Patents

Literature

54results about How to "Hot pressing temperature is low" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three-component compound magnetoelectric material using organic polymer as adhesive and its preparation method

InactiveCN1395325AImprove mechanical propertiesHigh magnetoelectric conversion coefficientPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyLead zirconate titanateBarium titanate

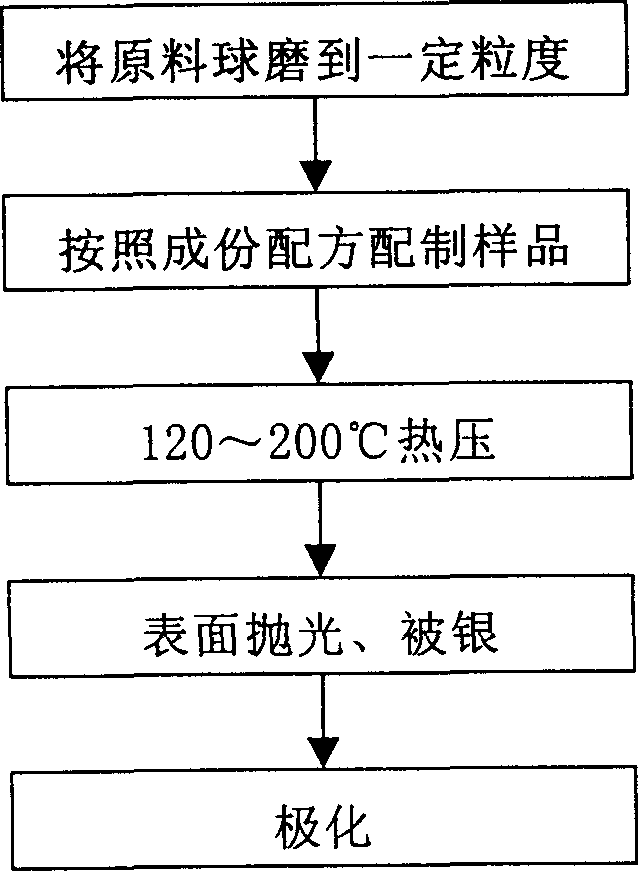

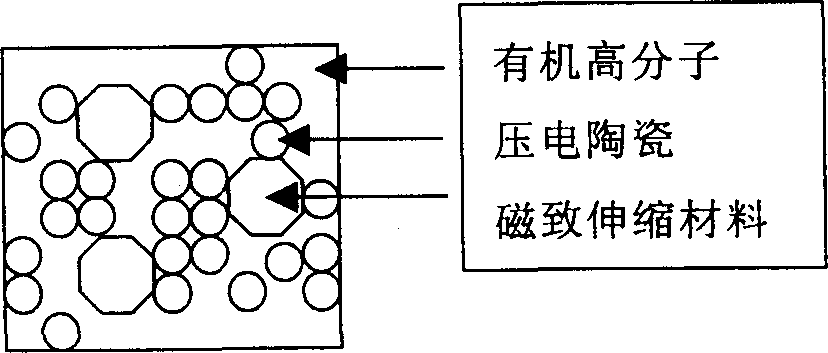

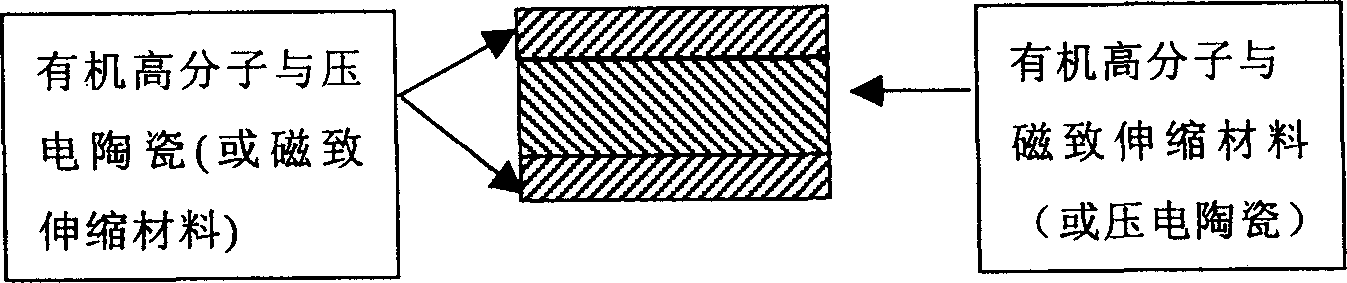

The invention relates to the ternary compound magneto-electric material by use of the organic macromolecule as the agglomerant as well as its preparation method.With the organic macromolecule being as the agglomerant the piezoelectric ceramic(such as lead zirconate titanate etc.)and the magnetostriction material(such as terbium-dysprosium-iron alloy)are taken shape by hot pressing at low temperature.The magneto-electric compound material can be made by the method.Comparing the prior art,the invention possesses the advantages of simple process,good mechanical characters of the material and high magneto-electric transformation factor.The hotpressing technique provides the features of low pressing temperature(about 120-200 deg.C),easy to change the magneto-electric characters by changing the sequence for adding the constituent and the relative content.

Owner:TSINGHUA UNIV

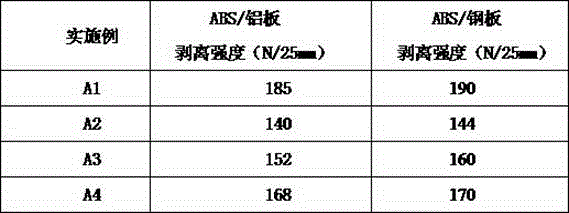

Novel hot melt adhesive and preparation method thereof

ActiveCN105733495AGood adhesionWill not deformNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAntioxidantPolyamide

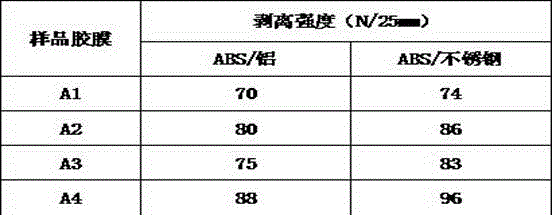

The invention discloses novel hot melt adhesive and a preparation method thereof and particularly provides novel hot melt adhesive applicable to bonding and compounding of metal and ABS plastic and a preparation method thereof. The novel hot melt adhesive is mainly characterized by being prepared from, by mass, 40-45% of nylon type copolyamide, 40-45% of thermoplastic polyurethane, 4-10% of compatilizer, 5-15% of tackifier, 1-5% of filler and 0.1-0.3% of antioxidant. The preparation method includes the steps that firstly, raw materials of a specific ratio are selected to conduct a polymerization reaction to generate the nylon type copolyamide which has good bonding performance for metal, then the nylon type copolyamide and the thermoplastic polyurethane are mixed and melted with other auxiliaries in proportion under the cooperative action of the specific compatilizer and then squeezed out, and the novel hot melt adhesive which has good bonding performance for both the metal and the ABS plastic is obtained; by means of a product of the novel hot melt adhesive, the requirement is met, the process is simple, and it is convenient to achieve industrial production and application.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

Anisotropic conductive rubber film comprising oxidation-reduction initiating system microcapsule and its preparation

InactiveCN1775884AImprove performanceShort hot pressing timeFilm/foil adhesivesElectrically-conducting adhesivesLacquerAnisotropic conductive adhesive

The invention discloses an anisotropy conductive lacquer containing oxidation reduction primosome system microcapsule. The feature is making the oxidation reduction primosome system to microcapsule and shielding its activity to achieve the effect of storing anisotropy conductive film in room temperature. The invention has advantages of high cementing reliability, good conductivity, and convenience using.

