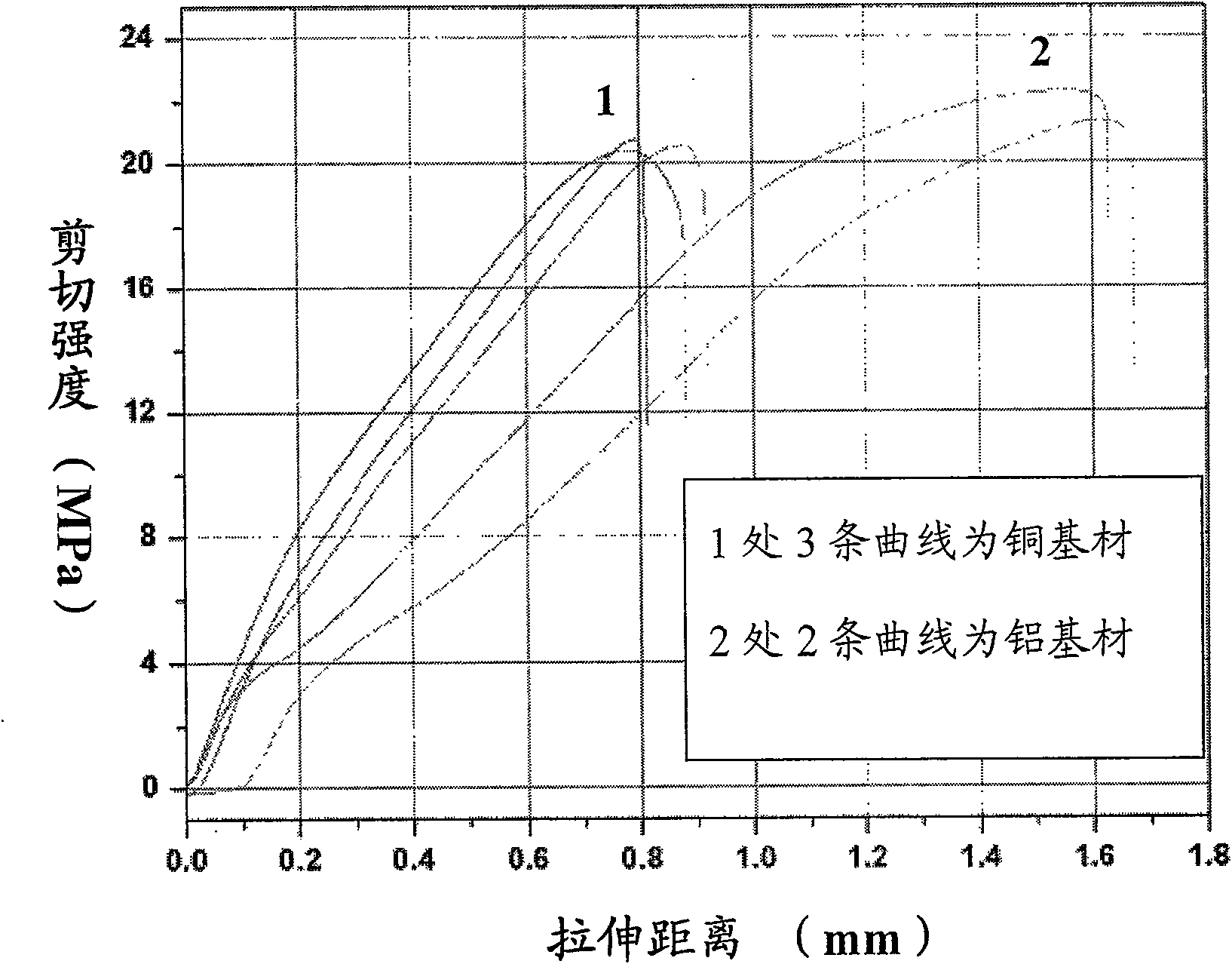

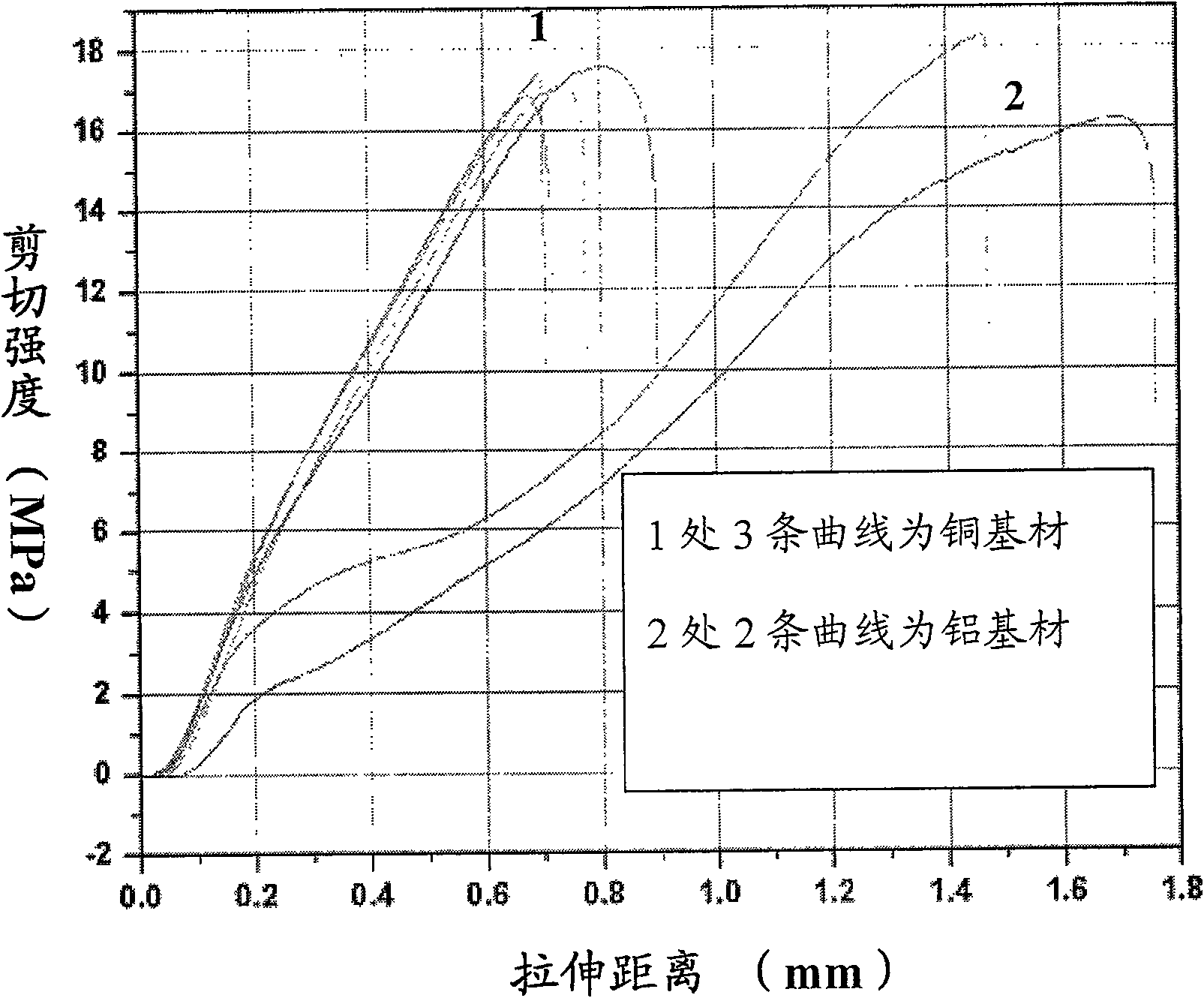

[0028] First, mix epoxy resin EPON828, core-shell toughened epoxy resin MX125, phenyltrimethoxysilane, multifunctional epoxy resin AG-80, fumed silica TS-720, toughness diluent NC513, and then Process in a vacuumized high-speed mixer at a rate of 2000 rpm for 3 minutes, then add dried silver nanowires in proportion to it, and process it in a mixer at 2000 rpm for 3 minutes, take it out after mixing, and add assimilated silver nanowires to it. agent methyltetrahydrophthalic anhydride and curing accelerator 2-ethyl-4-methyl-imidazole. After mixing at 2000 rpm for 30s, take it out and package it in a special rubber tube. The curing condition is 170°C, 30min. The shear ...

