Patents

Literature

90results about How to "Reduce free formaldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

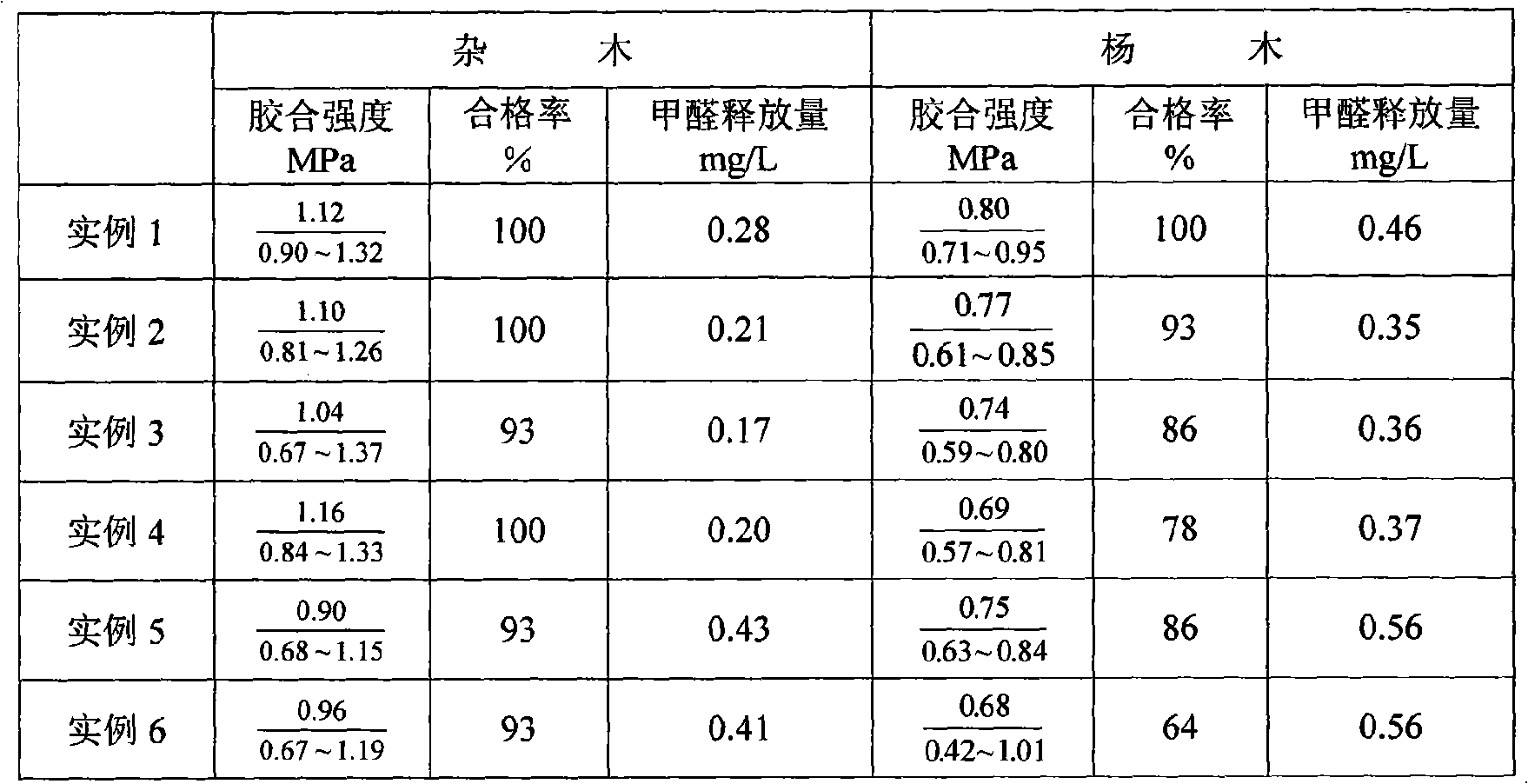

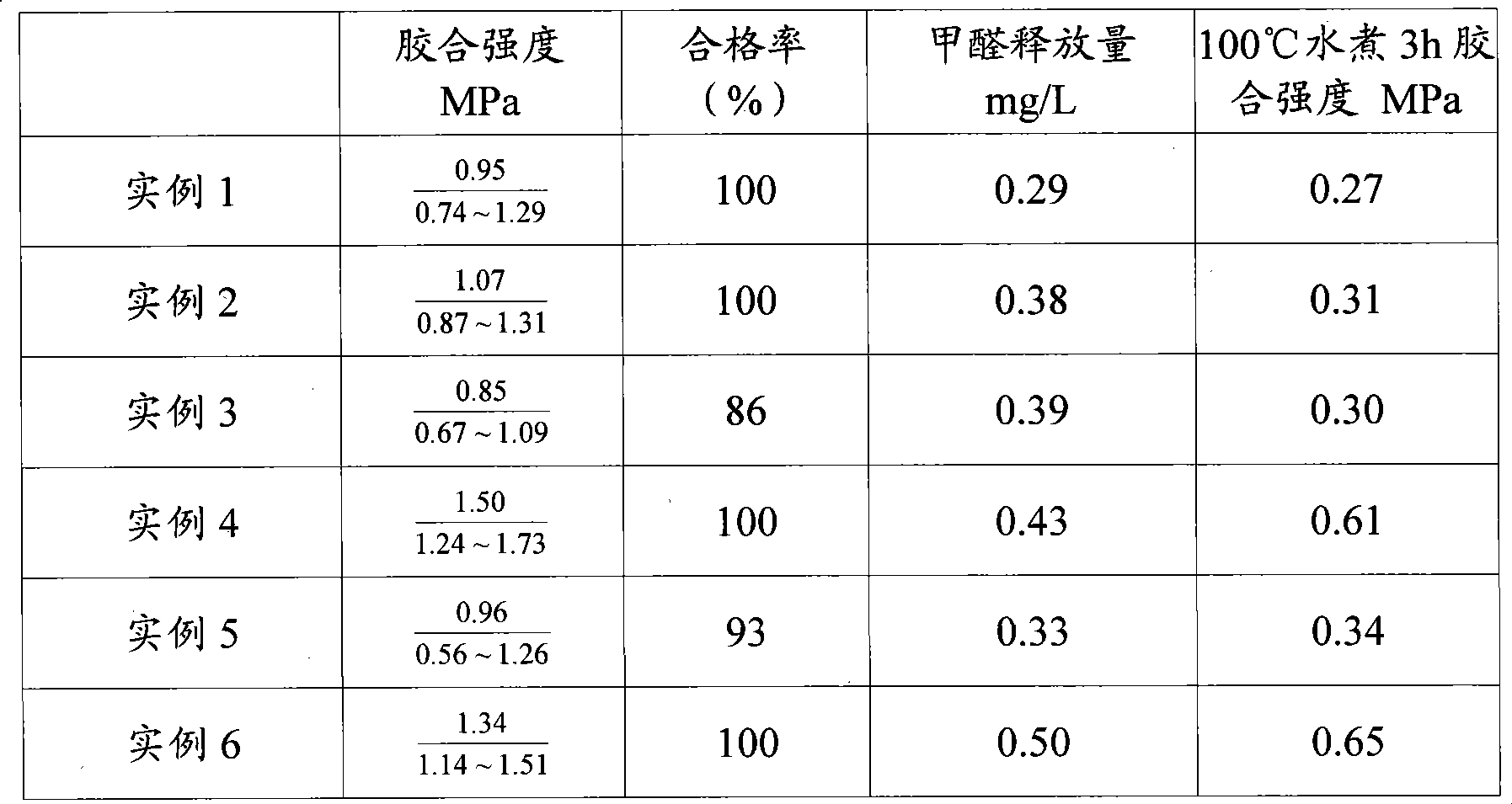

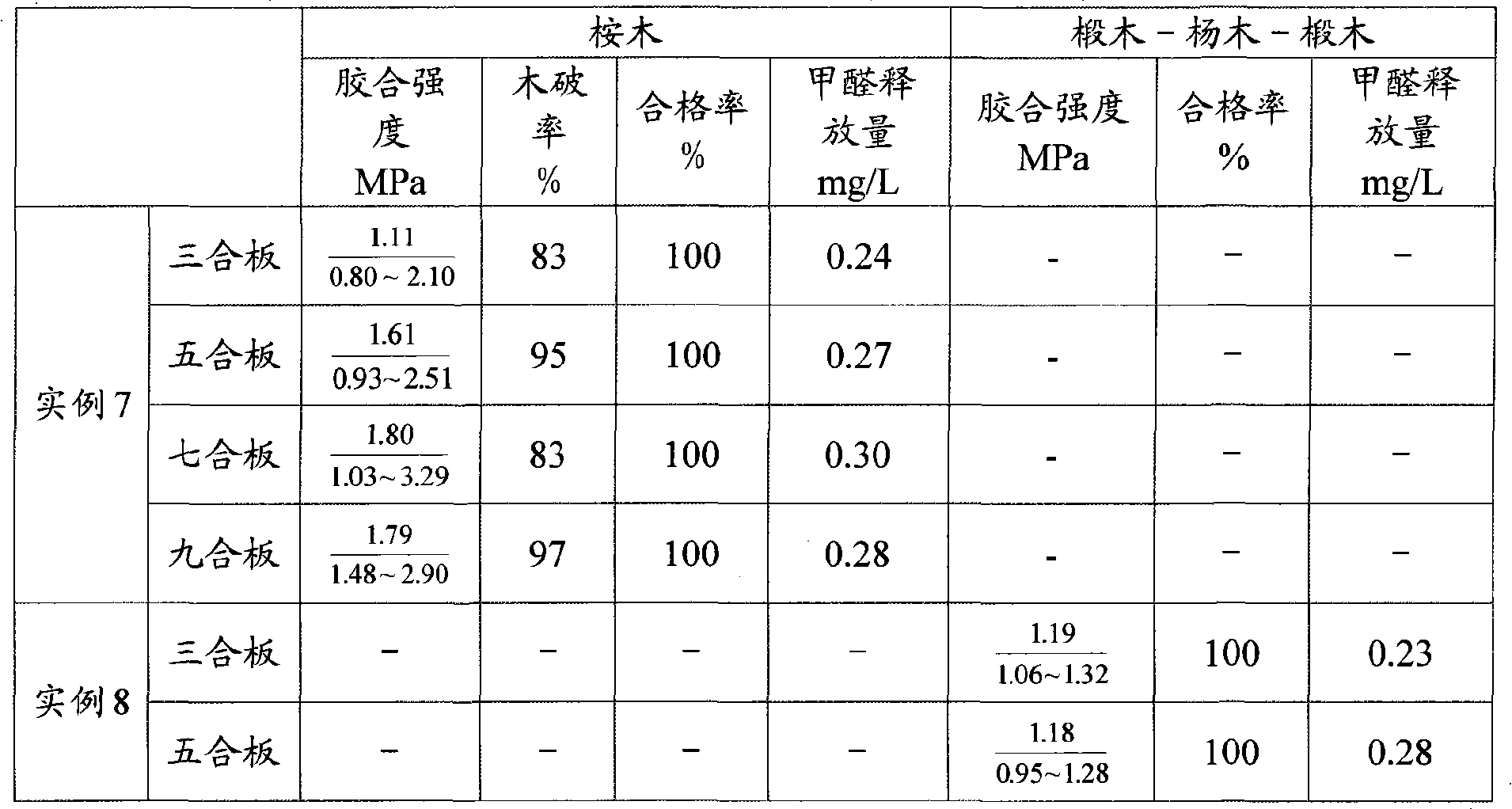

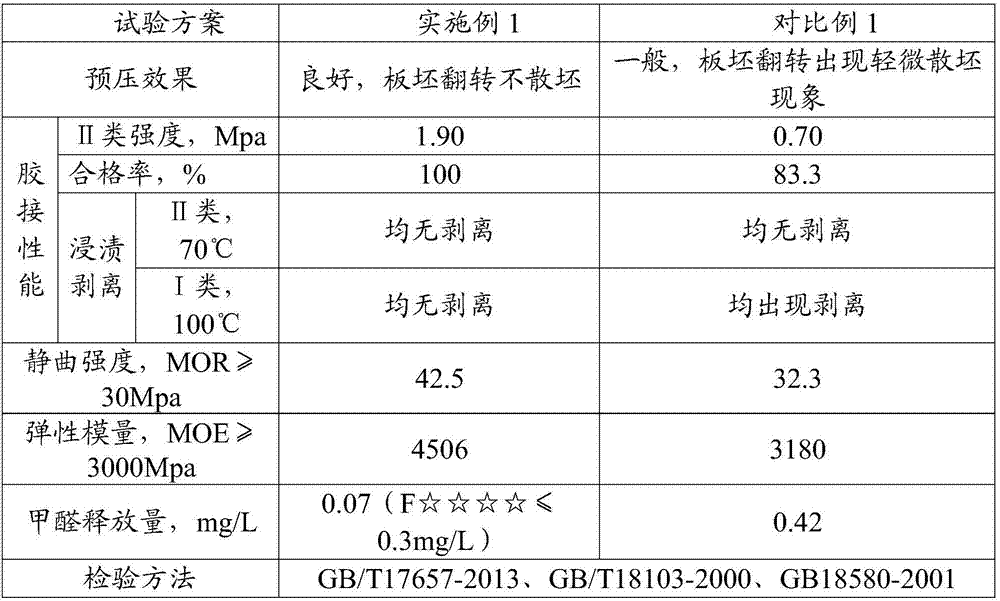

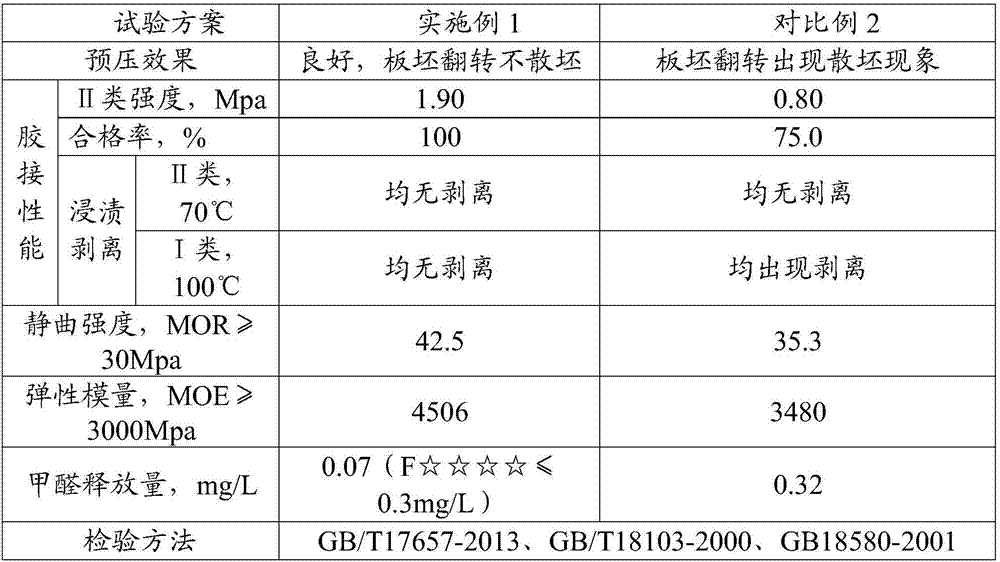

Preparation method of low-cost UMF resin adhesive used for E0-level plywood

InactiveCN101550323AReduce releaseIncrease the degree of cross-linkingAldehyde/ketone condensation polymer adhesivesEtherStrong acids

The invention discloses a preparation method of low-cost UMF resin adhesive used for an E0-level plywood. The preparation method of the adhesive is simple and has good reproducibility, lower cost and long storage period. For serayah plywood and poplar plywood pressed by the adhesive, the bonding strength and the formaldehyde emission thereof conform to the requirements of the E0-level plywood. The preparation method adopts the technique of a strong acid method, urea is selected for adding by four batches; melamine is added by three batches; the urea is added by batches, which can play the role of regulating the molecular weight of resin, especially the third adding of the urea not only can degrade macromolecule parts in rearranged molecules, but also can reduce the content of ether linkage therein, thus reducing the formaldehyde emission.

Owner:NANJING TECH UNIV

Production technology of furan resin for casting

ActiveCN102516482AEmission reductionAvoid pollutionFoundry mouldsFoundry coresFuranUltimate tensile strength

The invention relates to a production technology of furan resin, particularly to a production technology of the furan resin for casting, comprising the following steps: charging, heating up, dehydrating, opening a steam valve, heating up to 80-108 DEG C in 20-30 min, preserving heat for 60-90 min, discharging, packaging, and warehousing. According to the invention, a product with low free formaldehyde and high strength can be provided by the technology, and the production process has no generation of three wastes and is green.

Owner:共享新材料(山东)有限公司

Single-side surface layer densification processing method and product for wood

InactiveCN102672771AReduce manufacturing costReduce drying stepsWood compressionOpen tank impregnationSurface layerMaterials science

