Method for controlling alloyed hot dip galvanizing steel plate coating phase structure and alloyed hot dip galvanizing steel plate

A hot-dip galvanized steel sheet and alloying technology, which is applied in the coating phase structure of alloyed hot-dip galvanized steel sheet, and the field of alloyed hot-dip galvanized steel sheet, can solve problems such as poor surface quality, poor formability of steel sheet, and flaky shedding of the coating. Achieve the effects of good anti-powdering performance and good stamping performance of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

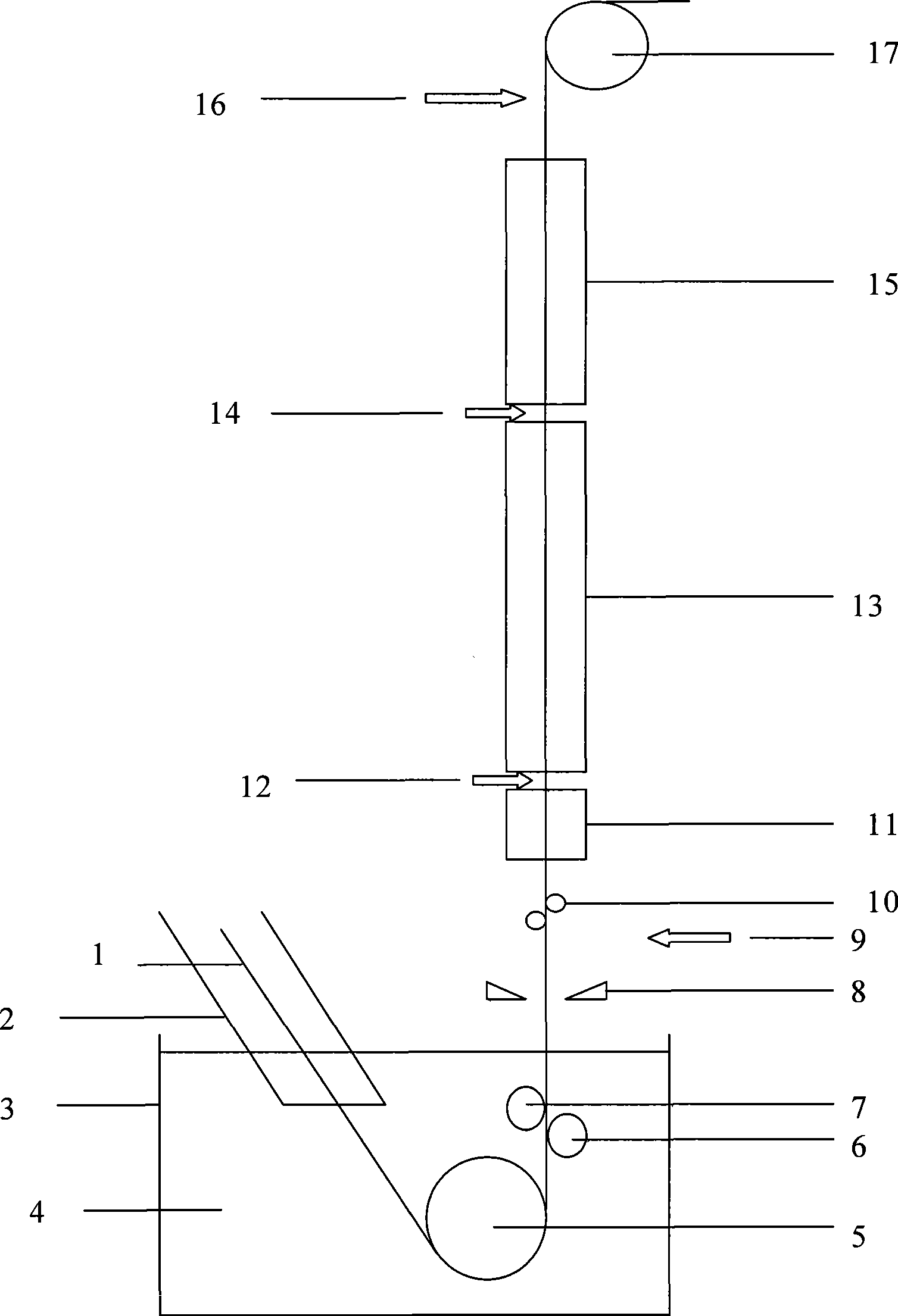

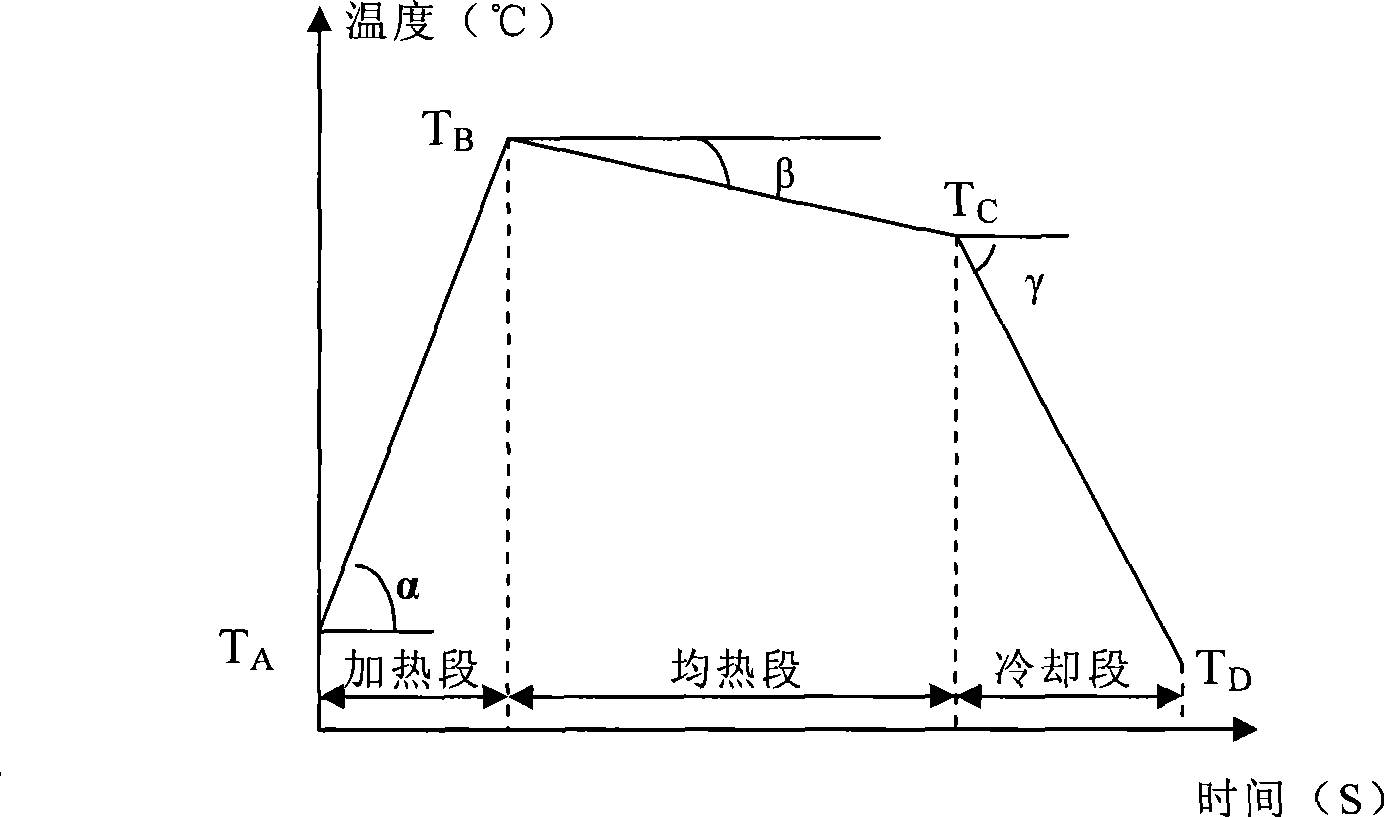

Method used

Image

Examples

example 1

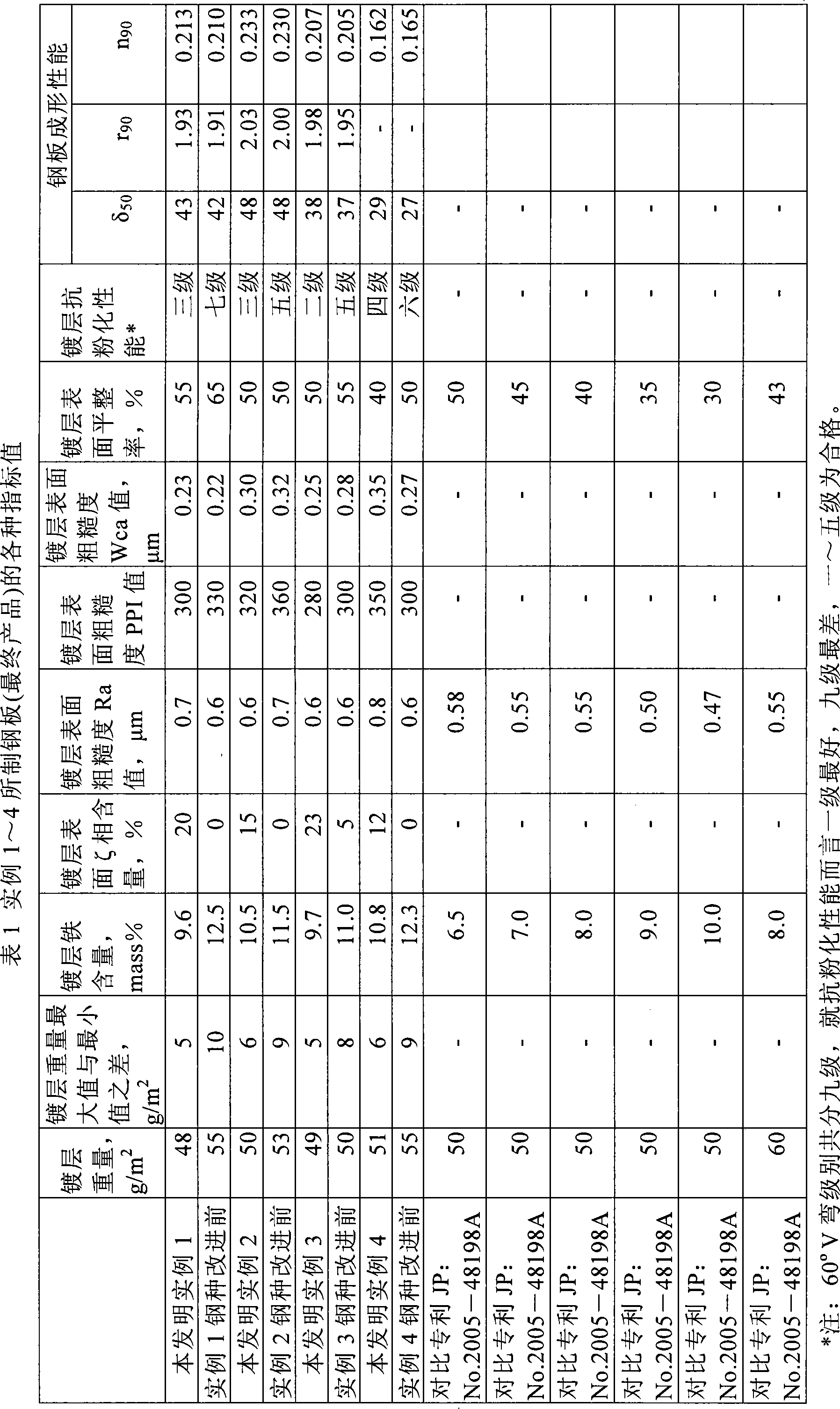

[0068] For a bake-hardened steel automotive outer panel with a thickness of 0.75mm, the chemical composition of the substrate is: C: 0.0023%; Si: 0.005%; Mn: 0.50%; P: 0.050%; S: 0.008%; N: 0.0023%; Sol. Al: 0.046%; Nb: 0.013%. After continuous casting, the slab is heated to 1200°C, held for 2 hours, and hot-rolled. The finishing temperature of hot rolling is 910°C, and the coiling temperature is 700°C. After the hot-rolled coil is naturally cooled, it is pickled and cold-rolled. The cold-rolled reduction