Water-based anti-carbonization coating and preparation method thereof

A water-based, coating technology, applied in the direction of coating, can solve the problems of low carbonization resistance of concrete, reduced service life, poor building durability, etc., and achieve excellent weather resistance, protection of substrates, and dense paint film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

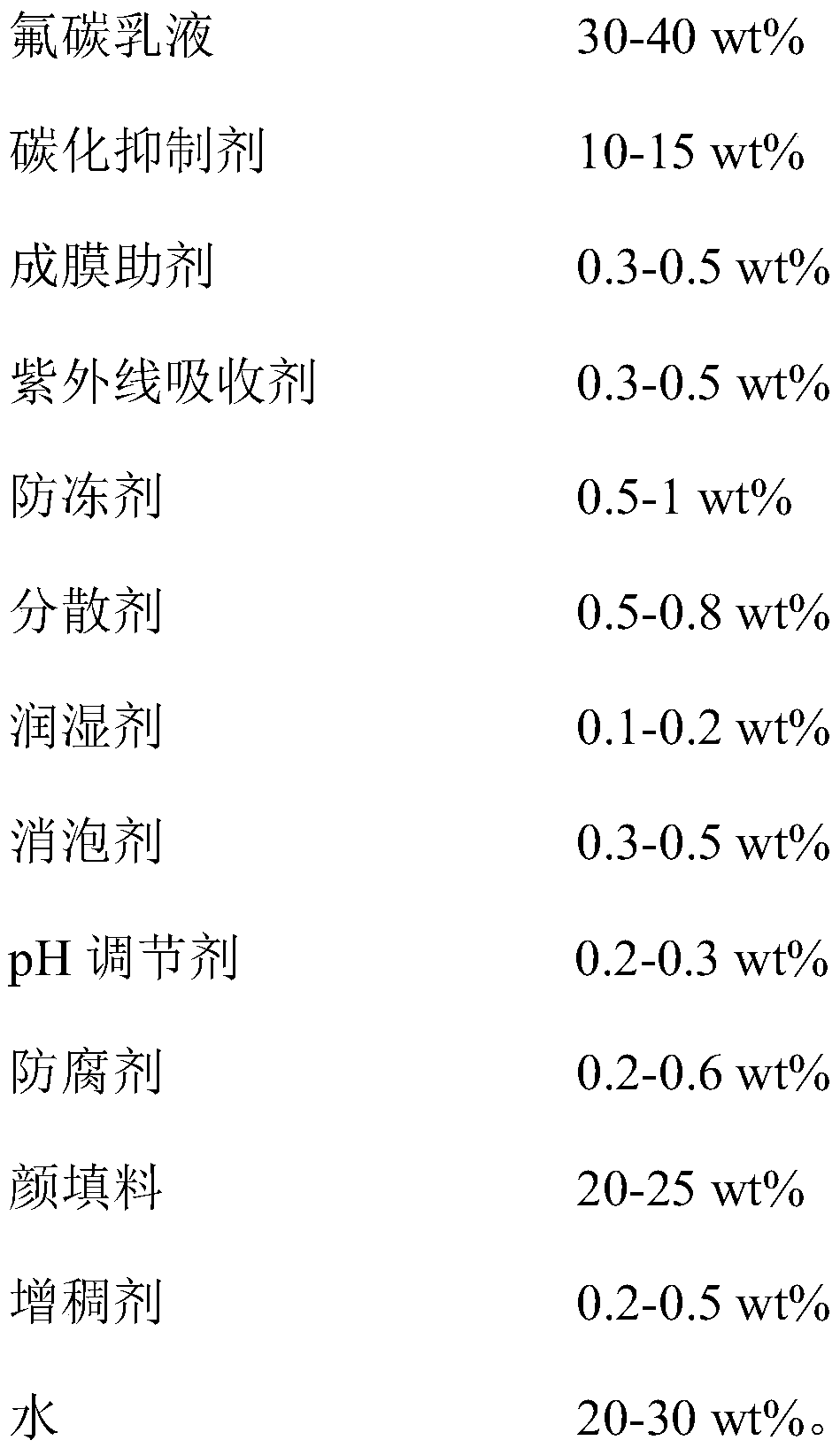

[0029] Water-based anti-carbonization coating described in the present embodiment, by mass percentage, is made up of following components:

[0030]

[0031] The preparation method of water-based anti-carbonization coating described in the present embodiment may further comprise the steps:

[0032] According to the amount of the above formula, first add accurately weighed water into the tank or large tank, slowly add the dispersant, wetting agent, and defoamer in sequence at a low speed of 400r / min, and stir for 1 min after the addition is completed to increase the Speed up to 700r / min at a medium speed, add pigments and fillers in turn, increase the speed to 1000r / min, disperse at high speed for 30 minutes, fineness ≤ 55um, add fluorocarbon emulsion, antifreeze, and film-forming aids at a low speed of 400r / min , Add film-forming aid slowly to prevent demulsification, pH adjuster, carbonization inhibitor, ultraviolet absorber, bactericide, anti-fungal agent, add thickener ...

