Patents

Literature

259 results about "Flat rated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

When an engine is Flat rated it means that an engine of high Horsepower rating is constrained to a lower horsepower rating. The engine output in this case will always remain the same, but when atmospheric conditions such as high temperatures and high altitude (Hot and High) reduce the power output of the engine it has more headroom before it falls below the limited maximum output. In some cases the total power output of an engine needs to be constrained because the airframe can only handle a certain force. This is the case with Gas Turbine engines. Flat rating allows airplanes to operate under more demanding conditions, without the need for extra structural strengthening due to higher peak power output of the engine.

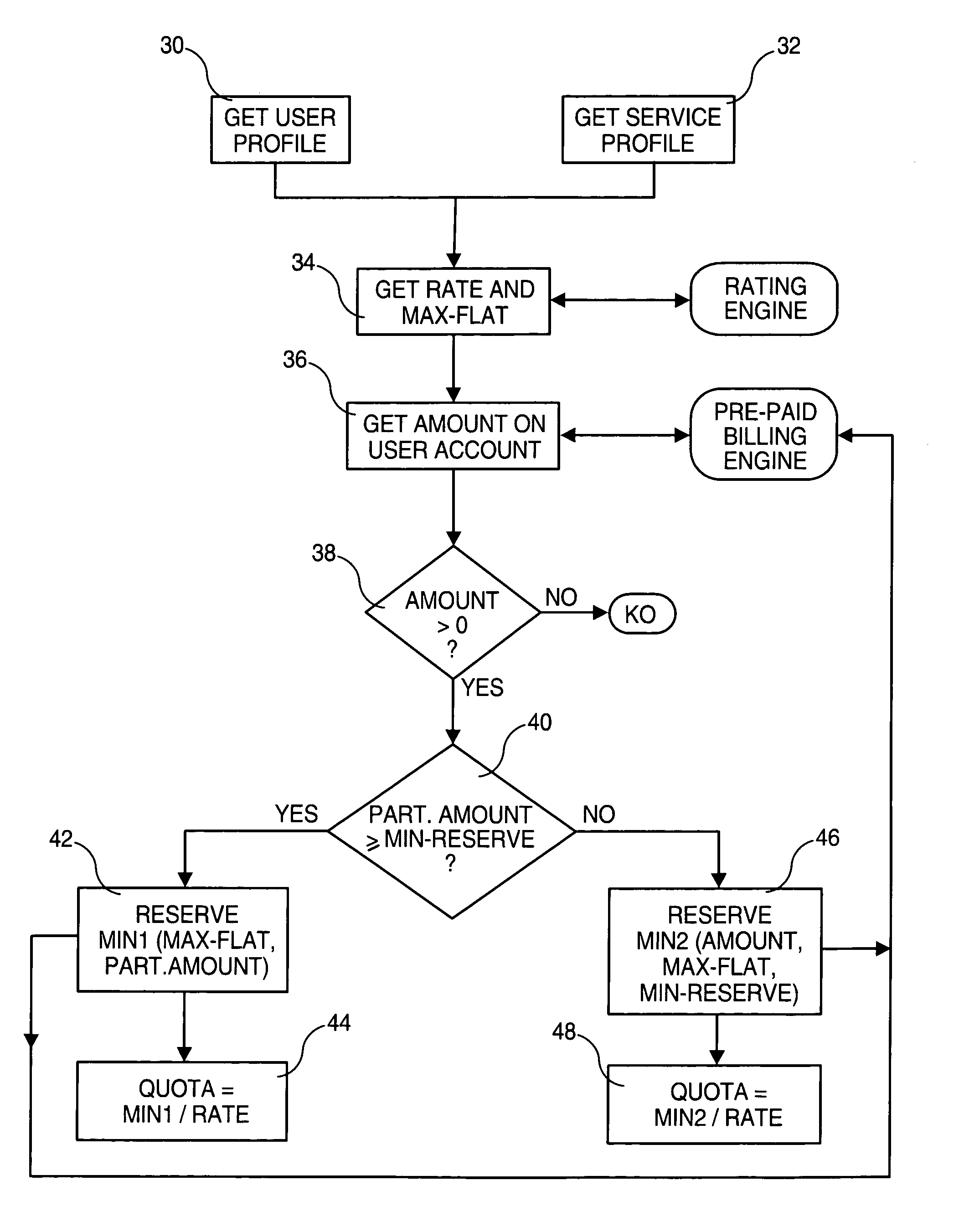

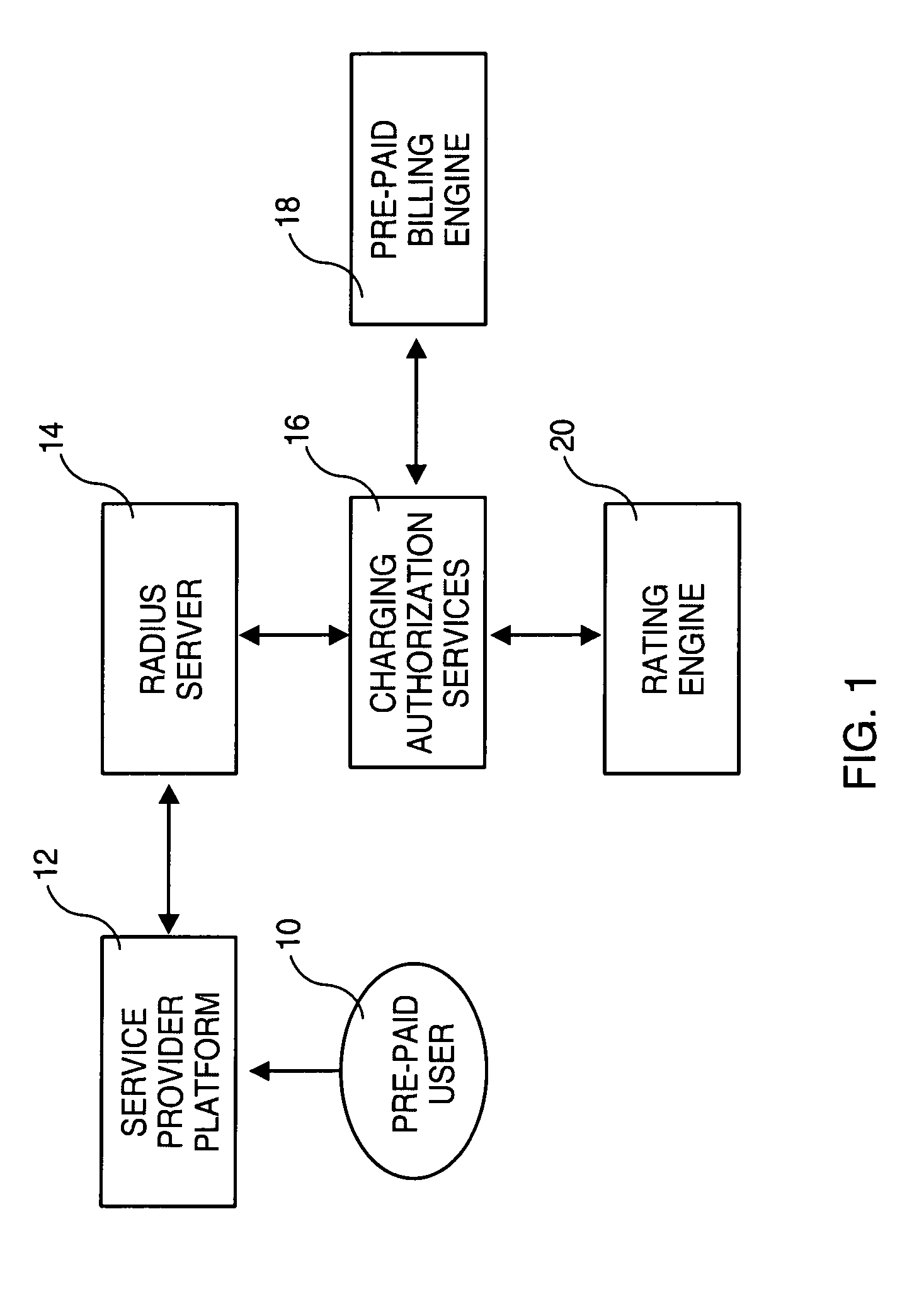

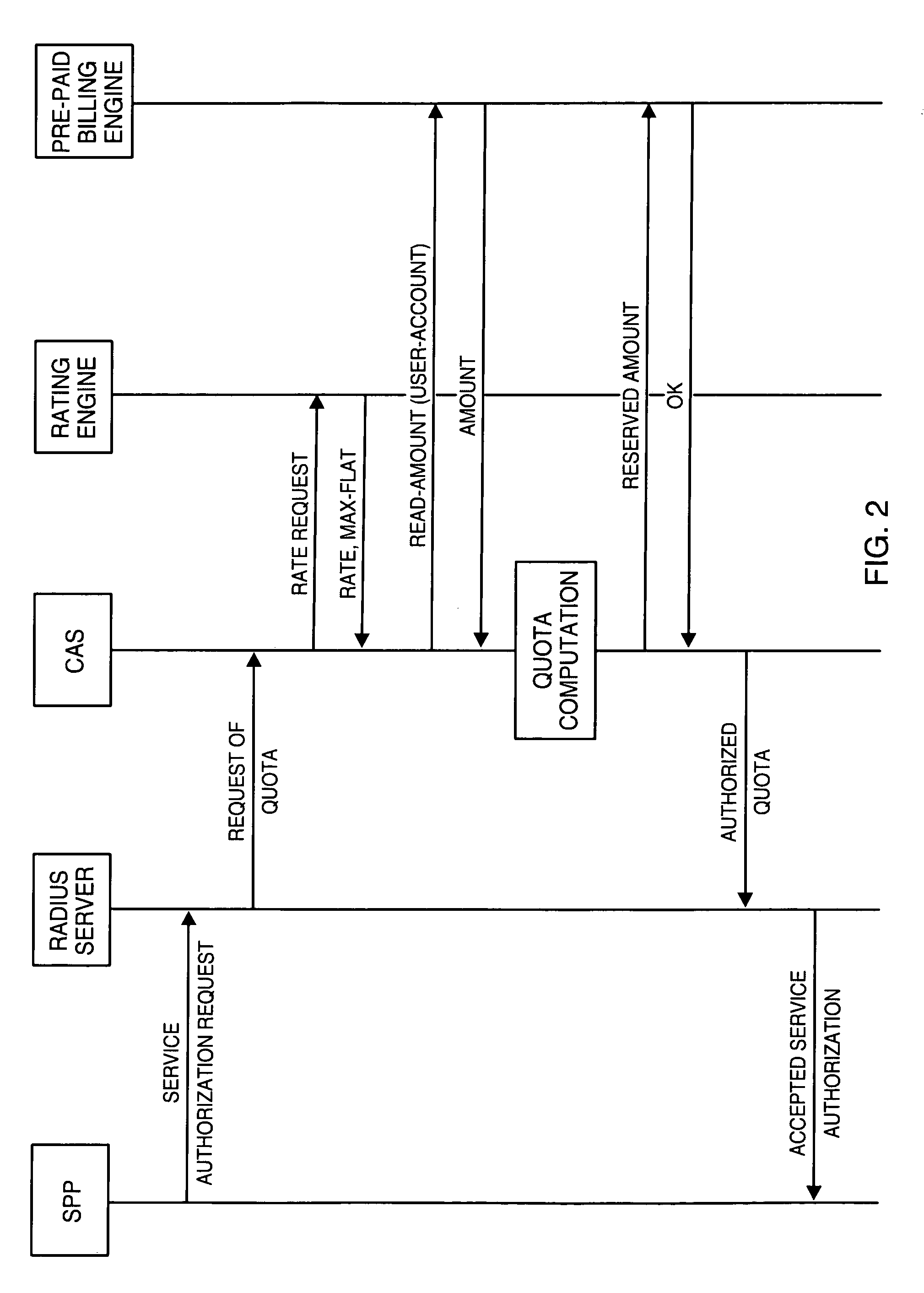

Method for computing a quota of service requested by a pre-paid user to a multi-service provider

Method for computing a quota of service time or volume requested by a user in a system wherein a service provider provides a plurality of services to the user having pre-paid an amount of money on a user account to access at least one service. This method comprises determining whether the product of the amount of money (AMOUNT) by a reserved part (PART) is greater than a predetermined minimum reserve of money (MIN-RESERVE), and computing the quota which is equal to the minimum (MIN1) of the product and a maximum quantity of service (MAX-FLAT) that the user may reserve while being in a flat rate interval divided by the cost of one unit of the requested service (RATE) if the product is greater than MIN-RESERVE or to the minimum (MIN2) of AMOUNT, MAX-FLAT and MIN-RESERVE, divided by RATE if the product is less than MIN-RESERVE.

Owner:IBM CORP

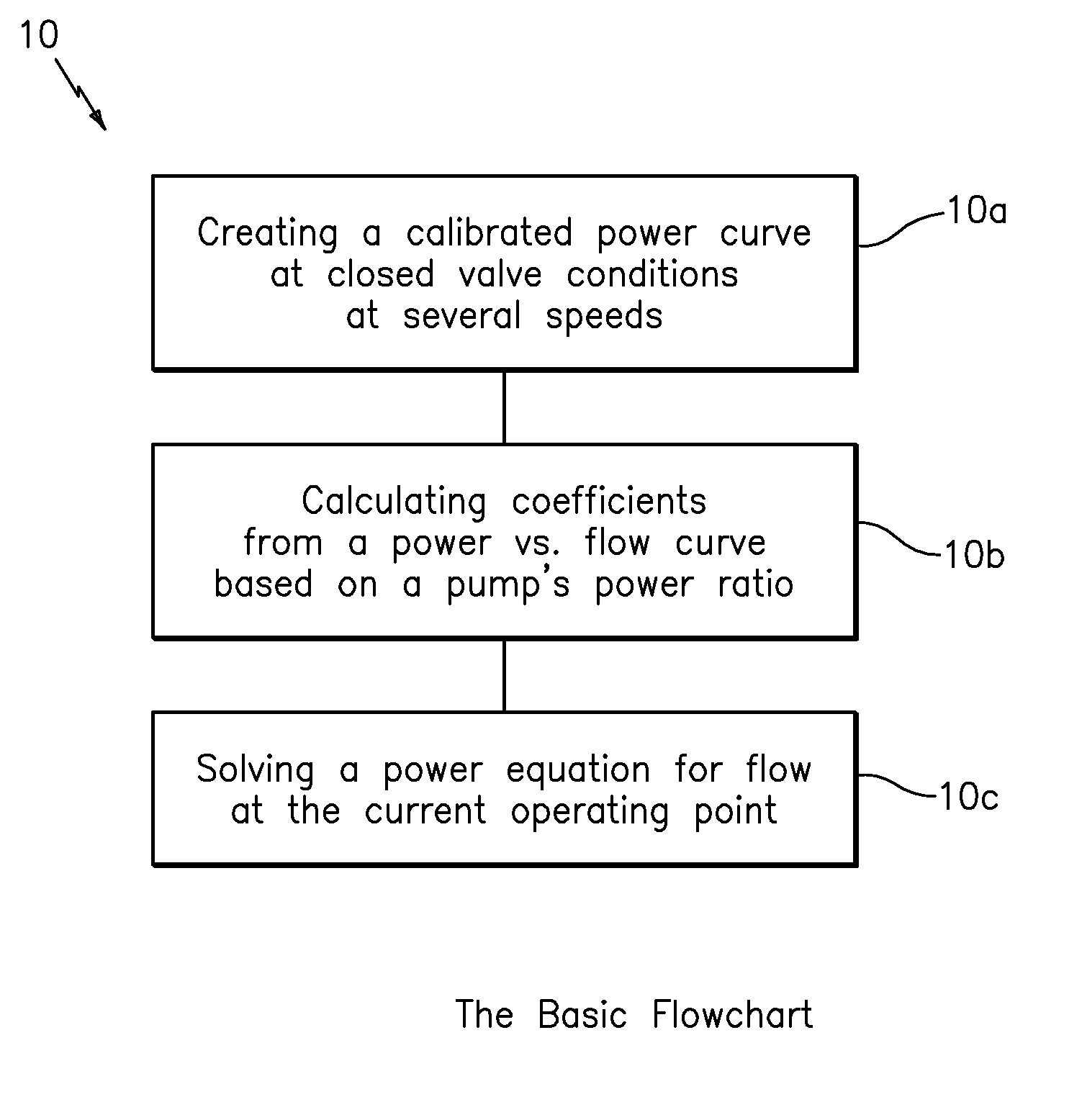

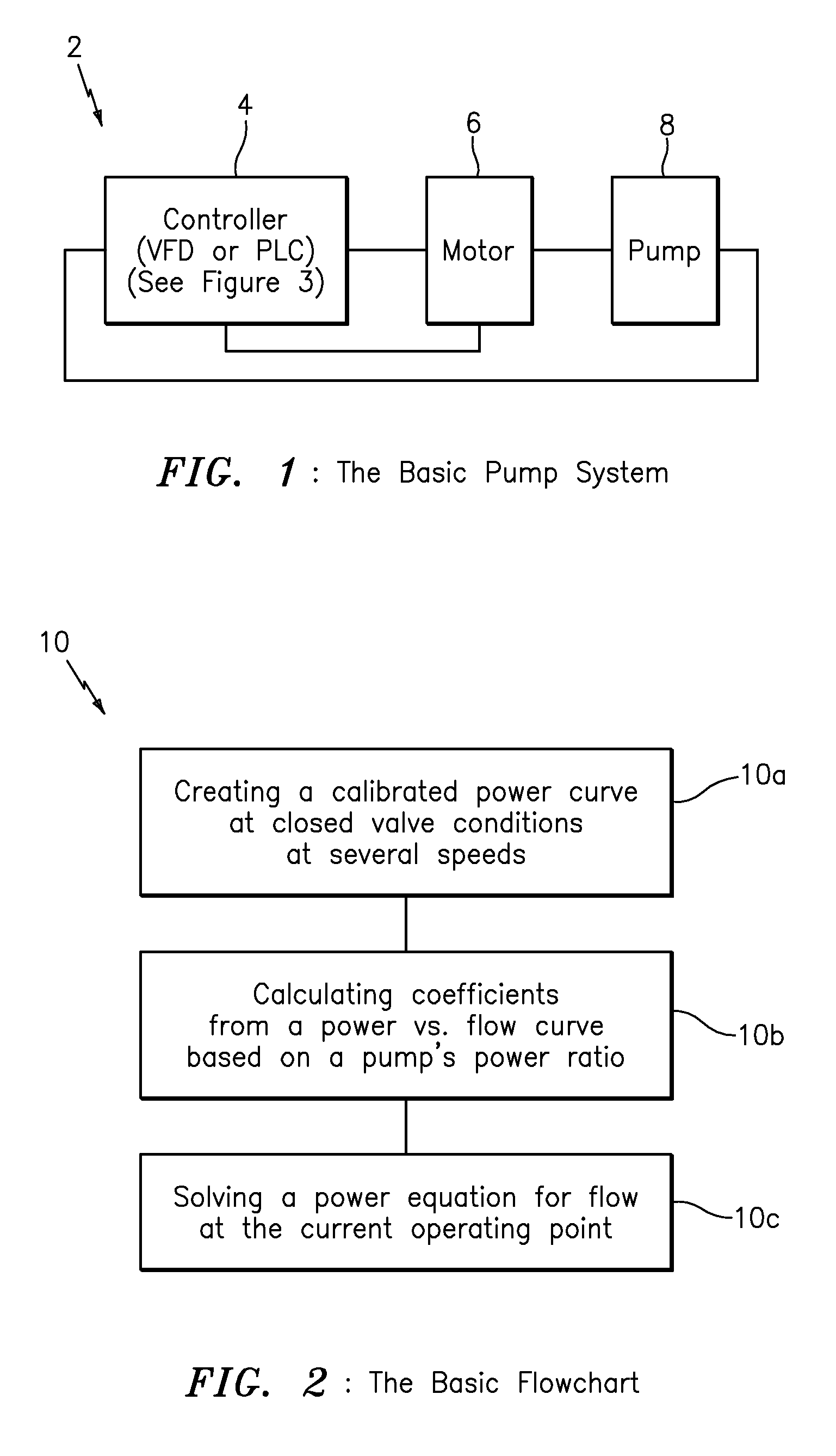

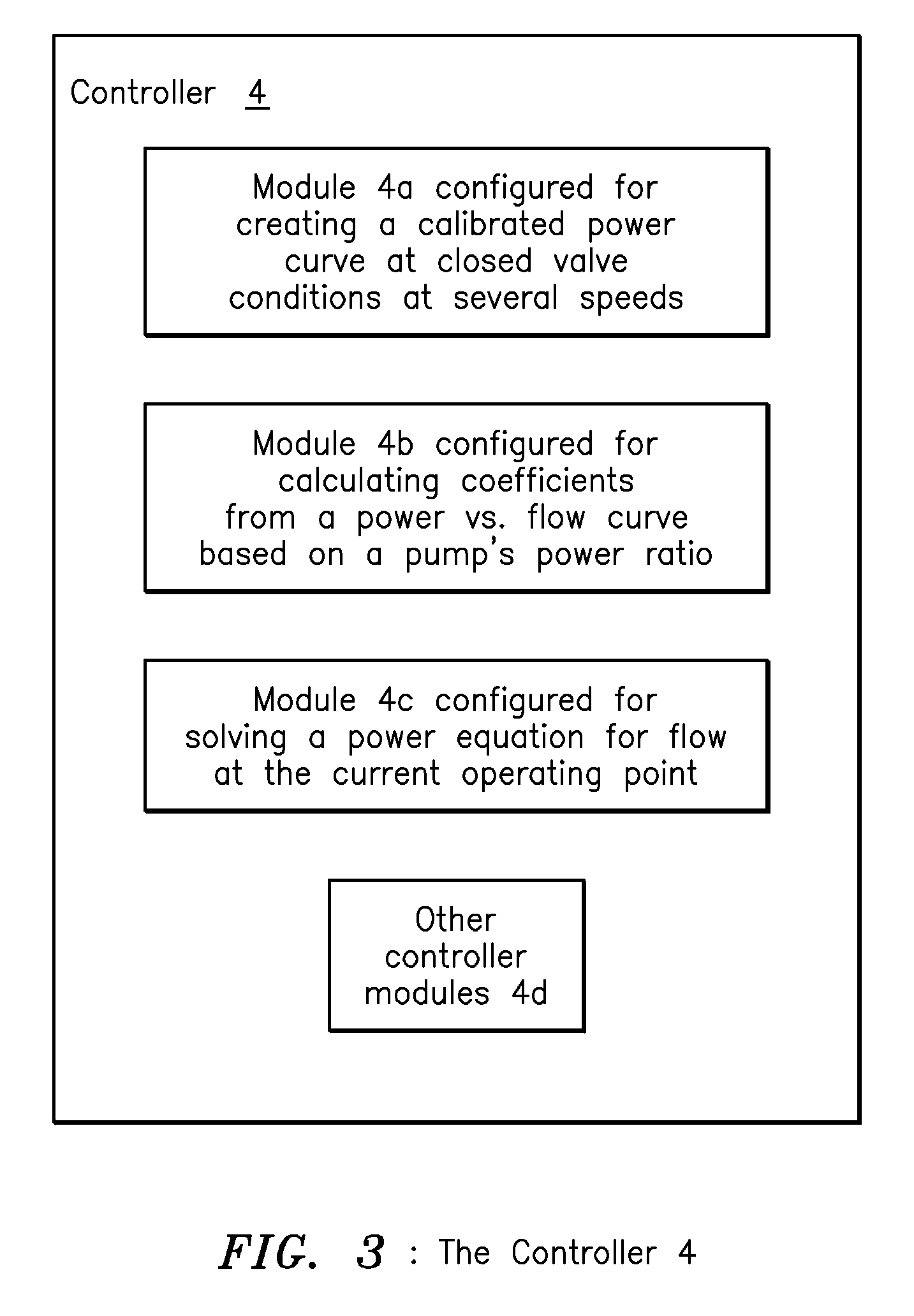

Method for determining pump flow without the use of traditional sensors

ActiveUS7945411B2Testing/calibration apparatusProcess and machine controlOperating pointMuller's method

A technique for determining pump flow without using traditional sensors features steps and modules for creating a calibrated power curve at closed valve conditions at several speeds; calculating coefficients from a normalized power curve based on a pump's power ratio; and solving a polynomial power equation for flow at the current operating point. The calibrated power curve may be created by increasing the speed of the pump from a minimum speed to a maximum speed and operating the pump with a closed discharge valve. This data is used to correct published performance for shutoff power and best efficiency point power at rated speed in order to determine the pump's power ratio. It is also used to accurately determine closed valve power at the current operating speed. The pump's power ratio is determined by the equation: Pratio=Pshutoff @100% / PBEP<sub2>—< / sub2>corr. The polynomial power equation may, for example, include a 3rd order polynomial equation developed using coefficients from the normalized power versus flow curve, and corrections may be made for speed, hydraulic efficiency and specific gravity in the polynomial power equation. Complex roots may be determined to solve the 3rd order polynomial equation using either Muller's method or some other suitable method, and the calculated actual flow may be determined for a specific operating point.

Owner:ITT MFG ENTERPRISES LLC

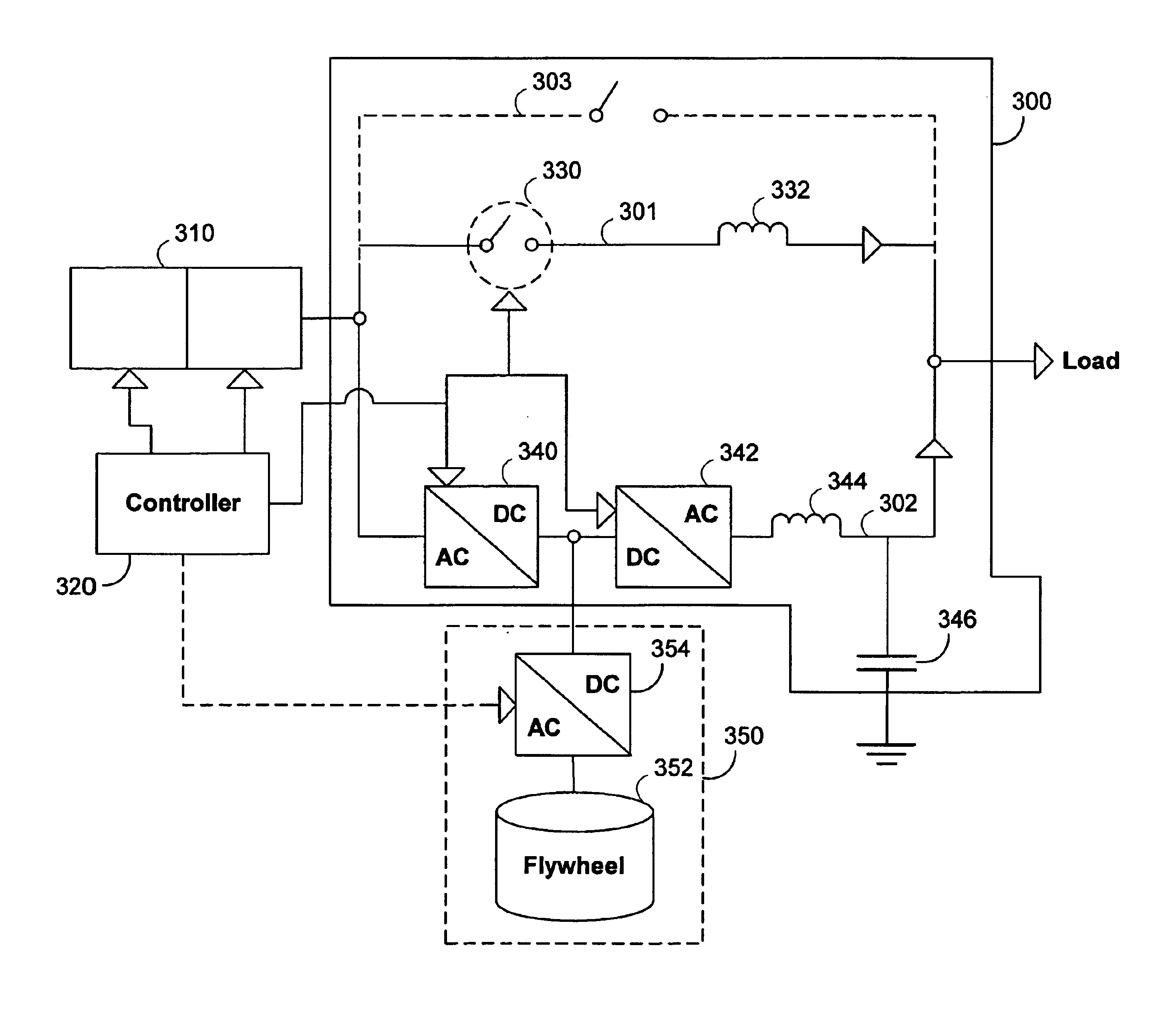

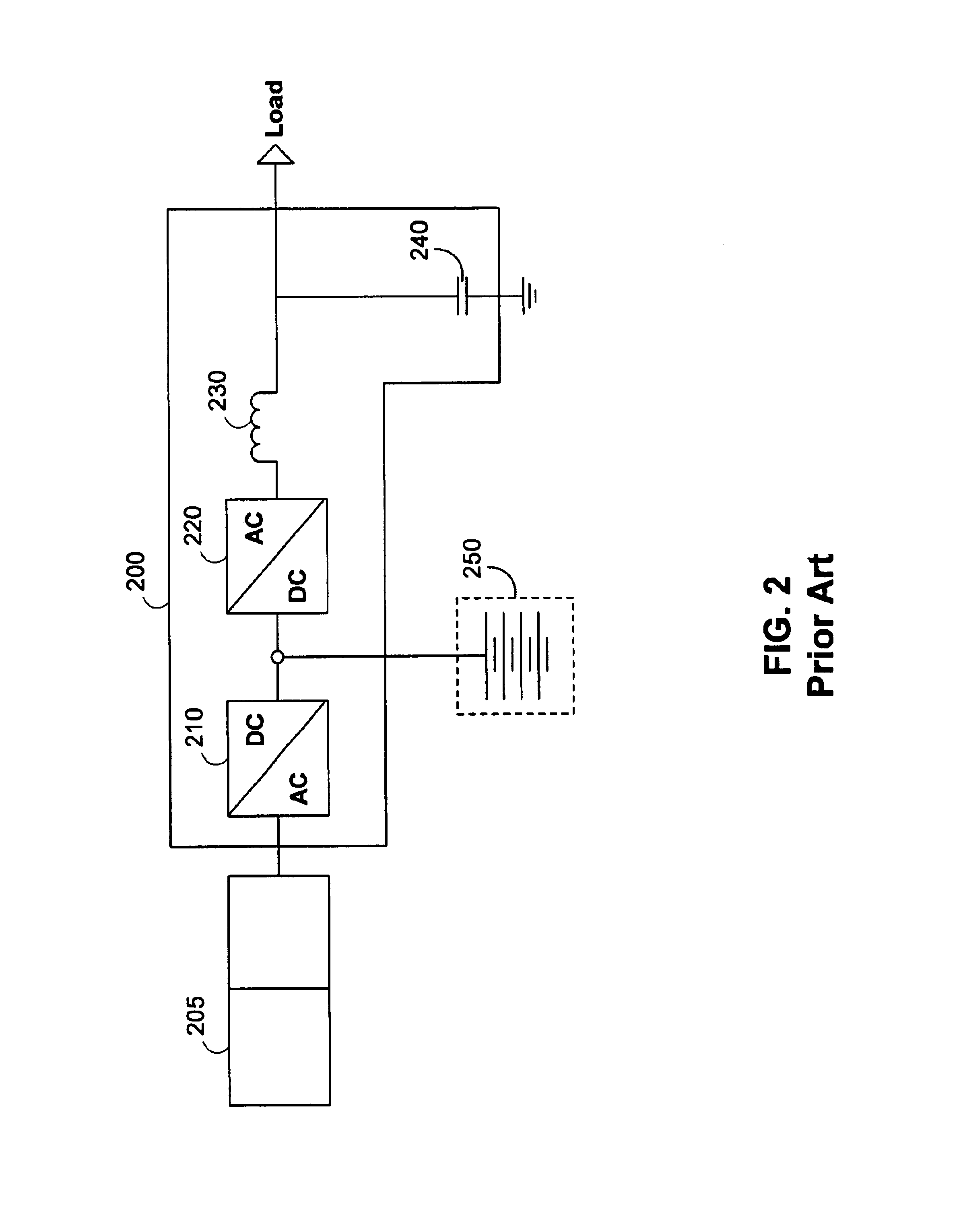

Multiple path variable speed constant frequency device having automatic power path selection capability

InactiveUS6844706B2Maximize engine efficiencySave fuelBatteries circuit arrangementsEmergency protective circuit arrangementsConstant frequencyInductor

The present invention relates to variable speed constant frequency (VSCF) devices and methods for maximizing engine generator efficiency. In one embodiment, a VSCF device may include at least two paths for conducting power to the load. One path, a line inductor path, may advantageously incur minimal power loss when the engine generator is supplying rated power to a load. A second path, a VSCF path, may be used to ensure that the frequency of the power is maintained at a substantially constant frequency under various load conditions. Another embodiment of the invention describes a process for determining optimal engine generator speed for a particular load. Because engine speed can be varied using any VSCF device, this process determines a speed that minimizes fuel consumption, emissions, and noise pollution for a given load.

