Patents

Literature

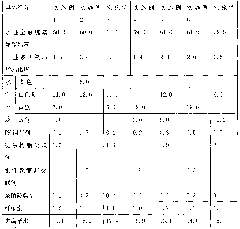

135 results about "Fluorocarbon Emulsions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-borne perfluoroalkyl fluorocarbon emulsion, water-borne cable anti-icing paint containing same and preparation method thereof

ActiveCN101798366AImprove stabilityIncrease crosslink densityAntifouling/underwater paintsPaints with biocidesCelluloseEmulsifying wax

The invention relates to a water-borne cable anti-icing paint containing water-borne perfluoroalkyl fluorocarbon emulsion, which comprises the following raw materials in percentage by weight: 58 to 62 percent of aqueous perfluoroalkyl fluorocarbon emulsion, 1.5 to 2.5 percent of water-borne polytetrafluoroethylene emulsifying wax, 15 to 20 percent of water-borne color paste, 0.1 to 0.5 percent of pH regulator, 1 to 2 percent of amino resin cross-linking agent or water-borne polyurethane cross-linking agent, 0.1 to 0.2 percent of antiseptic preservative, 1 to 1.2 percent of cellulose and the balance of deionized water, wherein the water-borne color paste is the mixture of the water-borne color paste with one color or the water-borne color paste with more than two colors. The water-borne cable anti-icing paint of the invention is big in water repellent angle, low in surface energy, excellent in water repellent and oil repellent properties, safe and environment-friendly, can firmly adhere to the surface of a cable in a low temperature and cold environment and is obvious in anti-icing function.

Owner:CHANGZHOU GUANGHUI CHEM

Self-cleaning antifouling inter wall paint

InactiveCN105131772AImprove water resistanceGood weather resistanceAntifouling/underwater paintsPaints with biocidesEmulsionFluorocarbon

The invention discloses a self-cleaning antifouling inter wall paint. The inner wall paint comprises raw materials: modified fluorocarbon emulsion, pure acrylic emulsion, light calcium carbonate, calcined kaolin, diatomite powder, forsterite powder, nano-stannic oxide, magnesium sulfate, hydroxyethyl cellulose, a dispersant SN-5040, a multifunctional auxiliary agent AMP-95, 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate, an antifoaming agent CF-16, negative ion-anti-microbial additives, sodium hexametaphosphate, a leveling agent L-150, a stain resistant agent JZM-1, glycol, mildew inhibitors, wetting agents and deionized water. The coating film of the inter wall paint is compact, and the inter wall paint is hydrophobic and oleophobic and has strong antifouling performance and self-cleaning capability. The coating effect is good and construction is convenient.

Owner:TIANCHANG YINHU PAINT

Waterborne fluorocarbon texture coating and preparation method and application thereof

InactiveCN101851450AImprove water resistancePollution resistantBuilding constructionsCoatingsLow speedWeather resistance

The invention discloses a waterborne fluorocarbon texture coating and a preparation method and application thereof. The coating comprises the following components in part by weight: 141 to 180 parts of fluorocarbon emulsion, 5 to 12 parts of film-forming aid, 5 to 6 parts of cosolvent, 80 to 100 parts of water, 1 to 2 parts of antifoaming agent, 3 to 6 parts of disinfectant, 1 to 3 parts of mildew preventive, 2 to 3 parts of pH regulator, 5 to 10 parts of thickening agent, 600 to 1,000 parts of color sand, and 0 to 89 parts of sheet. The preparation method comprises the following steps of: under the stirring at a high speed, adding the film-forming aid, the cosolvent, the antifoaming agent, the disinfectant, and the mildew preventive in turn, stirring at the high speed and reducing the stirring speed; adding the fluorocarbon emulsion, regulating the pH value, and regulating the viscosity by using the thickening agent to obtain pulp; stirring the pulp at a low speed, adding the color sand and sheet, and mixing to obtain the waterborne fluorocarbon texture coating. The waterborne fluorocarbon texture coating applied to a coated outer wall surface has good protection functions of water resistance, weather resistance, smudge resistance, and the like, and makes the wall surface have elegant, harmonious and serious aesthetic feeling.

Owner:SHANGHAI HENGFENG FLUOROCARBON MATERIAL

Ultraviolet-resistant three-proofing finishing agent

The invention relates to an ultraviolet-resistant three-proofing finishing agent and belongs to the technical field of textile auxiliaries. The ultraviolet-resistant three-proofing finishing agent comprises the following components in parts by weight: 12-16 parts of fluorocarbon emulsion, 8-12 parts of trifluoropropylmethylcyclotrisiloxane, 2-5 parts of a coupling agent, 1-3 parts of citric acid, 4-7 parts of 2-hydroxyl-4-methoxybenzophenone, 2-5 parts of bis-(2,2,6,6-tetramethyl-4-piperidyl)sebate, 3-5 parts of fat acid polyethenoxy ester and 120-150 parts of deionized water. The system of the ultraviolet-resistant three-proofing finishing agent provided by the invention is stable, and the ultraviolet-resistant three-proofing finishing agent not only has good water-proofing, oil-proofing and fouling-proofing functions, but also has a good ultraviolet-resisting function, and is easy to popularize and apply; a fabric finished by the ultraviolet-resistant three-proofing finishing agent touches better.

Owner:JIANGSU ZHONGXIN RESOURCES GRP

Special modified acrylic resin paint for building external walls

The invention discloses a special modified acrylic resin paint for building external walls, which is prepared from the following raw materials in parts by weight: 70-85 parts of acrylic resin, 15-30 parts of fluorocarbon emulsion, 20-35 parts of nano silica sol, 5-12 parts of light calcium carbonate, 3-15 parts of expanded vermiculite, 5-20 parts of meerschaum, 5-15 parts of nano titanium dioxide, 1-5 parts of kieselguhr, 5-15 parts of water, 1-3 parts of ethylene glycol, 0.5-2 parts of glycerol, 1.5-4 parts of polyethyleneglycol, 0.8-2 parts of wetting agent, 0.3-1 part of defoaming agent, 0.2-1.5 parts of 2-O-methylated-beta-cyclodextrin, 0.1-1 part of 2,3,6-trimethoxy-beta-cyclodextrin, 0.2-0.6 part of surfactant, 0.5-2 parts of composite thickener and 0.3-2 parts of film forming assistant. The special modified acrylic resin paint for building external walls has the advantages of high strength, excellent aging resistance, excellent water resistance and excellent heat-insulating property.

Owner:安徽嘉年华漆业有限公司

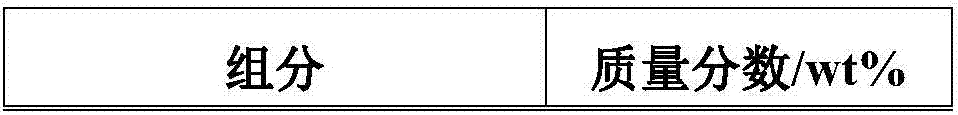

Waterborne PVDF (polyvinylidene fluoride) fluorocarbon coating and coating method thereof

InactiveCN107151493ALiquid surface applicatorsAntifouling/underwater paintsEmulsionPolyvinylidene difluoride

Waterborne PVDF (polyvinylidene fluoride) fluorocarbon coating comprises waterborne PVDF fluorocarbon coating primer (I), waterborne PVDF fluorocarbon coating finish (II), waterborne PVDF fluorocarbon coating metallic glossy paint (III), and waterborne PVDF fluorocarbon coating varnish (IV), wherein one or any of the waterborne PVDF fluorocarbon coating primer (I), the waterborne PVDF fluorocarbon coating finish (II), the waterborne PVDF fluorocarbon coating metallic glossy paint (III) and the waterborne PVDF fluorocarbon coating varnish (IV) are applied in sequence and comprise, by weight 10-75% of PVDF fluorocarbon emulsion, 25-50% of acrylic emulsion, 5-15% of a film-forming aid, 10-30% of a pigment, 15-30% of a filler, 1-3% of an aid, 0.1-0.5% of an antibacterial mildew preventive, 0.5-3% of a thickener, and the balance of water.

Owner:叶镜枝

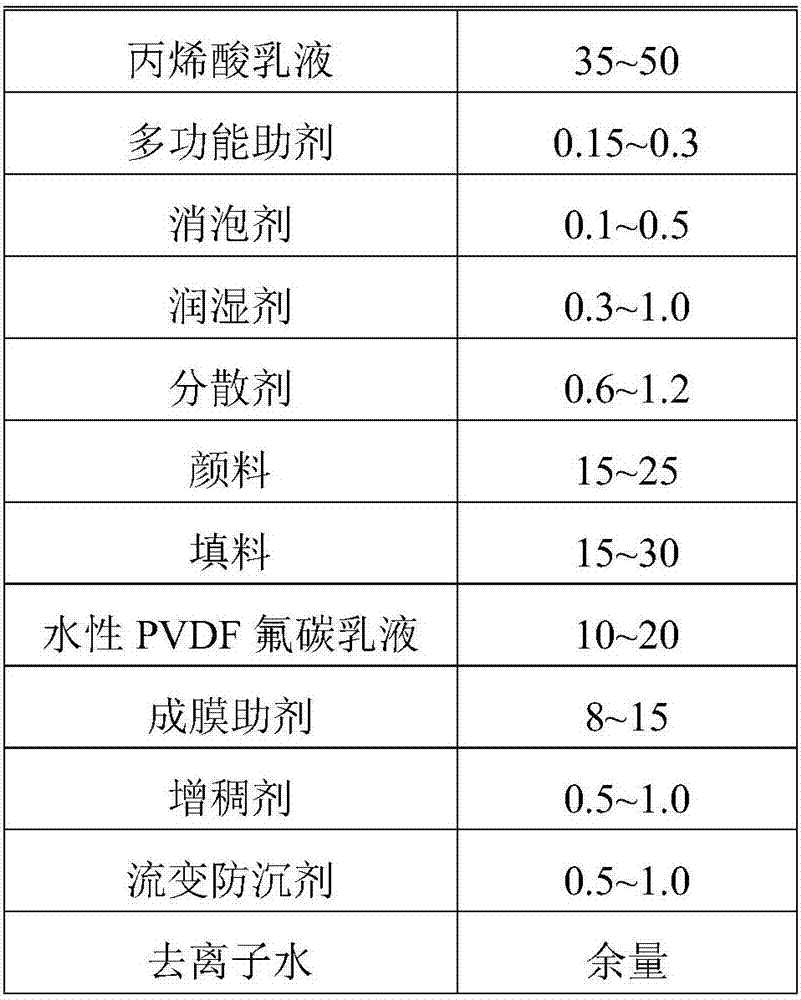

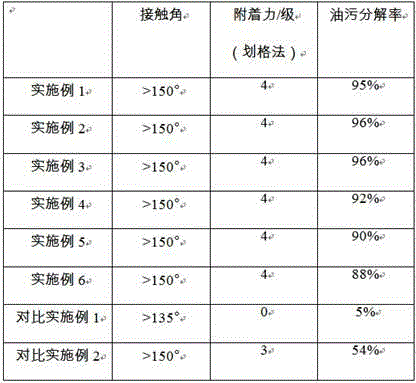

Ultra-durable self-cleaning reflective insulation simulation coating technical field

