Laser engraved ceramic coating anilox roller and production method thereof

A laser engraving, anilox roller technology, applied in ceramic layered products, chemical instruments and methods, printing and other directions, can solve problems such as high price, achieve long service life, guarantee technical effects, and ideal finish.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

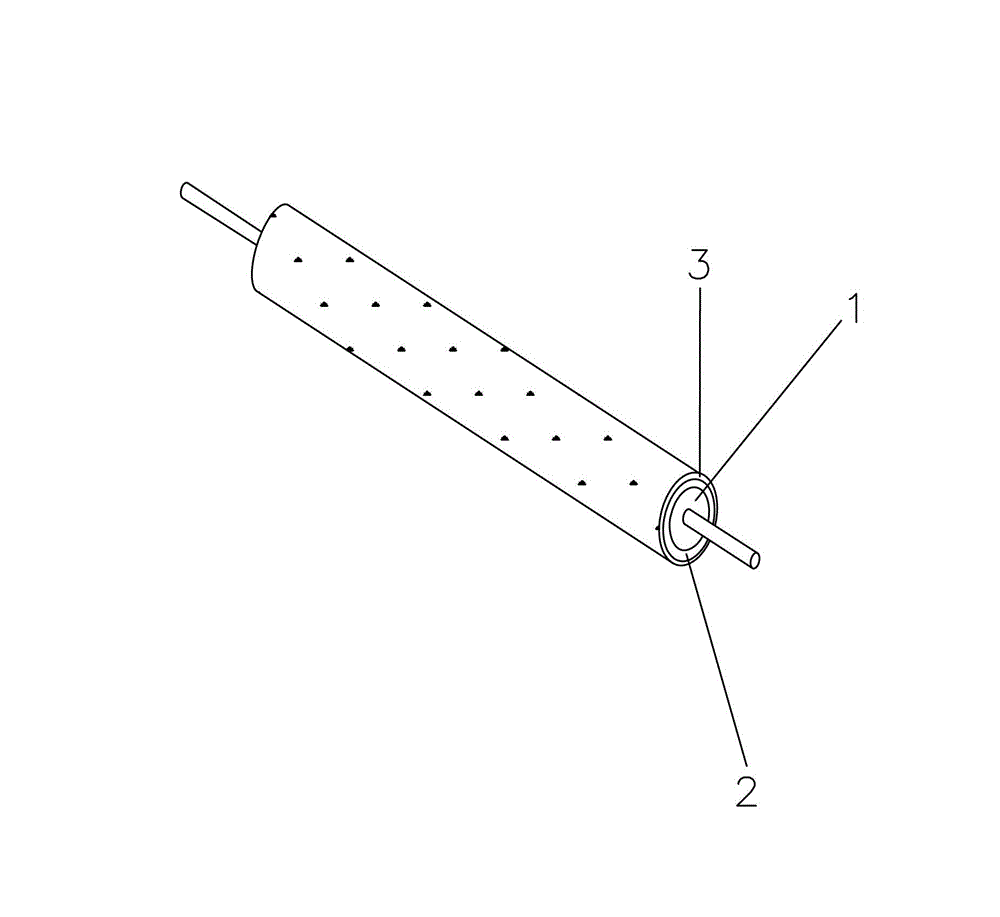

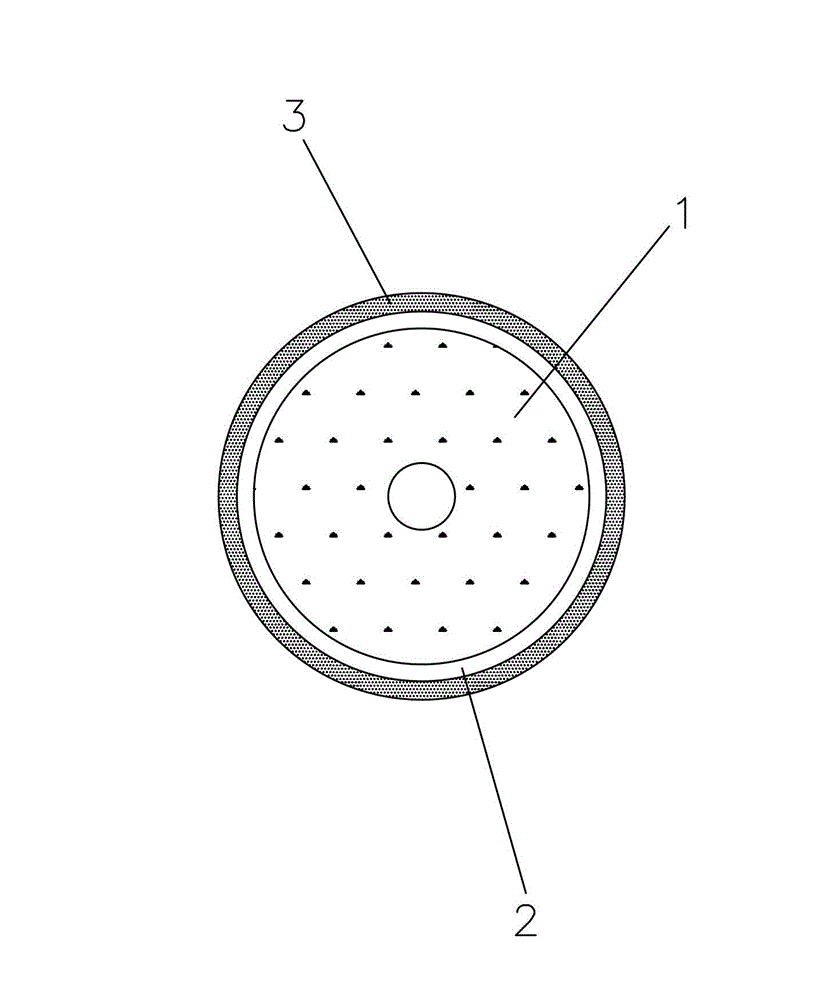

[0035] Such as figure 1 with figure 2 As shown, a laser-engraved ceramic coated anilox roll includes a roll base 1, a metal bonding bottom layer 2 and a ceramic coating 3; the metal bonding bottom layer 2 is fixed on the roll surface of the roll base 1, and the ceramic coating Layer 3 is fixed on said metal bonded bottom layer 2 .

