Patents

Literature

90results about How to "Guaranteed technical effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-toxicity solvent adhesive for bonding of rigid PVC plastic pipeline system

InactiveCN1844286AImprove hygieneIn line with the trend of health and environmental protectionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesivePolyvinyl chloride

The invention discloses a low-toxic solvent adhesive used in unplasticised polyvinyl chloride plastic duct system for adhesion. The adhesive of this invention consists of best matches of polychloroethylene basic resin, flexible polymer toughened and modified resin and low-toxic mixed solvent, also can include auxiliary agents auxiliary agent such as adhesion-promotion resin, anti-oxidant, thixotropic agent and bulk additive. Using the adhesive of this invention can make the adhesive site of the PVC-U pipe system possess good preliminary strength and final strength and have good sanitary performance. The invention is of simple process for preparing and low cost of manufacture.

Owner:GUANGDONG LIANSU TECH INDAL

Plush blanket and processing method thereof

The invention relates to a plush blanket and a processing method thereof, and belongs to the technical field of terylene fiber blankets. The plush blanket comprises a surface structure and base structure, wherein the surface structure is prepared from a raw material which is a 75-150D / 96F FDY (fully drawn yarn) irregular terylene yarn with 8-16 network points per meter and elongation of 2-5%; the base structure is prepared from a raw material which is a 68-100D DTY (draw textured yarn) terylene yarn; the mass percent of the FDY irregular terylene yarn in the blanket is 70-85%; and the mass percent of the DTY terylene yarn in the blanket is 30-15%. The plush blanket has the advantages that a pile surface with the pile height of 25-80 mm can be obtained; the noble and classic fashion pursuing of people is satisfied; and because the pile height reaches 25-80 mm, the blanket has perfect heat retention property, soft touch feeling and delicate sense. The processing method provided by the invention has no strict requirements on the processing steps and equipment, thus the technical effect of the plush blanket is guaranteed.

Owner:宿迁市群英纺织印染科技有限公司

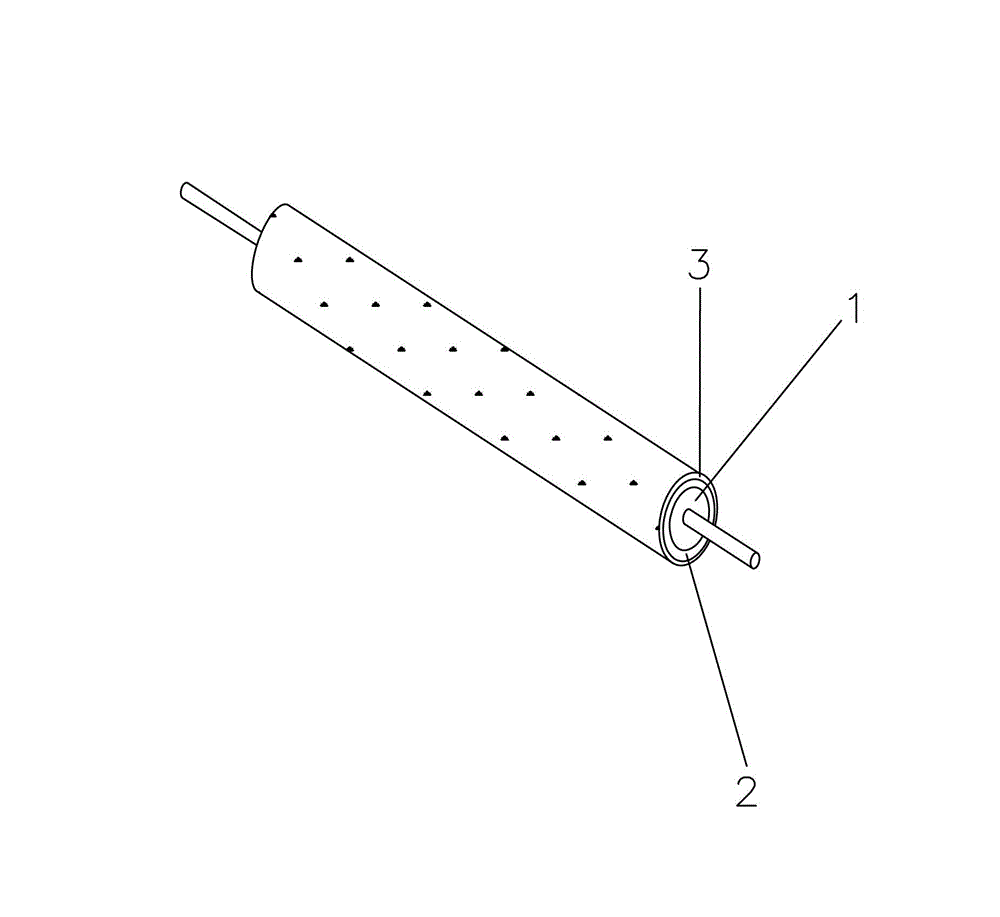

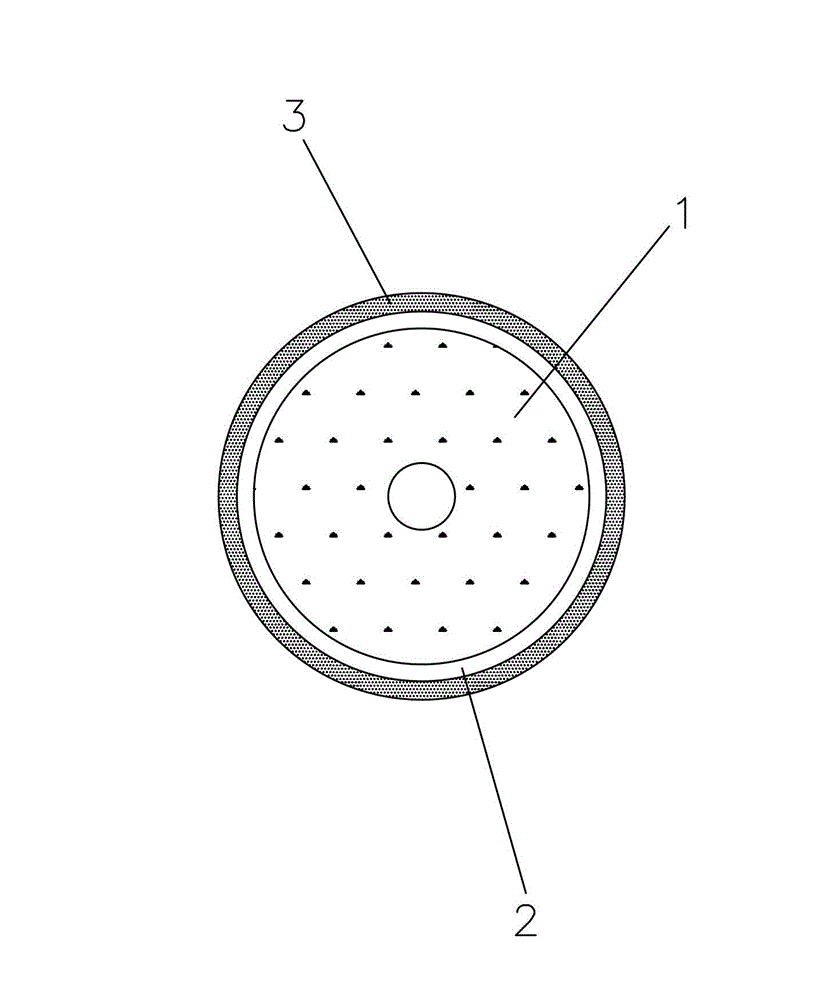

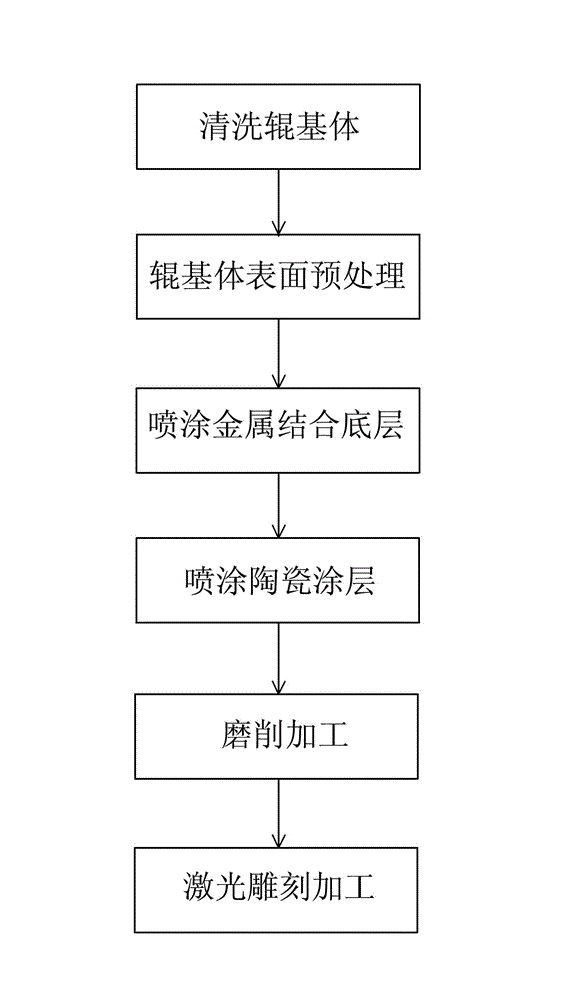

Laser engraved ceramic coating anilox roller and production method thereof

InactiveCN104002552AImprove printing accuracyHigh densityCeramic layered productsPrinting press partsCeramic coatingSpray coating

The invention discloses a laser engraved ceramic coating anilox roller and a production method thereof. The laser engraved ceramic coating anilox roller comprises a roller body, a transition layer and a working layer; the transition layer is a metal combined bottom layer, and the working layer is a ceramic coating layer; the transition layer is fixed onto the roller surface of the roller body, and the ceramic coating layer is fixed to the transition layer. The production method includes the steps of roller body cleaning, roller body surface pretreatment, metal combined bottom layer spray coating, ceramic working layer spray coating, spray coated ceramic working layer abrasive machining and ceramic working layer laser engraving machining. The laser engraved ceramic coating anilox roller has the advantages of long service life and high printing accuracy. The production method is fewer in process steps and not demanding in production conditions, can ensure the technical effect of the ceramic anilox roller, and is applicable to industrial batch production.