ActiveCN103059663AImprove blockageIncrease reflectionReflecting/signal paintsFluorocarbon EmulsionsChlorophyllin

The present invention discloses an ultra-durable self-cleaning reflective insulation simulation coating. The ultra-durable self-cleaning reflective insulation simulation coating includes the following components: water, an antifreeze, a thickener, a wetting agent, a dispersing agent, an antifoaming agent, a multifunctional additive, a pH adjusting agent, a bactericide, rutile titanium dioxide, an environmentally-friendly colored mixed-phase inorganic pigment, a coalescing agent, a dry film fungicide, a self-cleaning additive, a modified fluorocarbon emulsion, a covering hollow micro-emulsion, high-strength hollow glass beads, and hollow ceramic micro powder. The environmentally-friendly colored mixed-phase inorganic pigment adopted in the coating has excellent durability, excellent infrared-reflection function, and excellent insulation and cooling, and environmental protection and energy saving effect; additionally, the pigment also has a function of simulating chlorophyll, so the coating can be used for simulation in national defense and military fields; and the coating of the present invention has excellent resistance to staining, yellowing, alkali, acid rain, and salt spray, and ultra-long weather resistance, ultra-long durability and self-cleaning function.

Owner:江阴市天邦涂料股份有限公司

Aqueous anticorrosive conductive coating containing conductive polymer and preparation method thereof

ActiveCN102070960AImprove conductivityImprove anti-corrosion performanceElectrically-conductive paintsPolypyrroleConductive polymer

The invention discloses an aqueous anticorrosive conductive coating containing conductive polymer and a preparation method of the aqueous anticorrosive conductive coating. The aqueous anticorrosive conductive coating contains the following components in percentage by mass: 30%-60% of fluorocarbon emulsion, 8%-20% of polymer conductive powder, 5%-20% of conductive mica powder, 20%-40% of deionizedwater and 2%-5% of film-forming adjuvant, wherein the polymer conductive powder is one of polyaniline / attapulgite nano conductive composite material and polypyrrole / attapulgite nano conductive composite material. The preparation method is as follows: firstly, successively adding the deionized water, 0.5%-1.5% of wetting dispersing agent and the polymer conductive powder in a sand mill to grind for 0.5-2 hours; and transferring the ground mixture to an ultrasound dispersing mixer, successively adding the fluorocarbon emulsion, the conductive mica powder, the film-forming adjuvant and 0.5%-1.5%of defoamer, carrying out ultrasonic dispersion for 0.5-2 hours while stirring, and then obtaining the aqueous anticorrosive conductive coating. By using the preparation method, the mechanical property, conductivity and anticorrosion performance of the coating are obviously improved.

Owner:溧阳常大技术转移中心有限公司

Water-thinned Normal temperature hardening fluorosilicious paint with metal texture

InactiveCN1364838AExcellent super weather resistanceStrong pollution resistanceCoatingsFiberboardChemical stability

The water-thinned normal temperature hardening fluorosilicious paint with metal texture is mainly used in painting inner and outer wall in building and may be used in painting concrete, gypsum board, lignocellulose board and metal in order fields. It consists of water-thinned fluorocarbon emulsion, self-crosslinked organosilicon modified acrylic acid emulsion and acrylic acid emulsion as filming and adhering material, and pigments as supplementary material to produce metal texture. The water-thinned resin combination of the present invention has excellent weather resistance, strong pollution resistance, high air permeability, VOC value near zero and other advantages. The nano transparent ferric oxide system pigment and mica pigment combinatino produces metal texture and rich color.

Owner:张人韬

Energy-saving type building outer wall coating

InactiveCN104946058APlay the role of waterproof and oil-proofReduce manufacturing costAntifouling/underwater paintsPaints with biocidesWeather resistanceFluorocarbon Emulsions

The invention belongs to an energy-saving type building outer wall coating and a preparation method thereof, and relates to the field of coating production. The prepared coating comprises 40-60 parts of polymer emulsion, 10-30 parts of titanium dioxide nano powder, 10-30 parts of padding, one to five parts of coalescing agents, one to five parts of hydrophobic promoters, five to 15 parts of solvents, 0.2-0.8 part of dispersing agents, 0.1-0.2 part of antifoaming agents, 0.1-0.2 part of wetting agents, six to nine parts of putty and 10-20 parts of water. The polymer emulsion is a mixture of fluorocarbon emulsion and organosilicone modified acrylic emulsion. After the hydrophobic promoters, the padding and the solvents are mixed and react, suspension liquid is removed through filter to obtain the modified padding, after the modified padding, the polymer emulsion, the titanium dioxide nano powder, the dispersing agents, the antifoaming agents, the wetting agents and the water are evenly mixed according to the proportion, polymer powder, the putty and modified floating beads are added to be stirred evenly, and the energy-saving type building outer wall coating is prepared. Waterproofness and soiling resistance of the produced coating can be improved, the weather fastness and heat insulation property of the coating are improved, and energy saving and environmental protection are achieved.

Owner:ANJI QILONG NEW BUILDING MATERIAL

Sterilization and heat-insulation coating for textiles and preparation method thereof

The invention relates to a sterilization and heat-insulation coating for textiles and a preparation method thereof, and belongs to the technical field of coatings. The coating comprises the following components in parts by weight: 60-80 parts of water-based acrylic resin, 10-16 parts of fluorocarbon emulsion, 5-10 parts of nano titanium dioxide, 5-20 parts of pigment, 5-10 parts of polytetrafluoroethylene, 1-2 parts of lavender ethereal oil, 2-5 parts of texanol, 1-3 parts of a mould inhibitor, 2-4 parts of a dispersing agent, 1-3 parts of a foam killer and 180-200 parts of water. The preparation process is simple. The prepared coating is good in flexibility, has high adhesive attraction for the fabrics, and can be directly applied to various textiles. Meanwhile, the coating provided by the invention is diversified in function, not only has a good thermal insulation effect, but also has excellent sterilization and mold prevention efficacies. Besides, the coating taking water as a solvent is safe and environment-friendly.