Owner:PILLER USA INC

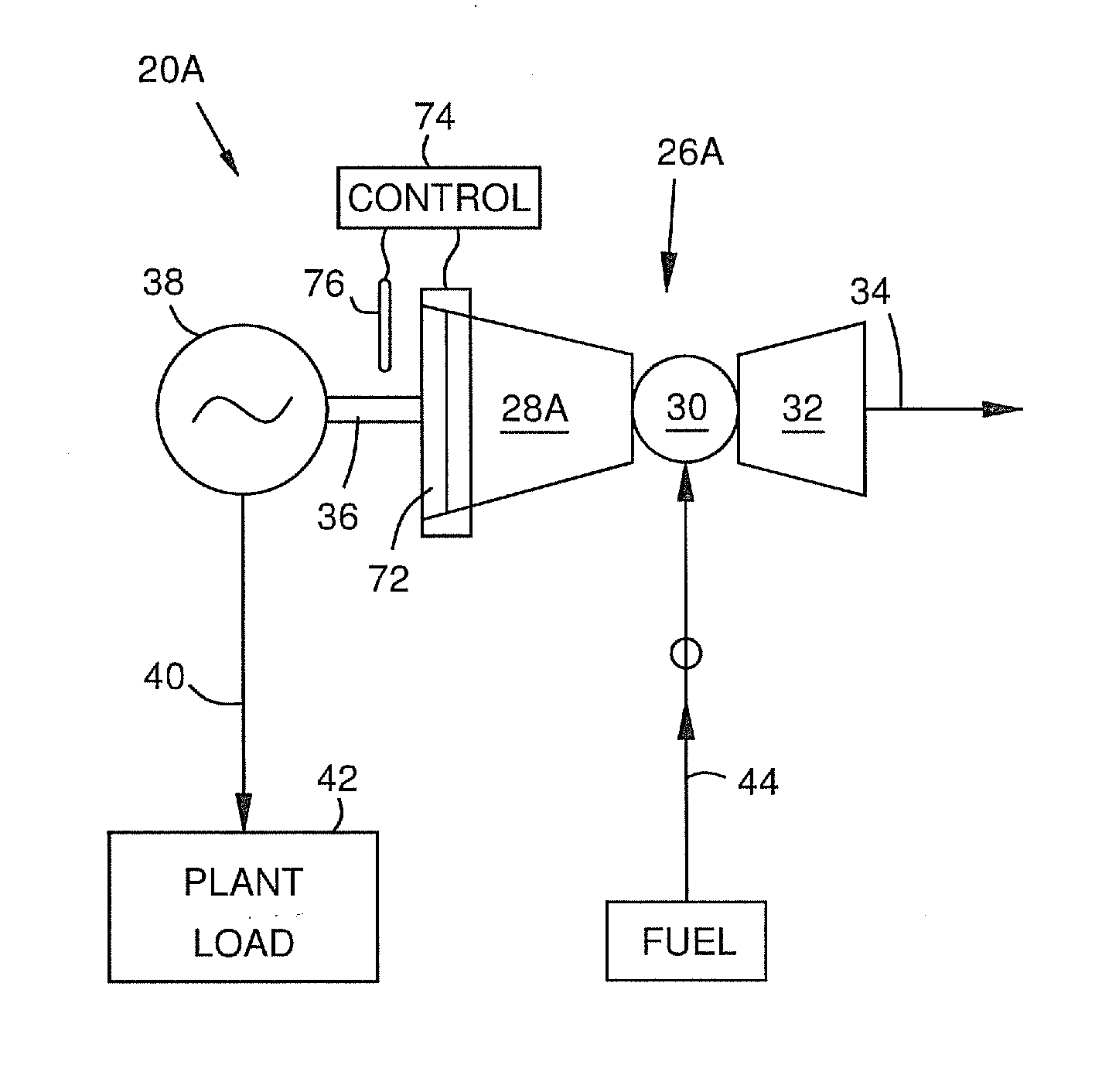

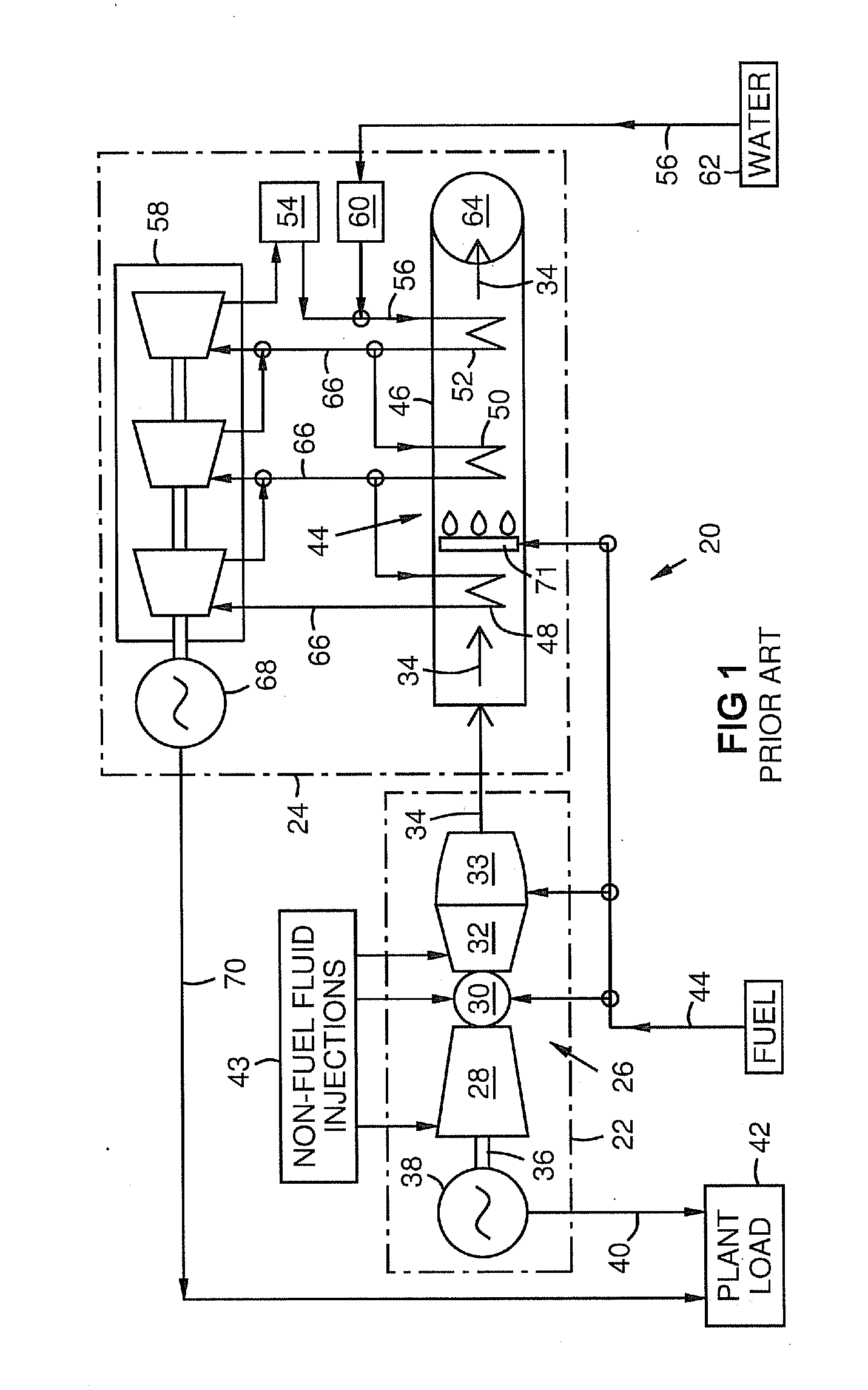

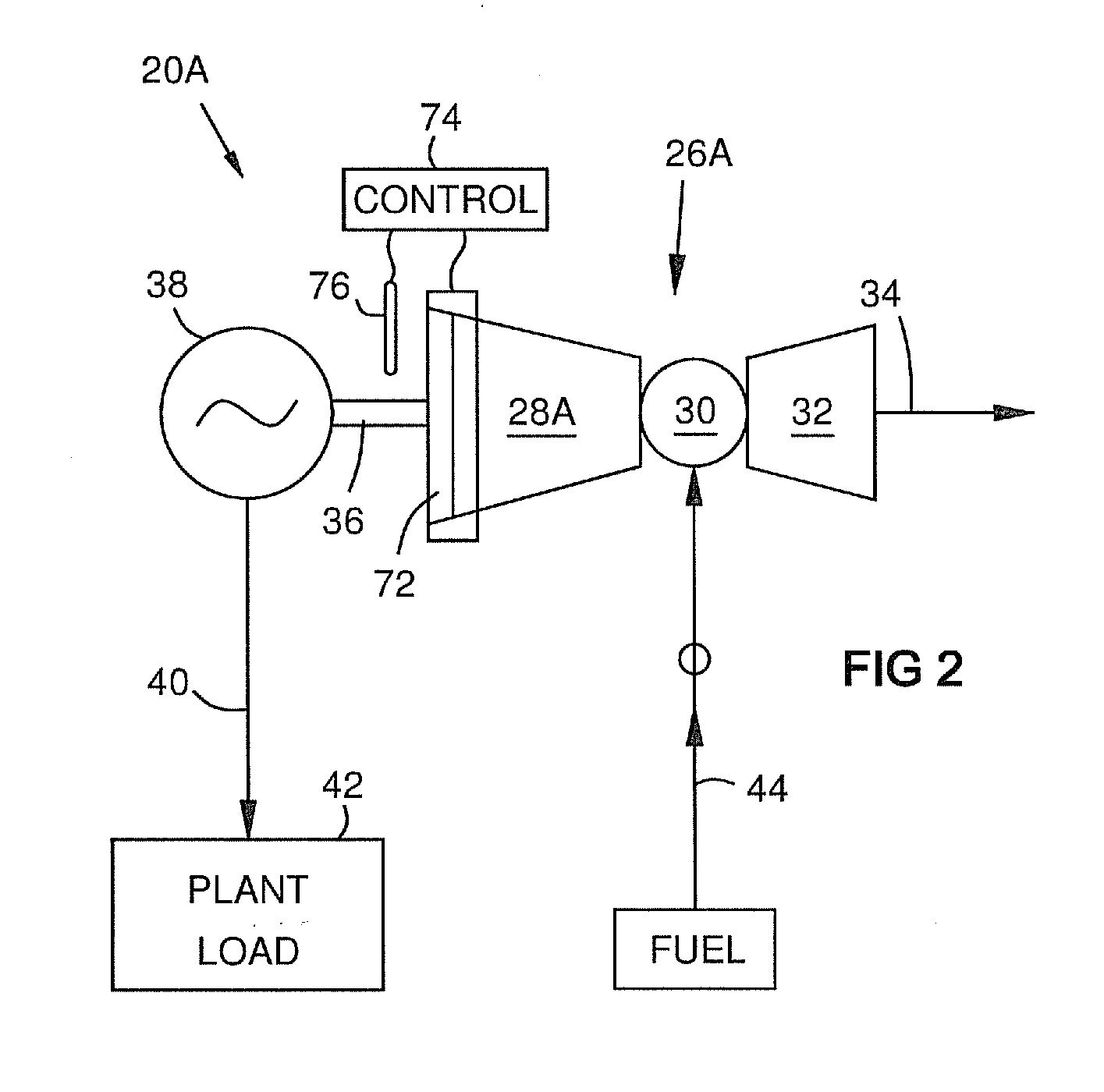

Gas turbine driven electric power system with constant output through a full range of ambient conditions

A gas turbine compressor (28A, 28B) sized to support respective maximum design points of other gas turbine driven electrical power generating system components (30, 32, 38, 46, 58, 68) during a least dense ambient condition within a design range of ambient conditions. A variable inlet (72) on the compressor automatically modulates to modulate airflow to supply just the amount needed to produce a rated output of the system throughout the full design range of ambient conditions. This safely and economically maintains rated power system output (94) over a full range of ambient conditions.

Owner:SIEMENS ENERGY INC

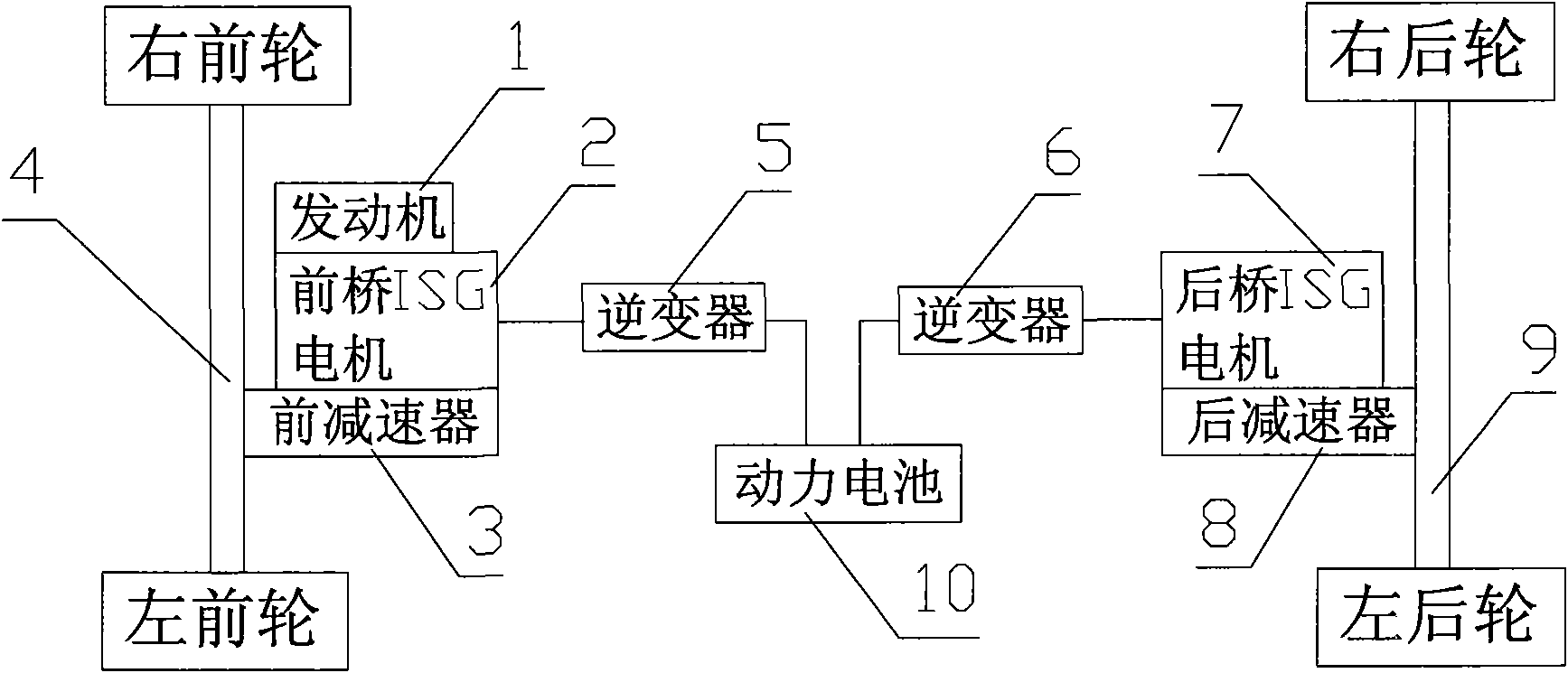

Driving system and control method thereof for four-wheel-drive hybrid vehicle

InactiveCN101590802APowerfulImprove powerHybrid vehiclesGas pressure propulsion mountingPower batteryElectricity

The invention aims to provide a driving system and a control method thereof for a four-wheel-drive hybrid vehicle which has high horsepower and higher fuel economical efficiency. The driving system comprises a power battery, a front driving unit, a rear driving unit and an entire vehicle controller for controlling the front driving unit and the rear driving unit to work, wherein the key points are that the front driving unit comprises an engine arranged on a front driving axle and a front axle ISG motor and a front speed reducer connected with the engine through a driving device, the rear driving unit comprises a rear axle ISG motor arranged on a rear driving axle and a rear speed reducer connected with the rear axle ISG motor through the driving device, the front axle ISG motor and the rear axle ISG motor are electrically connected with the power battery through an inverter respectively, and the ratio of the peak power of the front axle ISG motor to the rated power of the engine is over 40 percent. The driving system has a simple mechanical structure and less power loss, can improve the fuel economical efficiency of the vehicle while ensuring the dynamic property, and accord with the modern energy saving and environmental protection trend.

Owner:CHERY AUTOMOBILE CO LTD

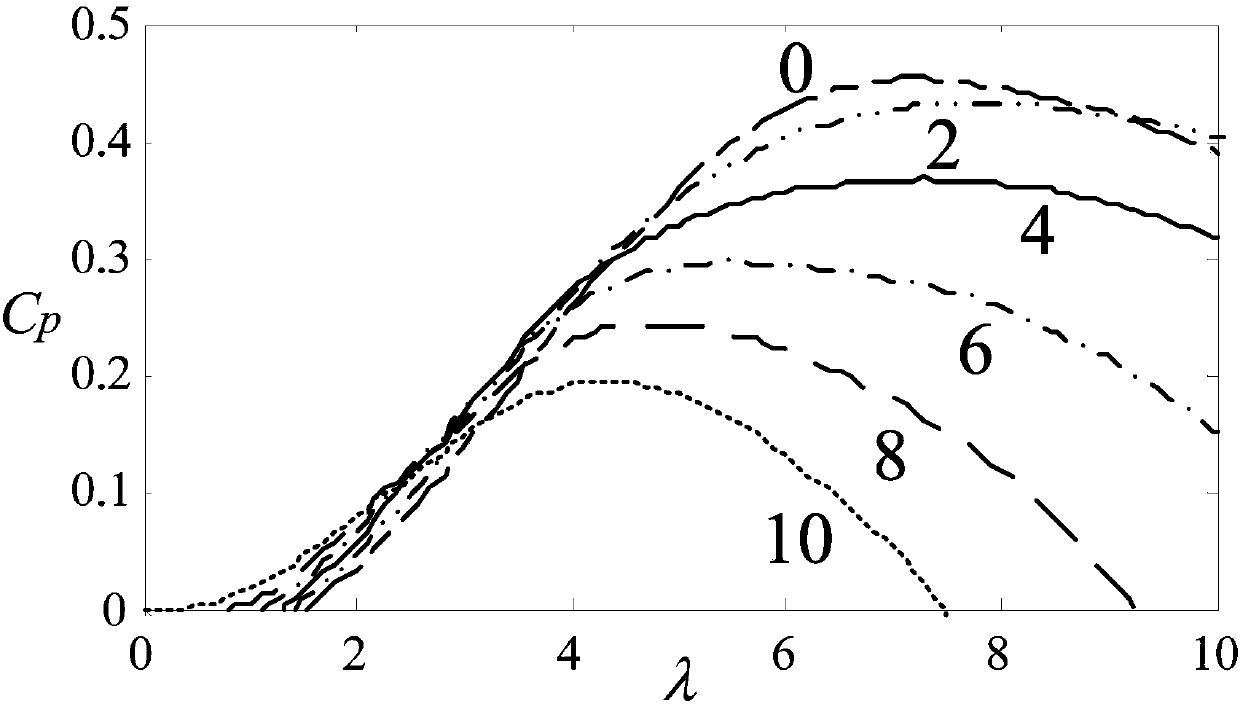

Stall controller and triggering condition control features for a wind turbine

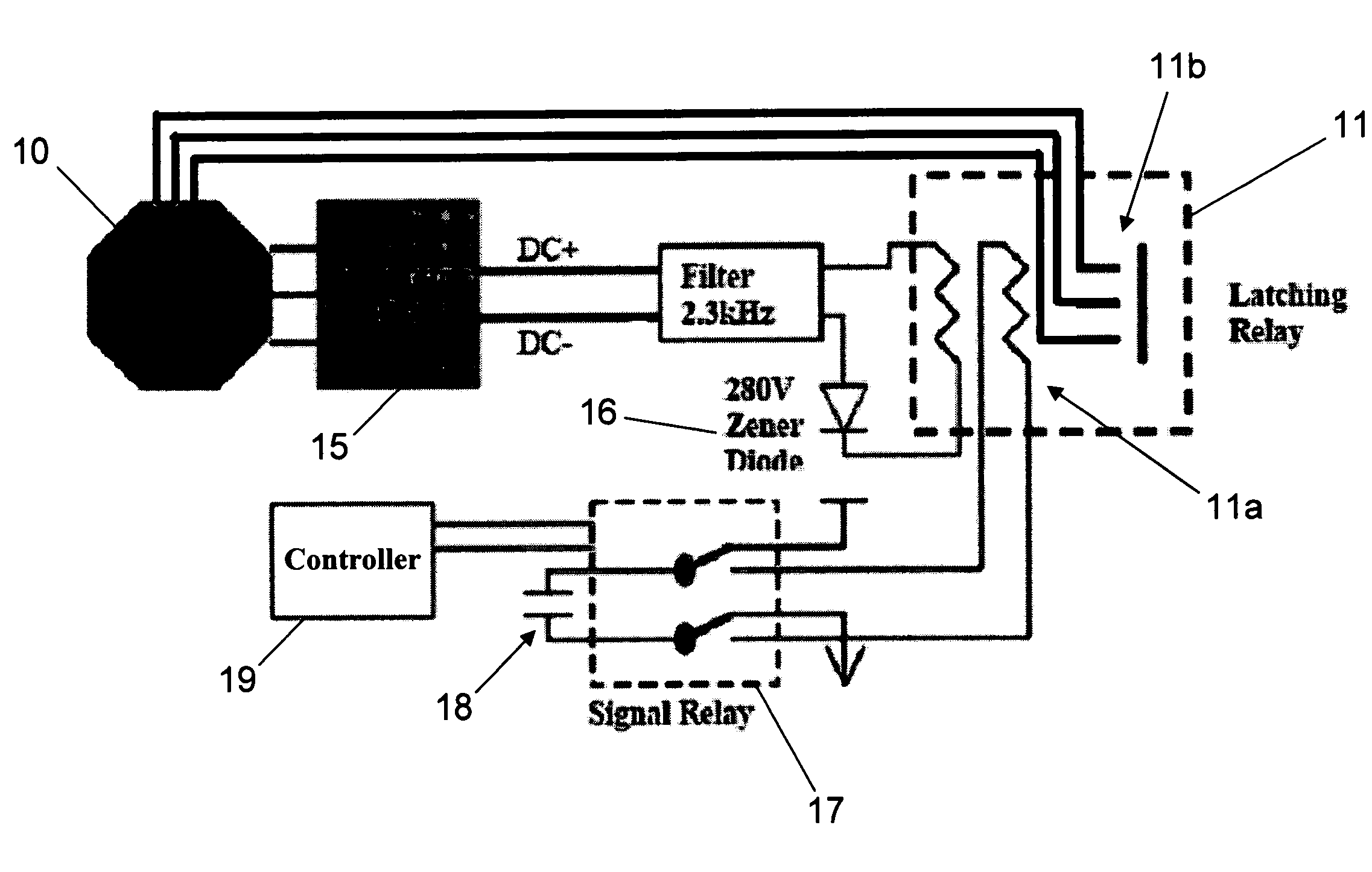

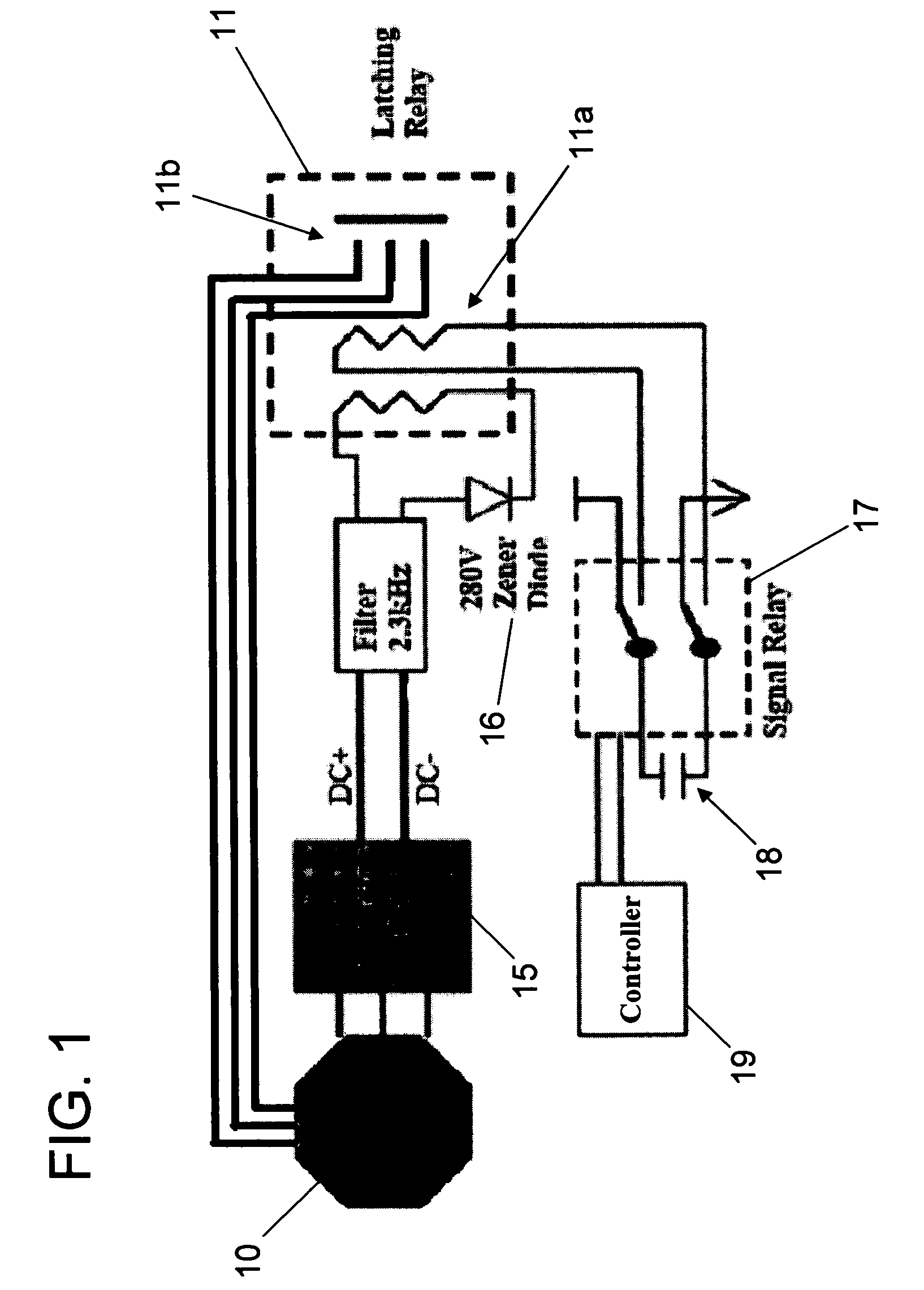

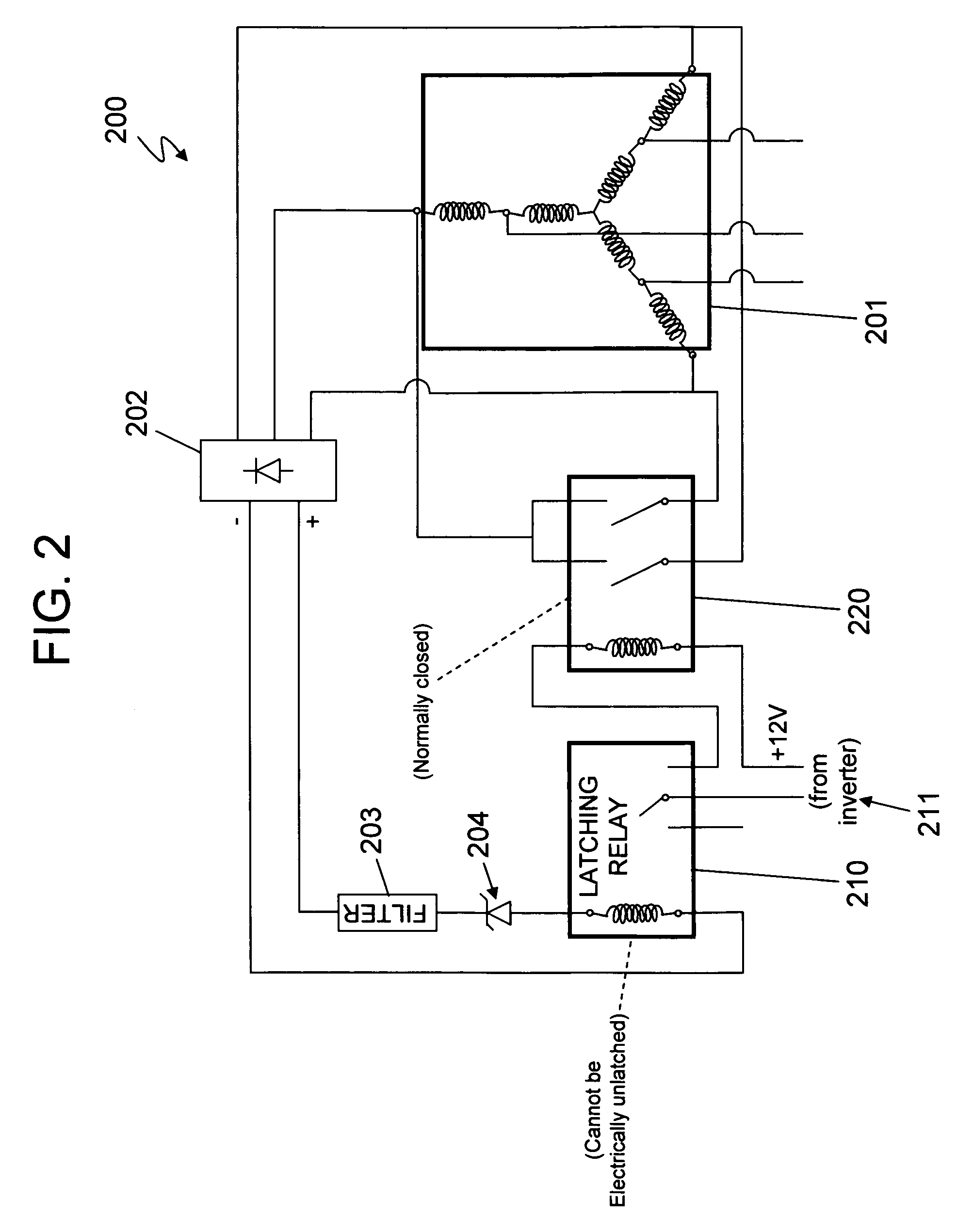

InactiveUS20070170724A1Degraded aerodynamic performanceIncrease torqueAC motor controlWind motor controlControl theoryConductor Coil

Control features for a wind turbine that control the turbine over a range of wind speeds and under triggering conditions with reduced noise, cost, and reliability issues associated with other such controls. Control is accomplished via control electronics, which adjust the torque produced by the electrical output generation device (e.g., alternator) within the wind turbine. During normal operation, torque is adjusted for optimum aerodynamic performance and maximum output of power. In winds above rated power, the control circuit regulates torque to lower aerodynamic performance, as necessary to maintain desired power level output. In triggering conditions, such as during simultaneous control circuit failure and loss of some portion of the electrical output generation device in extreme winds, wind turbine control is accomplished by increasing torque (e.g., via a separate controller) from the electrical output generation device via shorting of windings, so as to cause retardation of blade rotation.

Owner:WIND RESOURCE LLC

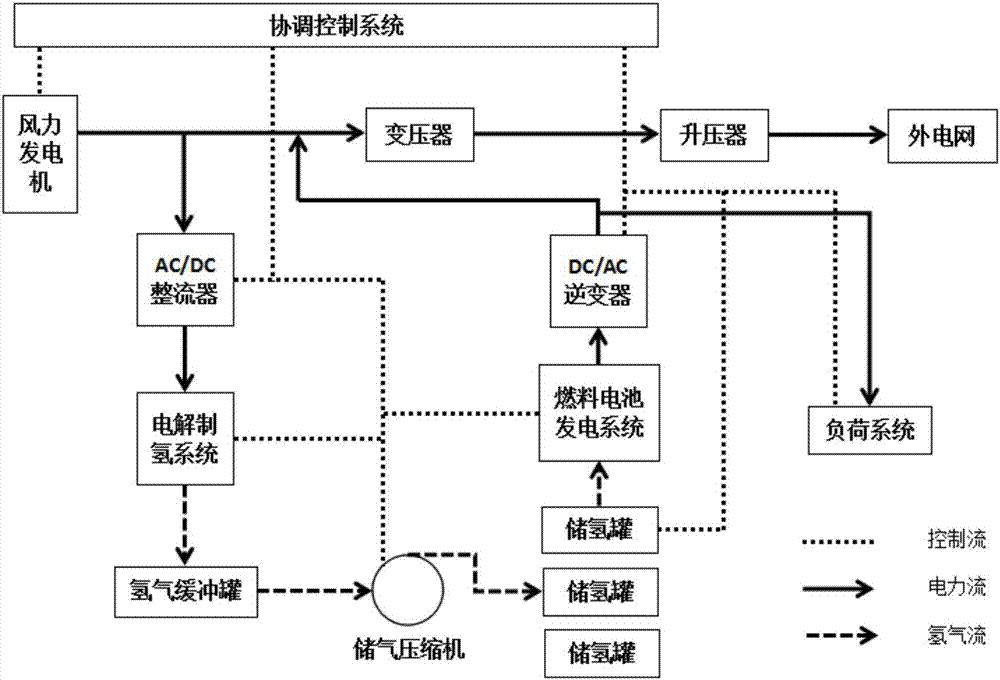

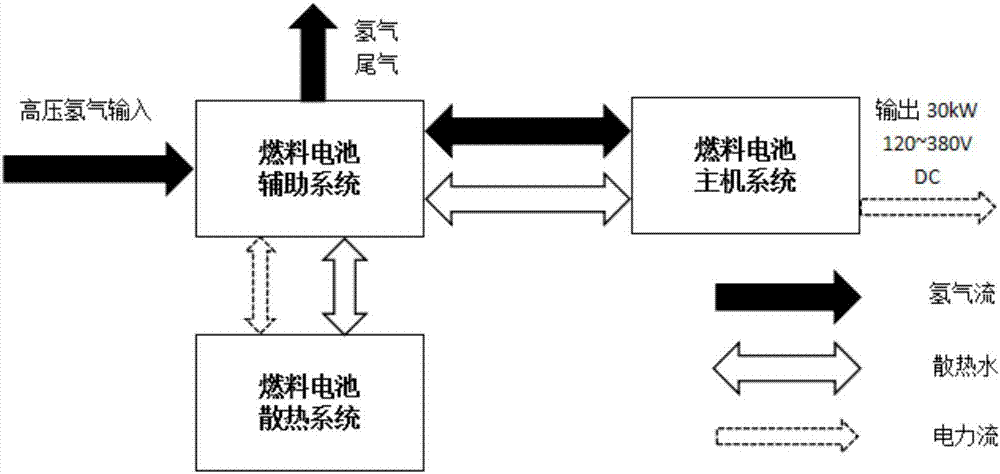

Wind-power hydrogen-manufacturing energy storage hydrogen fuel composite cell and power generation method thereof

InactiveCN107017651AImprove controllabilityImprove the level of stabilitySingle network parallel feeding arrangementsEnergy storageOperation modeHydrogen storage system

The invention discloses a wind-power hydrogen-manufacturing energy storage hydrogen fuel composite cell and a power generation method thereof. The cell comprises four working modes according to the intensity of wind. During strong wind, the cell employs a wind-power hydrogen-manufacturing energy storage power generation mode, and the wind power within the rated power is used for the power generation of an external grid, and the remaining wind power is converted into hydrogen for storage. When the intensity of wind is smaller, the cell employs an all-system operation mode, supplies the wind power to the external grid, starts a fuel cell power generation system, and converts the hydrogen energy of the hydrogen storage system into electric energy. When the quality of wind power is poorer, the cell employs a wind-power hydrogen-manufacturing fuel power generation mode, and the wind power is just used for manufacturing hydrogen and the fuel cell power generation system supplies power to the outside at the same time. When wind needs to be abandoned according to the scheduling requirements, the cell employs an independent operation mode, and the fuel cell power generation system enables the stored hydrogen to be converted into high-quality electric energy and enables the high-quality electric energy to be fed to a grid. The cell can effectively iron out the defects of the intermittency and fluctuation of renewable energy power generation (wind power), improves the controllability of output power of an electric field, and improves the stability level of power generation.