The invention discloses a single-side surface layer densification processing method and a product for wood. The method includes dipping treatment; a dried board base material is dipped into a dipping tank filled with agents, the dipping thickness of the surface of the board base material is controlled through control of the dipping depth of the board base material into the liquid level of the agents, the agents include urea resin and nano calcium carbonate granules, and the nano calcium carbonate granules enter the pores of the board base material during the dipping. A floorboard produced through the processing method is composed of a densification layer and the board base material, and the lower surface of the densification layer is connected with the upper surface of the board base material. According to the processing method, the dipping thickness of the floorboard is controlled through the increase and decrease of the liquid level height of the agents, only the surface of the floorboard contacts with the agents, therefore the agents are saved; drying after dipping is not needed, and quality problems caused by the dipping and drying can be avoided, processing steps are reduced, and outturn percentage is improved.

Owner:ZHEJIANG LINTAN WOOD SCI & TECH +1

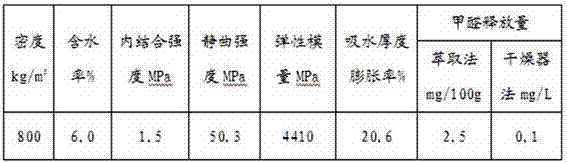

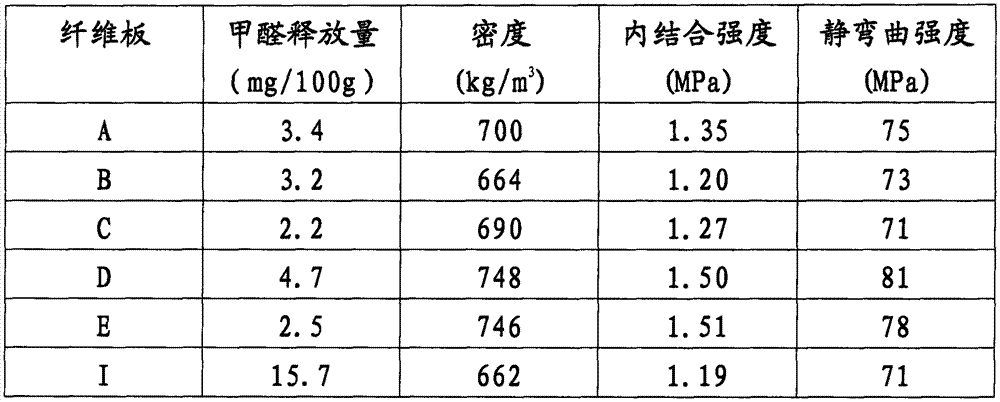

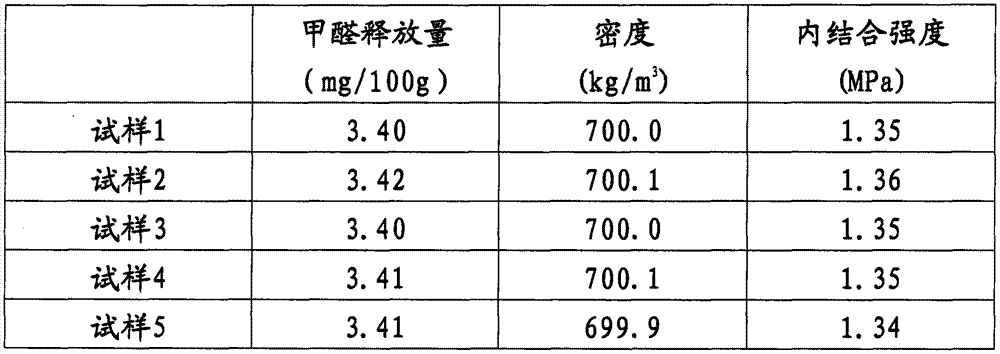

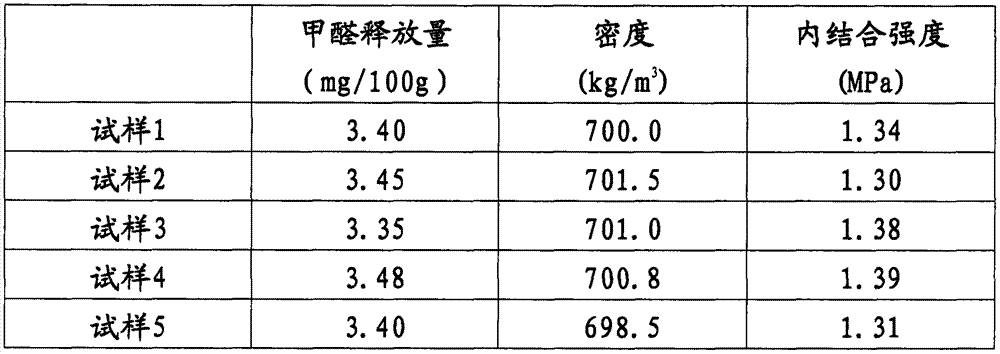

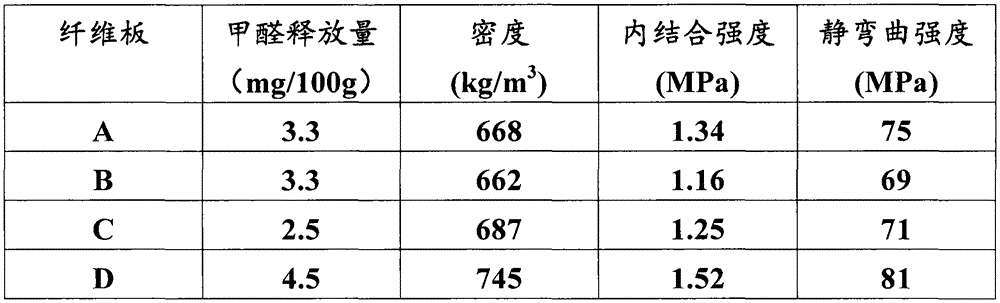

Method for manufacturing ultra-low formaldehyde emission medium-to-high density fiberboard

ActiveCN103496025ANo difference in physical propertiesNo appearanceFlat articlesDomestic articlesHigh densityFiberboard

The invention discloses a method for manufacturing an ultra-low formaldehyde emission medium-to-high density fiberboard, and relates to the technical field of chemical engineering. The method comprises the steps of timber chipping, washing, stewing, softening, grinding the chipped timber into a fiber in a hot mode, adding a mixed curing agent of a super E0 tackiness agent, urea and ammonium chloride, drying, winnowing, paving and forming, hot-pressing, cross sawing, cooling, sanding, edge cutting and identifying and packaging a sawn stock board according to the demand. In the process of manufacturing the fiberboard, the mixed curing agent of the super E0 tackiness agent, the urea and the ammonium chloride is added, the formaldehyde emission conforms to the standard, and ammonia smoking can be carried out without additionally installing equipment so that the problems that investment is increased and power is consumed cannot happen; the problems that the physical properties of the fiberboard are poor and the appearance of the fiberboard is defective do not exist, and ammonia gas and other pungent smells cannot be produced.