rate is 78%, and then it is cleaned, annealed and hot-dip galvanized. The annealing temperature is 850 ° C, and the holding time is 30 seconds. The temperature is 470°C, the temperature of the zinc liquid in the zinc pot is 460°C, the aluminum content of the zinc liquid is 0.125%, and the coating weight is 48g / m after the strip steel is purged by an air knife 2 , heated to 490°C by a high-frequency induction heating furnace, and then enter the heat preservation section for h...

example 2

[0070] For the IF steel automotive inner panel with a thickness of 0.8mm, the chemical composition of the substrate is as follows: C: 0.0015%; Si: 0.003%; Mn: 0.12%; P: 0.010%; S: 0.006%; N: 0.0020% ; Sol. Al: 0.030%; Ti: 0.030%; Nb: 0.015%. After continuous casting, the slab is heated to 1210°C, held for 2 hours, and hot-rolled. The finishing temperature of hot rolling is 920°C, and the coiling temperature is 720°C. After the hot-rolled coil is naturally cooled, it is pickled and cold-rolled. The cold-rolled reduction rate is 78%, and then it is cleaned, annealed and hot-dip galvanized. The annealing temperature is 860 ° C, and the holding time is 30 seconds. The temperature is 460°C, the temperature of the zinc liquid in the zinc pot is 455°C, the aluminum content of the zinc liquid is 0.130%, and the coating weight is 50g / m after the strip is purged by an air knife 2 , heated to 460°C by a high-frequency induction heating furnace, and then enter the heat preservation secti...

example 3

[0072] For a high-strength IF steel automotive outer panel with a thickness of 0.7mm, the chemical composition of the substrate is as follows: C: 0.0015%; Si: 0.045%; Mn: 0.39%; P: 0.030%; S: 0.008%; N: 0.0016 %; Sol. Al: 0.030%; Nb: 0.023%; Ti: 0.025%; B: 0.0002%. After continuous casting, the slab is heated to 1210°C, held for 2 hours, and then hot-rolled. The finishing temperature of hot rolling is 910°C, and the coiling temperature is 670°C. After the hot-rolled coil is naturally cooled, it is pickled and cold-rolled. The cold-rolled reduction rate is 75%, and then it is cleaned, annealed and hot-dip galvanized. The annealing temperature is 790 ° C, and the holding time is 30 seconds. The temperature is 470°C, the temperature of the zinc liquid in the zinc pot is 460°C, the aluminum content of the zinc liquid is 0.125%, and the coating weight is 49g / m after the strip is purged by an air knife 2 , heated to 500°C by a high-frequency induction heating furnace, and then ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com