Owner:SUZHOU ZHISHUN SURFACE TECH

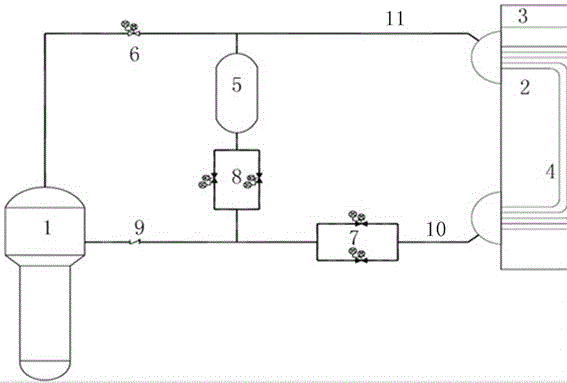

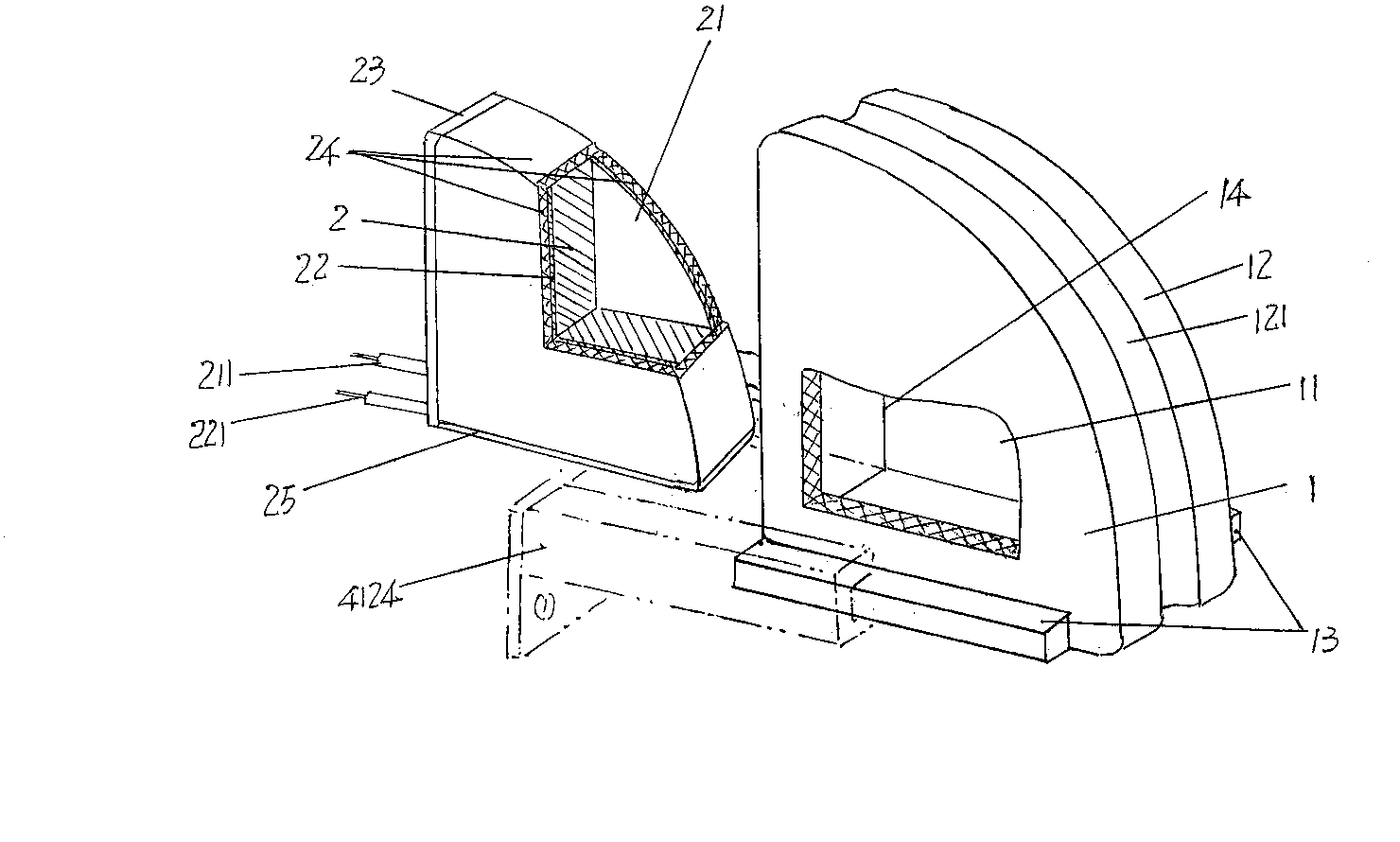

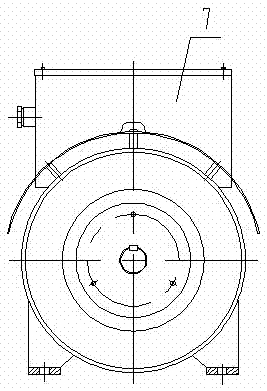

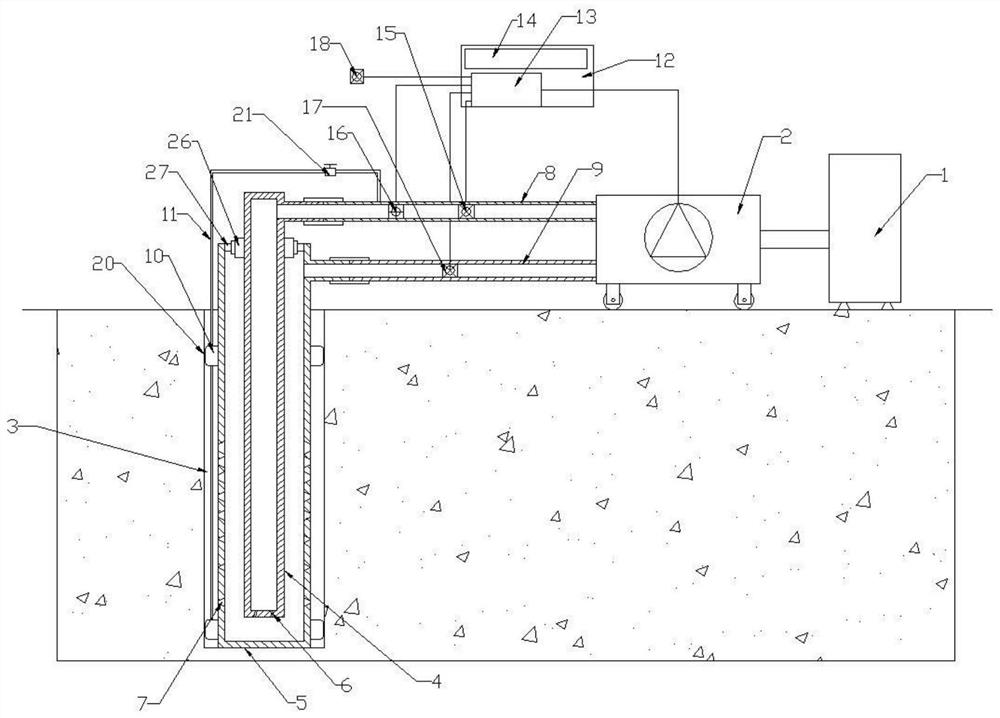

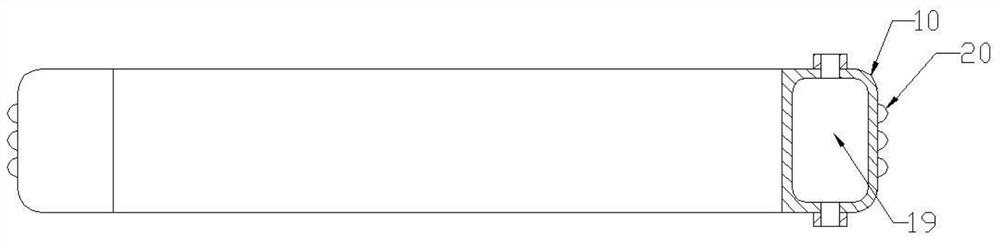

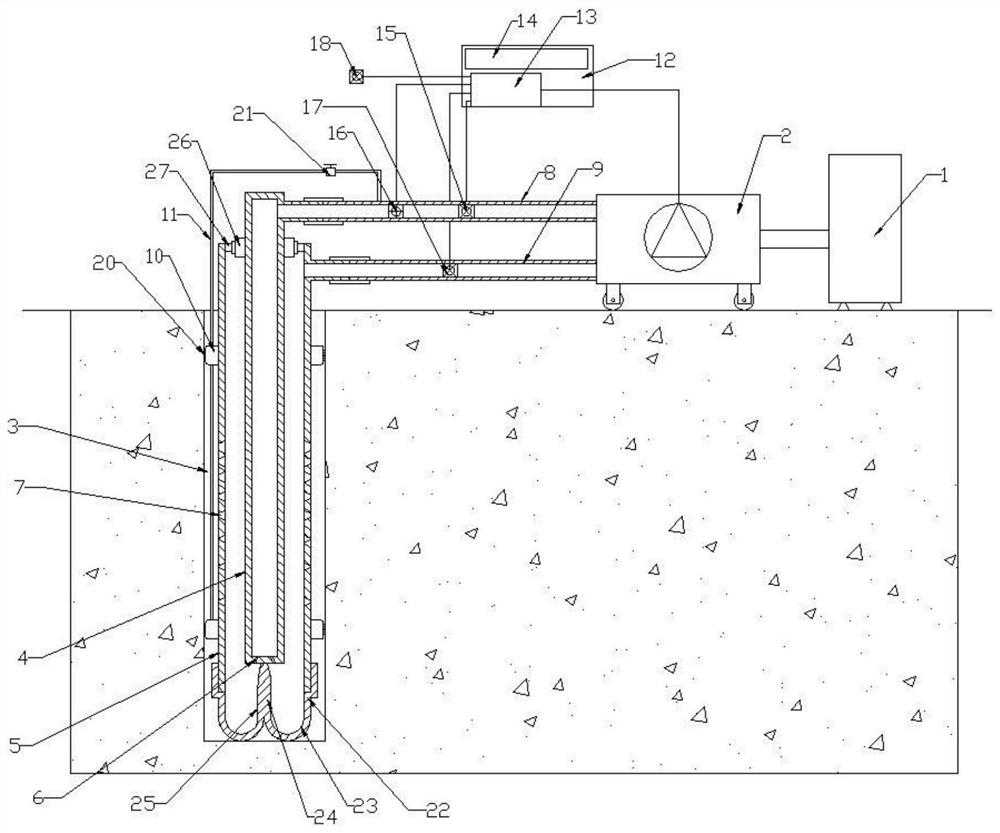

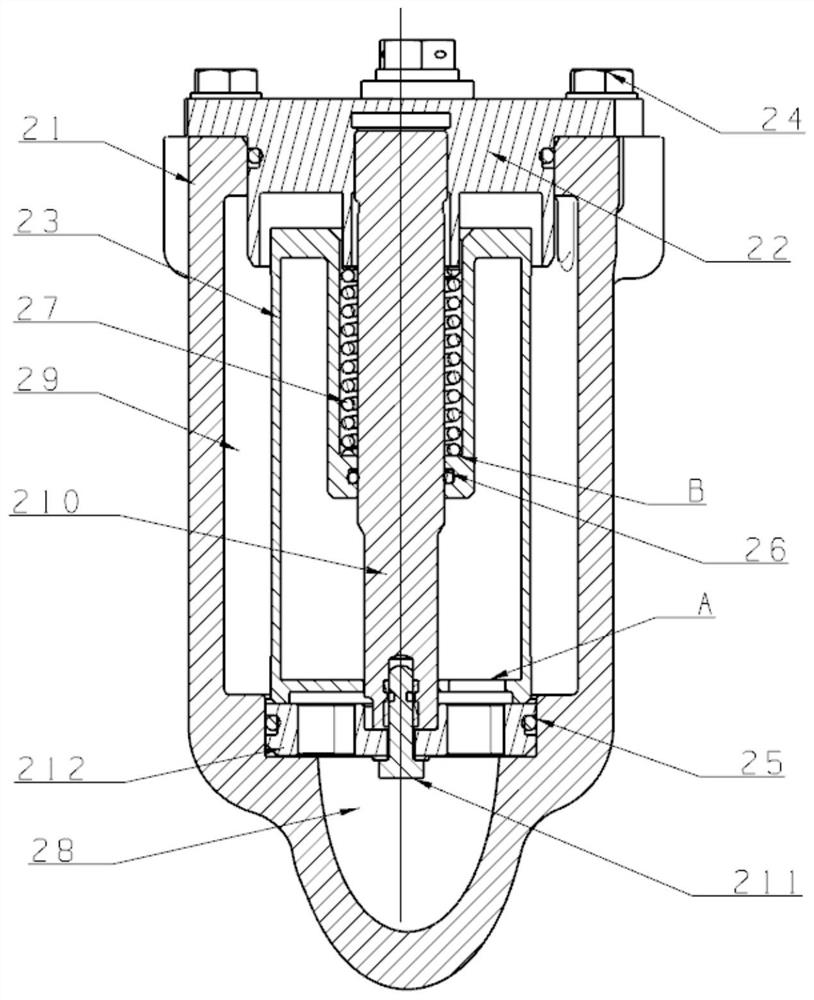

Steam generator secondary side passive residual heat removal system

ActiveCN105957567AGuaranteed technical effectNuclear energy generationCooling arrangementNuclear engineeringEvaporation

The invention discloses a steam generator secondary side passive residual heat removal system. The system comprises: a heat exchanger, which is placed in a cooling water tank, with one end of a condensation water pipe being connected to a lower seal head of the heat exchanger, and the other end being connected to a main water supply pipe of the steam generator; a steam pipeline, one end of which is connected to an upper seal head of the heat exchanger, and the other end of which is connected to a steam outlet of the steam generator; N water-replenishing tanks, the upper parts of which are communicated with the steam pipeline, and the lower parts of which are communicated with the condensation water pipe; M air coolers, the evaporation sections of which are arranged in the cooling water tank, and the condensation sections of which are arranged in the atmosphere outside the cooling water tank. The steam generator secondary side passive residual heat removal system provided by the invention reaches the technical effects of long-term export of core residual heat and maintenance of the reactor at a safe state.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Plush blanket and processing method thereof

The invention relates to a plush blanket and a processing method thereof, and belongs to the technical field of terylene fiber blankets. The plush blanket comprises a surface structure and base structure, wherein the surface structure is prepared from a raw material which is a 75-150D / 96F FDY (fully drawn yarn) irregular terylene yarn with 8-16 network points per meter and elongation of 2-5%; thebase structure is prepared from a raw material which is a 68-100D DTY (draw textured yarn) terylene yarn; the mass percent of the FDY irregular terylene yarn in the blanket is 70-85%; and the mass percent of the DTY terylene yarn in the blanket is 30-15%. The plush blanket has the advantages that a pile surface with the pile height of 25-80 mm can be obtained; the noble and classic fashion pursuing of people is satisfied; and because the pile height reaches 25-80 mm, the blanket has perfect heat retention property, soft touch feeling and delicate sense. The processing method provided by the invention has no strict requirements on the processing steps and equipment, thus the technical effect of the plush blanket is guaranteed.

Owner:宿迁市群英纺织印染科技有限公司

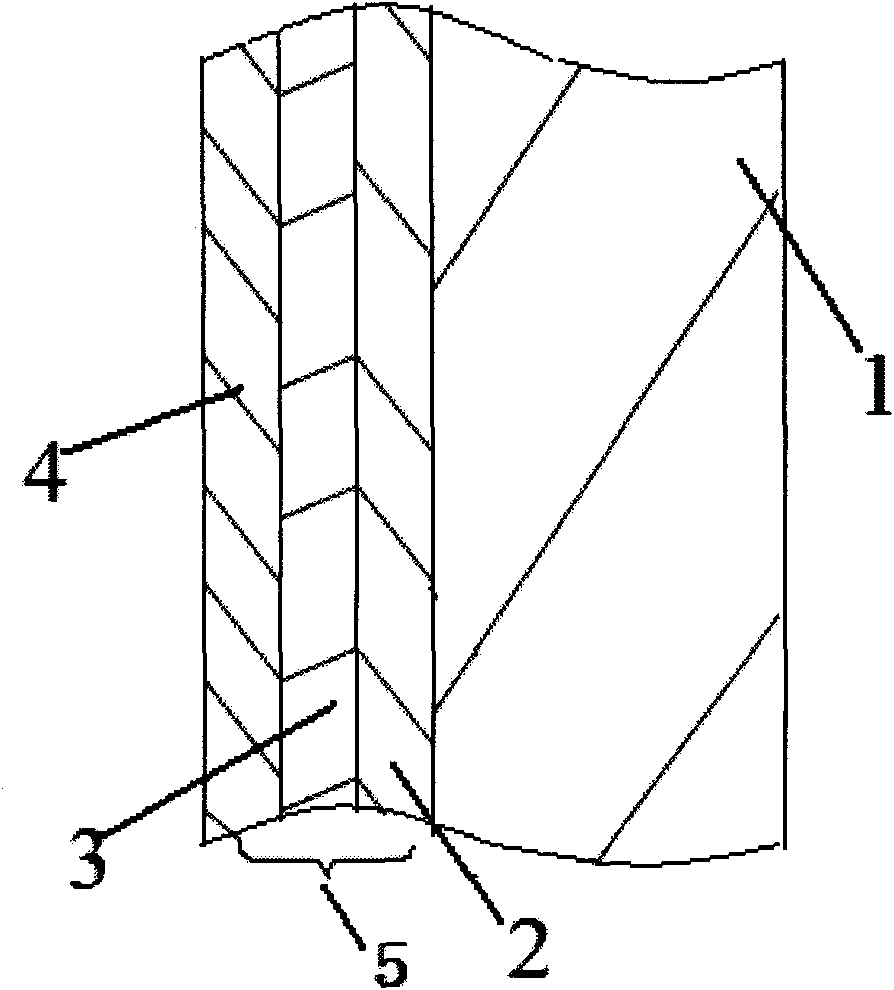

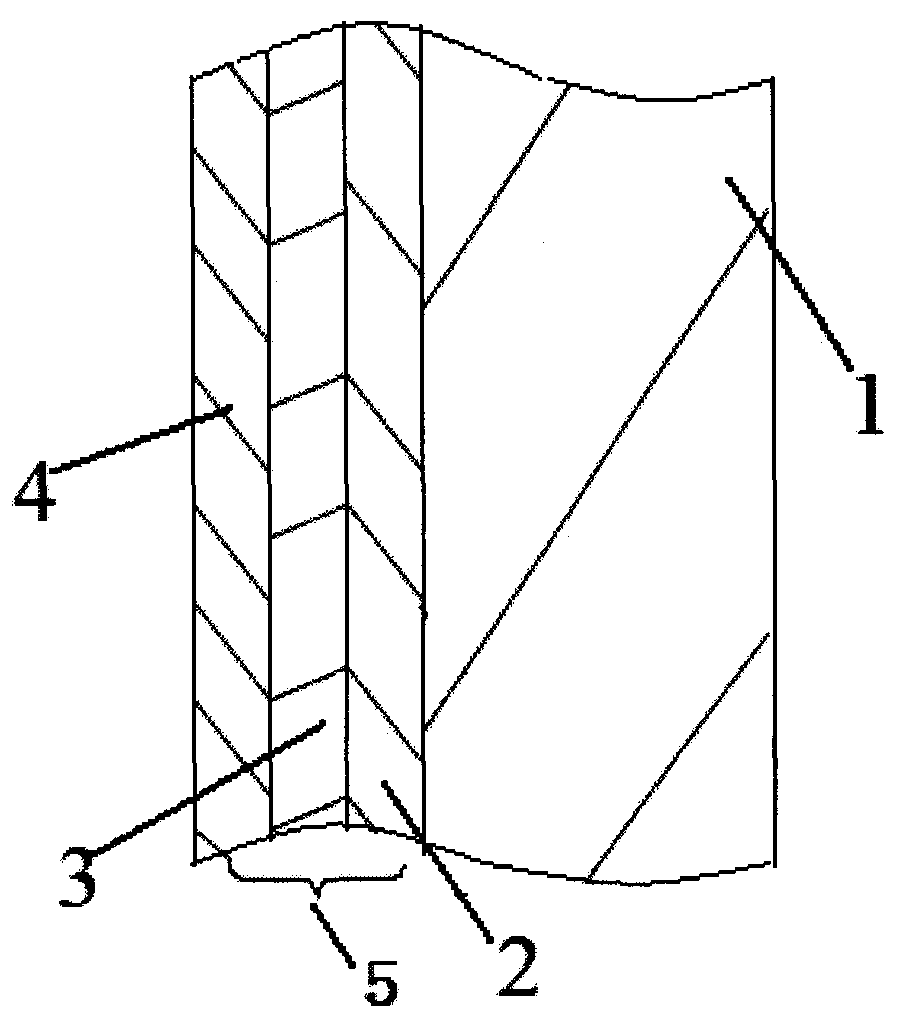

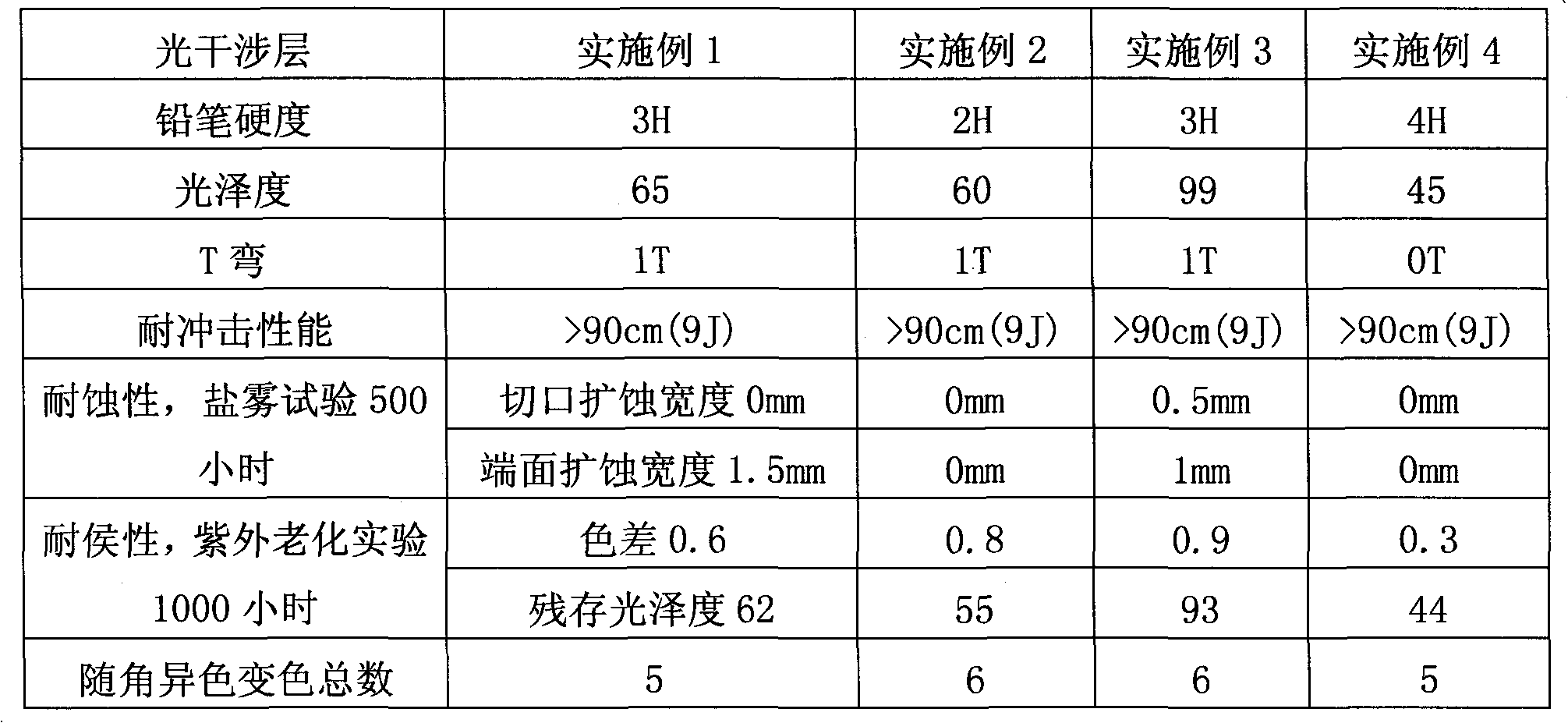

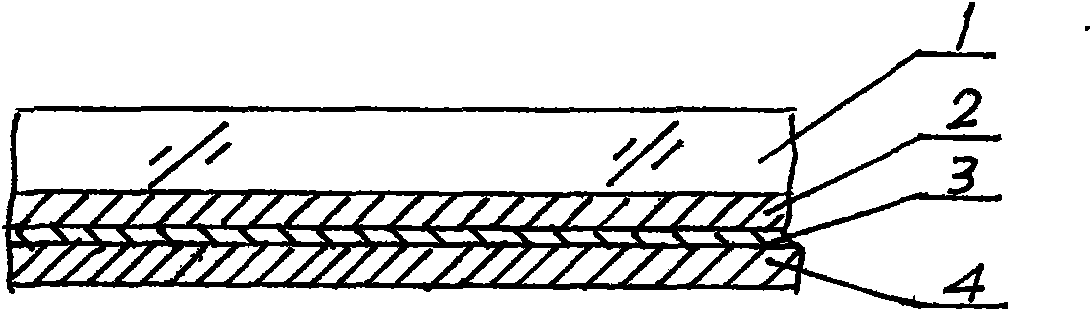

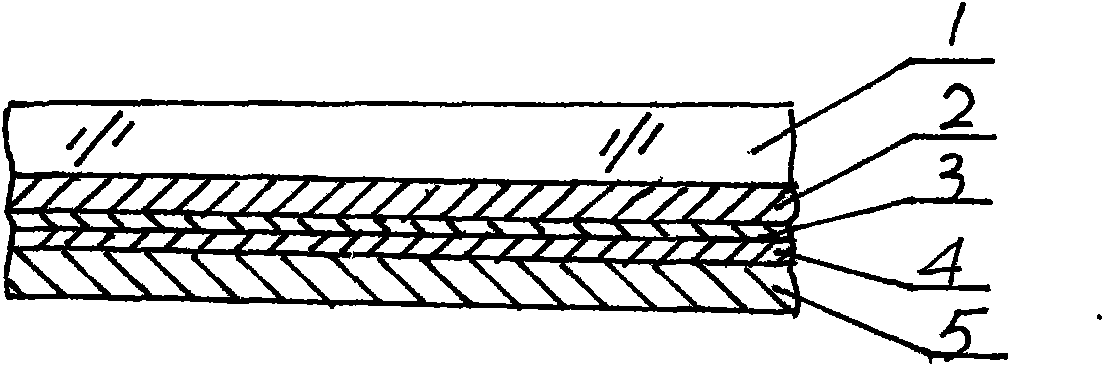

Chameleonic colored coating steel plate and machining method thereof

InactiveCN101811386AGuaranteed technical effectExtended service lifeSynthetic resin layered productsPretreated surfacesSheet steelMachining

The invention discloses a chameleonic colored coating steel plate which comprises a colored coating steel plate baseplate (1) with a colored coating (5) arranged on the surface of at least one side, wherein the colored coating (5) comprises a color masking layer (2) and an angle-dependent discoloring layer (3); the angle-dependent discoloring layer (3) is arranged on the color masking layer (2), and a light interference layer (4) is arranged on the surface of the angle-dependent discoloring layer (3). The machining method of the chameleonic colored coating steel plate comprises the following steps of: (A) uncoiling and butting to obtain a steel plate to be washed; (B) degreasing and washing; (C) carrying out passivating treatment; (D) coating the color masking layer; (E) coating the angle-dependent discoloring layer; and (F) coating the light interference layer. The colored coating steel plate has an angle-dependent discoloring reflection effect on lights with different colors along with the angle change, promotes the grade of the product, expands the anti-counterfeiting purpose and prolongs the service life of the steel plate; and the provided machining method has concise steps, can satisfy the industrial batch production requirements and has no influences on machining occasion environment.

