High-performance nano coating and preparation method thereof

A nano-coating, high-performance technology, used in anti-fouling/underwater coatings, paints containing biocides, etc., can solve the problems of not being very green and environmental protection, limiting the application of nano-materials, etc., to improve the poor suspension stability and strong physical properties. , the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

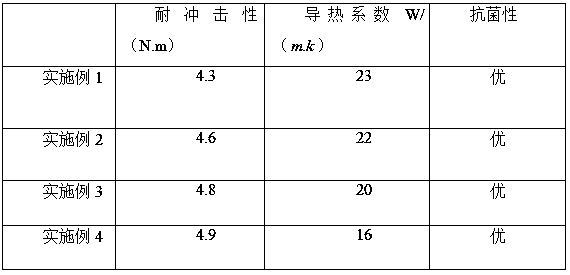

Embodiment 1

[0029] A kind of high-performance nano-coating of the present embodiment comprises the raw material of following weight portion:

[0030] 42 parts of nano-water-based fluorocarbon emulsion, 32 parts of styrene-acrylic emulsion, 26 parts of water-based polypropylene resin, 16 parts of mixed nanomaterials, 4 parts of antibacterial agent, 2 parts of surfactant, 1 part of thickener, and 1 part of pH regulator.

[0031] The mixed nanomaterials in this embodiment are nanometer zinc oxide, nanometer carbon fiber and nanometer silicon dioxide, according to the weight ratio of 1:3:2.

[0032] The antibacterial agent in this embodiment is a mixture of benzethonium chloride and isothiazolin-3-one in a weight ratio of 2:1.

[0033] The surfactant of the present embodiment is sodium dodecylbenzenesulfonate.

[0034] The thickener in this embodiment is a polyurethane rheological thickener.

[0035] The pH regulator in this embodiment is dimethylethanolamine.

[0036] The preparation meth...

Embodiment 2

[0041] A kind of high-performance nano-coating of the present embodiment comprises the raw material of following weight portion:

[0042] 48 parts of nano-water-based fluorocarbon emulsion, 34 parts of styrene-acrylic emulsion, 30 parts of water-based polypropylene resin, 20 parts of mixed nanomaterials, 6 parts of antibacterial agent, 4 parts of surfactant, 3 parts of thickener, and 2 parts of pH regulator.

[0043] The mixed nanomaterials in this embodiment are nanometer zinc oxide, nanometer carbon fiber and nanometer silicon dioxide, according to the weight ratio of 1:3:2.

[0044] The antibacterial agent in this embodiment is a mixture of benzethonium chloride and isothiazolin-3-one in a weight ratio of 2:1.

[0045] The surfactant of the present embodiment is sodium dodecylbenzenesulfonate.

[0046] The thickener in this embodiment is a polyurethane rheological thickener.

[0047] The pH regulator in this embodiment is dimethylethanolamine.

[0048] The preparation me...

Embodiment 3

[0053] A kind of high-performance nano-coating of the present embodiment comprises the raw material of following weight portion:

[0054] 45 parts of nano water-based fluorocarbon emulsion, 33 parts of styrene-acrylic emulsion, 28 parts of water-based polypropylene resin, 18 parts of mixed nanomaterials, 5 parts of antibacterial agent, 3 parts of surfactant, 2 parts of thickener, and 1.5 parts of pH regulator.

[0055] The mixed nanomaterials in this embodiment are nanometer zinc oxide, nanometer carbon fiber and nanometer silicon dioxide, according to the weight ratio of 1:3:2.

[0056] The antibacterial agent in this embodiment is a mixture of benzethonium chloride and isothiazolin-3-one in a weight ratio of 2:1.

[0057] The surfactant of the present embodiment is sodium dodecylbenzenesulfonate.

[0058] The thickener in this embodiment is a polyurethane rheological thickener.

[0059] The pH regulator in this embodiment is dimethylethanolamine.

[0060] The preparation me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com