Owner:湖北省化学研究院

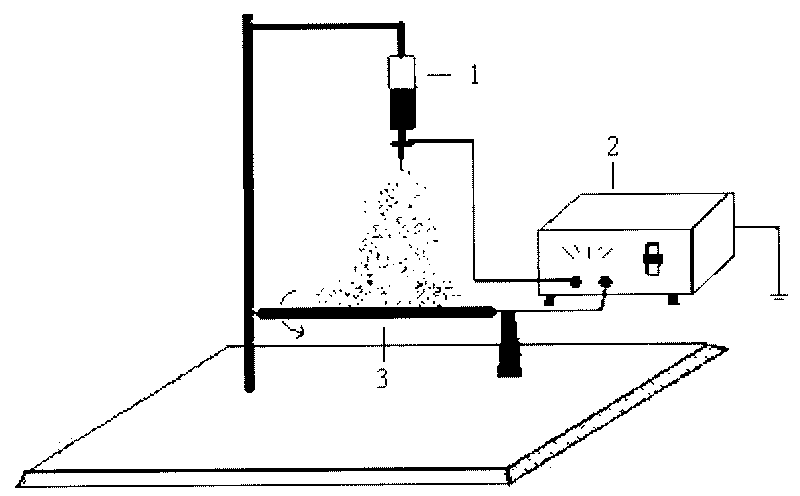

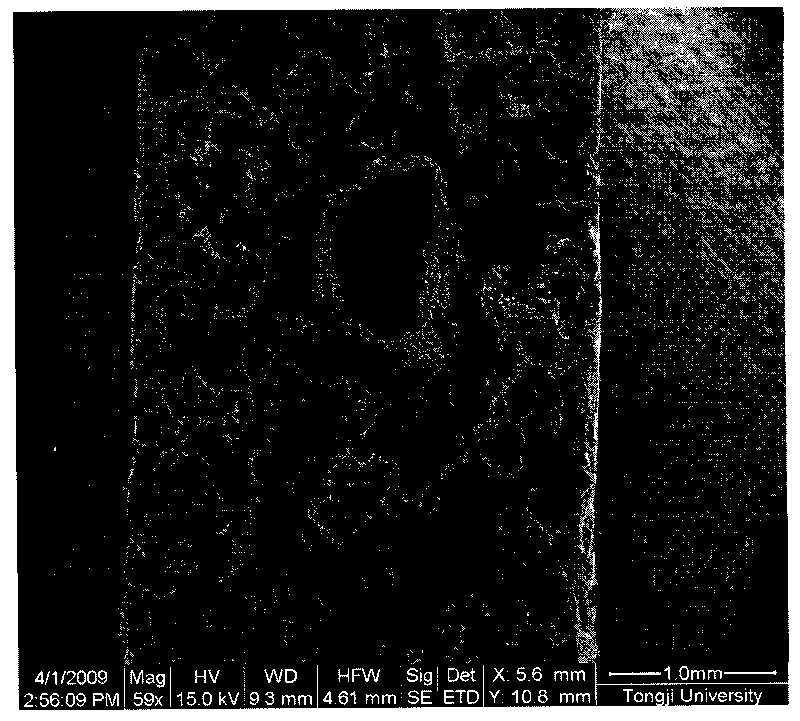

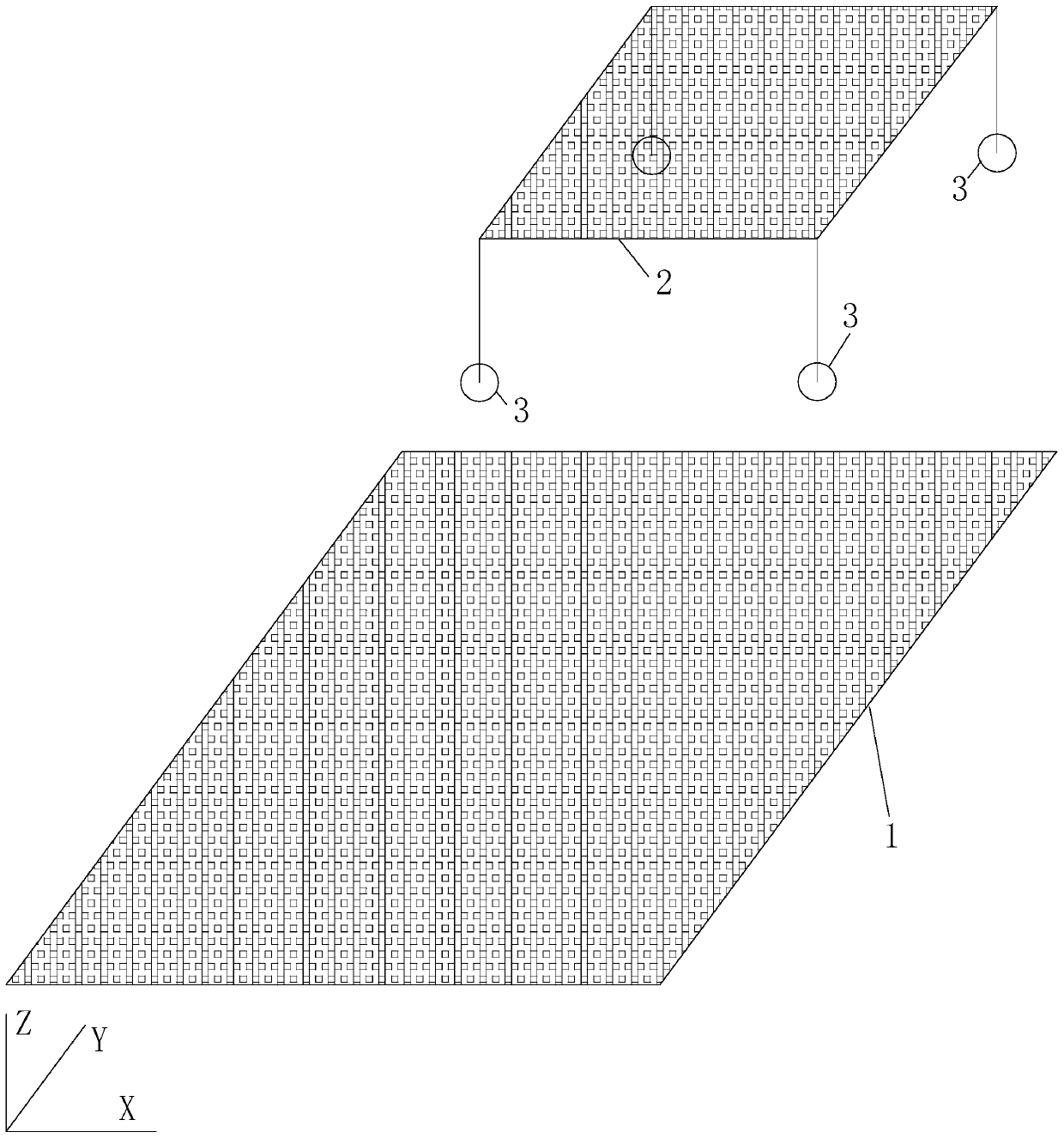

Method for constructing composite structure tissue engineering bracket containing different extracellular matrixes

The invention belongs to the technical fields of macromolecule materials and biomedical engineering, in particular to a method for constructing a composite structure tissue engineering bracket containing different extracellular matrixes. The method comprises the following steps: preparing a blood vessel bracket by an electrostatic spinning method; preparing a poriferous bracket part by adopting a blend of polylactic acid and polycaprolactone through a hot-pressing and salting-out method; and introducing the blood vessel bracket into the poriferous bracket. The composite structure tissue engineering bracket constructed in the invention realizes that different extracellular matrixes are constructed in a same bracket.

Owner:TONGJI UNIV

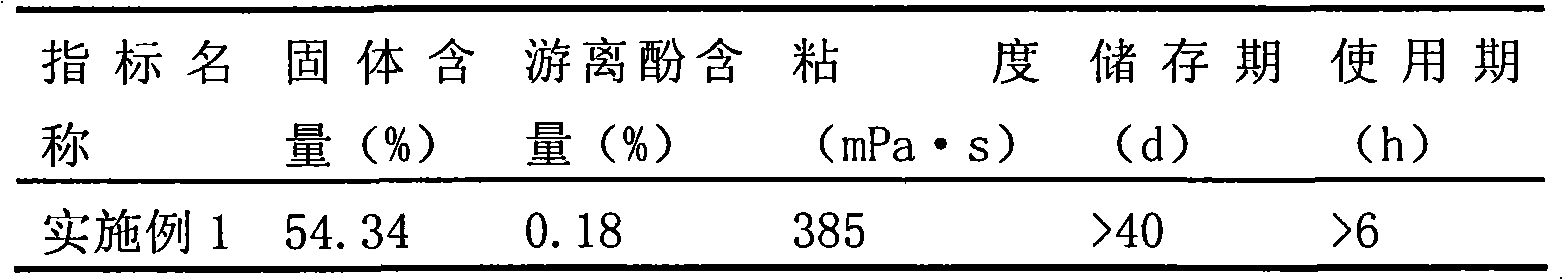

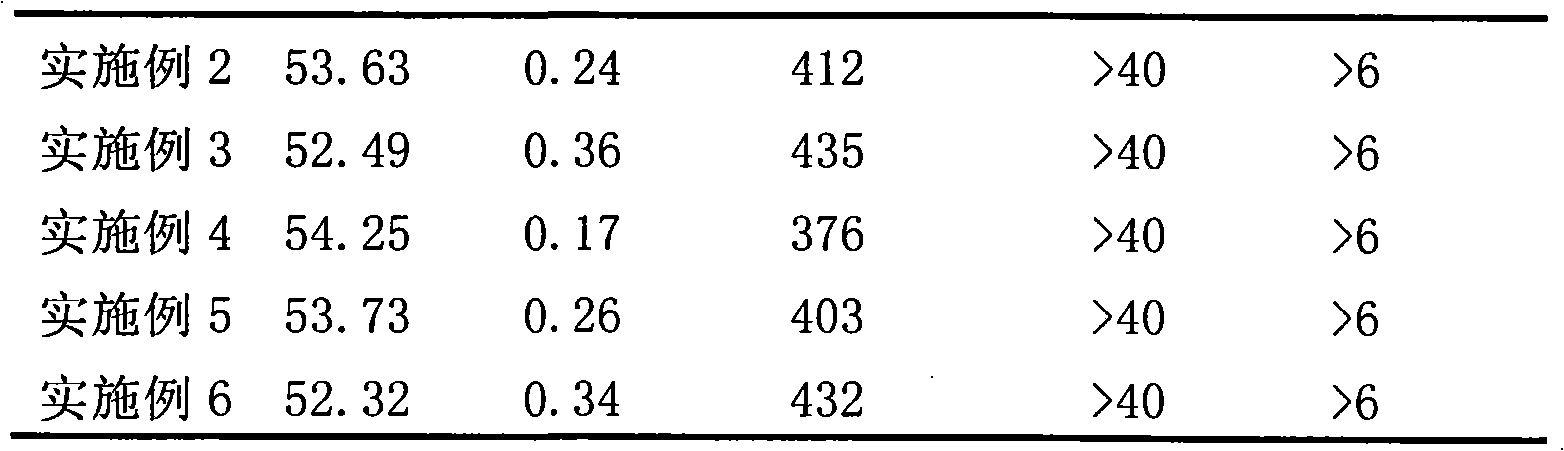

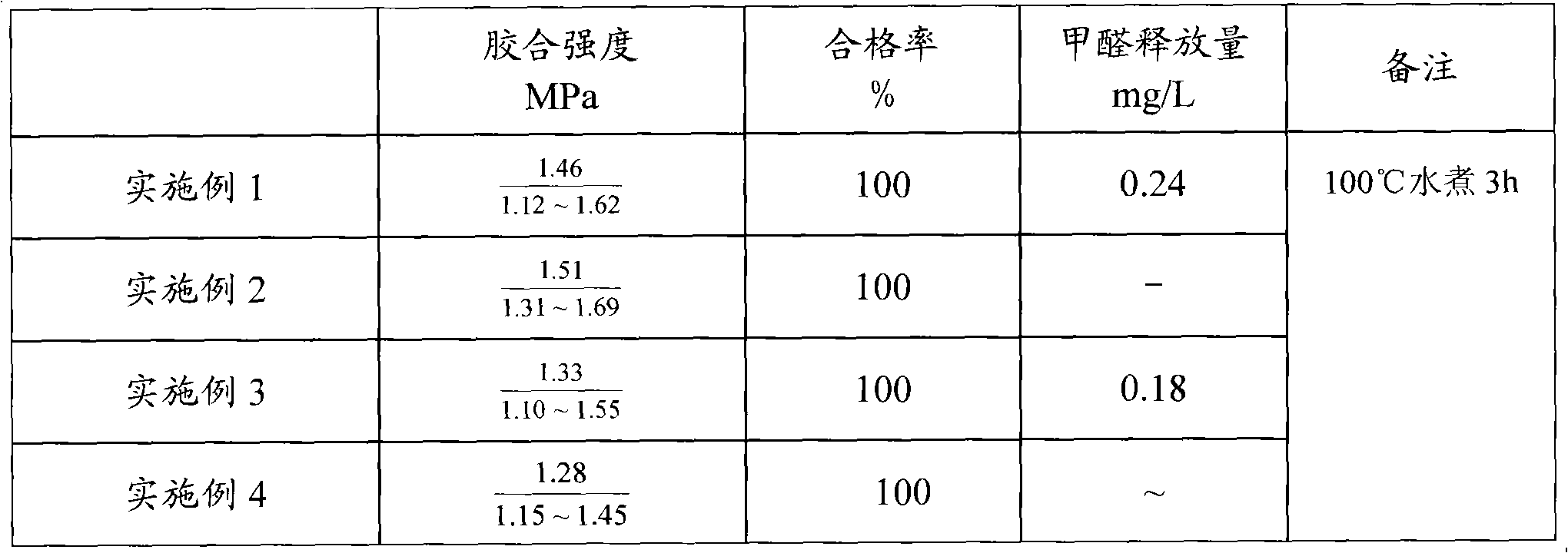

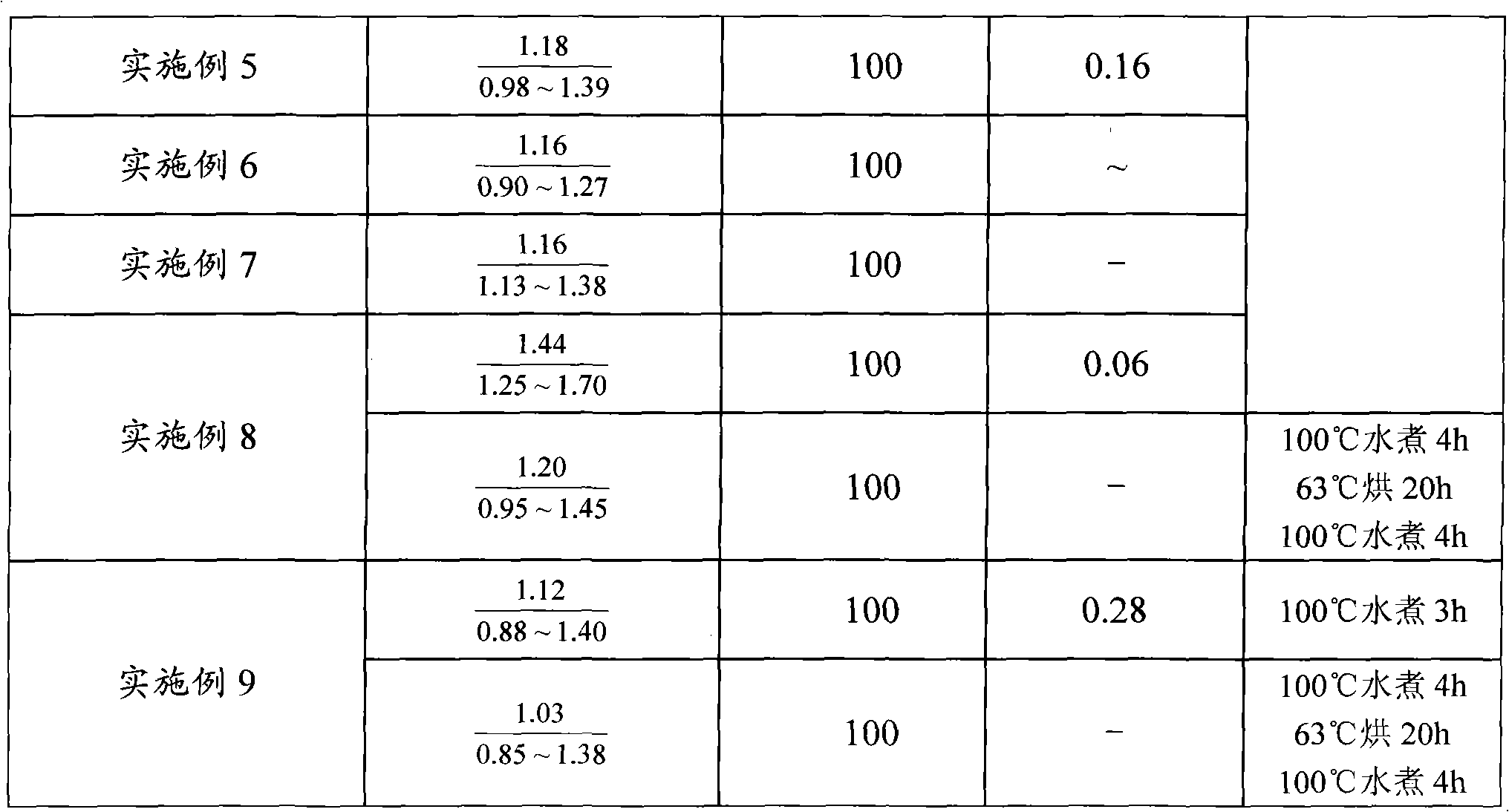

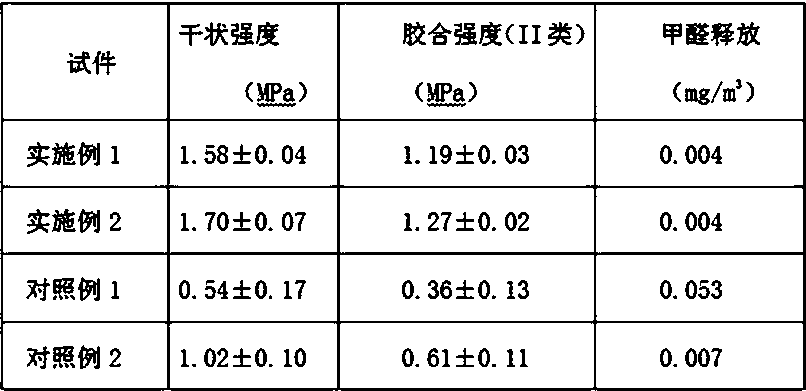

Preparation method of bio oil-phenol-methanal copolycondensation resin wood adhesive