Owner:JIANGSU ZHONGXIN RESOURCES GRP

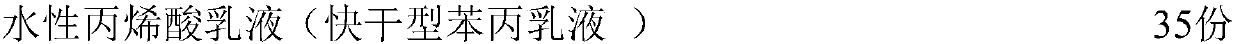

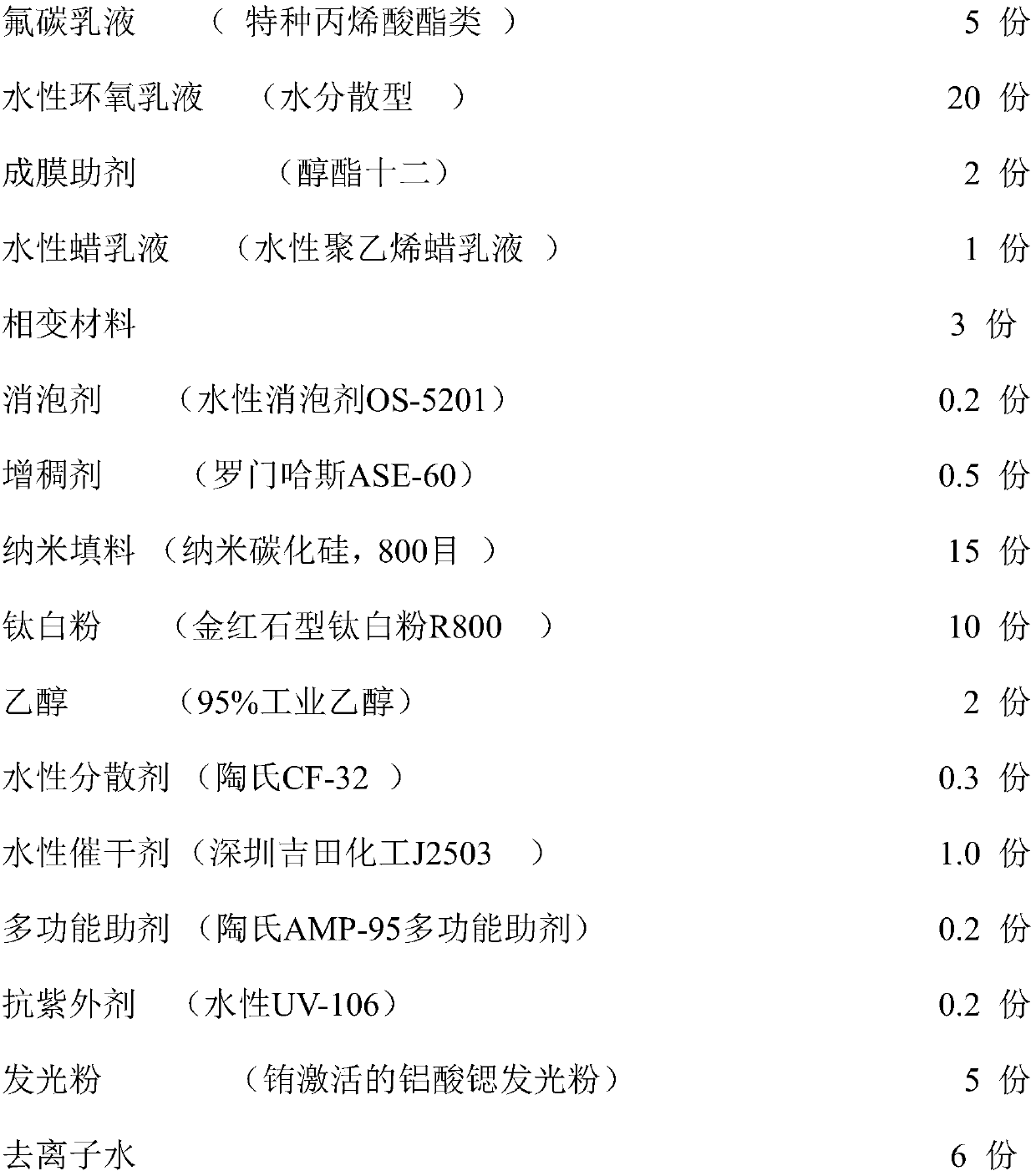

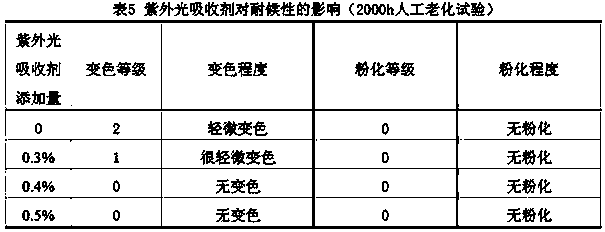

Water-based self-luminous marking coating and preparing method thereof

InactiveCN109651898AAlkali resistantGood weather resistanceAntifouling/underwater paintsLuminescent paintsEpoxyWater based

The invention relates to the technical field of chemical coatings, and particularly discloses a water-based self-luminous marking coating and a preparing method thereof. The water-based self-luminousmarking coating is prepared from 35-50 parts of water-based acrylic emulsion, 5-10 parts of fluorine-carbon emulsion, 10-20 parts of water-based epoxy emulsion, 1-3 parts of a film-forming auxiliary,1-3 parts of water-based wax emulsion, 3-7 parts of a phase-change material, 10-20 parts of a nanofiller, 10-20 parts of titanium dioxide, 1-3 parts of ethyl alcohol, 0.1-0.5 part of a water-based dispersing agent, 5-10 parts of luminescent powder and 4-6 parts of deionized water. By means of the water-based self-luminous marking coating, the quick dryness, weather resistance, abrasion resistance,fouling resistance, adhesion, crack resistance and other advantages of the water-based marking coating are improved, the marking identification degree at night is improved, and traffic driving safetyis ensured.

Owner:SUZHOU TOPOLINE TECH

Concrete outer wall protective agent and preparation method thereof

ActiveCN103805054AImprove the protective effectReduce adsorptionPolyurea/polyurethane coatingsPolymer scienceFluorocarbon Emulsions

The invention discloses a concrete outer wall protective agent and a preparation method thereof. The concrete outer wall protective agent comprises the following components in percentage by weight: 22-28% of deionized water, 25-45% of acrylic acid polyurethane emulsion, 20-40% of fluorocarbon emulsion, 0.1-0.2% of a wetting agent, 0.2-0.3% of a defoaming agent, 0.1-0.2% of preservatives, 4-7% of propylene glycol monoethyl ether, 0.3-0.5% of a thickener, and 0.3-0.5% of benzophenone sulfonic acid derivatives, wherein the fluorocarbon emulsion is prepared from chlorotrifluoroethylene and ethoxyethylene through emulsion; the propylene glycol monoethyl ether is used as a film forming aid; the benzophenone sulfonic acid derivatives are used as ultrasonic absorbent. The protective property of the protective agent can be improved by taking acrylic acid polyurethane emulsion and fluorocarbon emulsion as film forming aids and matching with multiple functional auxiliaries, and the protective agent is prominent in antifouling property and weather-resistant and aging-resistant. The invention further provides a preparation method for the concrete outer wall protective agent.

Owner:BEIJING MUNICIPAL ENG RES INST +2

Building external wall coating

InactiveCN104927504APlay the role of waterproof and oil-proofReduce manufacturing costAntifouling/underwater paintsPaints with biocidesPolymer scienceWeather resistance

The invention belongs to a building external wall coating and a preparing method thereof and relates to the field of coating production. The coating prepared through the method comprises 40-60 parts of polymer emulsion, 10-30 parts of titania nanonpowder, 10-30 parts of fillers, 1-5 parts of film formation auxiliaries, 1-5 parts of hydrophobic auxiliaries, 5-15 parts of solvents, 0.2-0.8 part of dispersing agents, 0.1-0.2 part of antifoaming agents, 0.1-0.2 part of wetting agents, 6-9 parts of putty and 10-20 parts of water. The polymer emulsion is a mixture of fluorocarbon emulsion and organosilicone modified acrylic emulsion. After the hydrophobic auxiliaries, the fillers and the solvents are mixed and react with one another, the mixture is filtered to remove suspension liquid so as to obtain modified fillers; then after the modified fillers, the polymer emulsion, the titania nanonpowder, the dispersing agents, the antifoaming agents, the wetting agents and the water are evenly mixed according to proportion, the putty and modified drift beads are added into the mixture to be evenly stirred, and the building external wall coating is obtained. The building external wall produced through the method can improve the waterproof and stain-resisting performance of the coating and the weather resistance of the coating.

Owner:ANJI QILONG NEW BUILDING MATERIAL

Environment-friendly type modified fluorocarbon exterior wall coating and preparation method thereof

InactiveCN104987786AOil resistantHigh temperature resistantConjugated diene hydrocarbon coatingsPolyurea/polyurethane coatingsWater basedPerfluorocarbon emulsion

The invention relates to an environment-friendly type modified fluorocarbon exterior wall coating and a preparation method thereof. The environment-friendly type modified fluorocarbon exterior wall coating comprises perfluorocarbon emulsion, a dispersing agent, a coalescing agent, a flatting agent, a thickening agent, bactericide, an antifoaming agent, a PH modifier, a coupling agent, deionized water and the like. The environment-friendly type modified fluorocarbon exterior wall coating has the advantages of being high in activity, good in stability, non-toxic, environmentally friendly, low in price and the like. The environment-friendly type modified fluorocarbon exterior wall coating is superior to a water-based fluorocarbon coating in the aspects of water resistance, alkali resistance, rubbing resistance, artificial aging resistance, high temperature resistance, oil resistance and other common performance. The environment-friendly type modified fluorocarbon exterior wall coating is suitable for building coating.

Owner:CHANGZHOU NUOJIN PRECISION MACHINERY

Sintered water-permeable ground tile with rare earth tailings added

InactiveCN105330327ASolve intractableHigh porositySolid waste managementCeramicwareWater basedSludge

The invention discloses a sintered water-permeable ground tile with rare earth tailings added. The ground tile is prepared from, by weight, 40-43 parts of sludge from a sewage plant, 6-7 parts of rice husks, 4-5 parts of potassium feldspar powder, 10-12 parts of coal ash, 10-12 parts of water glass, 30-33 parts of rare earth secondary tailings, 13-15 parts of black talc, 13-14 parts of river sand, 2-3 parts of sodium carbonate, 4-5 parts of water-based fluorine-carbon emulsion, 2-3 parts of pulp mill waste liquid and 5-7 parts of kaolin. According to the sintered water-permeable ground tile, the rare earth secondary tailings are adopted, aggregate such as the kaolin and the river sand and caking elements such as the water glass are further combined for preparing a tile body high in strength, elements such as the sodium carbonate and the pulp mill waste liquid are further added, through sintering, the tile body is made to be more compact, the strength is further improved, meanwhile, communicated pores can be generated, the good water permeation efficacy is achieved, by means of the ground tile, recycling of waste resources can be achieved, energy is saved, environmental protection is achieved, cost is low, and the process is convenient to control industrially.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

Granite imitating coating material and preparation method thereof

InactiveCN103333564AReduce free formaldehydeSmall smellCoatingsFluorocarbon EmulsionsOrganic compound

The invention relates to an environmental protection type granite imitating coating material developed by using a surface treated silicate gel and an aqueous fluorocarbon emulsion and provided for surface decorations of indoor and outdoor wall surfaces, ceilings, gypsum boards, handicraft products and the like, wherein a decoration effect of the granite imitating coating material is the same as a decoration effect of granite, and the environmental protection type granite imitating coating material has characteristics of low odor, low volatility organic compound, and low formaldehyde. The preparation process comprises: preparing a base paint, preparing a pigment, adding the base paint to the pigment, adjusting the paint, sequentially adding a gel, a film forming additive, an antifoaming agent, colored particles, a preservative, an anti-freezing agent, a silicone-acrylate emulsion, and a thickening agent at a low speed, and packaging after passing qualified inspection to obtain the environmental protection type granite imitating coating material.

Owner:NANAN DONGBAO NEW BUILDING MATERIALS

High-performance water-based fluorocarbon paint

ActiveCN103788783AImprove adhesionImprove antifouling performanceCoatingsPolymer scienceActive agent

The invention discloses high-performance water-based fluorocarbon paint which comprises the following components in percentage by mass based on 100% in total: 50-80% of water-based fluorocarbon emulsion, 0.1-0.4% of siloxane crosslinking agent, 0.01-0.1% of surfactant, 0.2-0.5% of antifoaming agent, 0.2-0.5% of preservative, 2.0-4.0% of ethylene glycol, 2.0-5.5% of film forming aid, 0.05-0.3% of multifunctional auxiliary, 7.5-30% of titanium dioxide and the balance of water. According to the high-performance water-based fluorocarbon paint disclosed by the invention, through the improvement of the water-based fluorocarbon emulsion and in combination with the siloxane crosslinking agent and other related auxiliaries, the adhesion of the water-based fluorocarbon paint can be effectively improved; the improved fluorocarbon emulsion and the selected fluorine surfactant SURFLONS-386 promote each other; in combination with other related auxiliaries, the antifouling capacity of the water-based fluorocarbon paint can be effectively improved; by adopting the improved fluorocarbon emulsion, siloxane and fluorine surfactant SURFLONS-386 as main functional materials and in combination with the effects of the auxiliaries such as antifoaming agent, a preservative, ethylene glycol, a film forming aid, a multifunctional aid, titanium dioxide, water and the like, the prepared water-based fluorocarbon paint has the advantages of water and alkali resistance, strong solvent resistance, mildew and moisture prevention, high adhesion and good antifouling capacity.

