Self-stratifying polymer cement photocatalytic coating and preparation method and application thereof

A cement and coating technology, applied in the field of self-layered photocatalytic coatings, can solve the problems of low surface layer ratio, difficulty in taking into account interfacial adhesion, weather resistance, water resistance and mechanical properties, uneven dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

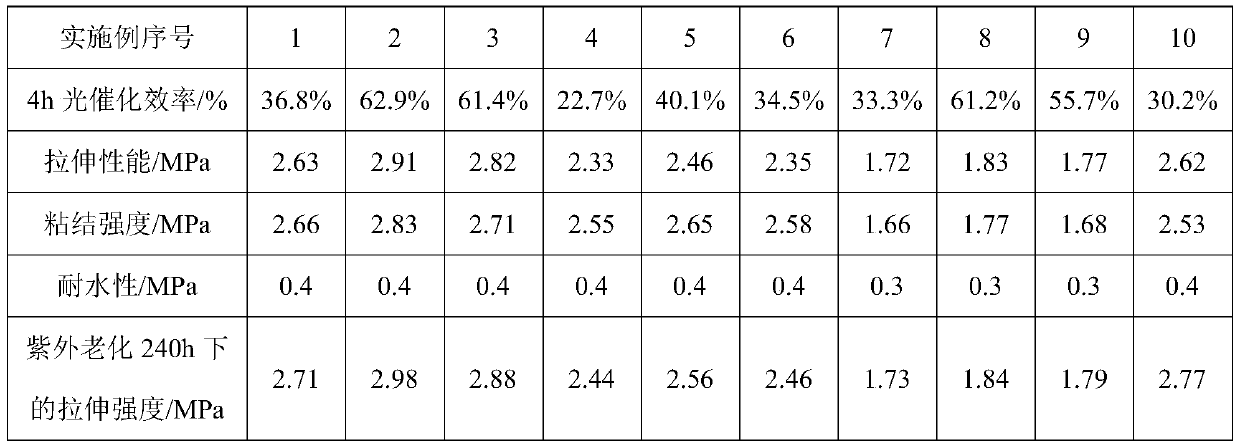

Examples

Embodiment 1

[0085] A self-layering polymer cement photocatalytic coating and a preparation method thereof, comprising the steps of:

[0086] 1. Nano-TiO 2 Preparation of bamboo charcoal composite material:

[0087](1) Bamboo charcoal pretreatment: Take bamboo charcoal in a beaker, add distilled water, heat to boil, filter and dry at 100°C until constant weight. Take 10 parts of dried bamboo charcoal, add 50 parts of absolute ethanol, and ultrasonically disperse for 0.5 h to obtain activated carbon alcohol solution. Dilute the silane coupling agent with 30 parts of distilled water and 5 parts of absolute ethanol, stir at 100rmp for 2h to obtain the hydrolyzate of the silane coupling agent; add the bamboo charcoal alcohol solution and the hydrolyzate of the silane coupling agent to the flask, and use 0.5mol / L) and ammonia solution (pH=8) to adjust the pH value to be neutral, magnetically stir at 70°C for 2h, suction filter and dry at 120°C for 2h, cool, and pass through a 200-mesh standar...

Embodiment 2

[0094] A self-layering polymer cement photocatalytic coating and a preparation method thereof, comprising the steps of:

[0095] 1. Nano-TiO 2 Preparation of bamboo charcoal composite material:

[0096] (1) Bamboo charcoal pretreatment: Take bamboo charcoal in a beaker, add distilled water, heat to boil, filter and dry at 120°C until constant weight. Take 30 parts of dried bamboo charcoal, add 55 parts of absolute ethanol, and ultrasonically disperse for 1.0 h to obtain activated carbon alcohol solution. Dilute the silane coupling agent with 40 parts of distilled water and 10 parts of absolute ethanol, stir at 500rmp for 1h to obtain the hydrolyzate of the silane coupling agent; 1.0mol / L) and ammonia solution (pH = 9) to adjust the pH value to neutral, magnetically stirred at 50°C for 2.5h, suction filtered and dried at 110°C for 2h, cooled, and passed through a 200-mesh standard after grinding Sieve to obtain modified bamboo charcoal powder;

[0097] (2) 2 parts of P25 na...

Embodiment 3

[0103] A self-layering polymer cement photocatalytic coating and a preparation method thereof, comprising the steps of:

[0104] 1. Nano-TiO 2 Preparation of bamboo charcoal composite material:

[0105] (1) Bamboo charcoal pretreatment: Take bamboo charcoal in a beaker, add distilled water, heat to boil, filter and dry at 110°C until constant weight. Take 30 parts of dried bamboo charcoal, add 60 parts of absolute ethanol, and ultrasonically disperse for 1.2 hours to obtain activated carbon alcohol solution. Dilute the silane coupling agent with 35 parts of distilled water and 8 parts of absolute ethanol, stir at 400rmp for 1h to obtain the hydrolyzate of the silane coupling agent; add the bamboo charcoal alcohol solution and the hydrolyzate of the silane coupling agent to the flask, and use 1.0mol / L) and ammonia solution (pH = 8) to adjust the pH value to neutral, magnetically stirred at 60°C for 2.5h, filtered with suction and dried at 100°C for 2h, cooled, and passed thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com