A kind of preparation method of flake silver powder

A flake silver powder and silver powder technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of affecting the conductivity of silver powder, affecting the purity of silver powder, and low dispersion, so that the preparation conditions are not harsh, the conductivity is guaranteed, and the vibration The effect of high solid density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The embodiment of the present invention provides a preparation method of flaky silver powder. In this method, the silver powder is first dispersed and then coated, and then the coated silver powder particles are ball-milled, which effectively prevents the silver powder particles from agglomerating during the ball-milling process. Agglomeration and agglomeration, the prepared flake silver powder has a small particle size and a high tap density.

[0040] In order to better understand the above technical solution, the above technical solution will be described in detail below in conjunction with specific implementation manners.

Embodiment 1

[0042] A preparation method of flake silver powder, the steps comprising:

[0043] S1: Add the solvent to the silver powder raw material, mix well and then add the coating agent;

[0044] S2: injecting carbon dioxide into the product of step S1 for coating treatment;

[0045] S3: the product obtained in the solid-liquid separation step S2, and the solid product is subjected to ball milling;

[0046] S4: washing the product after ball milling in step S3 after sintering;

[0047] S5: Add a dispersant to the product obtained in step S4, stir evenly, and obtain the flaky silver powder after drying;

[0048] The solvent is an alcohol solution of bismuth halide.

[0049] In step S1, the mass ratio of the solvent to the silver powder raw material is (120-150):1. The coating agent includes at least one of sodium hydroxide or potassium hydroxide. The mass ratio of the silver powder raw material to the coating agent is 1:(30-50). In the solvent, the concentration of the halogen bi...

Embodiment 2

[0057] This example has actually prepared a kind of flaky silver powder, and specific steps include:

[0058] S1: Add the solvent to the silver powder raw material, mix well and then add the coating agent;

[0059] S2: injecting carbon dioxide into the product of step S1 for coating treatment;

[0060] S3: the product obtained in the solid-liquid separation step S2, and the solid product is subjected to ball milling;

[0061] S4: washing the product after ball milling in step S3 after sintering;

[0062] S5: Add a dispersant to the product obtained in step S4, stir evenly, and obtain the flaky silver powder after drying;

[0063] The solvent is ethanol solution of bismuth chloride.

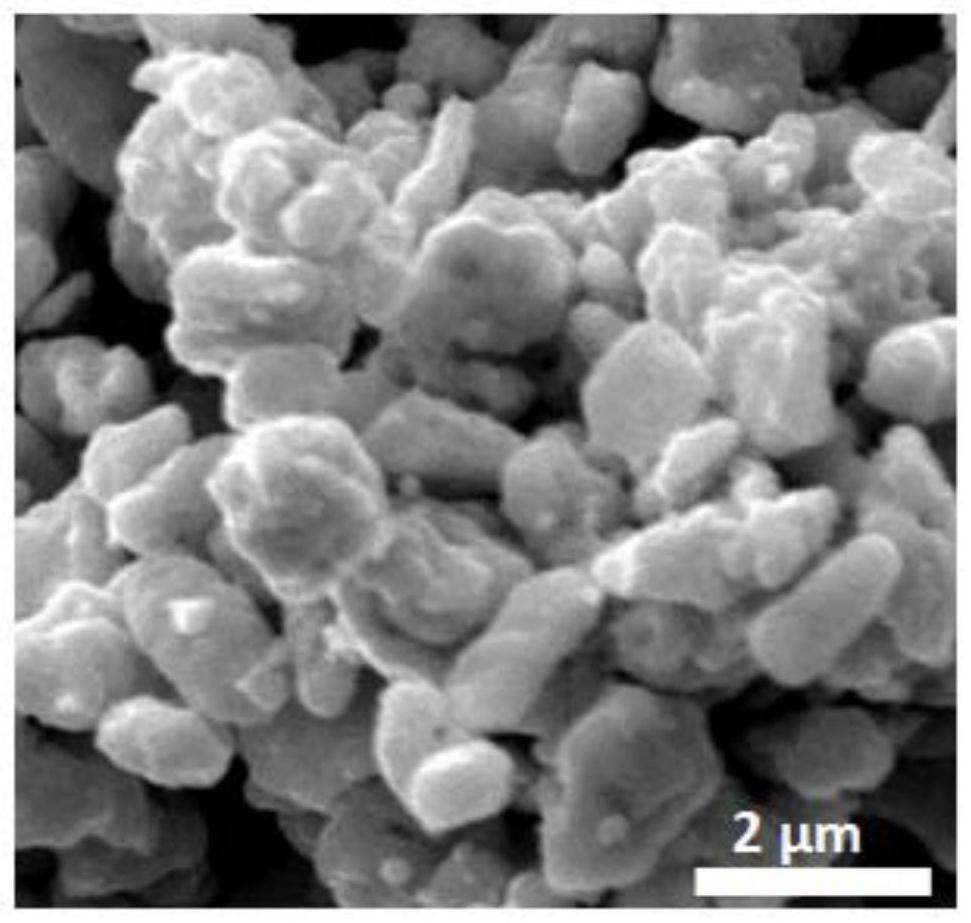

[0064] The microscopic morphology of the silver powder raw materials used is as follows: figure 1 As shown, the shape is irregular and the surface is rough. The tap density is 4.2g / cm 3 .

[0065] In step S1, the mass ratio of the solvent to the silver powder raw material is 120:1. After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com