Owner:广东黑马新材料科技有限公司

Waterproof and moisture permeable coating

ActiveCN105419510AReduce adhesionImprove adhesionAntifouling/underwater paintsPaints with biocidesSodium polyacrylateFluorocarbon Emulsions

The invention provides a waterproof and moisture permeable coating. The coating comprises a bottom layer coating and a surface layer coating, wherein the bottom layer coating comprises a component A and a component B. The component A is prepared from the following raw material components: ethylene-vinyl acetate copolymer emulsion, reactive polysiloxane, waterborne polyurethane, sodium polyacrylate, hydroxyethylmethylcellulose, silica sol, an antifoaming agent and a sterilizing agent. The component B of the bottom layer coating is an isocyanate curing agent. The surface layer coating is prepared from the following components: water-based fluorine carbon emulsion, packing, waterborne polyurethane, an antifoaming agent and a dispersing agent. The coating provided by the invention can block liquid water and moisture can penetrates through the coating.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL

Self-cleaning aqueous fluorocarbon building coating and preparation method thereof

InactiveCN109294352AGood effectGood optical performanceAntifouling/underwater paintsPaints with biocidesWater basedAdhesive

The invention provides a self-cleaning aqueous fluorocarbon building coating and a preparation method thereof. The method comprises the following steps: a nano silica water adhesive solution, a silanecoupling agent, alcohol, a surfactant, and aluminum hydroxide colloid are mixed to prepare a nano silica emulsion A, hydroxyethyl cellulose is dissolved in water to prepare a solution B. a wetting dispersing agent and the emulsion A are mixed to prepare a solution C, the solution B, the solution C, an inorganic pigment and water are mixed, and a mixture is added to the inorganic filler to prepare a slurry D, and the slurry D is uniformly mixed with the wetting dispersing agent, a defoaming agent, a bactericide, a water-based fluorocarbon emulsion, a film-forming auxiliary agent, a thickenerand water to obtain the self-cleaning aqueous fluorocarbon building coating. The method is characterized in that the hydrophobic particles are dispersed in water by coating with a surfactant, and combined with the aqueous fluorocarbon coating, so that the optical properties, anti-aging properties and washing performance of the fluorocarbon coating are greatly improved, the hydrophilicity is good,and the self-cleaning performance is excellent.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

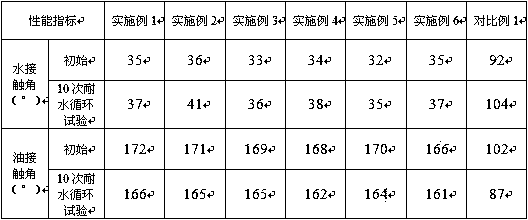

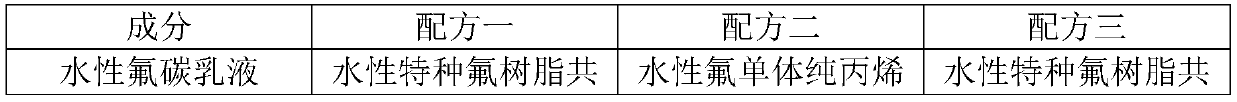

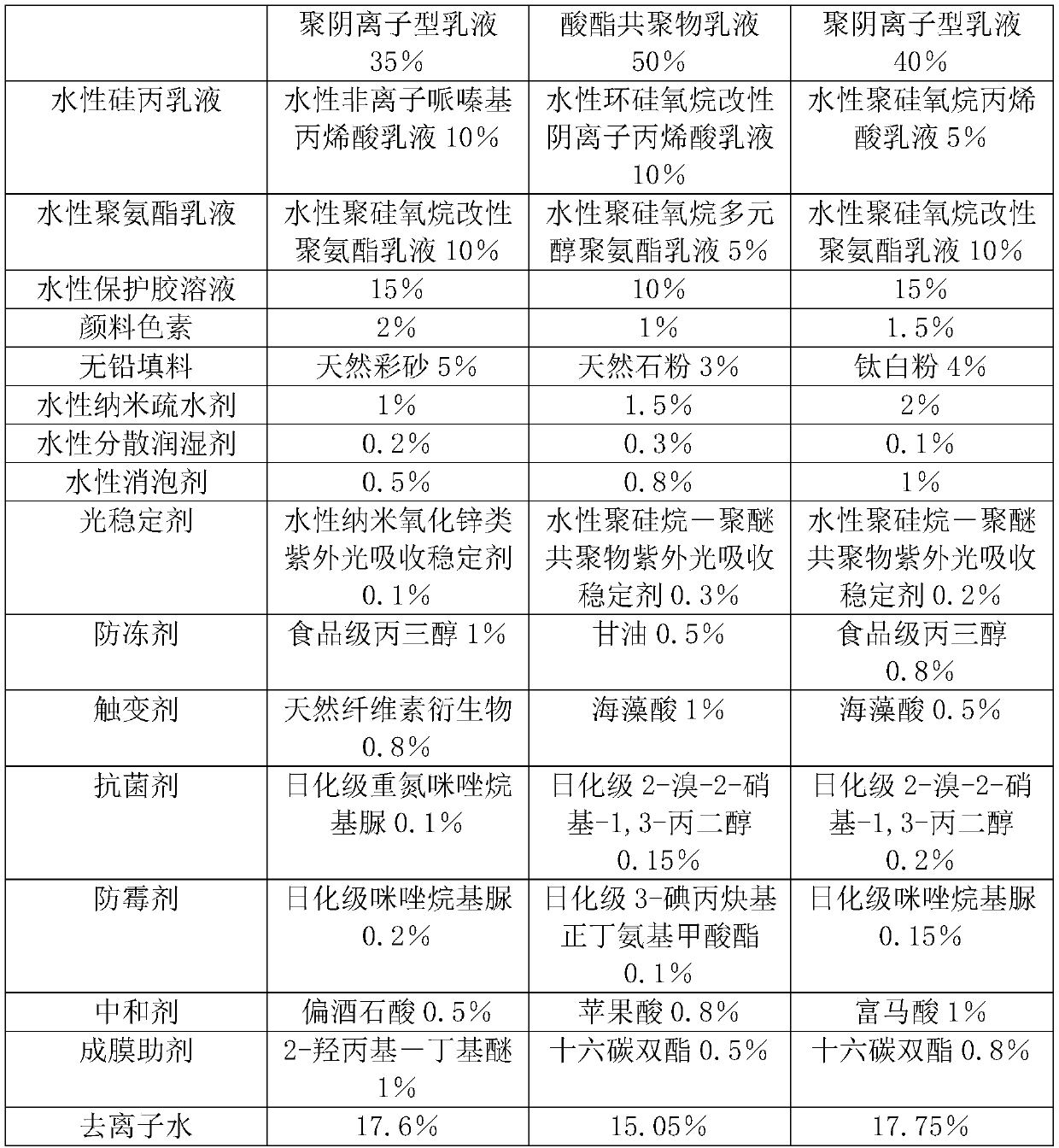

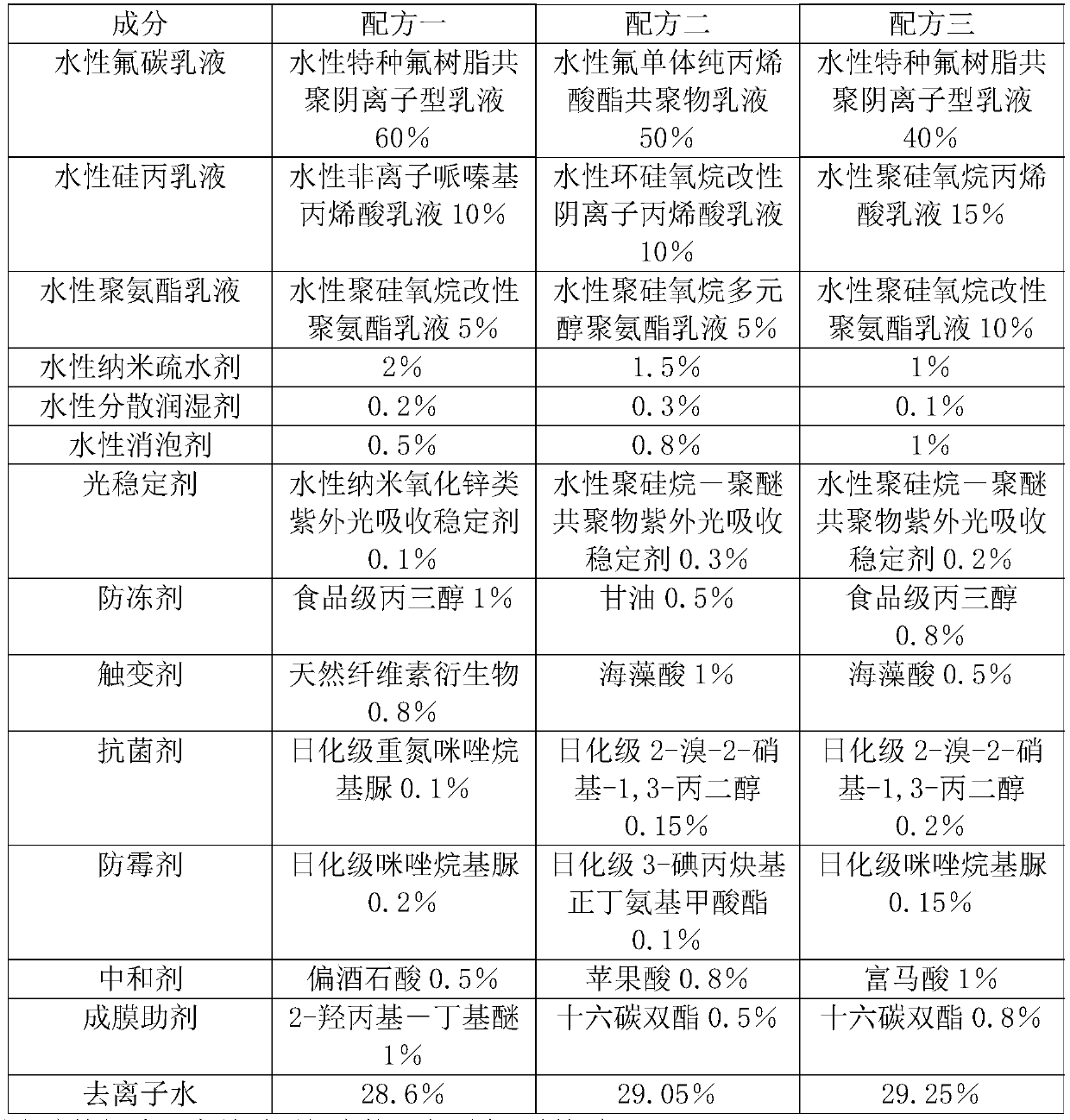

Long-acting high-weather-resistant self-cleaning aqueous multicolor coating material and preparation method thereof

