Environment-friendly fiber board preparation method and furniture processing technology

A fibreboard, environmental protection technology, applied in the field of furniture manufacturing, can solve the problems of excessive formaldehyde content of fibreboard, human health damage, etc., and achieve the effect of adsorption and degradation of indoor air formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

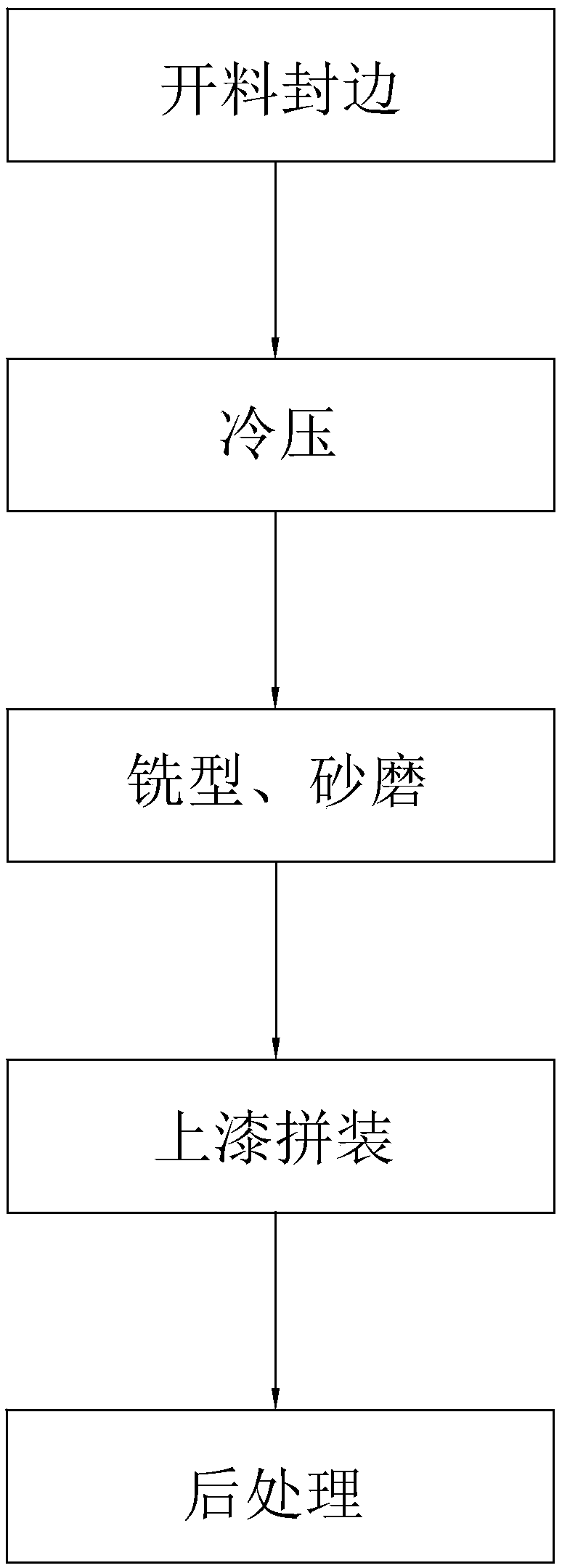

Method used

Image

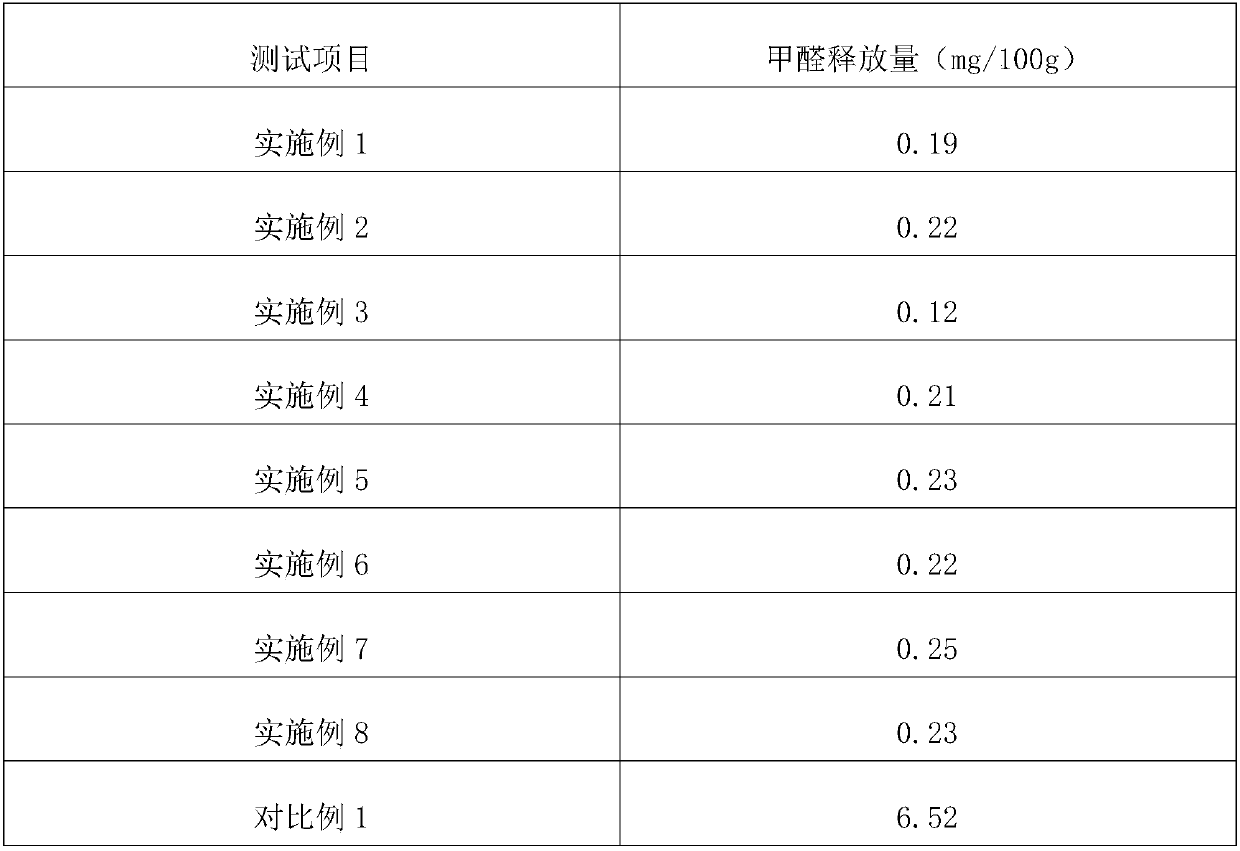

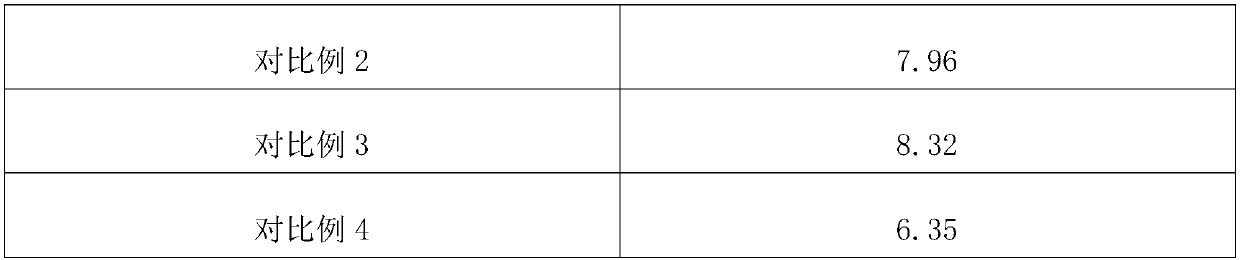

Examples

Embodiment 1

[0039] Embodiment 1: a kind of preparation method of environmental protection fiberboard, comprises the following steps:

[0040] (a) Preparation of modified adhesive: put formaldehyde into the reaction kettle and stir, add melamine in three batches, and the parts by weight of the three batches of melamine are equal, keep the pH value at 8, and the temperature at 65°C, so that the melamine is completely After the dissolution reaction is completed, a slurry is obtained;

[0041] Add anhydrous methanol into the reaction kettle, adjust the pH to acidic with concentrated hydrochloric acid, and keep it warm at 55°C for 1.5 hours. After the slurry is completely reacted and becomes a clear solution, the reaction is completed, and then the modified adhesive is obtained by distillation under reduced pressure;

[0042] (b) pulverizing and mixing the bamboo fiber and the modified sepiolite, adding the mixture to water to make fiber slurry;