Owner:GUANGXI SUNWAY FOREST PROD IND

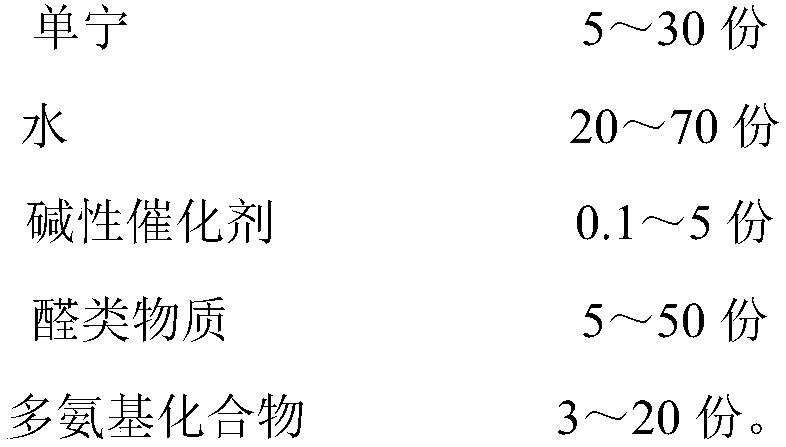

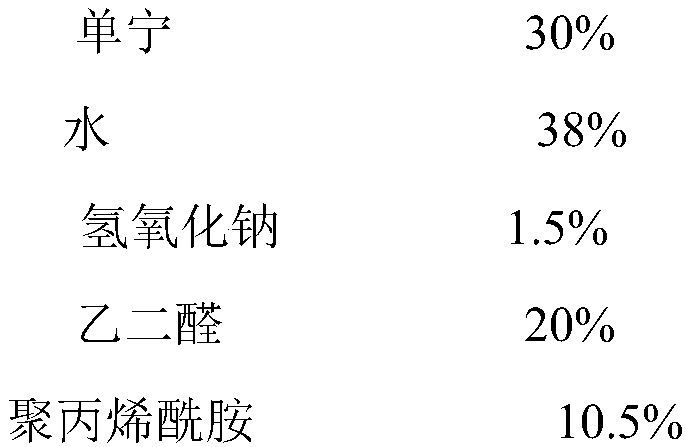

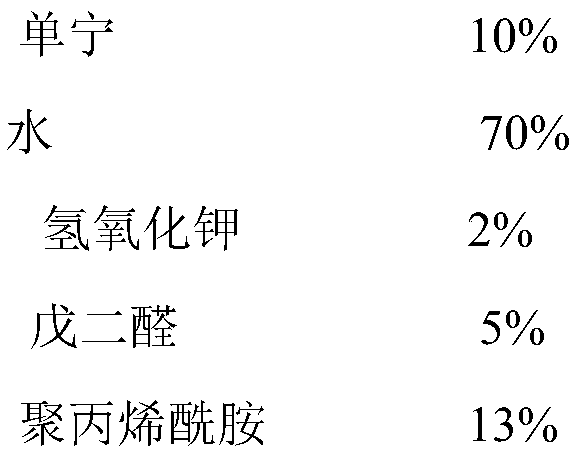

Polymerization reaction type formaldehyde catching agent and preparation method thereof

ActiveCN108727546AImprove water resistanceHigh bonding strengthAldehyde/ketone condensation polymer adhesivesMacromolecular adhesive additivesWater resistantStructural unit

The invention discloses a polymerization reaction type formaldehyde catching agent, which is prepared from 5 to 30 parts of tannin, 20 to 70 parts of water, 0.1 to 5 parts of basic catalysts, 5 to 50parts of aldehyde substances and 3 to 20 parts of polyamino compounds. The invention also discloses a preparation method of the polymerization reaction type formaldehyde catching agent. Through addition polycondensation, water-soluble polymers using tannin water-resistant structures are main bodies and comprising a great number of amino groups and hydroxymethyls are formed; amino groups and activereaction hollow sites in the polymers can achieve the goal of capturing formaldehyde through reaction with formaldehyde; in addition, through polymerization reaction, water-resistant tannin structureunits are embedded into urea formaldehyde and modified urea formaldehyde resin; the water resistance and the bonding intensity of the urea formaldehyde and the modified urea formaldehyde resin can beimproved; the resin curing time is shortened; no adverse influence is caused on the active period of the resin. The polymerization reaction type formaldehyde catching agent can be added into the ureaformaldehyde and the modified urea formaldehyde bonding agents to reduce the free formaldehyde in the resin adhesive; the polymerization reaction type formaldehyde catching agent can be sprayed and smeared onto the surface of artificial board products to directly reduce the formaldehyde release quantity of the artificial boards.

Owner:灌南县天和胶业有限公司

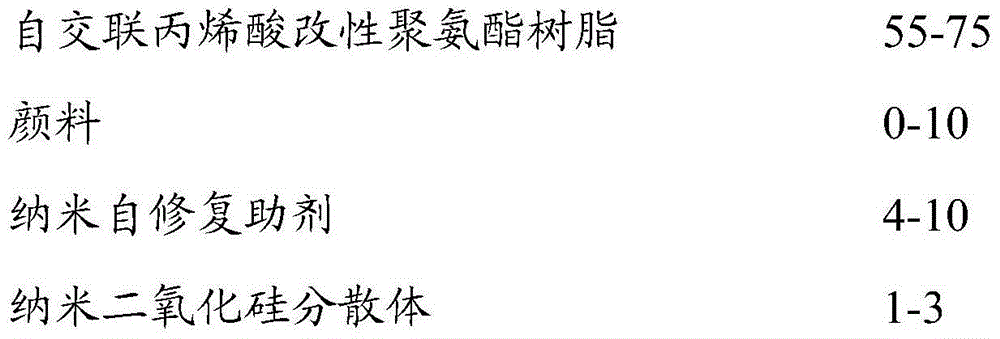

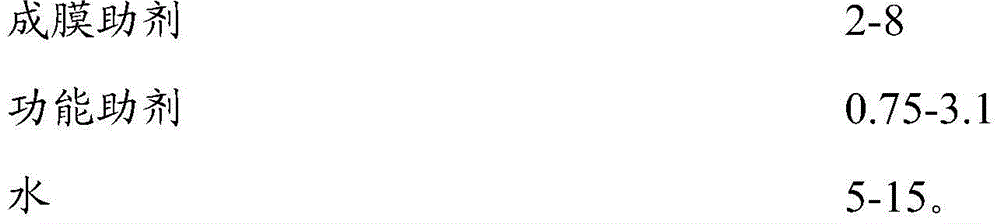

Self-repairing waterborne woodware finishing coat

The invention discloses a self-repairing waterborne woodware finishing coat, which is prepared from the following raw materials in parts by weight: 55-75 parts of self-crosslinked polyacrylic modified polyurethane resin, 0-10 parts of a pigment, 4-10 parts of a nano self-repairing assistant, 1-3 parts of nano silica dispersion, 2-8 parts of a coalescing agent, 0.75-3.1 parts of a function additive and 5-15 parts of water. According to the self-repairing waterborne woodware finishing coat designed aiming at the problems that the current waterborne paint is low in hardness, poor in scratch resistance and the like, self-repairing of micro cracks on the woodware surface can be achieved; the service life of the woodware is prolonged; and meanwhile, artificial repairing is avoided.

Owner:广东朗法博涂装新材料科技有限公司

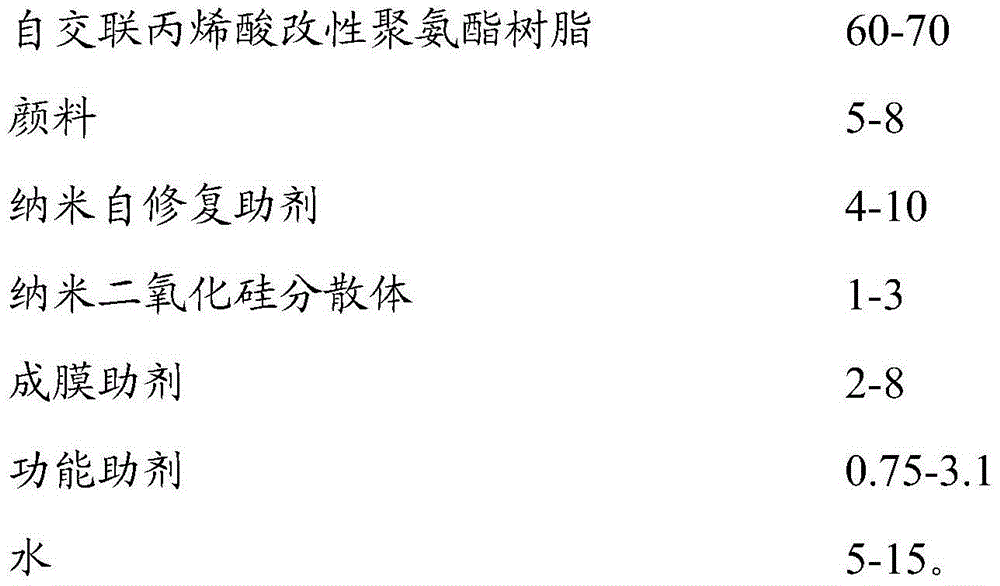

Formaldehyde removing agent composition

The invention relates to a novel formaldehyde removing composite agent, with low cost, non secondary pollution and formaldehyde removing function. The inventive agent comprises at least one imidazolidinyl, at least one alkali compound and a solvent, wherein, the mass ratio between the imidazolidinyl and the alkali compound is 500:1-50:1, and the solvent mass is 0-99%. The inventive removing agent can be uniformly dissolved in general aquosity or oil paint, with excitation on the human body. And the inventive agent can be dissolved into solution to be added into the processed decorative material, or be plated on the face of object and around air, therefore, the free imidazolidinyl in air and material is reduced under 0.08mg / m2 as national standard.

