Building external wall coating

A technology for building exterior walls and coatings, applied in antifouling/underwater coatings, reflection/signal coatings, coatings, etc., can solve problems such as not being able to improve the indoor environment, reduce production costs, improve weather resistance, and increase adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

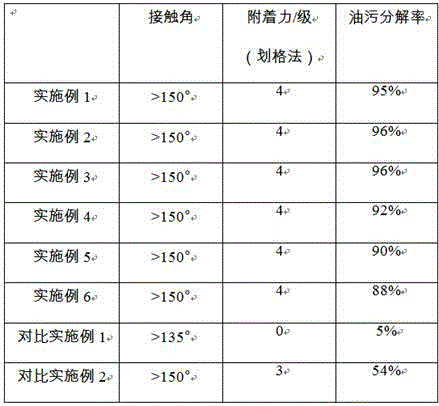

Examples

Embodiment 1

[0053] Mix 1 part of hydrophobic aid, 10 parts of silica nanopowder and 5 parts of xylene, and then stir continuously at 60°C for 1.5 hours, then filter and remove the suspension to obtain modified filler, then 10 parts of modified filler, polymerized 40 parts of emulsion (10 parts of fluorocarbon emulsion, 30 parts of silicone modified acrylic emulsion), 10 parts of titanium dioxide nanopowder, 0.2 parts of dispersant, 0.1 part of silicone defoamer, 0.1 part of wetting agent and 10 parts of water The ratio is mixed evenly, and then 7 parts of putty and 5 parts of modified bleaching beads are added in sequence and mixed evenly to prepare a coating.

[0054] The putty formula is the same as the putty formula 1;

[0055] Modified floating beads are made by method A:

[0056] Method A: Feed fly ash floating beads into a high-efficiency powder mixer with a spray head, and under normal temperature stirring, spray quantitatively into the pre-prepared special slurry for modified flo...

Embodiment 2

[0070] Mix 3 parts of hydrophobic additives, 20 parts of silica nanopowder and 10 parts of xylene, stir continuously at 90°C for 2 hours, then filter and remove the suspension to obtain modified fillers, then mix 20 parts of modified fillers, polymerize 50 parts of compound emulsion (12.5 parts of fluorocarbon emulsion, 37.5 parts of silicone modified acrylic emulsion), 20 parts of titanium dioxide nanopowder, 0.5 part of dispersant, 0.2 part of silicone defoamer, 0.2 part of wetting agent and 15 parts of water The ratio is mixed evenly, and then 9 parts of putty and 3 parts of modified floating beads are added in sequence and mixed evenly to prepare a coating.

[0071] The putty formula is the same as the putty formula 2;

[0072] Modified floating beads are made by method A:

[0073] Method A: Feed fly ash floating beads into a high-efficiency powder mixer with a spray head, and under normal temperature stirring, spray quantitatively into the pre-prepared special slurry for...

Embodiment 3

[0087] Mix 3 parts of hydrophobic additives, 20 parts of silica nanopowder and 10 parts of xylene, stir continuously at 90°C for 2 hours, then filter and remove the suspension to obtain modified fillers, then mix 20 parts of modified fillers, polymerize 50 parts of compound emulsion (11 parts of fluorocarbon emulsion, 39 parts of silicone modified acrylic emulsion), 20 parts of titanium dioxide nanopowder, 0.5 part of dispersant, 0.2 part of silicone defoamer, 0.2 part of wetting agent and 15 parts of water The ratio is mixed evenly, and then 7 parts of putty and 6 parts of modified bleaching beads are added in sequence and mixed evenly to prepare a coating.

[0088] The putty formula is the same as the putty formula three;

[0089] Modified floating beads are made by method A:

[0090] Method A: Feed fly ash floating beads into a high-efficiency powder mixer with a spray head, and under normal temperature stirring, spray quantitatively into the pre-prepared special slurry fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com