InactiveCN110698930AImprove performanceExcellent long-lasting protection with excellent performanceAntifouling/underwater paintsPaints with biocidesPolymer scienceWeather resistance

The invention discloses a long-acting high-weather-resistant self-cleaning aqueous multicolor coating material, which comprises a component A and a component B, wherein the component A comprises: 35-50% of aqueous fluorocarbon emulsion, 5-10%of aqueous silicone acrylic emulsion, 5-10% of aqueous polyurethane emulsion, 10-15% of an aqueous protection glue solution, 1-2% of a pigment, 3-5% of a lead-free filler, 1-2% of an aqueous nanometer hydrophobic agent, 0.1-0.3% of a light stabilizer, 0.5-1% of an anti-freezing agent, 0.5-1% of a thixotropic agent, 15-20% of deionized water and other aqueous auxiliary agents, and the component B comprises: 40-60% of aqueous fluorocarbon emulsion, 10-15% of aqueous silicone acrylic emulsion, 5-10% of aqueous polyurethane emulsion, 1-3% of an aqueous nanometer hydrophobic agent, 0.1-0.3% of a light stabilizer, 0.2-0.5% of an anti-freezing agent, 0.2-0.5% of a thixotropic agent, 25-35% of deionized water and other aqueous auxiliary agents. The prepared coating material of the invention is good in weather resistance and excellent in self-cleaning property.

Owner:石家庄市油漆厂

Cationic fluorine-containing emulsion and preparation method therefor

The present invention discloses a preparation method for cationic fluorine-containing emulsion, and belongs to the technical field of fine chemical preparation. Fluoropolymer emulsion containing a sulfonic acid group consists of the following raw materials: fluorine-containing acrylate, butyl acrylate, styrene, acrylic acid, dimethylaminoethyl methacrylate or methacryloyloxyethyl trimethyl ammonium chloride, an emulsifier, an initiator and water. The preparation comprises: carrying out high speed shearing on all types of the raw materials (wherein 70% of the water is added, and the remaining 30% of the water is kept for later use) for 30 minutes, taking the remaining 30% of water and 5% of the pre-emulsion after obtaining pre-emulsion, raising the temperature of the water and the pre-emulsion to 50-80 DEG C under stirring, and starting to carry out heat preservation; and starting to dropwise add the remaining pre-emulsion after carrying out the heat preservation for 30 minutes, enabling the remaining pre-emulsion to react for 5-25 hours, cooling the remaining pre-emulsion to the room temperature, and discharging the cooled pre-emulsion, thereby preparing the cationic fluorine-containing emulsion. According to the present invention, the emulsifier in the emulsion directly reacts with a polymeric monomer, thereby avoiding a migration problem of a conventional emulsifier; and meanwhile the water is used as a dispersion medium, so that no organic solvent is contained, resources are saved, and environment-friendly requirements are satisfied.

Owner:SHAANXI UNIV OF SCI & TECH

Self-stratifying polymer cement photocatalytic coating and preparation method and application thereof

The invention belongs to the technical field of self-stratifying photocatalytic coatings, and particularly relates to a self-stratifying polymer cement photocatalytic coating and a preparation methodand application thereof. The photocatalytic coating is prepared from the following raw materials in parts by weight: 25-30 parts of polyacrylate emulsion, 20-25 parts of carbon adsorption nano TiO2 modified fluoroacrylic emulsion and 15-20 parts of cement. The coating has a gradient self-stratifying function in a film forming process, the polyacrylate emulsion moves towards the base layer, the adhesive force with the building surface is increased, the fluorocarbon emulsion component modified by adsorbing the nano TiO2 by the bamboo charcoal moves towards the surface layer and the utilization rate of nano TiO2 is increased, so that the photocatalytic function of limited nano TiO2 in the coating is exerted to the greatest extent, the function of the photocatalytic coating with higher nano TiO2 content is achieved under the condition of lower doping amount of nano TiO2 and the cost is reduced.