Owner:北京鑫海港亿科技有限公司 +1

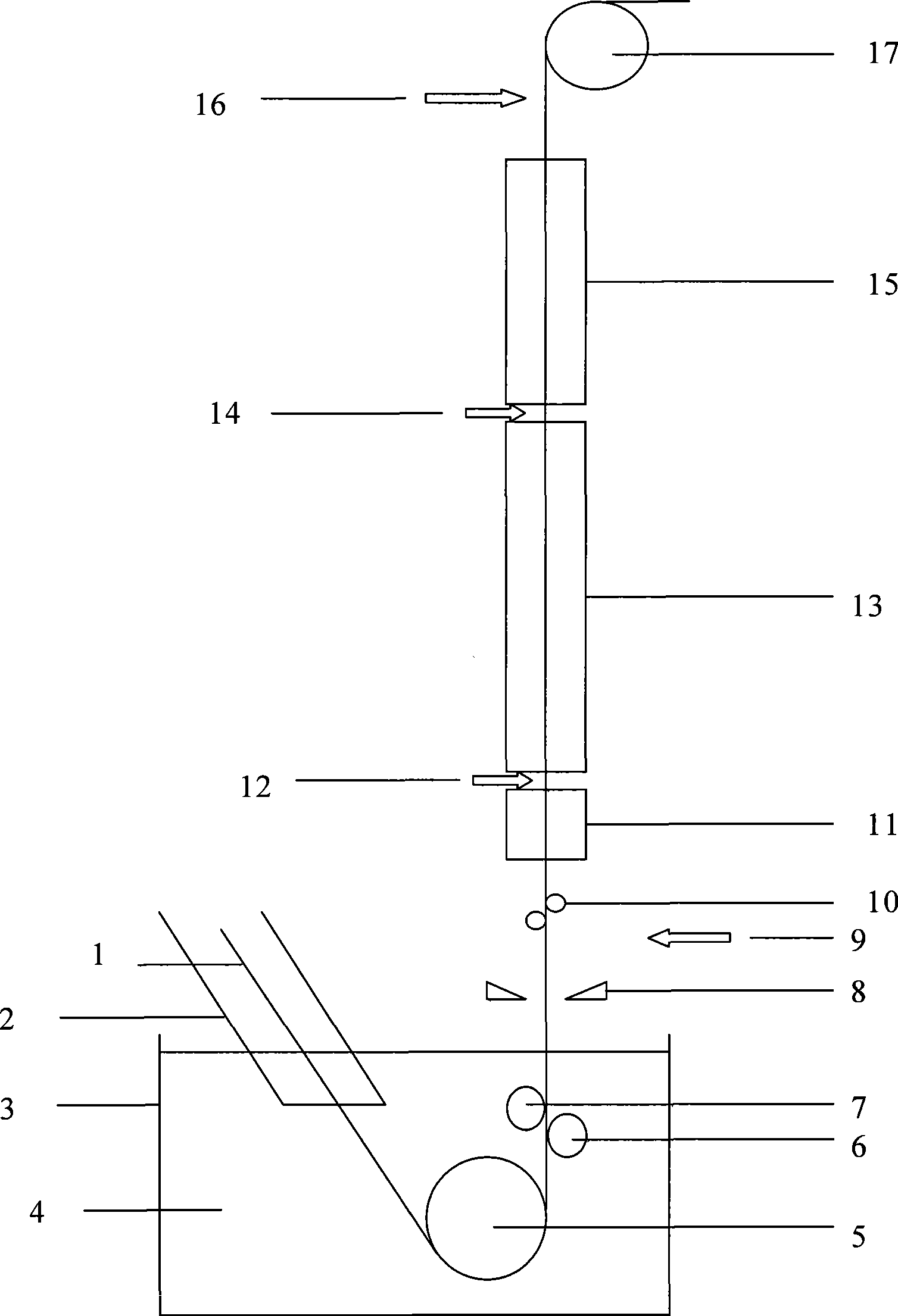

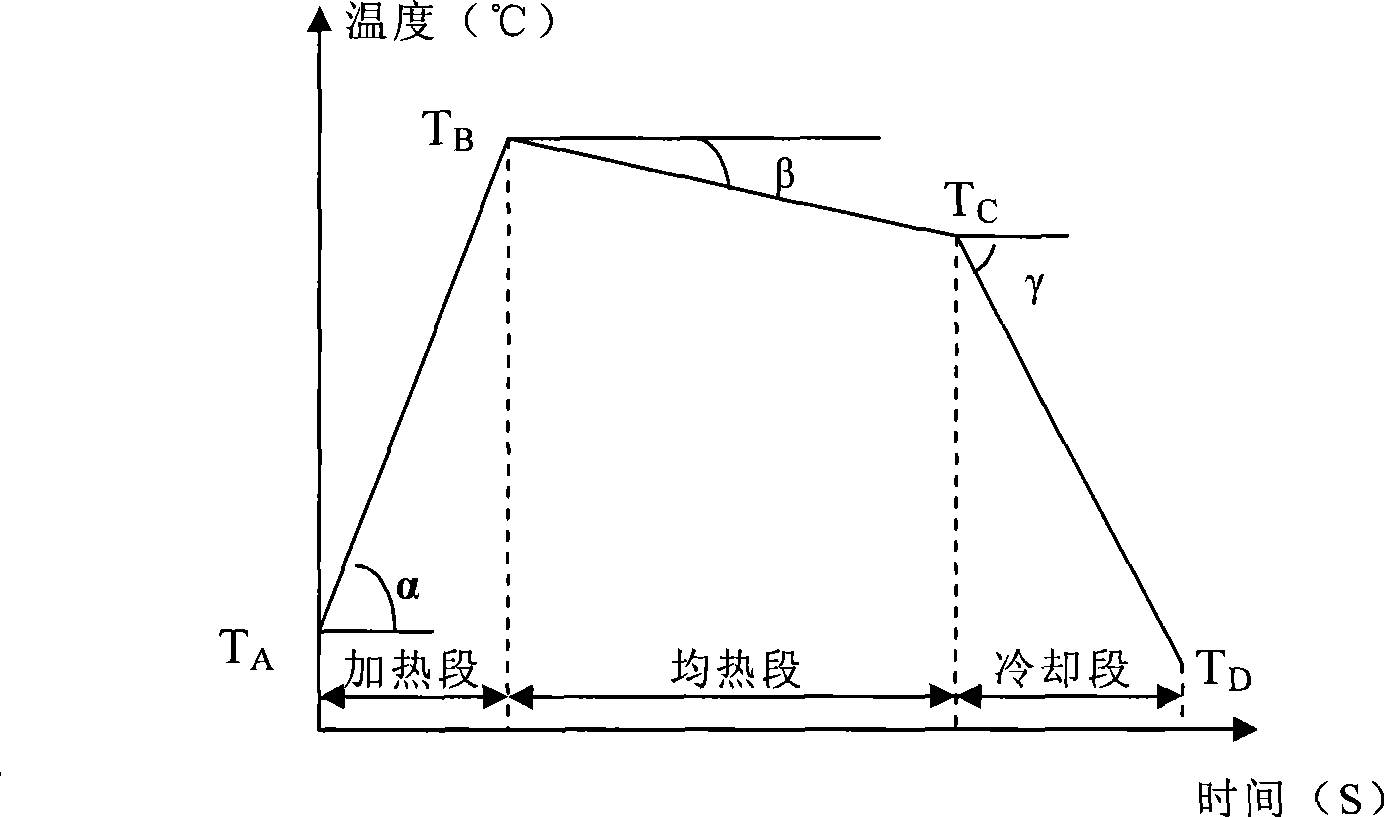

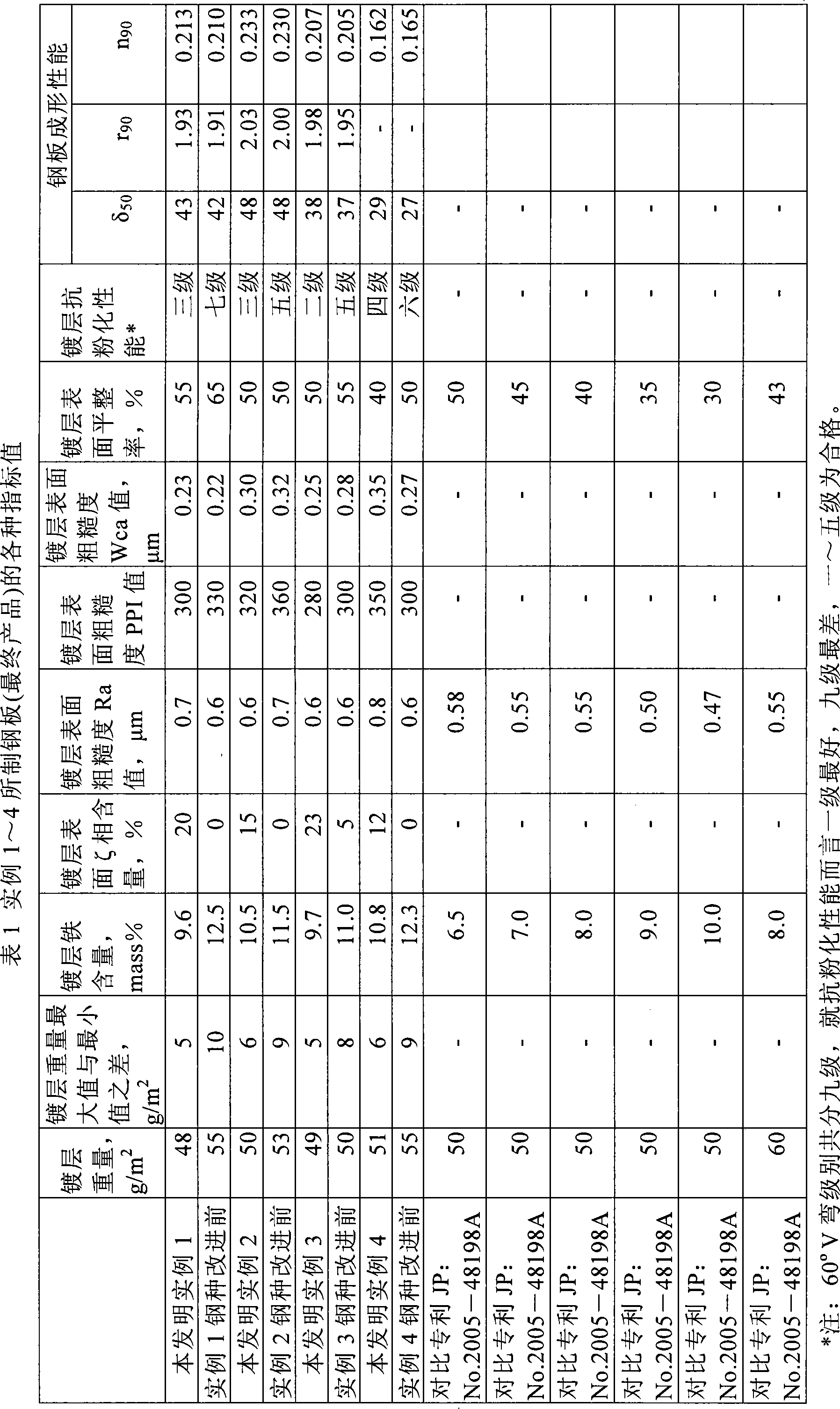

Method for controlling alloyed hot dip galvanizing steel plate coating phase structure and alloyed hot dip galvanizing steel plate

InactiveCN101376956AGood chalking resistanceGood stamping performanceHot-dipping/immersion processesFurnace typesSheet steelSurface roughness

The invention provides a method for controlling alloyed hot-dip galvanized cladding, in particular hot-dip galvanized steel sheet cladding phase structure. The method comprises the following steps: at least a set of strip steel which is provided with a steel stabilizing device and can stably control hot-dip galvanization process parameters and air knife parameters to obtain even thickness of the cladding is arranged between an air knife and a top roller; an inclined alloyed cladding heat treatment annealing curve with even temperature sections from high temperature to low temperature is selected and the strip steel is evenly alloyed, to improve the evenness of the alloying process and the alloying degree of the strip steel cladding; in addition, flat roll surface roughness and flat extensibility are selected, to control the cladding surface roughness and cladding surface flat rate and improve the shaping performance of the steel sheet. The invention also provides an alloyed hot-dip galvanized steel sheet manufactured by the method for controlling the alloyed hot-dip galvanized steel sheet cladding phase structure; the hot-dip galvanized steel sheet has excellent cladding powder resistance and shaping performance, and is very applicable to automobile internal and external plates as well as household electric appliance external plates.

Owner:BAOSHAN IRON & STEEL CO LTD

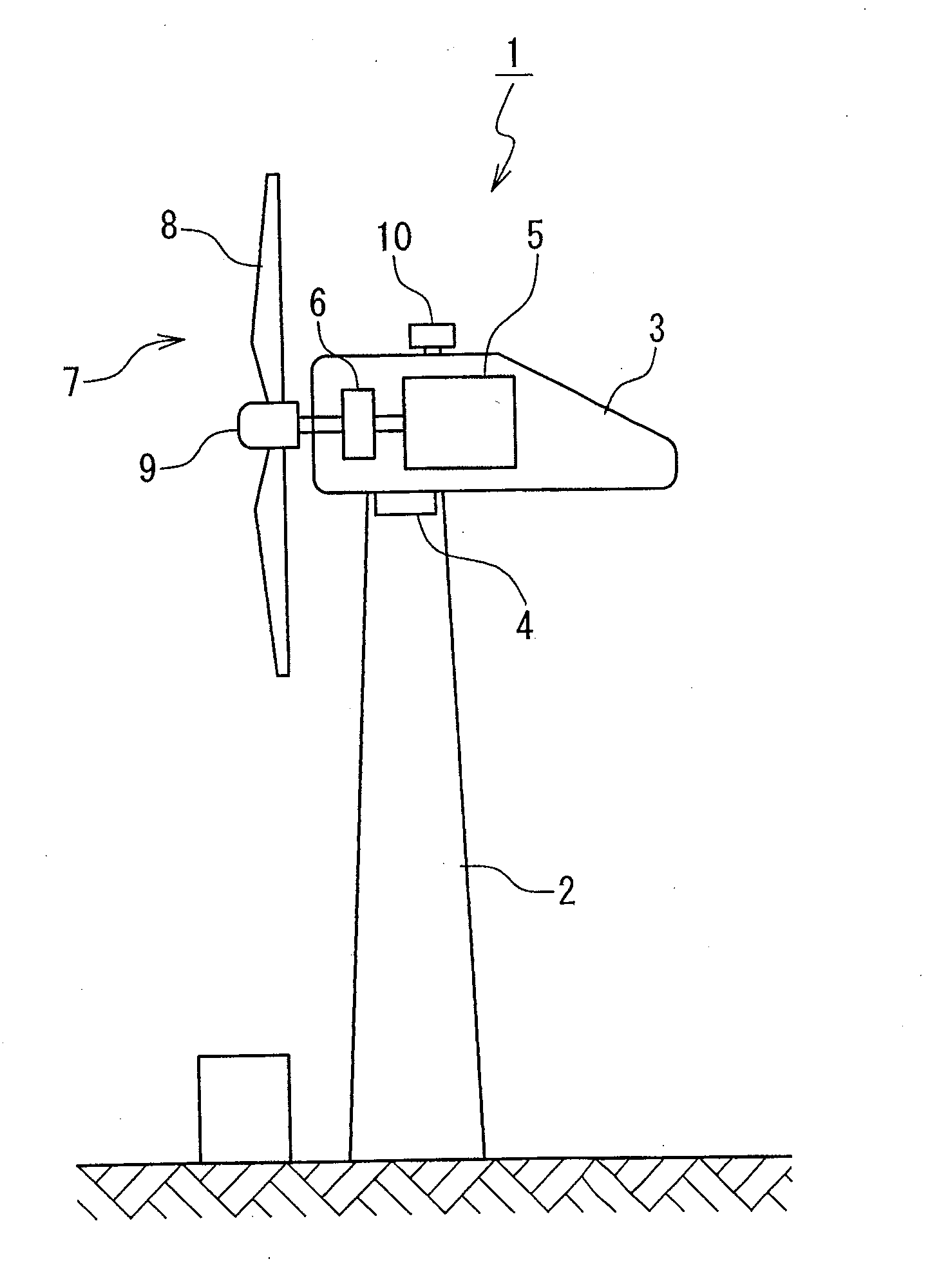

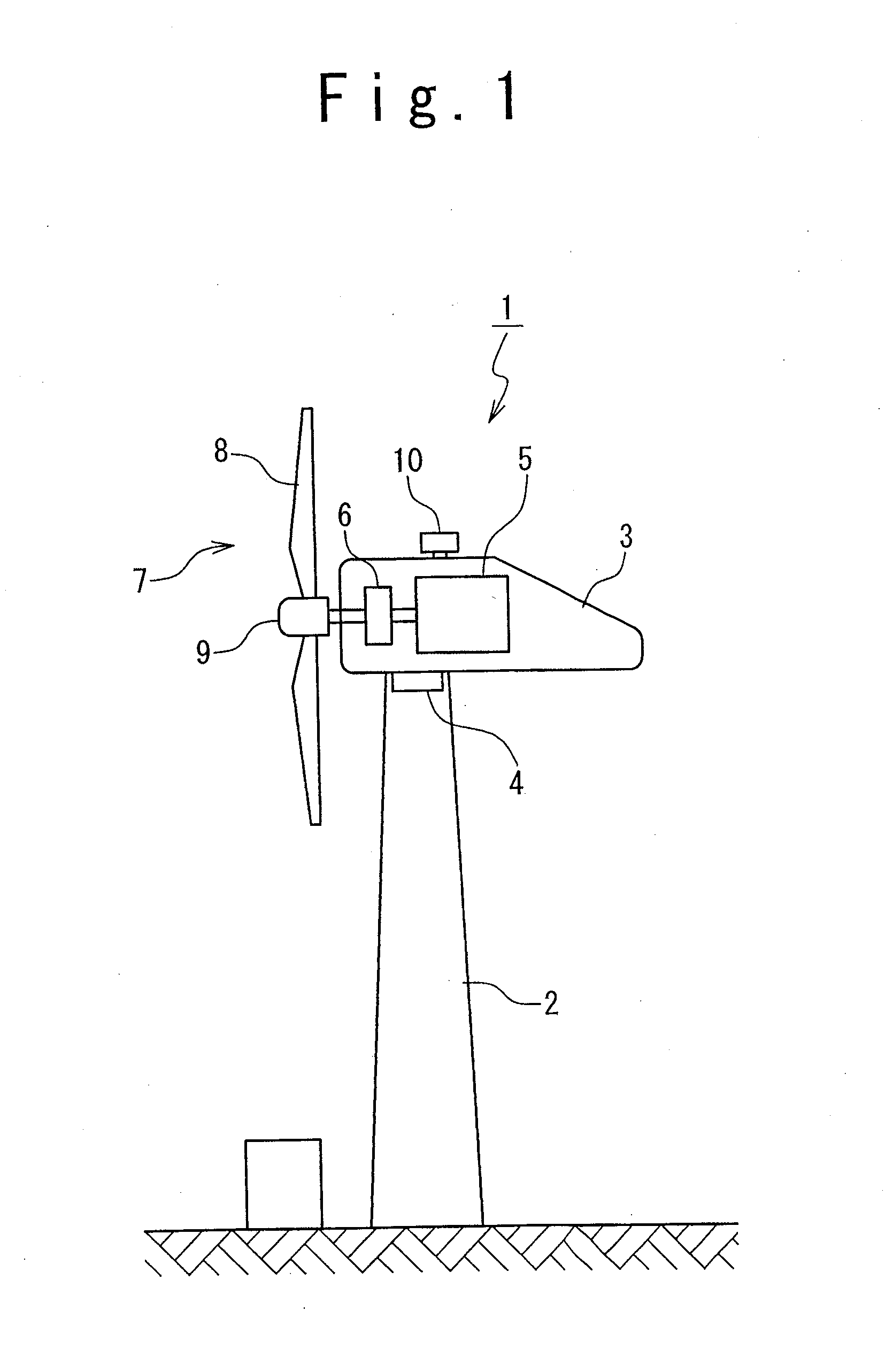

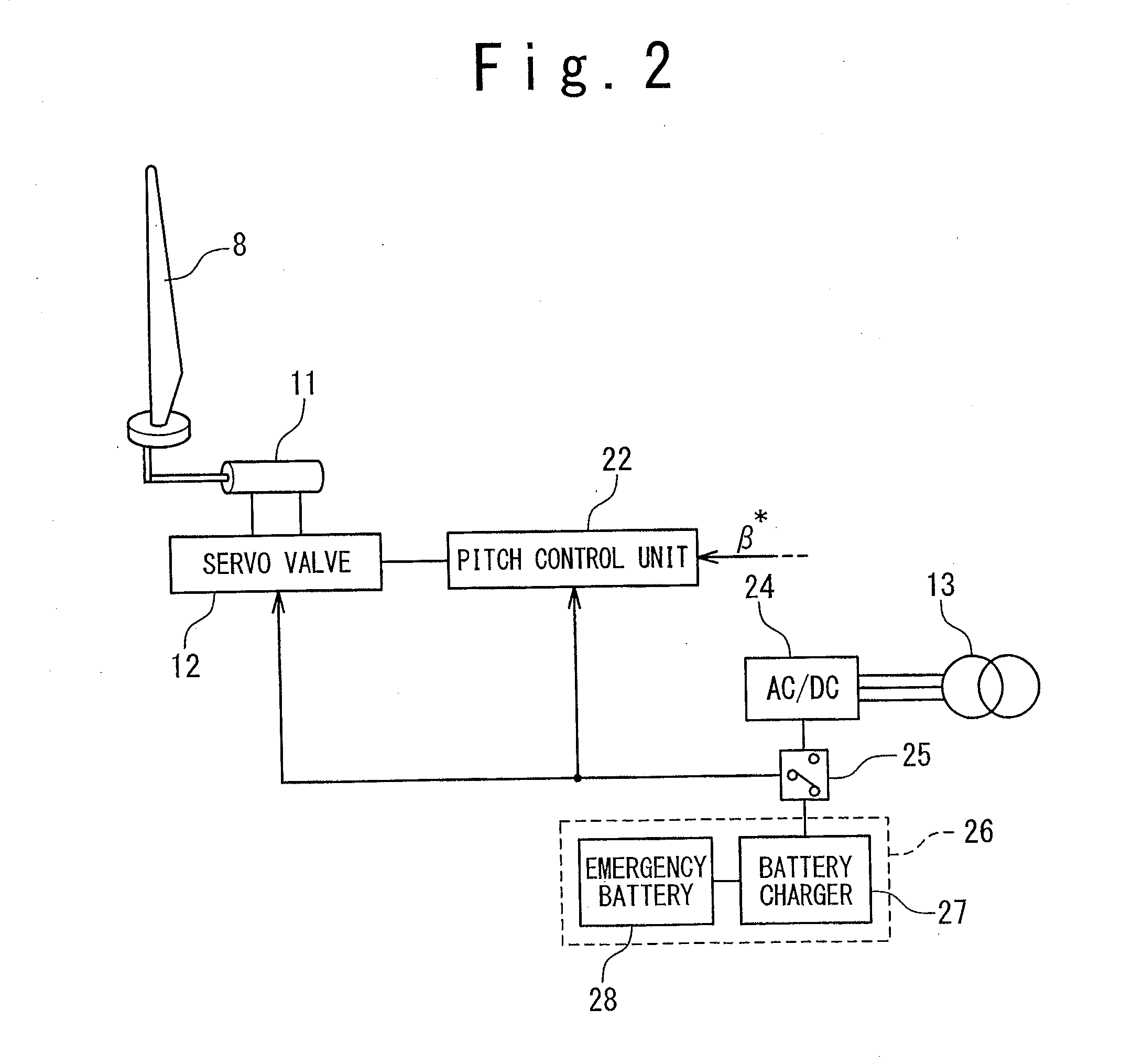

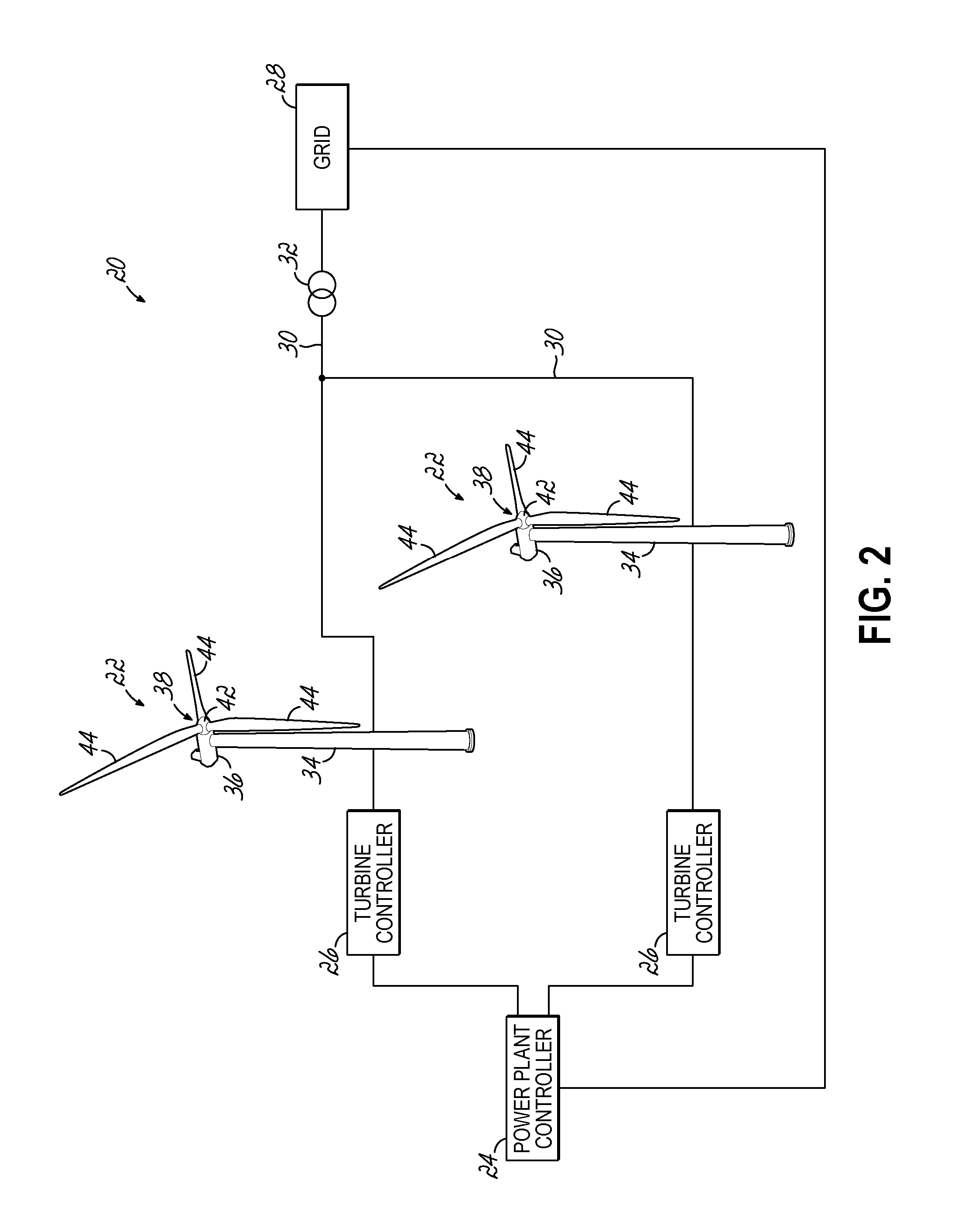

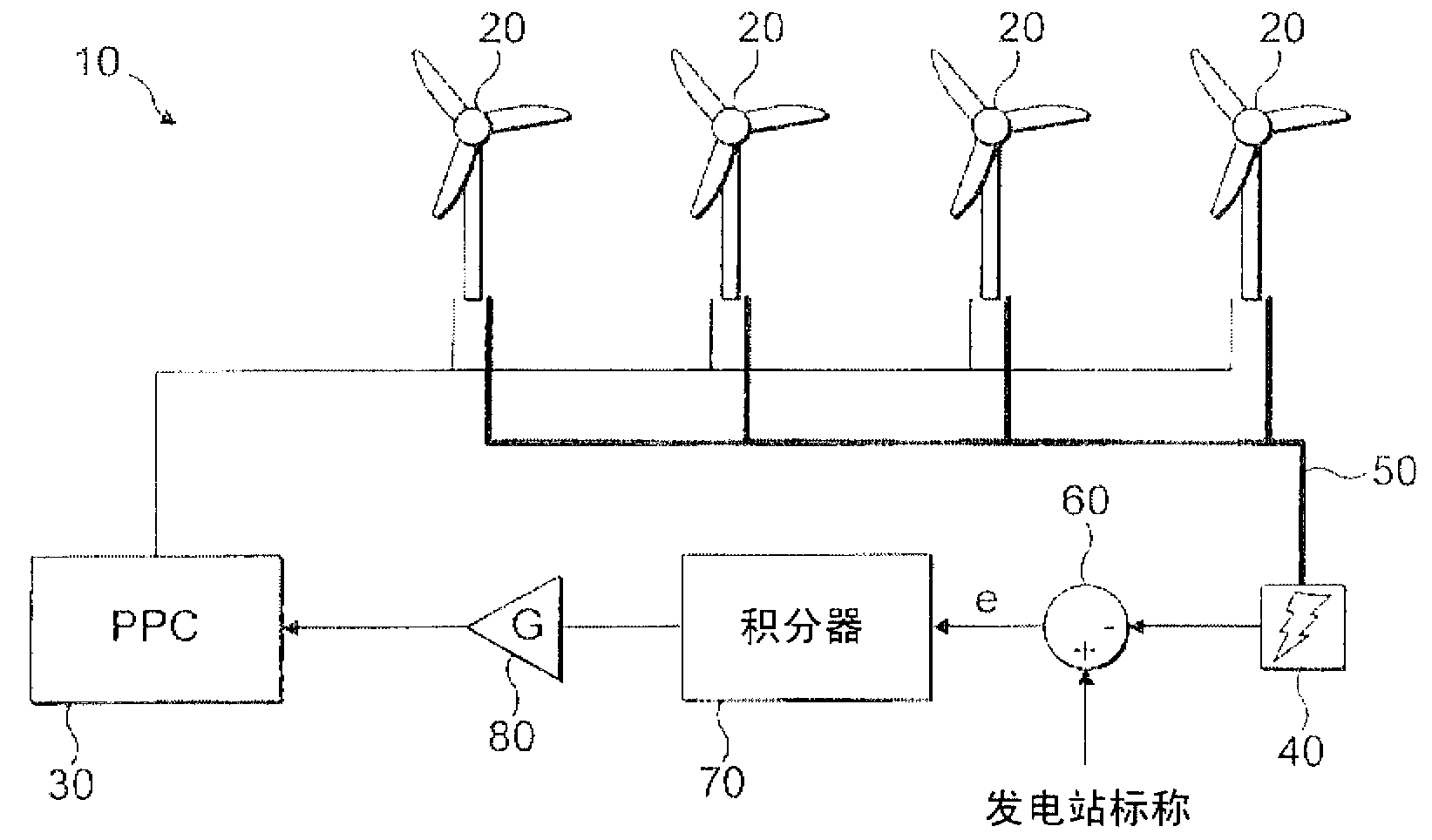

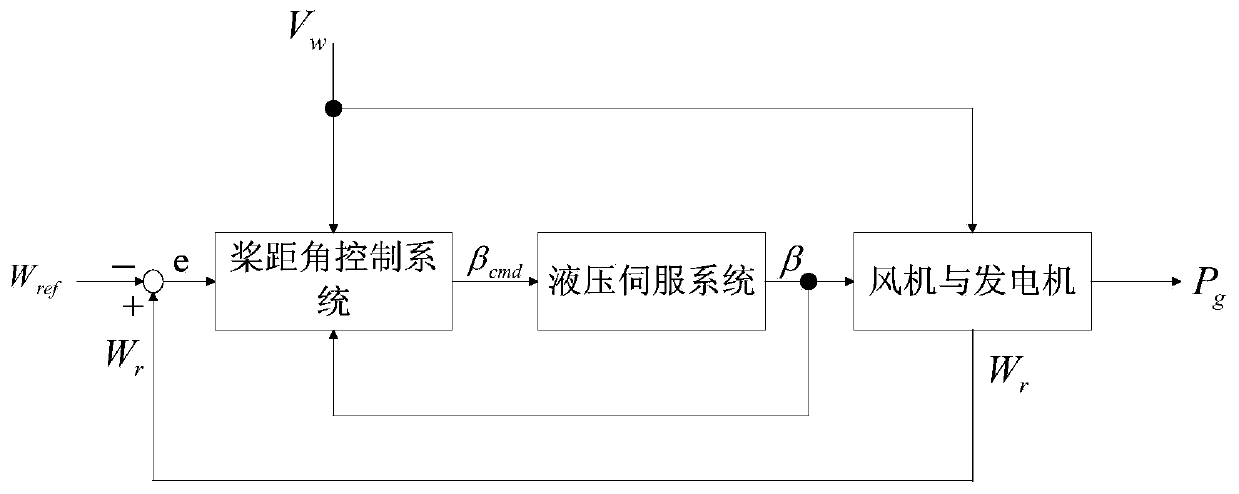

Wind turbine generator system and control method of the same

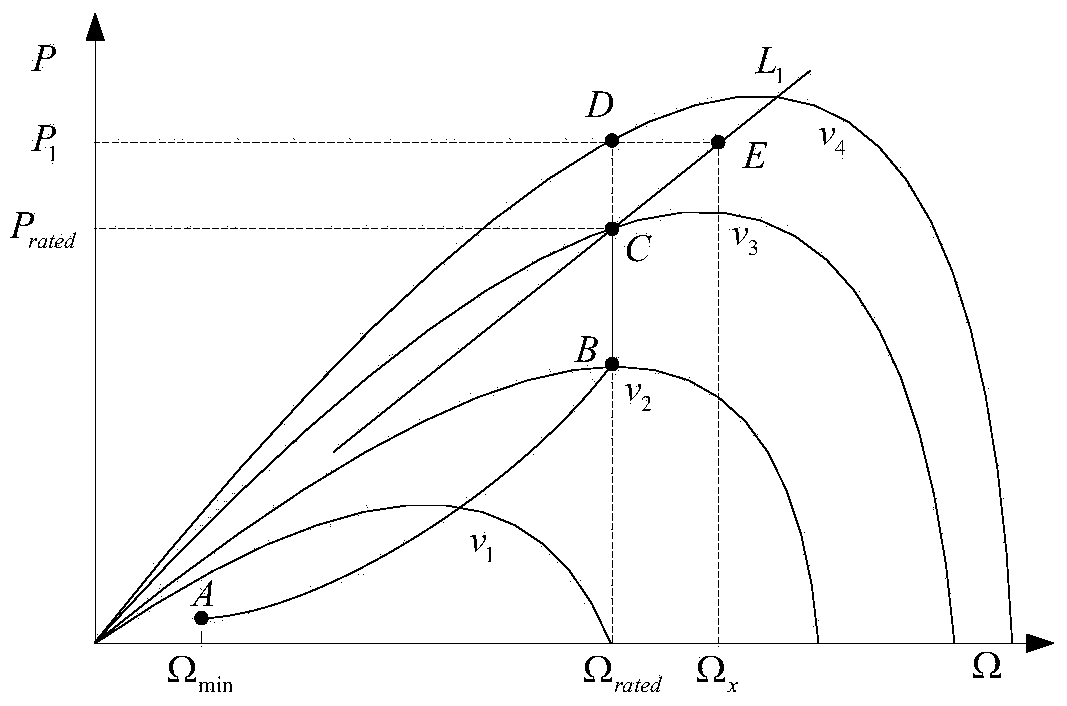

ActiveUS20110089694A1Suppress output power fluctuationsGenerating efficiency is reducedMechanical power/torque controlLevel controlControl theoryFlat rated

A wind turbine generator system includes: a wind turbine rotor including a blade having a variable pitch angle; a generator driven by the wind turbine rotor; and a control unit controlling the output power of the generator and the pitch angle of the blade in response to the rotational speed of the wind turbine rotor or the generator. The control unit performs a first control in which the output power is controlled in accordance with a predetermined power-rotational speed curve until the rotational speed is increased to reach a predetermined rated rotational speed, and performs a second control in which the output power is controlled to a predetermined rated power when the rotational speed exceeds the rated rotational speed; the control unit is responsive to the pitch angle for maintaining a state of performing the second control is or for switching to a state of performing the first control, when the rotational speed is reduced below the rated rotational speed after the control unit is once placed into the state of performing the second control.