[0043] (c) Add the modified adhesive and star...

Embodiment 2

[0054] Embodiment 2: a kind of preparation method of environment-friendly fiberboard, the difference with embodiment 1 is:

[0055] (a) Preparation of modified adhesive: put formaldehyde into the reaction kettle and stir, add melamine in three batches, and the parts by weight of the three batches of melamine are equal, keep the pH value at 8.5, and the temperature at 69°C, so that the melamine is completely After the dissolution reaction is completed, a slurry is obtained;

[0056] Add anhydrous methanol into the reaction kettle, adjust the pH to acidic with concentrated hydrochloric acid, and keep it warm at 59°C for 2 hours. After the slurry is completely reacted and becomes a clear solution, the reaction is completed, and then the modified adhesive is obtained by distillation under reduced pressure;

[0057] It is all identical with embodiment 1.

Embodiment 3

[0058] Embodiment 3: a kind of preparation method of environmental protection fiberboard, the difference with embodiment 1 is:

[0059] (c) Add the modified adhesive and starch to the fiber slurry and mix evenly, wherein 180Kg of modified adhesive and 5Kg of starch are added to each cubic meter of fiber slurry, and then added to the forming mold, under the hot press Pressing, the hot-pressing temperature of the hot-pressing machine is 200°C, the hot-pressing pressure is 7MPa, and the hot-pressing time is 30min;

[0060] It is all identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com