Owner:JIANGSU FEYMER TECH

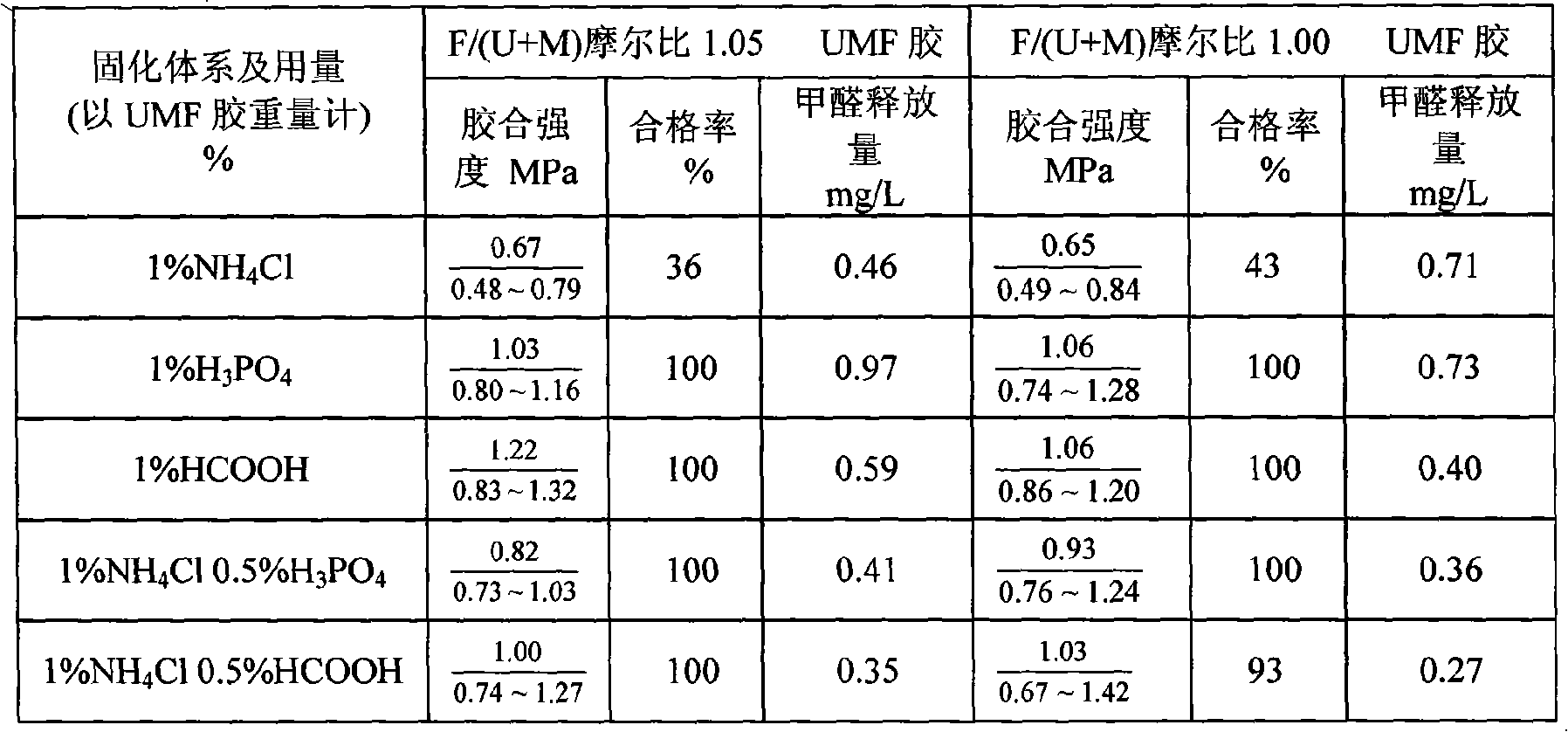

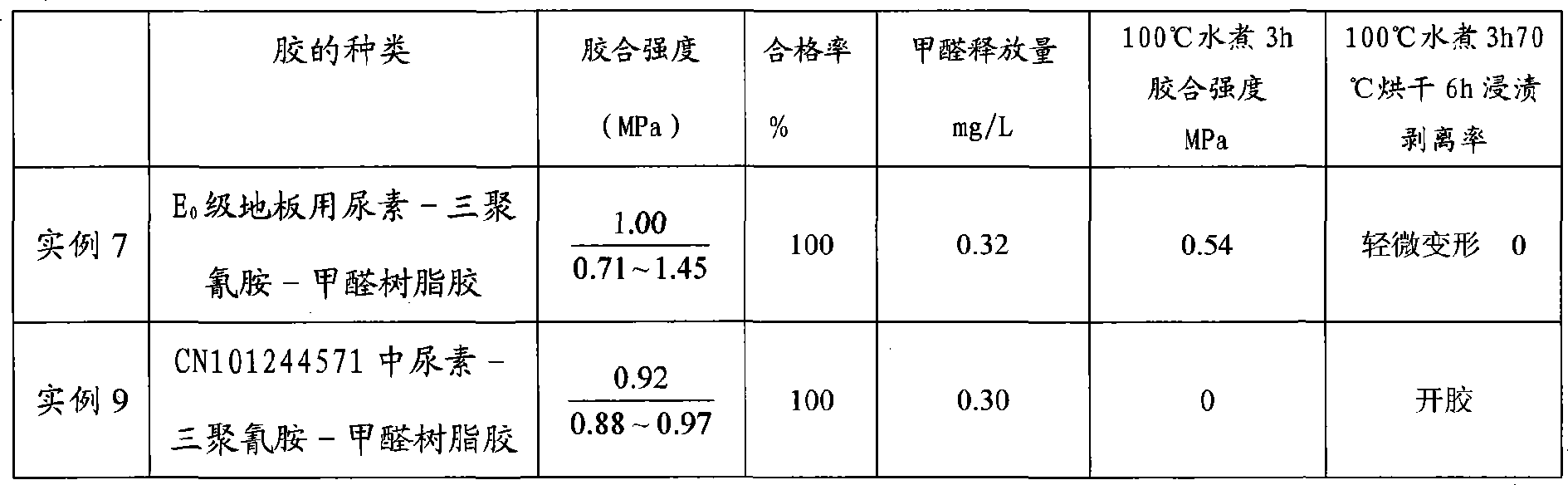

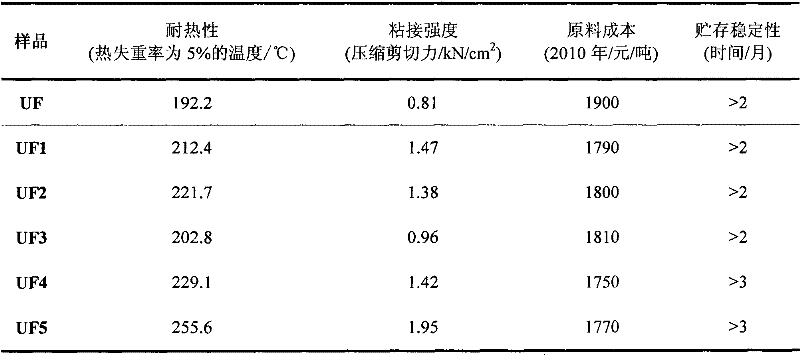

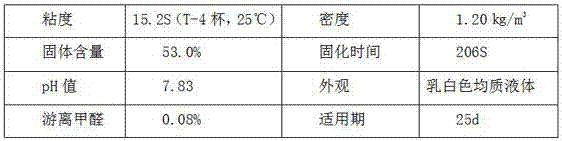

Preparation of urea-melamine-formaldehyde resin adhesive for E0 floor

InactiveCN101481593AReduce the content of ether linkagesReduce releaseAldehyde/ketone condensation polymer adhesivesUreaUrea melamine formaldehyde

The invention discloses a method for preparing a urea-melamine-formaldehyde resin adhesive for an E0-level floor. In the first step, formaldehyde solution, melamine and urea are mixed, the pH value of the mixture is regulated, the temperature is raised to 80-95 DEG C, and the reaction lasts 40-60 minutes, wherein, the mol ratio between formaldehyde and the total amount of the urea and the melamine is 2.05-2.12 : 1; in the second step, the pH value is regulated to be 5.0-6.0, and the reaction is underway till the turbidity point; in the third step, the pH value is regulated to be 6.0-6.9, the urea and the melamine are added, and the mol ratio between the formaldehyde and the total amount of the urea and the melamine which are added in the first step and the second step is 1.48-1.74 : 1, and the reaction lasts 30-70 min at a temperature of 90 DEG C; in the fourth step, the pH value is regulated to be 7.5-9.0, the melamine is added, and the reaction lasts 20-80 min at a temperature of 80-90 DEG C; and in the fifth step, the urea is added, the mol ratio between the formaldehyde and the total amount of all the urea and all the melamine is 1.02-1.30 : 1, and the material is cooled and discharged after the reaction is finished. A veneer formed by pressing the resin adhesive has good boiled-water resistance and low formaldehyde release, and the reaction is gentle and also easy to control.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

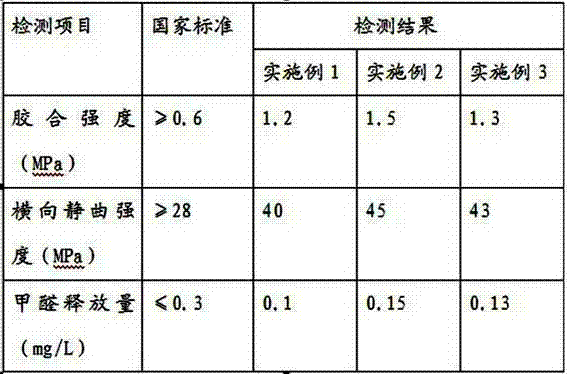

Adhesive with ultralow formaldehyde release amount, and preparation method of same

ActiveCN103484045AImprove performanceReduce free formaldehydeAldehyde/ketone condensation polymer adhesivesUnsaturated alcohol polymer adhesivesChemistryUrea

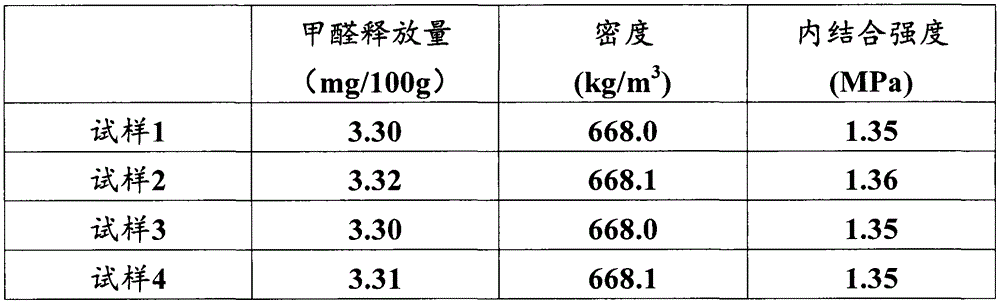

The invention discloses an adhesive with ultralow formaldehyde release amount and a preparation method of the adhesive, and relates to the technical field of adhesives for artificial boards. The adhesive comprises the following raw materials: 990 to 1,000 parts of formaldehyde, 810 to 840 parts of urea, 38 to 45 parts of melamine, 28 to 32 parts of sodium hydroxide, 6 to 8 parts of formic acid, 2 to 3 parts of triethanolamine and 1.5 to 2.5 parts of polyvinyl alcohol. According to inspection, the formaldehyde release amount of the adhesive provided by the invention is 2.0 to 3.0 mg / 100 g (0.1 to 0.3 mg / L by a dryer method), and the adhesive strength and the transverse static bending strength accord with the national standard, so damage of artificial boards manufactured by the adhesive to a human body is close to zero, the indoor air quality is good and the preparation process is simple.