Owner:MITSUBISHI HEAVY IND LTD

Low-power fuel battery automobile as well as control system and control method thereof

ActiveCN107310420ADynamic fluctuation of small power outputReduced Power RequirementsConverter typesElectric vehicle charging technologyPower inverterPower battery

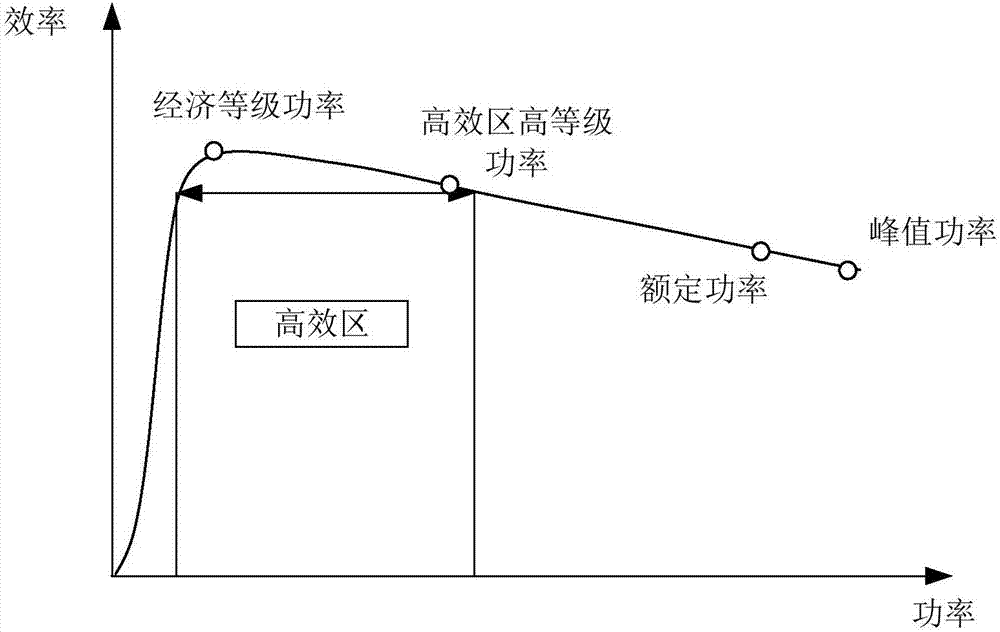

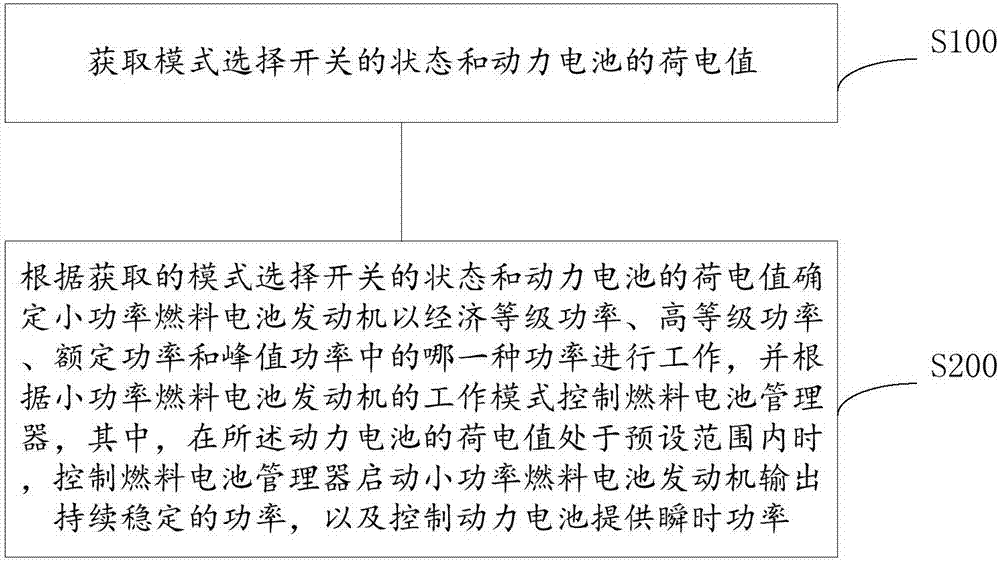

The invention discloses a control system of low-power fuel battery automobile. The control system comprises a low-power fuel battery engine, a DC / DC converter, a fuel battery manager, a power battery, a power battery manager, a mode selection switch, an inverter and a whole vehicle controller. The whole vehicle controller determines that the low-power fuel battery engine works at economic power, high-level power, rated power or peak power according to a state of the mode selection switch and a charge value of the power battery, and controls the fuel battery manager according to a working mode of the low-power fuel battery engine; when the charge value of the power battery falls within a preset range, the whole vehicle controller controls the fuel battery manager to start the low-power fuel battery engine to output continuously stable power and controls the power battery to provide instant power. The control system can optimize energy distribution of a whole vehicle to enable the working point of a fuel battery system to be stable, so that the service life of the fuel battery system is prolonged.

Owner:CHINA FIRST AUTOMOBILE

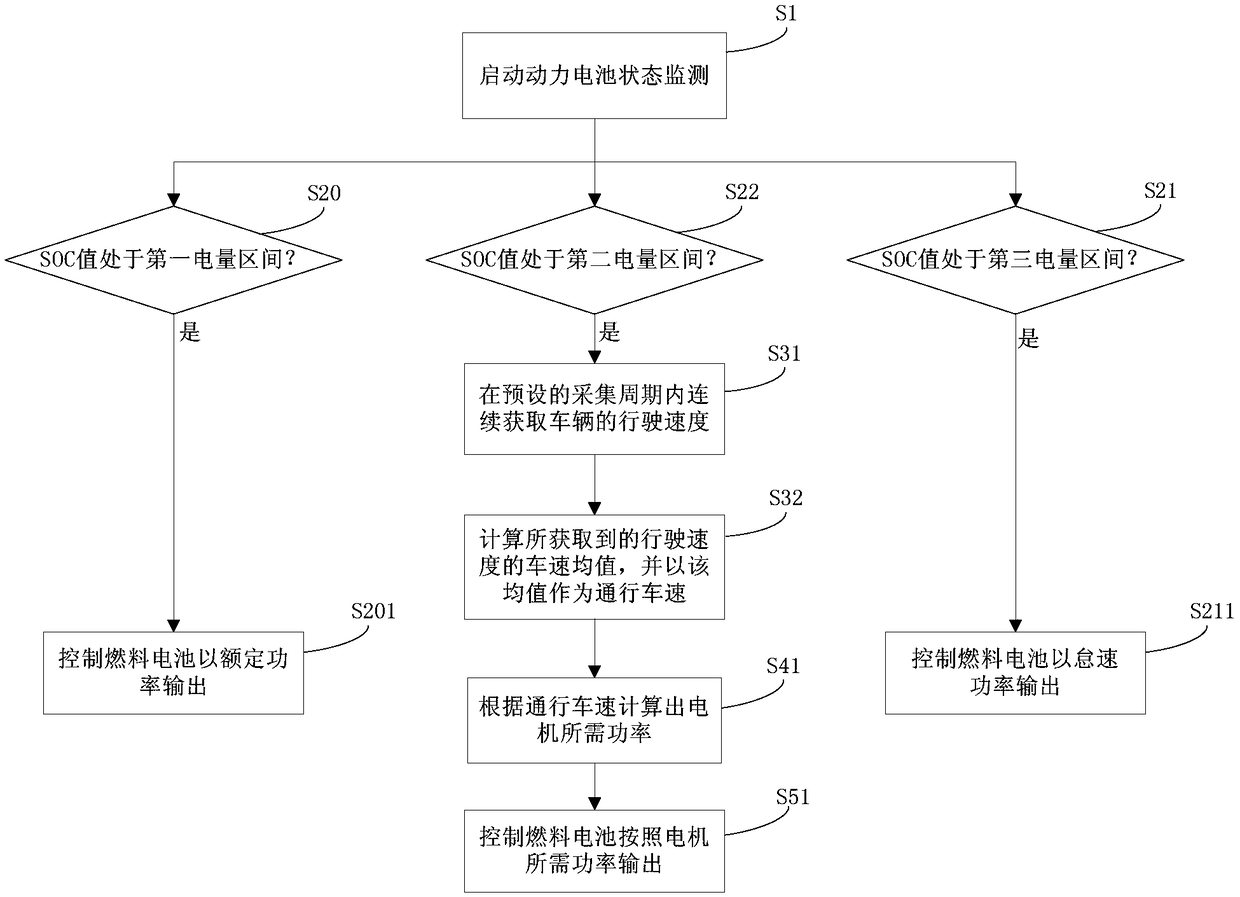

Fuel cell vehicle energy management and control method

ActiveCN108944900AImprove economyGuaranteed service lifeTransportation hydrogen technologyPower batteryFuel cells

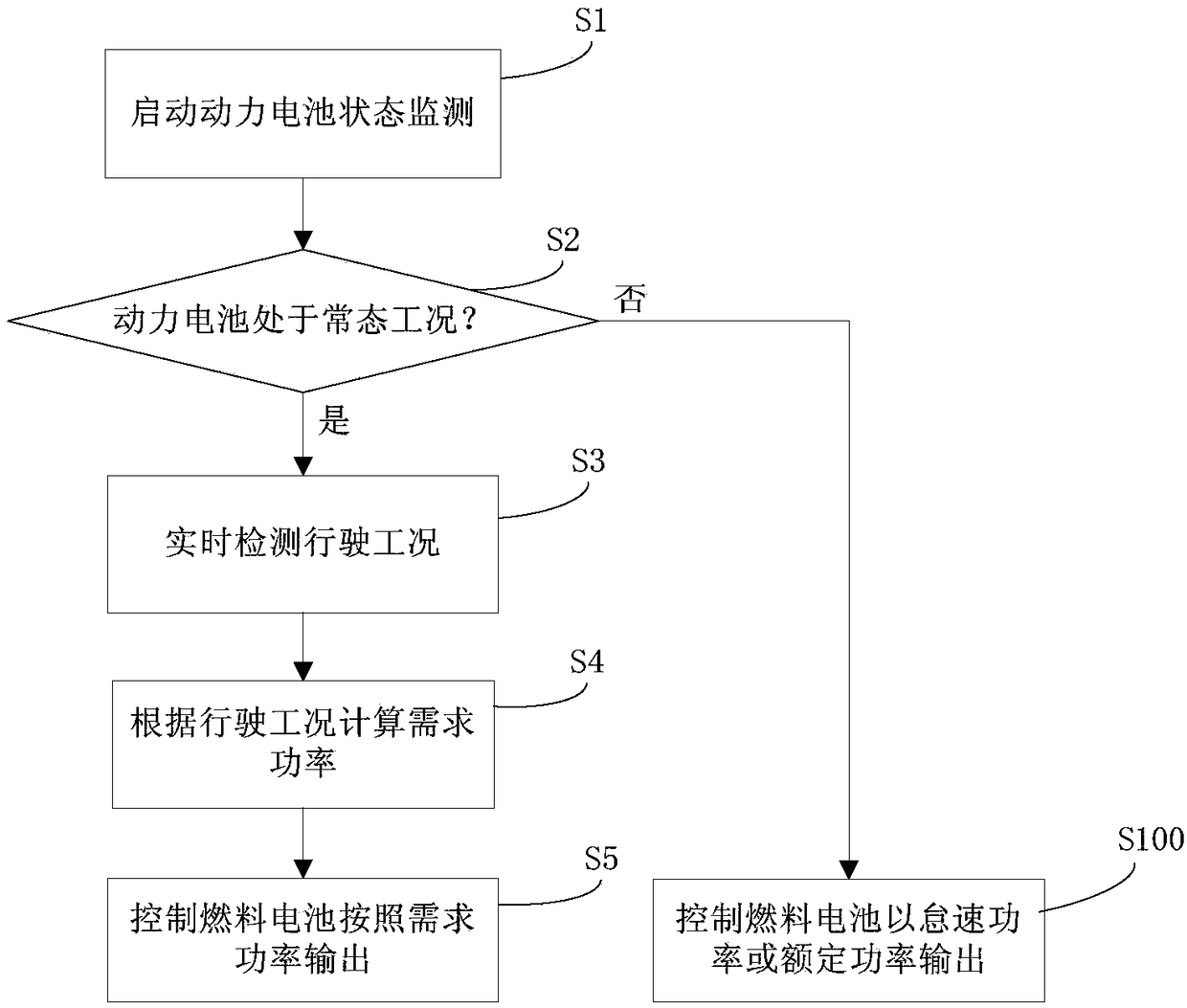

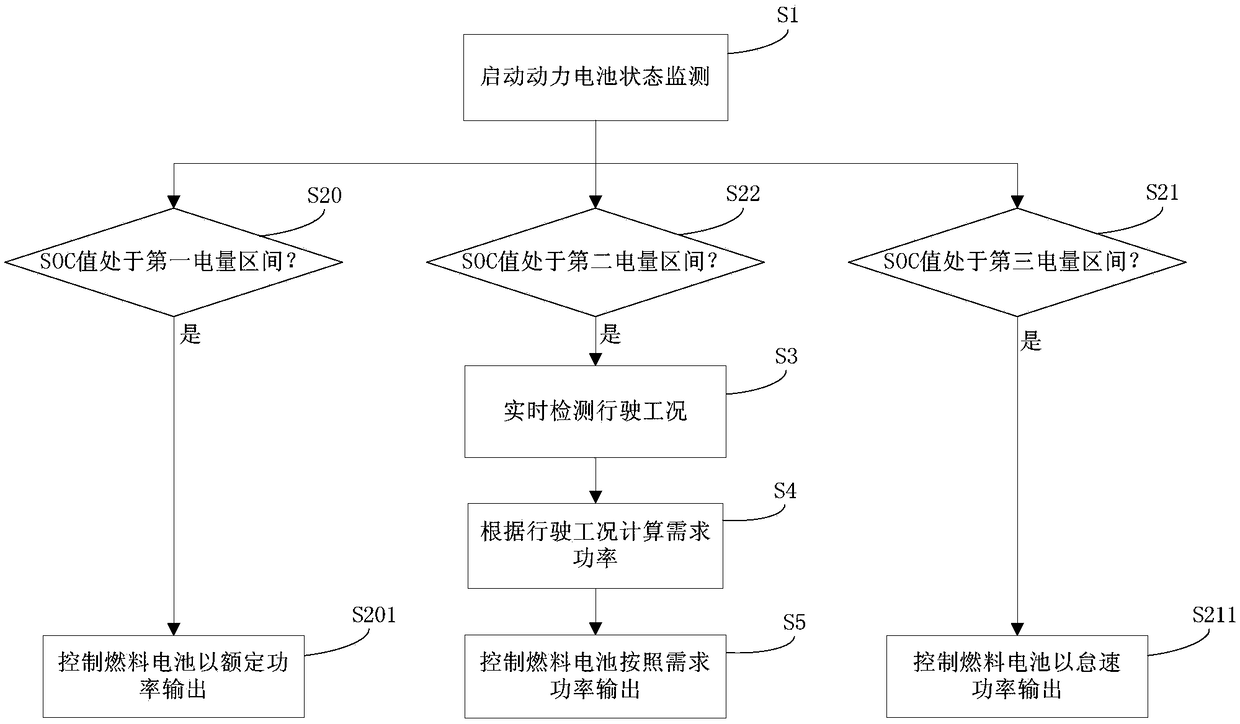

The invention discloses a fuel cell vehicle energy management and control method, which comprises the following steps: starting the condition monitoring of a power cell; Judging whether the power battery is in a normal working condition, wherein the normal working condition refers to that the power battery is in a state where the internal resistance changes steadily when discharging; controlling the fuel cell to output the power at idle speed or rated power if not; detecting the driving condition in real time if so; Calculating the required power according to the driving condition; Controllingfuel cell power output on demand. The invention is beneficial to optimizing the economic performance of the whole vehicle and ensuring the service life of the fuel cell, realizes the energy distribution of the fuel cell vehicle based on the actual working condition, -effectively avoids the problem that the life of the battery decreases due to the frequent changes of the output state of the fuel cell, thereby achieving the purpose of saving fuel and increasing the range of the fuel cell.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

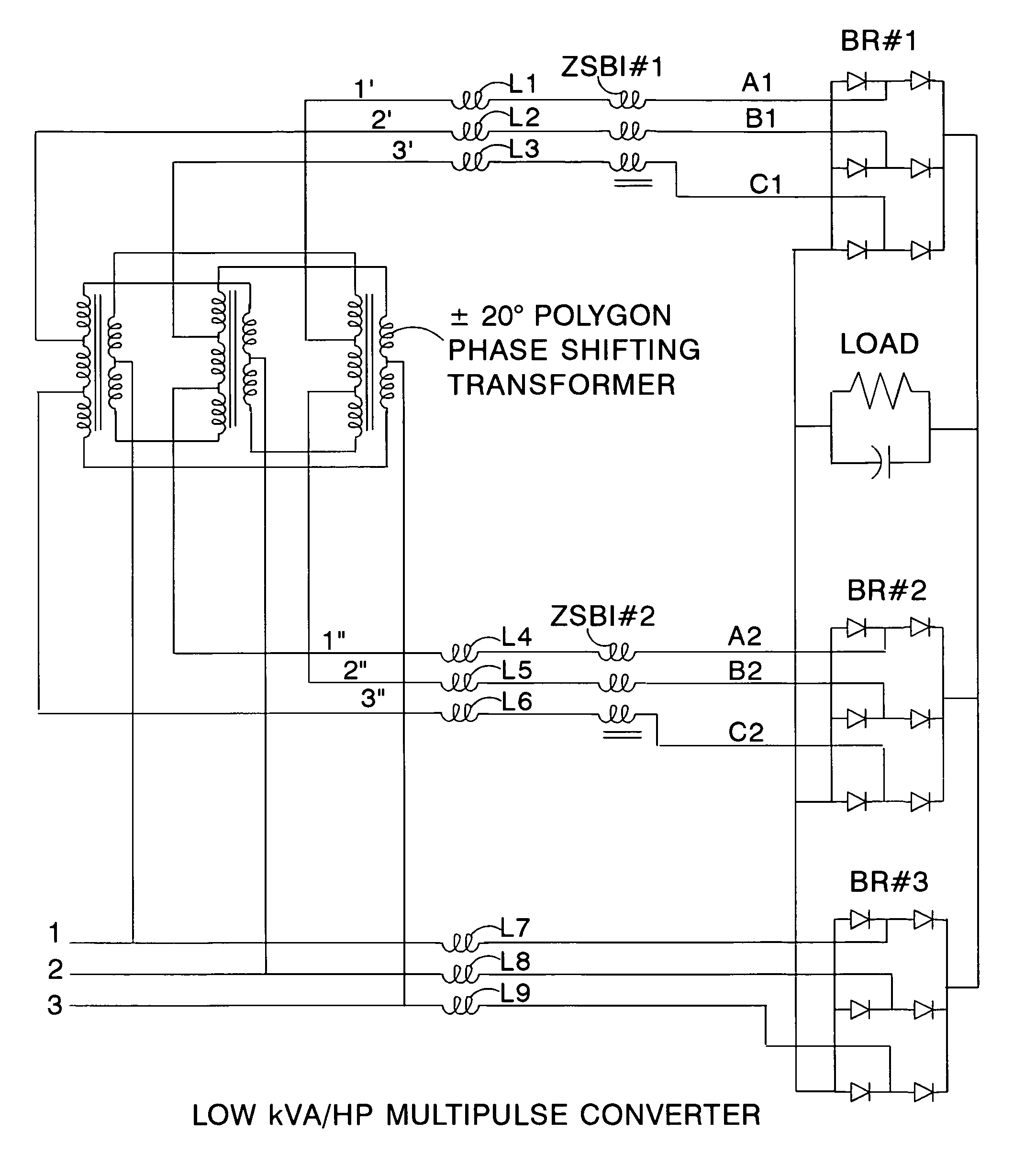

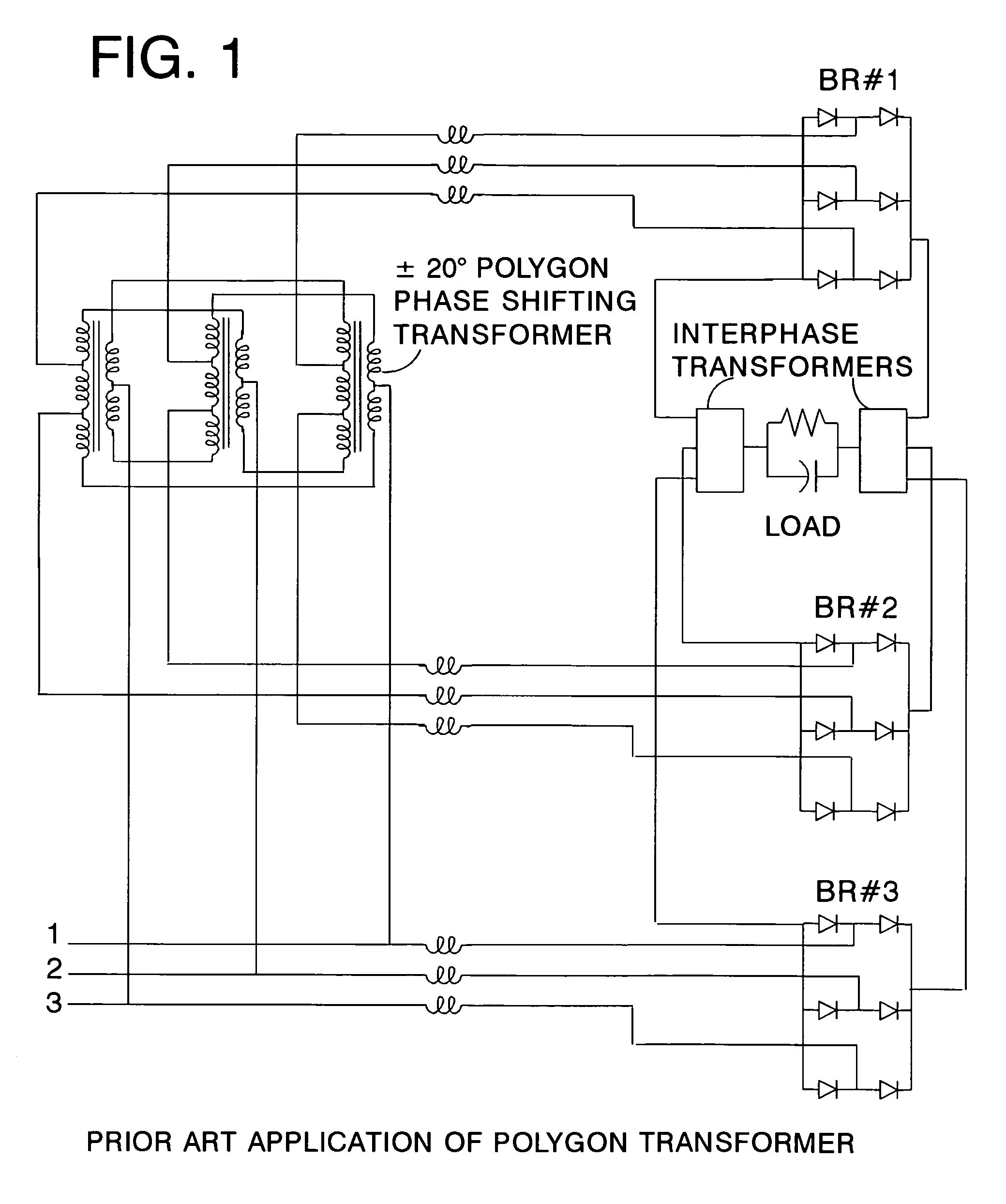

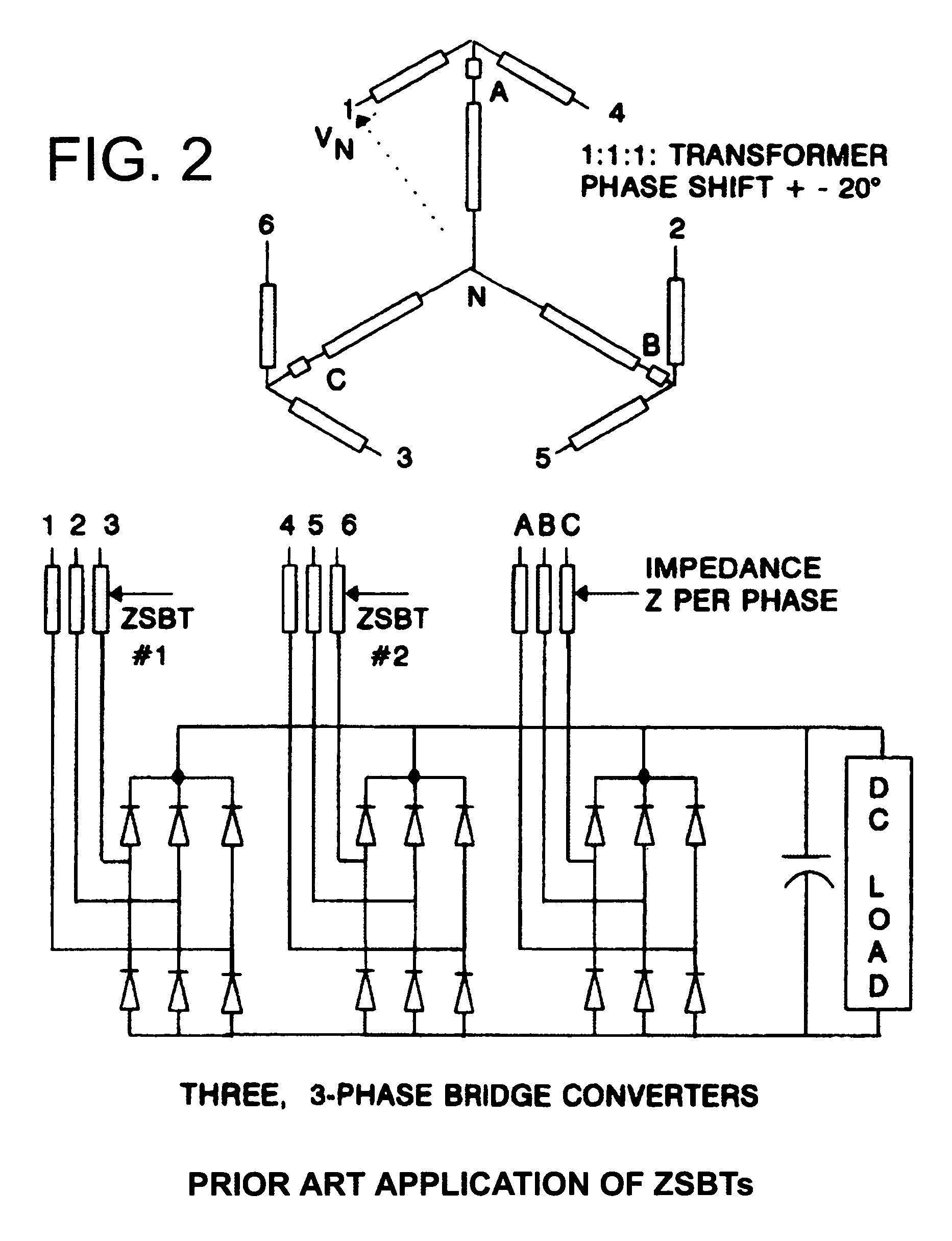

Low kVA/kW transformers for AC to DC multipulse converters

A polygon connected autotransformer in conjunction with zero sequence blocking inductor(s) enables multipulse AC to DC converters to use lower kVA parts rating by using appropriate phase-shifted voltage sets in conjunction with inductors that extend the conduction period and reduce rms current. Also, lower harmonic voltages in the transformer facilitate use of lower performance magnetic steel. Designs for 12, 18, and 24-pulse use the same conceptual approach. Very efficient high power ratings are feasible. Means are given to limit the maximum no-load DC output voltage. A technique is disclosed that reduces the size of polygon transformers supplying loads with substantial third harmonic.

Owner:SCHAFFNER MTC LLC

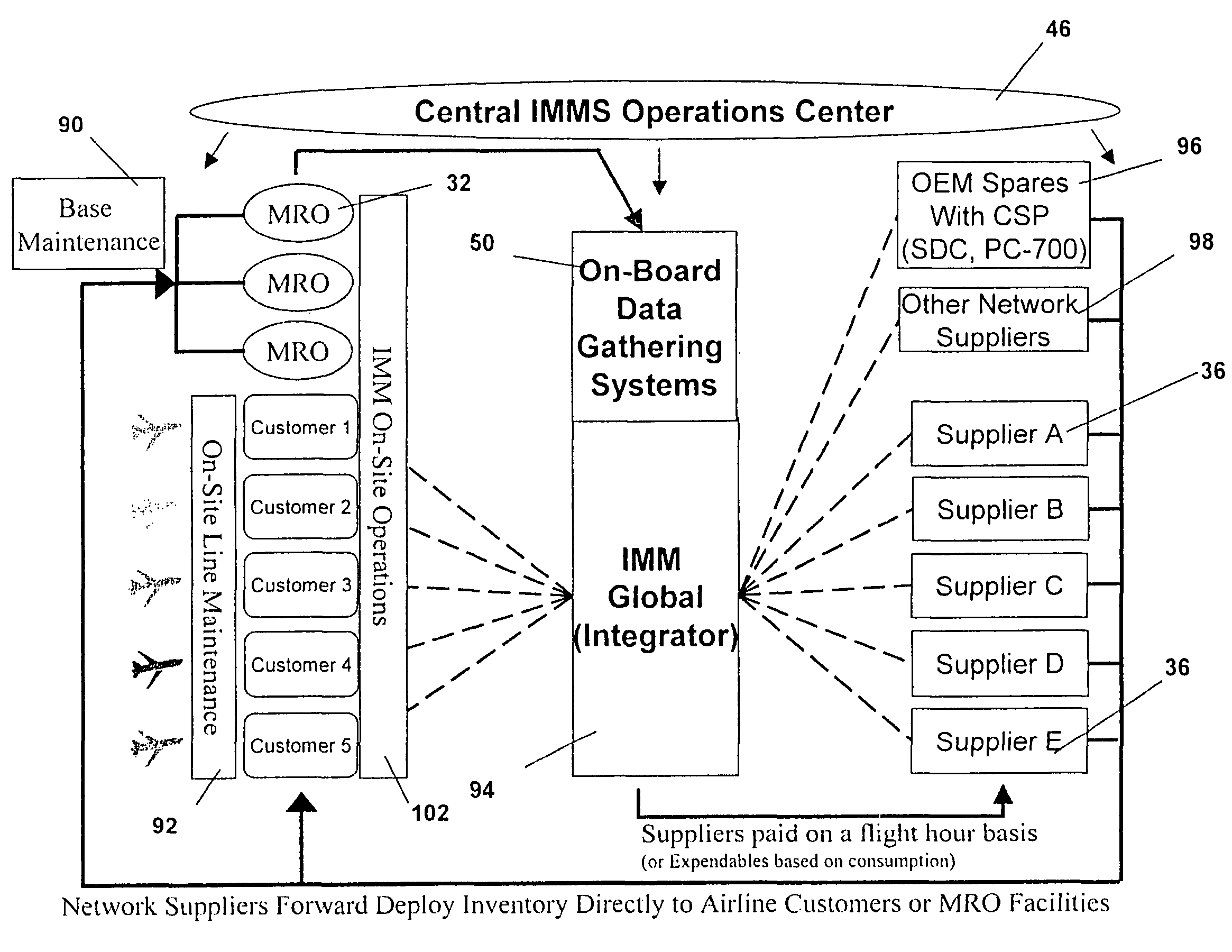

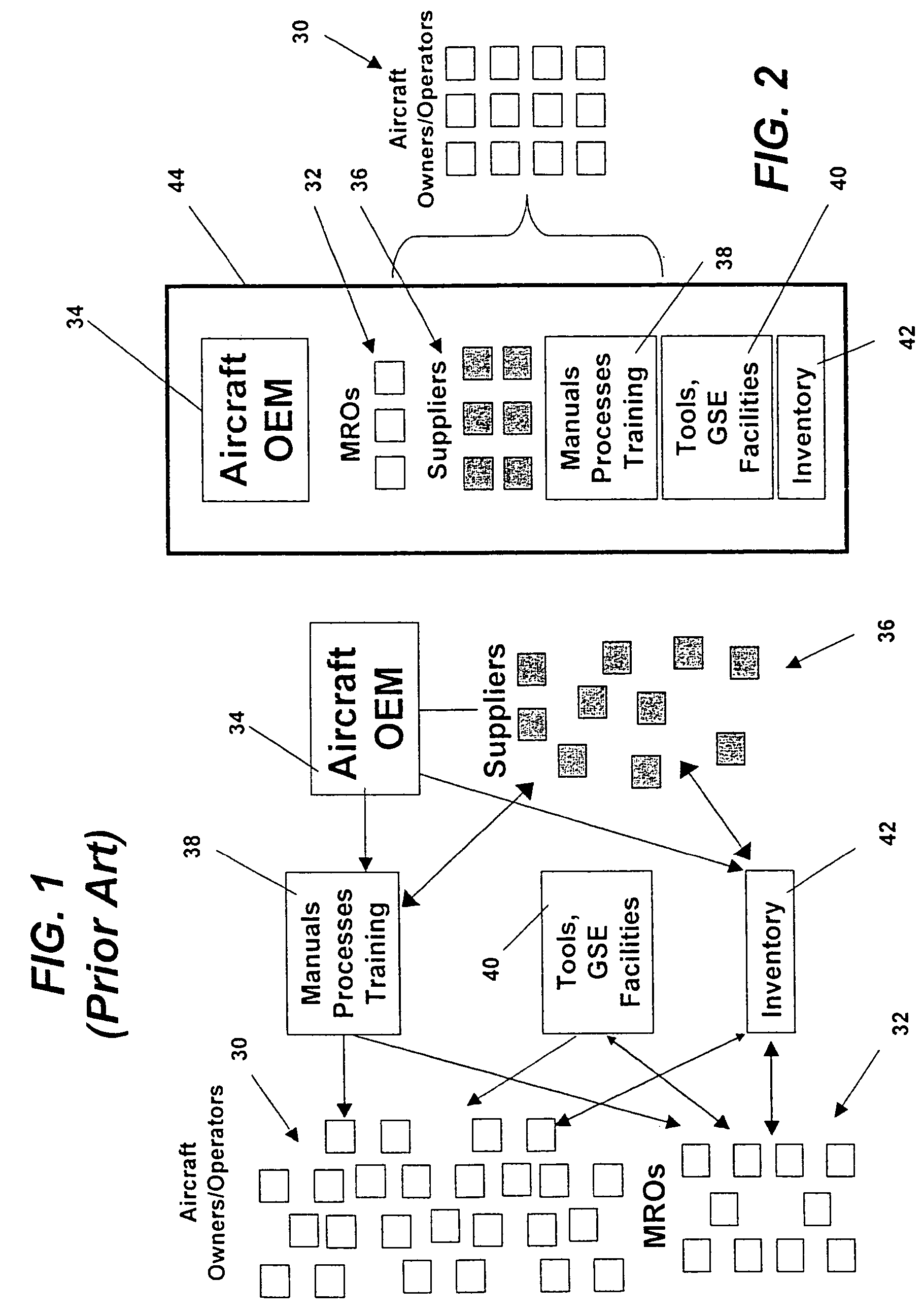

Integrated maintenance and materials services for fleet aircraft using aircraft data to improve maintenance quality

ActiveUS7761201B2Improve efficiencyLow costVehicle testingRegistering/indicating working of vehiclesMaintenance planningOn board

