Self-cleaning antifouling inter wall paint

A self-cleaning technology for interior wall coatings, applied in the field of coatings, can solve the problems of unsatisfactory antifouling effect of antifouling interior wall coatings, failure to achieve antifouling effects, and inability to form paint films, etc., to achieve strong antifouling properties Self-cleaning ability, good coating effect, dense coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

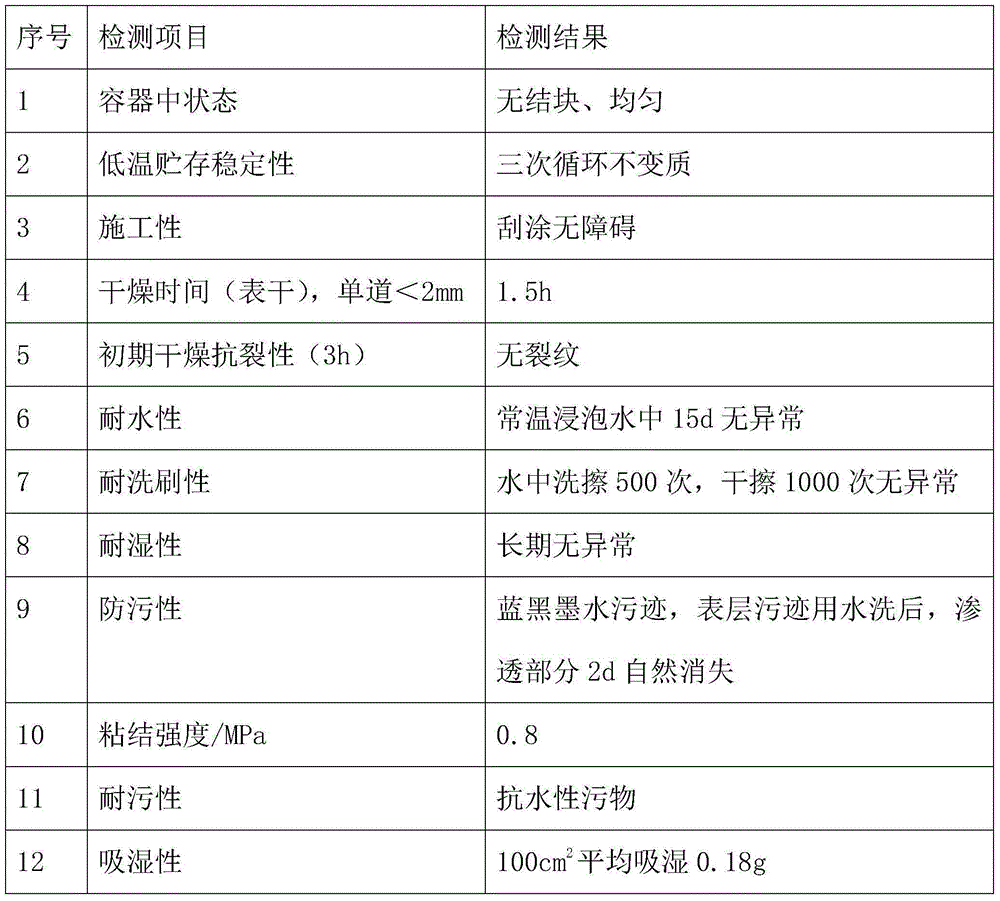

Examples

Embodiment 1

[0019]The self-cleaning antifouling interior wall paint of the present invention, its raw material comprises by weight: 40 parts of modified fluorocarbon emulsions, 6 parts of pure acrylic emulsions, 6 parts of light calcium carbonate, 15 parts of calcined kaolin, 3 parts of diatomite powders , 4 parts of forsterite powder, 2 parts of nano-tin oxide, 6 parts of magnesium sulfate, 0.1 part of hydroxyethyl cellulose, 0.7 parts of dispersant SN-5040, 0.1 part of multifunctional additive AMP-950, 0.8 part of alcohol ester twelve, Defoamer CF-160.2 parts, negative ion-antibacterial additive 1.0 parts, sodium hexametaphosphate 0.2 parts, leveling agent L-1500.5 parts, stain resistance agent JZM-10.5 parts, ethylene glycol 1.8 parts, antifungal agent 0.3 parts, 0.5 parts of wetting agent, 50 parts of deionized water;

[0020] The modified fluorocarbon emulsion was prepared according to the following process: vacuumize the reaction kettle and pass nitrogen gas, add 160 parts of deioni...

Embodiment 2

[0024] The self-cleaning antifouling interior wall coating of the present invention, its raw material comprises by weight: 60 parts of modified fluorocarbon emulsions, 1 part of pure acrylic emulsion, 16 parts of light calcium carbonate, 10 parts of calcined kaolin, 6 parts of diatomite powder 2 parts, 2 parts of forsterite powder, 4 parts of nano-tin oxide, 4 parts of magnesium sulfate, 0.3 parts of hydroxyethyl cellulose, 0.5 parts of dispersant SN-5040, 0.2 parts of multifunctional additive AMP-950, 0.5 parts of alcohol ester twelve, Defoamer CF-160.4 parts, negative ion-antibacterial additive 0.7 parts, sodium hexametaphosphate 0.5 parts, leveling agent L-1500.3 parts, stain resistance agent JZM-11.0 parts, ethylene glycol 0.5 parts, antifungal agent 1.2 parts, 0.3 parts of wetting agent, 70 parts of deionized water;

[0025] The modified fluorocarbon emulsion is prepared according to the following process: vacuumize the reaction kettle and feed nitrogen gas, add 180 parts...

Embodiment 3

[0029] The self-cleaning antifouling interior wall coating of the present invention, its raw material comprises by weight: 45 parts of modified fluorocarbon emulsions, 5 parts of pure acrylic emulsions, 8 parts of light calcium carbonate, 12 parts of calcined kaolin, 4 parts of diatomite powders , 4 parts of forsterite powder, 2 parts of nano-tin oxide, 6 parts of magnesium sulfate, 0.1 part of hydroxyethyl cellulose, 0.7 parts of dispersant SN-5040, 0.1 part of multifunctional additive AMP-950, 0.7 part of alcohol ester twelve, Defoamer CF-160.2 parts, negative ion-antibacterial additive 0.9 parts, sodium hexametaphosphate 0.3 parts, leveling agent L-1500.5 parts, stain resistance agent JZM-10.6 parts, ethylene glycol 1.2 parts, antifungal agent 0.5 parts, 0.4 parts of wetting agent, 60 parts of deionized water;

[0030] The modified fluorocarbon emulsion was prepared according to the following process: the reaction kettle was vacuumed and nitrogen gas was introduced, and 170...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com