Alkali lignin oxidized starch modified urea-formaldehyde glue and production method thereof

A technology of oxidizing starch and modifying urea-formaldehyde, applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc. Low cost and less free formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

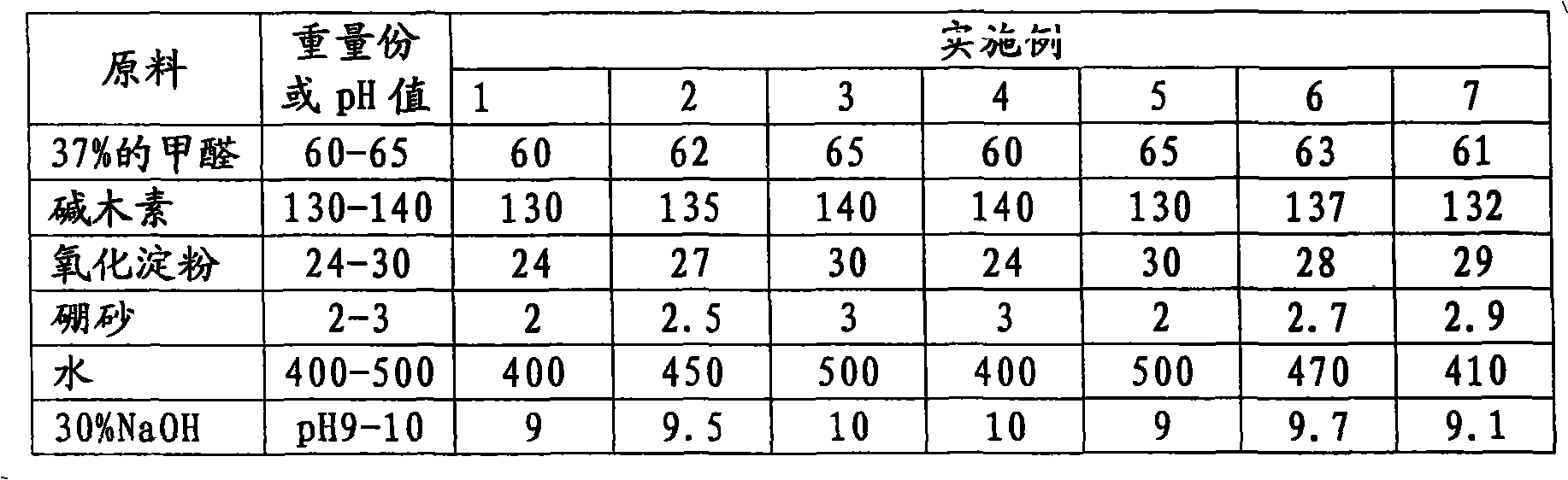

[0016] Embodiment 1 (comparison table 1 raw material and its weight portion proportioning value and pH value): the industrial formaldehyde, 130 parts of alkali lignin, 24 parts of oxidized starch, 2 parts of borax that the purity of 60 parts by weight are respectively and 400 parts of industrial water are added to the reaction kettle at one time, and the pH value of the reaction environment in the kettle is adjusted to 9 with a NaOH solution of 30% by weight, and the temperature is raised to 90 ° C within 30 minutes, and the temperature is maintained for 65 minutes after the reaction Cool to room temperature, and put it in barrels.

Embodiment 2

[0017] Embodiment 2: Add raw materials and their parts by weight with reference to the values shown in Example 2 in Table 1, adjust the pH value to 9.5 with 30% NaOH, heat up to 93° C. in 45 minutes, keep the reaction for 60 minutes, cool to normal temperature and put Packed in drums.

Embodiment 3

[0018] Embodiment 3: Add raw materials and parts by weight with reference to the value shown in Example 3 in Table 1, adjust the pH value to 10 with 30% NaOH solution, heat up to 95°C within 60 minutes, keep the temperature for 55 minutes, and cool to normal temperature Packed in buckets.