ActiveCN101974301AHigh mechanical strengthImprove waterproof performanceAldehyde/ketone condensation polymer adhesivesHydrocarbon oils treatmentAdhesiveAging resistance

The invention relates to a preparation method of a bio oil-phenol-methanal copolycondensation resin wood adhesive, belonging to the technical field of fine chemistry and high polymer materials, which comprises the following steps of filtering and refining bio oil to prepare the refined bio oil; adding sulfur and sodium hydroxide solution to the refined bio oil; stirring, heating and reacting to prepare the modified bio oil; and adding phenol and a catalyst to the modified bio oil to prepare the adhesive after reacting. In the method of the invention, the bio oil is taken as a substrate to synthesize the adhesive for wood, and the content of the bio oil is 50 to 60% of the total content of the adhesive. The prepared adhesive has the advantages of high mechanical strength, good waterproof performance and aging resistance, and can be used for preparing the products in high accessories of outdoor stage plywood, particle boards, fiberboards, layer base materials and the like. Moreover, thepreparation technology for pyrolyzing the bio oil wood adhesive is simple and fast, and the resins have the advantages of strong adhesion performance and long storage life.

Owner:BEIJING FORESTRY UNIVERSITY

Aldehyde-free liquid glue and artificial board processing method

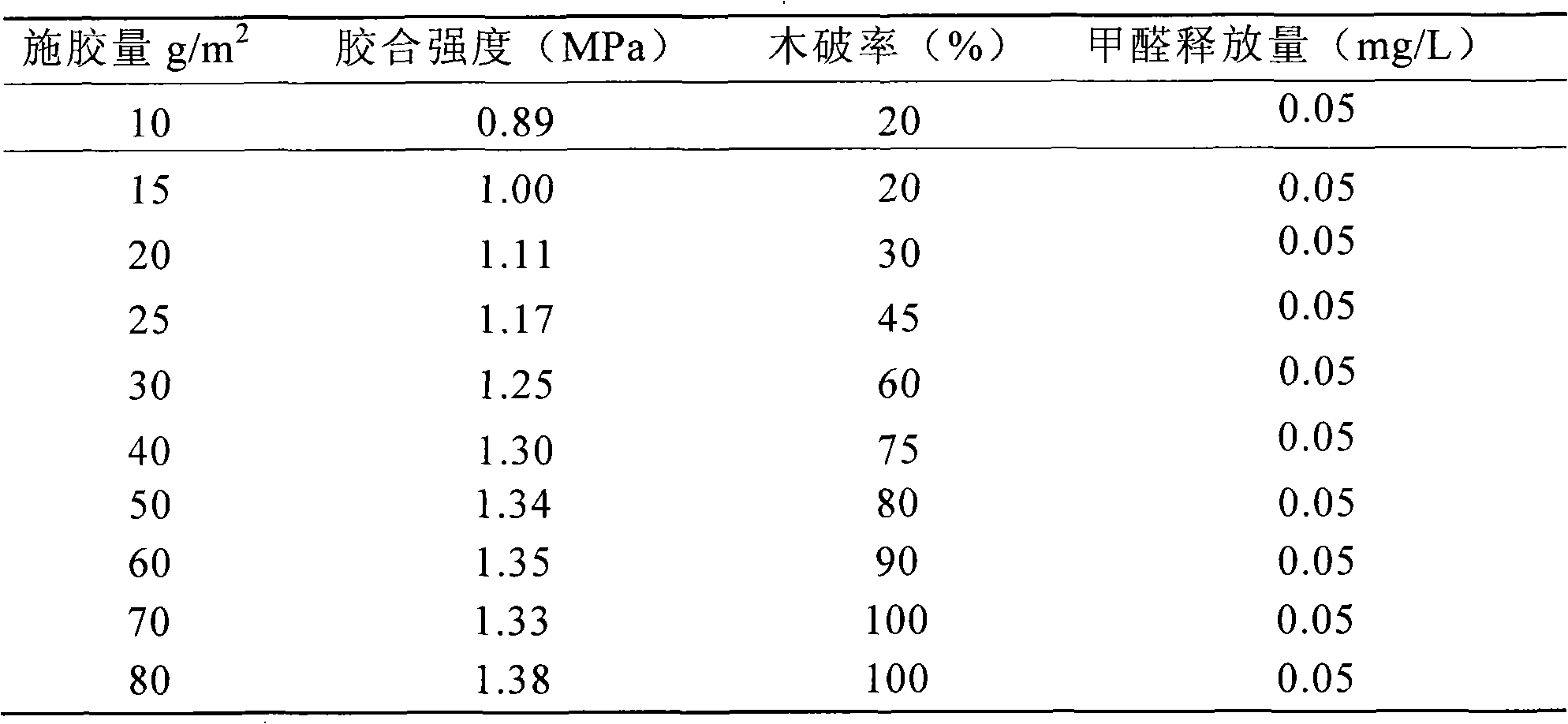

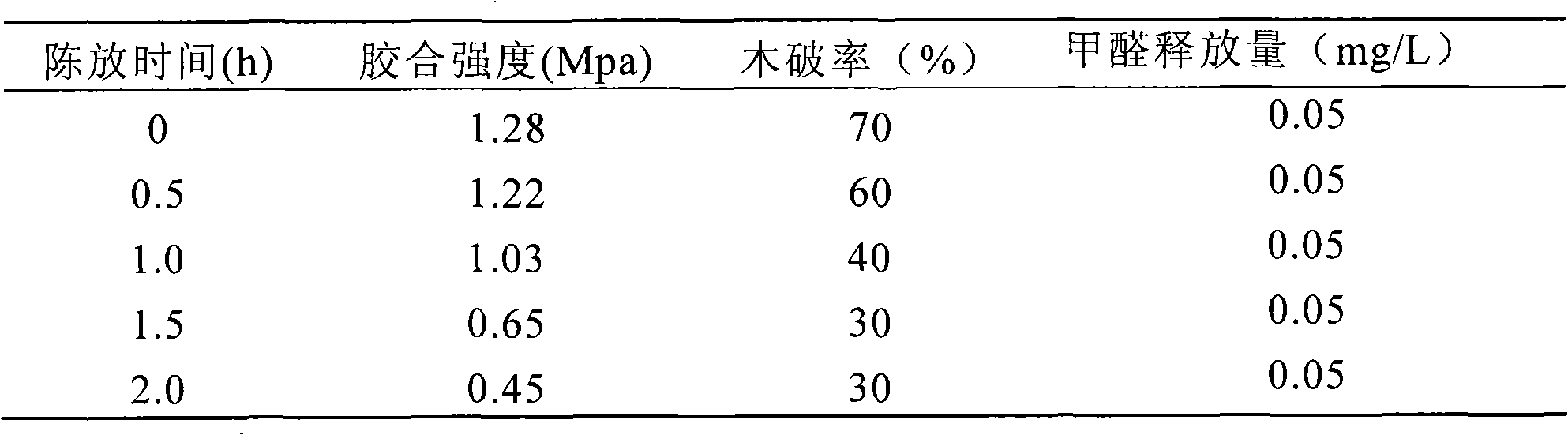

ActiveCN105295740AGood for sales promotionHigh bonding strengthWood veneer joiningInorganic adhesivesHabitMechanical equipment

The invention relates to aldehyde-free liquid glue and an artificial board processing method. The liquid glue is prepared by mixing and blending an magnesium chloride aqueous solution and magnesium oxide powder, serving as inorganic materials, according to the ratio of 1: 1; the magnesium chloride aqueous solution is prepared from magnesium chloride powder or halogen pieces and water according to the ratio of 1: 1 to 1: 3, and the purity of the magnesium chloride powder or the halogen pieces is 45% to 99%. Therefore, the liquid glue does not contain formaldehyde, also has favorable gluing strength, is low in price and can also be directly applied to existing mechanical equipment to process artificial boards, without adding or transforming original mechanical equipment, and also without changing an operation mode of longtime habit. The liquid glue is easily accepted by artificial board manufacturers, high in market competitiveness and easily promoted and sold; in addition, when the liquid glue is used for manufacturing the artificial boards, the artificial boards can be directly subjected to hot pressing after coated with the aldehyde-free liquid glue, without undergoing cold pressing, so that the processing procedures are simplified, the production efficiency is high, and meanwhile, the hot pressing temperature is relatively low, the energy consumption is reduced and the production cost is lower.

Owner:佛山市乐居轻钢房屋有限公司

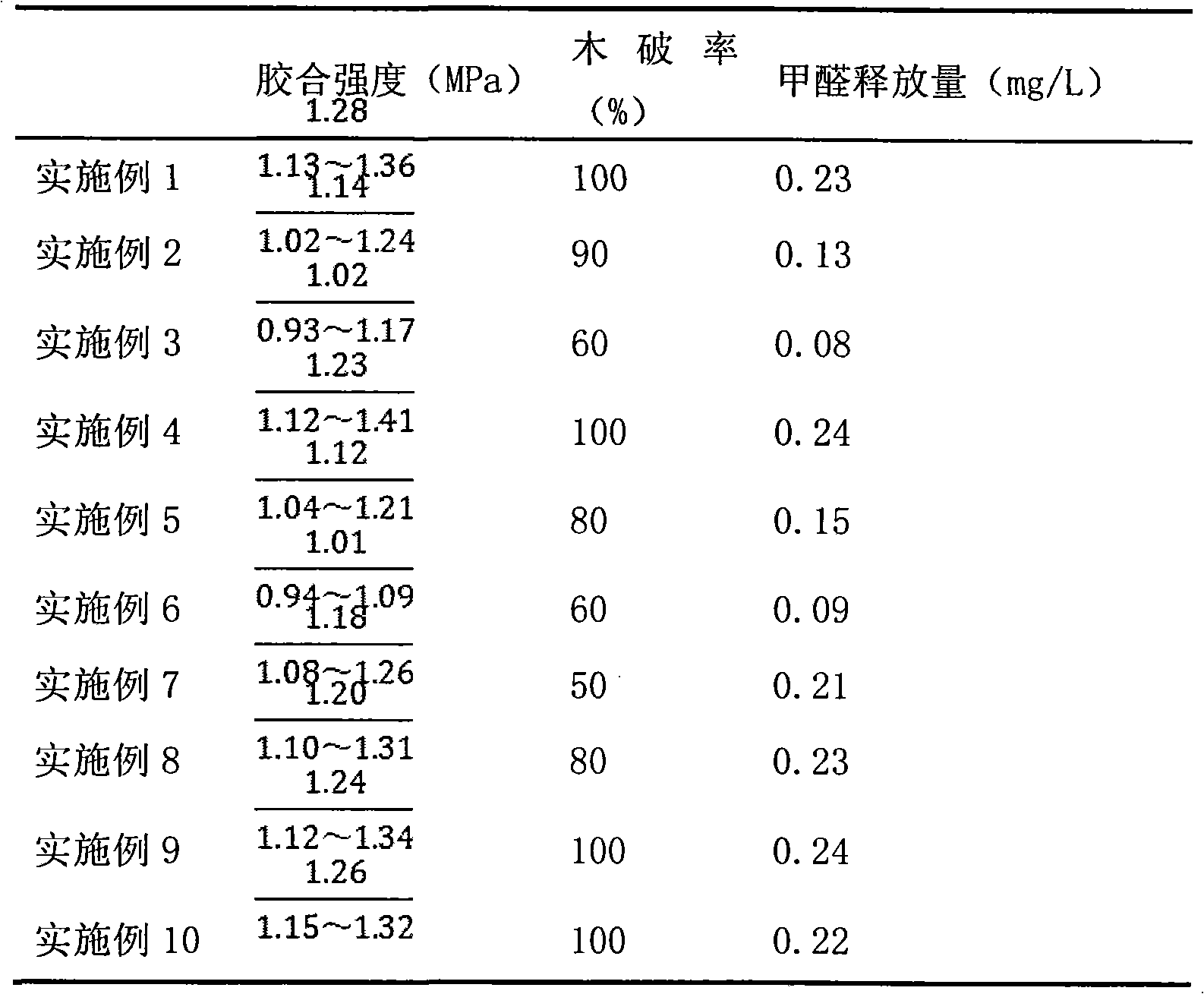

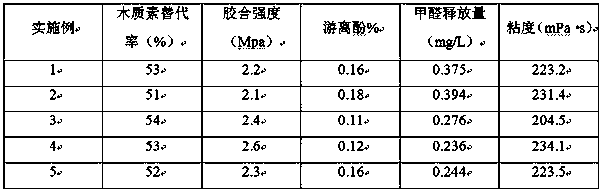

Preparation method of xylogen phenolic resin adhesive

InactiveCN107841270ALow manufacturing process requirementsReduce releaseNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesHazardous substanceOxygen ions