Owner:GUANGXI SUNWAY FOREST PROD IND

Low formaldehyde melamine adhesive with expanding characteristic and preparation method

The melamine resin prepared with formaldehyde and melamine as main material and in the presence of Lewis acid or alkali has free formaldehyde content of about 0.1 %. The adhesive possesses excellent expansion performance during formation and is suitable for use in producing various kinds of board. The products with the adhesive have low formaldehyde release amount, excellent mechanism performance, excellent weather resistance, etc. The liquid resin may be spray dried to prepare melamine adhesive powder capable of maintaining reaction activity for long time. The adhesive of the present invention has no need of adding formaldehyde trapping agent.

Owner:倪卓

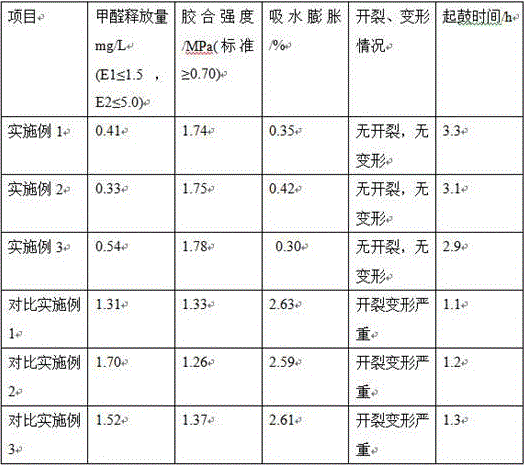

Method for producing total-eucalyptus plywood by adopting moisture-proof composite urea resin

InactiveCN106313203ALow residual formaldehydeImprove water resistanceNon-macromolecular adhesive additivesVeneer manufactureSilanesAdhesive

The invention discloses a method for producing total-eucalyptus plywood by adopting moisture-proof composite urea resin. The method comprises the following steps: rotatably cutting wood boards; drying each board; gluing; performing cold pressing for three times; stewing and conditioning; performing hot pressing for three times; cooling and conditioning; determining the thickness of a board blank and sanding the board blank. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, magnesium oxide is taken as an antiaging agent, hexamine and triglycidyl isocyanurate are taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher and aliphatic polyurethane acrylate is taken as a moisture-proof agent to prepare the composite urea resin; the composite urea resin has the advantages of being low in formaldehyde residual volume, good in water resistance and good in moisture resistance; therefore, the produced total-eucalyptus plywood is low in formaldehyde residual volume, hard to expand after absorbing water and hard to arch and deform, and a wear-resistant layer is hard to damage.

Owner:南宁市创锦胶合板有限责任公司

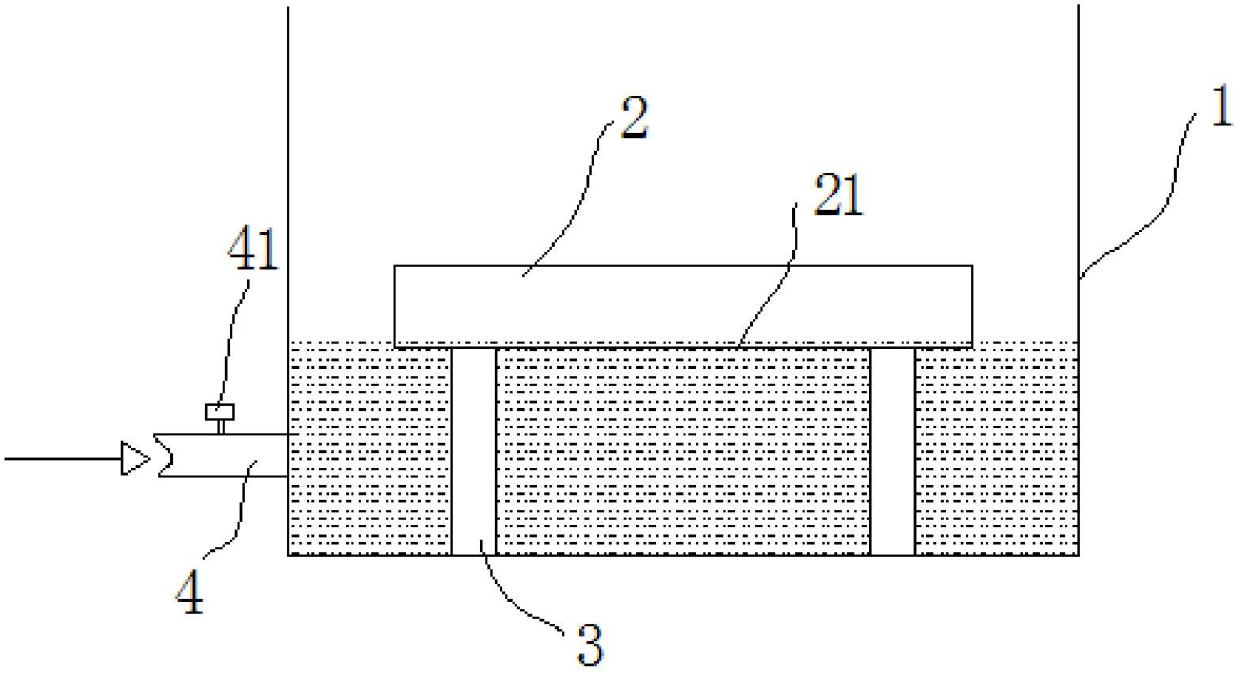

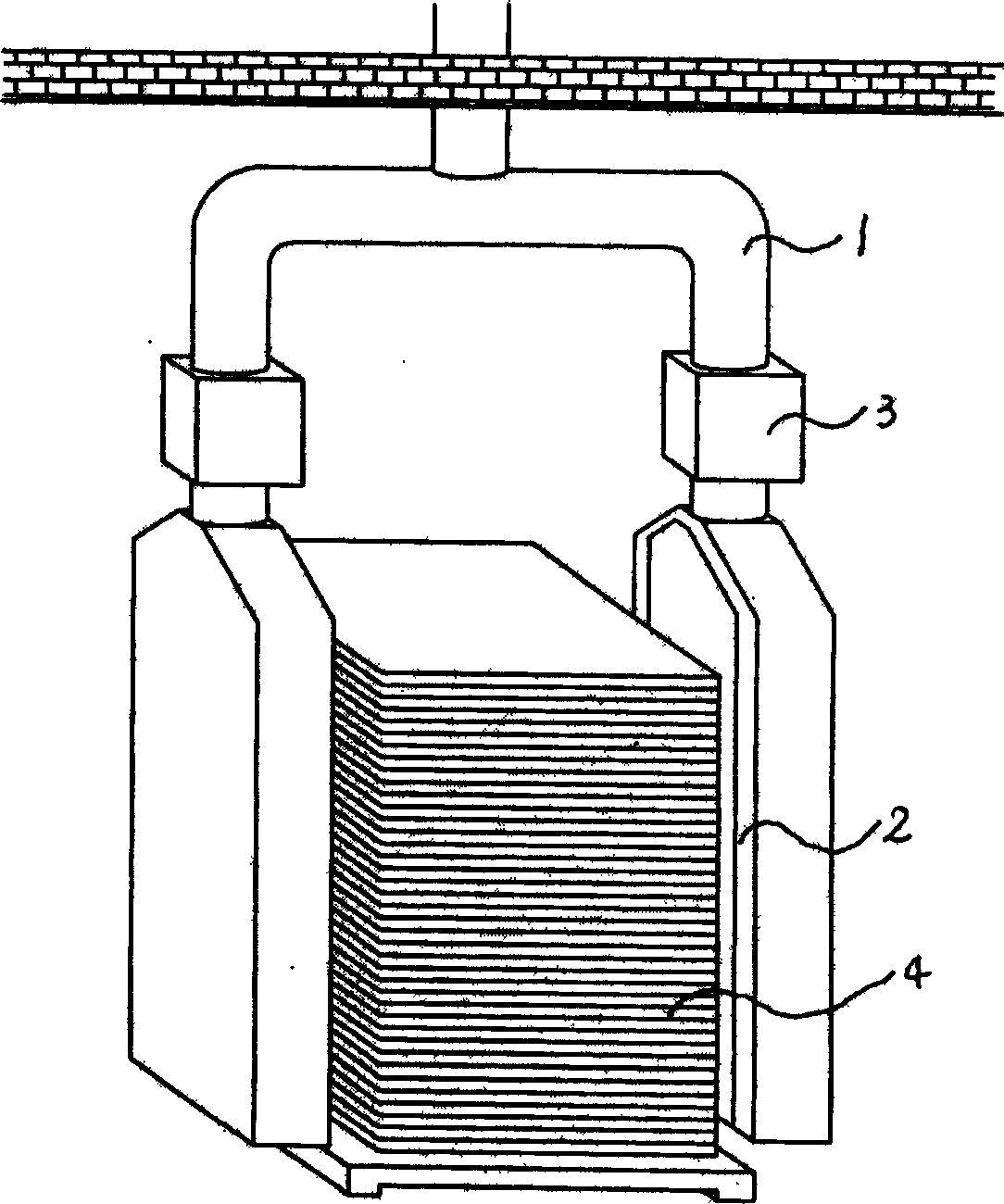

Technique and equipment for lowering formaldehyde in procedure for processing lumber-core board

InactiveCN1796070AReduce the content of free formaldehydeLow free formaldehyde contentCoating impregnationCoatingsMachining processPressure - action

The present invention discloses a formaldehyde-reducing process in the production process of veneered strip-glued board and its equipment. Said equipment mainly includes ventilating ducts and fan, and its formaldehyde-reducing process includes the following steps: spaced stacking the adhesive-coated mechanically-matched or hot-pressed board blanks, making the air inlets of ventilating ducts be positioned at two sides of board blank stack respectively, making the air outlets of ventilating ducts be positioned in the exterior of processing field, under the action of the fan a negative pressure action is formed around the board blank stack, so that the peripheral air of the board blank stack can be led out to the exterior of processing field so as to quickly discharge out free formaldehyde produced in the adhesive-coating process, and effectively prevent the free formaldehyde from being absorbed by board core and finished product board and can reduce formaldehyde content in the product obviously.

Owner:CHANGLIN WOOD IND

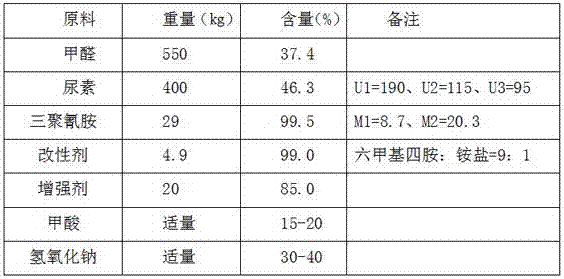

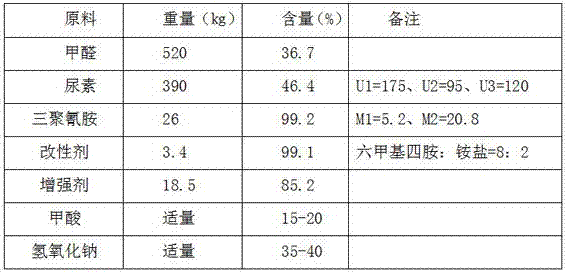

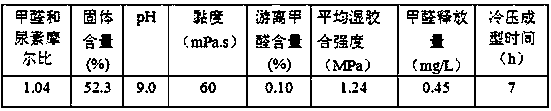

E0-level melamine modified urea formaldehyde resin adhesive

ActiveCN106883366AImprove water resistanceReduce free formaldehydeNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesResin adhesiveParquetina

The invention discloses a preparation method of E0-level melamine modified urea formaldehyde resin. The E0-level melamine modified urea formaldehyde resin is prepared by the following steps of feeding urea by three batches, and feeding melamine by three batches. The invention also discloses the E0-level melamine modified urea formaldehyde resin and an E0-level melamine modified urea formaldehyde resin adhesive. The method has the advantages that the distribution of the internal molecular structure of the urea formaldehyde resin is changed by the multi-batch feeding type, the prepared resin is added into an adhesive mixer, a formaldehyde removing agent, a reinforcing agent, an acid curing agent and industrial flour are stirred until all the components are uniformly mixed, so as to obtain a mixed adhesive, and the obtained mixed adhesive is applied into the production of parquets; the hot pressing cycle can be shortened, the hot pressing time is shortened from conventional 70-79s / mm to 30-35s / mm under the condition of no change of pressure and temperature parameters, and the utilization rate and production efficiency of a hot press are greatly improved; the release amount of formaldehyde in the prepared plate reaches superE0 level.