Owner:CHANGSHU HUAYE STEEL STRIP

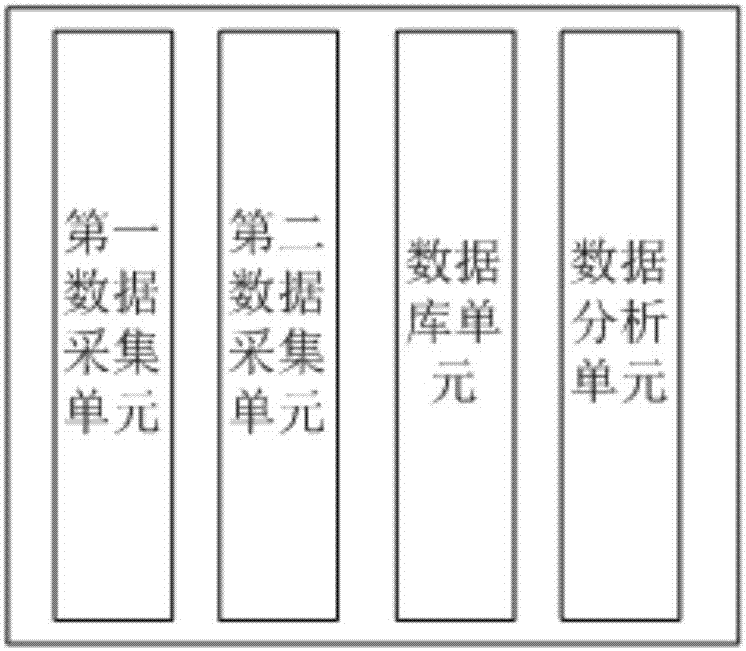

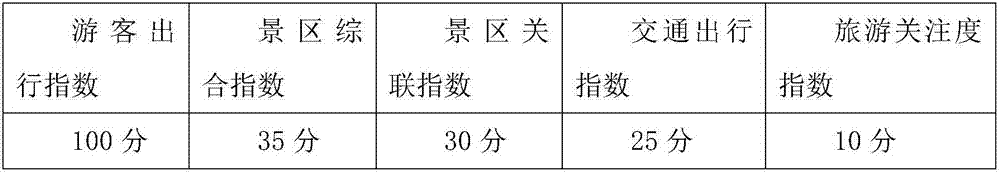

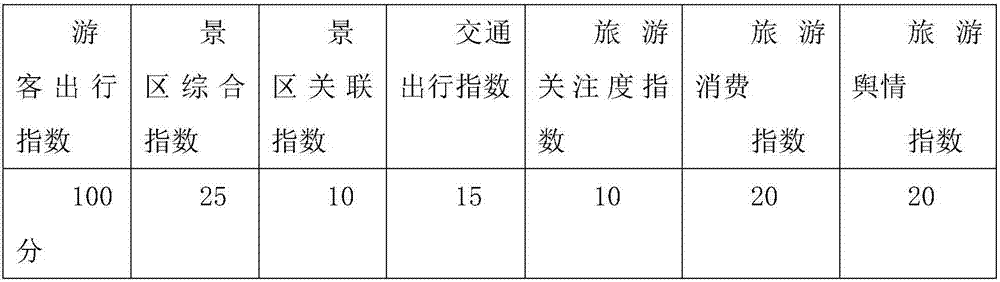

Tourism fitness index calculating system and tourism fitness calculating method based on big data

InactiveCN106910027AComprehensive protectionConvenient travelResourcesCorrelation analysisComputing systems

The invention discloses a tourism fitness index calculating system and a tourism fitness calculating method based on big data. The system comprises the components of a first data acquisition unit which is used for acquiring first tourism related data from a tourism direct management department; a second data acquisition unit which is used for acquiring second tourism related data from a tourism indirect participating department; a database unit which is used for storing the acquired first tourism related data and the second tourism related data; and a data analysis unit which is used for performing correlation analysis on the first tourism related data and the second tourism related data and generating a real-time tourism fitness index of a corresponding scenic region. The tourism fitness index calculating system and the tourism fitness index calculating method realize technical effects of generating the related tourism fitness index by the system according to comprehensive and accurate real-time tourism data for visitors, and ensuring visitor tourism satisfaction index.

Owner:成都中科大旗软件股份有限公司

Glass wall paper composite board and producing method thereof

InactiveCN101585287AImprove protectionReduced service lifeCovering/liningsSpecial ornamental structuresSurface patternPulp and paper industry

The present invention discloses a glass wall paper composite board and a producing method thereof, capable of prolonging a service lifetime of the wall paper greatly, improving a decorative effect andrigidity of the wall paper, especially being adapt to a fixed building, the plumbing installation of a toilet and a bathroom and facilities of a swimming pool. the glass wall paper composite board includes a glass layer and a wall paper surface pattern layer, wherein a transparent or semi-transparent adhesive layer is provided between the glass layer and the wall paper surface pattern layer, thebottom of the wall paper surface pattern layer is provided with a complementary color protective layer, so as to form a glass wall paper composite board with a four-layer structure. An optimum methodis that a thin complementary color protective layer is coated on a bottom face of the wall paper surface pattern layer, and a thick paint protective layer is coated on a bottom face of the complementary color protective layer.

Owner:何庭佳

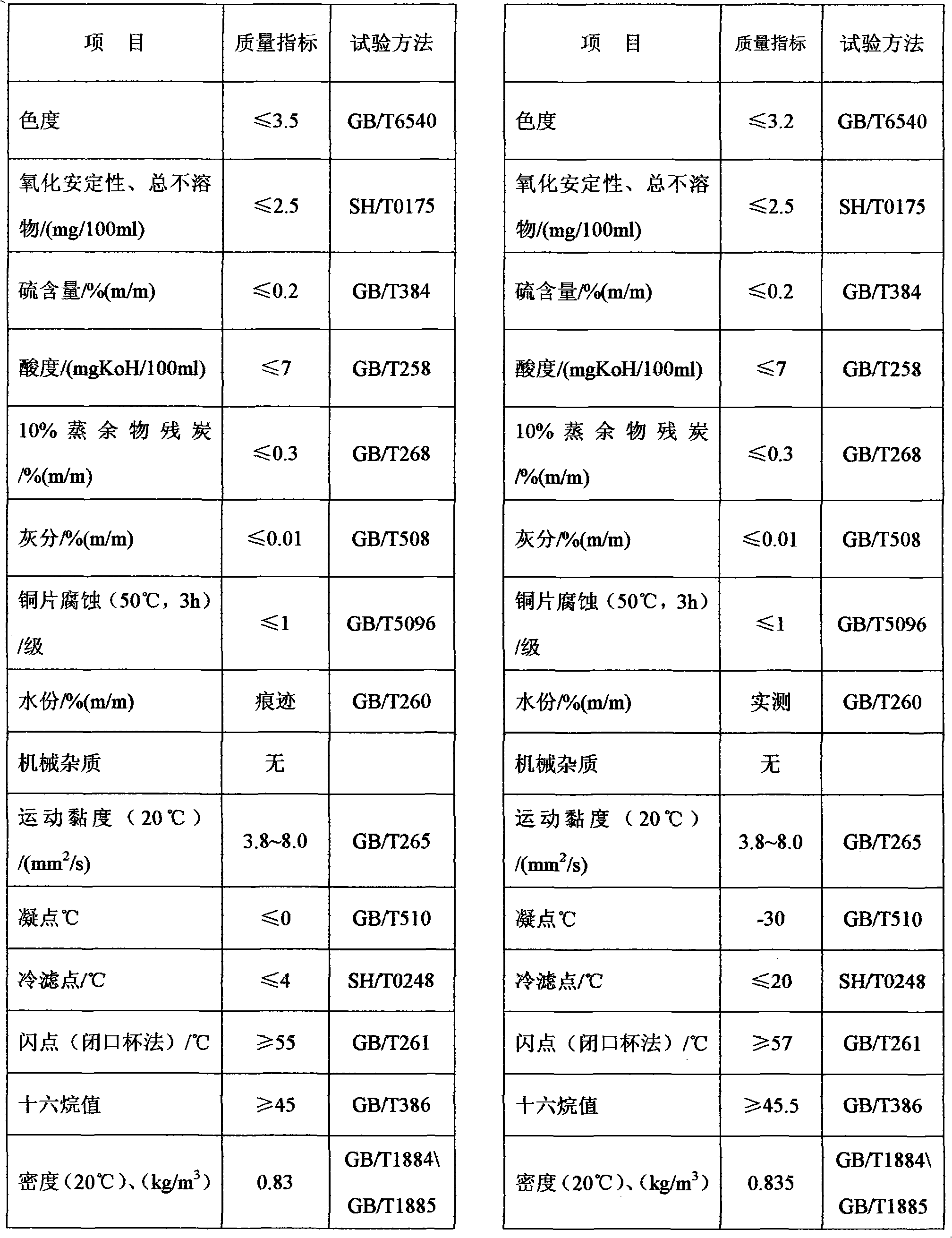

Microemulsified watered diesel, additive used thereby and preparation process thereof

InactiveCN101967411AAdvancedImprove startupLiquid carbonaceous fuelsFuel additivesPotassiumOil additive

The invention provides a microemulsified watered diesel additive, which comprises the following components in percentage by weight: 65 to 85 percent of fatty acid, 1 to 10 percent of diethylamine, less than or equal to 15 percent of methanol, 1 to 5 percent of potassium chloride, and 1 to 10 percent of tetrahydrofuran. The microemulsified watered diesel using the additives comprises: additive containing the above components and cetane number improver. The microemulsified watered diesel using the additive comprises the following components in percentage by weight: 50 to 90 percent of diesel, 5 to 30 percent of the microemulsified watered diesel additive, and 5 to 30 percent of water. The method for preparing the microemulsified watered diesel comprises the following steps: preparing the microemulsified watered diesel additive; mixing and stirring 50 to 90 percent of the diesel, 5 to 30 percent of the microemulsified watered diesel additive and 5 to 30 percent of the water until the mixture is transparent at normal temperature to obtain the microemulsified watered diesel. Compared with the prior art, the microemulsified watered diesel has good stability, high heat value, high power, good starting performance and high cetane number, and has expected tremendous economical value and social value.

Owner:张宝臣

Earth and rockfill concrete core wall asphalt concrete and paving method thereof

InactiveCN104314053AReduce dosageReduce processing costsEarth-fill damsRock-fill damsConstruction aggregateAsphalt concrete

Earth and rockfill concrete core wall asphalt concrete and a paving method thereof break through the limitation to the maximal aperture of core wall asphalt concrete coarse aggregate in the prior art; the specific paving method is used for assisting, so the machining efficiency of coarse aggregate is greatly improved, the use level of asphalt is reduced and the engineering building and construction cost is reduced.

Owner:GEZHOUBA GRP NO 2 ENG +1

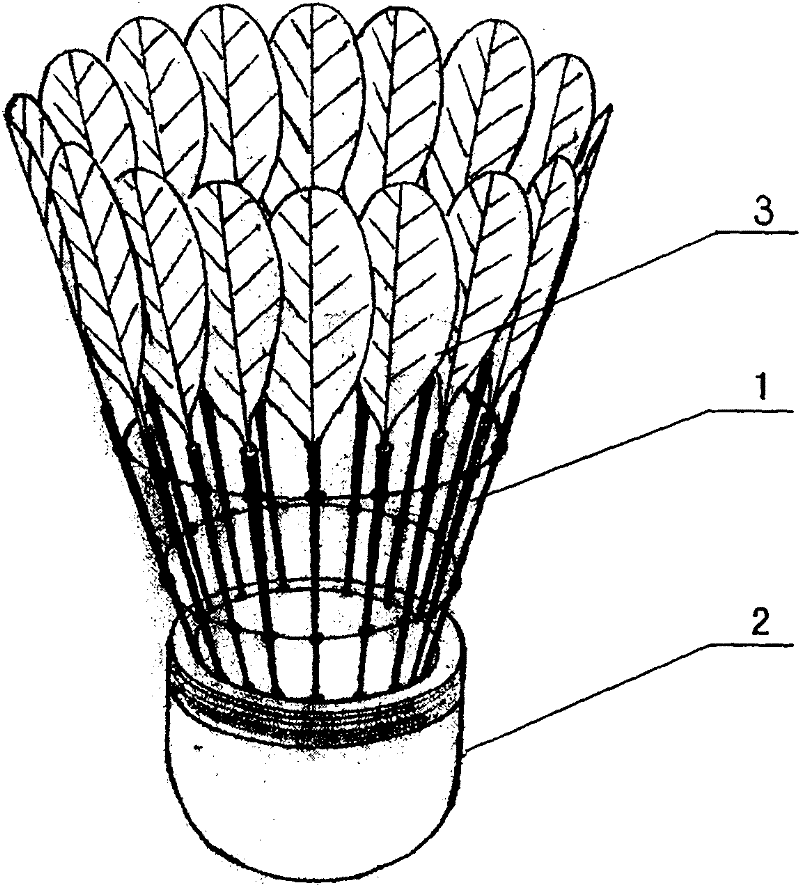

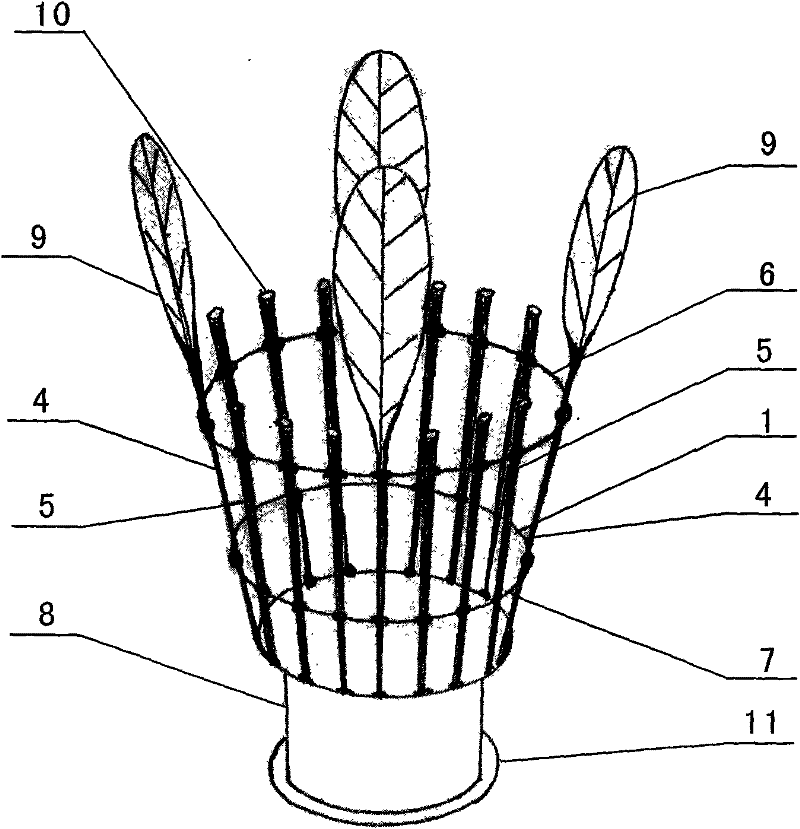

Badminton

InactiveCN102527008AReduce production man-hoursGreat increase in work efficiencySport apparatusEngineeringPlastic materials

The invention discloses badminton, and particularly relates to badminton which is formed by combining detachable feathers, a badminton head and a connecting frame with the artificial feathers, wherein the connecting frame with the artificial feathers consists of vertical stems with the artificial feathers, vertical stems with feather implanting holes, connecting ribs and a badminton head clamping base, and is machined by using a high-strength plastic material; the detachable feathers comprise feather leaves and feather roots at lower ends and can be manufactured by natural feathers or non-natural materials artificially; and the badminton head comprises an outer badminton head body and a clamping base hole. According to the badminton manufactured by the technology, complex processes can be saved, the production efficiency can be improved, and the cost can be reduced; the sizes, shapes and weights of the badminton are consistent, and the motion performance of the badminton is improved; and particularly, the phenomena of the breakage of feather leaves and feather stems and looseness of weaved strings in the conventional badminton are reduced obviously, the service life of the badminton is prolonged, and the cost performance is improved.

Owner:欧明华

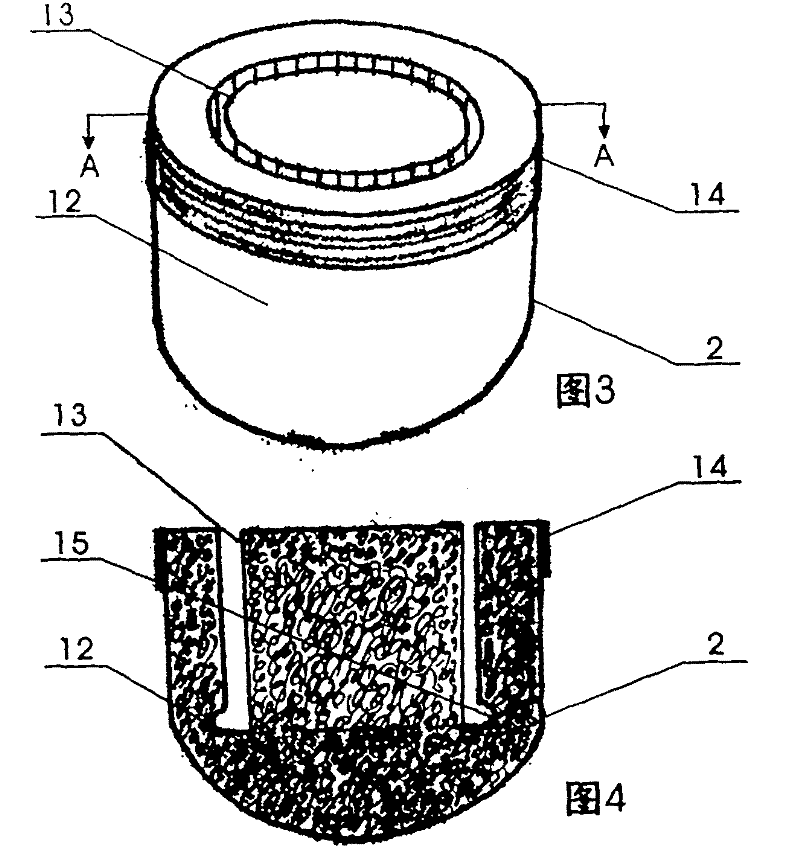

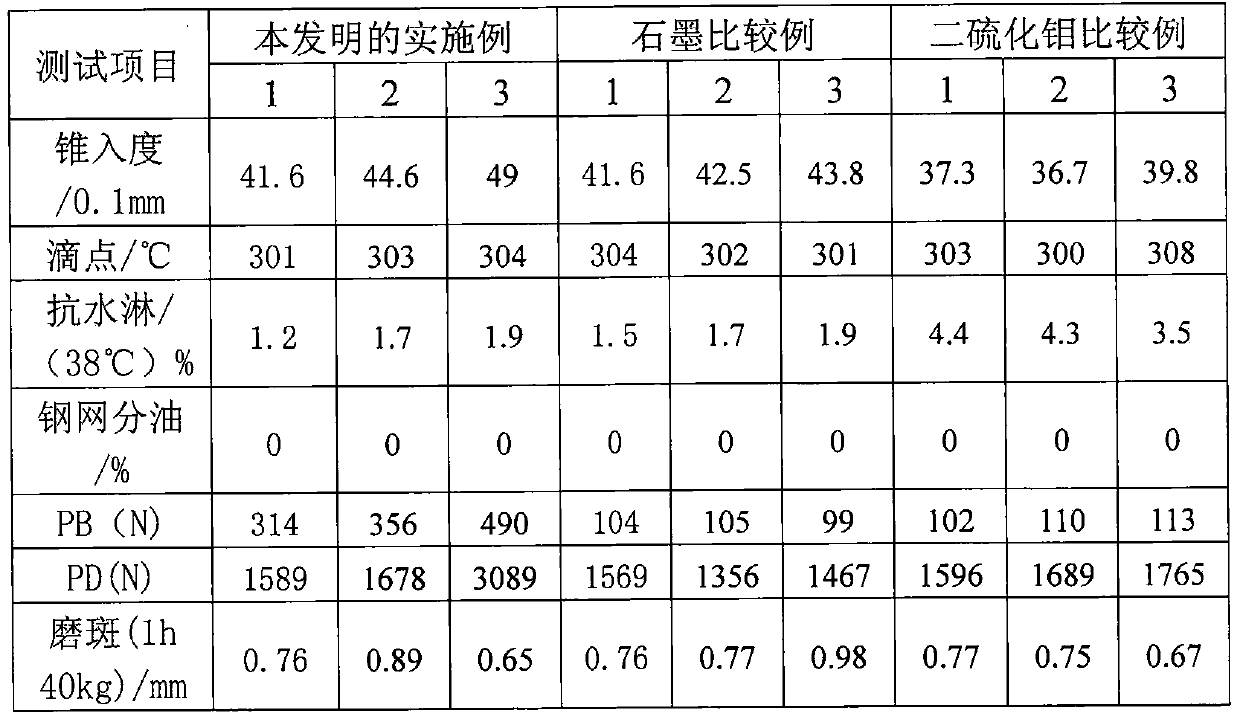

Polyurea lubricating grease and preparation method thereof

InactiveCN103740443AReduce key energyReduce friction factorLubricant compositionCarbon monofluorideHeat stability

The invention provides a polyurea lubricating grease and a preparation method thereof, and belongs to the technical field of lubricating grease. The polyurea lubricating grease comprises the following components in percentage by weight of polyurea lubricating grease: 10 to 30% of urea-based thickener, 54 to 89% of base oil, and 1 to 16% of additive, wherein the additive is carbon monofluoride. The polyurea lubricating grease has the advantages that the friction is reduced; the lubricating performance is improved; the performances on resisting abrasion, reducing friction and resisting extreme pressure are improved; the friction factors of a bearing running under a high temperature are reduced; the energy consumption is lowered; the consumption of lubricating grease is reduced, and thus the service life of the lubricating grease is prolonged; in addition, the oxidization stability, heat stability and comprehensive performances of the polyurea lubricating grease are also improved. The preparation method is simple in process and small in requirements on process factors, and realizes overall embodiment of the technical effect of the polyurea lubricating grease.