Owner:UNIV OF JINAN +1

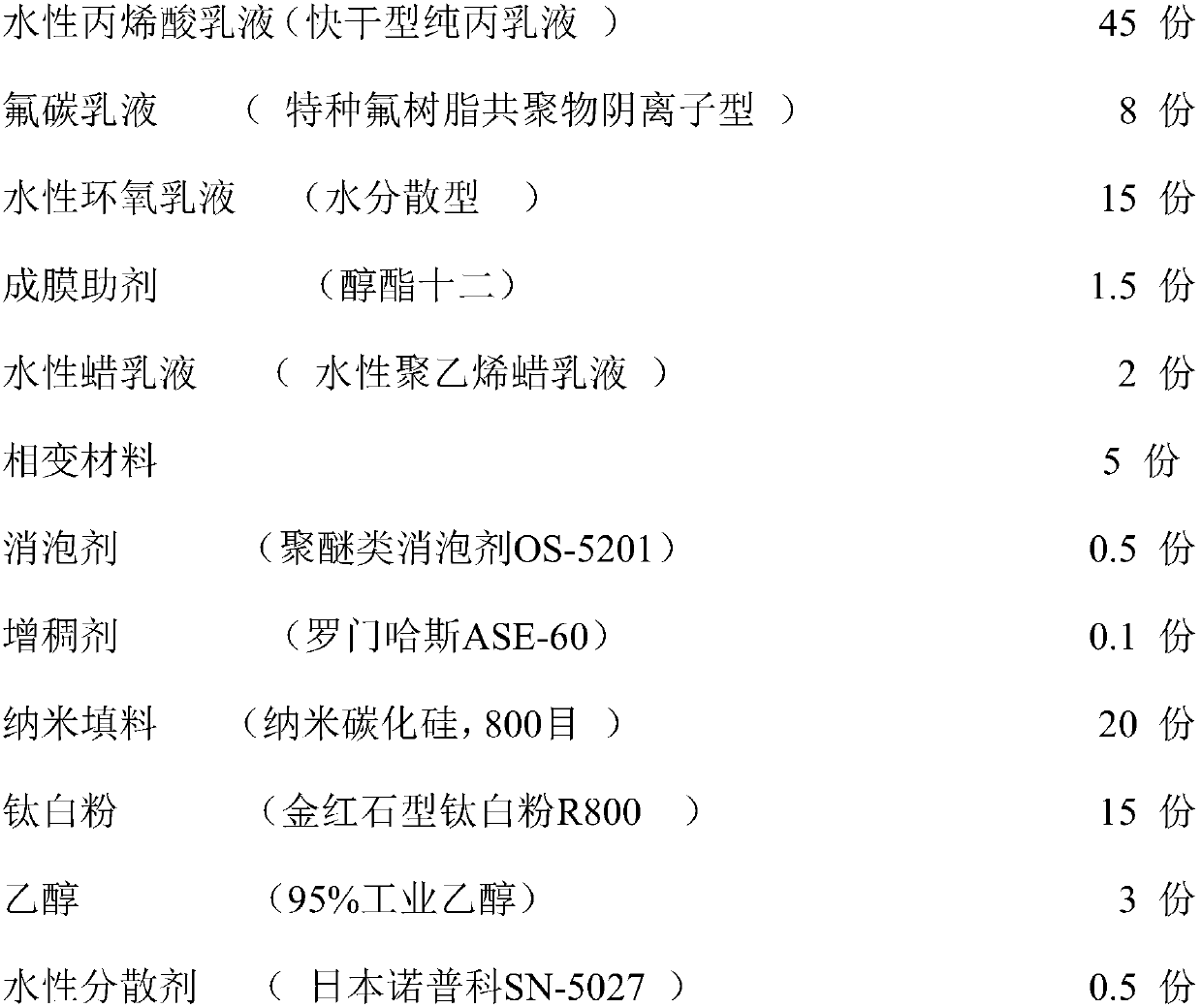

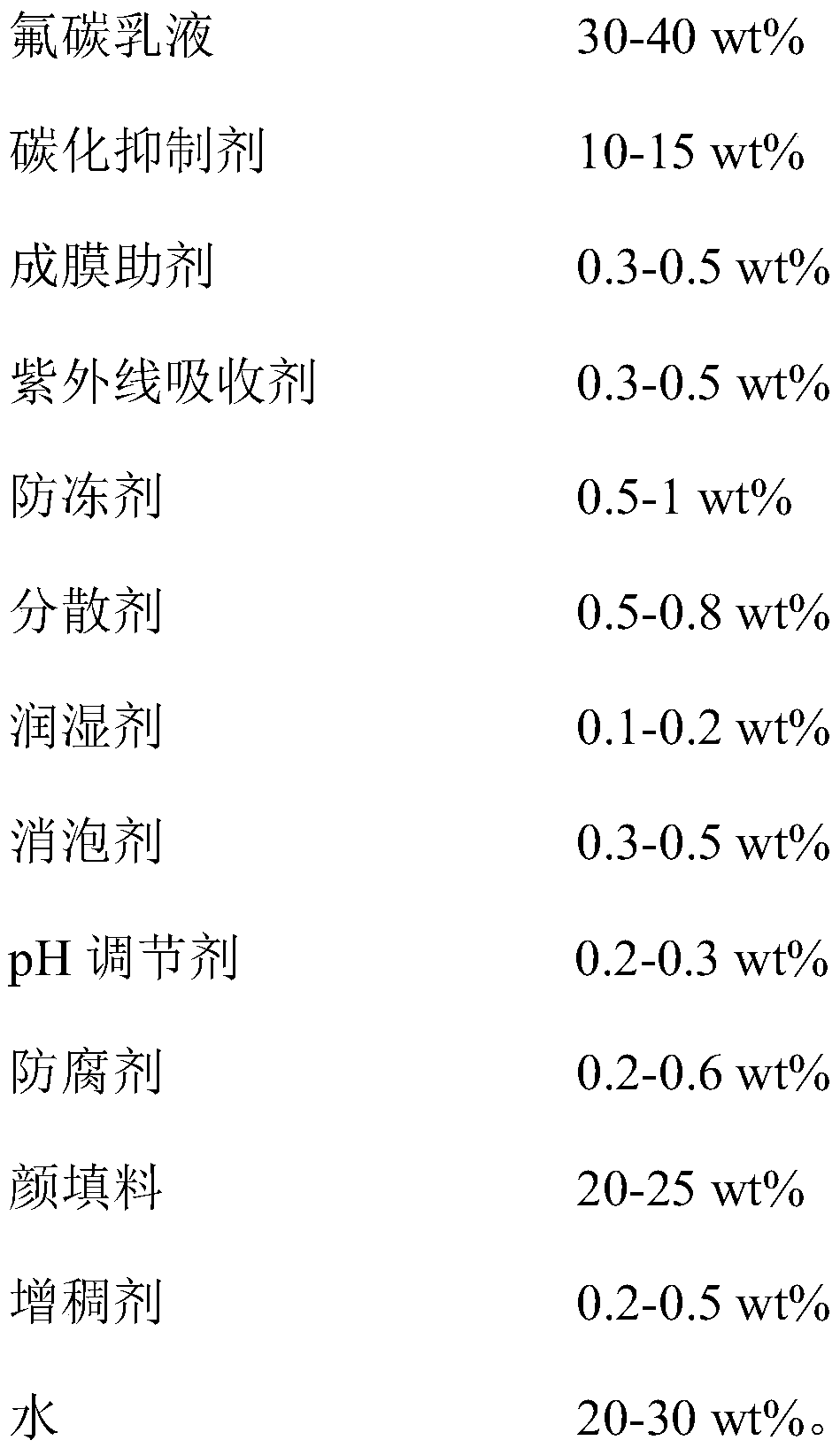

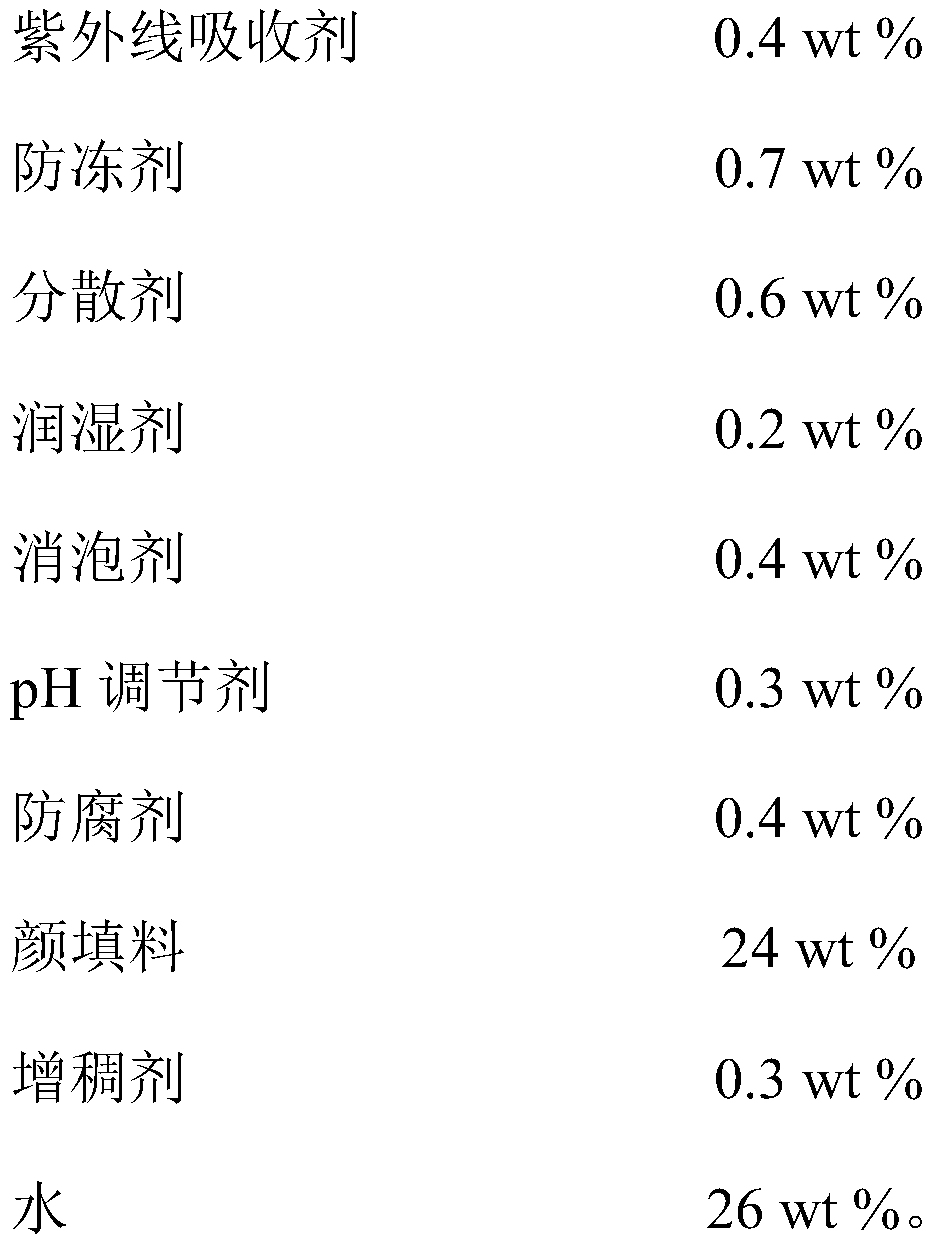

Water-based anti-carbonization coating and preparation method thereof

InactiveCN111234618AGood weather resistanceImprove corrosion resistanceCoatingsUltraviolet lightsFluorocarbon Emulsions

The invention provides a water-based anti-carbonization coating and a preparation method thereof. Mass percent, the water-based anti-carbonization coating comprises the following components: 30 to 40%of fluorocarbon emulsion, 10 to 15% of a carbonization inhibitor; 0.3 to 0.5% of a film forming auxiliary agent; 0.3 to 0.5% of an ultraviolet light absorber, 0.5 to 1% of an anti-freezing agent, 0.5to 0.8% of a dispersing agent, 0.1 to 0.2% of a wetting agent, 0.3 to 0.5% of a defoaming agent, 0.2 to 0.3% of a pH regulator, 0.2 to 0.6% of a preservative, 20 to 25% of pigment and filler, 0.2 to0.5% of a thickening agent and 20 to 30% of water. And the coating has excellent weather resistance, corrosion resistance, low temperature resistance, ultraviolet resistance and the like.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