Owner:广州市长安粘胶制造有限公司

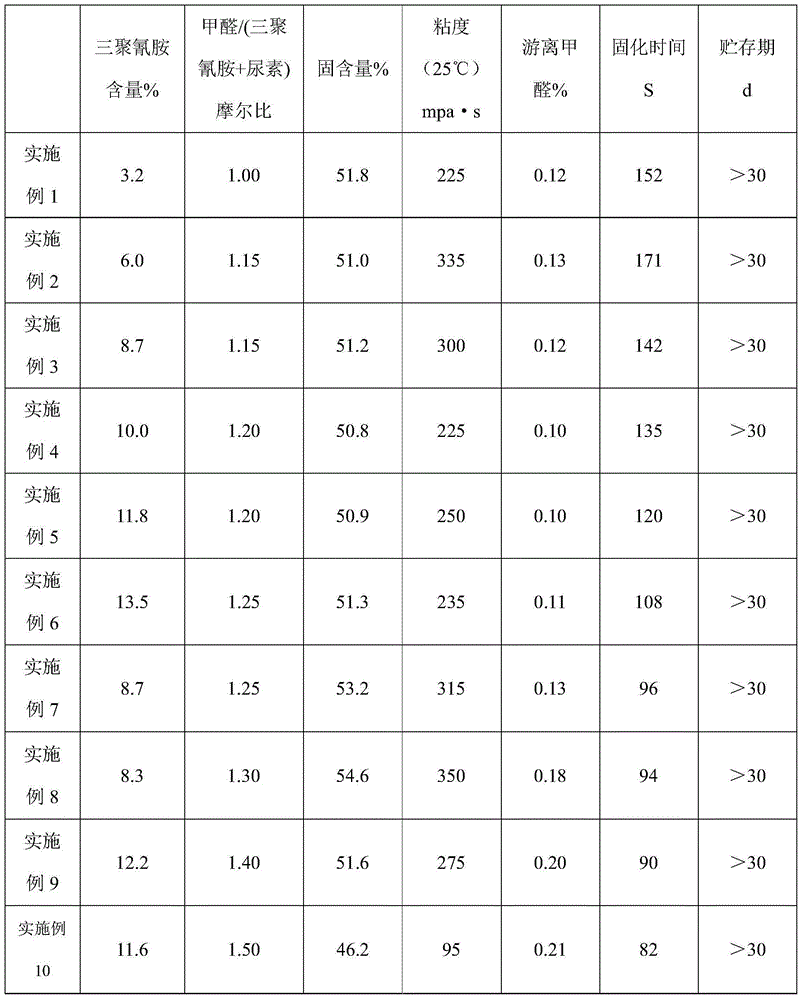

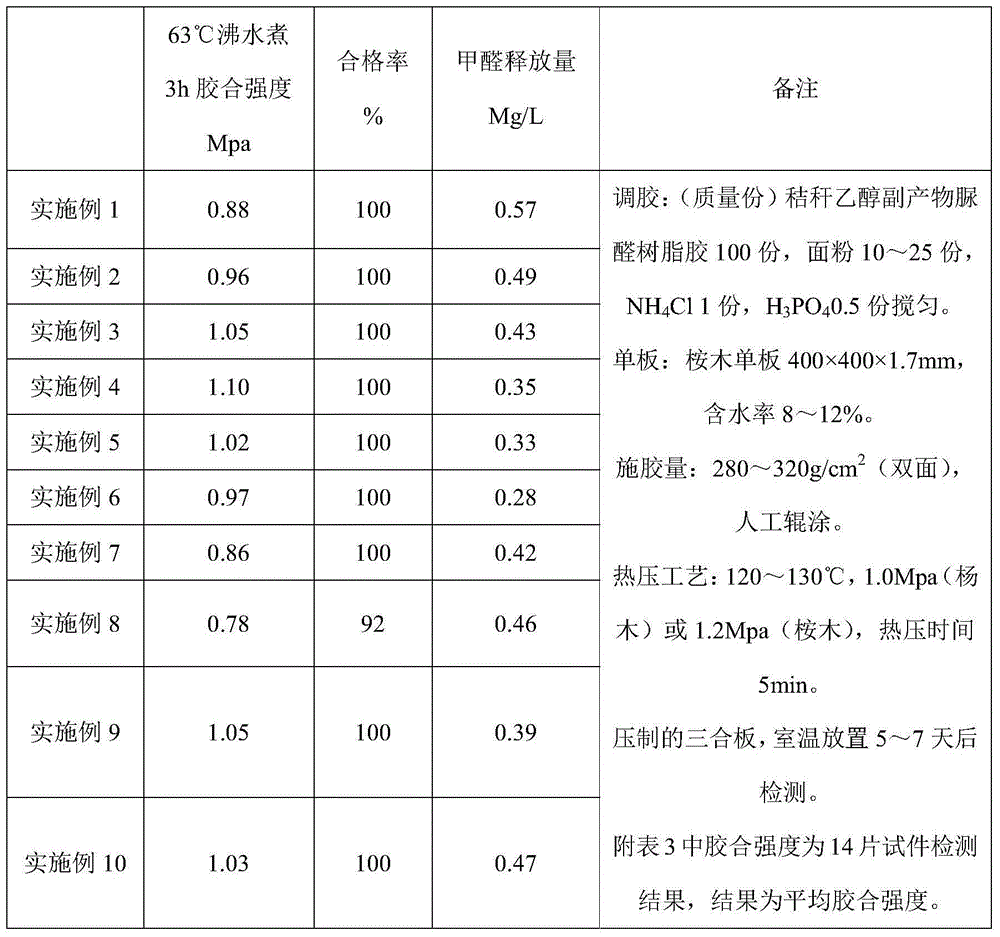

Preparation method of urea-formaldehyde resin from straw ethanol byproduct

ActiveCN104086731ALow sugarSave oil resourcesNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesChemistryPetroleum

The invention relates to a preparation method of a urea-formaldehyde resin from a straw ethanol byproduct, which comprises the following steps: 1. adding a formaldehyde solution, water, a prepressing modifier, a first batch of urea, a first batch of melamine and a first batch of straw ethanol byproduct into a reactor, regulating the pH value, and heating to react; 2. regulating the pH value and controlling the temperature to react to a cloud point; 3. adding a second batch of urea, a second batch of melamine and a second batch of straw ethanol byproduct, regulating the pH value and controlling the temperature to react; 4. adding a third batch of melamine and a third batch of straw ethanol byproduct, regulating the pH value and controlling the temperature to react; and 5. cooling, adding a third batch of urea to react, cooling and discharging. The straw ethanol byproduct used by the method has the advantages of lower ash content and lower sugar content, and the lignin molecule structure maintains multiple phenolic hydroxyl groups, alcoholic hydroxyl groups and replaceable active hydrogen. By using the straw ethanol byproduct instead of part of the urea or phenol to prepare the adhesive, the method can save the petroleum resources and implement waste recovery.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method of manufacturing medium density fiber board thick plate using spray evaporation-vacuum hot pressing technology

InactiveCN1493438AGood effectSmall deviation of section density distributionWood working apparatusFlat articlesFiberThick plate

A process for preparing the thick medium-density fibreboard by steam spraying-vacuum hot pressing technology includes hot pressing to make its density be 0.2-0.7 g / cu.cm while spraying steam under 0.2-1.0 MPa for 2-20S, and vacuumizing for 5-40 S for removing condensed water.

Owner:NANJING FORESTRY UNIV

Preparation method of compound microcapsule-coated ammonium polyphosphate master batch

InactiveCN105086455AHigh char formation rateImprove flame retardant performanceEpoxyFORMALDEHYDE SOLUTION

The invention discloses a preparation method of a compound microcapsule-coated ammonium polyphosphate master batch. The preparation method comprises that melamine and a formaldehyde solution form a performed polymer, the performed polymer is coated with ammonium polyphosphate in an ethanol aqueous solution, the ammonium polyphosphate-coated performed polymer and epoxy-modified organic silicone resin are mixed and pressed to form the master batch by polymerization. The preparation method improves a processing temperature, widens an application range, utilizes organosilicon to improve a char yield and promotes flame retardation effects.

Owner:ZIBO FUEN CHEM TECH CO LTD

Modified urea-formaldehyde resin with low content of formaldehyde, and preparation method and application thereof

InactiveCN104845038AEvenly mixedAbsorb evenlyWood working apparatusDomestic articlesPropyl benzoateFiberboard

The invention belongs to the technical field of adhesives, and relates to a modified urea-formaldehyde resin with a low content of formaldehyde. The modified urea-formaldehyde resin with a low content of formaldehyde comprises urea-formaldehyde resin and propyl benzoate. The invention also relates to a preparation method of the modified urea-formaldehyde resin, and a use of the modified urea-formaldehyde resin in production of fiberboards. The modified urea-formaldehyde resin can be used in the fields of building, decoration and industrial manufacturing, and can be used in bonding sheets, ceramics and plastics as an adhesive.

Owner:王良源

Method for preparing modified urea resin for coating abrasive tools

InactiveCN102199267AReduce free formaldehydeReduce pollutionAldehyde/ketone condensation polymer adhesivesHeat resistanceGlycerol

The invention discloses a method for preparing modified urea resin for coating abrasive tools. The method comprises the following steps of: adding formaldehyde at one time is a stoichiometric ratio, regulating the pH to be 7.5-10.0, adding the first batch of urea, heating to the temperature of between 50 and 80DEG C, controlling the reaction time to be 30-90 minutes, adding the second batch of urea, heating to the temperature of between 70 and 100DEG C, controlling the reaction time to be 30-90 minutes, adding a modifier of glycerol, regulating the pH to be 4.0-6.5, and reacting at the temperature of between 80 and 100DEG C for 10 to 60 minutes; and regulating the pH to be 7.0-10.0, keeping the temperature of between 69 and 90 DEG C, adding the third batch of urea and a modifier of soluble starch, and reacting for 10 to 60 minutes by keeping the temperature, adding modified hydroxy silicone oil, controlling the pH to be 7.0-9.0, reacting for 30 to 90 minutes, and finishing the reaction to obtain the urea resin for coating the abrasive tools, which is low in cost, stable in storage, and good in heat resistance and bonding strength.