The invention provides a preparation method of a xylogen phenolic resin adhesive. The method comprises the steps of preparing activated lignin through microbial fermentation, enabling the activated lignin and phenol to react to partially substitute the phenol, and by adopting a hyperbranched polyester as a medium, utilizing a porous material quartz powder for loading anion powder and xylogen substituted phenol to react with formaldehyde so as to prepare to obtain the xylogen phenolic resin adhesive. The phenolic resin adhesive prepared by the invention is high in abrasion resistance, fast in curing speed, high in adhesion strength, and less in release amount of hazardous substance formaldehyde at the same time, contacts with air to release negative oxygen ions, has a better air purification capacity, belongs to an environment-friendly high polymer material, and has an excellent development potential.

Owner:深圳市吉田化工有限公司

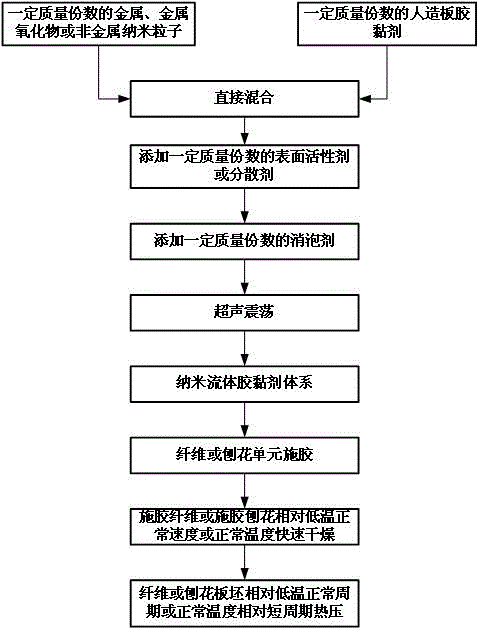

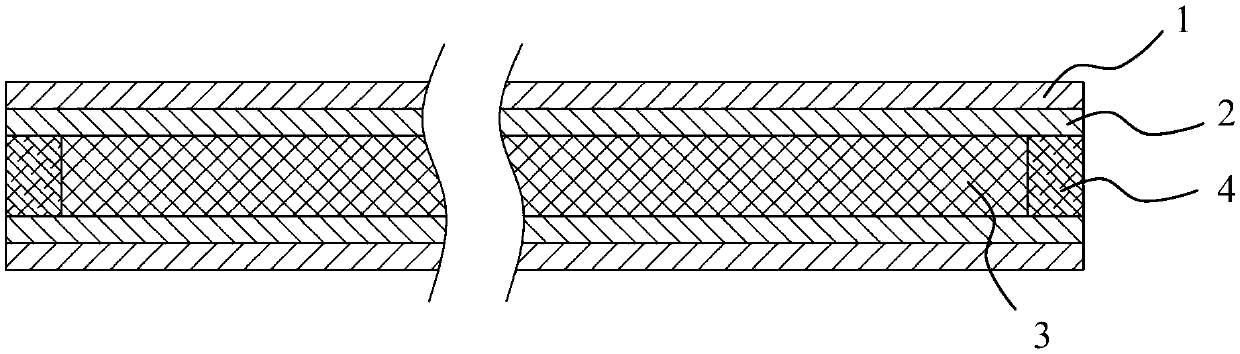

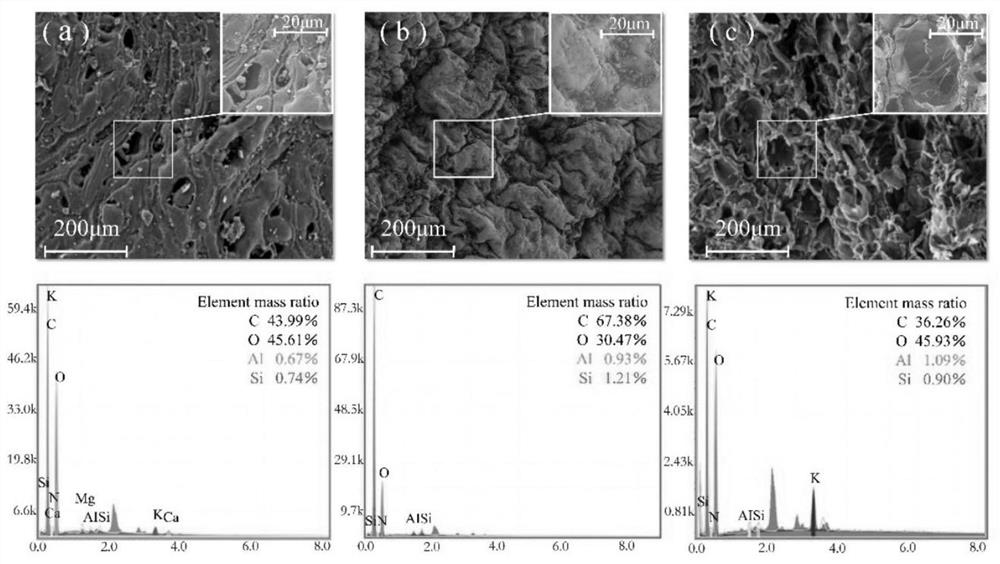

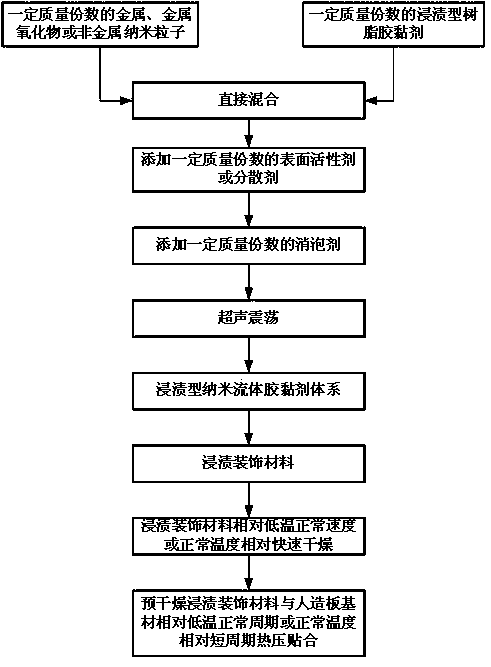

High-heat-conductive nano fluid adhesive, preparation method of same, and application thereof in production of artificial boards

ActiveCN106497468AImprove thermal conductivityLow drying temperatureNon-macromolecular adhesive additivesProtein adhesivesFiberMetal oxide nanoparticles

The invention discloses preparation of a high-heat-conductive nano fluid adhesive and an application thereof in production of artificial boards. The adhesive includes, by mass, 1-15% of high-heat conductivity metal nano particles, metal oxide nano particles or non-metal nano particles, 83-98.8% of an adhesive for production of a fiber board or a particle board, 0.1-1% of a surfactant or a dispersant, and 0.1-1% of a defoamer, all the components are mixed and are subjected to supersonic vibration to form the adhesive. The invention also discloses a preparation method of the adhesive and an application thereof in production of the artificial boards. The high-heat-conductive nano fluid adhesive has the character that the heat conductivity is significantly increased, so that the adhesive can significantly increase drying speed of the fibers and wood particles after application of the adhesive during production of the fiber board or the particle board, and meanwhile, can significantly reduce hot-pressing time or reduce the hot-pressing temperature of the fiber board or the particle board.

Owner:NANJING FORESTRY UNIV

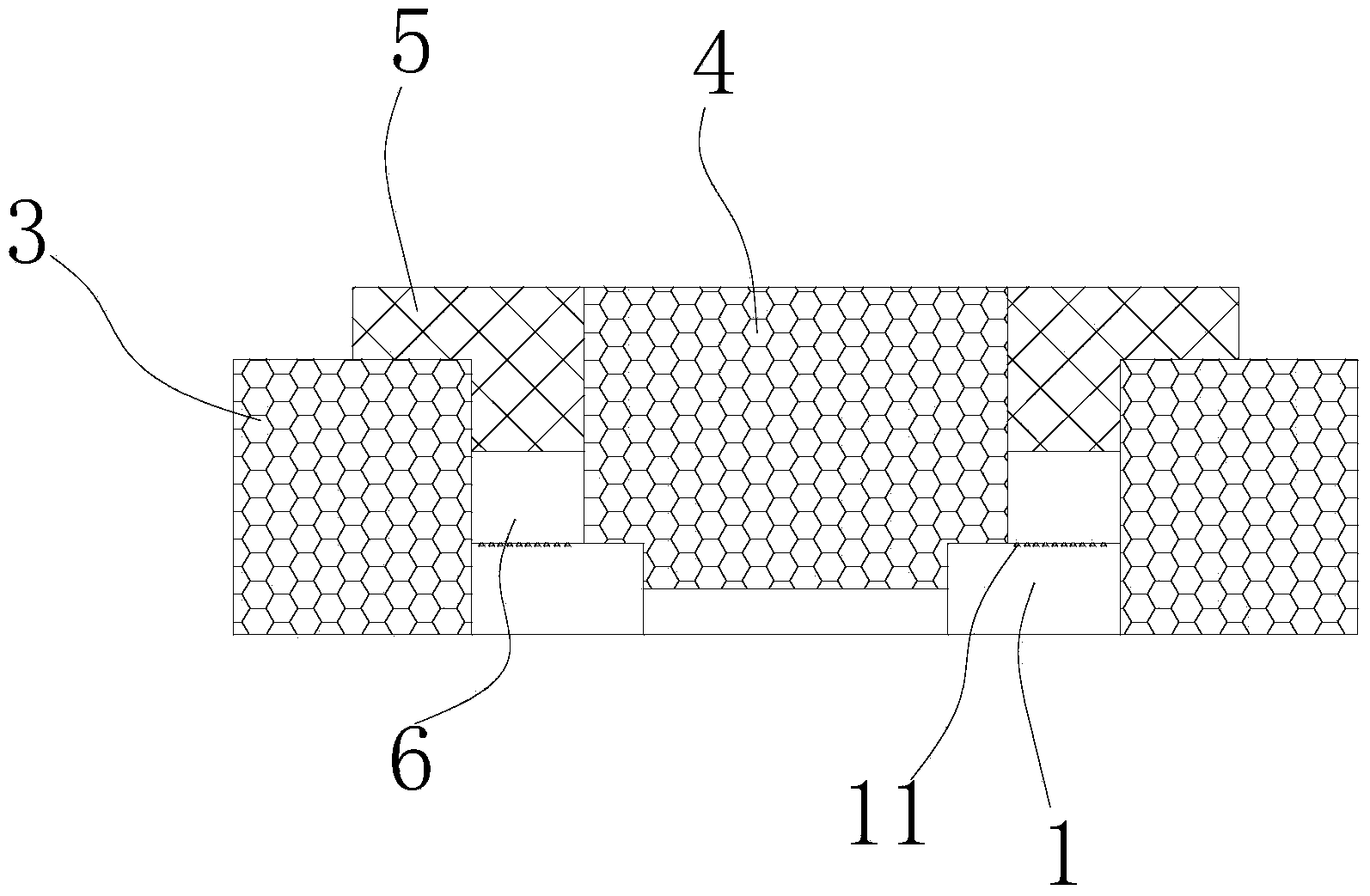

Preparation method of high-strength lightweight composite honeycomb panel

InactiveCN107718849AReduce usageReduce consumptionLamination ancillary operationsLaminationPerformance indexHigh pressure

The invention discloses a preparation method of a high-strength lightweight composite honeycomb panel. The preparation method is characterized by comprising the following steps: selecting materials for the composite honeycomb panel, wherein the materials comprise an aramid paper honeycomb core material, a cured glass fiber prepreg panel and a high-pressure decorative laminated board; cutting the composite honeycomb panel into a set shape; performing adhesive-glue blade coating on an adhesive face of the materials for the composite honeycomb panel; stacking and adhering the high-pressure decorative laminated board, the cured glass fiber prepreg panel, the aramid paper honeycomb core material, the cured glass fiber prepreg panel and the high-pressure decorative laminated board from top to bottom or from bottom to top so as to obtain a crude slab of the composite honeycomb panel; performing hot pressing on the composite honeycomb panel in hot-pressing equipment, wherein the hot-pressing temperature is 55-65 DEG C, and the temperature and pressure maintaining time is 80-100 minutes; finally, obtaining the semi-finished composite honeycomb panel. According to the method disclosed by theinvention, the hot-pressing temperature is reduced, the temperature maintaining time is shortened, the various performance indexes of the aramid composite honeycomb panel are ensured, the energy consumption is reduced, and the energy is saved.