Owner:THE BOEING CO

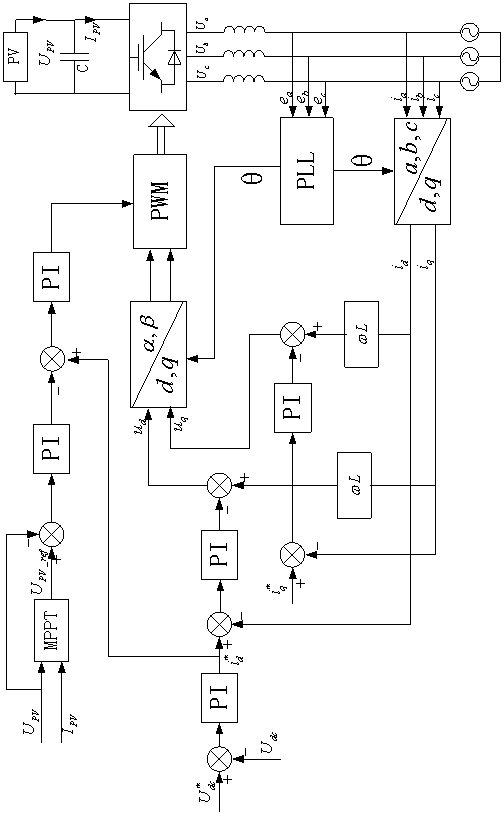

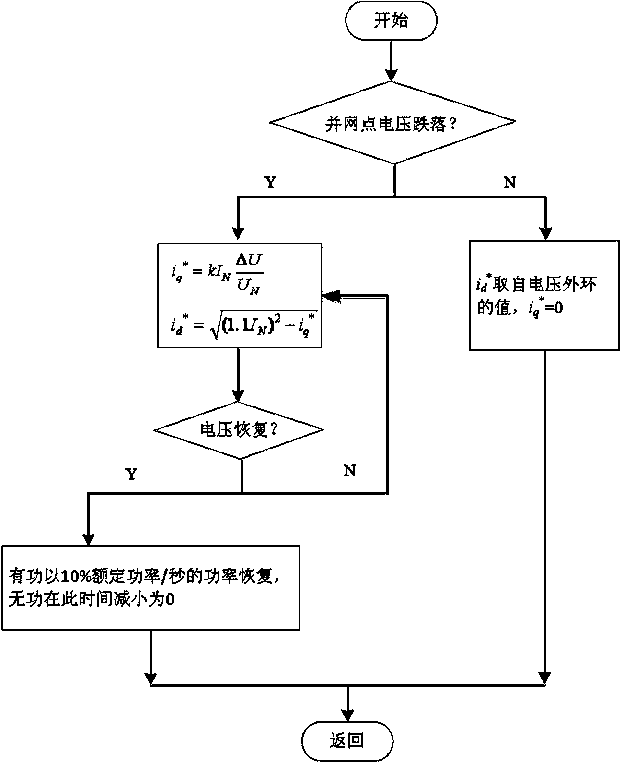

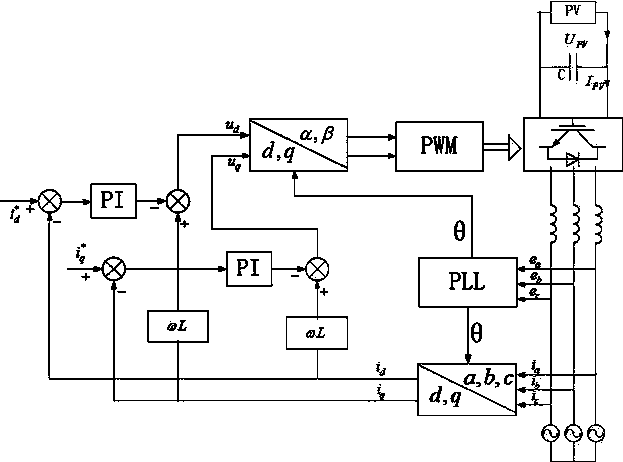

Symmetrical drop-off low voltage ride through reactive power control method of photovoltaic power generation system

InactiveCN103972904AReduce investmentSave resourcesSingle network parallel feeding arrangementsReactive power adjustment/elimination/compensationEngineeringPower equipment

The invention relates to a symmetrical drop-off low voltage ride through reactive power control method of a photovoltaic power generation system. A controller detects whether a grid connection point voltage drops off in real time, and if the voltage does not drop off to 90% of a nominal voltage, an active current reference value id* is taken from an outer voltage loop, and grid connection control when the voltage is normal is adopted; if the grid connection point voltage drops off below 90% of the nominal voltage, the outer voltage ring is disconnected, low-voltage ride through control is adopted, namely inner current loop control is adopted, definite reactive power is output to a power grid by the photovoltaic power generation system according to the drop-off amplitude, and recovery of the voltage of the power grid is facilitated; if it is detected that the voltage recovers, the active power of the photovoltaic power generation system recovers at 10% rated power / second, reactive power is gradually reduced to zero at the same time, and finally the grid connection control when the voltage is normal is adopted. According to the method, an outlet current of a photovoltaic grid-connected inverter is limited within an over-current protection action current, reactive power support is provided for the grid voltage to recover to the normal value, investment of reactive power equipment is saved, and resources are saved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

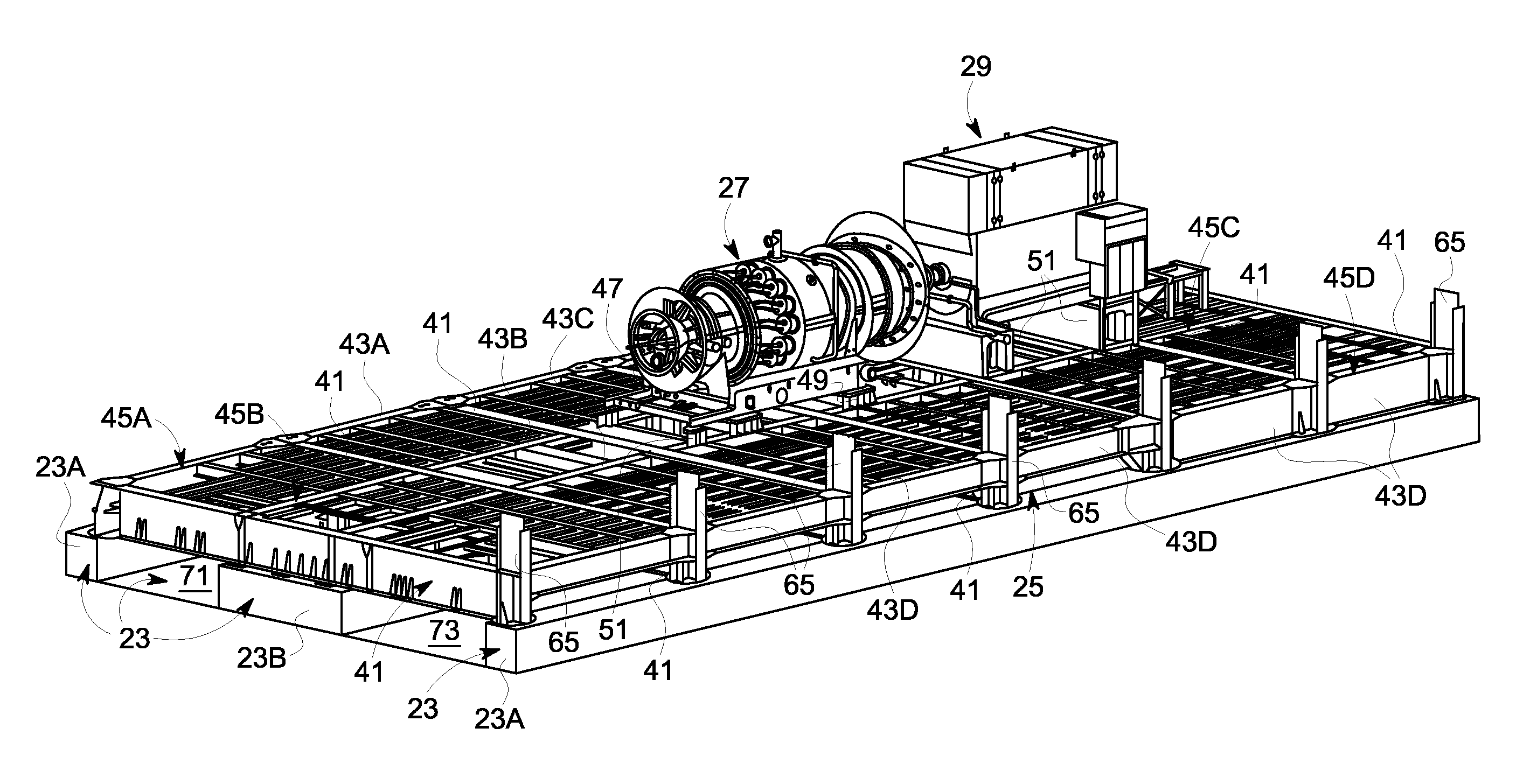

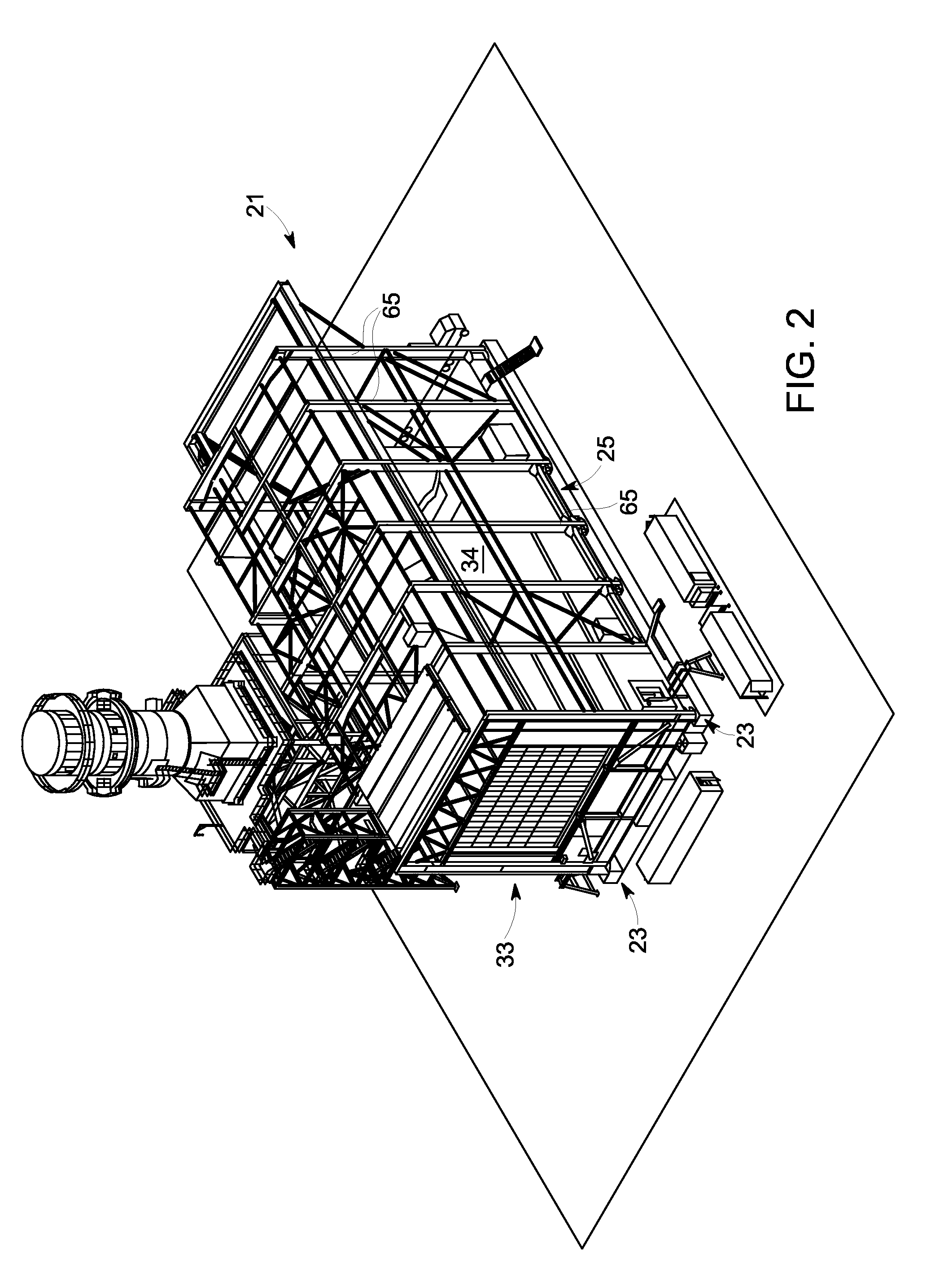

Modular gas turbine plant with a heavy duty gas turbine

ActiveUS20150184591A1Shortens tune requiredHuge savingsPortable framesEngine fuctionsTurbineFlat rated

A transportable gas turbine module including a baseplate supporting at least a gas turbine and a load drivingly connected to the gas turbine. The module further comprises a structure surrounding the gas turbine and the load and connected to the baseplate. The baseplate is designed such that it can support a heavy duty as turbine having a rated power of not less than 80 MW.

Owner:NUOVO PIGNONE TECH SRL

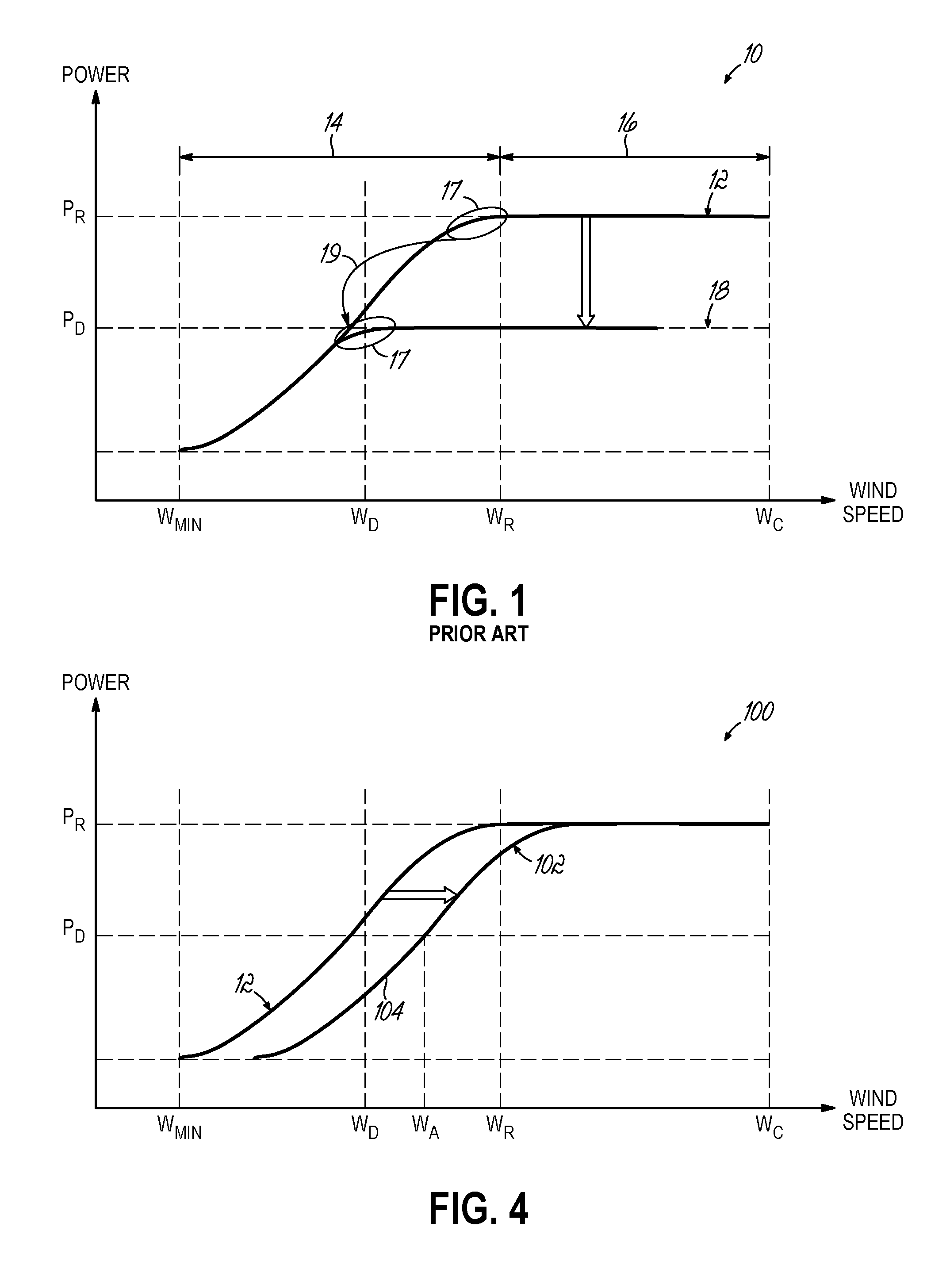

Partial-load de-rating for wind turbine control

InactiveUS20150267686A1Reduction factorWind motor controlMachines/enginesEngineeringDegrees of freedom

Methods, controllers and computer program products for controlling a wind turbine. Under de-rated operating conditions in which the power requested from a wind turbine is less than the available power, a controller adjusts blade pitch of the wind turbine to reduce the rotor power coefficient. The captured wind power is thereby reduced to be approximately equal to the requested electrical power, which is less than either the available power or the rated power of the wind turbine generator. This reduction in captured power provides the controller with an additional degree of freedom that allows the controller to increase the electrical power output of the wind turbine in response to wind fluctuations without damaging the wind turbine. By allowing increases in power under de-rated conditions, the controller may reduce the amount of pitching necessary to prevent the turbine from exceeding its rated power output level.