Owner:SUZHOU HUIFENG LUBRICANT

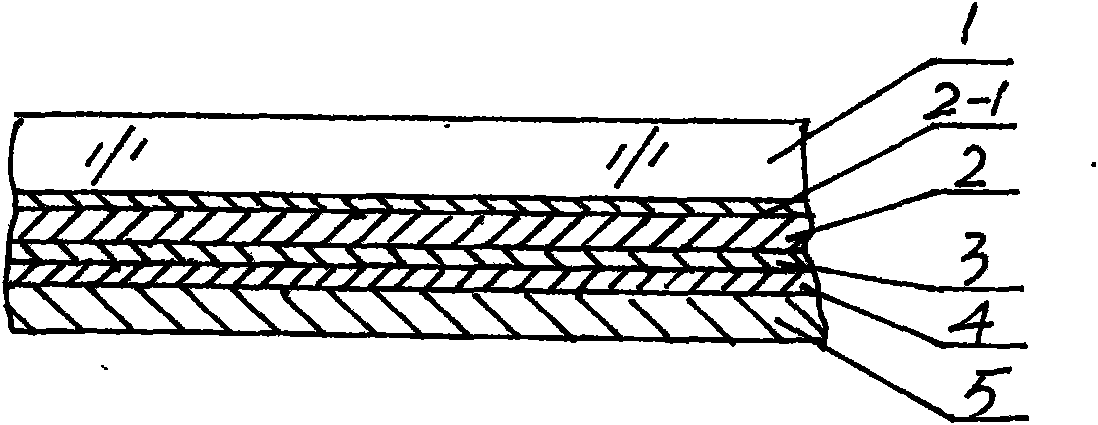

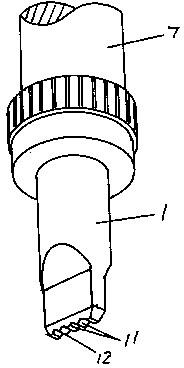

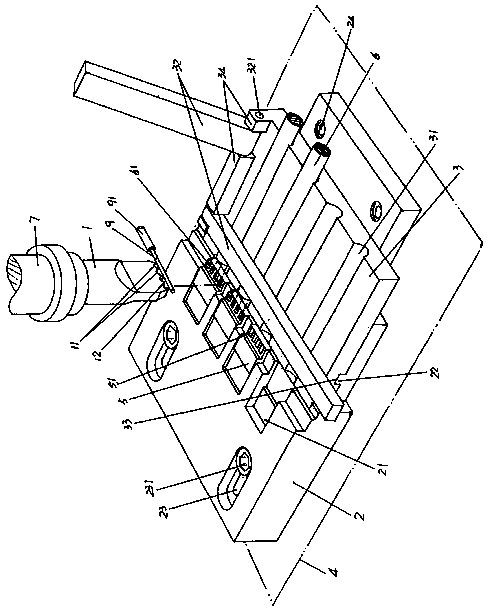

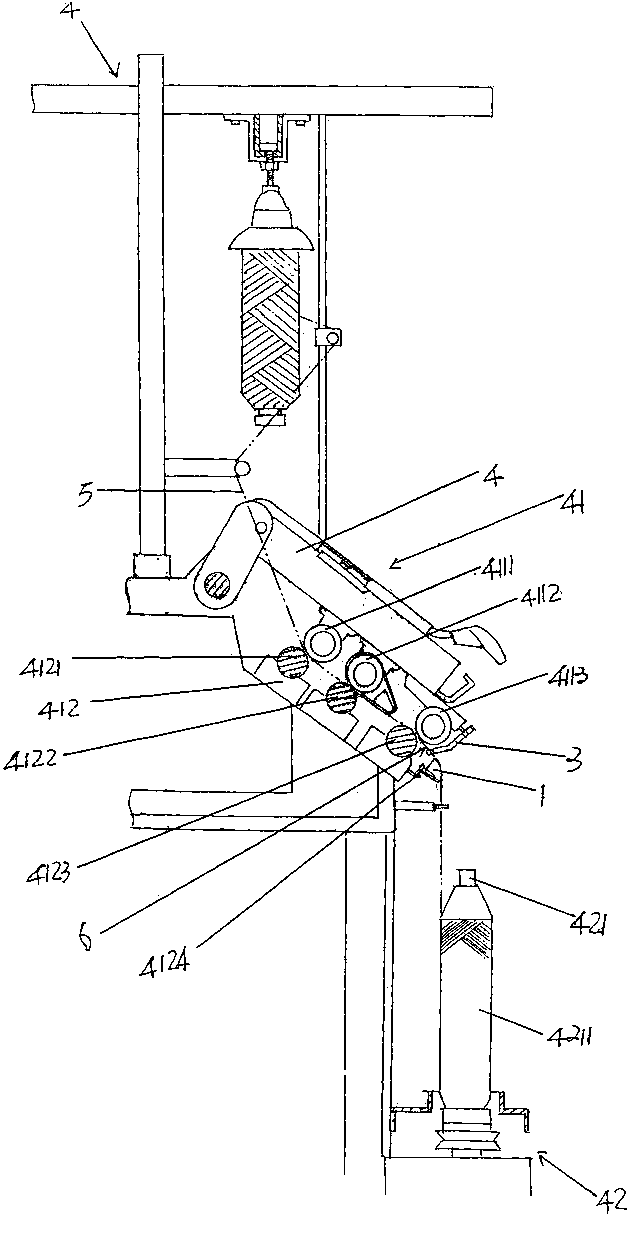

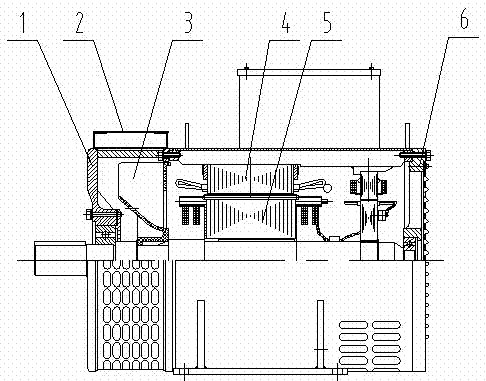

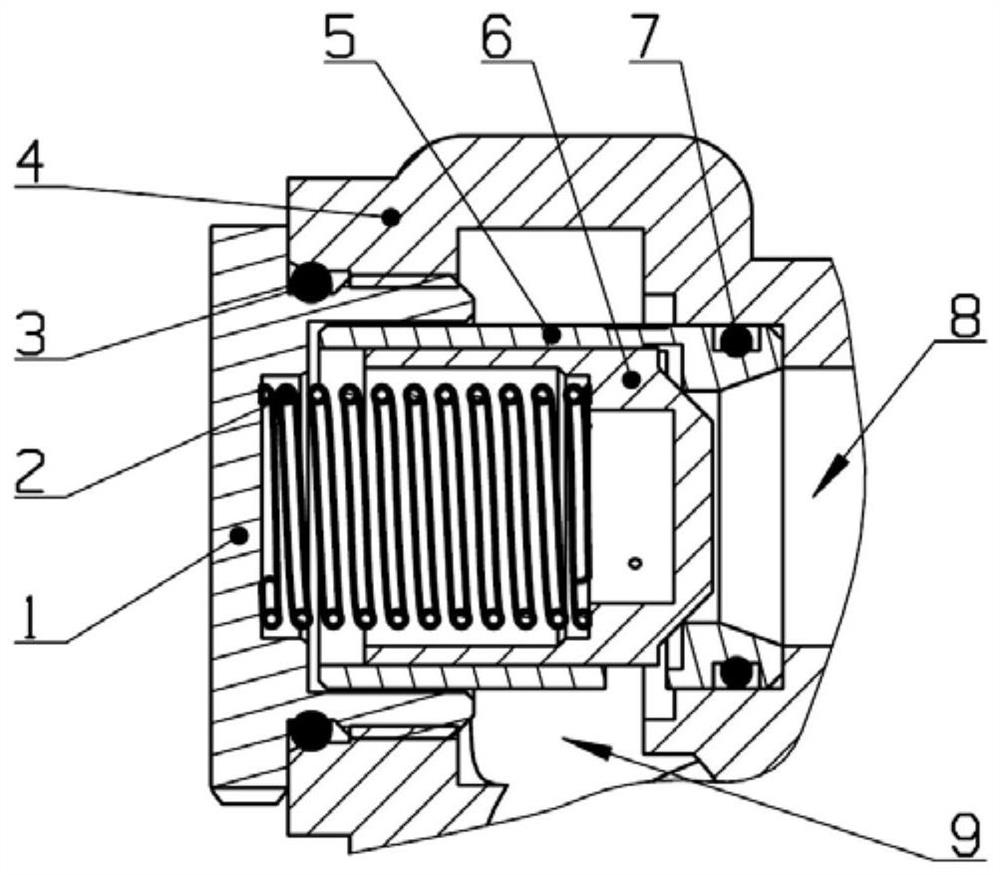

Welding wire equalization welding head for multi-welding-spot welding and welding method

ActiveCN104384649AGuaranteed technical effectGuarantee the full expression of technical effectsConductorsMetal working apparatusElectrical conductorEqualization

The invention relates to a welding wire equalization welding head for multi-welding-spot welding and a welding method, which belong to the technical field of a wire and cable welding device. The welding wire equalization welding head comprises a welding head body, and is characterized in that the end surface of one end, facing downwards when in use, of the welding head body is provided with a plurality of conductor accommodating valleys which are identical to the amount of conductors to be welded in one step at intervals along the length direction of the end surface, and a projection area between every two adjacent conductor accommodating valleys respectively forms a welding wire equalization edge for segmenting a welding wire. By adopting the welding wire equalization welding head and the welding method, the welding quality of the conductor and a welding disc can be improved, the welding time is shortened, the welding efficiency is improved, and the welding material is prevented from being scattered when the welding head body is pressed downwards, and the uniformity and consistency of welding spots can be guaranteed; the process step is simple, convenience in operation is realized, and not only can the application in the industry be satisfied, but also the technical effect of the welding head body can be guaranteed.

Owner:HUIZHOU DEHONG TECH CO LTD

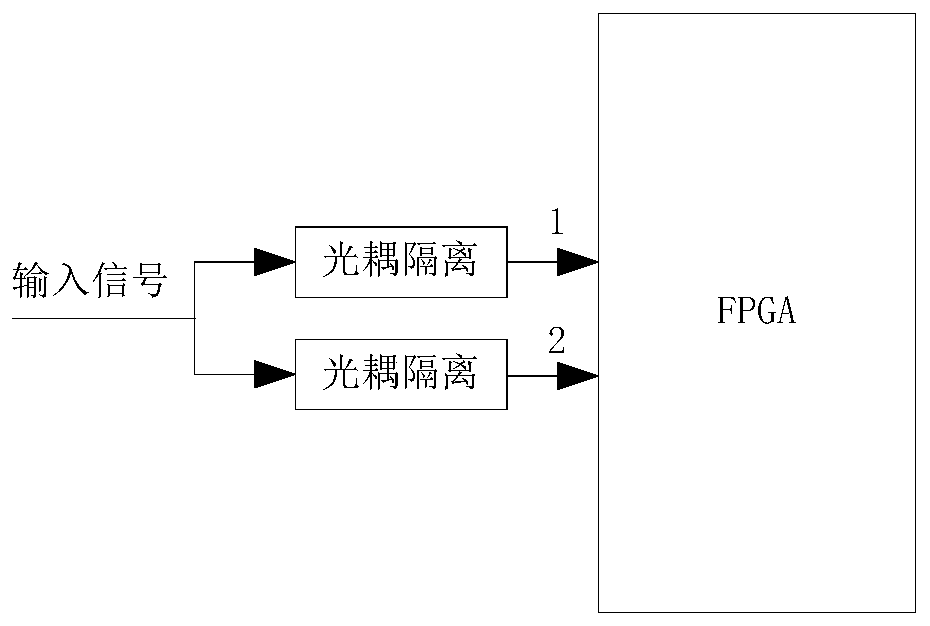

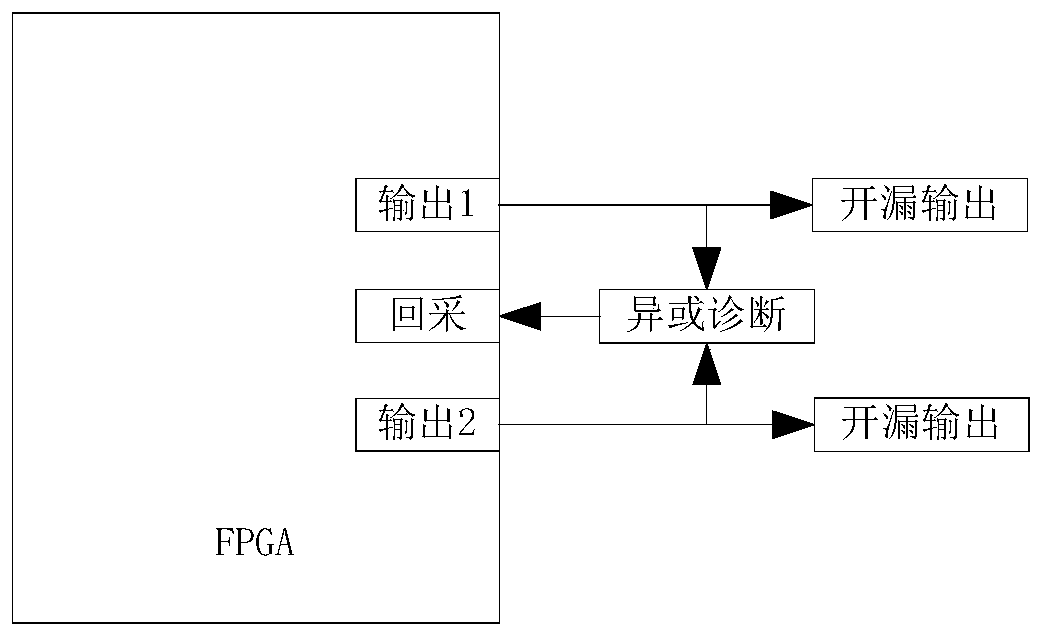

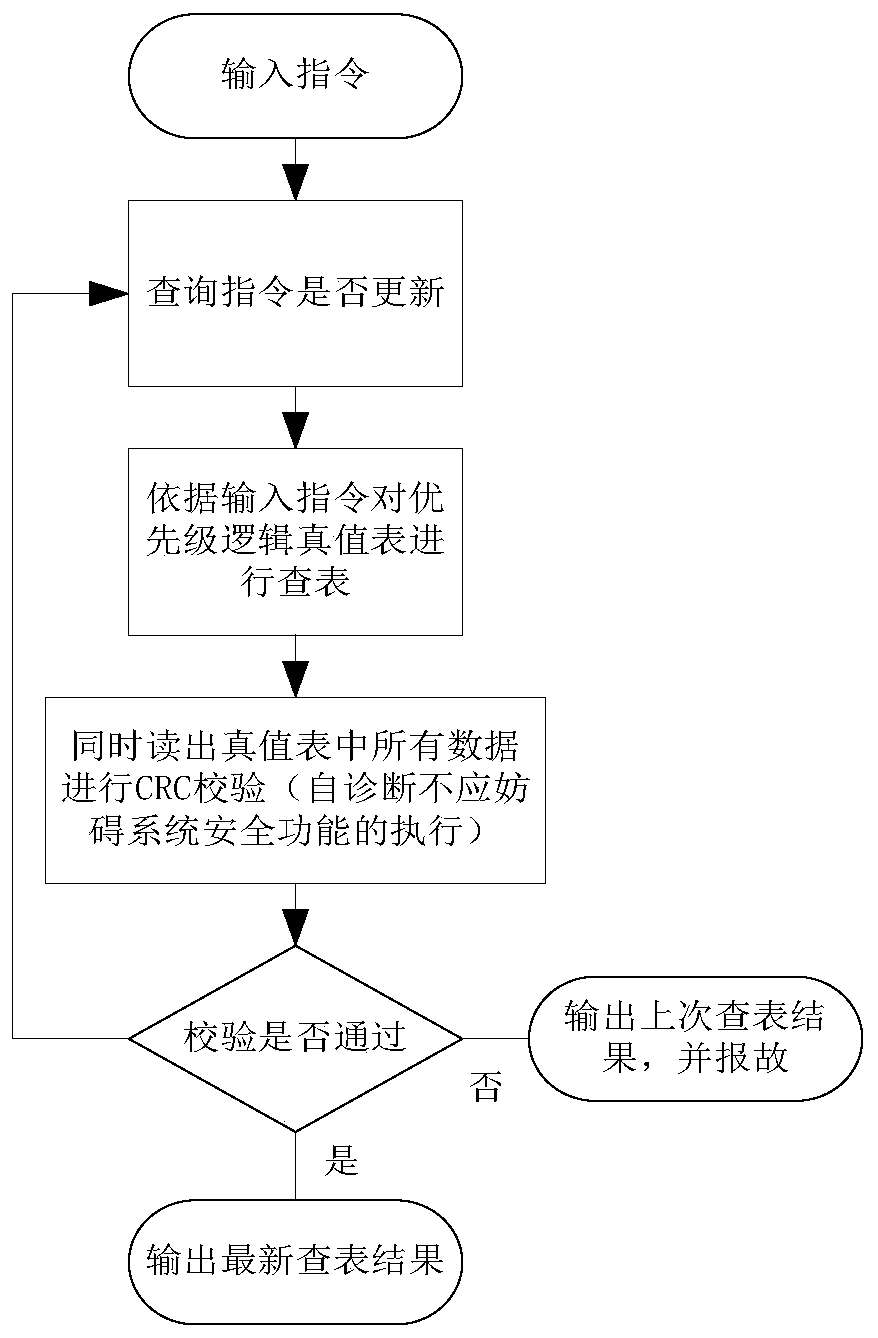

Self-diagnosis method based on FPGA

ActiveCN109839918AImplement priority judgmentGuaranteed technical effectElectric testing/monitoringTruth valueComputer module

The invention discloses a self-diagnosis method based on FPGA. The method comprises the following steps of diagnosing an input interface of a preferred module, a driving output interface of the preferred module, and a priority logic of the preferred module, wherein the diagnosis of the input interface of the preferred module includes: comparing homologous input interface signals of the preferred module so as to check whether the signals are consistent; the diagnosis of the driving output interface of the preferred module includes: comparing an output control logic of the preferred module withan output feedback signal so as to check whether the logic and the signal are consistent; and the diagnosis of the priority logic of the preferred module includes: carrying out priority logic diagnosis while priority logic selection is performed on an input instruction of the preferred module, which means that all priority truth table data stored in an internal ROM or logic is read and CRC verification is performed so as to check whether the CRC verification is correct; and carrying out priority determination on the signals of different systems for the preferred module so that a guarantee is provided for ensuring that a driven device executes actions according to the correct signal.