Owner:ZHONGSHAN CLG AUTOMATION EQUIP

Dry grinding wheel and manufacturing method thereof

InactiveCN103962977AMaterials are readily availableImprove hardness performanceAbrasion apparatusGrinding devicesPolyvinyl alcoholPolyvinyl chloride

The invention discloses a dry grinding wheel. The dry grinding wheel comprises a substrate and a grinding head arranged on the substrate. The grinding head is prepared from, by weight, 130 parts to 200 parts of diamond, 100 parts to 130 parts of silicon carbide, 60 parts to 100 parts of polyvinyl chloride resin powder, 5 parts to 10 parts of coupling agents, 200 parts of silicon carbide micro powder, 10 parts to 20 parts of anti-abrasion agents, and 60 parts to 100 parts of polyvinyl alcohol gelatine powder. The invention discloses a manufacturing method of the dry grinding wheel. The raw materials are weighed according to the formula of the grinding head, then, an evenly mixed mixture is obtained through the mixing technology, and finally the dry grinding wheel is obtained through the forming technology. The dry grinding wheel has the advantages that the materials are easy to obtain, grinding sharpness and hardness performance of a grinding wheel matrix are good, and the service life is long. The manufacturing method has the advantages of being low in sintering temperature, low in manufacturing cost and capable of achieving energy conservation and environmental protection.

Owner:FOSHAN DINGSHUN TECH CO LTD

A kind of formaldehyde-free liquid adhesive and wood-based panel processing method

ActiveCN105295740BGood for sales promotionHigh bonding strengthWood veneer joiningInorganic adhesivesHalogenAdhesive

The invention relates to a aldehyde-free liquid adhesive and a wood-based panel processing method. The liquid adhesive is prepared by mixing magnesium chloride aqueous solution and magnesium oxide powder of inorganic materials in a ratio of 1:1; the magnesium chloride aqueous solution is made of magnesium chloride powder or halogenated Tablets and water are prepared according to the ratio of 1:1 to 1:3, and the purity of magnesium chloride powder or halogen flakes is 45% to 99%. In this way, the liquid adhesive does not contain formaldehyde, but also has good bonding strength, and the price is extremely low. It can also be directly applied to existing mechanical equipment to process wood-based panels, without adding or modifying old mechanical equipment, and without changing long-term habitual operations. The model is easy to be accepted by wood-based panel manufacturers, has strong market competitiveness, and is easy to promote and sell; and when used in the manufacture of wood-based panels, it can be directly hot-pressed after coating the formaldehyde-free liquid adhesive, without cold pressing, and the processing process is simplified. , higher production efficiency, lower hot pressing temperature, less energy consumption and lower production cost.

Owner:佛山市乐居轻钢房屋有限公司

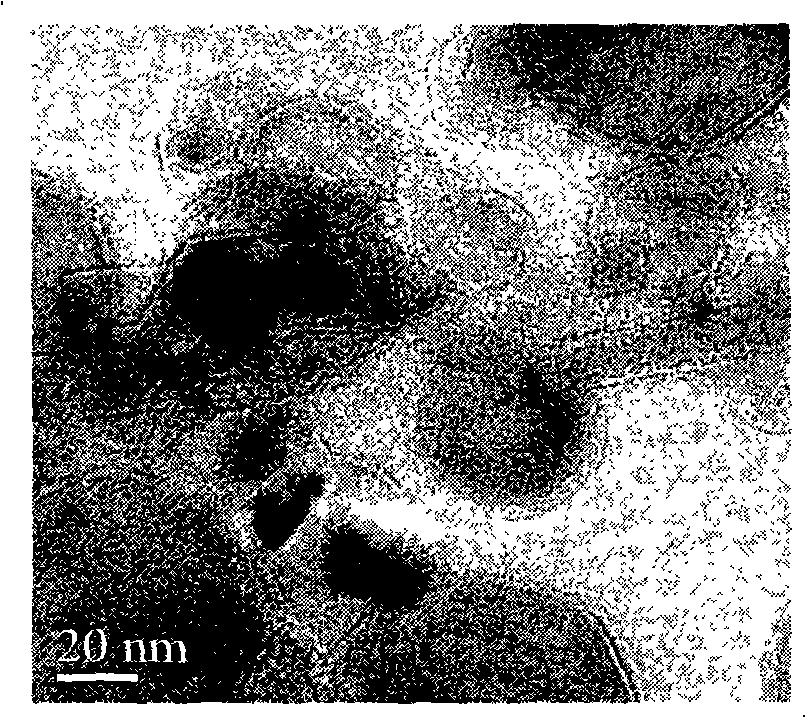

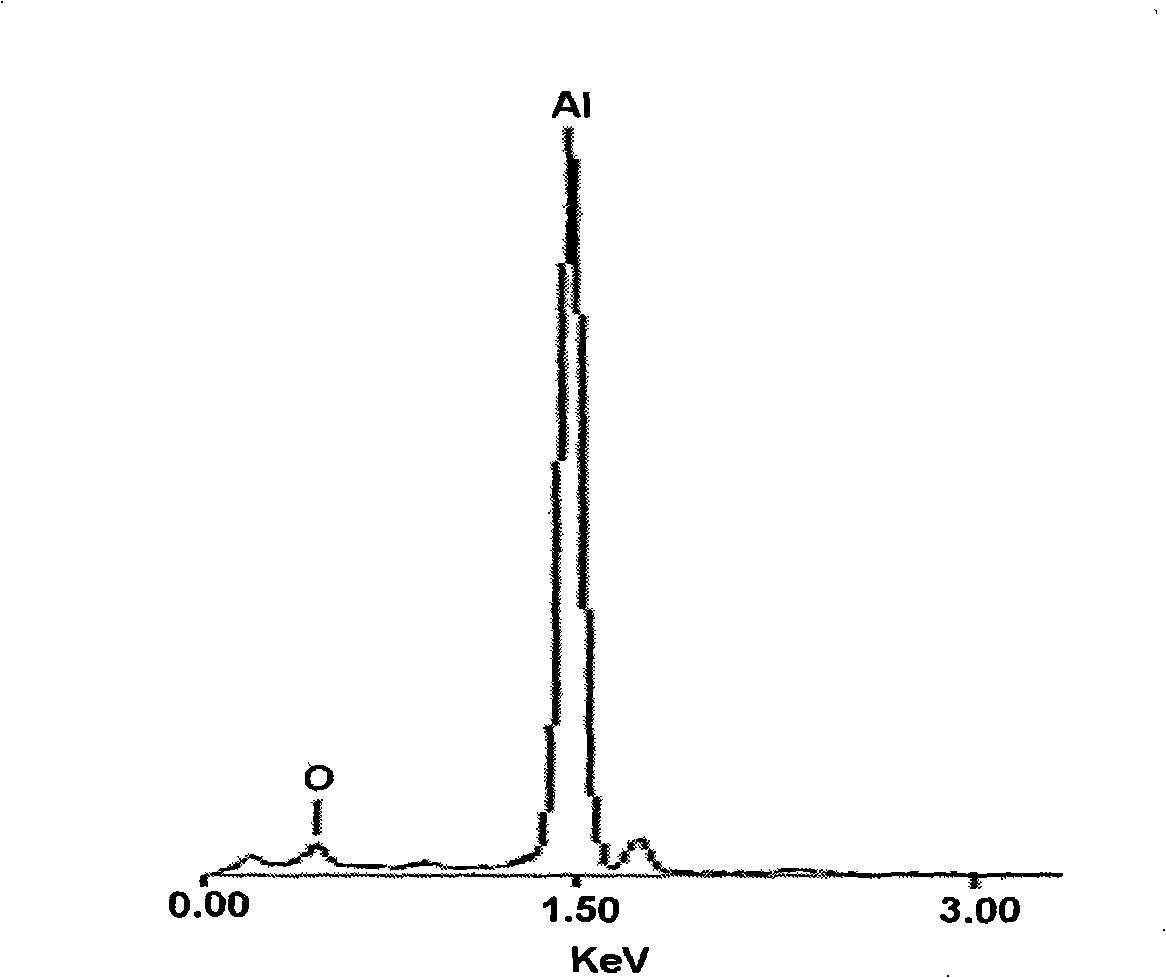

Highly dielectric composite material containing core-shell structured packing and preparation method thereof

InactiveCN101293986ALow densityAvoid leakage conductanceNon-conductive material with dispersed conductive materialDomestic articlesAcetic acidDielectric loss

The invention belongs to the technology field of composite materials, more particularly relates to a high dielectric composite material containing fillers with a core-@-shell structure and a production method thereof. The composite material contains 10-45 wt% of aluminum and 55-90 wt% of polystyrene. The production method comprises the following steps: subjecting aluminum powder to surface passivation treatment to obtain fillers with a core-@-shell structure, preparing ethyl acetate solution of polystyrene, adding the treated aluminum powder into the ethyl acetate solution at different mass fractions, stirring, casting, sun-drying, oven-drying, molding and shaping to obtain the high dielectric composite material containing fillers with core-@-shell structure. An oxide coating is formed on the surface of the aluminum powder after the surface passivation treatment, so as to efficiently avoid the formation of leakage conductance due to mutual contact between eclectically-conducting additives and thereby to reduce the dielectric loss of the material. The composite material has high dielectric constant, low density and good flexibility. The production method of the composite material has the advantages of simple and controllable process, low hot-pressing temperature, energy conservation and environmental protection.

Owner:TSINGHUA UNIV

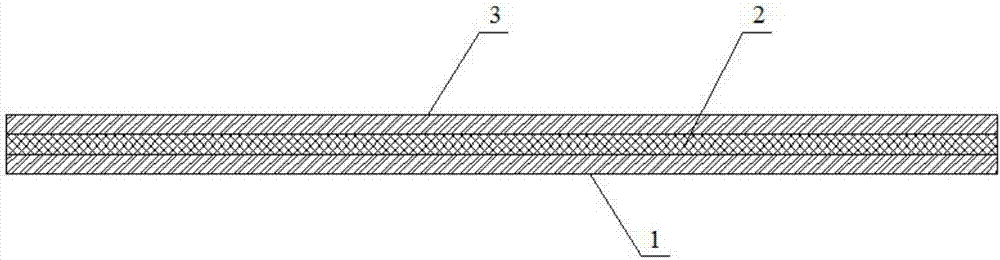

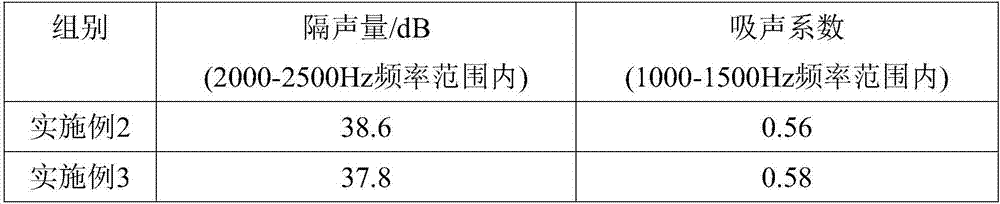

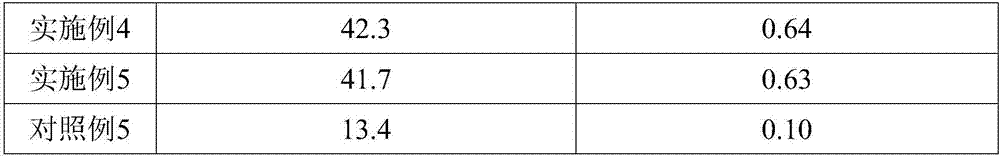

Sound insulation and noise reduction type composite bamboo fiberboard

ActiveCN107877624AImprove sound insulation and noise reductionGuaranteed physical and mechanical performanceLaminationLamination apparatusFiberNoise reduction

The invention discloses a sound insulation and noise reduction type composite bamboo fiberboard, and relates to the technical field of bamboo fiberboard processing. The sound insulation and noise reduction type composite bamboo fiberboard is composed of three layer structures of a bamboo fiber bottom board, a sound insulation and noise reduction layer and a bamboo fiber panel, and the sound insulation and noise reduction layer is arranged between the bamboo fiber bottom board and the bamboo fiber panel and is made of an asbestos wool-foamed aluminum-magnesium composite. According to the soundinsulation and noise reduction type composite bamboo fiberboard, the asbestos wool-foamed aluminum-magnesium composite serves as the sound insulation and noise reduction layer, so that the manufactured composite bamboo fiberboard has excellent sound insulation and noise reduction performance; and the sound insulation and noise reduction performance of the manufactured composite bamboo fiberboard is further enhanced by using the self-made bamboo fiber bottom board or bamboo fiber panel, meanwhile, physical and mechanical using performance of the composite bamboo fiberboard is ensured, and construction requirements of building decoration are met accordingly.