[0036] Wherein, the thickness of the metal bonded bottom layer 2 is designed between 0.05-0.15 mm, and its material is FeCrAlY, and NiCrAlY, CoCrAlY, MCrAlY, NiAl or NiCr can also be used here, which is not limited here, and these all belong to the present invention protection range; the thickness of the ceramic coating is designed to be 0.2-0.5mm, and its material is Cr 2 o 3 , 10-20wt% Al can also be used here 2 o 3 and 80-90wt% Cr 2 o 3 The mixture of the two is not limited here, and these also belong to the protection scope of the present invention.

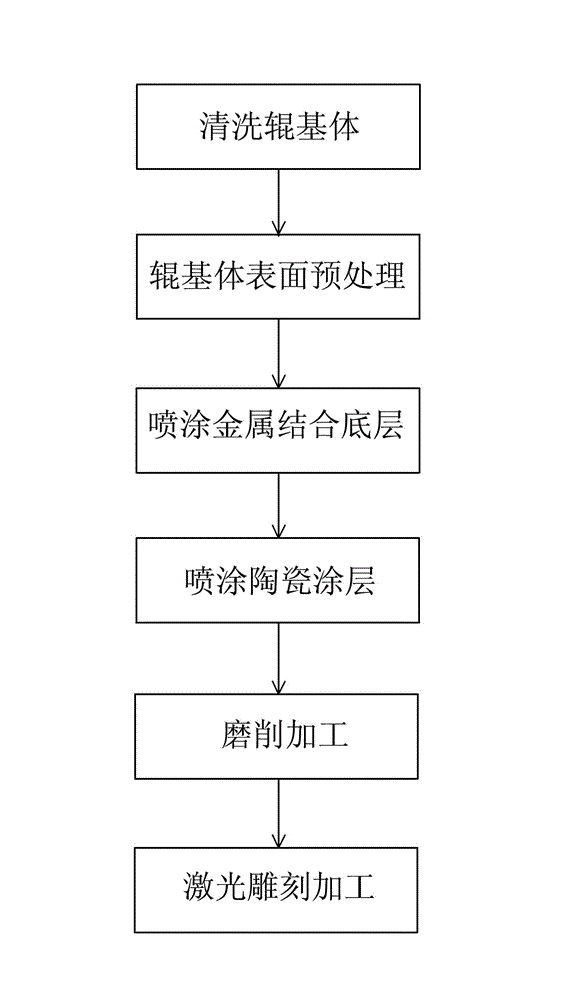

[0037] On this basis, another task of the present invention is accomplished like this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com