Method for preparing melamine-urea-formaldehyde resin adhesives for outdoor plywood low in formaldehyde release

A technology with low formaldehyde release and melamine, applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesives, manufacturing tools, etc., can solve the problems of reducing phenolic resin glue, dark color, etc., achieve fast curing speed, simple preparation process, Good reproducibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The second step: use 20%NH 4 Adjust the pH of the Cl solution to 5.8, and react to the cloud point at 90°C;

[0030] Step 3: Adjust the pH to 6.5 with 30% NaOH solution, add the second batch of melamine 10.5g and the second batch of urea 16g, and react at 90°C for 40min;

[0031] Step 4: Adjust the pH value to 8.5 with 30% NaOH solution, add the third batch of melamine 59g, and react at 85-90°C for 40 minutes;

[0032] Step 5: Lower the temperature to 70°C, add the third batch of urea 16g, continue the reaction at 60°C for 20 minutes, and cool and discharge.

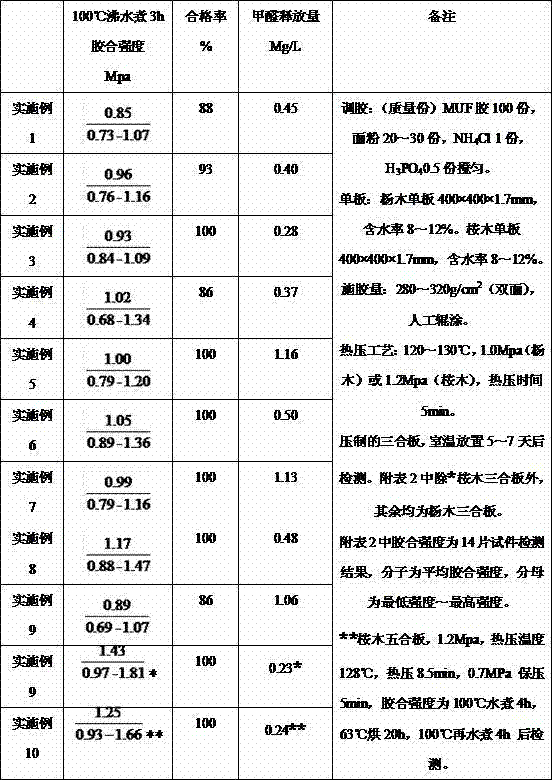

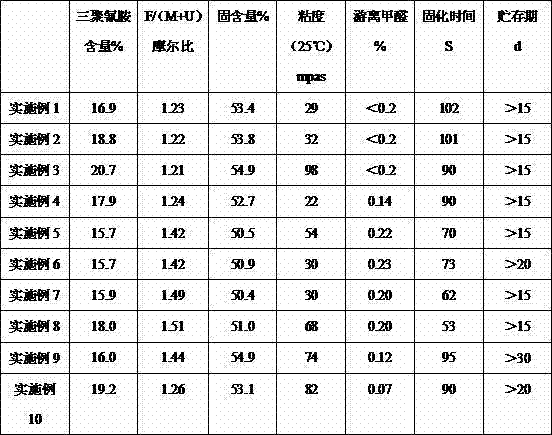

[0033] Test its performance, the results are listed in attached table 1. With 1% NH 4 Cl and 0.5% H 3 PO 4 The curing agent is used to press poplar plywood, and the test results are listed in Attached Table 2.

[0034]

[0035] Example 2

Embodiment 2

[0037] The second step: use 20%NH 4 Adjust the pH of the Cl solution to 5.7, and react to the cloud point at 90°C;

[0038] Step 3: Adjust the pH to 6.6 with 30% NaOH solution, add the second batch of melamine 12.0g and the second batch of urea 14g, and react at 89°C for 40min;

[0039] Step 4: Adjust the pH value to 8.7 with 30% NaOH solution, add the third batch of melamine 66g, and react at 89°C for 40min;

[0040] Step 5: Lower the temperature to 70°C, add the third batch of urea 14g, continue the reaction at 60°C for 20 minutes, and cool and discharge.

[0041] Test its performance, the results are listed in attached table 1. With 1% NH 4 Cl and 0.5% H 3 PO 4 The curing agent is used to press poplar plywood, and the test results are listed in Attached Table 2.

[0042]

[0043] Example 3

Embodiment 3

[0045] The second step: use 20%NH 4 Adjust the pH of the Cl solution to 5.7, and react to the cloud point at 90°C;

[0046] Step 3: Adjust the pH to 6.8 with 30% NaOH solution, add the second batch of melamine 13.5g and the second batch of urea 12g, react at 88°C for 40min;

[0047] Step 4: Adjust the pH value to 8.2 with 30% NaOH solution, add the third batch of melamine 73g, and react at 89°C for 40min;

[0048] Step 5: Lower the temperature to 70°C, add the third batch of urea 12g, continue the reaction at 60°C for 20min, cool and discharge.

[0049] Test its performance, the results are listed in attached table 1. With 1% NH 4 Cl and 0.5% H 3 PO 4 The curing agent is used to press poplar plywood, and the test results are listed in Attached Table 2.

[0050]

[0051] Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com