Owner:胡应模

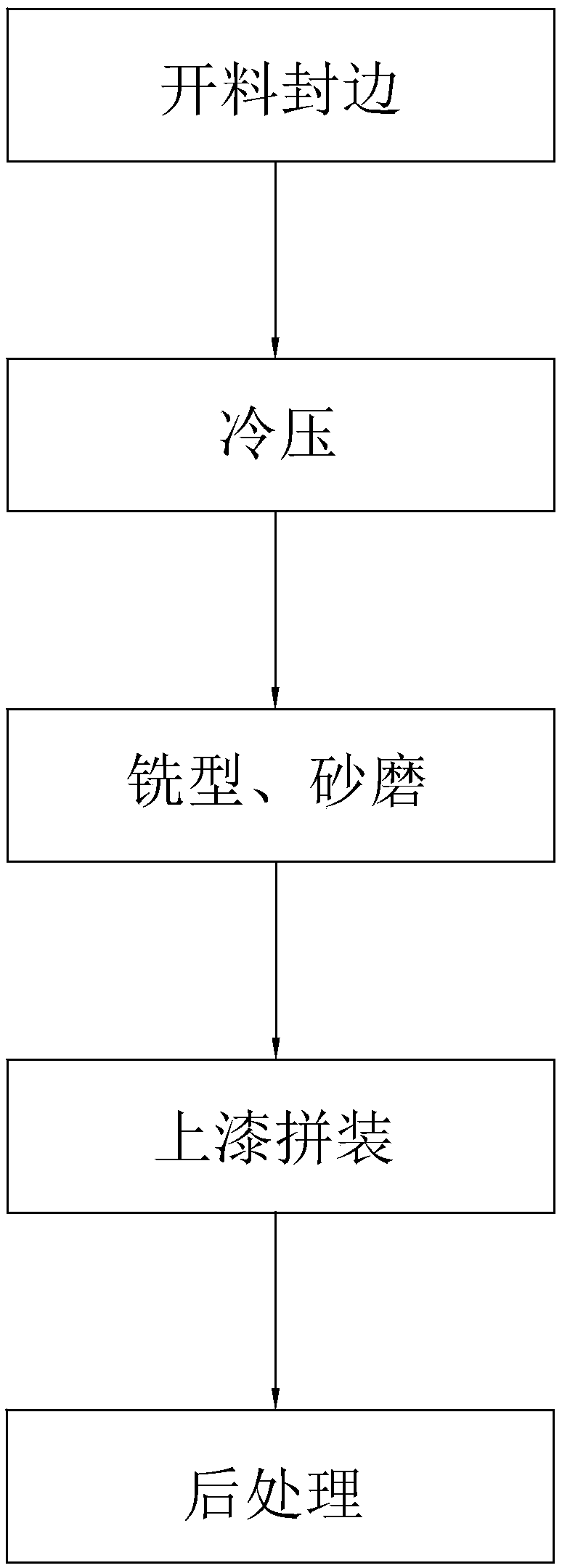

Environment-friendly fiber board preparation method and furniture processing technology

ActiveCN109577104AReduce the amount of free formaldehydeReduce free formaldehydeFibreboardWood working apparatusFiberManufacturing technology

The invention discloses an environment-friendly fiber board preparation method and a furniture processing technology, and relates to the technical field of furniture manufacture. The technical schememainly includes that the environment-friendly fiber board preparation method includes the steps: (a) preparing modified adhesives; (b) crushing and uniformly mixing bamboo fibers and modified sepiolite and adding mixture into water to prepare fiber stuff; (c) adding the modified adhesives and starch into the fiber stuff, uniformly mixing the modified adhesives, the starch and the fiber stuff, adding mixture into a forming die and pressing the mixture under a hot press; (d) drying a formed board at the temperature of 80-90 DEG C until water content is 5-10.6% to obtain an environment-friendly fiber board. The adhesives are modified, and the modified sepiolite is doped to prepare the environment-friendly pollution-free fiber board capable of purifying air.

Owner:上海朴美家具有限公司

Preparation method of nano silicon dioxide/rosin modified urea-formaldehyde resin

ActiveCN104725775AShort curing timeImprove resin performanceNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesChemistryRosin

The invention belongs to the technical field of urea-formaldehyde resin preparation, and particularly relates to a preparation method of a nano silicon dioxide / rosin modified urea-formaldehyde resin. The method comprises the following steps: preparing a urea-formaldehyde resin from urea and formaldehyde by a weak alkali-weak acid-weak alkali technique, and modifying with nano silicon dioxide and rosin to obtain the nano silicon dioxide / rosin modified urea-formaldehyde resin. The method has the advantages of simple technique and accessible raw materials, and is suitable for industrialized mass production. The prepared urea-formaldehyde resin has the advantages of favorable viscosity, high softening point, low free formaldehyde content, environment friendliness, higher water resistance, favorable toughness and improved aging resistance, is suitable for artificial board production, and can be used as an adhesive in material binding, bamboo / wood processing, paper binding, steel paints, multicolor pattern paints and other industries.

Owner:桂林兴松林化有限责任公司

Phenol-formaldehyde resin and preparation method thereof

The invention relates to the technical field of synthesis of phenol-formaldehyde resin, in particular to the phenol-formaldehyde resin which is thermosetting resin. Bisphenol type compounds and aldehyde compounds 1 are mixed and subjected to a constant-temperature reaction under certain pressure under the action of a catalyst, and an intermediate body is obtained; the intermediate body and aldehyde compounds 2 are subjected to a constant-temperature reaction under certain pressure under the action of the catalyst, and the phenol-formaldehyde resin is obtained. The phenol-formaldehyde resin is obtained through the reactions at different temperatures under different pressures in combination of the adding quantity of catalysts and formaldehyde, the obtained phenol-formaldehyde resin is the thermosetting resin, and the phenol-formaldehyde resin can be cured at the high temperature without a curing agent; fabric, paper and boards prepared from the phenol-formaldehyde resin have lower free formaldehyde content, are more environment-friendly and have lower odor, and the use environment is more excellent.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Method for adopting high-temperature-resisting composite urea resin for producing whole-eucalyptus solid wood composite floor

ActiveCN106272849AWhite colorGood film formingOther plywood/veneer working apparatusNon-macromolecular adhesive additivesLacquerAntioxidant

The invention discloses a method for adopting high-temperature-resisting composite urea resin for producing a whole-eucalyptus solid wood composite floor. The method includes the steps of board rotary slicing, veneer drying, gluing, three times of cold pressing, standing maintaining, three times of hot pressing, heat dissipating maintaining, slab fixed-thickness sanding, base material surface layer gluing, maintaining grooving and paint spraying, drying and sizing. The production method is characterized in that the high-temperature-resisting composite urea resin is prepared by adopting melamine modified urea resin as the main material of an adhesive, adding oxidized starch as a viscosity complexing agent, adopting polyvinyl alcohol as a toughening agent, adopting hydrogenated rosin as an antioxidant, adopting polyisocyanate as a curing agent, adopting isobutyl triethoxy silane as a bridging agent, adopting phenolate lignin as a formaldehyde catching agent and adding high-temperature-resisting filler. The high-temperature-resisting composite urea resin prepared through the method is used for producing the whole-eucalyptus solid wood composite floor so that the whole-eucalyptus solid wood composite floor can have good heat resistance performance, no obvious crack phenomenon happens under high-temperature and high-strength ultraviolet irradiation or long-time ultraviolet irradiation, and economic losses are reduced.

Owner:广西横县正林木业有限公司

Fluorocarbon coating good in adhesive force

InactiveCN106978019AImprove aging resistanceImprove adhesionFireproof paintsAnti-corrosive paintsCarbon nanotubePolyvinylidene difluoride

The invention discloses a fluorocarbon coating good in adhesive force. The fluorocarbon coating good comprises the following raw materials in parts by weight: 40-50 parts of polyvinylidene fluoride, 15-25 parts of acrylic modified alkyd resin, 2-4 parts of a crosslinking agent, 20-30 parts of a urea composition, 4-10 parts of glass beads, 2-8 parts of calcined kaolin, 4-8 parts of a carbon nanotube, 1-4 parts of nano titanium dioxide, 1-2 parts of magnesium oxide, 1-2 parts of a waterproof agent, 1-3 parts of an antiageing agent and 1-3 parts of polyethylene wax. The fluorocarbon coating good in adhesive force disclosed by the invention is excellent in ageing resistance, excellent in strong chemical corrosion resistance and good in adhesive force, and avoids bubbling and falling phenomena in severe environments, and the service life is prolonged.