Owner:广西平乐爱森新材料有限公司

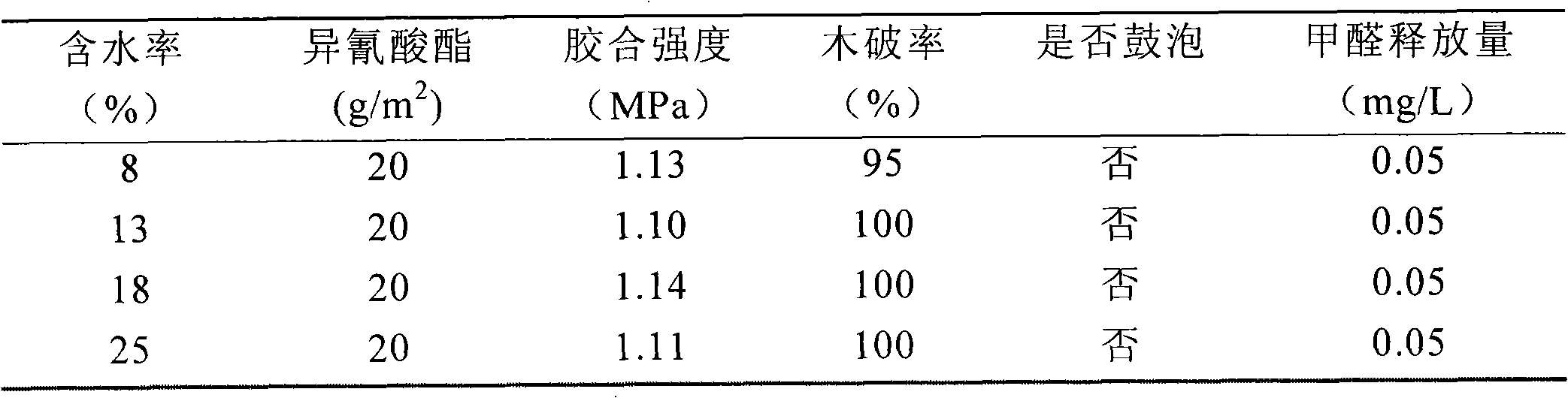

Aldehyde-free veneer and producing method thereof

ActiveCN101524857BLow costReduce drying energy consumptionWood veneer joiningWood layered productsAdhesiveSingle plate

The invention provides an aldehyde-free veneer which comprises a plurality of combined single plates, the contiguous layers of the single plates are in a crossed structure or a parallel structure, a glue layer is arranged between contiguous single plates, and the adhesive of the glue layer is isocyanate. The invention also includes the producing method of the aldehyde-free veneer. In the normal producing method of veneer, isocyanate adhesive is used, the hot pressing time in the work procedures is shortened, the hot pressing temperature is lowered, and the requirement of the water content of the single plate is lowered. Spraying glue application method is used in the work procedure of applying glue to the veneer to greatly reduce the applied glue amount of the veneer, thus besides the formol release amount is greatly lower than that of the relevant standard, and the aldehyde-free veneer also has more reasonable technology.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Method of preparing alkali lignin modified phenolic resin

InactiveCN101492522BAdequate responseTo achieve the purpose of modifying phenolic resinAldehyde/ketone condensation polymer adhesivesResource utilizationAdhesive

A method for preparing alkali lignin modified phenol-formaldehyde resin comprises the following steps: phenol, a first batch of formaldehyde solution, alkali lignin, metal oxide and dilution water are added into a reactor; a second batch of formaldehyde solution is added into the reactor; and a third batch of formaldehyde solution and a first batch of alkaline solution are added, formaldehyde trapping agent and a second batch of alkaline solution are added, and then material is discharged after cooling. The invention adopts the copolymerization technique to prepare an alkali lignin phenol formaldehyde adhesive, lignin and the phenol are added simultaneously, obtained hydroxymethylated lignin is reacted with hydroxymethyl phenol, a small part of the obtained hydroxymethylated lignin participates in the polycondensation of the hydroxymethyl phenol to form a main chain, and a large part of the obtained hydroxymethylated lignin forms branch chains through graft copolymerization, therefore, the lignin is introduced into a molecular chain and the aim of modifying phenol-formaldehyde resin is achieved. The invention can replace the use of 30-50 percent of the phenol, realizes stable and easy reaction control and easy industrial production; the bonding strength satisfies the requirements of national I-level plates; formaldehyde release reaches E0 level; therefore, the invention provides a new approach to the development of environment-friendly biomass-based wood adhesive and resource utilization of waste materials.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

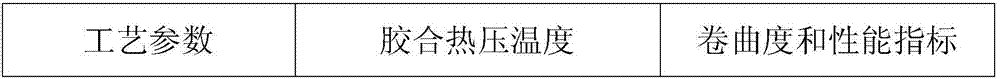

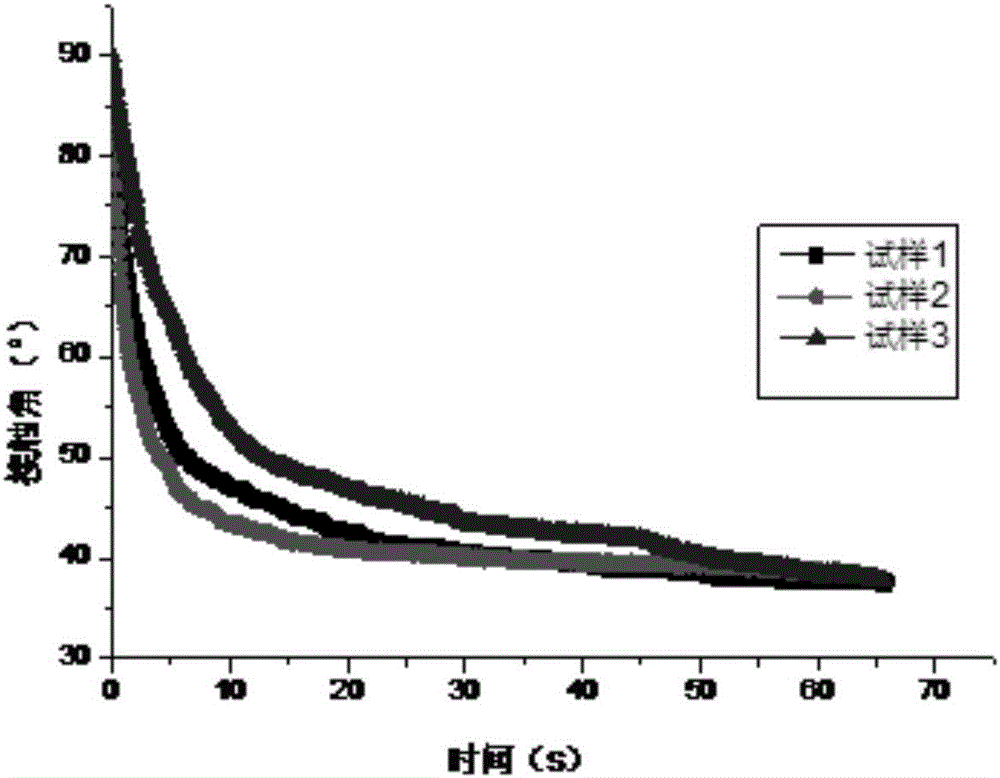

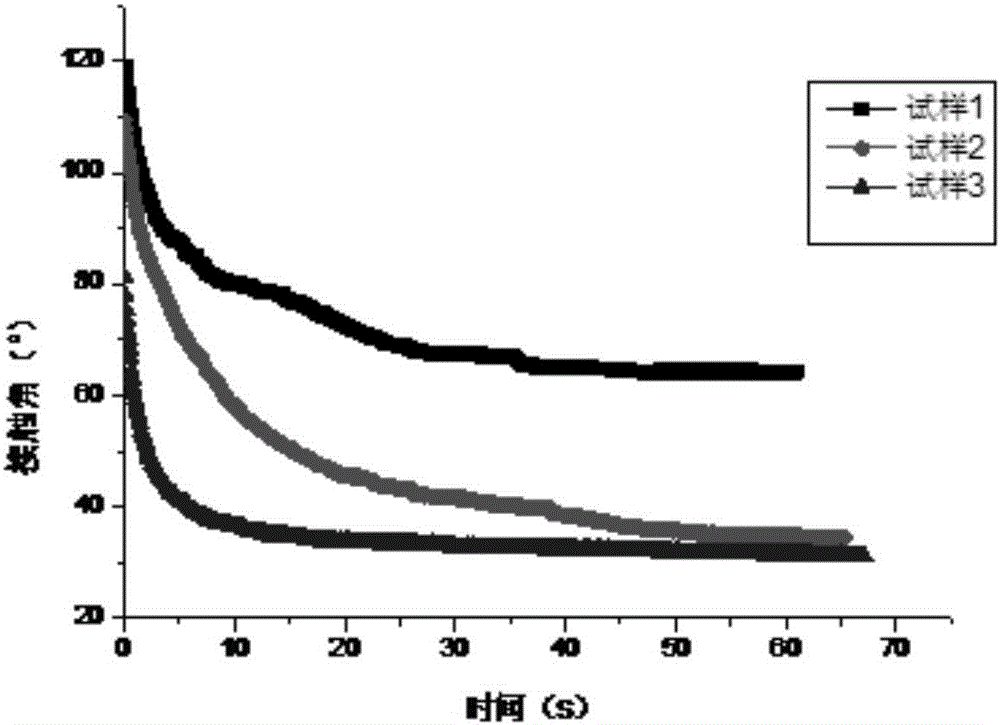

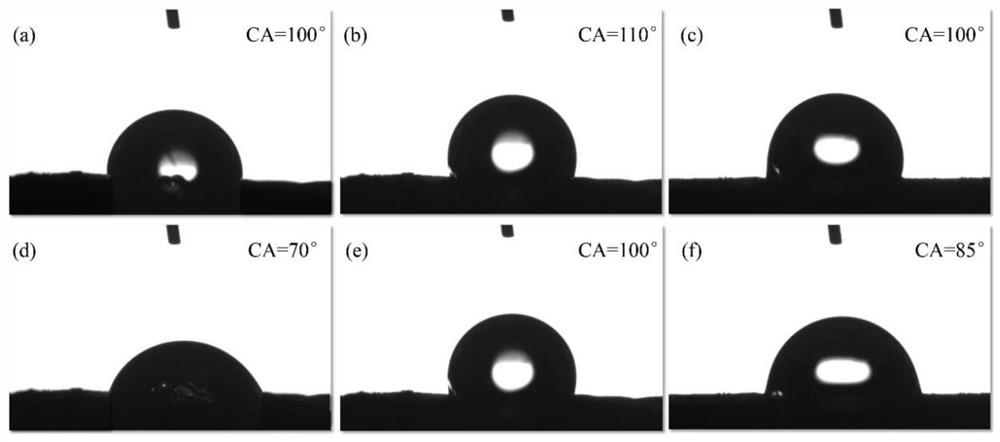

Method for improving interface bonding performance between composite flexible decorative veneer and surface facing through plasma modification