Owner:VESTAS WIND SYST AS

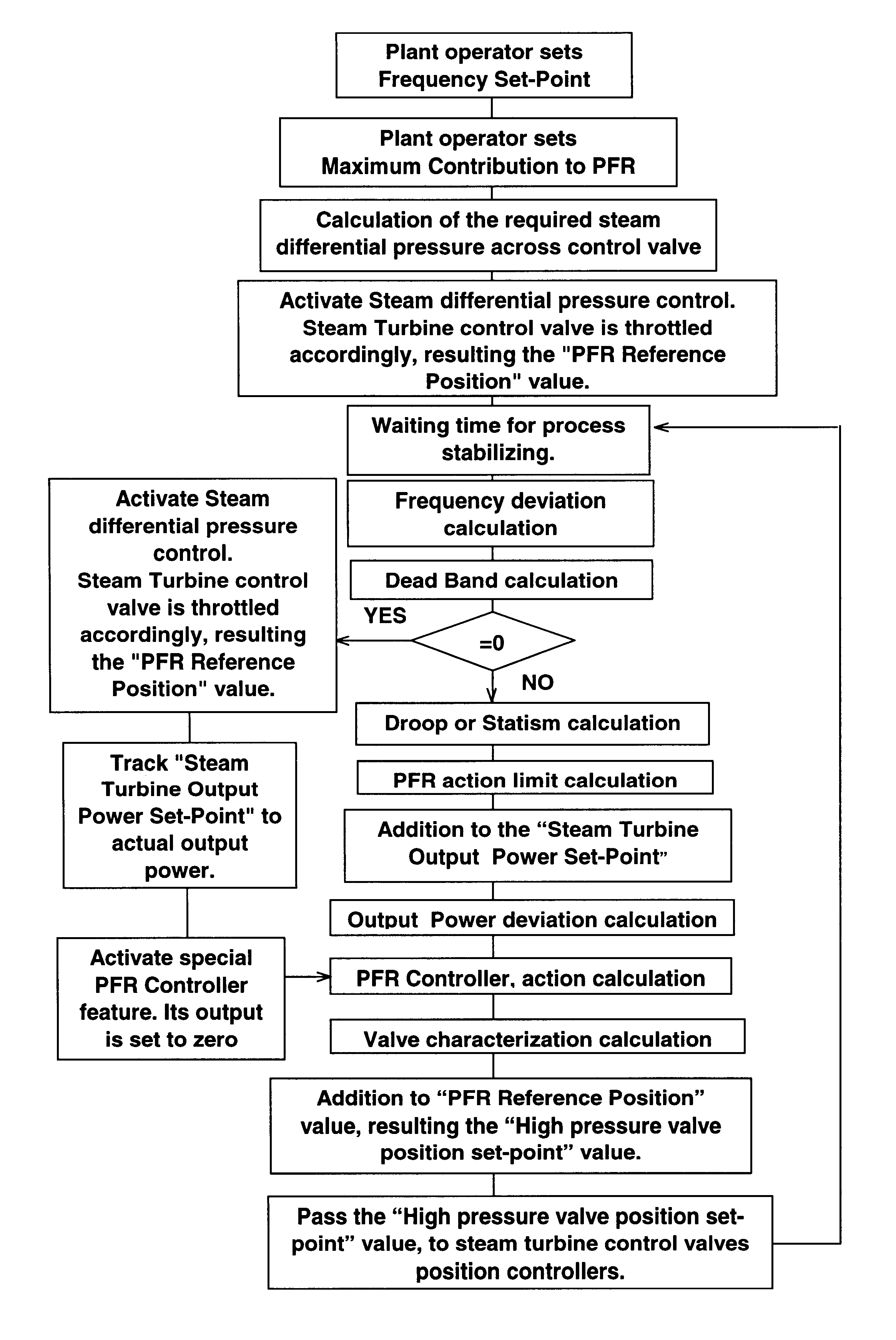

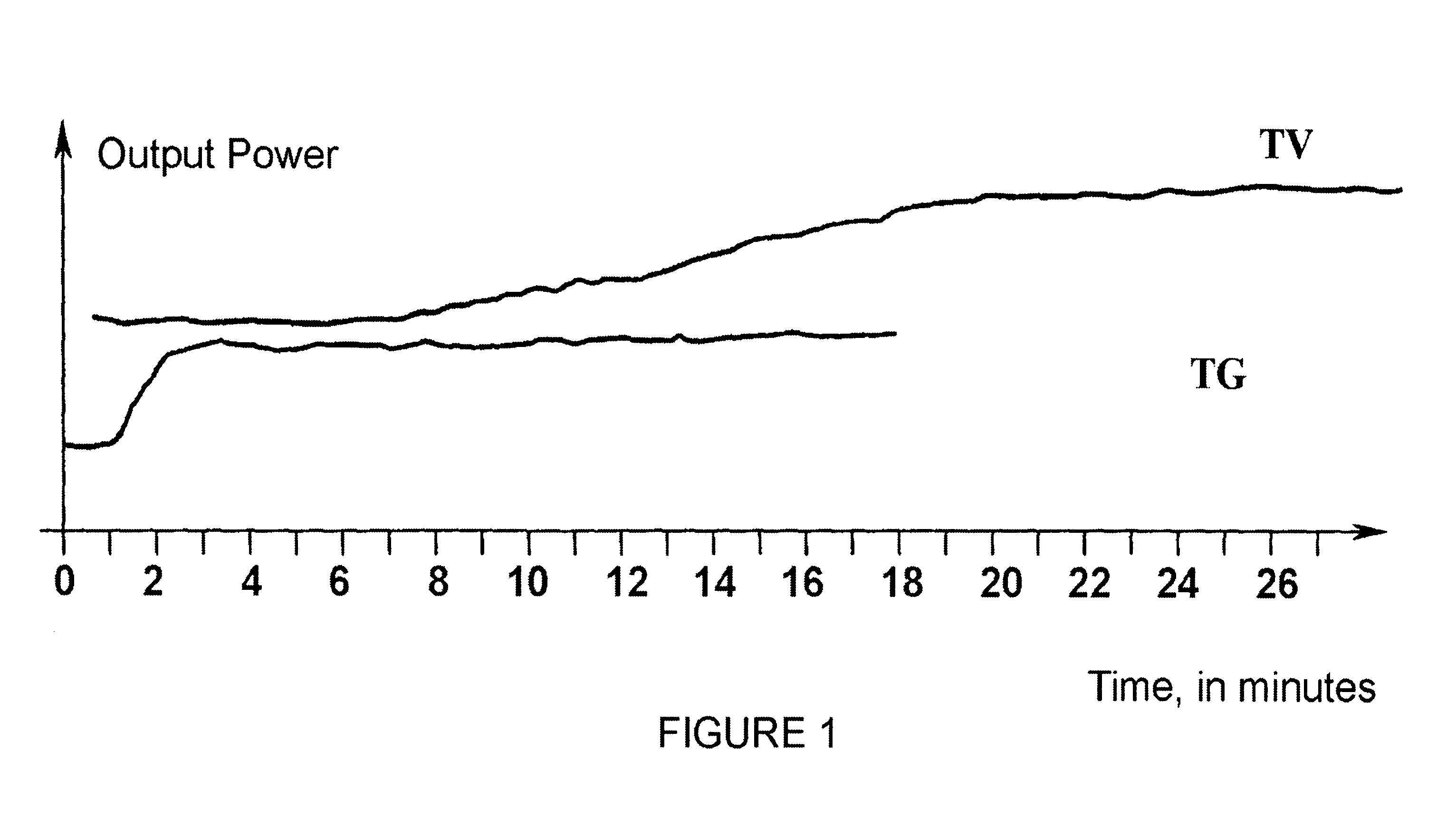

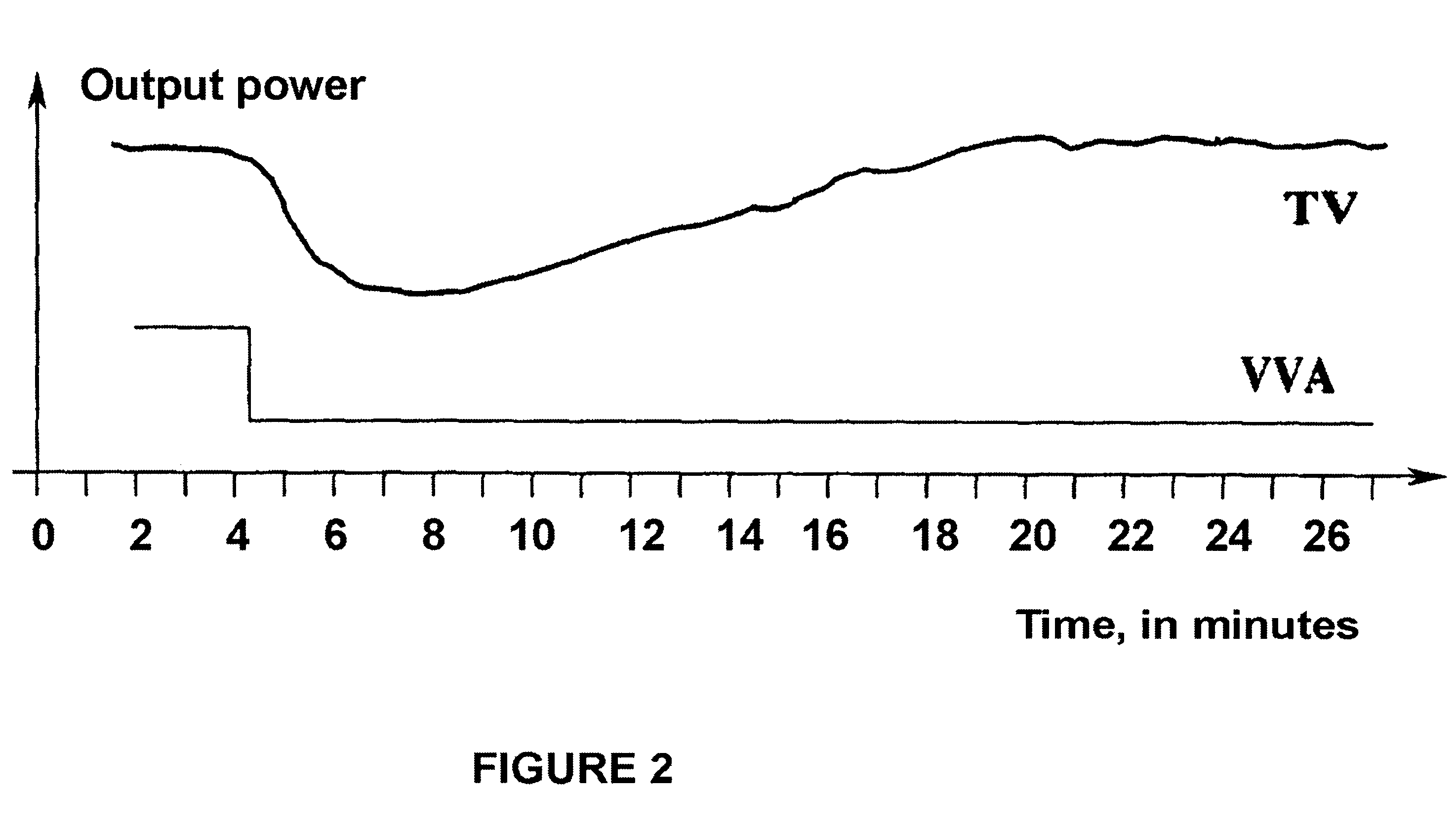

Primary frequency regulation method in combined-cycle steam turbines

Owner:PETROBRAS ENERGIA

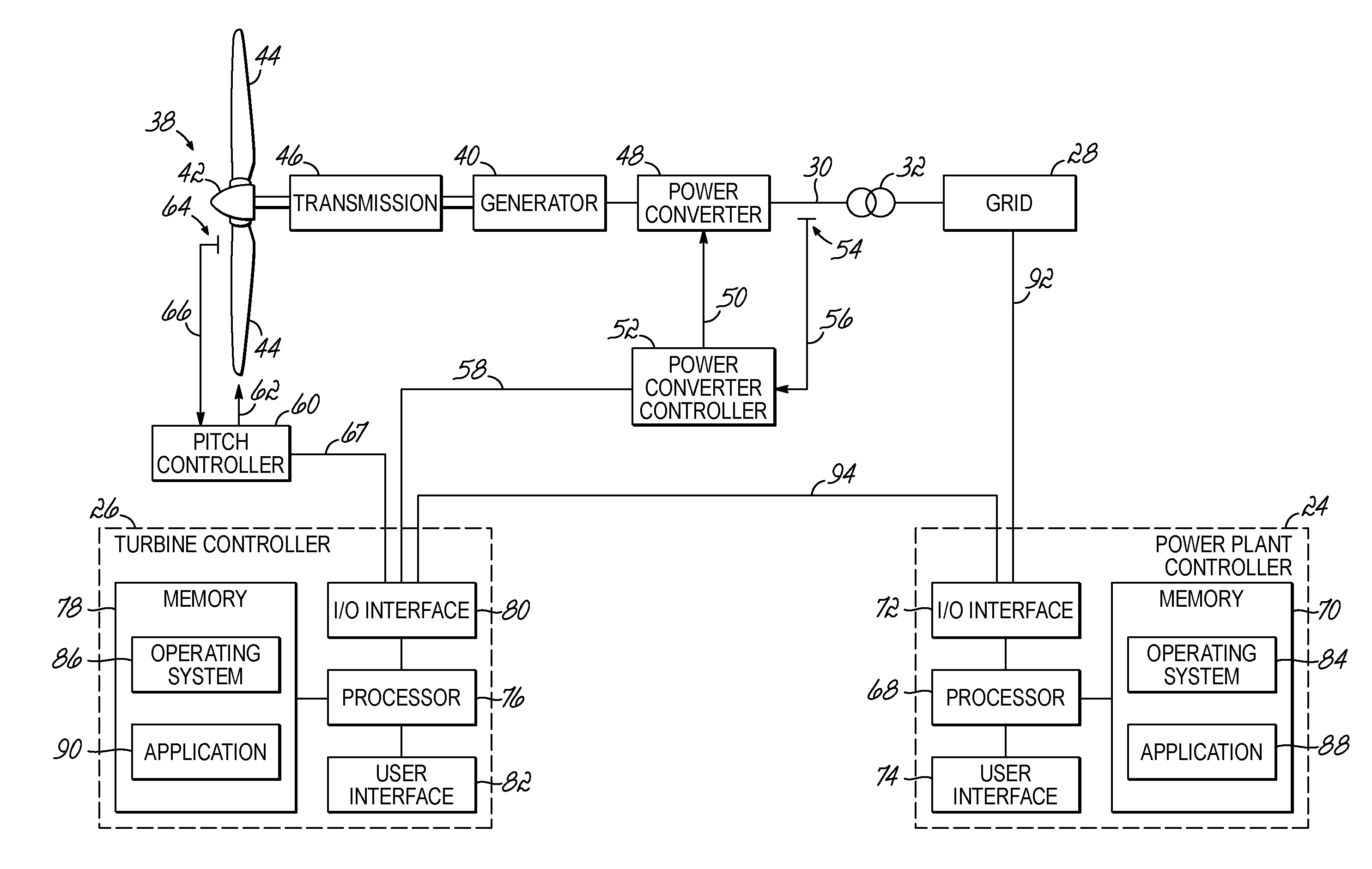

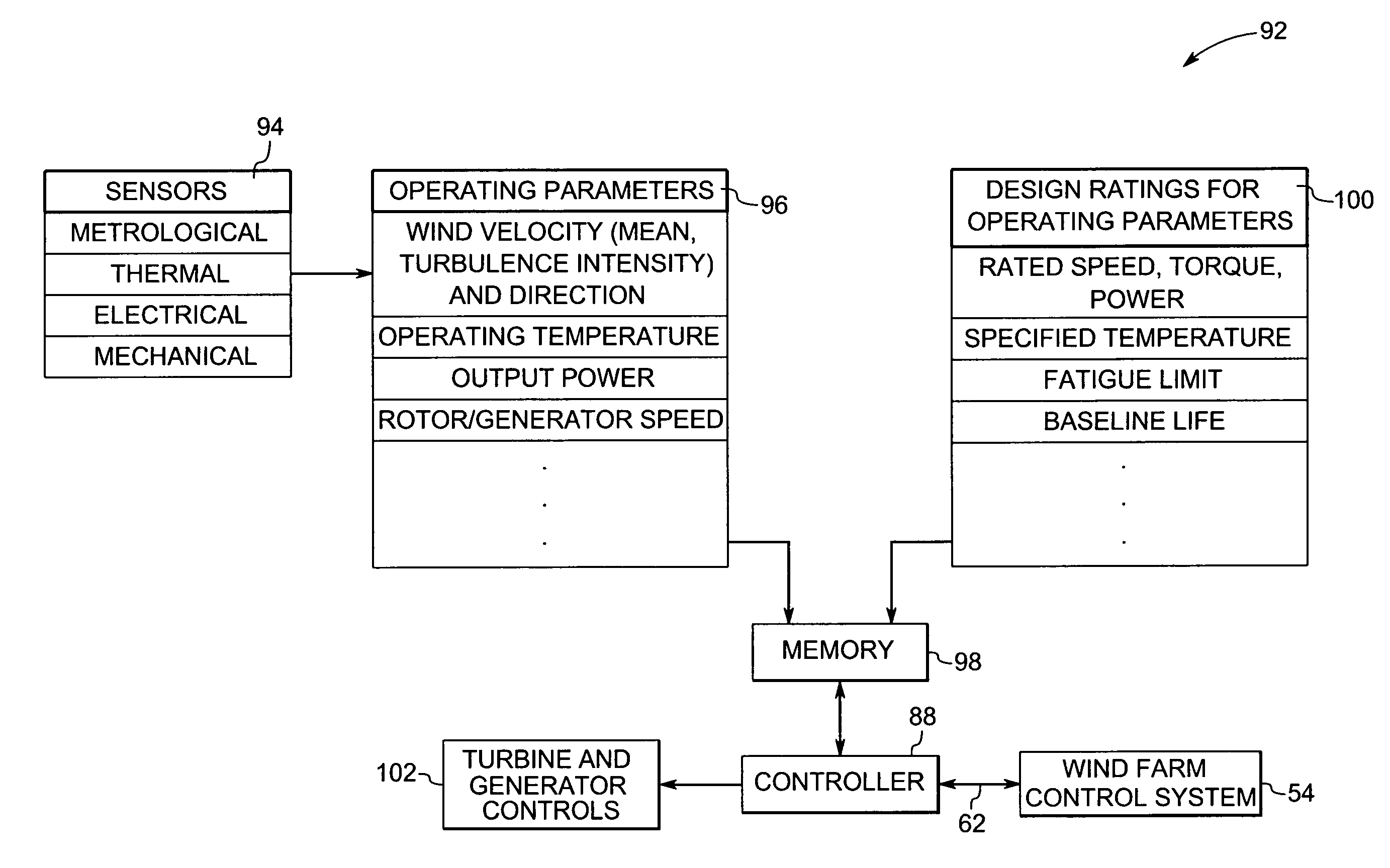

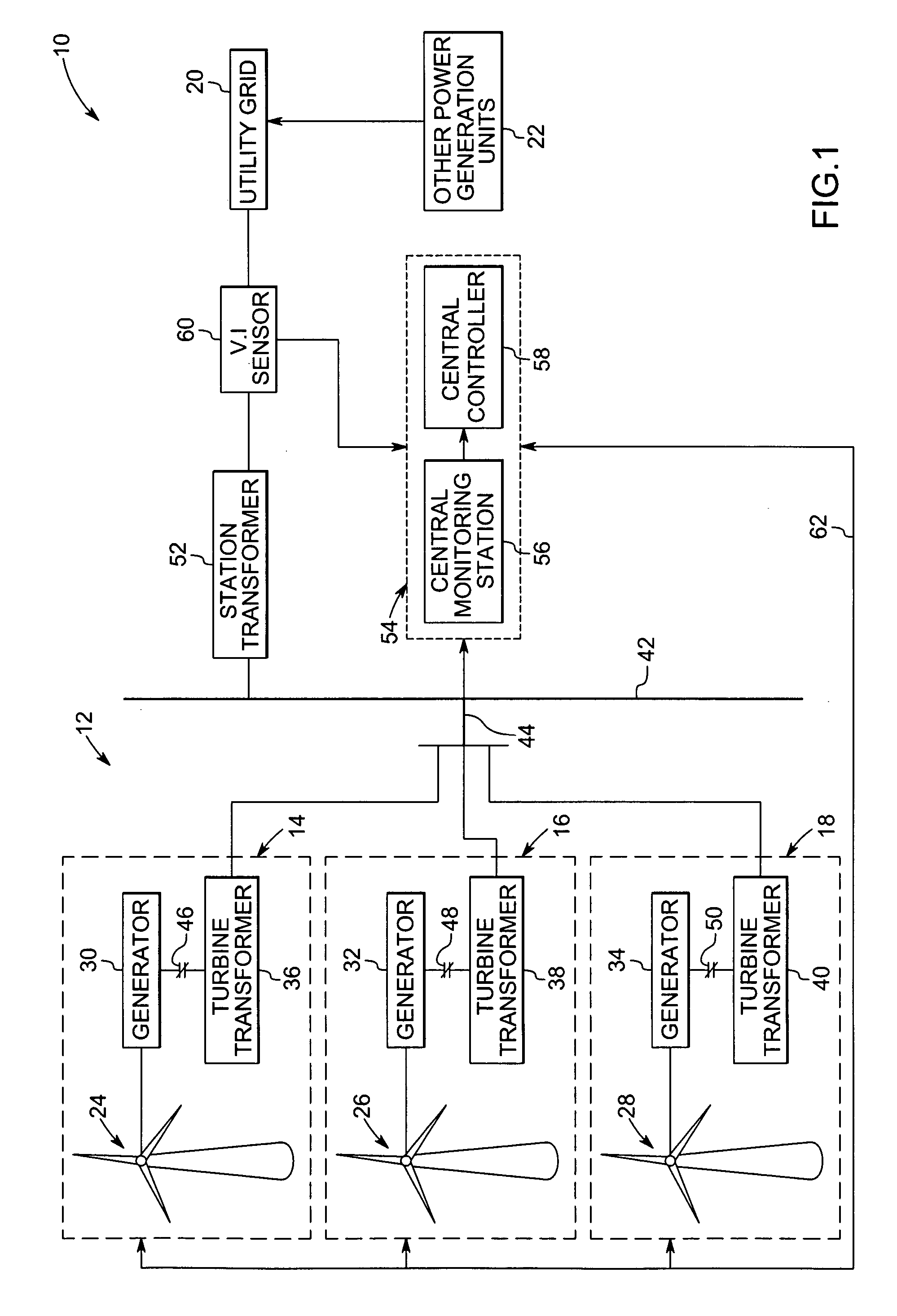

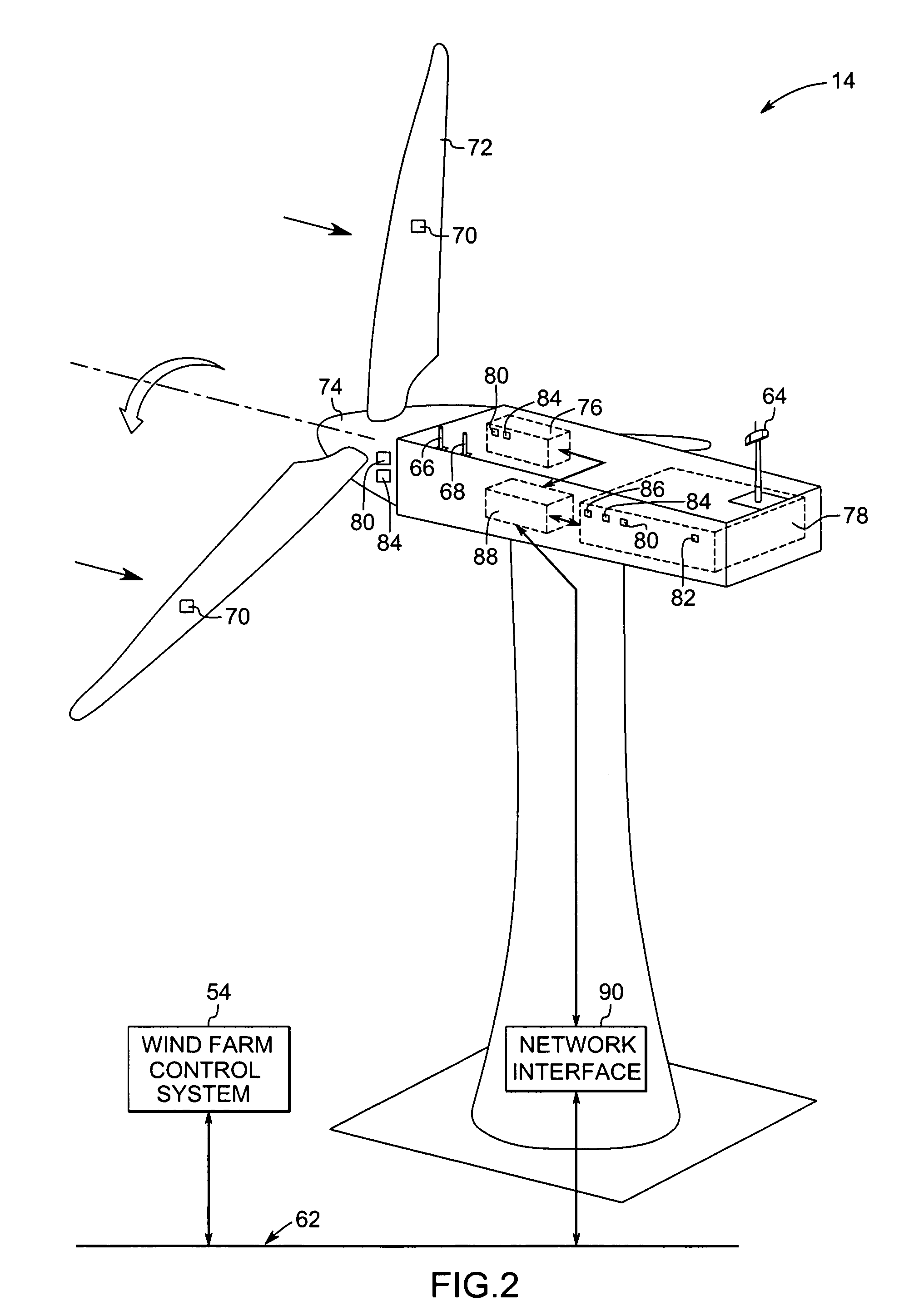

System and method for operating a wind farm under high wind speed conditions

A technique is provided for operating a wind farm at increased rated power output. The technique includes sensing a plurality of operating parameters of the wind turbine generator, assessing the plurality of operating parameters with respect to respective design ratings for the operating parameters, and intermittently increasing a rated power output of the wind turbine generator based upon the assessment.

Owner:GE INFRASTRUCTURE TECH INT LLC

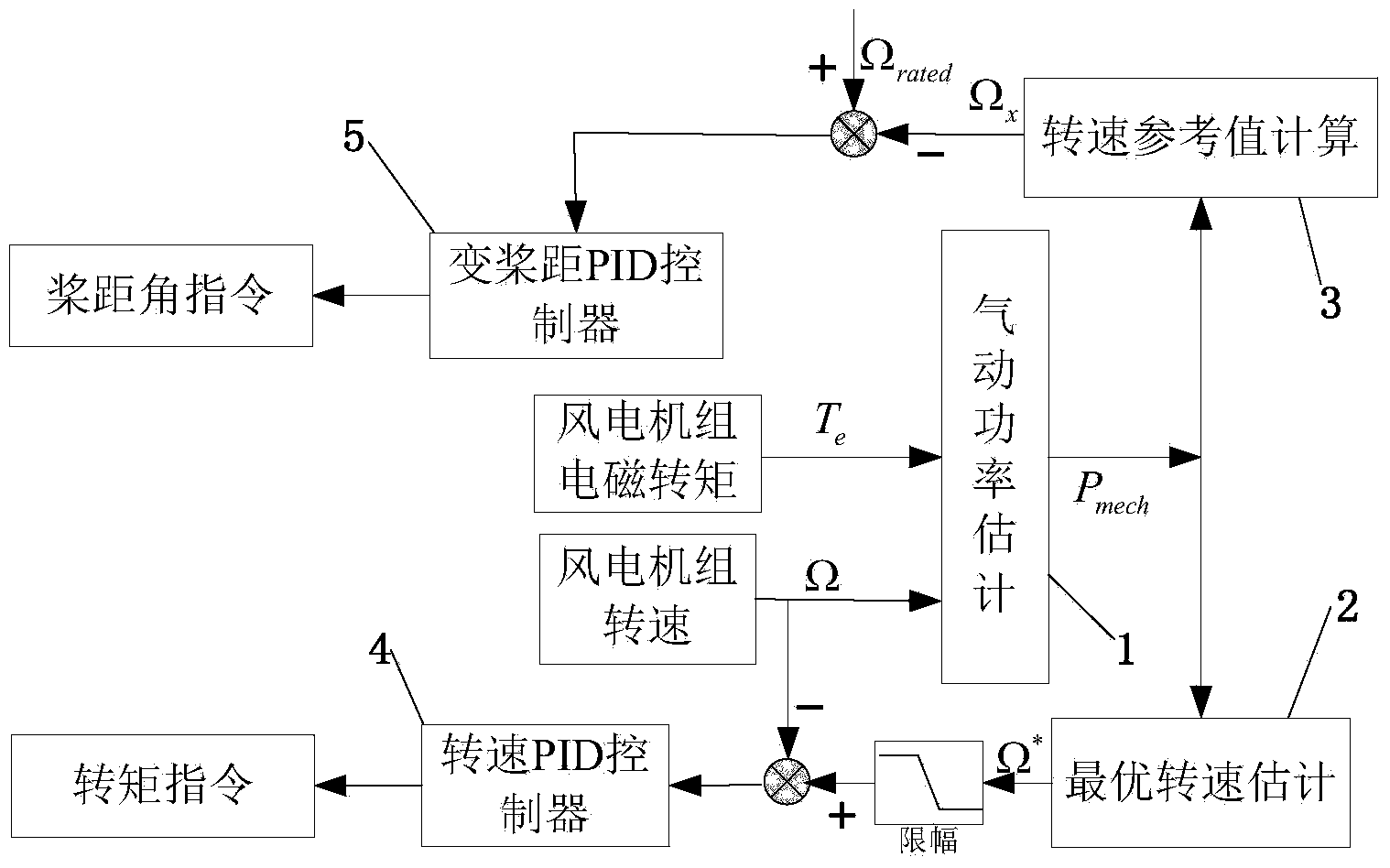

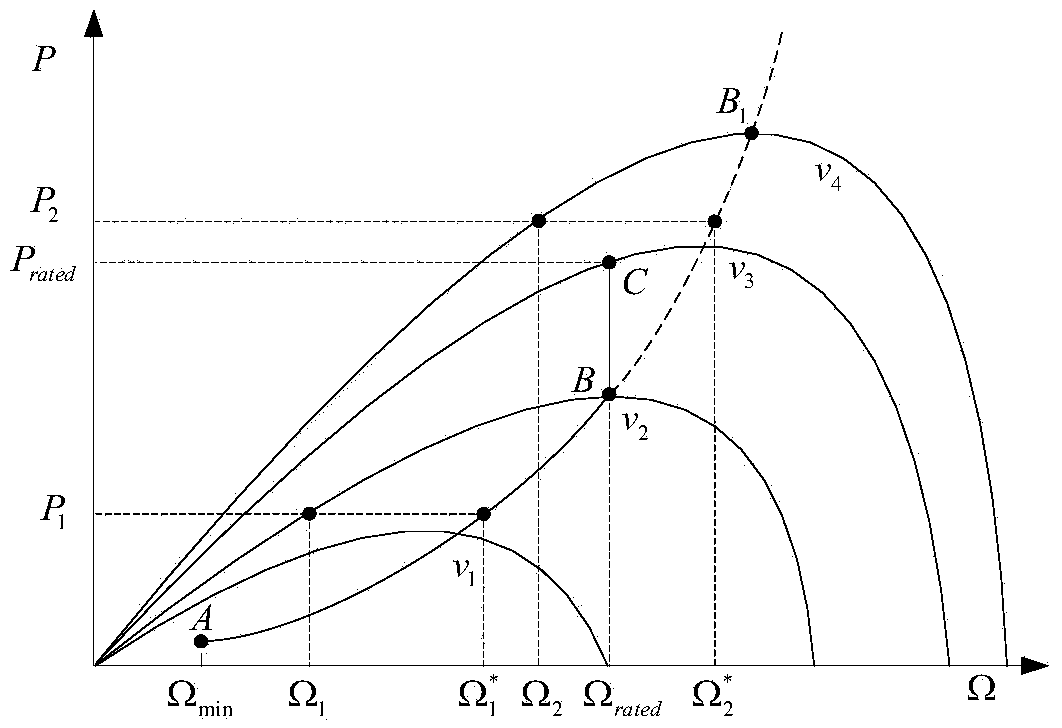

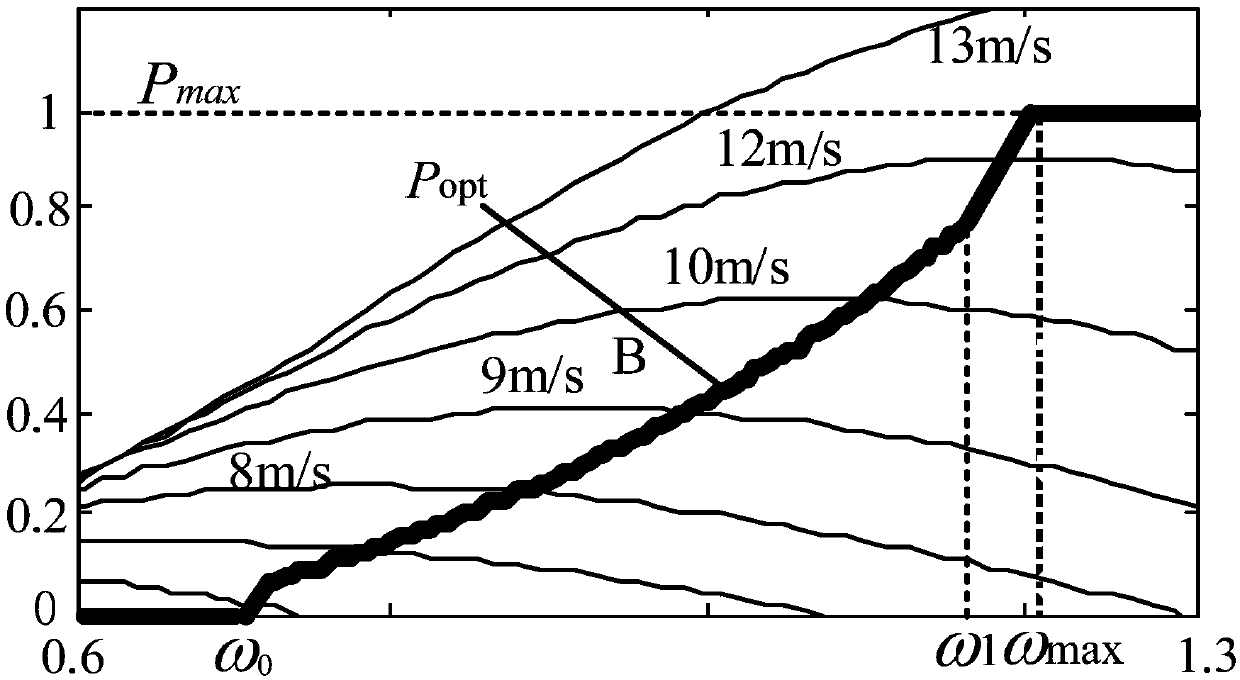

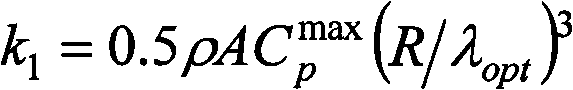

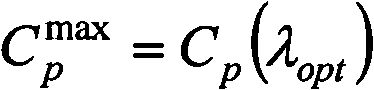

Variable speed-variable pitch combined control method of variable speed constant-frequency wind turbine generator

ActiveCN103939286AGood running controlExpand the variable speed operation areaWind motor controlMachines/enginesDroop speed controlElectricity

The invention discloses a variable speed-variable pitch combined control method of a variable speed constant-frequency wind turbine generator. According to the control method, an optimal rotating speed estimated value and a rotating speed reference value are introduced to respectively serve as reference quantities of rotating speed control and variable pitch control. A rotating speed PID controller performs torque command regulation according to the deviation of the optimal rotating speed estimated value and the rated rotating speed of the wind turbine generator, a variable pitch PID controller performs pitch angle command regulation according to the deviation of the rotating speed reference value and the rated rotating speed of the wind turbine generator, decoupling control between rotating speed control and variable pitch control is achieved, and interference between rotating speed control and variable pitch control is avoided. When wind speed fluctuates nearby the rated value and pneumatic power captured by the wind turbine generator is larger than rated power, the rotating speed reference value corresponding to a pneumatic power estimated value is larger than the rated rotating speed of the wind turbine generator, the variable pitch PID controller regulates a pitch angle command before a torque command output by the rotating speed PID controller reaches the rated value, and variable speed-variable pitch combined control is achieved in advance to control rotating speed of the wind turbine generator and overshooting of output power.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

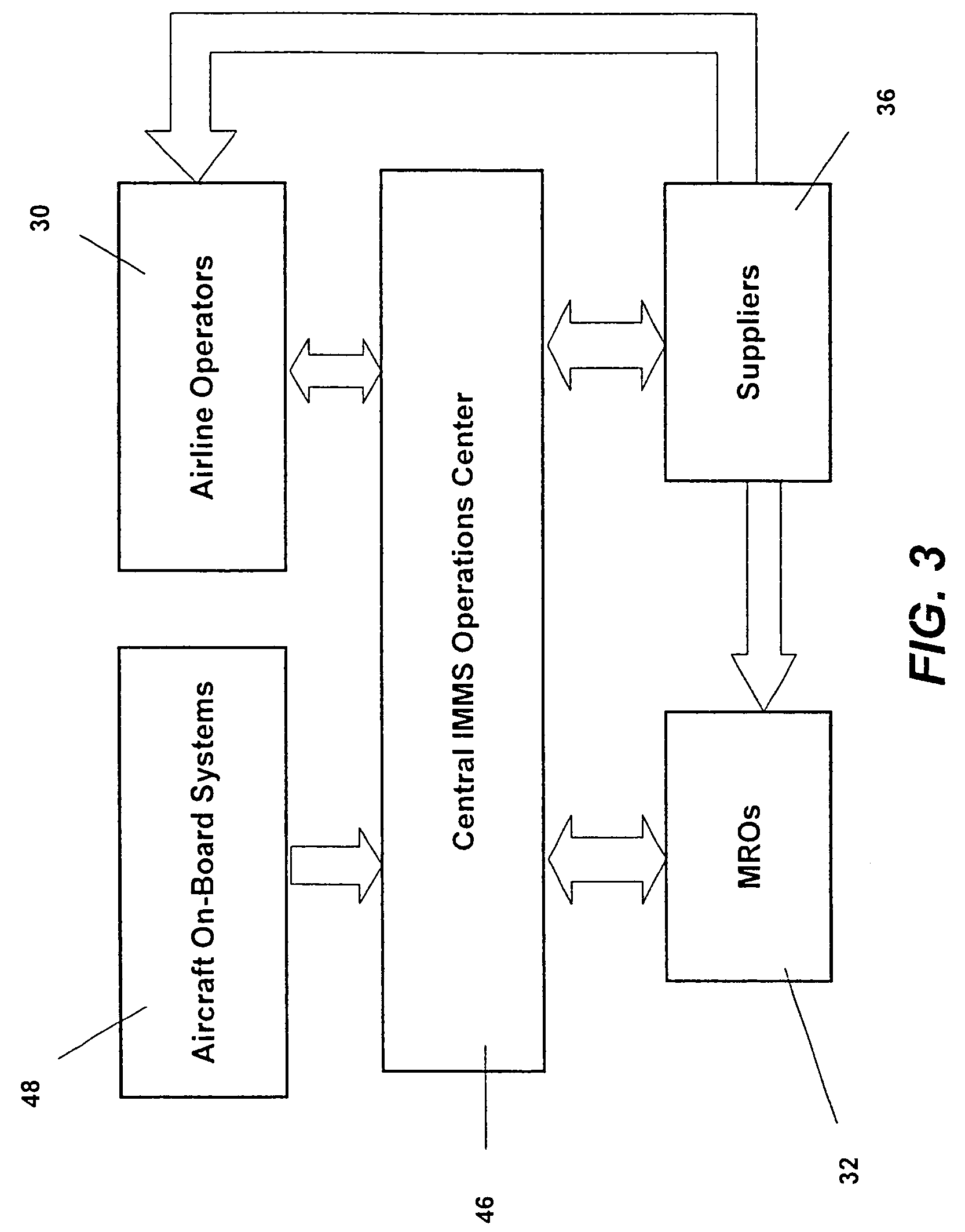

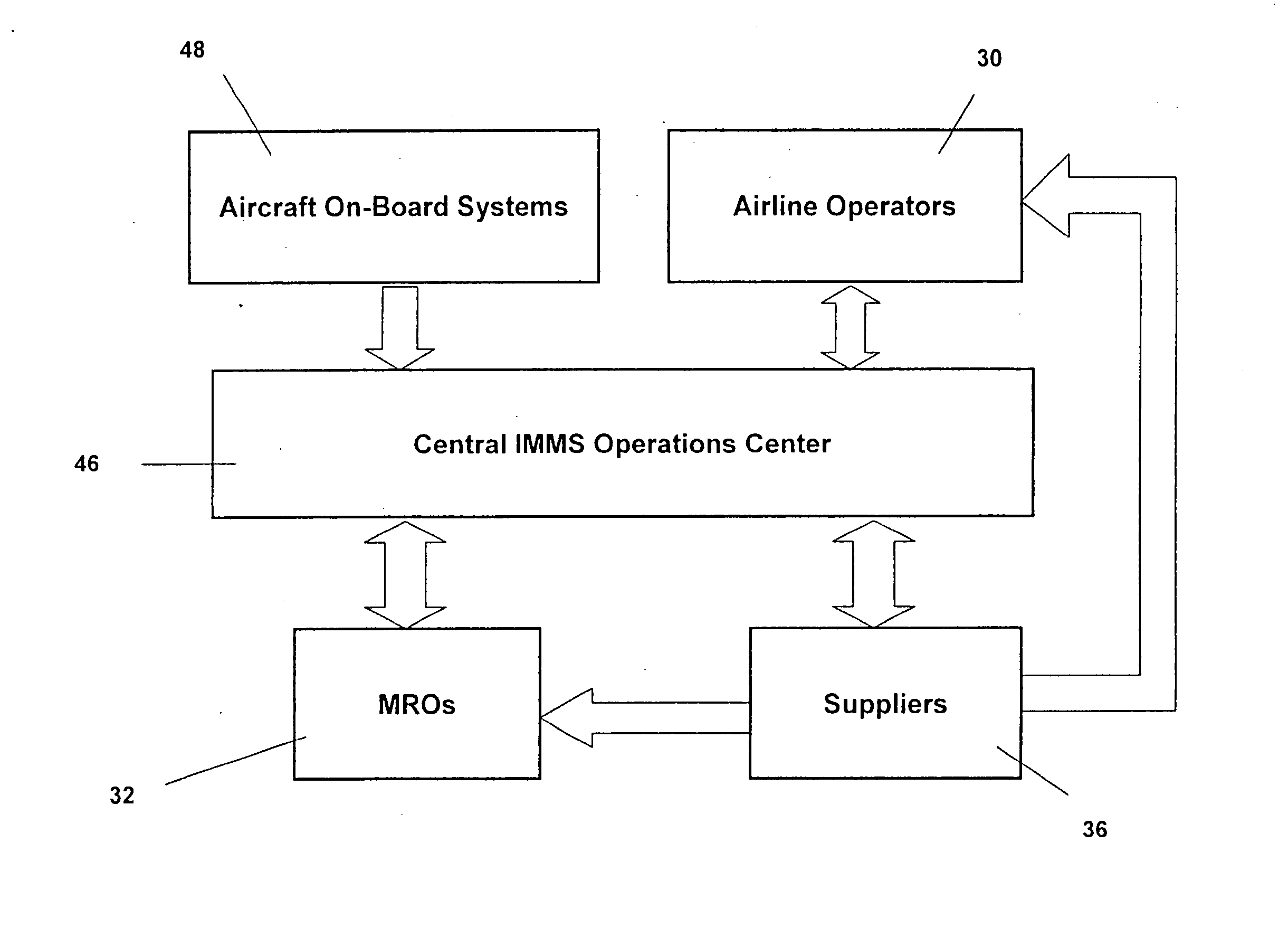

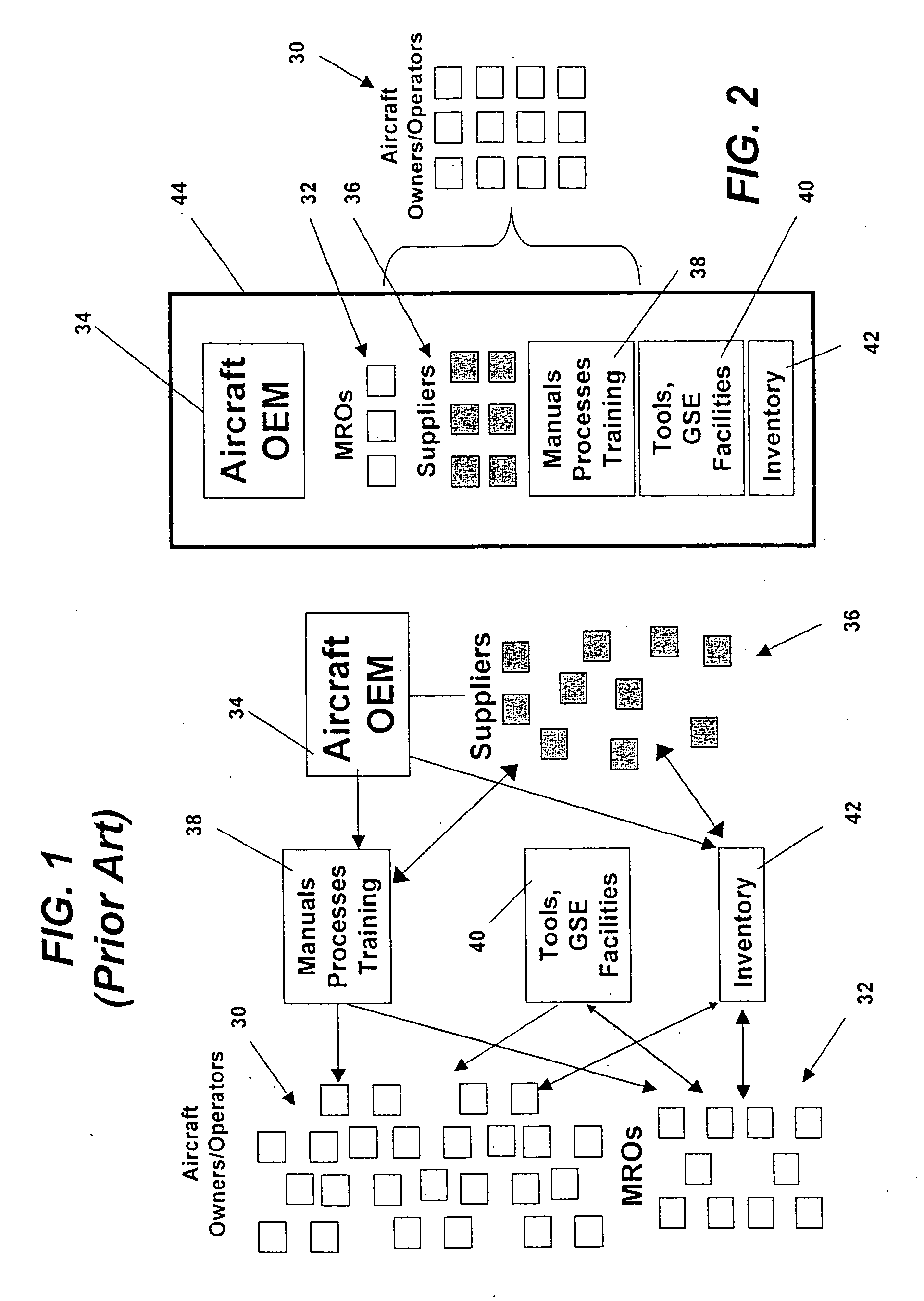

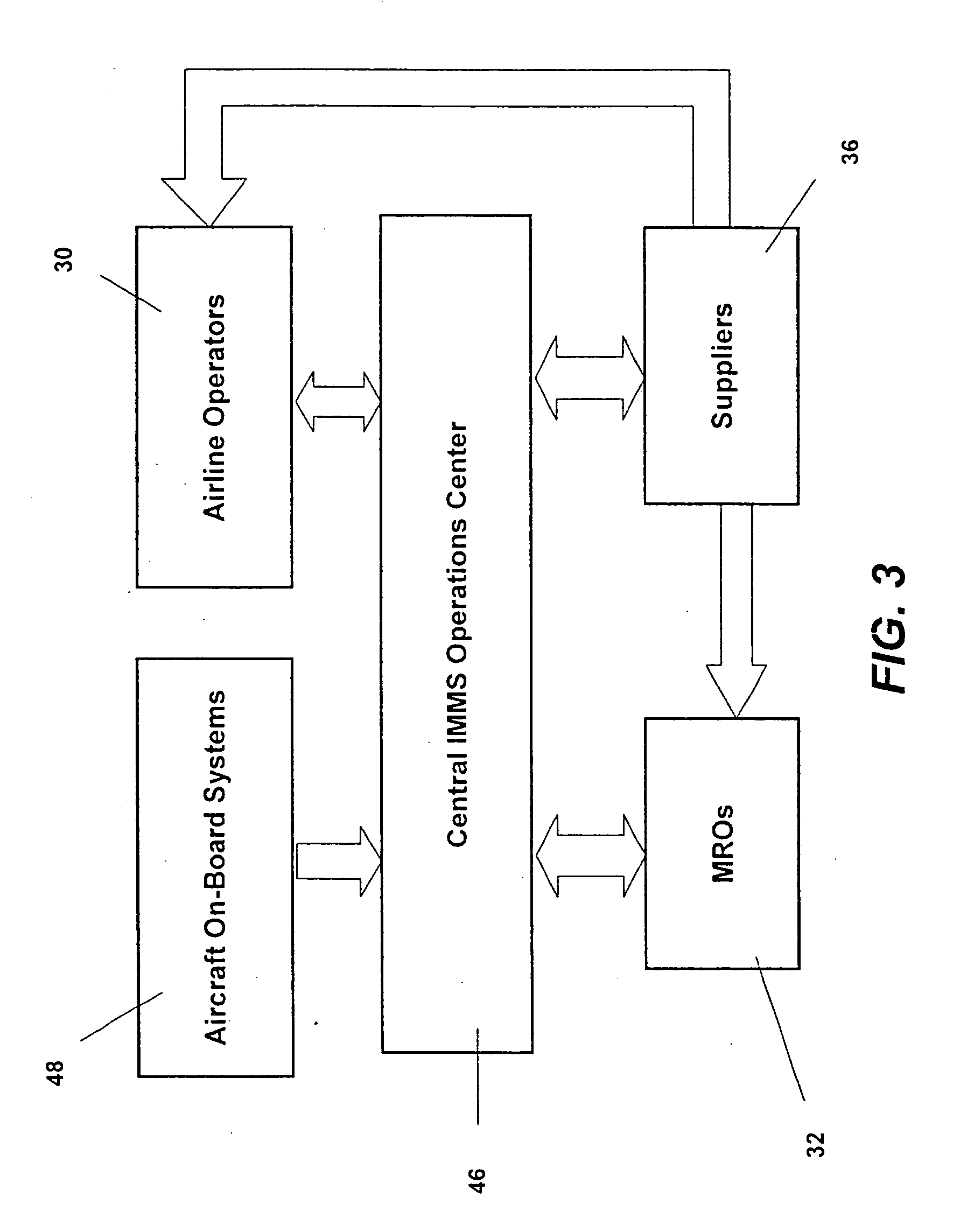

Integrated maintenance and materials services for fleet aircraft using aircraft data to improve maintenance quality

ActiveUS20070112489A1Improve efficiencyLow costVehicle testingRegistering/indicating working of vehiclesMaintenance planningOn board

Turnkey maintenance of a customer's aircraft fleet is managed by a single management service provider (MSP) controlling integrated maintenance and materials services from a central operations site. The MSP converts data received directly from on-board aircraft systems into information it uses to manage maintenance service providers and parts suppliers. The MSP contracts with and manages maintenance, repair and overhaul organizations (MROs) who perform the maintenance on the customers' aircraft at line and base stations. The MSP either remotely manages part inventories at the customer's site, or manages suppliers who deliver the parts to the MROs. Maintenance planning, scheduling and execution information is exchanged between the MSP, MROs, part suppliers and the customers through a shared data communication network controlled by the MSP. The MSP charges the customer for the maintenance services based on a flat rate per unit of aircraft flying time.