Owner:CHINA NUCLEAR CONTROL SYST ENG

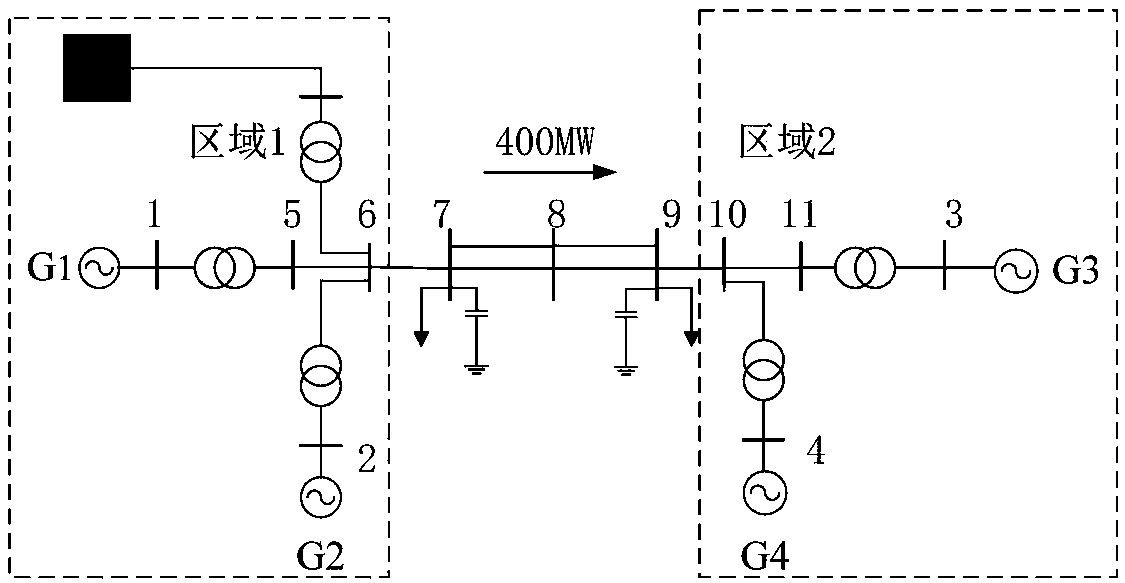

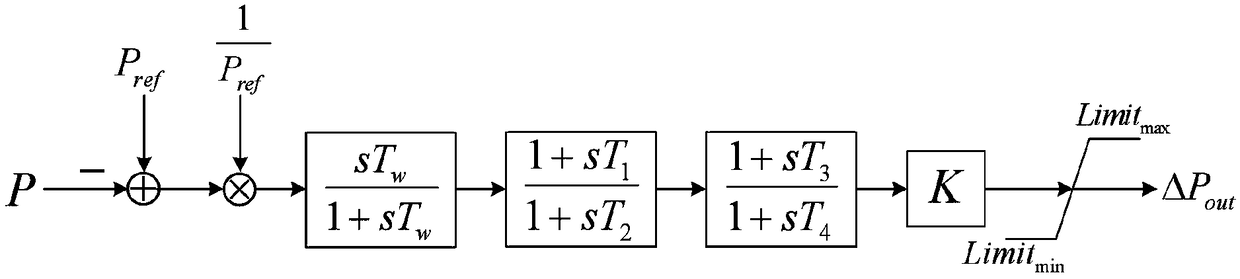

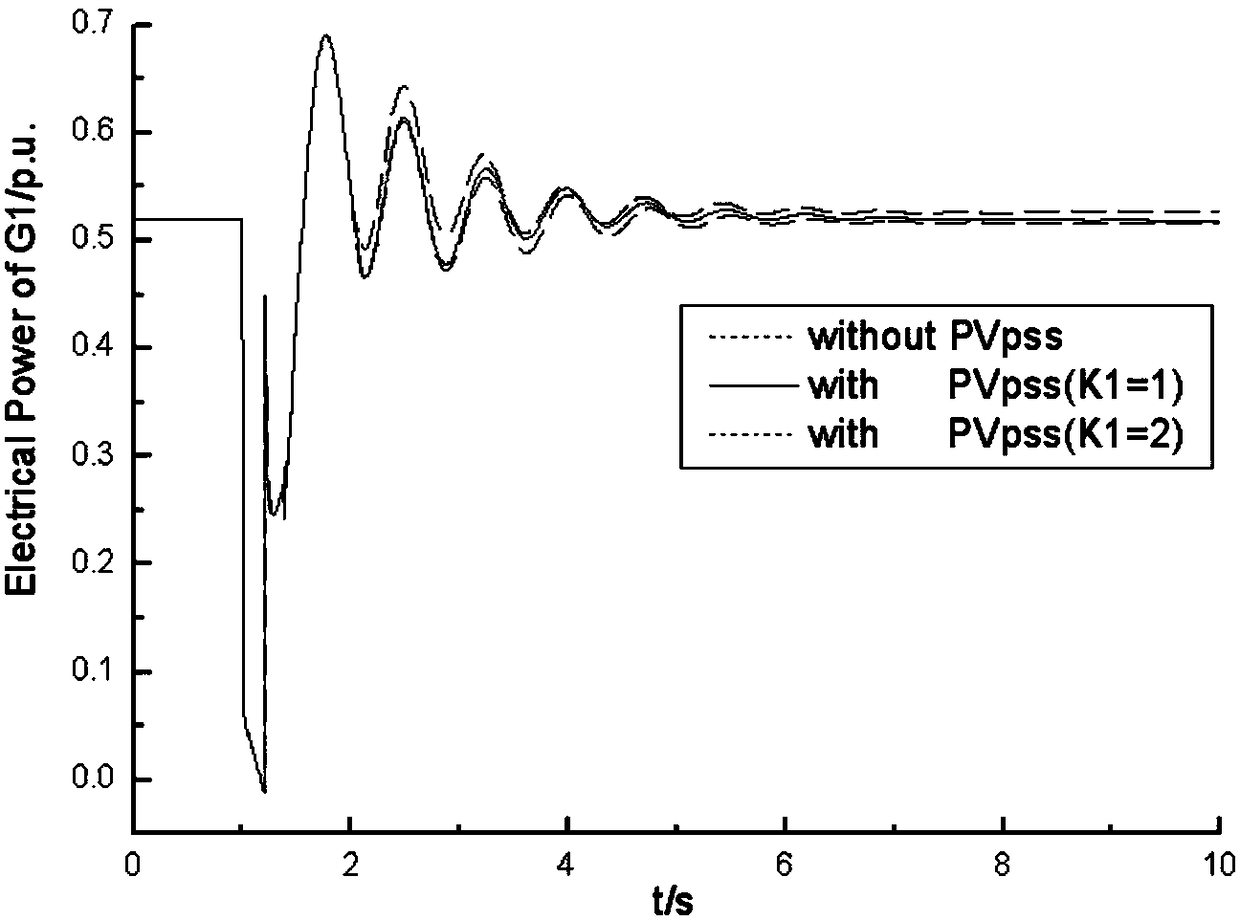

Control method and system for suppressing low-frequency oscillation during photovoltaic power generation

PendingCN108233397AAvoid affecting power generation capacitySuppress low frequency oscillationPower oscillations reduction/preventionControl systemVoltage control loop

The invention relates to a control method and a control system for suppressing low-frequency oscillation during photovoltaic power generation. The control method comprises the following steps: inputting the amplitude value of active power of a grid-connected point of a photovoltaic power station into a pre-established control model of a low-frequency oscillation suppressing device, and calculatinga control output signal value; superposing the control output signal value with a reference value of a reactive power / voltage control loop of a photovoltaic power generating system, and participatingin control of the reactive power / voltage control loop of the photovoltaic power generating system, wherein the pre-established control model of the low-frequency oscillation suppressing device comprises a blocking link, two lead-lag links, a proportional link and an amplitude limiting link. The technical scheme provided by the invention is an additional photovoltaic power generation damping control method for effectively suppressing the low-frequency oscillation of a power system; through the reactive power adjusting margin and the reactive power adjusting capability of the photovoltaic powergenerating system, the low-frequency oscillation is suppressed, so that utilization of the active power by the existing method is avoided and influence on the power generating capability of the photovoltaic system is avoided.

Owner:CHINA ELECTRIC POWER RES INST +3

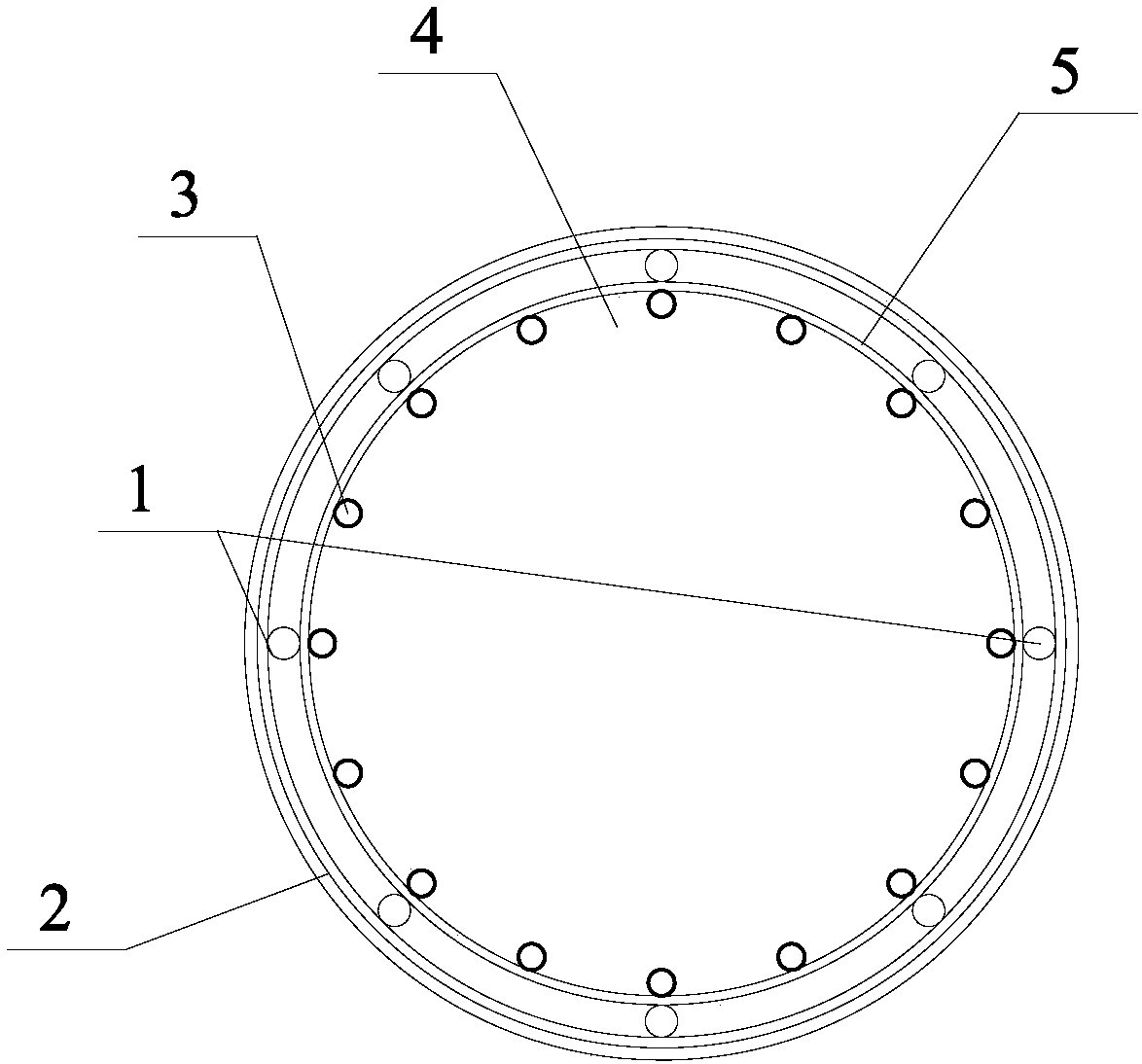

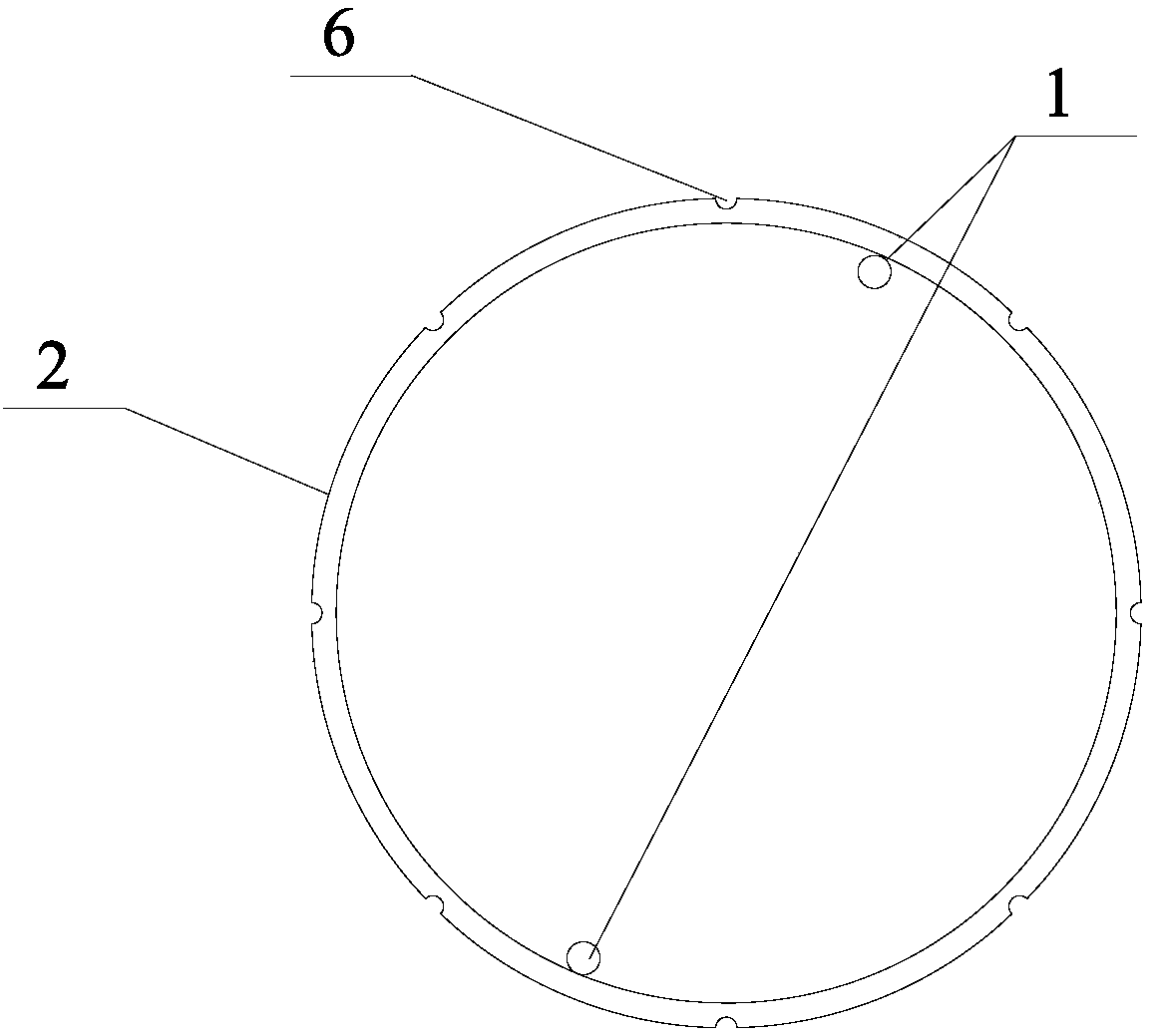

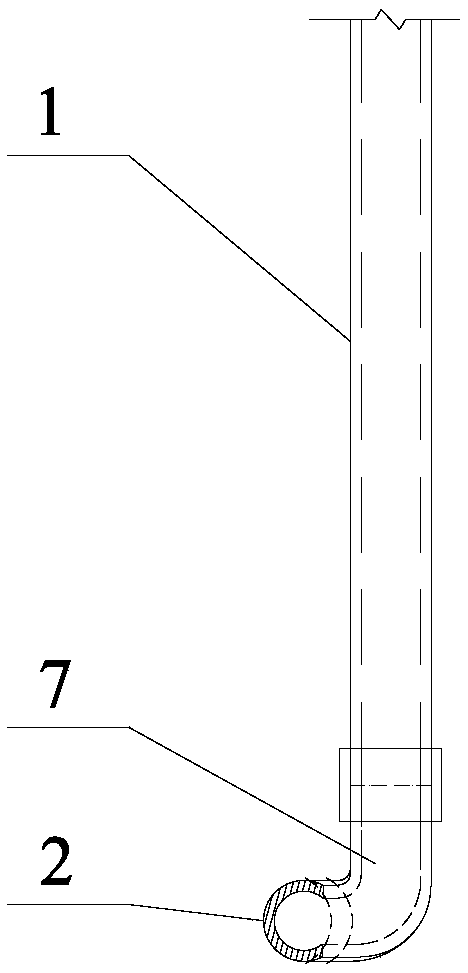

Uplift pile side post grouting device and construction method

The invention discloses an uplift pile side post grouting device. The uplift pile side post grouting device comprises a plurality of grouting vertical tubes and a plurality of grouting ring tubes withdifferent elevations, wherein the grouting vertical tubes are fixed on the periphery of an uplift pile reinforcement cage; the grouting ring tubes are connected with the grouting vertical tubes and are fixed on the outer sides of the grouting vertical tubes; the bottom ends of each two grouting vertical tubes communicate with one corresponding grouting ring tube; a plurality of slurry outlet nozzles are arranged on each grouting ring tube along the periphery; and each slurry outlet nozzle can be temporarily closed by a closing device which can be flushed away by water pumped in by a water pump. A construction method of the uplift pile side post grouting device comprises the following steps: fixing the prefabricated grouting vertical tubes and the prefabricated grouting ring tubes on a pile body reinforcement cage; temporarily closing the slurry outlet nozzles on the grouting ring tubes by wrapping adhesive tapes or one-way valves, wherein each one-way valve is connected with water-permeable and slurry-tight slurry bags at intervals in a sealed manner; and unplugging the grouting vertical tubes and the grouting ring tubes by high-pressure water and completing pile side post grouting in twice or at a time. By the device and method, post grouting on the side surfaces of the peripheries of uplift piles can be uniformly distributed along the peripheries, grouting is smooth, and theconstruction efficiency is high.