ActiveCN107030802AResolve curlSolve discolorationLayered product treatmentElectric wood treatmentAdhesiveEngineering

The invention discloses a method for improving the interface bonding performance between composite flexible decorative veneer and surface facing through plasma modification. The method sequentially comprises the following technology steps that surface pretreatment of the decorative veneer, low-temperature plasma treatment of the surface of the decorative veneer, low-temperature plasma treatment of the surface of a plastic film, assembly and hot pressing of the decorative veneer and the plastic film, and facing hot-pressing of the plastic-film-reinforced flexible decorative veneer. By the adoption of the method for improving the interface bonding performance between the composite flexible decorative veneer and the surface facing through plasma modification, woodwork surface facing is conducted through the plastic-film-reinforced flexible decorative veneer manufactured through plasma modification treatment, an adhesive is not needed, the procedure of applying the adhesive can be omitted, the bonding strength of the facing surface of the product can be improved by 10%-70%, the adhesive force of a paint film can be improved by 20%-40%, the production cost can be reduced by 10%-50%, energy is saved, environmental friendliness is achieved, operation is easy and convenient, and efficiency is high.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Non-formaldehyde recombined laminated wood and manufacture method thereof

InactiveCN105799004AFill in the gapsSolve the problem of sticky boardMonocarboxylic acid ester polymer adhesivesPolyureas/polyurethane adhesivesEmulsionPolyvinyl acetate

The invention relates to non-formaldehyde recombined laminated wood and a manufacture method thereof. The non-formaldehyde recombined laminated wood is formed by a scrimber veneer strip and an adhesive layer. The scrimber veneer strip is formed through diametral plane splicing and chord plane gluing, the scrimber veneer strip comprises recombination bamboo and recombination wood, during the diametral plane splicing process, the adhesive arranged on the adhesive layer is a polyvinyl acetate emulsion adhesive or an aqueous high-molecular isocyanate adhesive, and during the chord plane gluing process, the adhesive arranged on the adhesive layer is an isocyanate adhesive. With respect to the non-formaldehyde recombined laminated wood, non-aldehyde adhesives are employed, during the diametral plane splicing process, the polyvinyl acetate emulsion adhesive (white emulsion) or the aqueous high-molecular isocyanate adhesive is employed, and during the chord plane gluing process, the isocyanate adhesive is employed, the formaldehyde release amount of the non-formaldehyde recombined laminated wood is far lower than 1.5 mg / L which is prescribed in the national standard E1 grade, and the non-formaldehyde aim is achieved.

Owner:LANGFANG HUARI FURNITURE CO LTD

Novel hot-melt adhesive and preparation method thereof

ActiveCN105860917AWill not deformGood adhesionNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyAntioxidant

The invention discloses a novel hot-melt adhesive and a preparation method thereof, particularly a novel hot-melt adhesive suitable for bonding and compounding metals and ABS (acrylonitrile-butadiene-styrene) plastics and a preparation method thereof. The invention is mainly characterized in that the novel hot-melt adhesive comprises the following raw materials in percentage by mass: 45-50% of nylon type copolyamide, 34-37% of thermoplastic polyurethane, 0.3-1% of epoxy compatilizer, 10-15% of tackifier, 1-5% of filler and 0.1-0.3% of antioxidant. The preparation method comprises the following steps: selecting raw materials according to specific percents, carrying out polymerization reaction to form the nylon type copolyamide with favorable bonding properties for metals, and proportionally carrying out blend melting and extrusion on the nylon type copolyamide, thermoplastic polyurethane and the other auxiliary materials under the synergistic action of the specific compatilizer, thereby obtaining the novel hot-melt adhesive with favorable bonding properties for metals and ABS plastics. The product disclosed by the invention satisfies the demands, is simple in technique, and is convenient for industrial production and application.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

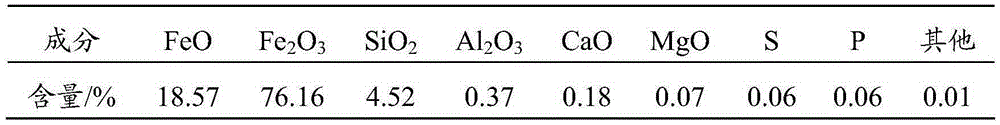

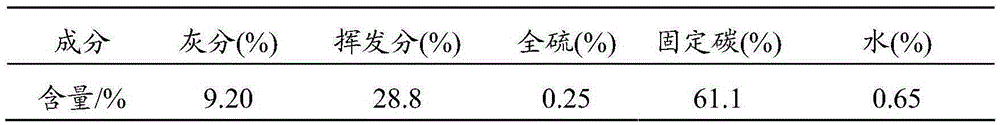

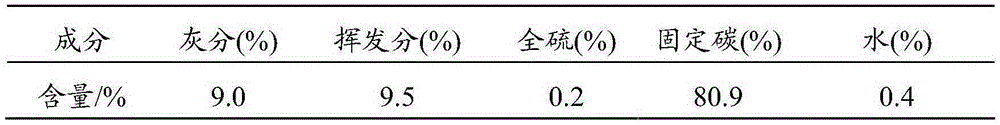

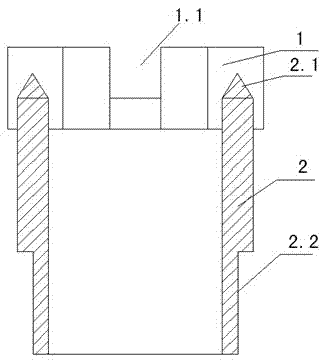

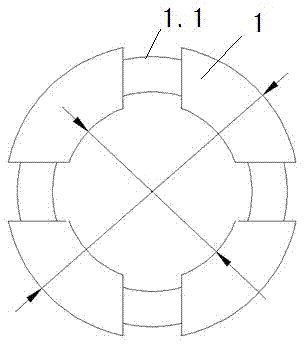

Hot-pressed iron coke for ironmaking and preparation method thereof

The invention belongs to the technical field of ironmaking, and specifically relates to a hot pressed iron coke for ironmaking and a preparation method thereof. The raw materials are composed of 10% to 30% iron ore powder, 60% to 80% bituminous coal powder, and 10% to 20% anthracite coal powder; the raw materials are fully mixed to obtain a mixture, and the mixture is heated in a heating furnace to 200-350°C, quickly hot-press and shape it to produce hot-pressed iron coke green pellets. Place the iron coke green pellets in a tunnel kiln to heat up to a certain temperature at a certain rate for high-temperature carbonization, then take out the stewed material and cool it to obtain hot-pressed iron coke green pellets. Iron coke. The prepared hot-pressed iron coke has excellent compressive strength, wear resistance, reactivity and post-reaction strength. It can replace part of the coke in blast furnace ironmaking and improve the adaptability of blast furnace ironmaking to fuel. It has a wide range of raw material sources, low production cost, simple process flow and no need to use binders, and has broad industrial application prospects.

Owner:NORTHEASTERN UNIV LIAONING

Standard abrasion piece suitable for petroleum drilling stratum rock abrasivenesss detection

InactiveCN105445090AHigh hardnessReduce hardnessStrength propertiesPolycrystalline diamondRock sample

The invention relates to a standard abrasion piece suitable for petroleum drilling stratum rock abrasivenesss detection. The standard abrasion piece is characterized by adopting a mini-type coring bit structure comprising a grinding component and a steel connecting component, wherein the grinding component comprises a phenolic resin base material and an artificial polycrystalline diamond grinding material; the standard abrasion piece is integrally formed via sintering according to a hot pressing technology, and is connected onto the spindle of a test device via the steel connecting component after being machined and trimmed. The standard abrasion piece has the benefits that the wear resisting property is reasonable; the self-sharpening property is excellent; rock can be drilled effectively; moreover, own abrasion of the standard abrasion piece reflects the abrasion of a diamond bit during a practical well drilling process; the structural is small and exquisite; the matched test device is simple; the operation is convenient; the technical conditions are stable; the consumption of a test rock sample or an on-site rock core can be greatly reduced under the condition that simulation requirements of a diamond bit dynamic grinding rock breaking process are met, and test cost is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Electronic product with metal connecting structure and method for producing the same

InactiveCN101316487ANo deformationGood lookingCasings/cabinets/drawers detailsElectrically conductive adhesive connectionsHot-melt adhesiveMetal

The invention discloses an electronic product provided with a metal connecting structure. The electronic product comprises a metal shell and at least one metal part which is fixed at the inner side of the metal shell by hot melt adhesive layer. In addition, the invention also discloses a method for preparing the electronic product provided with the metal connecting structure. The electronic product has the advantages of simple preparation and elegant appearance.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

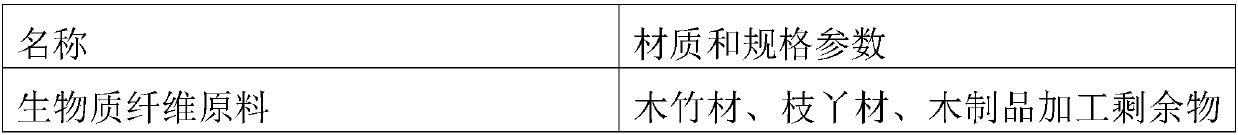

High-efficiency heat-conducting high-density fiberboard and manufacturing method thereof

ActiveCN109605536AImprove dispersion uniformityImprove dispersion stabilityWood working apparatusFlat articlesFiberHigh density

The invention discloses a high-efficiency heat-conducting high-density fiberboard. The high-efficiency heat-conducting high-density fiberboard is composed of biomass fibers, a heat conduction materialand an additive, and the heat conduction material comprises tourmaline powder and aluminum oxide powder. The invention further discloses a manufacturing method of the high-efficiency heat-conductinghigh-density fiberboard. The preparation method comprises the following steps that fiber slurry is prepared; water mixture liquid of heat conduction material powder, surface modifier and partial adhesive are sprayed into the fiber slurry; the rest of the adhesive is continuously applied again and dried to obtain dried fibers; and after assembly and pre-pressing are performed on the dried fibers, the high-efficiency heat-conducting and high-density fiberboard is obtained through hot pressing, edge cutting, heat dissipation and growth and sanding. According to the high-efficiency heat-conductinghigh-density fiberboard, aluminum oxide powder and tourmaline powder are adopted as heat conduction materials, a pressurization spraying mode is adopted, and the heat conduction material powder and the fibers are highly dispersed by means of the pre-adhesion of the partial adhesive, so that the dispersion uniformity and stability of the heat conduction material are improved, and the heat transferefficiency of the high-density fiberboard is enhanced.

Owner:GUANGXI UNIV

Formaldehyde-free bamboo glulam and manufacturing method thereof

ActiveCN101934538BFill in the gapsReduce heating energy consumptionWood veneer joiningPolymer sciencePolyvinyl acetate

Owner:蔡宝珍

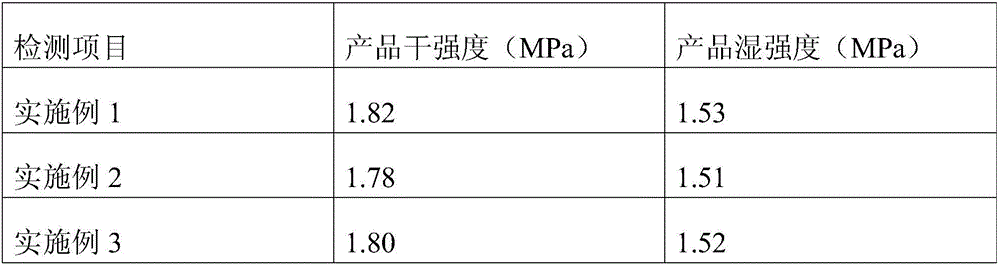

Aldehyde-free low-cost polysaccharide adhesive and preparation method thereof

ActiveCN110437766AImprove water resistance bonding performanceBroaden the field of applicationMacromolecular adhesive additivesAmide/imide polymer adhesivesDispersed mediaChemistry

The invention discloses an aldehyde-free low-cost polysaccharide adhesive and a preparation method thereof. The aldehyde-free low-cost polysaccharide adhesive is prepared from the following componentsin parts by weight: 20-25 parts of a main agent, 55-60 parts of dispersed medium water, 6-16 parts of a crosslinking agent, 1-2 parts of a reinforcing agent and 1-3 parts of a viscosity regulator. The preparation method of the polysaccharide-based adhesive comprises the following steps: firstly, all the components are weighed according to the weight ratio, the reinforcing agent and the dispersedmedium water are mixed, and ultrasonic dispersion is conducted for 15 minutes; then, the main agent is added into a prepared solution, and a mixed solution is homogenized for 15 minutes under the pressure of 70 MPa through a high-pressure homogenizer; and finally, the crosslinking agent and the viscosity regulator are added into a mixture obtained in the second step successively, and even stirringis conducted. The adhesive prepared through the simple preparation method has the advantages of high crosslinking density, good water-resistance performance, high dry and wet strength, adjustable viscosity, low curing temperature and the like, the practical requirements for a plywood adhesive are met, the production cost is low, the preparation process is simple, large-scale mass production can be conducted, and development of the environment-friendly high-performance adhesive industry is promoted advantageously.