Owner:THE BOEING CO

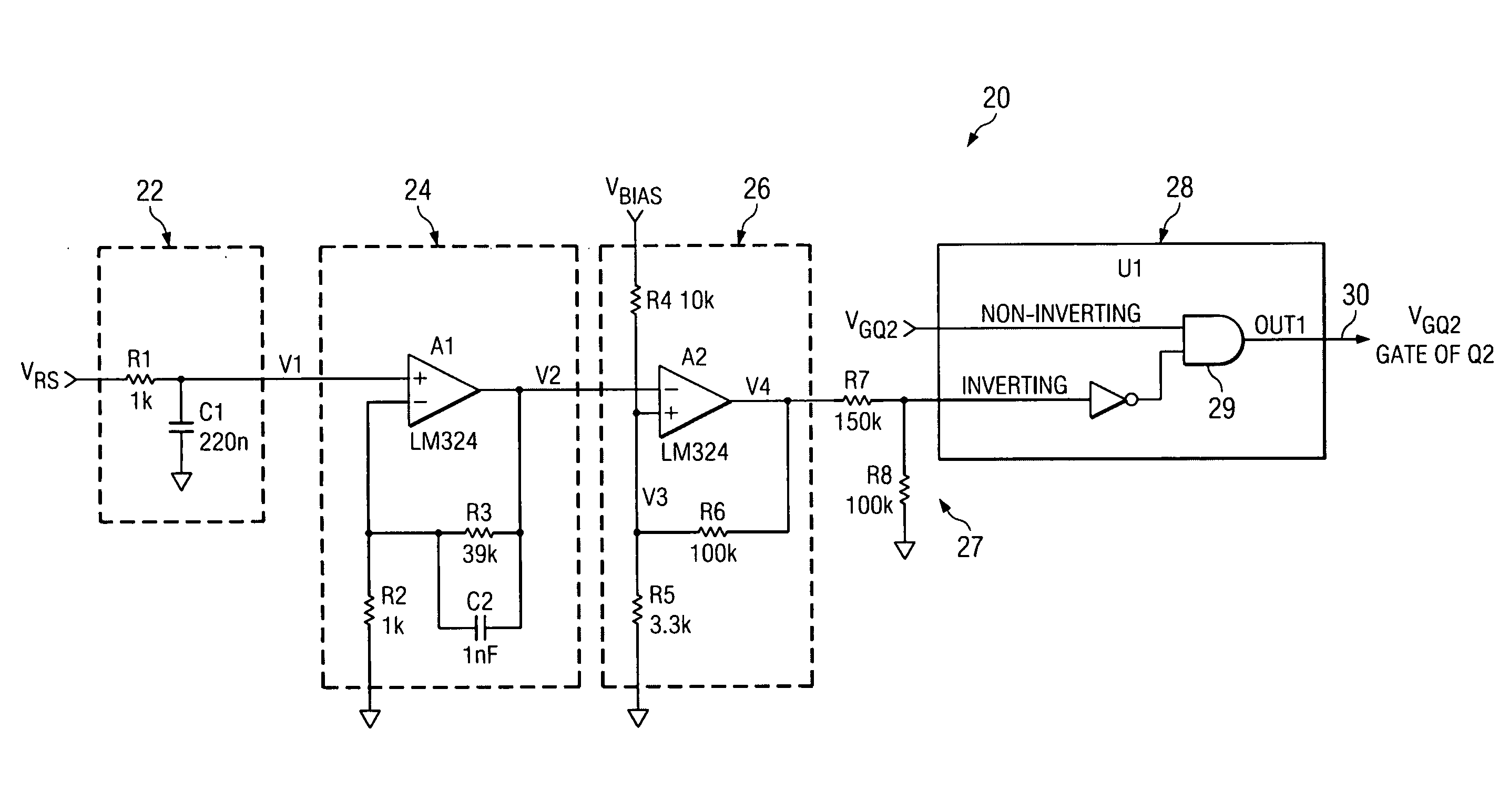

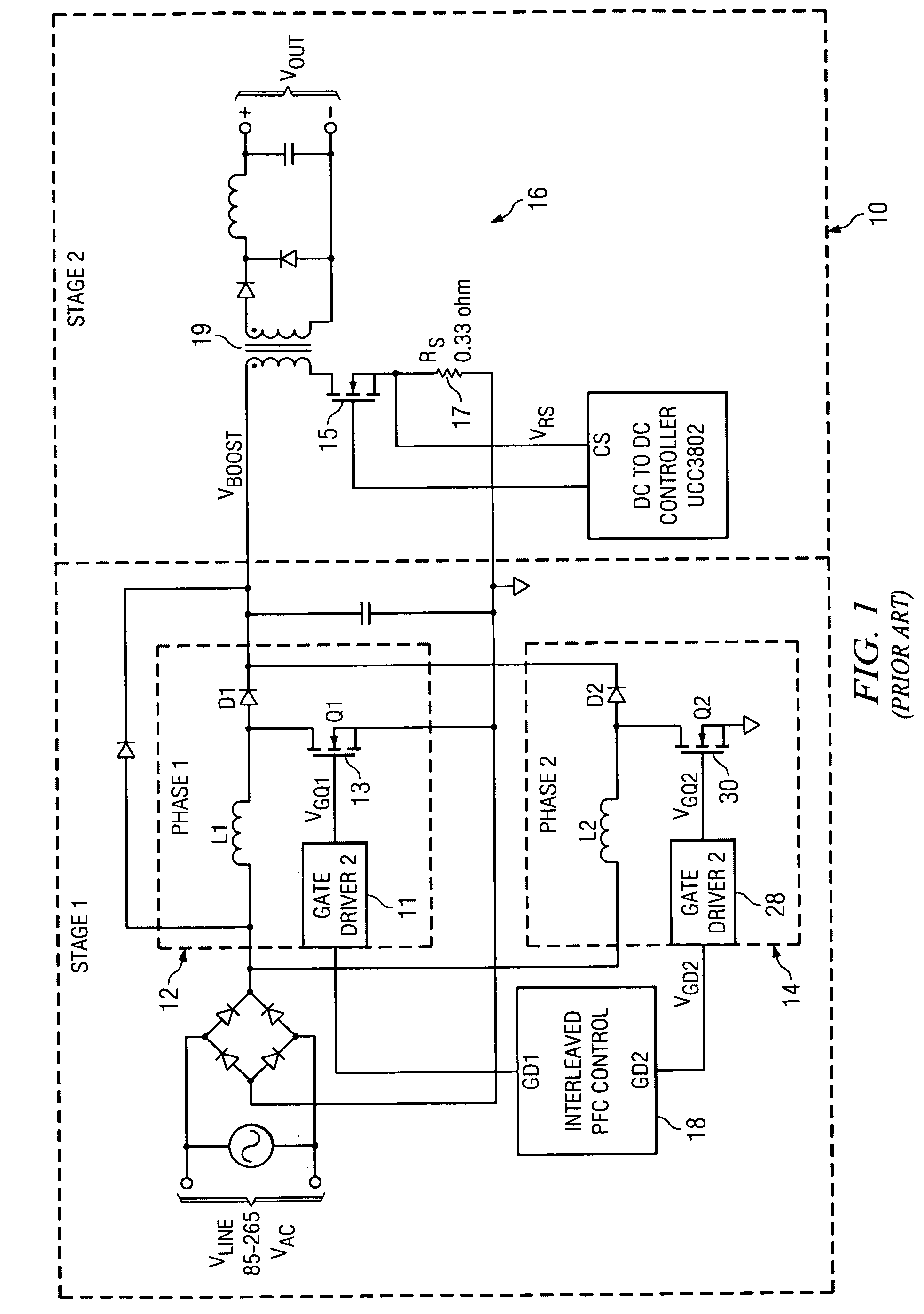

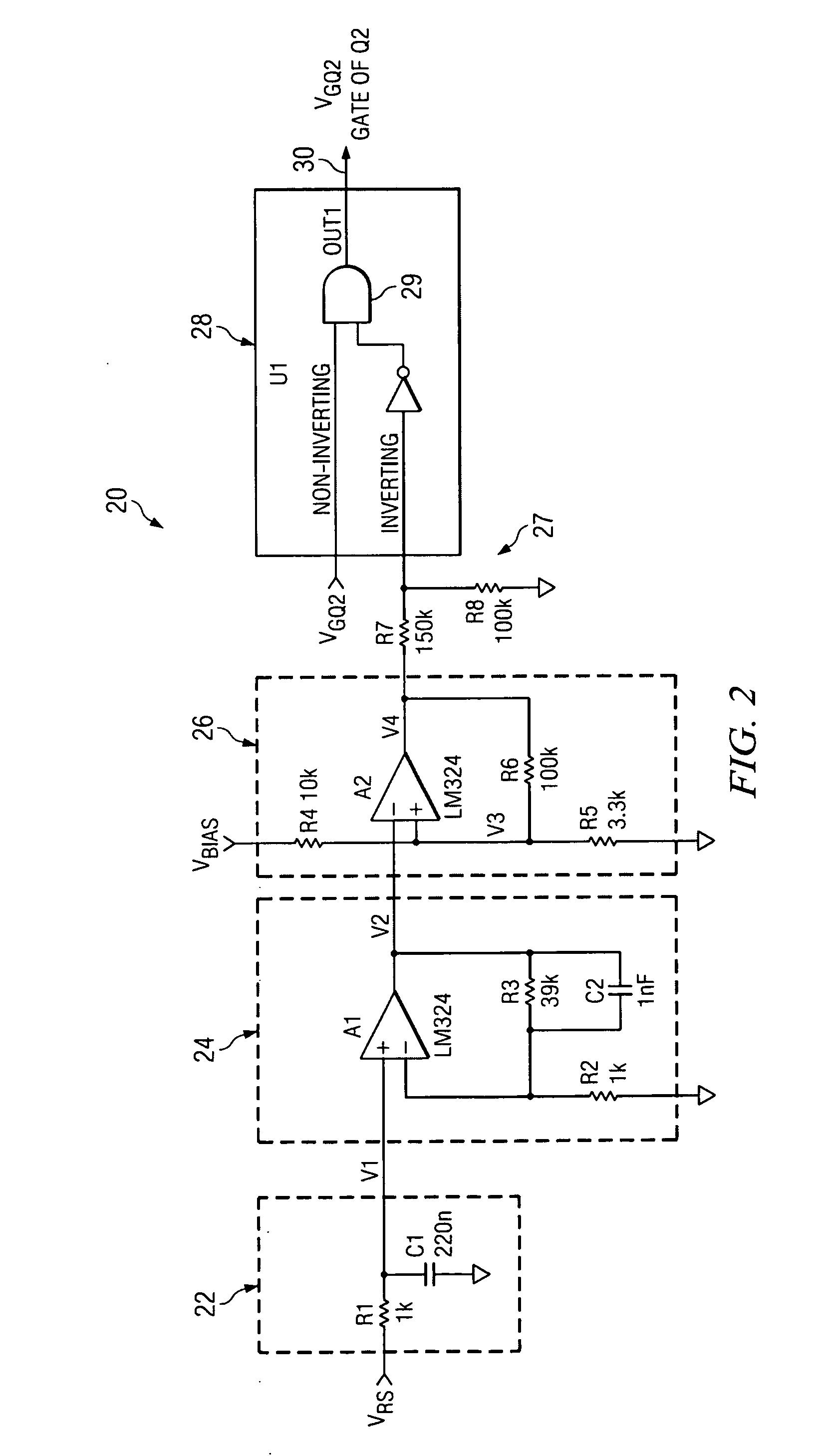

Interleaved power factor correction pre-regulator phase management circuitry

ActiveUS20080316783A1Improve power efficiencyLight power loadEfficient power electronics conversionAc-dc conversionAverage currentVoltage reference

Methods for power factor correction (PFC) and for reducing conduction losses and switching losses in a power converter as well as the power converter and phase management circuitry for the power converter. The power converter includes a first PFC pre-regulator interleaved with at least one additional PFC pre-regulator, and a step down converter. The average input power is measured downstream of the front end at the step down converter and the average current sense signal is compared to a reference voltage. Each additional PFC pre-regulator is disable when output power generated by the front end is less than a first pre-designated rated power level and each additional PFC pre-regulator is enabled when the output power is greater than a second pre-designated rated power level.

Owner:TEXAS INSTR INC

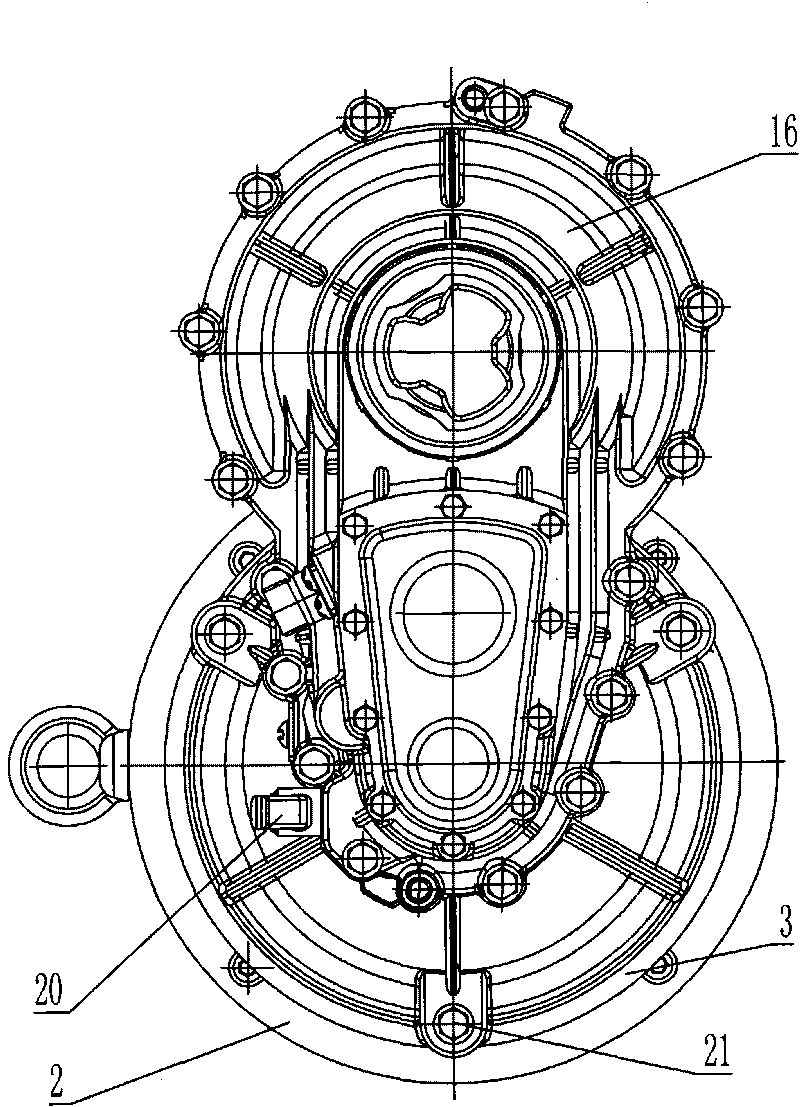

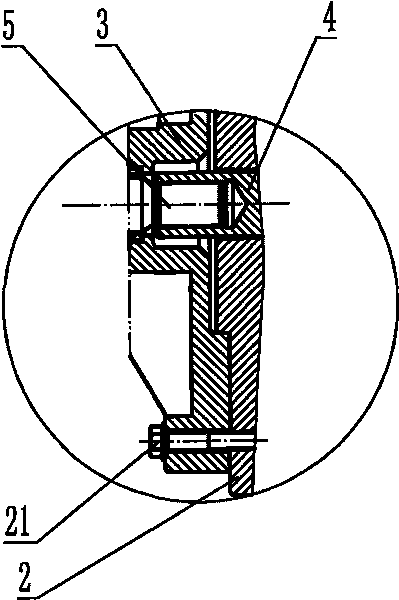

Power assembly for two-shift motor vehicle

InactiveCN101704340AReduced power ratingEasy to assembleElectric propulsion mountingTransmission elementsLow speedElectric machine

The invention provides a power assembly for a two-shift motor vehicle. A driving motor is integrally connected with a two-shift transmission so as to form a modularized power assembly which is simple to assemble and maintain. The transmission of the power assembly is a speed-change mechanism with two working shifts, namely a low-speed shift and a high-speed shift. The vehicle runs by using the low-speed shift while climbing under a heavy load and runs by using the high-speed shift while running on smooth road surface under a light road. The speed-change mechanism is implemented by using a synchronizer on a second shaft, and is jointed with a low-speed or a high-speed driven gear respectively through the synchronizer so as to realize low-speed and high-speed operations. The power assembly for the two-shift motor vehicle has a compact structure and flexible and convenient operation, and can reduce rated power for driving the motor.

Owner:锦州万得汉拿电机有限公司

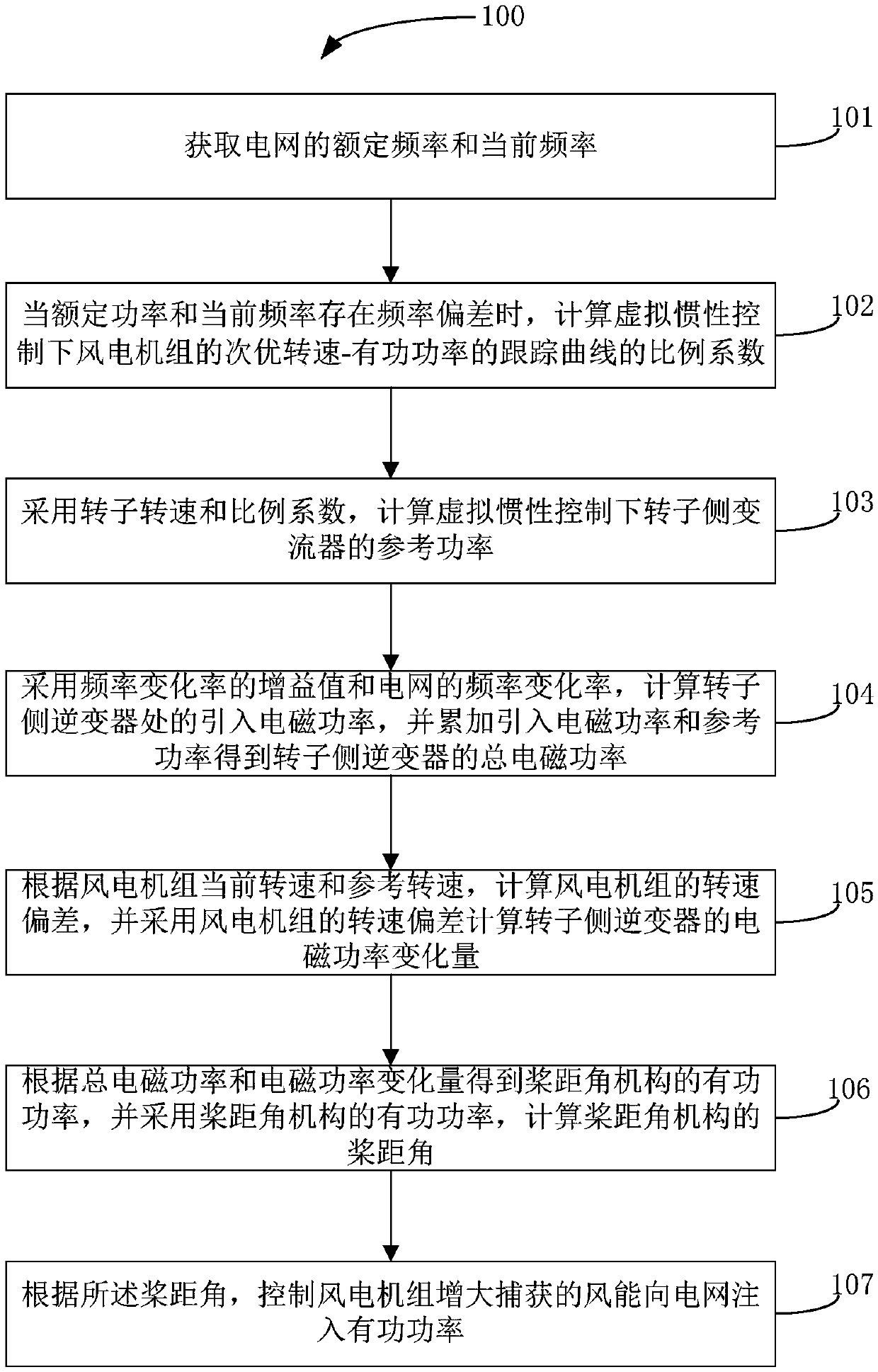

Method for controlling wind turbine to participate in power grid frequency modulation based on virtual inertia and pitch angle

InactiveCN107910896AEffective inertia supportImprove mechanical energySingle network parallel feeding arrangementsPower oscillations reduction/preventionInertial controlEngineering

The invention discloses a method for controlling a wind turbine to participate in power grid frequency modulation based on virtual inertia and a pitch angle. The method comprises the following steps:when a frequency deviation exists between the rated power of a system power grid and the current frequency, calculating a proportionality factor of a tracking curve of the sub-optimal rotating speed-active power of the wind turbine under the control of the virtual inertia; calculating a reference power of an inverter at a rotor side under the control of the virtual inertia; calculating an introduced electromagnetic power at the rotor side inverter according to the frequency change rate, and accumulating the introduced electromagnetic power and the reference power to obtain a total electromagnetic power of the rotor side inverter; calculating the rotating speed deviation of the wind turbine, and adopting the rotating speed deviation of the wind turbine to calculate the electromagnetic powervariation of the rotor side inverter; obtaining an active power of a pitch angle mechanism according to the total electromagnetic power and the electromagnetic power variation, and calculating the pitch angle of the pitch angle mechanism by adopting the active power of the pitch angle mechanism; and controlling the wind turbine to increase captured wind energy and inject the active power into thepower grid according to the pitch angle.

Owner:SOUTHWEST JIAOTONG UNIV

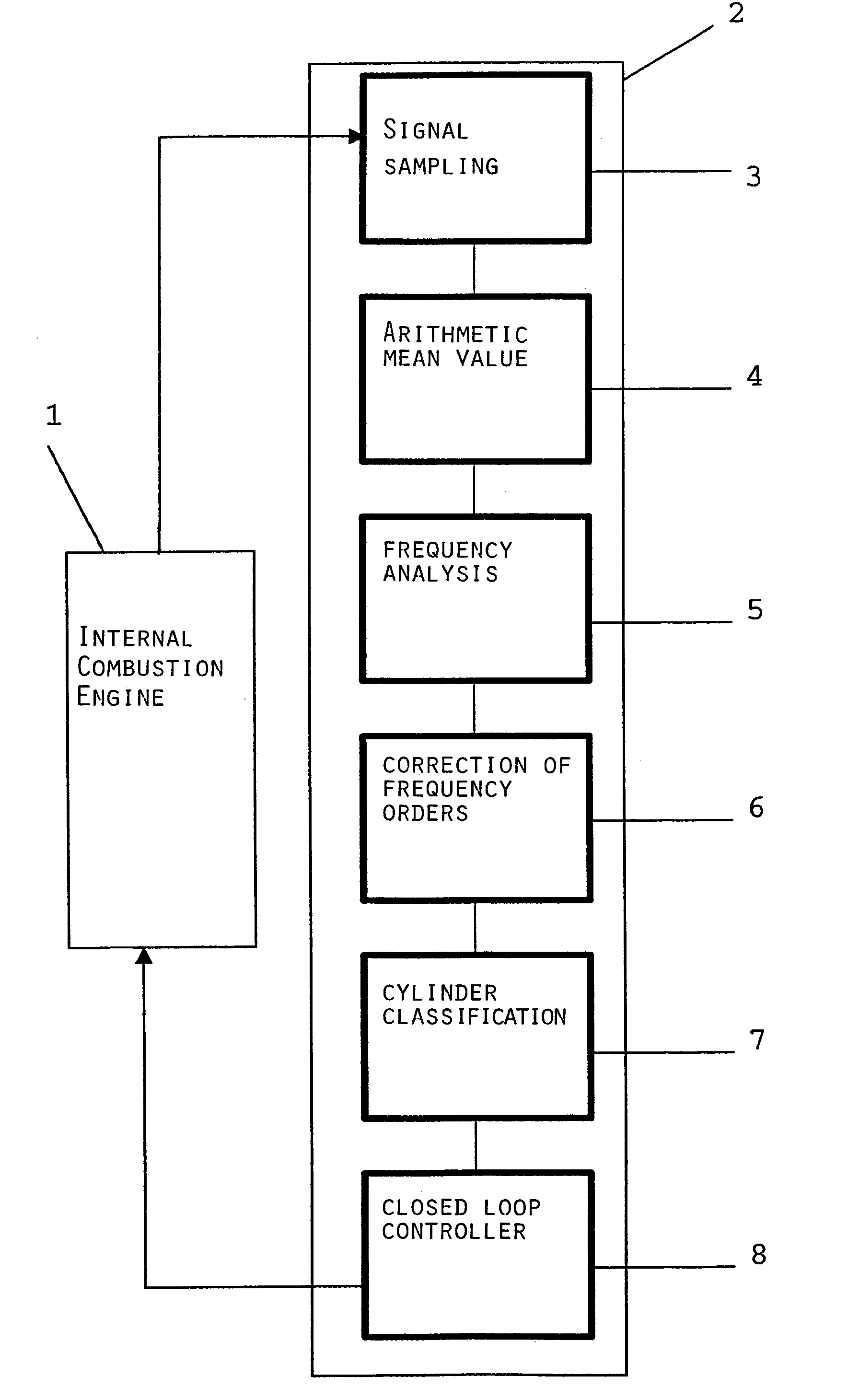

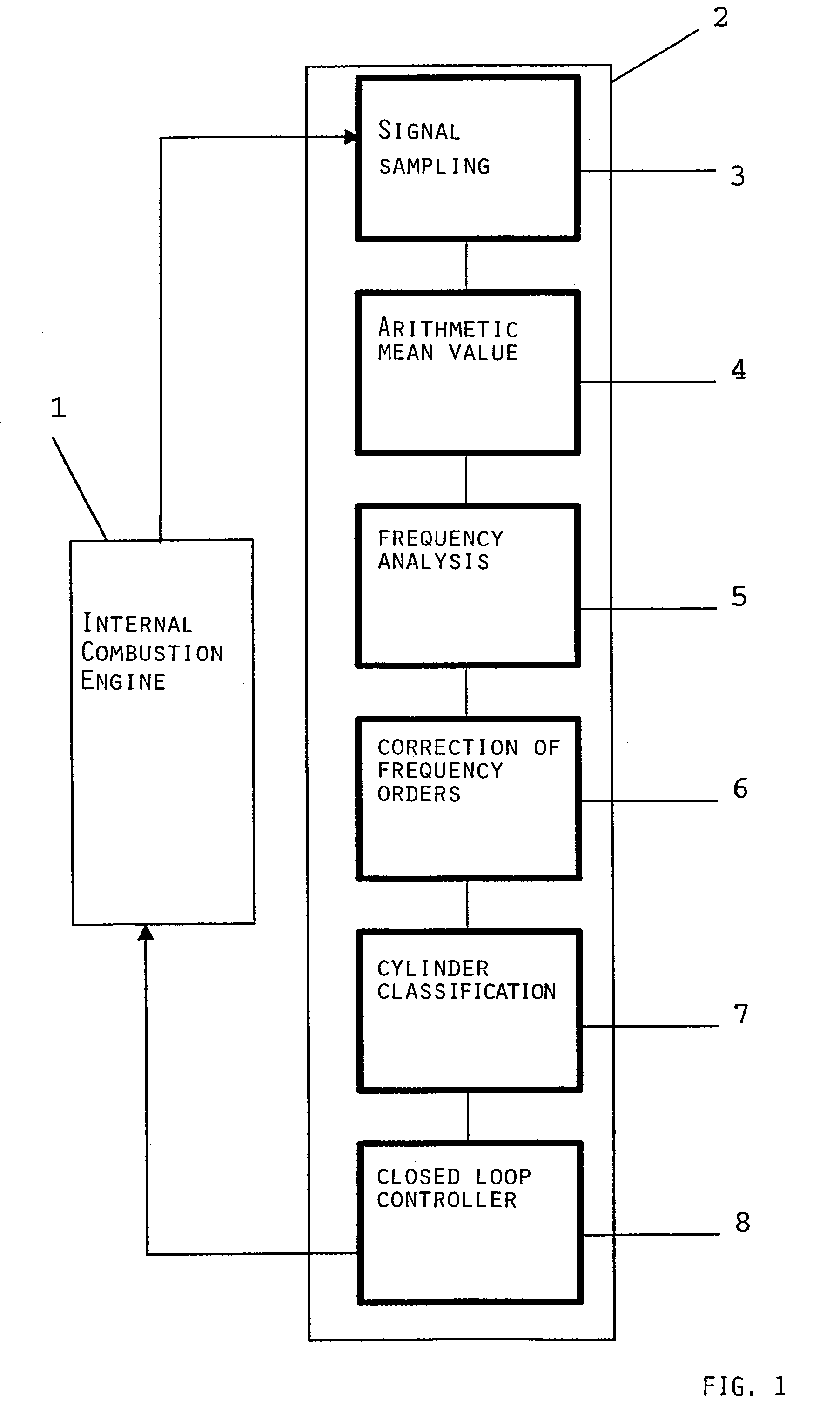

Regulating the mode of operation of an internal combustion engine

InactiveUS7219003B2Increase vibrationUneven runningAnalogue computers for vehiclesElectrical controlCombustionControl signal

Combustion failures of an internal combustion engine are controlled in closed loop fashion by sampling an engine r.p.m. to obtain a speed signal. The speed signal is subjected to a Hartley-Transformation to obtain angular frequencies or engine orders which are further processed to identify the cylinder which had a combustion failure and thereby reduced an actual engine power output compared to a rated power output. A power output correcting signal is produced and supplied to the engine. The system for performing these steps includes at least a speed signal sampler, a frequency analyzer to perform the Hartley-Transformation, a cylinder identifier or classifier and a controller which supplies the closed loop control signal to the engine.

Owner:CONTI TEMIC MICROELECTRONIC GMBH

Stall controller and triggering condition control features for a wind turbine

InactiveUS7420288B2Increase torqueCost issueAC motor controlWind motor controlPartial lossControl theory

Control features for a wind turbine that control the turbine over a range of wind speeds and under triggering conditions with reduced noise, cost, and reliability issues associated with other such controls. Control is accomplished via control electronics, which adjust the torque produced by the electrical output generation device (e.g., alternator) within the wind turbine. During normal operation, torque is adjusted for optimum aerodynamic performance and maximum output of power. In winds above rated power, the control circuit regulates torque to lower aerodynamic performance, as necessary to maintain desired power level output. In triggering conditions, such as during simultaneous control circuit failure and loss of some portion of the electrical output generation device in extreme winds, wind turbine control is accomplished by increasing torque (e.g., via a separate controller) from the electrical output generation device via shorting of windings, so as to cause retardation of blade rotation.

Owner:WIND RESOURCE LLC

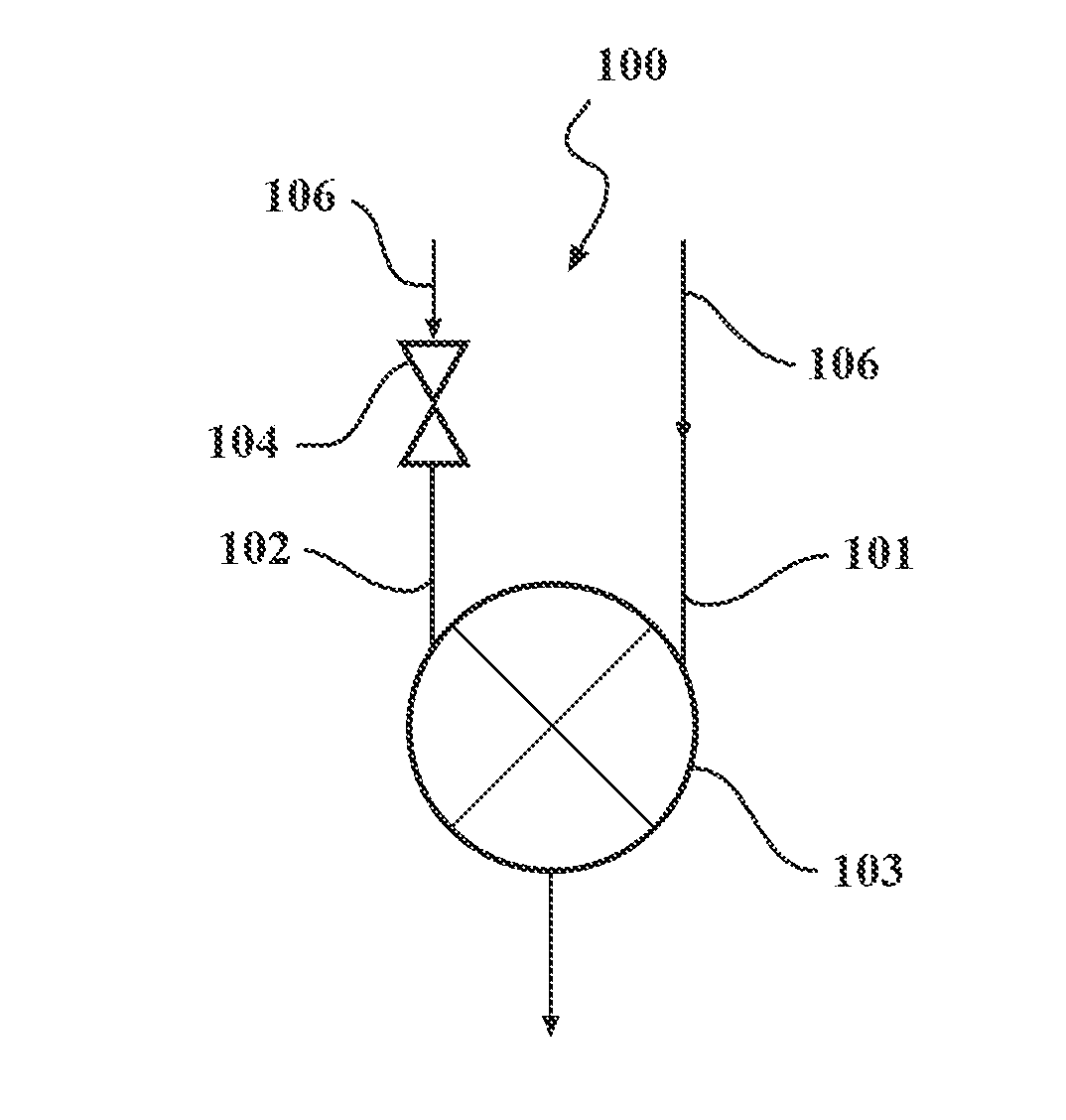

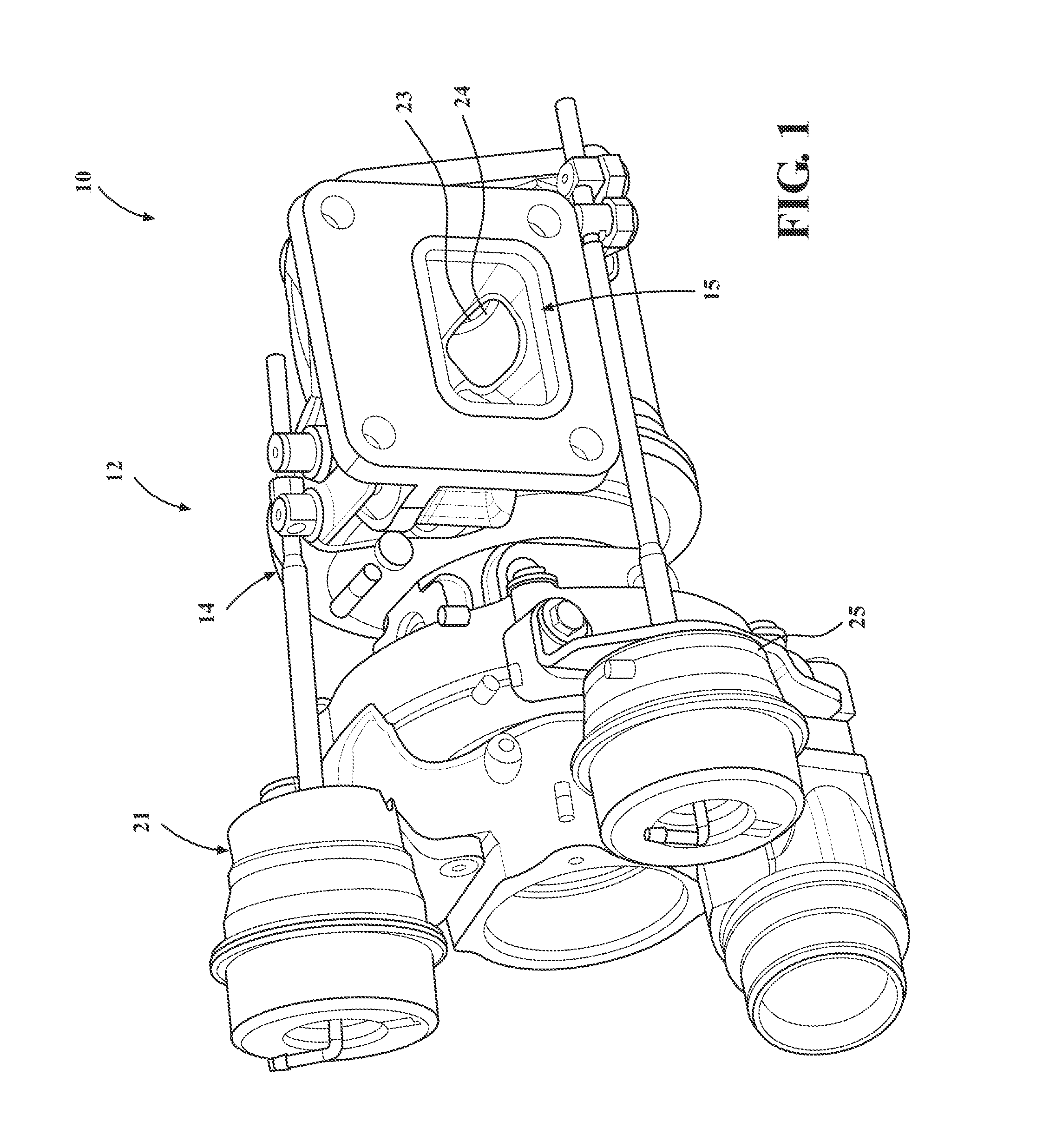

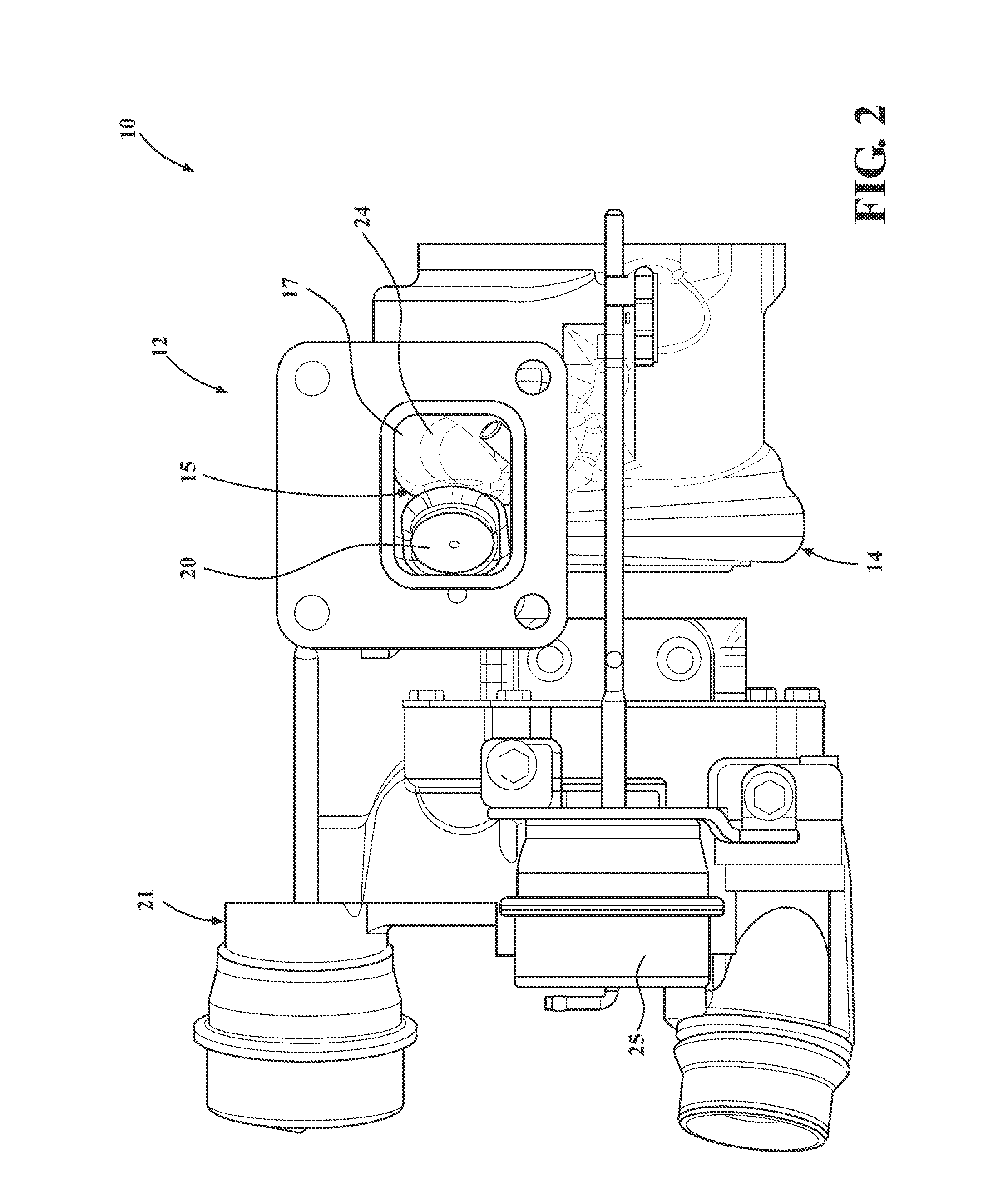

Mixed flow twin scroll turbocharger with single valve

ActiveUS20150315961A1Less costFew partsInternal combustion piston enginesEngine controllersTurbine wheelWastegate

A turbocharger (100) has an asymmetric, twin scroll volute design, having a first volute (101) and a larger second volute (102). The larger second volute (102) eliminates the need for a wastegate and its associated actuator. The smaller first volute (101) is sized for rapid transients and rated torque, while the second volute (102) is sized such that the turbine inlet pressure is satisfactory for rated power. Furthermore, the turbocharger (100) preferably incorporates a mixed flow turbine wheel (108) rather than a radial wheel, which allows for a larger wheel size to be used while still maintaining inertia. The turbine housing (103) is improved wherein the first and second volutes (101) and (102) are asymmetric with respect to each other and preferably, are leaned toward the bearing housing to match the axial component of the mixed flow turbine wheel inducer (112).