Owner:NINGBO HONGCHEN CONSTR

Wetting ironing method of spinning fiber bundle and PTC ironing device used by same

The invention discloses a wetting ironing method of a spinning fiber bundle and a PTC ironing device used by the wetting ironing method of the spinning fiber bundle, and belongs to the spinning technical field. The method includes the steps of enabling the spinning fiber bundle to pass through and be wetted by, under an advancing condition, a wetting device at a twisting triangular area portion in front of a front leather roller and a front roller of a twisting device which is arranged on and corresponds to a ring spinning frame, controlling the advancing speed of the spinning fiber bundle and water content of the wetted spinning fiber bundle, enabling the wetted spinning fiber bundle to enter the PTC ironing device, installed on the ring spinning frame along with the wetting device, to be ironed after getting out of the wetting device, controlling the ironing temperature of the PTC ironing device, and enabling the spinning fiber bundle which is ironed by the PTC ironing device to be wound on a spool through a winding device of the ring spinning frame to form a spindle. The amount of filoplume is reduced and therefore quality of yarn is improved; filoplume is prevented from being produced, a good and even evenness effect is obtained, the ignition point range of the yarn is avoided, and safety is ensured.

Owner:JIANGSU NEW LINZHI ELECTRONIC TECH CO LTD

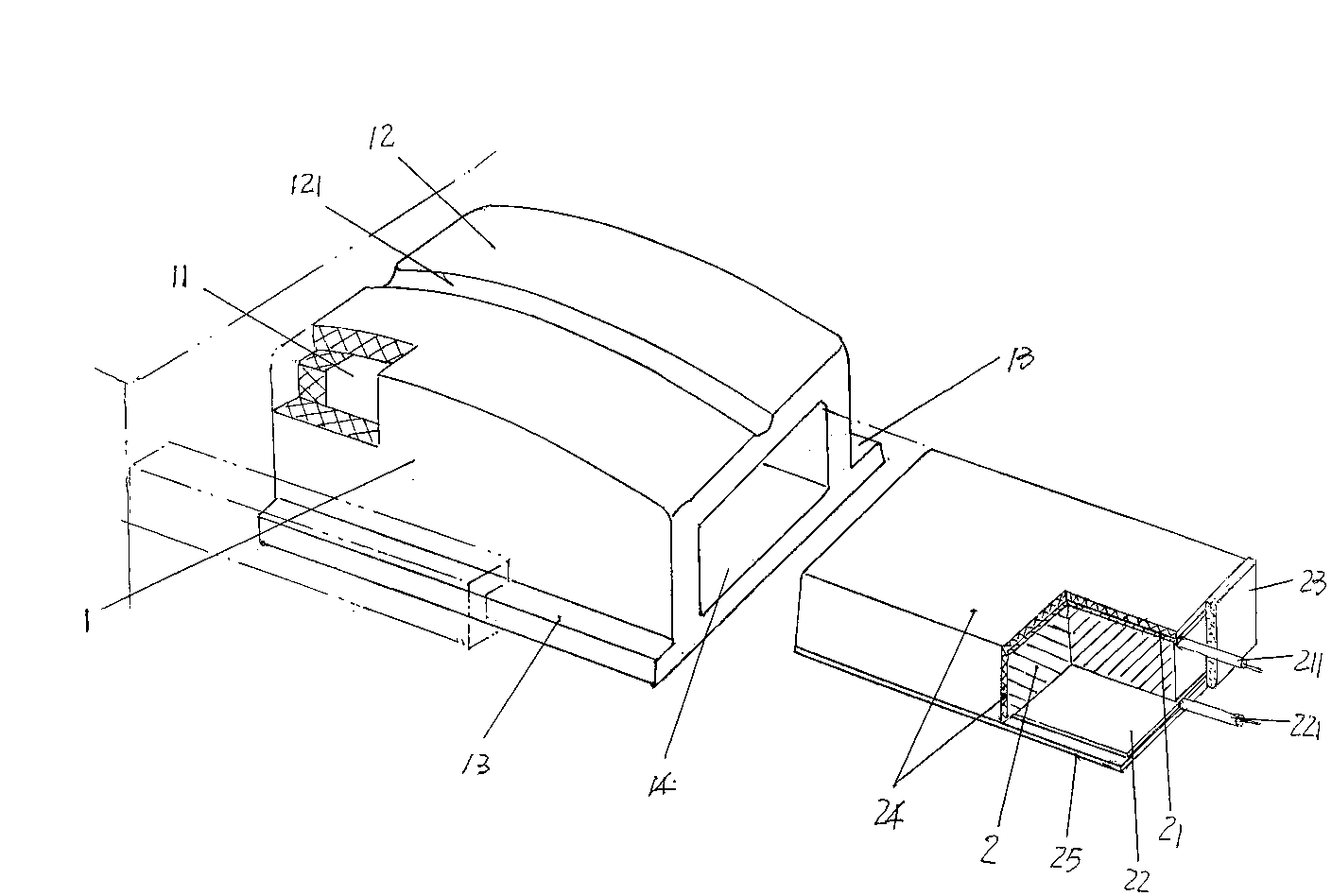

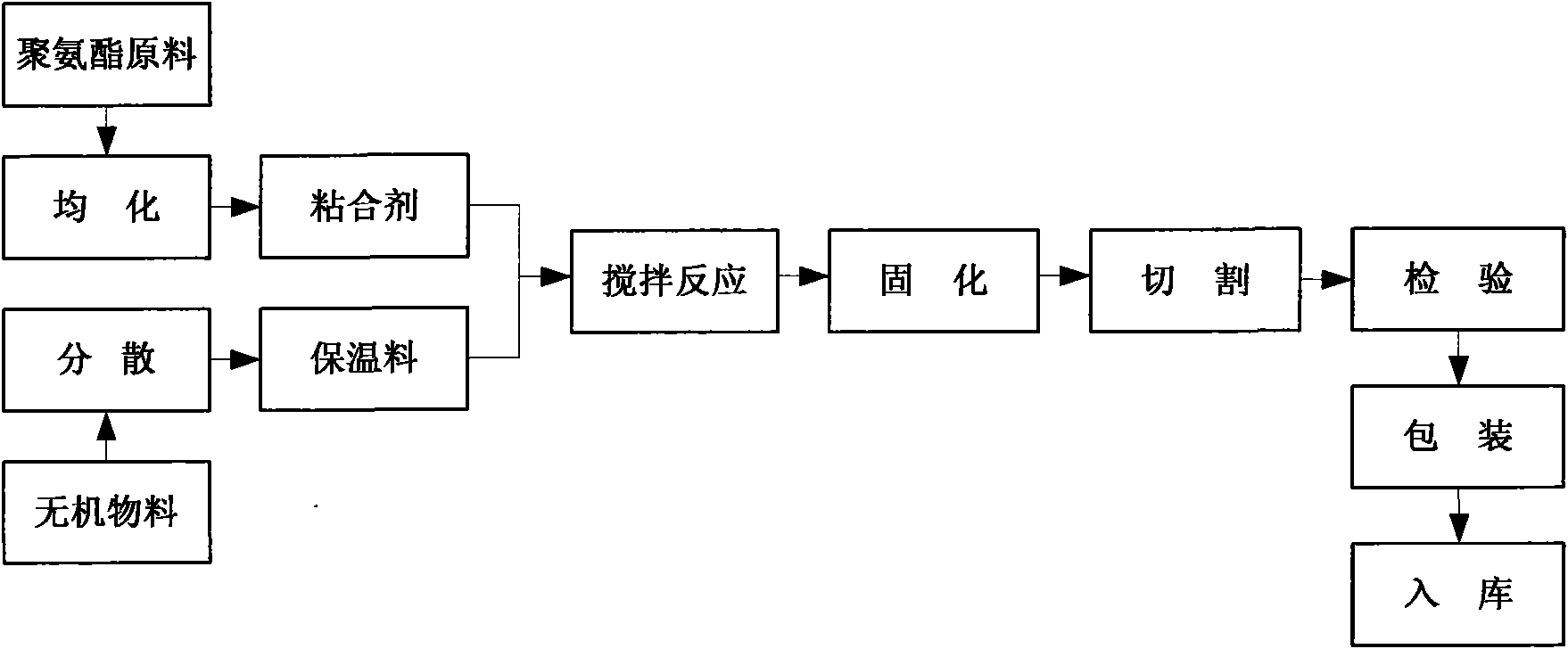

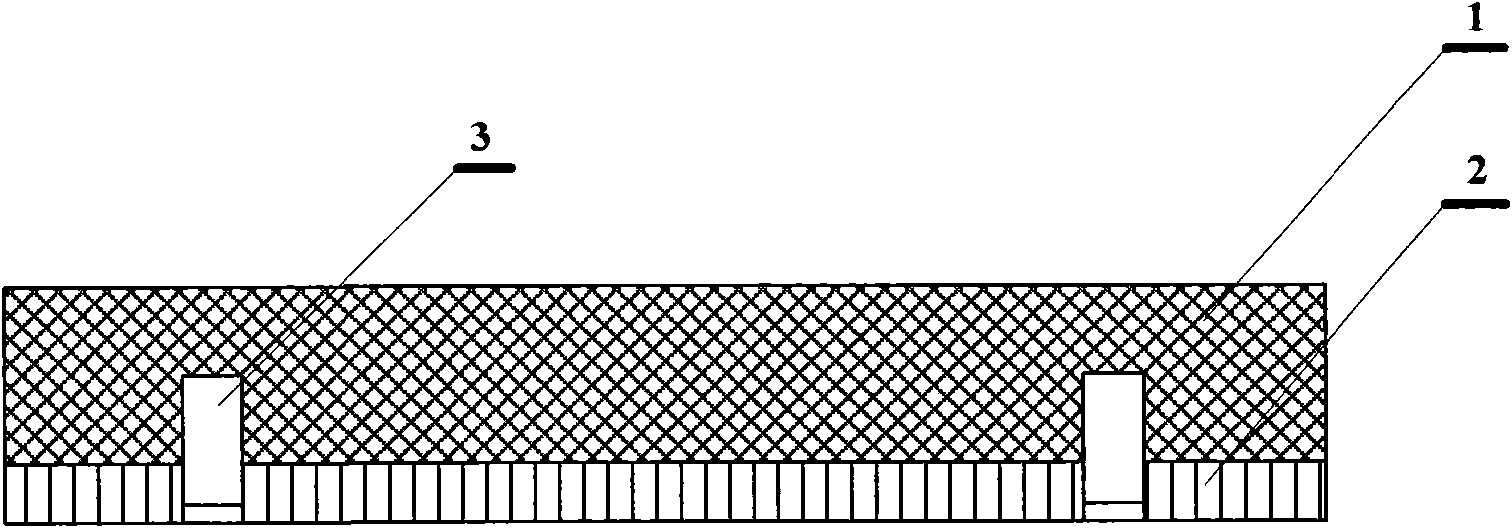

Polyurethane composite-type waterproof thermal-insulation decorative board, and production method

InactiveCN102828594AGuaranteed technical effectImprove flame retardant performanceCovering/liningsCeramic shaping apparatusThermal insulationThermal conductivity

The invention discloses a polyurethane composite-type waterproof thermal-insulation decorative board and a production method of the board. The board is the composite board formed by thermal-insulation layer material comprising expanded perlite of inorganic ore material, hollow glass beads, coal ash and serozem, binder comprising high-strength foaming polyurethane, and decorative panel comprising marble, ceramic tile and calcium silicate board with microporous. The production method comprises the following steps: arranging inorganic thermal-insulation material and polyurethane binder raw material into a container according to the proportion, wherein the container is provided with a stirrer, stirring continuously in order to enable the inorganic thermal-insulation material to fully contact the polyurethane, flowing the mixture directly to the back surface of the decorative panel from a discharge, foaming, curing, and molding into a board, cutting and packaging, thereby obtaining the product. The board is low in volume weight, low in coefficient of thermal conductivity, high in compression strength, is fireproof, so that the board is an ideal outer wall thermal-insulation decorative material.

Owner:BEIJING LIGAO WATERPROOF ENG CO LTD +1

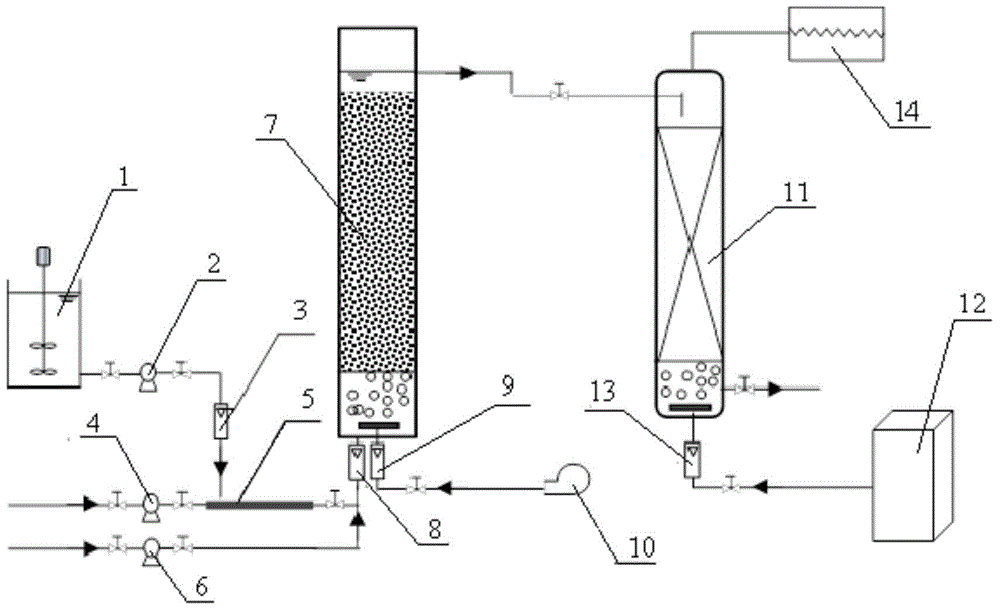

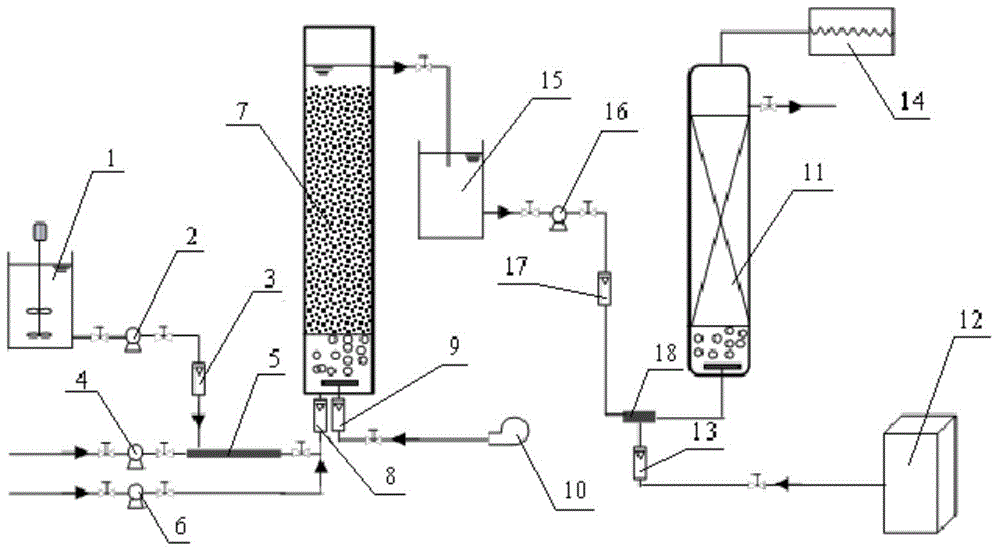

Phosphorus removal biological aerated filter-catalytic ozonation coupling device and use method thereof

InactiveCN104787974AImprove adsorption capacityAchieve removalMultistage water/sewage treatmentCatalytic oxidationTower

The invention discloses a phosphorus removal biological aerated filter-catalytic ozonation coupling device which comprises a water inlet system (4), a pipeline mixer (5), a biological aerated filter (7), an ozonation tower (11) and an ozone destruction system (14) which are communicated with one another in sequence, and further comprises a chemical feeding system, an air supply system (10) and an ozone supply device (12), wherein the chemical feeding system is communicated with the end, connected with the water inlet system (4), of the pipeline mixer (5); the air supply system (10) is communicated with the bottom of the biological aerated filter (7); the ozone supply device (12) is communicated with the bottom of the ozonation tower (11). The invention further discloses a phosphorus removal method for wastewater. The biological aerated filter has a relatively good phosphorus removal function; discharged wastewater can be injected into a follow-up ozonation unit to realize a catalytic oxidation effect; both the phosphorus removal efficiency and the organic pollutant removal efficiency are high.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Automobile engine cleansing agent

InactiveCN104017669AGuaranteed technical effectExtended service lifeDetergent compounding agentsTetrachloroethyleneEther

The invention discloses an automobile engine cleansing agent which belongs to the field of cleansing agents in the mechanical industry. The automobile engine cleansing agent consists of the following raw materials in percentage by weight: 1.5-2 percent of sodium silicate, 2.5-3 percent of sodium tripolyphosphate, 1.3-2 percent of dodecyl sulphonic acid, 9-15 percent of tetrachloroethylene, 2.5-3 percent of ethylene glycol butyl ether, 0.2-0.5 percent of hydrazine and the balance of high distillate, totally 100 percent. The automobile engine cleansing agent has the beneficial effects that oil sludge in an engine can be cleansed without demounting the engine, so that the cleansing efficiency is high, the technical performances of the engine can be maintained, the service life of the engine is prolonged and the cleansing effect is good.

Owner:陈建宝

Variable-speed constant-voltage generator

InactiveCN105449964AGuaranteed technical effectImprove technical performanceAsynchronous induction motorsHarmonicFlat rated

The invention provides a variable-speed constant-voltage generator. The generator adopts fundamental wave and harmonic wave excitation. Firstly, stator and rotor cores are lengthened so that the generator can reach the rated power at relatively low rotating speed; through using the fundamental wave and harmonic wave excitation, when the rotating speed range of the generator is changed, the technical performance of the generator can be ensured at the changed rotating speed; a shaft is of alloy steel, the comprehensive mechanical property of the shaft is enhanced, when the rotating speed of the generator is changed, the motor shaft still can bear the rated load. The generator uses the excitation system which is good in performance and is composed of fundamental wave and harmonic wave coils and AVR; when designing the electromagnetism, main sizes and parameters are selected and determined rationally, and both technical performance and economic performance are taken into consideration when the rotating speed of the generator is changed.

