Preparation method of modified urea formaldehyde resin for container bottom plate

A container bottom plate and urea-formaldehyde resin technology, applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesive types, adhesives, etc., can solve the problems of long cold pressing time, poor aging resistance, and poor water resistance of urea-formaldehyde resin. Improve the initial adhesion, improve the brittleness of the adhesive layer, and improve the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

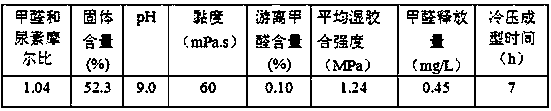

Examples

preparation example Construction

[0018] In an embodiment of the present invention, a method for preparing a modified urea-formaldehyde resin for a container bottom plate is provided, including synthesizing a low-molecular-weight urea-formaldehyde resin prepolymer modified by a toughening agent, using melamine, urea and a reinforcing agent to modify the urea-formaldehyde resin prepolymerization Body and other steps.

[0019] First, urea, toughening agent and aldehyde compounds are synthesized into primary molecular weight urea-formaldehyde resin: add 55~65 parts of aldehyde compounds, 15~25 parts of urea, and 0.5~5 parts of toughening agent into a three-necked flask, and use a basic catalyst for 5~ 10 parts, adjust the pH to 7.0~8.0, and raise the temperature to 95°C and keep it warm for a period of 100 minutes in total, so as to generate a large amount of the compounds required for the crosslinking reaction - hydroxy and dimethylolurea; then use 0.5~1 part of acidic catalyst to The pH value of the reactant is...

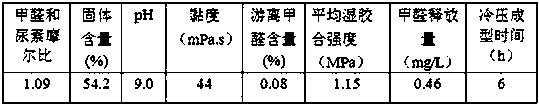

Embodiment 2

[0031] In this embodiment, 40 parts of urea, 60 parts of formaldehyde, 5 parts of toughening agent, 7 parts of melamine and 4 parts of reinforcing agent are used to synthesize the modified urea-formaldehyde resin for container floor, and the specific steps are as follows:

[0032] ①Addition reaction: use heating and alkaline conditions (pH=8.0) to dissolve urea and formaldehyde and mix them evenly, then react at a constant temperature of 95°C for 70 minutes;

[0033] ②Synthesis of primary molecular weight urea-formaldehyde resin prepolymer: Use acidic conditions (pH=5.0) to fully react the methylol urea generated in step (1) at 95°C, and stop the reaction when the viscosity appears smoky turbidity point. The stage reaction time is about 45 minutes;

[0034] ③Add the second batch of formaldehyde and urea, a certain amount of melamine and reinforcing agent to the mixed resin under alkaline conditions (pH=8.0). ), react until the precipitation turbidity point appears, and immedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com