Inorganic cementing material product and preparation method thereof

A technology of inorganic cementitious materials and products, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as fragility, and achieve the effect of thin toughness and enhanced toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

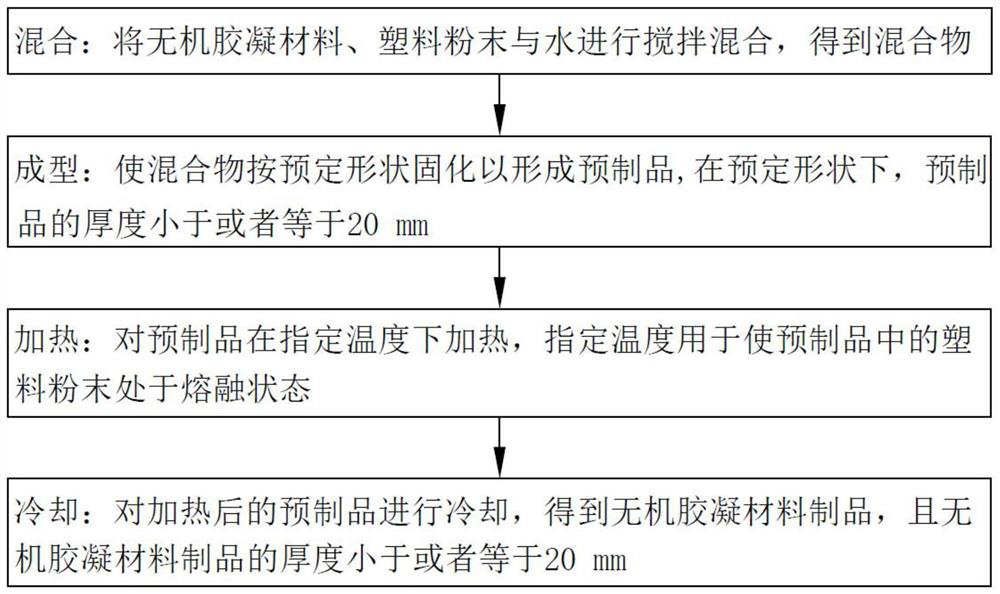

[0036] The preparation method of the inorganic cementitious material product comprises the following steps: stirring and mixing the inorganic cementitious material, plastic powder and water to obtain a mixture; solidifying the mixture according to a predetermined shape to form a pre-product, and under the predetermined shape, the thickness of the pre-product is less than or equal to 20mm; heat the preform at a specified temperature, and the specified temperature is used to make the plastic powder in the preform in a molten state; cool the heated preform to obtain an inorganic cementitious material product with a thickness of less than or equal to 20mm .

[0037] In the embodiment of the present application, by stirring and mixing the inorganic cementitious material, plastic powder and water, the plastic powder is dispersed in the inorganic cementitious material, so that when the mixed and dispersed mixture is cured to form a pre-product, the plastic powder will be in the inorga...

Embodiment 1

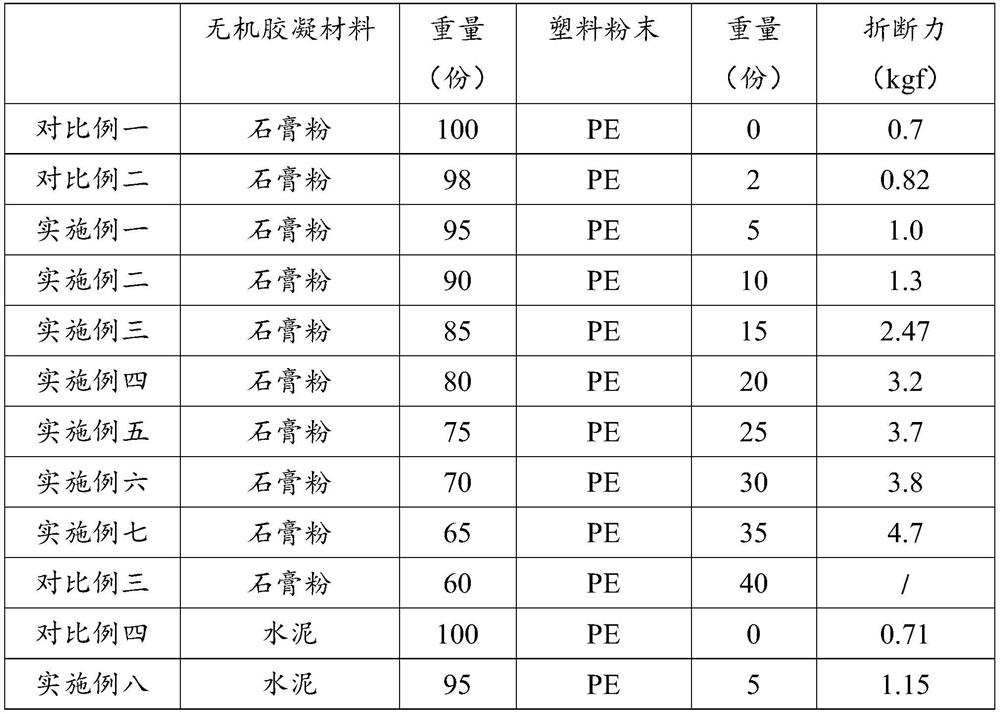

[0075] This embodiment provides an inorganic cementitious material product, which, in parts by weight, includes: 95 parts of inorganic cementitious material and 5 parts of plastic powder. The inorganic cementitious material is gypsum powder, and the plastic powder is PE.

[0076] This embodiment also provides a preparation method of an inorganic cementitious material product. The preparation method is prepared according to the following steps: placing gypsum powder, PE and water in a stirring tank, stirring evenly with a stirring rod, and obtaining a slurry mixture; pour the mixture into a plate-shaped mold, solidify and form at normal temperature and pressure, and obtain a flat-plate preform after demoulding; put the flat-plate preform into a constant temperature furnace, and heat it for 0.3h under the condition of air atmosphere and 150°C; The heated preform was cooled to obtain an inorganic cementitious material product, and the thickness of the inorganic cementitious mater...

Embodiment 2

[0078] The difference between this embodiment and the first embodiment is only that the weight parts of the inorganic cementitious material and the plastic powder are different. In this embodiment, the inorganic cementitious material products, in terms of weight parts, include: 90 parts of inorganic cementitious materials , 10 parts of plastic powder. The inorganic cementitious material is gypsum powder, and the plastic powder is PE.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com