Owner:BEIJING FORESTRY UNIVERSITY

Manufacturing method of high-gluability flame-retardant plywood

InactiveCN106363715AHigh bonding strengthImprove hydrophilicityWood treatment detailsLaminationEquilibrium moisture contentEnergy consumption

The invention discloses a manufacturing method of high-gluability flame-retardant plywood. The manufacturing method of the high-gluability flame-retardant plywood includes the operation steps that (1) impregnation liquid is obtained by mixing a commercial flame retardant solution with the mass concentration being 15-20%, a magnesium hydrate solution with the mass concentration being 0.5-1.0%, and a sodium dehydroacetate solution with the mass concentration being 0.1-0.3%; (2) after being impregnated, veneers are dried to reach the equilibrium moisture content; and (3) ammonium chloride and flour are added to self-made MUF resin, the mixture is evenly stirred and then evenly smeared on the veneers dried in the step (2), afterwards, hot pressing is carried out under the conditions that the temperature is 110-120 DEG C and the pressure is 1.2-1.5 MPa, and the high-gluability flame-retardant plywood is obtained. The gluing strength of the flame-retardant plywood manufactured through the method is enhanced, the hydrophily of the flame-retardant plywood is greatly improved, and thus the purpose of improving the quality of the flame-retardant plywood is realized. Furthermore, after the impregnation liquid is adopted for impregnation, the hot pressing temperature of the veneers is reduced, energy consumption is reduced, and production efficiency is improved.

Owner:GUANGXI UNIV

Lamination process, lamination equipment and mechanical hand applied to lamination equipment

InactiveCN111490283AImprove uniformityImproved fit tightAssembling battery machinesLarge-sized flat cells/batteriesRobot handElectrical battery

The invention relates to the field of lithium ion battery preparation, and discloses a lamination process, lamination equipment and a mechanical hand applied to the lamination equipment. The mechanical hand is assembled on a movable mechanical arm; a vacuum chuck used for adsorbing a pole piece is arranged on the bottom surface of the mechanical hand; and a first heating device is further arrangedon the bottom surface of the mechanical hand so as to heat the pole piece adsorbed on the bottom surface of the mechanical hand. By applying the scheme, the thermal uniformity in the preparation process of the laminated battery is favorably improved, the process effect of a hot pressing procedure is improved, and the preparation efficiency, the yield and the electrical property of the lithium ionbattery are favorably improved.

Owner:江苏丰盈科技有限公司

Camellia-oleifera-based particle board and preparation method thereof

ActiveCN113601630ARealize industrial productionReduce pollutionWood veneer joiningDomestic articlesBiotechnologyWood shavings

The invention discloses a camellia-oleifera-based particle board and a preparation method thereof. The camellia-oleifera-based particle board is a sandwich-structure particle board formed by sequentially compounding a surface layer, a core layer and a surface layer, and the surface layers and the core layer are formed in a manner that camellia oleifera fruit shell particles and wood shavings are taken as main raw materials, and an adhesive is added for gluing; and the adhesive is a melamine modified urea-formaldehyde resin adhesive. The camellia-oleifera-based particle board disclosed by the invention has good physical and mechanical properties; compared with a traditional wood particle board, the camellia-oleifera-based particle board has the advantages that recycling of agricultural and forestry waste is achieved; compared with wood, the camellia-oleifera-based particle board is lower in price; and compared with an existing camellia-oleifera-based particle board, the camellia-oleifera-based particle board has the advantages that production cost can be reduced, and environmental pollution can be reduced.

Owner:贵州省林业科学研究院

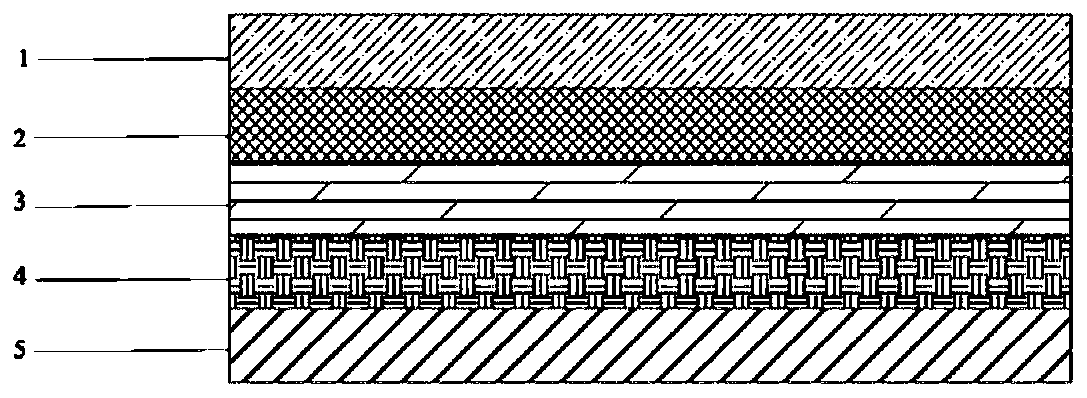

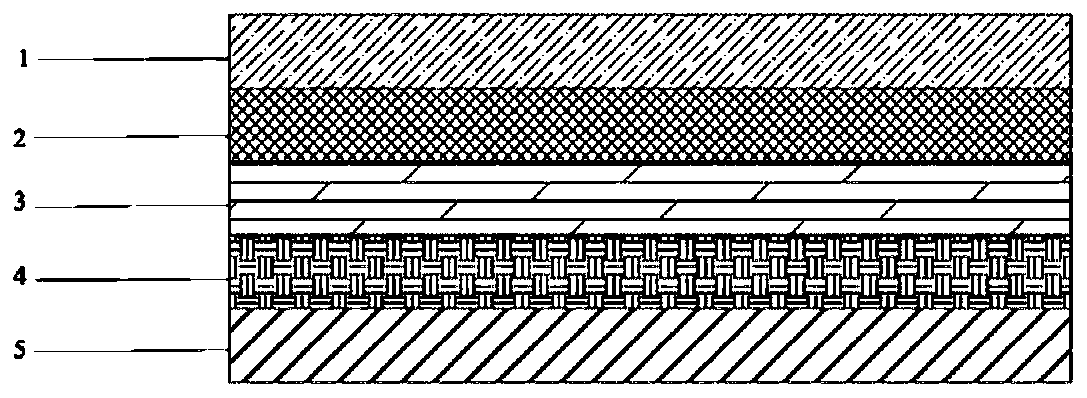

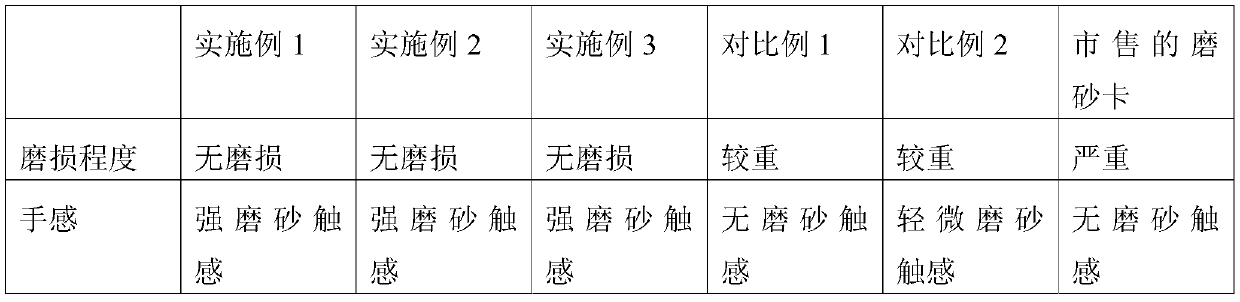

Preparation method of frosted card

ActiveCN109978120AFeel comfortableGood lookingRecord carriers used with machinesWear resistanceNanotechnology

The invention discloses a preparation method of a frosted card. The preparation method comprises the following steps of printing, binding and laminating. The laminating step comprises: a touch film with a frosted effect covers a protective film on the front surface of the card body, and under pressure of 2.5 MPa-7MPa and temperature of 100 to 130 DEG C, performing hot pressing for 2-20 minutes, then performing cold pressing at 5-25 DEG C to prepare the frosted card. The preparation method disclosed by the invention is simple in preparation process, particularly low in hot pressing temperatureand energy-saving, the prepared frosted card is comfortable in hand feeling, and particularly, the frosted surface of the prepared frosted card is good in wear resistance.

Owner:EASTCOMPEACE TECH

A standard wear part suitable for determining the abrasiveness of rocks in oil drilling formations

InactiveCN105445090BHigh hardnessReduce hardnessStrength propertiesPolycrystalline diamondRock sample

The invention relates to a standard wearing part suitable for determining the abrasiveness of oil drilling formation rocks. The technical solution is: the standard wear part is designed as a miniature core drill structure, which is composed of grinding parts and steel body connecting parts. Among them, the grinding parts are composed of phenolic resin matrix material and artificial polycrystalline diamond grinding material. The pressure process is integrated and sintered, and after processing and trimming, it is connected to the main shaft of the test device through the steel body connecting parts. Its beneficial effect is: it has reasonable wear resistance and good self-sharpening performance, and can effectively drill into rocks, and at the same time, it produces wear amount, which reflects the essence of diamond drill bit wear in the actual drilling process; The device is simple, the operation is convenient, and the technical conditions are stable. Under the conditions of simulating the dynamic grinding and rock breaking process of the diamond drill bit, the consumption of test rock samples or field cores is greatly reduced, and the test cost is saved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

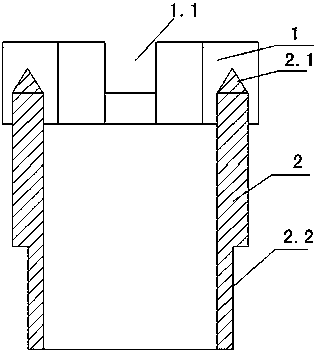

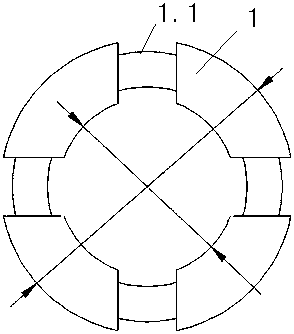

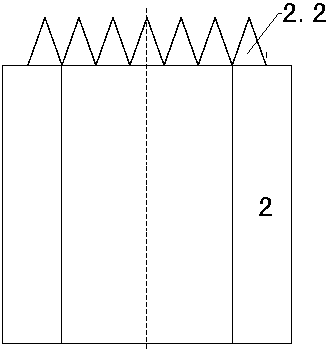

Impregnated high thermal conductivity nanofluid adhesive, preparation method and its application in wood-based panel decoration

ActiveCN106497469BDry fastLower pre-drying temperatureNon-macromolecular adhesive additivesMacromolecular adhesive additivesMetal oxide nanoparticlesWear resistant

The invention discloses an impregnation type highly-heat-conducting nano-fluid adhesive. The adhesive comprises, by mass, 1 to 10% of metal nanoparticles, metal oxide nanoparticles or non-metal nanoparticles with a high heat conduction coefficient, 89 to 98.8% of an impregnation type resin adhesive, 0.1 to 0.5% of a surfactant or dispersing agent and 0.1 to 0.5% of an antifoaming agent. The above materials are mixed and then undergo ultrasonic concussion so as to form the impregnation type highly-heat-conducting nano-fluid adhesive. The invention also discloses a preparation method and application of the impregnation type highly-heat-conducting nano-fluid adhesive. The impregnation type highly-heat-conducting nano-fluid adhesive accords with the characteristic that the heat conduction coefficient of a nano-fluid substantially increases. As applied to preparation of artificial board decoration materials, the impregnation type highly-heat-conducting nano-fluid adhesive can be used for impregnating surface paper, wear-resistant paper, decoration paper, covering paper, bottom paper, recombinant decorative veneer, sliced veneer, rotary-cut veneer, fabrics and the like, and the adhesive can reduce predrying temperature for the above decorative materials after impregnation or shorten predrying time; and hot-pressing temperature can be decreased or hot-pressing time can be shortened when the predried impregnated decorative materials are used for decoration of the artificial boards.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com