Embodiment 2~10

[0033] A method for preparing a single-component high-temperature-resistant isotropic conductive adhesive, the preparation process and process are the same as in Example 1. The mass percentages of each component are as follows:

[0034]

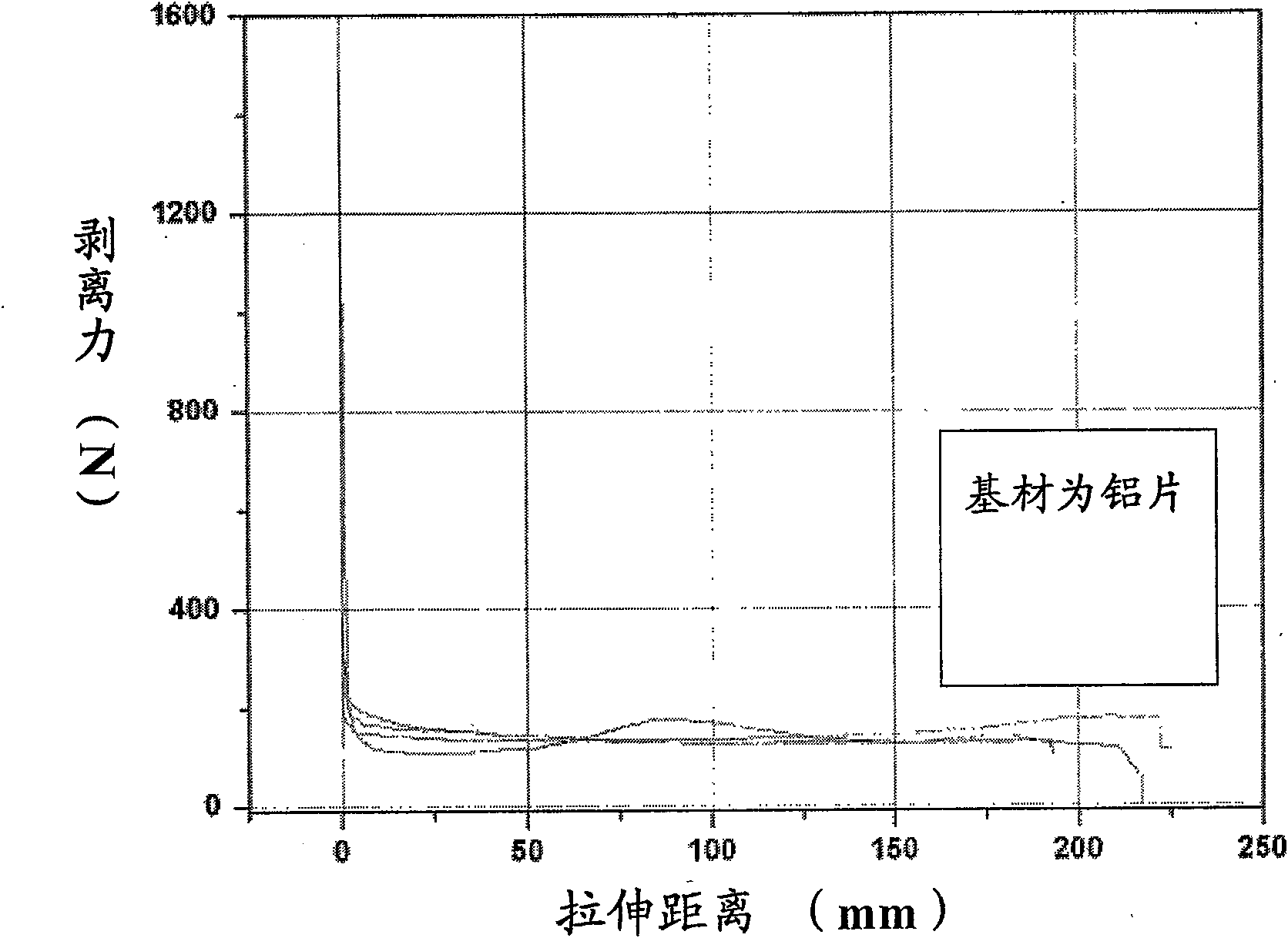

[0035] Each embodiment can prepare a single-component high-temperature-resistant isotropic conductive adhesive product. The comprehensive performance has the characteristics and effects described in the content of the present invention, and can meet the bonding of structural parts of different substrates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com