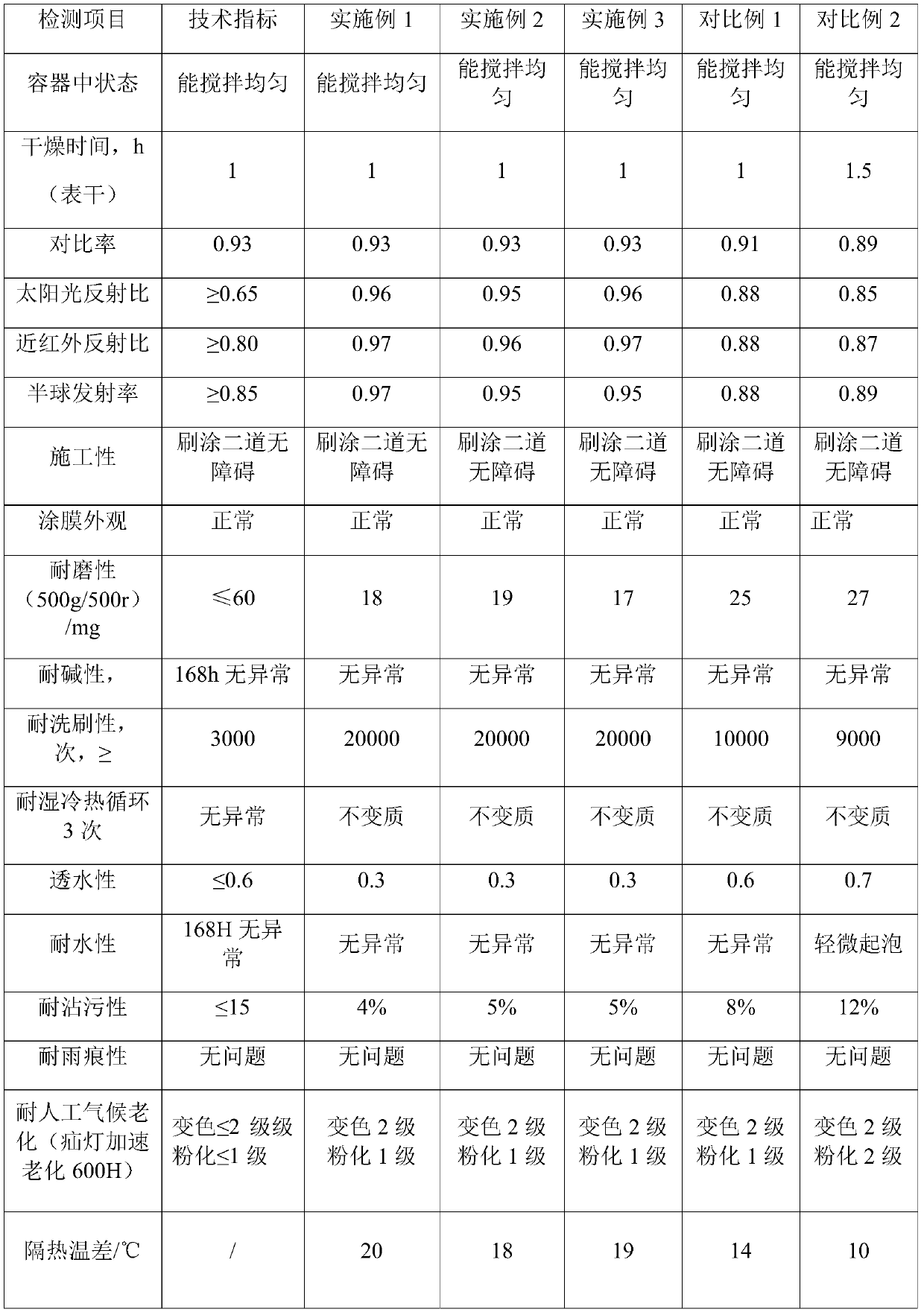

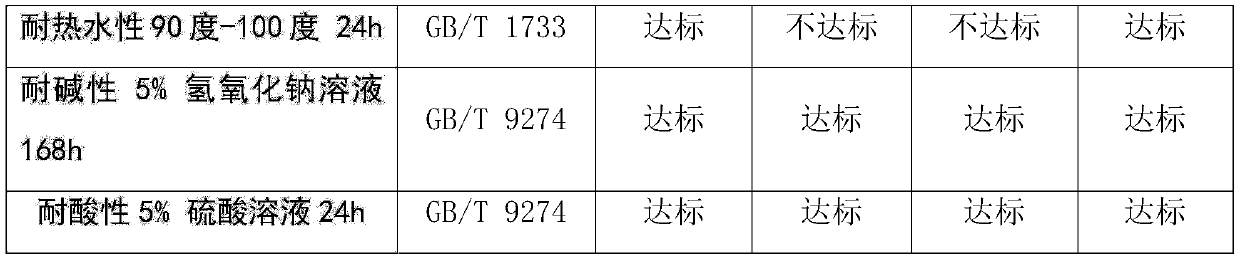

Water-based reflective insulation coating and preparation method thereof

InactiveCN110734686AImprove wear resistanceGood scrub resistanceEpoxy resin coatingsReflecting/signal paintsEpoxyYTTERBIUM OXIDE

The invention discloses a water-based reflective thermal insulation coating and a preparation method thereof, the reflective thermal insulation coating selects carbon nanotube modified epoxy resin andorganosilicon modified fluorocarbon emulsion for compounding as a film forming substance, the flexibility and frictional wear performance of a paint film are significantly enhanced, and the adhesiveforce of the paint film is improved; silicon-aluminum coated modified nano titanium dioxide is selectively added, so that the paint film is endowed with extremely high weather resistance and reflective heat-insulating property; high-hardness particles such as nano ytterbium oxide, kaolin and ground calcium carbonate are matched, so that the high-hardness particles are embedded in the compact paintfilm formed by film forming matters when the coating forms a film, and when the surface of the paint film is rubbed by the outside, the high-hardness particles bear most of friction force, so that the abrasion effect of the surface of the paint film is reduced, and the reflective heat insulation property, the abrasion resistance and the washing resistance of the paint film are comprehensively improved. According to the reflective thermal insulation coating provided by the invention, the thermal insulation temperature difference reaches 17-20 DEG C, the reflectivity reaches 90% or above, and the reflective thermal insulation coating has a relatively high practical value.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

High-temperature-resistant water-based fluorocarbon amino baking varnish and preparation method thereof

The invention discloses a high-temperature-resistant water-based fluorocarbon amino baking varnish and a preparation method thereof. The high-temperature-resistant water-based fluorocarbon amino baking varnish comprises the following components in parts by weight: 10 to 40 parts of fluorocarbon emulsion; 10 to 30 parts of organic silicon modified acrylic emulsion; 0.5-1 part of a water-based dispersing agent; 0.2 to 0.5 part of a water-based surfactant; 0.2-0.5 part of a water-based base material wetting agent, 0.5-3 parts of a pH regulator acid-base neutralizer, 0.1-0.5 part of a thickener, 0.5-1 part of an adhesion promoter, 1-5 parts of a rheological modified wax dispersion, 5-15 parts of amino resin, 12-40 parts of a high-temperature-resistant pigment filler and 10-25 parts of an environment-friendly solvent. The high-temperature-resistant water-based fluorocarbon amino baking varnish contains the fluorocarbon, organic silicon modified acrylic emulsion, amino resin and high-temperature-resistant pigment, a paint film formed by baking the baking varnish has certain hardness and flexibility, has excellent weather resistance, water resistance, acid resistance, alkali resistance and corrosion resistance, and can achieve better high-temperature resistance after hard drying.

Owner:WUXI HUADONG ZINDN TECH

Patient oxygenation using stabilized fluorocarbon emulsions

InactiveUS20050256211A9Short organ retention timeEffect organ retention timeHalogenated hydrocarbon active ingredientsTransportation and packagingFluorocarbon EmulsionsPolymer chemistry