Owner:BORGWARNER INC

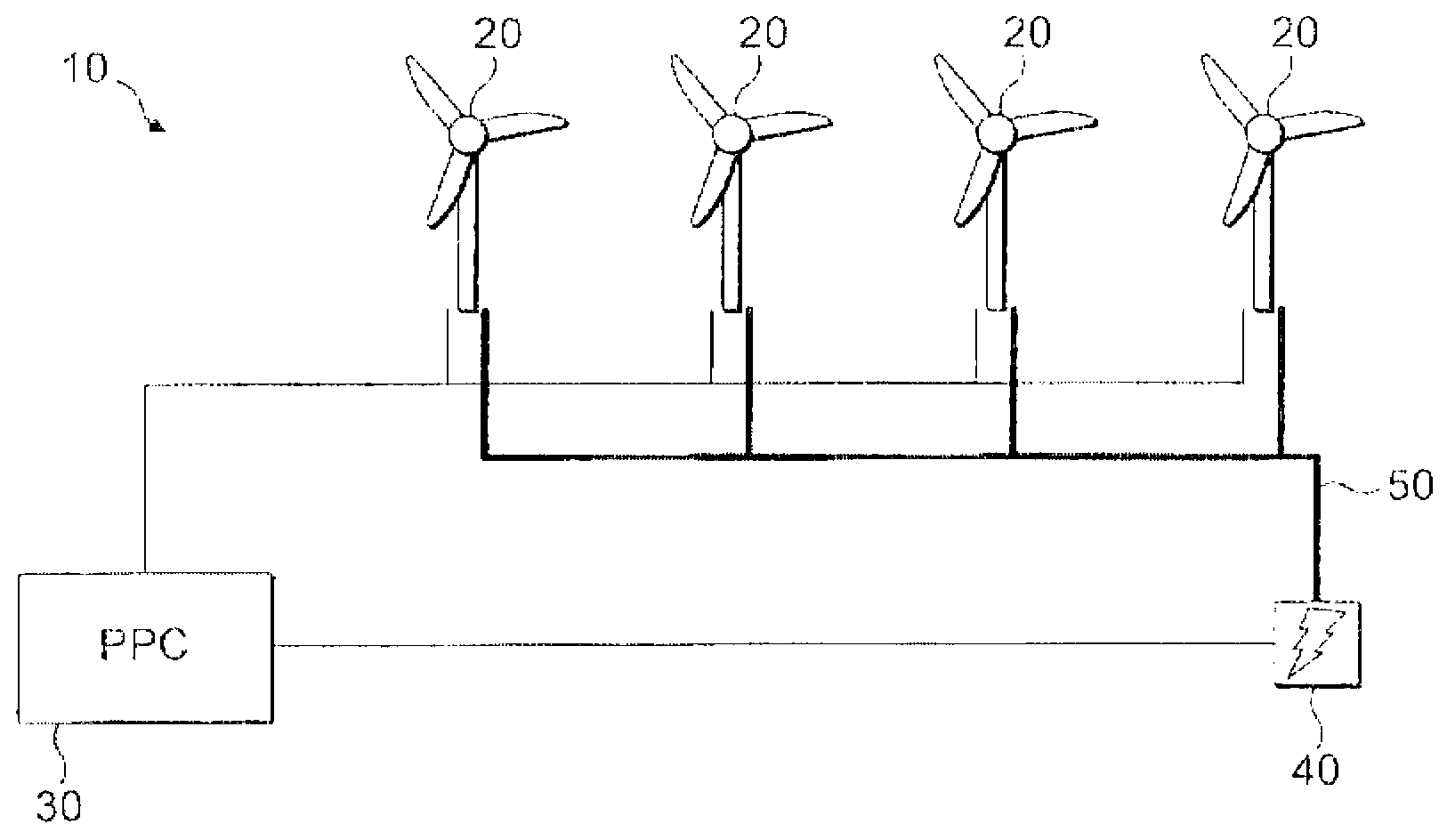

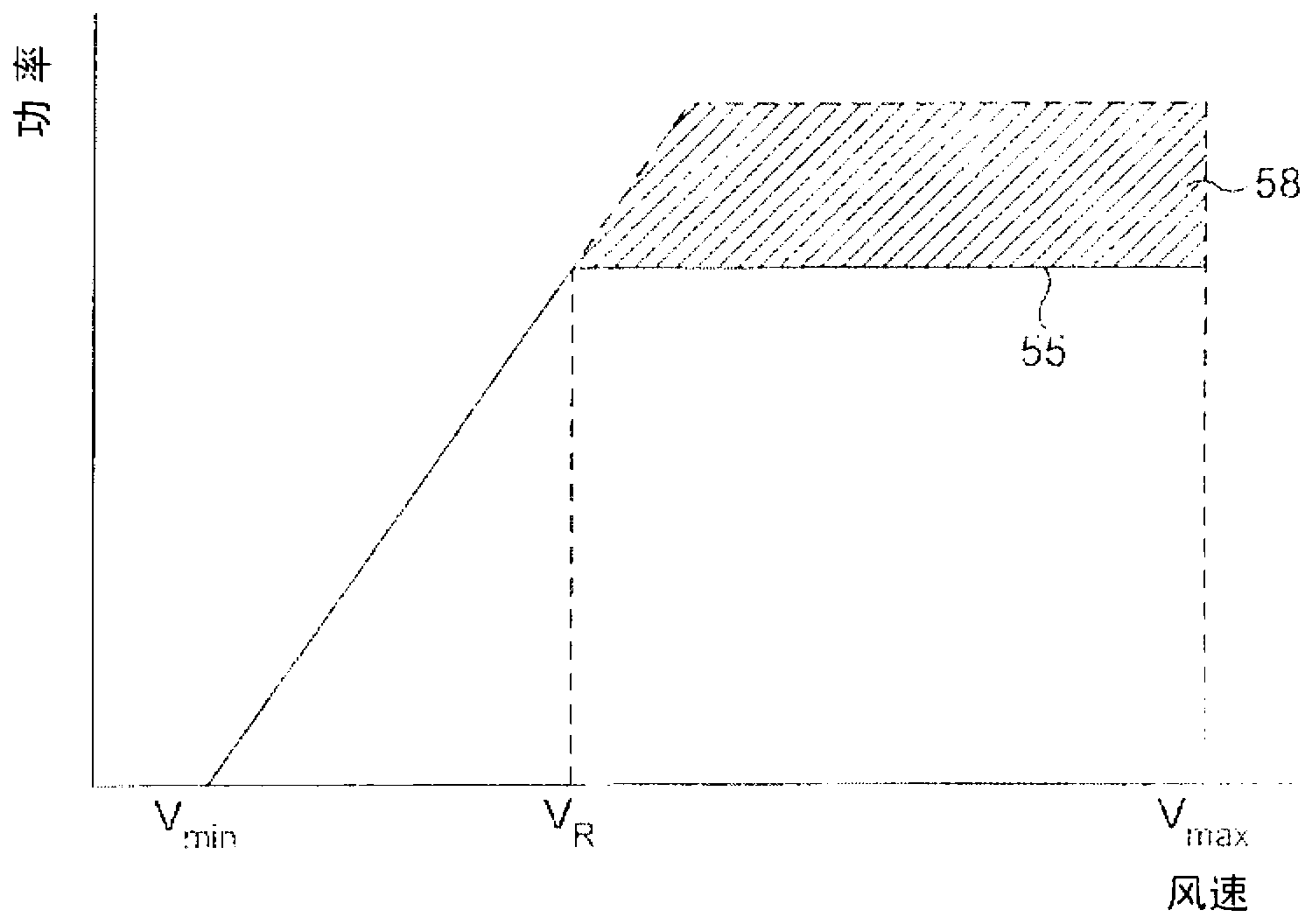

Over-rating control of wind turbines and power plants

ActiveCN103237984AHigh outputIncrease incomeWind motor controlWind motor combinationsElectricity pricingElectricity price

A wind turbine power plant comprises a plurality of wind turbines, each having a rated output and under the control of a power plant controller. The power plant also has a rated output which may be over-rated in response to one or more electricity pricing data, power plant age and operator demand. This may comprise a schedule of output set point changes which effect seasonal or intraday changes in electricity prices or which reflect aging of the power plant. It may also reflect the price of electricity on spot or futures markets. Once the over-rating of the power plant has been set, the output may be increased by over-rating individual turbines or operating turbines at rated power if the sum of the rated outputs of the turbines exceeds or is equal to the new power plant output set point.

Owner:VESTAS WIND SYST AS

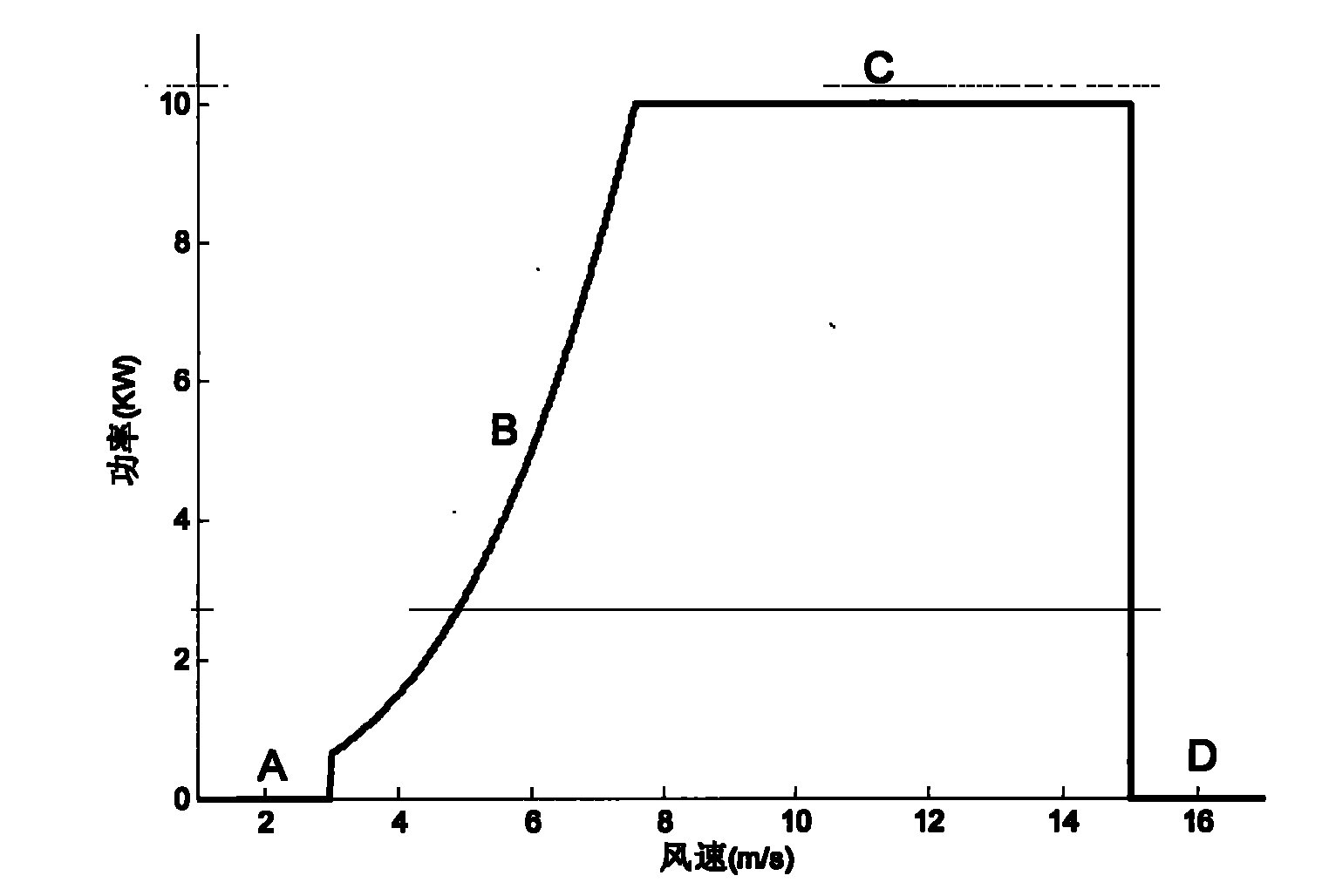

Power control method of low-rated wind speed wind driven generating system

InactiveCN101813059AGuaranteed uptimeNo flying accidentsWind motor controlMachines/enginesWind drivenEngineering

The invention discloses a power control method of a low-rated wind speed wind driven generating system, having the following four characteristics: (1) a fan is in a stop state and the output power is zero when the wind speed is lower than a cut-in wind speed; (2) the fan is in a maximum wind energy tracking state and the output power and the wind speed are in a cubic function relation when the wind speed is higher than the cut-in wind speed and lower than a rated wind speed; (3) the fan is in a limit-rated power operation state, and the generation power fluctuates below the rated power when the wind speed is higher than the rated wind speed and lower than the cut-in wind speed; and (4) the fan is in the stop state and the output power is zero when the wind speed is larger than the cut-in wind speed. The invention can realize the safe, reliable and high-efficiency operation of the low-rated wind speed wind driven generating system and avoids overspeed, overload and galloping accidents.

Owner:JIANGSU ELECTRIC POWER RES INST

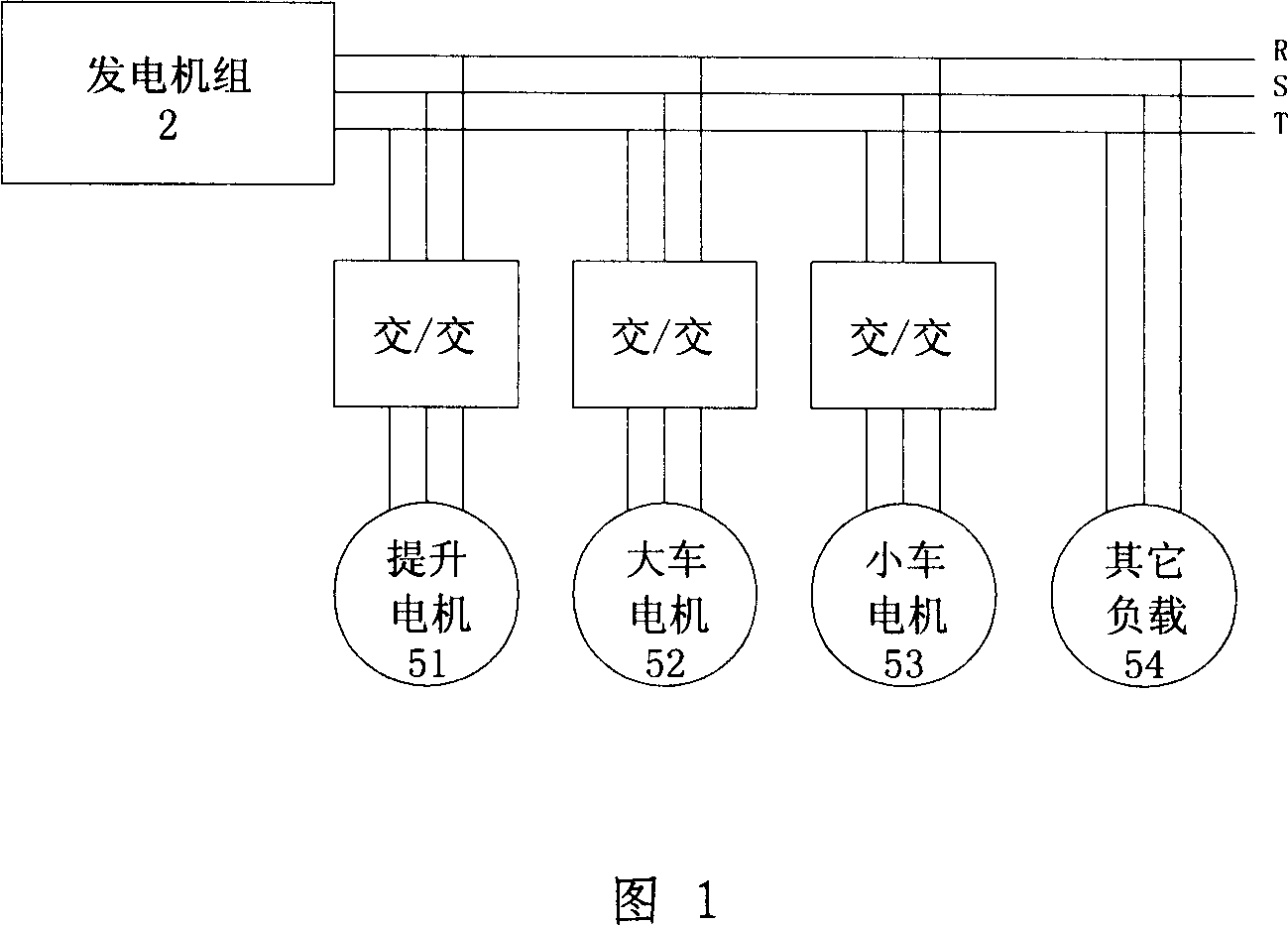

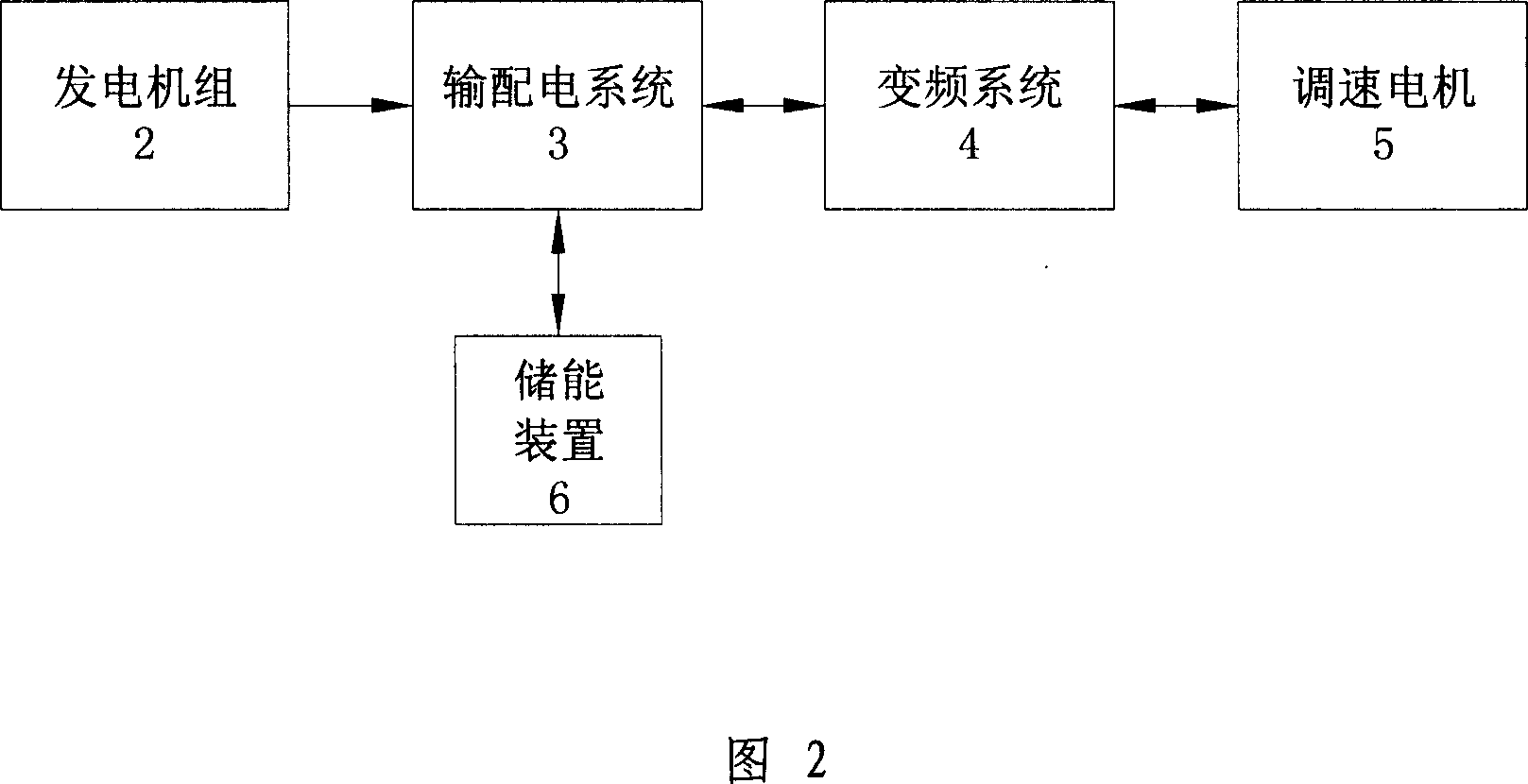

DC bus powered crane power system

InactiveCN1945963ALow running costEmission reductionElectrical storage systemMotor control for low load efficiencyFrequency conversionFlat rated

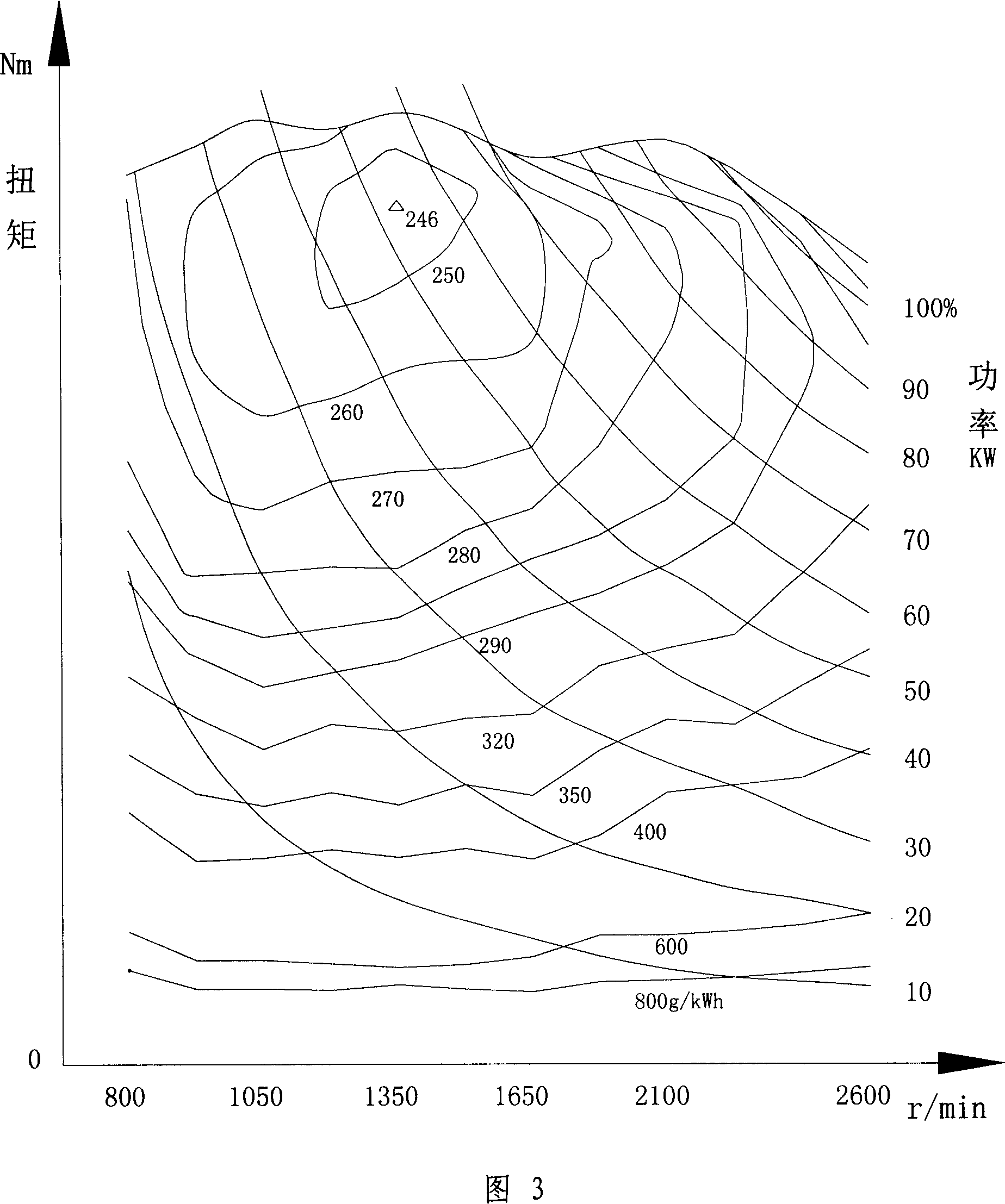

This invention discloses a hoist power system supplied by DC bus including a generator set, a supply and distribution system, a frequency conversion system and a speed regulation motor, in which, the supply and distribution system includes a large power commutation device, a DC bus and an energy management unit, the DC bus is parallel with a DC energy-storage device capable of supplying the conversion system at the same time, which includes several inverters connected on the DC bus, the speed regulation motor is a lifted motor, a jumbo motor or a trolley motor, in which, the lifted motor is converted to generator mode to store the re-generated energy source to an energy storage device when a lifted subject falls, the energy management unit controls the operation speed and generation volume of the generator set to realize real time match of output power and load power.

Owner:罗中柱

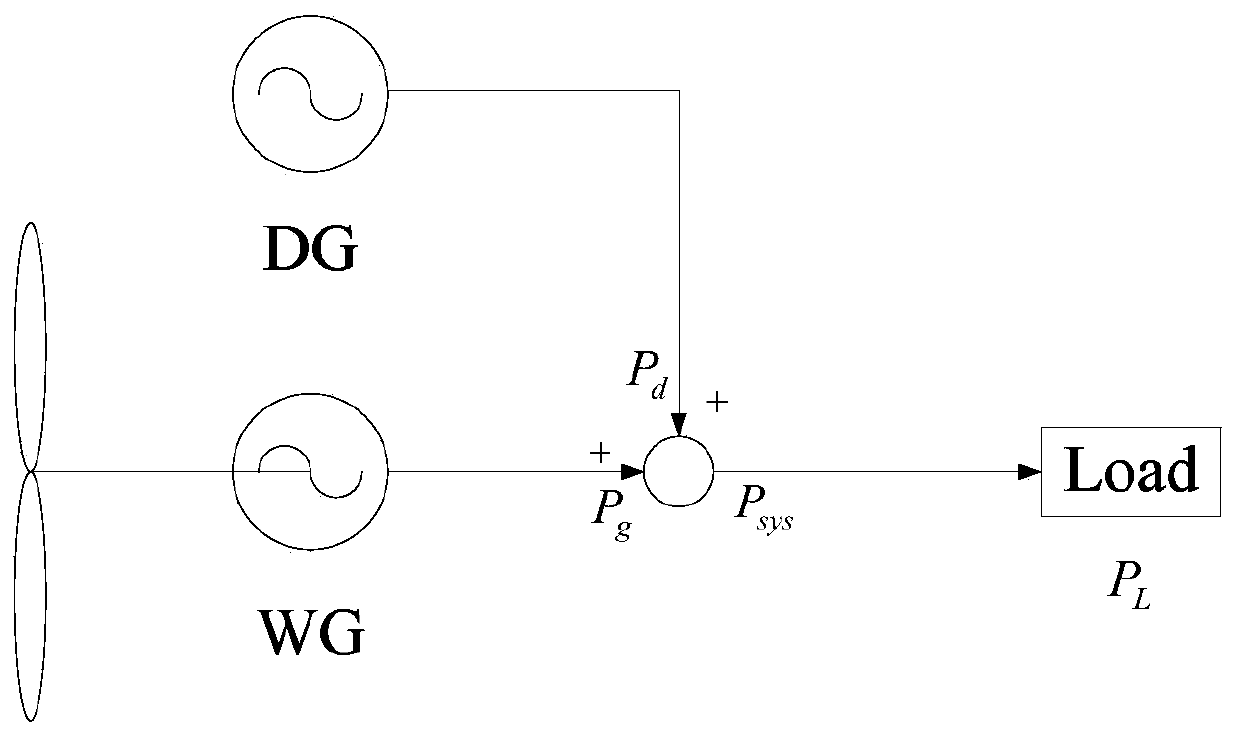

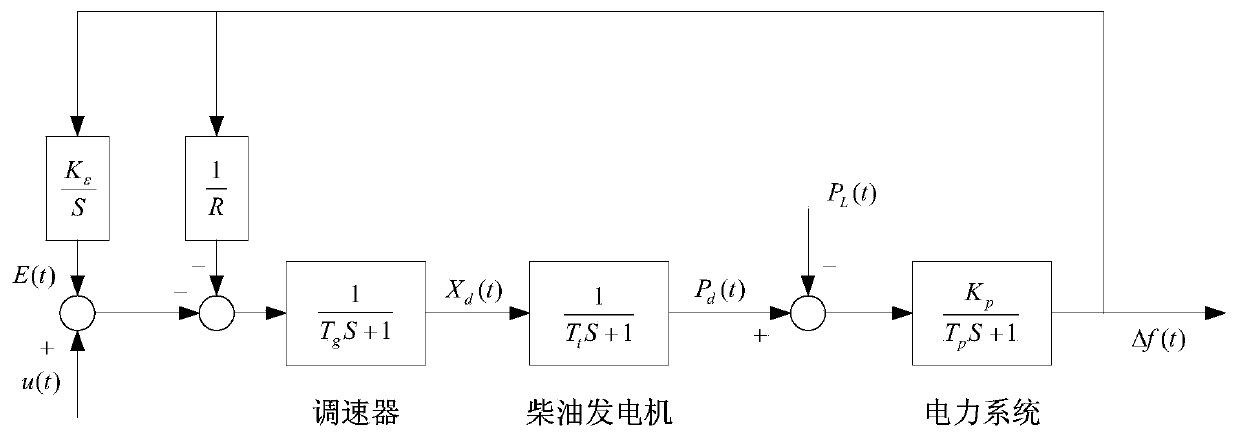

Load-frequency control method for wind-diesel hybrid electric power system mainly relying on diesel engine side

InactiveCN103595046AGood effectGood chatter suppression effectElectric generator controlAc network circuit arrangementsWind drivenElectric power system

The invention relates to a load-frequency control method for a wind-diesel hybrid electric power system mainly relying on a diesel engine side. The method comprises the following steps of (1) controlling the output power of a wind driven generator by adopting a PID variable pitch control method according to the rated power of the wind driven generator; (2) controlling the output power of a diesel engine subsystem by adopting a sliding-mode control method based on a BP neural network observer, and establishing a system state equation by using the output power of the wind driven generator in the step (1) as a measurable disturbing term in the sliding-mode control; (3) calculating control input u(t) by adopting a reaching law method, and optimizing the frequency deviation of the whole hybrid electric power system according to the control input. Compared with the prior art, the load-frequency control method for the wind-diesel hybrid electric power system mainly relying on the diesel engine side has the advantages of being high in control precision, and improving the load frequency deviation of the electrical power system effectively.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com