Owner:HEFEI LYUJIE ENVIRONMENTAL PROTECTION TECH

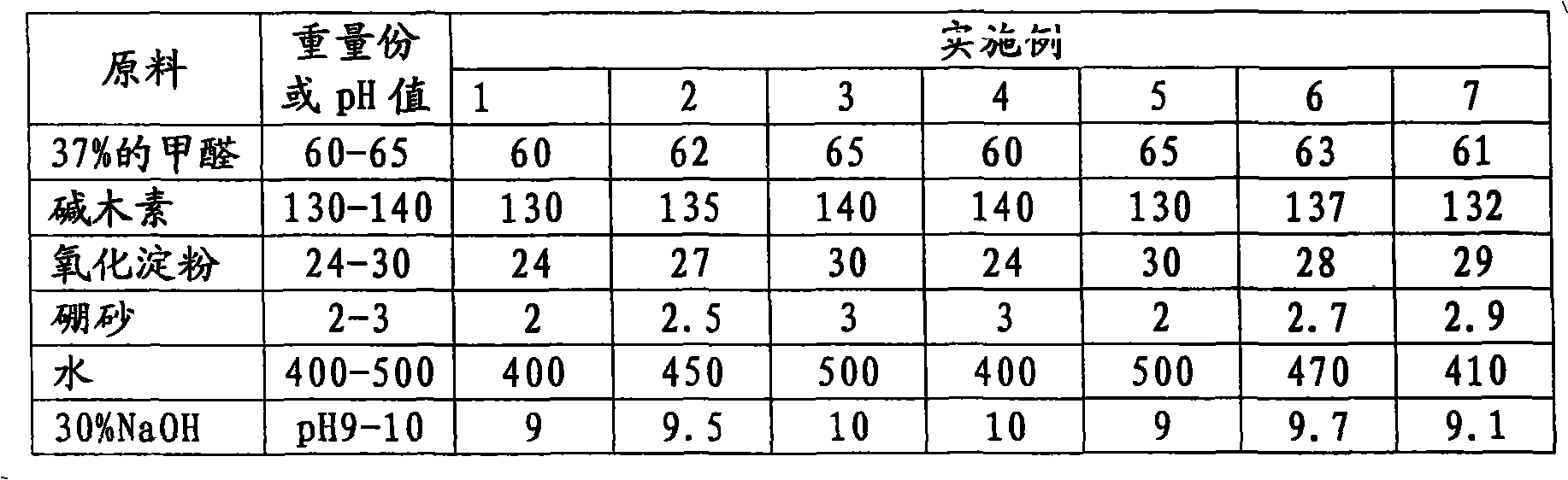

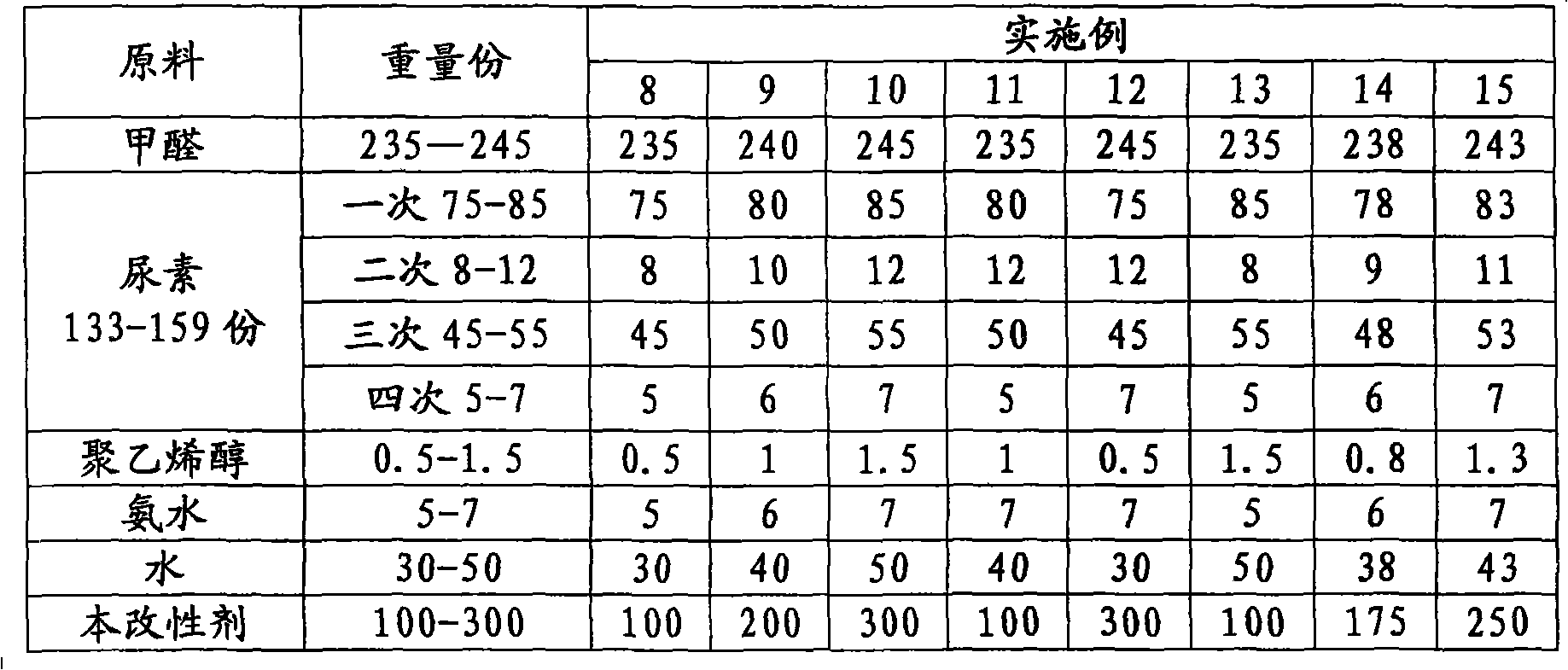

Alkali lignin oxidized starch modified urea-formaldehyde glue and production method thereof

InactiveCN101575487AReduce free formaldehydeImprove water resistanceAldehyde/ketone condensation polymer adhesivesChemistryRaw material

Owner:ZHEJIANG FORESTRY UNIVERSITY

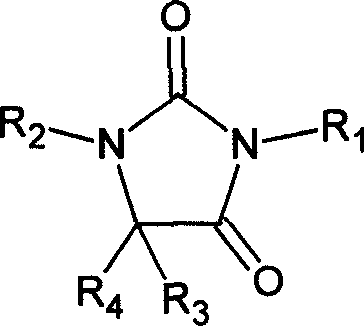

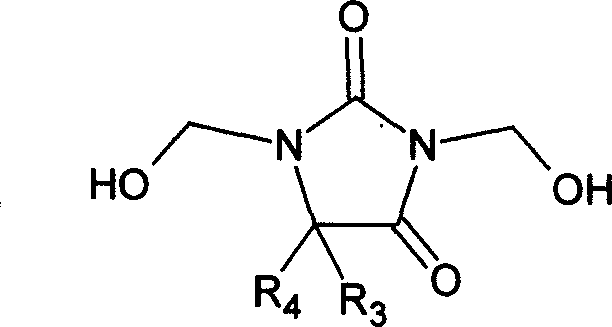

Preparation method and application of cross-linked resin for spinning

InactiveCN105542099AReduce free formaldehydeGood colorWrinkle resistant fibresShrinking resistant fibresCross-linkGlyoxal

The invention provides a preparation method of cross-linked resin for spinning. The preparation method comprises the following steps: carrying out a cyclization reaction on glyoxal and urea, thus obtaining a reaction solution; enabling the reaction solution to react with formaldehyde, and generating first condensate; carrying out an etherification reaction on the first condensate and an etherifying agent; finally modifying by adding a bleaching agent and water. The invention also provides the application of the cross-linked resin for spinning. The application comprises the following steps: selecting the cross-linked resin prepared by the preparation method; drying the cross-linked resin under the action of a catalyst when the temperature is 60 DEG C to 80 DEG C; baking under 145 DEG C after carrying out pressing and forming on fabric. According to the cross-linked resin prepared by using the preparation method, free formaldehyde on the surface of a cloth cover is low; meanwhile, by using the cross-linked resin, not only can original characteristics of a product be kept, but also the color of the cloth cover is increased, the color is fresher, the grains are clearer, and the cross-linked resin can be used for special technology, reworking and shading treatment of the cloth cover.

Owner:中山市巴斯基纺织助剂有限公司

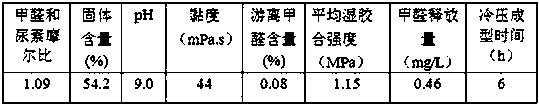

Modified adhesive for manufacturing laminate flooring base material

InactiveCN106883798AEasy to manufactureEasy to operateNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveProcess conditions

The invention discloses a modified adhesive for manufacturing a laminate flooring base material. The modified adhesive for manufacturing the laminate flooring base material is prepared by the following raw materials in parts by weight: 51.0-55.0 parts of industrial formaldehyde, 36.0-40.0 parts of industrial urea, 2.0-2.9 parts of melamine, 0.2-0.49 parts of a modifying agent and 1.6-2.0 parts of a reinforcing agent; the mass concentration of the industrial formaldehyde is 37%; in the preparation process of the modified adhesive for manufacturing the laminate flooring base material, the raw materials are enabled to react under a weak acid condition, a slightly weak acid condition to a neutral condition and a weak alkali condition. The modified adhesive for manufacturing the laminate flooring base material, disclosed by the invention, has the advantages of short adhesive manufacturing time, high efficiency, low cost and low requirements on synthesis equipment and production process condition; the modified adhesive for manufacturing the laminate flooring base material can be manufactured without additional equipment in adhesive manufacturing workshops of wood-based panel enterprises; an E1 / E0-grade laminate flooring base material can be manufactured by using the modified adhesive and has the advantages of high bonding strength, short curing time, good waterproofness and water resistance, low free formaldehyde release and so on.

Owner:GUANGXI FENGLIN WOOD IND GRP CO LTD

Preparation method of modified urea formaldehyde resin for container bottom plate

InactiveCN108794712AImproved initial adhesionExcellent adhesionAldehyde/ketone condensation polymer adhesivesMelamineToughening

The invention discloses modified urea formaldehyde resin for a container bottom plate. In addition, the invention also discloses a preparation method of modified urea formaldehyde resin for the container bottom plate. The method is characterized in that urea and an aldehyde compound are used as major raw materials; in the urea formaldehyde resin synthesis process, melamine, a toughening agent anda reinforcing agent are used for modification; the aldehyde compound and urea alkali-acid-alkali secondary polycondensation process is used for improving the urea formaldehyde resin condensation degree; meanwhile, the urea is added in batches, so that the prepared urea formaldehyde resin can realize fast curing and low formaldehyde release quantity at normal temperature. The preparation method hasthe advantages that the low-mole raw material proportion is used; the toughening agent and the reinforcing agent are used for modification; a secondary polycondensation synthesis process and a urea stage addition method are used; the prepared urea formaldehyde resin can be fast cured under the normal temperature condition; high bonding strength and low formaldehyde release quantity are realized.The basic flow process of the method approaches to a common process; the process is simple; the operation is convenient; the modification on the existing equipment is not needed.

Owner:SICHUAN AGRI UNIV

Preparation method of nitrogen-free furan resin

The invention discloses a preparation method of nitrogen-free furan resin, and belongs to the technical field of furan resin production. The method comprises the following steps: adding solid formaldehyde and furfuryl alcohol into a reaction kettle, performing stirring and mixing, and adjusting the pH value to 4.5-6 by using an acid; adding a catalyst zinc acetate under the acidic condition, performing a catalytic reaction at 130-150 DEG C, and maintaining the temperature for 3-5 h to obtain a polymer; adding an aldehyde removing agent and a coupling agent, and performing stirring for uniformmixing; and adjusting the obtained solution to be neutral by using a sodium hydroxide solution, performing continuous stirring, and discharging the obtained material to obtain the product. Raw materials in all above reaction stages comprise, by weight, 5-9 parts of solid formaldehyde, 95-100 parts of furfuryl alcohol, 0.2-0.5 part of zinc acetate, 6-10 parts of the aldehyde removing agent and 0.4-0.8 part of the coupling agent. The raw materials and the production process are improved to obtain the nitrogen-free furan resin having the advantages of no nitrogen, low free formaldehyde, low cost,energy saving, environmental protection and high strength nitrogen, and the nitrogen-free furan resin can be directly used for producing steel castings.

Owner:山东永创材料科技有限公司

Modified urea-formaldehyde resin, and preparation method and applications thereof

InactiveCN105001819AReduce formaldehyde contentReduce free formaldehydeNon-macromolecular adhesive additivesWood working apparatusPolymer sciencePropyl p-hydroxybenzoate

The invention belongs to the technical field of adhesive, and relates to a modified urea-formaldehyde resin prepared from urea-formaldehyde resin and propyl p-hydroxybenzoate. The invention also relates to a preparation method and applications of the modified urea-formaldehyde resin in manufacturing fiberboard. The modified urea-formaldehyde resin can be used for bonding materials such as sheet material, ceramic, and plastic in the field of building, decoration, and industry.

Owner:金爱莲

Preparation method of full-alkaline synthetic melamine urea-formaldehyde resin and wood impregnation method thereof

ActiveCN110014487AUniform penetrationExcellent impregnationWood treatment detailsPretreatment apparatusReaction temperatureMelamine formaldehyde resin

The invention provides a preparation method of full-alkaline synthetic melamine urea-formaldehyde resin and a wood impregnation method thereof. The preparation method comprises the following steps: adding 900-1200 parts by weight of a formaldehyde solution, 4-8 parts by weight of a sodium hydroxide solution, 20-120 parts by weight of melamine and 225-500 parts by weight of urea, then adjusting thetemperature to 60-90 DEG C, carrying out a constant-temperature reaction for 0.5-5 hours, and keeping the pH value to be 7-10; keeping the temperature of the constant-temperature reaction to be 60-90DEG C, then adding 150-475 parts by weight of urea and 90-300 parts by weight of maltodextrin or polyvinyl alcohol or starch, and carrying out a reaction for 0.5-5 hours; and adding 10-300 parts by weight of ammonia water and 2-30 parts by weight of triethylene tetramine, carrying out stirring for 5-20 minutes, and carrying out cooling to room temperature for discharging. During use, wood blocksobtained after log sawing are put into a kiln for drying, sodium borate, ammonium borate and quaternary ammonium copper are added into the melamine formaldehyde resin impregnation liquid obtained by the method, adding the dried wood blocks into the mixed solution obtained by the method for impregnation; and drying the impregnated wood block samples to finally obtain a finished product.

Owner:同威信达技术(江苏)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com