Self-cleaning aqueous fluorocarbon building coating and preparation method thereof

A water-based fluorocarbon and architectural coating technology, applied in the field of coatings, can solve the problems of human environmental damage, poor pollution resistance and antibacterial properties, and poor wear resistance of paint films, and achieve excellent self-cleaning properties and improve optical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

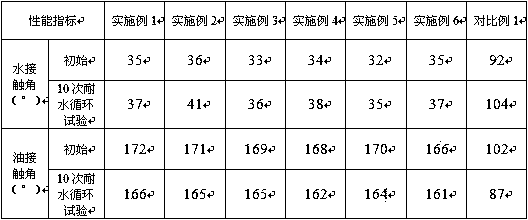

Examples

Embodiment 1

[0039] The preparation process is:

[0040] (1) Disperse nano-silica in water to make glue, then add water-soluble alcohol, then add silane coupling agent to form hydrophobic particles, then add surfactant and aluminum hydroxide colloid to form coating Membrane, make nano-silica emulsion A; In nano-silica emulsion A, nano-silica 17 weight parts, water 55 weight parts, water-soluble alcohol 7 weight parts, silane coupling agent 4 weight parts, 4 parts by weight of surfactant, 13 parts by weight of aluminum hydroxide colloid;

[0041] (2) Dissolving hydroxyethyl cellulose in water to prepare solution B; in solution B, 26 parts by weight of hydroxyethyl cellulose and 74 parts by weight of water;

[0042] (3) Mix the wetting and dispersing agent and nano-silica emulsion A uniformly to prepare solution C; in solution C, 3 parts by weight of wetting and dispersing agent and 86 parts by weight of nano-silica emulsion A;

[0043] (4) Mix solution B, solution C, inorganic pigment and...

Embodiment 2

[0047] The preparation process is:

[0048] (1) Disperse nano-silica in water to make glue, then add water-soluble alcohol, then add silane coupling agent to form hydrophobic particles, then add surfactant and aluminum hydroxide colloid to form coating Film, made nano silicon dioxide emulsion A; In nano silicon dioxide emulsion A, nano silicon dioxide 15 weight parts, water 62 weight parts, water-soluble alcohol 5 weight parts, silane coupling agent 3 weight parts, 3 parts by weight of surfactant, 12 parts by weight of aluminum hydroxide colloid;

[0049] (2) Dissolving hydroxyethyl cellulose in water to prepare solution B; in solution B, 20 parts by weight of hydroxyethyl cellulose and 80 parts by weight of water;

[0050] (3) Mix the wetting and dispersing agent and nano-silica emulsion A uniformly to prepare solution C; in solution C, 2 parts by weight of wetting and dispersing agent and 93 parts by weight of nano-silica emulsion A;

[0051] (4) Mix solution B, solution C...

Embodiment 3

[0055] The preparation process is:

[0056] (1) Disperse nano-silica in water to make glue, then add water-soluble alcohol, then add silane coupling agent to form hydrophobic particles, then add surfactant and aluminum hydroxide colloid to form coating Film, made nano silicon dioxide emulsion A; In nano silicon dioxide emulsion A, nano silicon dioxide 20 weight parts, water 47 weight parts, water-soluble alcohol 8 weight parts, silane coupling agent 5 weight parts, 5 parts by weight of surfactant, 15 parts by weight of aluminum hydroxide colloid;

[0057] (2) Dissolving hydroxyethyl cellulose in water to prepare solution B; in solution B, 30 parts by weight of hydroxyethyl cellulose and 70 parts by weight of water;

[0058] (3) Mix the wetting and dispersing agent and nano-silica emulsion A evenly to prepare solution C; in solution C, 5 parts by weight of wetting and dispersing agent and 75 parts by weight of nano-silica emulsion A;

[0059] (4) Mix solution B, solution C, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com