Embodiment 2

[0034] Water-based anti-carbonization coating described in the present embodiment, by mass percentage, is made up of following components:

[0035]

[0036] The preparation method of water-based anti-carbonization coating described in the present embodiment may further comprise the steps:

[0037] According to the above formula, first add accurately weighed water into the tank or large tank, slowly add dispersant, wetting agent, and defoamer in sequence at a low speed of 500r / min, and stir for 2 minutes after adding to improve the Speed up to 800r / min at a medium speed, add pigments and fillers in turn, increase the speed to 1100r / min, disperse at high speed for 30 minutes, fineness ≤ 55um, add fluorocarbon emulsion, antifreeze, and film-forming aids at a low speed of 600r / min , Add film-forming aid slowly to prevent demulsification, pH adjuster, carbonization inhibitor, ultraviolet absorber, bactericide, anti-fungal agent, add thickener after stirring for 3 minutes, and ...

Embodiment 3

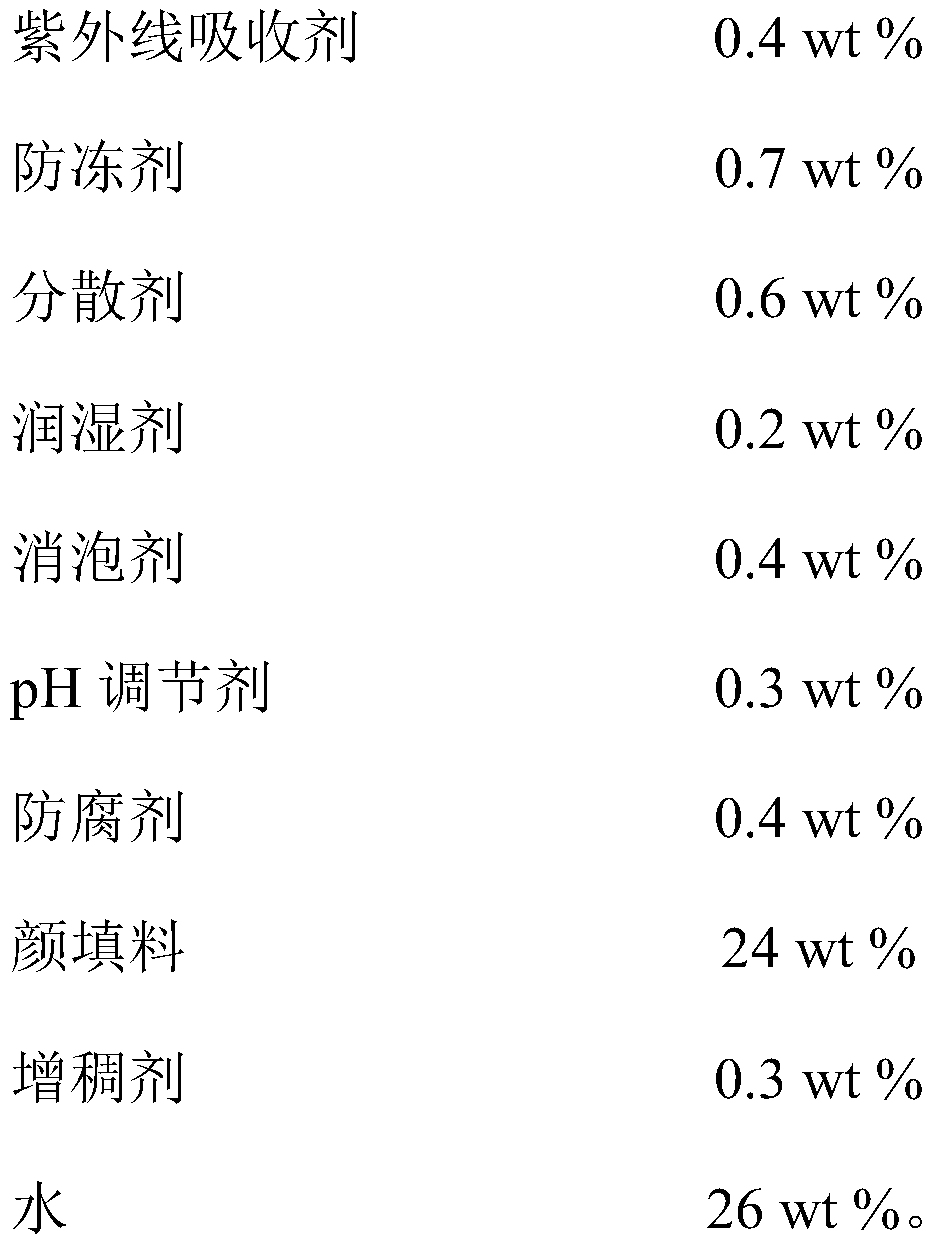

[0039] Water-based anti-carbonization coating described in the present embodiment, by mass percentage, is made up of following components:

[0040]

[0041]

[0042] The preparation method of water-based anti-carbonization coating described in the present embodiment may further comprise the steps:

[0043] According to the amount of the above formula, first add accurately weighed water into the tank or large tank, slowly add dispersant, wetting agent, and defoamer in sequence at a low speed of 600r / min, and stir for 2 minutes after adding to improve the Speed up to 900r / min at medium speed, add pigments and fillers in turn, increase speed to 1200r / min, disperse at high speed for 30 minutes, fineness ≤ 55um, add fluorocarbon emulsion, antifreeze, film-forming aid at low speed of 600r / min , Add film-forming aid slowly to prevent demulsification, pH adjuster, carbonization inhibitor, ultraviolet absorber, bactericide, anti-fungal agent, add thickener after stirring for 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com