Formaldehyde removing agent composition

A technology of formaldehyde removal agent and composition, which is applied in the direction of coating to achieve good anti-mold effect and the effect of reducing free formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

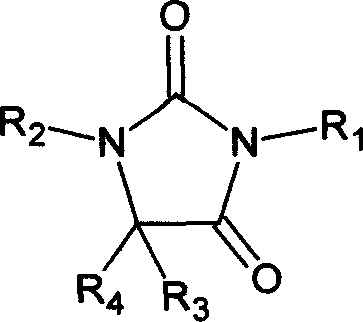

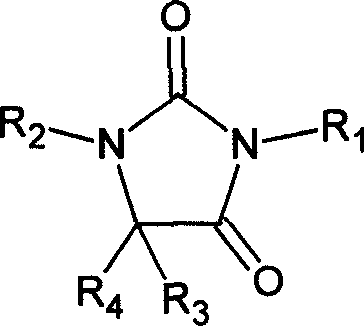

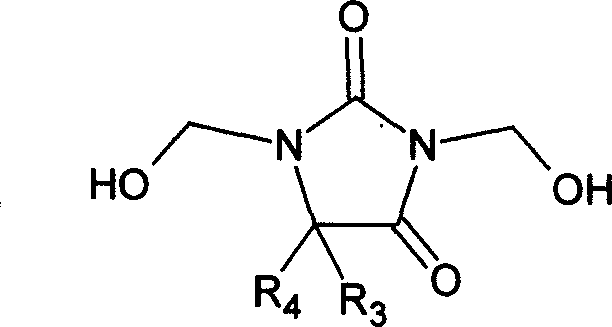

Method used

Image

Examples

Embodiment 1

[0025] Add 1167Kg of water into the 2000L enamel kettle and start stirring. Control the water temperature in the enamel kettle at 35°C±5°C. Add 1.2Kg sodium carbonate and 0.01Kg potassium hydroxide. Then, 0.01 Kg of hydroxyethyl cellulose and 100 Kg of 5,5-dimethylimidazolidinedione were added. After all the materials are dissolved, turn off the stirring, and after cooling down to 20°C, filter and discharge the material and fill it into the container.

Embodiment 2

[0027] Dissolve 1.0Kg of sodium carbonate and 0.02Kg of potassium hydroxide in 100Kg of water to make alkaline water. Add 1024Kg of ethanol into the 2000L enamel kettle and start stirring. Control the water temperature in the enamel kettle at 35°C±5°C. Then add 95Kg 5,5-dimethylimidazolidinedione, and add the alkaline water that has just been added after all the materials are dissolved. After all the materials are evenly mixed, turn off the stirring, cool down to 20°C, filter and discharge the material and fill it into the container.

Embodiment 3

[0029] Dissolve 1.4Kg sodium bicarbonate and 0.12Kg potassium hydroxide in 10Kg water to make alkaline water. Add 1280Kg of ethanol into the 2000L enamel kettle and start stirring. Control the water temperature in the enamel kettle at 35°C±5°C. Then add 87Kg 5,5-dimethylimidazolidinedione and 17Kg glycerol, and add the alkaline water that has just been added after all the materials are dissolved. After all the materials are evenly mixed, turn off the stirring, cool down to 20°C, filter and discharge the material and fill it into the container.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com