Owner:KUNGFU SCI TECH CO LTD

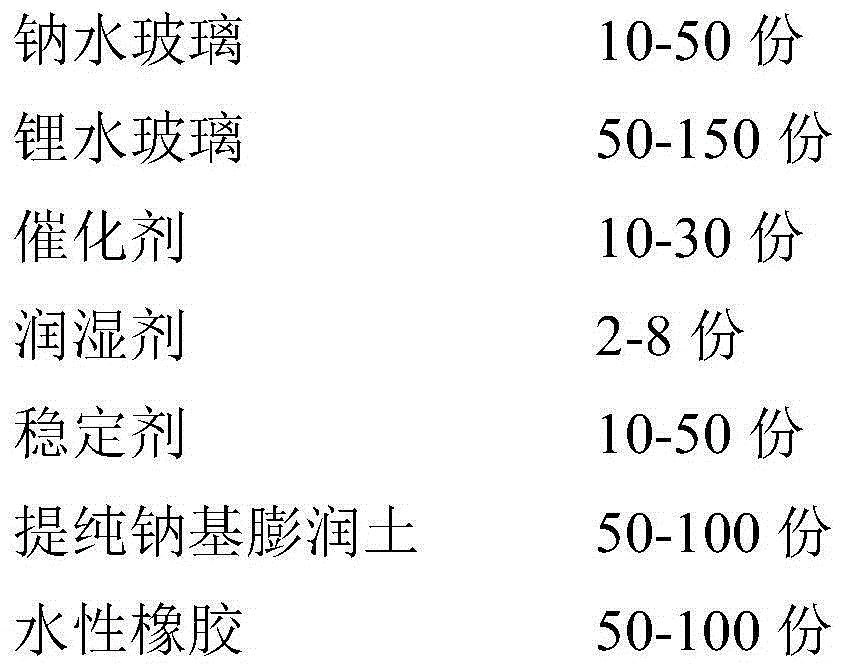

Permeable reactive waterproof anticorrosion additive and mortar combination containing additive

The invention relates to a permeable reactive waterproof anticorrosion additive and a mortar combination containing the additive, in particular to a permeable reactive waterproof anticorrosion additive, excellent in waterproofing and anti-corrosion performances, simple for construction and permeable and reactive. The permeable reactive waterproof anticorrosion additive can serve as a waterproof anticorrosion barrier for newly-built structures, and the problem that the existing structures already suffer water leakage is solved.

Owner:广东南珠建材科技有限公司

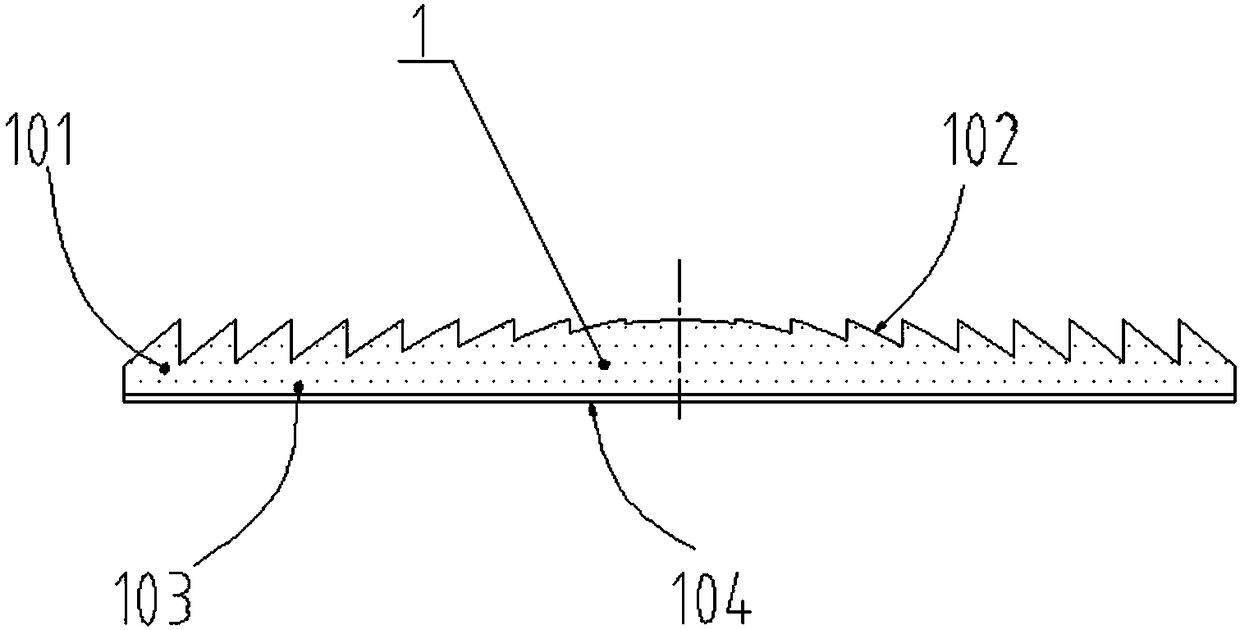

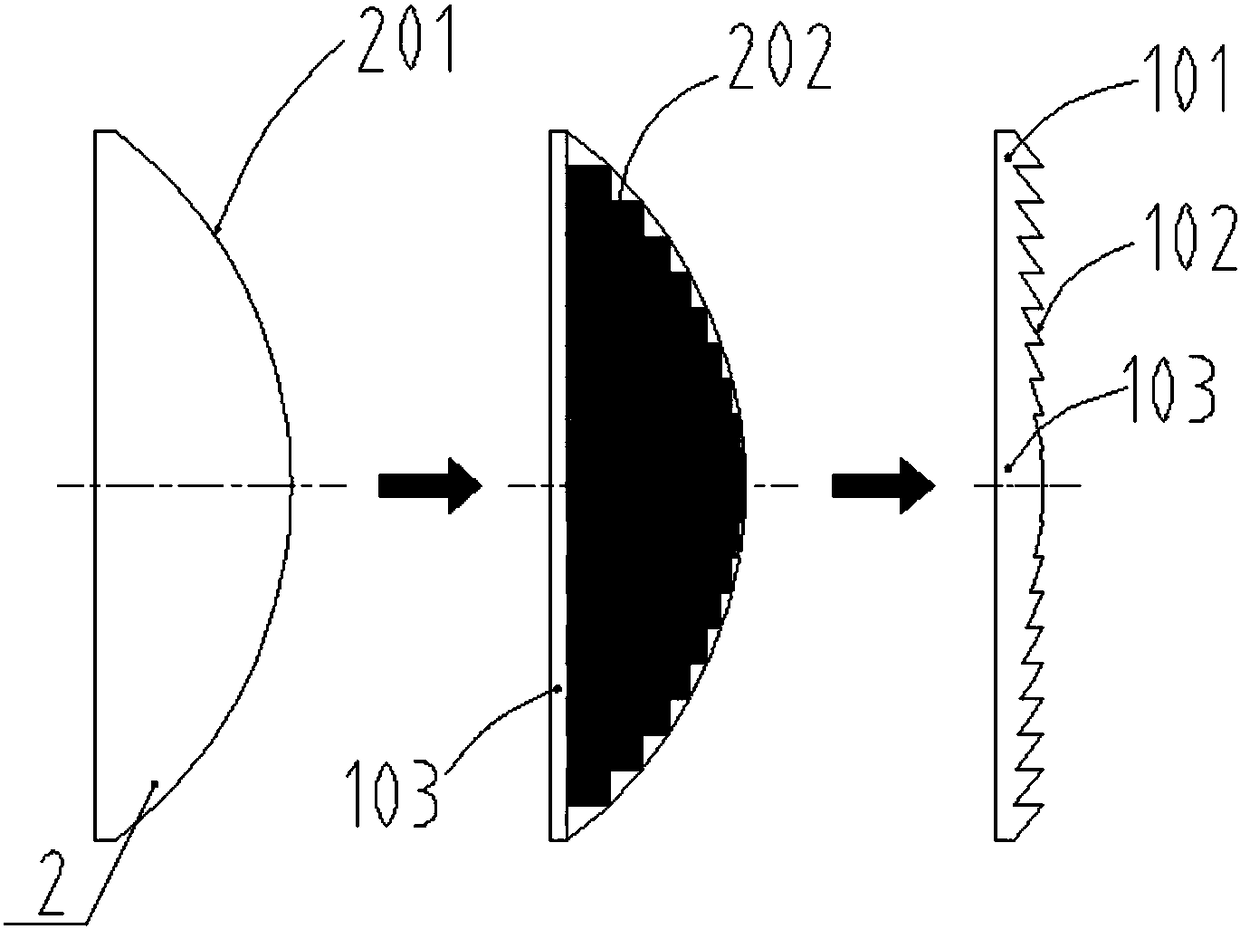

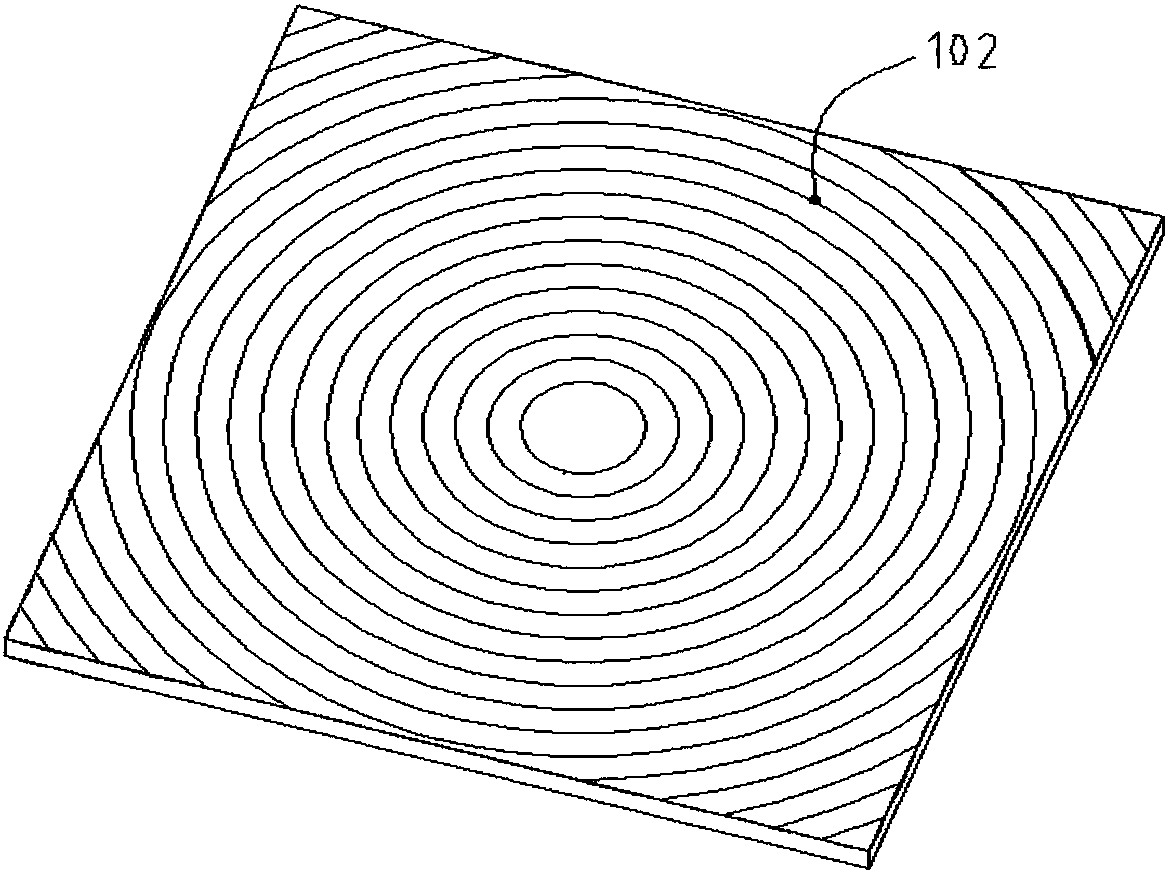

OCM Fresnel Lens and moulding technology thereof

InactiveCN108802868AImprove thermal stabilityHigh precisionOptical articlesLensFresnel lensReflection loss

The invention relates to a lens and a moulding technology thereof, and specifically relates to an OCM Fresnel Lens and a moulding technology thereof; the OCM Fresnel Lens comprises an lens main body;the lens body comprises a substrate; an lens body is arranged one side of the substrate; a reflection reducing coating is arranged on the other side of the substrate; the lens body is provided with aplurality of annular insection rings; the advantages are that 1, the lens thermal stability and optically focused precision can be improved; 2, lens reflection losses are reduced, and the lens surfaceis protected from being eroded by sands; 3, the method ensures OCM Fresnel Lens technology performance, production efficiency and manufacture costs, thus realizing target technology performance and manufacture cost desired values.

Owner:北京首耀科技有限公司

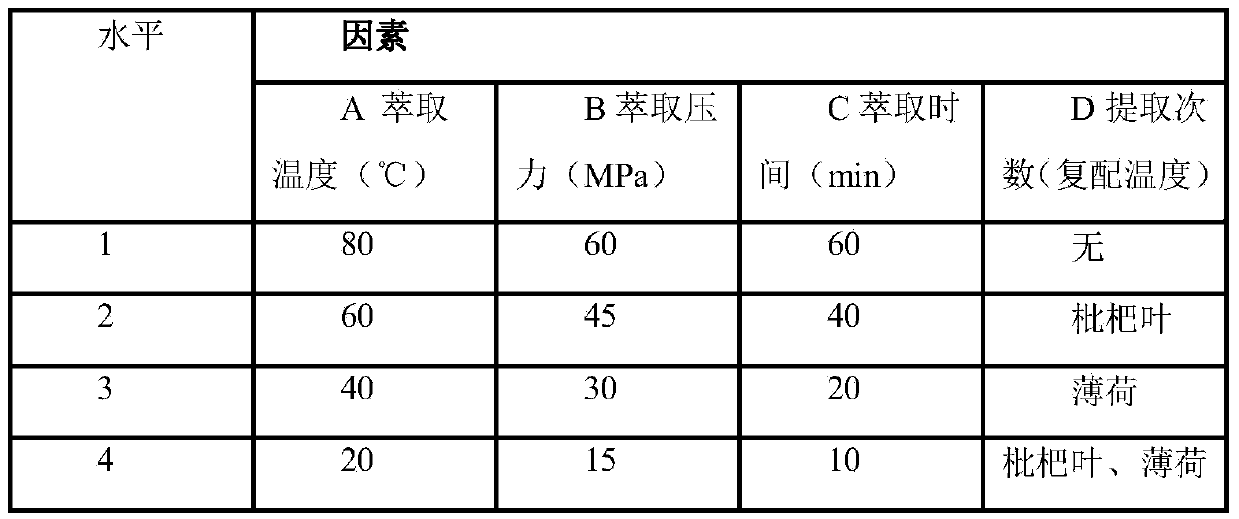

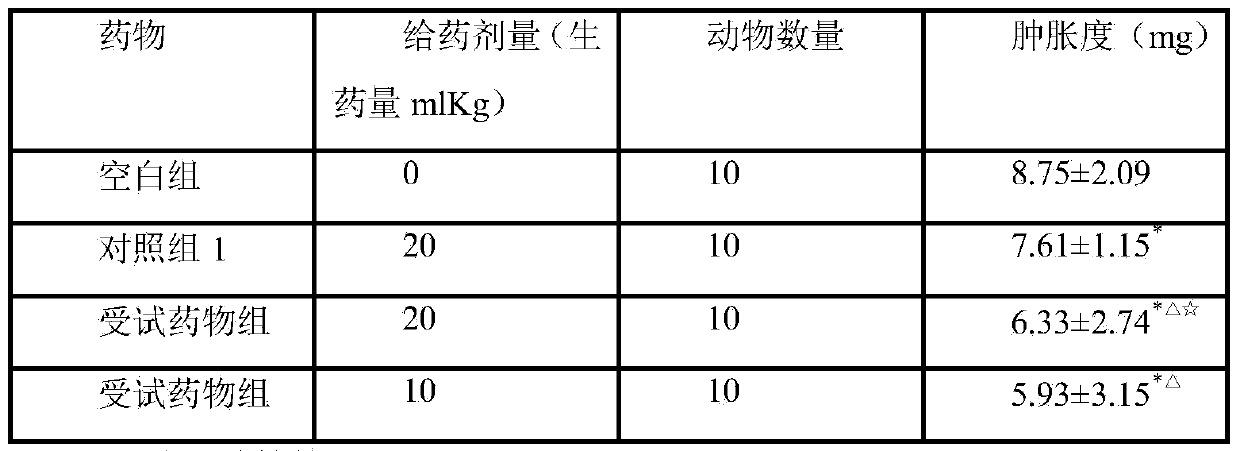

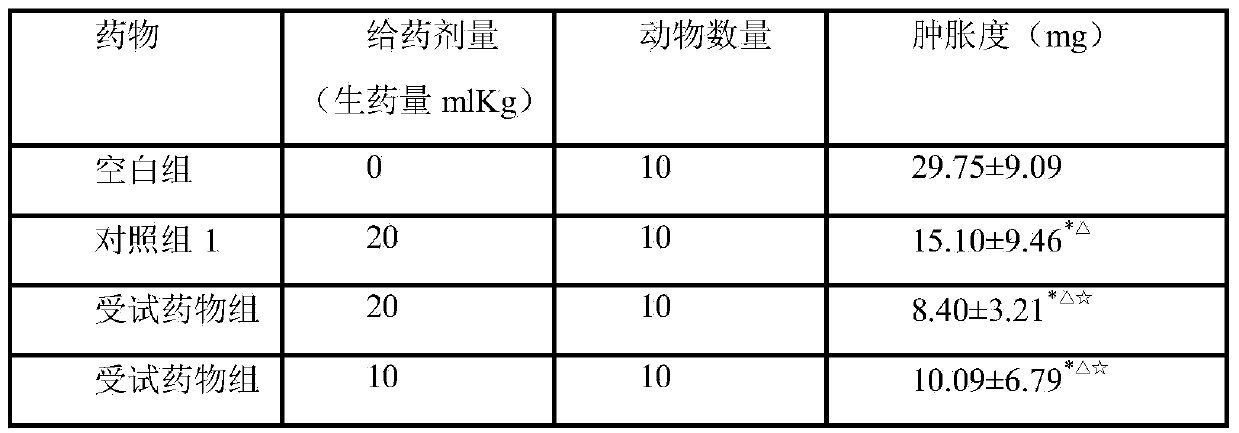

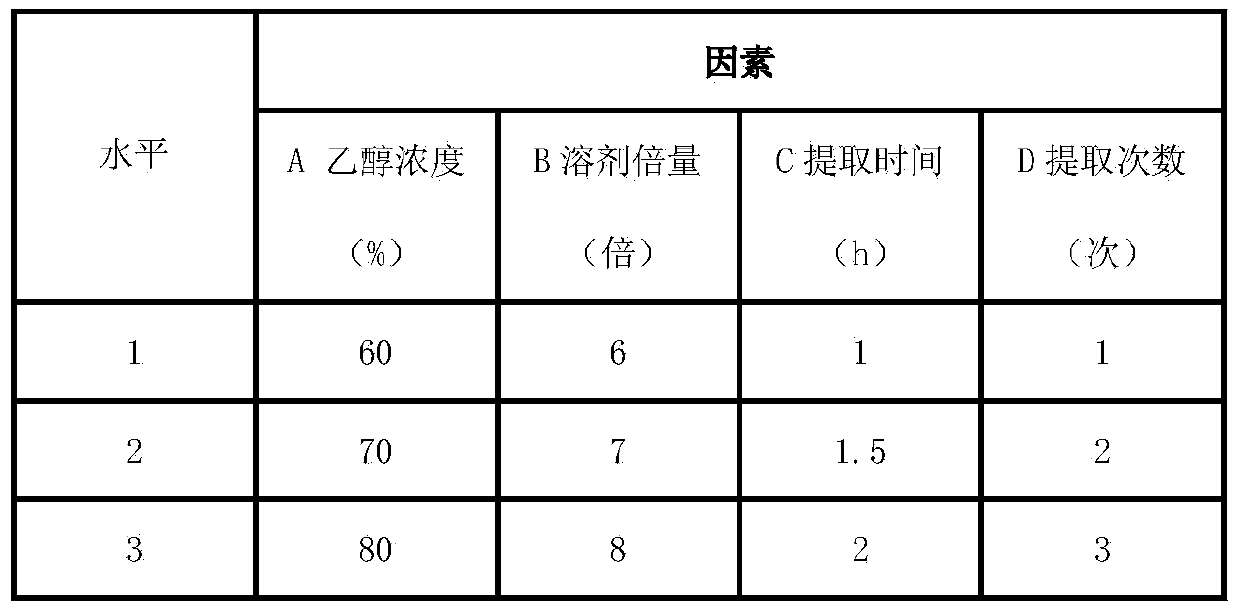

Unibract fritillary bulb lung-heat-clearing syrup and production process thereof

InactiveCN104001014AImprove stabilityMedication time is shortPharmaceutical non-active ingredientsRespiratory disorderPharmacySucrose

The invention discloses unibract fritillary bulb lung-heat-clearing syrup, and belongs to the field of pharmacy. The unibract fritillary bulb lung-heat-clearing syrup is prepared by performing ultra-critical CO2 extraction on the following raw materials in parts by weight at three stages: 200-300 parts of loquat leaf, 40-60 parts of bitter almond kernel, 3-8 parts of unibract fritillary bulb, 30-80 parts of dwarf lilyturf root, 30-80 parts of rehmannia, 30-80 parts of liquoric root, 20-40 parts of platycodon root, 10-25 parts of peppermint, 100-200 parts of sugar cane and 400-600 parts of isomalto-oligosaccharide, wherein process parameters of each stage are that: at the first stage, the pressure is 50-60 MPa, the temperature is 25-35 DEG C, and the extraction time is 30-60 minutes; at the second stage, the pressure is 30-40 MPa, the temperature is 40-55 DEG C, and the extraction time is 20-40 minutes; at the third stage, the pressure is 15-20 MPa, the temperature is 60-80 DEG C, and the extraction time is 5-10 minutes.