[0019] The rest of Examples 4-7 were added according to the raw materials, parts by weight, and pH values corresponding to Examples 4-7 in the table, and the rest were made by referring to the methods of Examples 1-3.

[0020] It should be noted that the percentage concentration of the NaOH solution used as a catalyst does not have to be limited to a value of 30%, and can be selected in a range of 20%-40% or even wider. However, as a material preparation, it is only necessary to prepare the most commonly used concentration. Therefore, let's target 30%.

[0021] Alkalis such as magnesium hydroxide and potassium hydroxide can also be used to adjust the pH value.

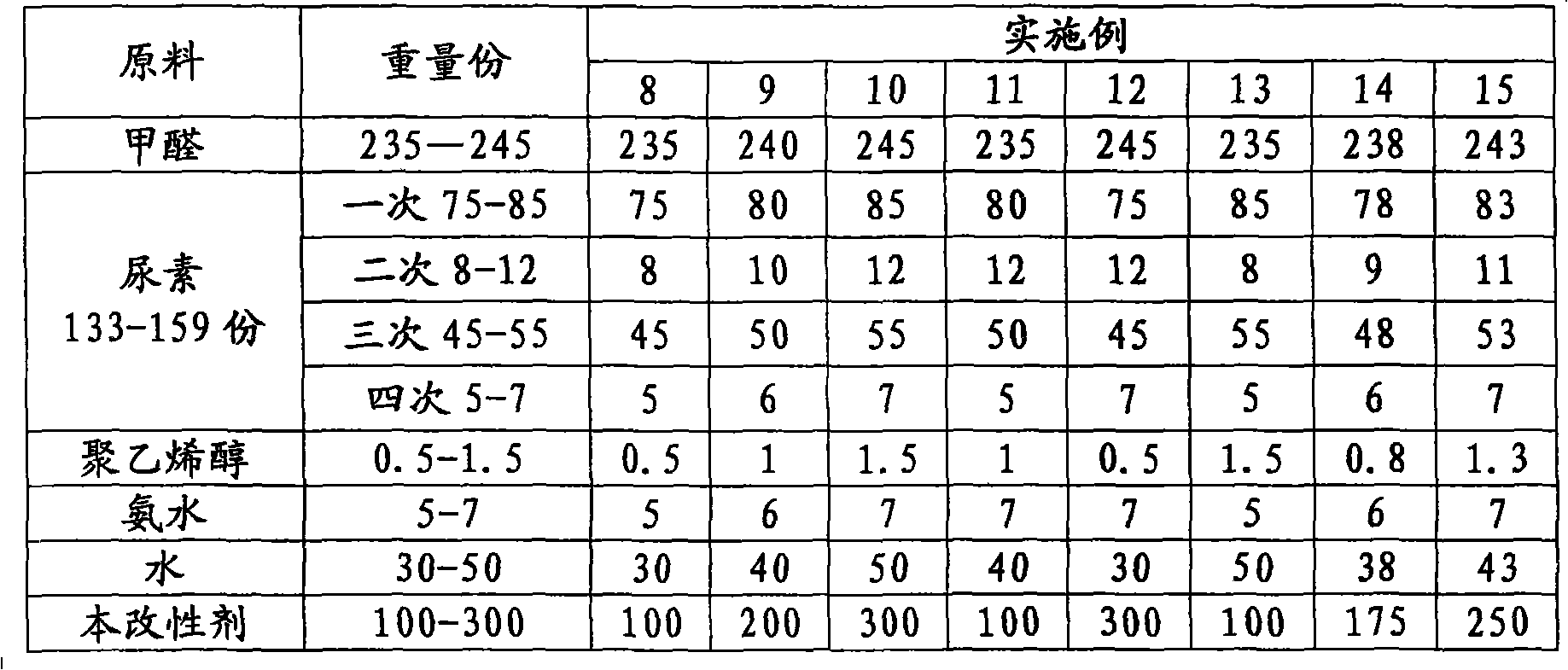

[0022] Among the above s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com