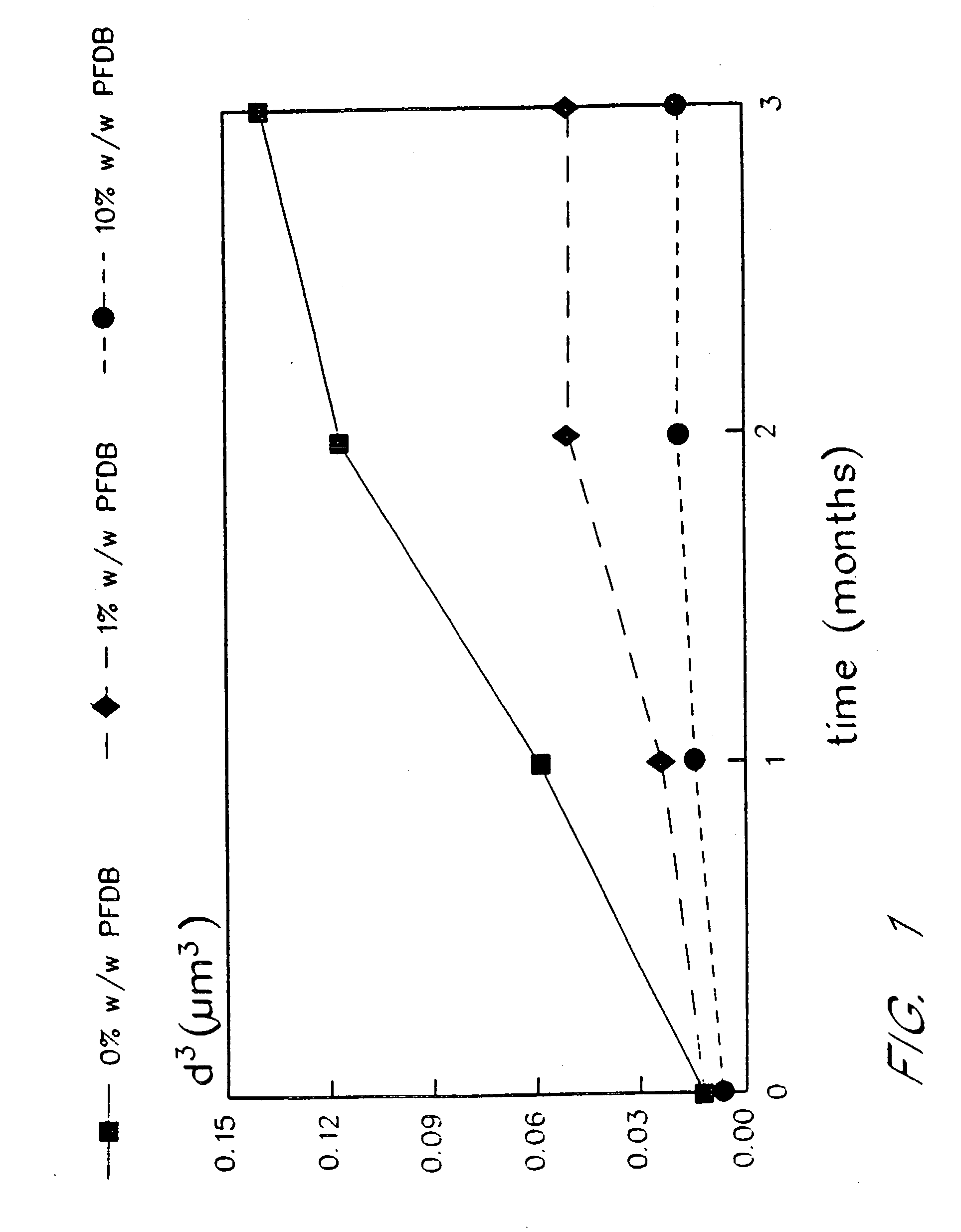

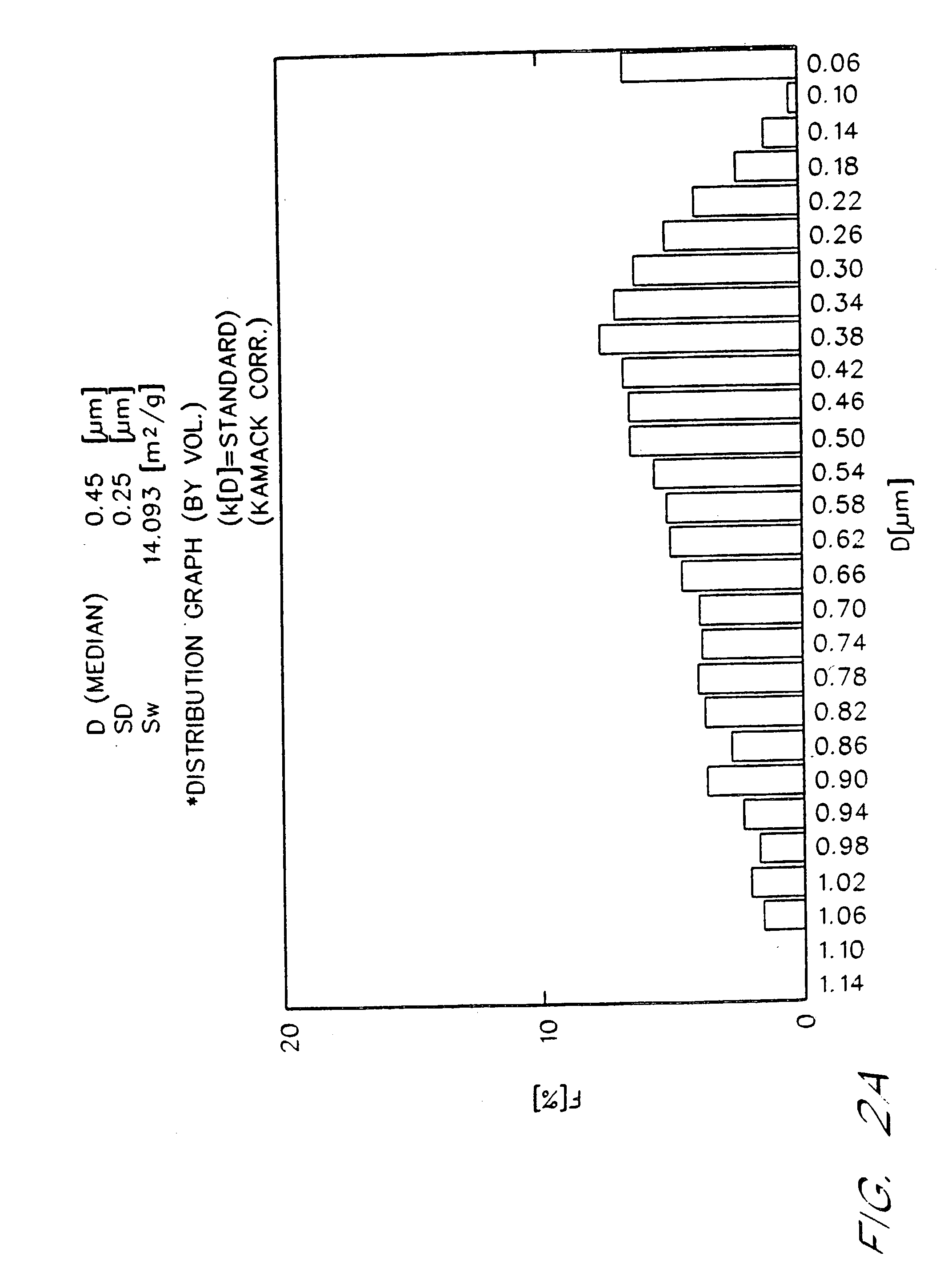

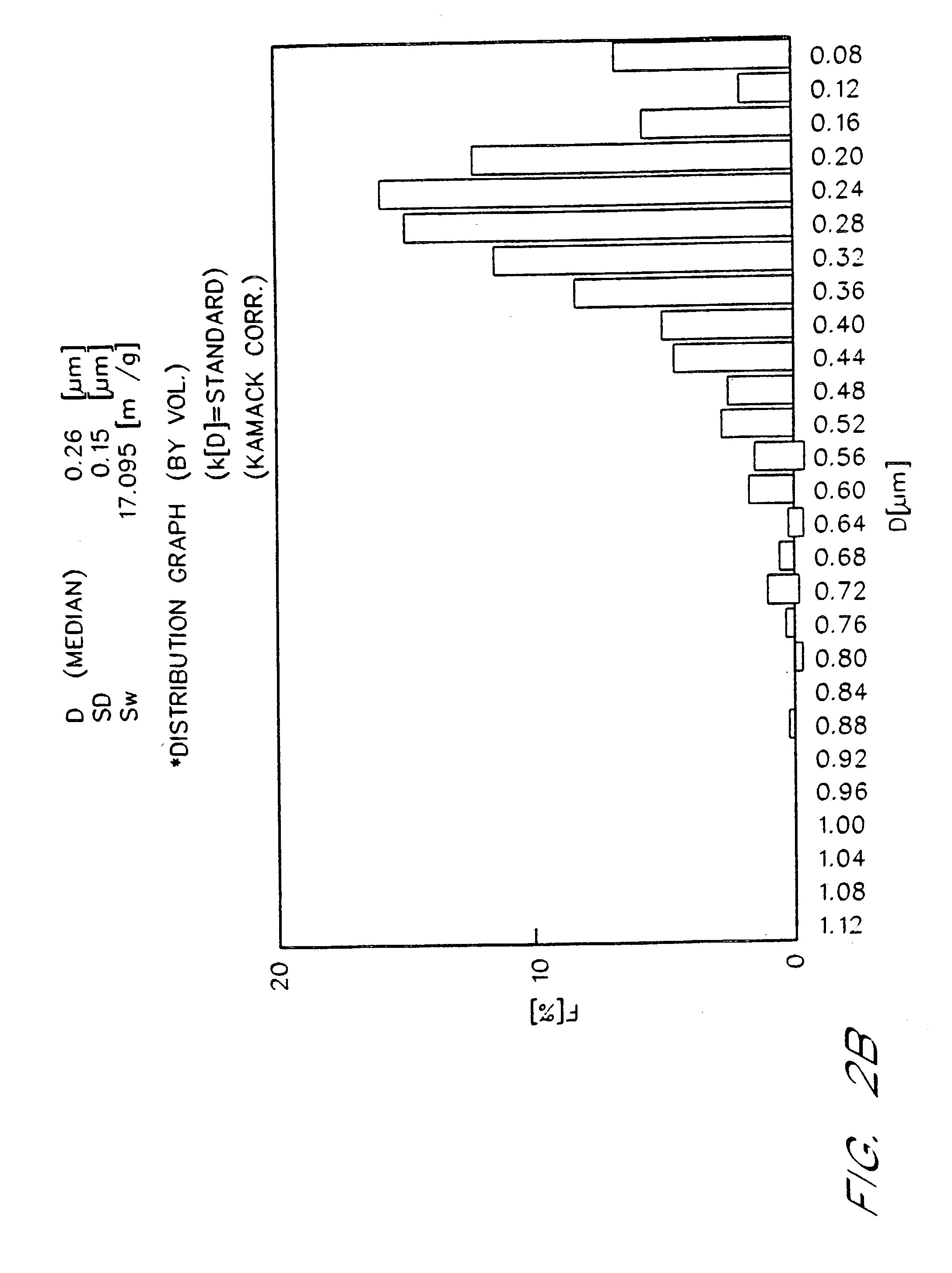

Storage stable fluorocarbon emulsions having a continuous aqueous phase and a discontinuous fluorocarbon phase, in which the fluorocarbon phase comprises a major amount of a first fluorocarbon or fluorocarbon mixture, and a minor amount of a second fluorocarbon or fluorocarbon mixture, in which the second fluorocarbon has a molecular weight greater than that of the first fluorocarbon and the second fluorocarbon includes a lipophilic moiety in its structure, whereby the second fluorocarbon serves to promote particle size stability in the emulsion while simultaneously providing favorably short organ retention times when administered to animals in vivo.

Owner:PFC THERAPEUTICS L L C

Airplane runway maintenance slurry

The invention discloses airplane runway maintenance slurry. The airplane runway maintenance slurry mainly comprises an aqueous fluorocarbon emulsion, nanometer white carbon black, aramid pulp, a penetrating agent and a coupling agent as auxiliary agent. The airplane runway maintenance slurry can be mixed with sand and broken stones and then is used for maintenance of injuries and cracks having different sizes and depth values of cement concrete runways and asphalt runways, and the maintained layer has a long service life, good water resistance and excellent impact resistance.

Owner:张文知

High-performance nano coating and preparation method thereof

InactiveCN108456466AImprove performanceSmall particle sizeAntifouling/underwater paintsPaints with biocidesPolypropyleneAntibacterial property

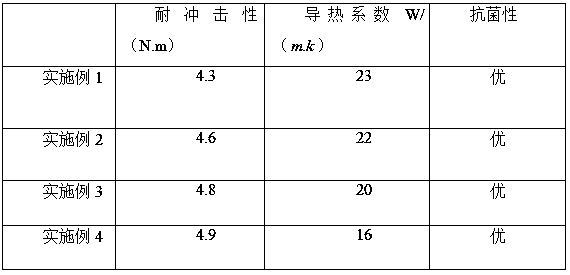

The invention discloses a high-performance nano coating which comprises the following raw materials in parts by weight: 42-48 parts of nano-aqueous fluorocarbon emulsion, 32-34 parts of styrene-acrylic emulsion, 26-30 parts of waterborne polypropylene resin, 16-20 parts of a mixed nanometer material, 4-6 parts of an antibacterial agent, 2-4 parts of a surfactant, 1-3 parts of a thickening agent and 1-2 parts of a pH regulator. The purpose of the invention is to provide the high-performance nano coating. The nano coating has excellent aging resistance and antibacterial property, is green and environmentally friendly and has high application value and good application prospects.

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

Water-based antirust agent for filter and preparation thereof

The invention relates to a water base rust preventive for a filter, which comprises 50 to 60 weight parts of hydroxyalkyl starch, 40 to 50 weight parts of acetic ester starch, 80 to 100 weight parts of aqueous fluorocarbon emulsion, 300 to 350 weight parts of water, 55 to 75 weight parts of polyfluortetraethylene emulsion, 8 to 10 weight parts of micron or nanometer zinc powder, 40 to 50 weight parts of isopropanol and 20 to 30 weight parts of acetone, wherein the hydroxyalkyl starch is ethoxyl starch or hydroxypropyl starch; the aqueous fluorocarbon emulsion is multipolymer of fluorothene and an oxhydryl vinyl ether, the weight percentage concentration of fluorin is from 8 percent to 11.5 percent, and a main chain comprises fluorin atoms. A preparation method comprises traditional methods of mixing, heating stirring and ultrasonic dispersion. The rust preventive has the advantages of good antirust effect, high temperature resistance, favorable adhesive attraction to polyester powder coatings, and the like and can satisfy the antirust requirements of a metal outer casing and a treaded cover plate of the filter. The preparation method is technically simple and uses less equipment.

Owner:NANTONG HUAXING OIL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com