Owner:余中华

Ecological scatter-feed method for medlar chicken

InactiveCN106857397AImprove chicken immunity and disease resistanceGood quality meatAnimal feeding stuffCultivating equipmentsFeeding MethodsDisease

The invention discloses an ecological scatter-feed method for medlar chicken. The method is achieved by comprising the following steps 1, selecting a site, 2, building a medlar garden, 3, constructing a chicken house, 4, selecting baby chicken and 5, feeding the medlar chicken. The invention belongs to the technical field of poultry feeding and particularly provides the ecological scatter-feed method for the medlar chicken. The disease resistance of the chicken is enhanced by the method, the meat is delicious and the flavor is a unique, and the nutrition is rich.

Owner:薛广奎

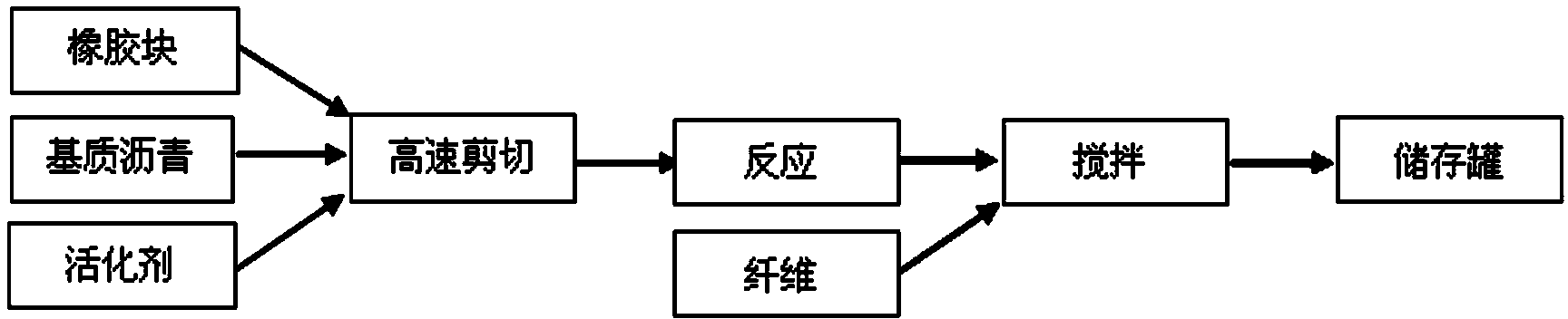

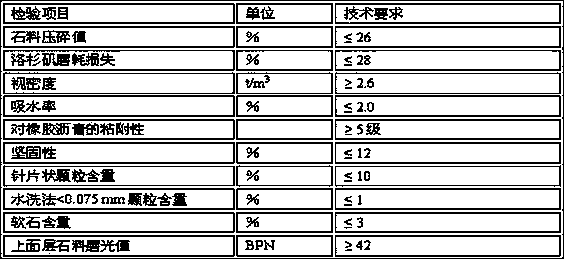

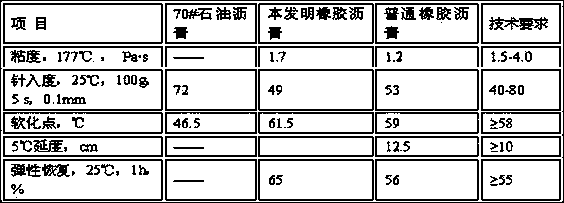

Large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer and preparation method thereof

The invention discloses a large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer and a preparation method thereof, and relates to a pavement structure layer consisting of large-grain-diameter rubber block-modified asphalt and fiber together with single-grain-diameter gravels, and a preparation method thereof. The large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer consists of aggregate, fiber and rubber block-modified asphalt. The preparation method comprises the following steps: 1) sweeping, blowing dust and cleaning an underlayer; 2) preparing the rubber block-modified asphalt; 3) preparing the rubber block-modified asphalt mastic; 4) before sprinkling the rubber asphalt mastic, inspecting various indexes; 5) sprinkling the rubber block-modified asphalt mastic; 6) scattering and paving the gravels; 7) performing rolling compaction; 8) sweeping the large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer. The large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer is low in production cost, low in energy consumption, free of pollution and high in storage stability. The preparation method is convenient in construction, simple and feasible, and can be easily applied to industrial production.

Owner:NANJING TONGAN ROAD ENG +2

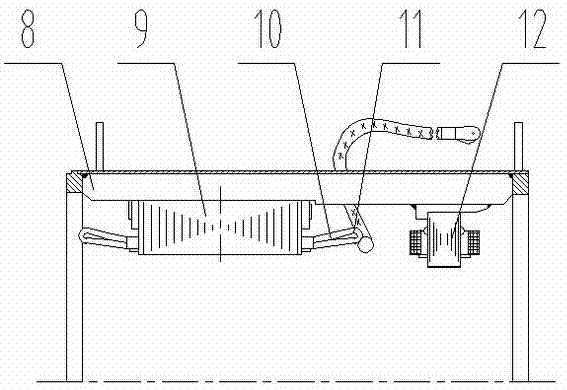

Grouting device for controlling settlement of height railroad bed and grouting method

The invention relates to a grouting device for controlling settlement of a height railway roadbed and a grouting method. The grouting device for controlling the settlement of the height railway roadbed comprises a pulping machine, a grouting pipe and a grouting pump, wherein the grouting pipe comprises an inner pipe and an outer pipe which sleeve with each other, the inner pipe and the outer pipe communicate with each other, and grout outlet holes are formed in the outer pipe; meanwhile, the inner pipe and the outer pipe are connected with the grouting pump through a communicating pipe and a circulating pipe correspondingly; meanwhile, the outer pipe further sleeves with an expansion sleeve, and the expansion sleeve is connected with the communicating pipe through an expansion pipe. According to the grouting device for controlling the settlement of the height railway roadbed, slurry is buffered through the design of the inner pipe and the outer pipe, so that the pressure change amplitude of the slurry is reduced; meanwhile, drainage is conducted to the far end of the grouting pipe through adjustment of the hole diameter and the distribution density of the grout outlet holes, and therefore uniform distribution of grout is guaranteed; the grouting pipe is fixed in a mounting hole after the expansion sleeves at the two ends of the grouting pipe are expanded, so that the vibration of the grouting pipe is further reduced, and the grouting quality is improved; an inlet and an outlet of the grout are formed in the top of the grouting pipe, the grouting pipe can be installed at any angle, and the application range of the grouting pipe is expanded.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

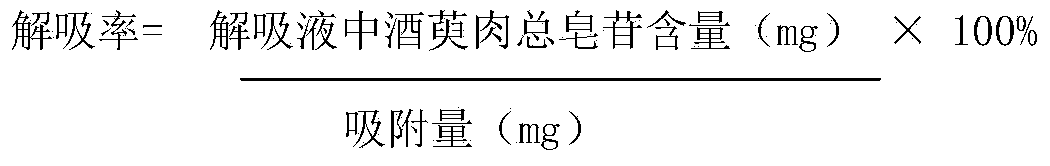

Preparation method of concentrated six-taste glutinous rehmannia capsule

InactiveCN104000994AGuaranteed technical effectImprove bioavailabilitySenses disorderMetabolism disorderSide effectCurative effect

The invention relates to a preparation method of a concentrated six-taste glutinous rehmannia capsule. In the preparation method, after moutan bark is extracted by using a supercutical fluid, dregs of a decoction are precipitated by using ethanol extraction water; Fructus Corni is extracted by using ethanol and purified by using macroporous resin after being crushed; moutan bark volatile oil is subjected to clathration by using cyclodextrin; prepared rehmannia root, Poria cocos and rhizoma alismatis are decocted in water and precipitated by using ethanol. The concentrated six-taste glutinous rehmannia capsule prepared by the process is good in treatment effect, the preparation is stable and side effects are less.

Owner:余中华

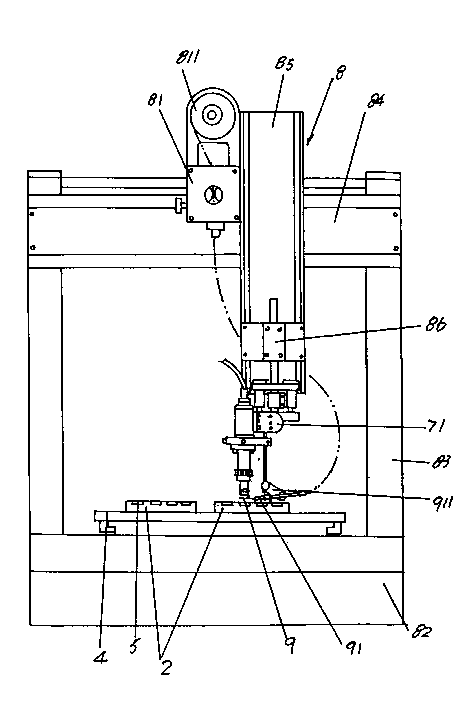

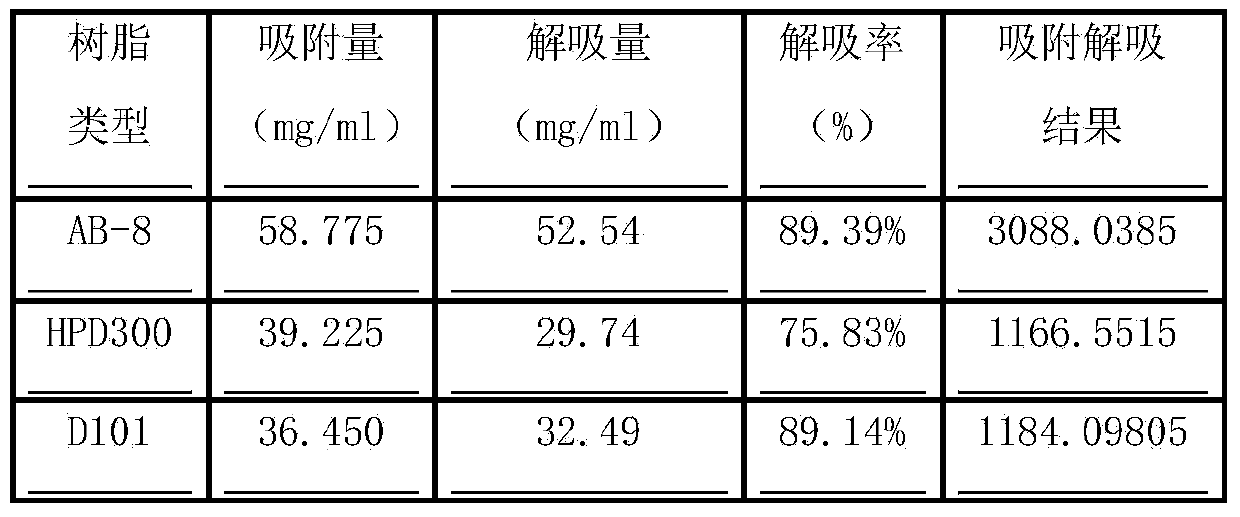

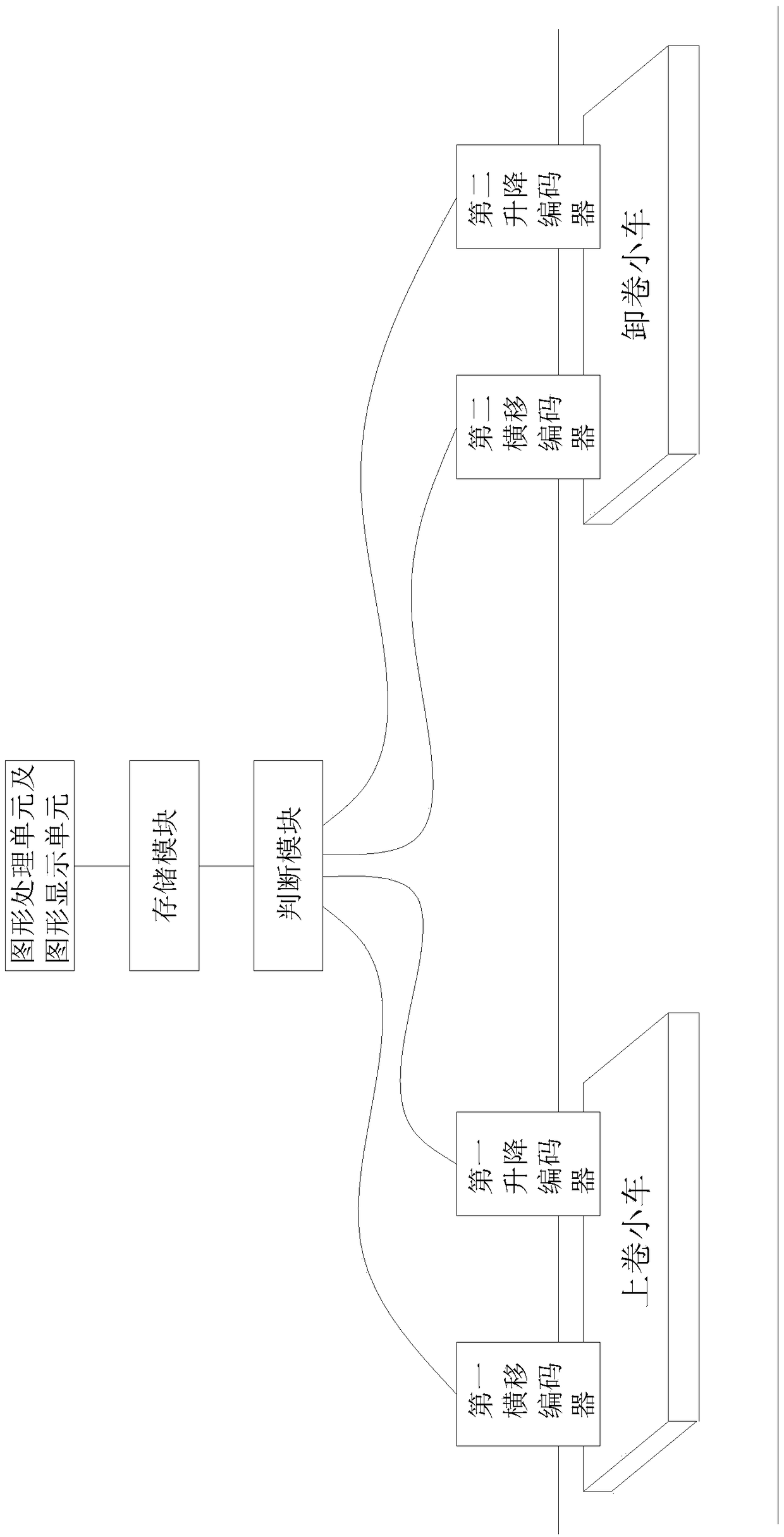

Device and method for monitoring locating precision of continuous wire unwinding trolley

ActiveCN109127777AEasy maintenance planningGrasp the deterioration trendPosition/course control in two dimensionsEngineeringEncoder

The invention relates to a device and method for monitoring the locating precision of a continuous wire unwinding trolley. The device comprises a first translation encoder, a first lifting encoder, asecond translation encoder, a second lifting encoder, a judgment module and a storage module. In the production process, winding trolley coil receiving position locating precision monitoring, windingtrolley waiting position locating precision monitoring, winding trolley winding position locating precision monitoring, coil unloading trolley coil receiving position locating precision monitoring, coil unloading trolley waiting position locating precision monitoring and coil unloading trolley unwinding position locating precision monitoring can be carried out in real time. According to the deviceand method for monitoring the locating precision of the continuous wire unwinding trolley, the locating precision of the trolley can be monitored in real time, the degradation trend of the locating precision of the trolley is mastered, and a targeted repair schedule can be made for a walking mechanism of the trolley.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Safety valve and oil filter integrated assembly

ActiveCN112403071AHigh implementabilityGuaranteed technical effectTurbine/propulsion fuel valvesStationary filtering element filtersSafety valveBypass valve

The invention relates to the technical field of valve structures, oil filters and the like, in particular to a safety valve and oil filter integrated assembly. The assembly comprises a shell (21), a filter screen assembly (23) and a spring (27), and the filter screen assembly (23) is installed in a cavity of the shell (21); an oil path (28) and an oil path (29) are formed in the shell (21), and the oil path (28) is communicated with one end A of the filter screen assembly (23) and is communicated with the oil path (29) from an inner cavity of the filter screen assembly (23) to a filter screen;one end of the spring (27) abuts against the other end B of the filter screen assembly (23), and the other end of the spring (27) abuts against an oil filter cover (22); and the oil filter cover (22)is connected with the shell (21) through a hexagon head screw (24) or a bolt. Compared with the prior art, a bypass valve does not need to be installed any more, one assembling hole system is omitted, one oil inlet way and one oil outlet way are omitted, and the application range of the self-washing oil filter is greatly expanded.

Owner:XIAN AERO ENGINE CONTROLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com