High-temperature-resistant water-based fluorocarbon amino baking varnish and preparation method thereof

A high-temperature-resistant, water-based fluorine technology, applied in coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of high-temperature resistance that cannot meet market demand, unfavorable development of industrial water-based coatings, and failure to achieve anti-corrosion performance. Application value and significance, excellent weather resistance, good grinding and filling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

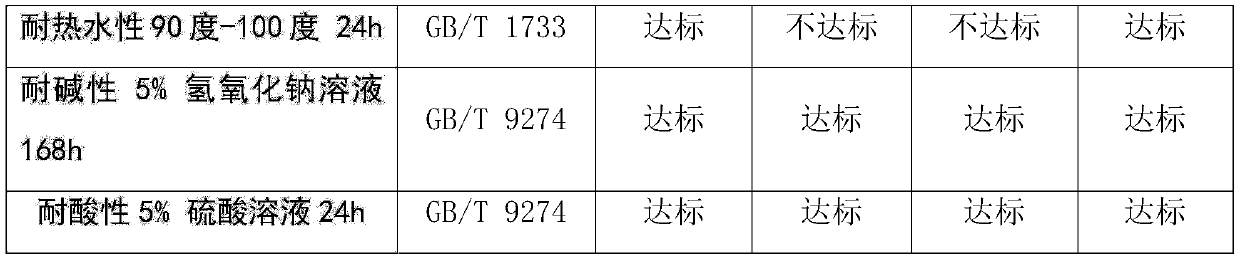

Examples

Embodiment 1

[0031] Proportion: 23 parts of fluorocarbon emulsion (45% solid content, 12% fluorine content), 22 parts of silicone modified acrylic emulsion (47% solid content), 2 parts of PH regulator (DMEA), water-based dispersant (Mikesi 855W) 0.7 parts, water-based surfactant (SURFYNOL 104E) 0.5 parts, water-based substrate wetting agent (Digo 4100) 0.3 parts, thickener (Hemings 299) 0.3 parts, adhesion promoter (Longhai Chemical 2504) 0.6 parts, amino resin (Cytec 327) 6 parts, rheology modified wax dispersion (BYK8421) 2.1 parts, water-based aluminum paste (Xuyang Aluminum Pigment LX-PS8216) 4.5 parts, mica powder ( 800 mesh) 10 parts, (JYA-15 calcined kaolin) 8 parts, deionized water 6 parts, environmental solvent 14 parts.

[0032] Preparation:

[0033] 1) Weigh the raw materials according to the above ratio, put the fluorocarbon emulsion into the mixer, the stirring speed is 500r / min, then add dimethylethanolamine and environmental solvent, adjust the stirring speed to 600r / min, a...

Embodiment 2

[0038]Proportion: 15 parts of fluorocarbon emulsion (45% solid content, 12% fluorine content), 25 parts of silicone modified acrylic emulsion (47% solid content), 0.5 part of PH regulator (AMP-95), water-based Dispersant (Mikesi 855W) 0.8 parts, water-based surfactant (SURFYNOL 104E) 0.5 parts, water-based substrate wetting agent (Digo 4100) 0.3 parts, thickener (Hemings 299) 0.3 parts, (Mai Figure Coatosil MP200) 0.6 parts, amino resin (Cytec 327) 6 parts, rheology modified wax dispersion (BYK8421) 1.6 parts, water-based aluminum paste (Silver Arrow ZL-2510 and Longhai Chemical 6001 water-based aluminum powder treatment agent Oily aluminum powder to water-based aluminum powder) 6 parts, mica powder (800 mesh) 20 parts, deionized water 12 parts, environmental solvent 11.4 parts.

[0039] Preparation method: with embodiment 1.

Embodiment 3

[0041] Proportion: 20 parts of fluorocarbon emulsion (45% solid content, 12% fluorine content), 18 parts of silicone modified acrylic emulsion (47% solid content), 2 parts of PH regulator (DMEA), water-based dispersant (Mikesi 855W) 0.6 parts, water-based surfactant (SURFYNOL 104E) 0.5 parts, water-based substrate wetting agent (Digo 4100) 0.3 parts, thickener (Hemings 299) 0.3 parts, amino resin (cyanide Special 327) 5 parts, rheology modified wax dispersion (BYK8421) 3.3 parts, water-based aluminum paste (Changsha Zuxing aluminum silver paste ZXG914 and Longhai Chemical 6001 water-based aluminum powder treatment agent to make oily aluminum powder to water-based aluminum powder) 12 Parts, (JYA-15 calcined kaolin) 15 parts, deionized water 9 parts, environmental solvent 14 parts.

[0042] Preparation method: with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com