Modified adhesive for manufacturing laminate flooring base material

A technology of laminated flooring and adhesives, applied in the direction of adhesives, adhesive additives, adhesive types, etc., can solve the problems of high manufacturing cost of laminated flooring substrates, pollution from free formaldehyde release, poor water resistance, etc., and achieve good water resistance , strong market competitive advantage, and simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

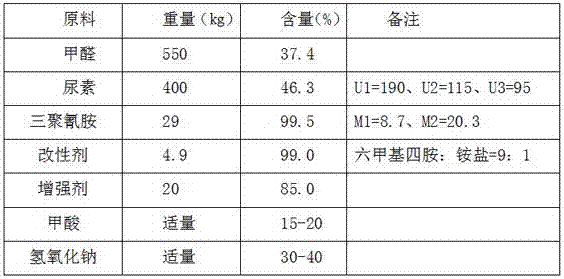

[0030] A modified adhesive for the manufacture of reinforced floor base material, its raw material formula is as shown in table 1:

[0031] Table 1

[0032]

[0033] Note: U1, U2, and U3 represent the first, second, and third additions of urea, respectively; M1, M2 represent the first and second additions of melamine, the same below.

[0034] Wherein, the modifying agent is a mixture of hexamethyltetramine and ammonium salt, the hexamethyltetramine:ammonium salt=6:4; the reinforcing agent is oxidized starch.

[0035] The preparation method of the modified adhesive for the manufacture of the above-mentioned reinforced floor base material comprises the following process steps:

[0036] (1) Put formaldehyde, modifier and the first melamine (M1) into the reaction kettle, start the agitator, stir and heat up to 45-65°C, and keep it warm for 10-20 minutes;

[0037](2) Check the pH value, add formic acid solution to adjust the pH value to 5.0-5.2, add the first industrial urea (...

Embodiment 2

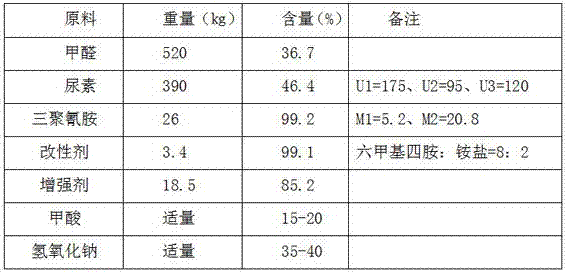

[0046] A modified adhesive for the manufacture of laminated floor base material, its raw material formula is as shown in table 3:

[0047] table 3

[0048]

[0049] Wherein, the modifying agent is a mixture of hexamethyltetramine and ammonium salt, the hexamethyltetramine:ammonium salt=9:1; the reinforcing agent is oxidized starch.

[0050] The preparation method of the modified adhesive for the manufacture of the above-mentioned reinforced floor base material comprises the following process steps:

[0051] (1) Put formaldehyde, modifier and the first melamine (M1) into the reaction kettle, start the agitator, stir and heat up to 45-65°C, and keep it warm for 20-30 minutes;

[0052] (2) Check the pH value, add formic acid solution to adjust the pH value to 5.7-6.0, add industrial urea (U1) for the first time, continue to heat up to 80-85°C, and keep warm for 10-20 minutes;

[0053] (3) Check the polymerization degree of the reaction. When the viscosity of Tu-4 cups (25°C)...

Embodiment 3

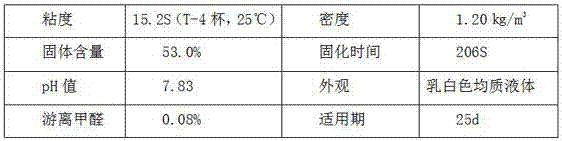

[0061] A modified adhesive for the manufacture of reinforced floor base material, its raw material formula is as shown in table 5:

[0062] table 5

[0063]

[0064] Wherein, the modifying agent is a mixture of hexamethyltetramine and ammonium salt, the hexamethyltetramine:ammonium salt=8:2; the reinforcing agent is oxidized starch.

[0065] The preparation method of the modified adhesive for the manufacture of the above-mentioned reinforced floor base material comprises the following process steps:

[0066] (1) In the reaction kettle, put formaldehyde, modifier and the first melamine (M1), start the agitator, stir and heat up to 45-65°C, keep warm for 10-20min;

[0067] (2) Check the pH value, add formic acid solution to adjust the pH value to 5.2-5.5, add the first industrial urea (U1), continue to heat up to 80-90°C, and keep warm for 10-20 minutes;

[0068] (3) Check the polymerization degree of the reaction. When the viscosity of Tu-4 cups (25°C) is 15-16s, immediate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com