Patents

Literature

36results about How to "No need for high temperature sintering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

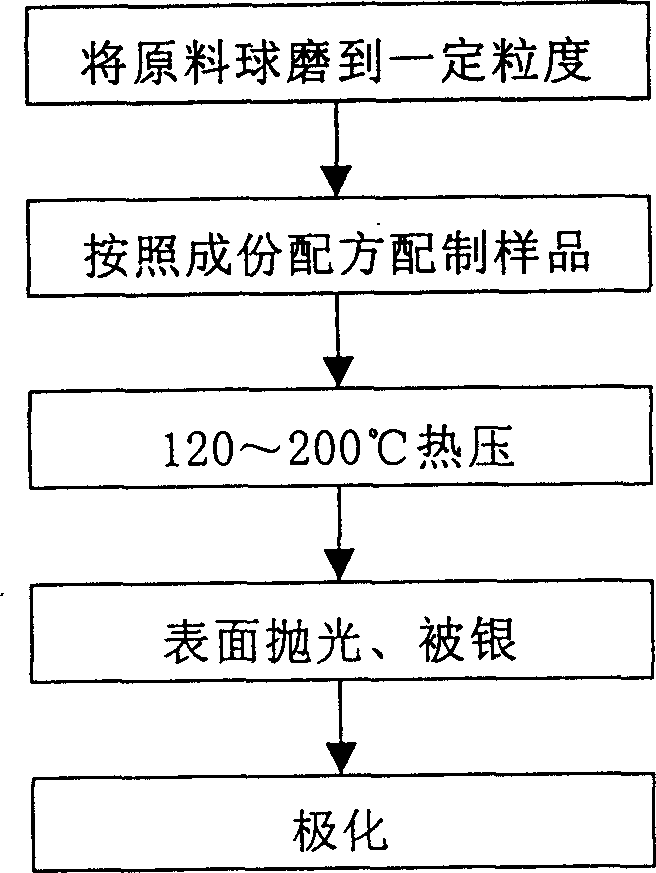

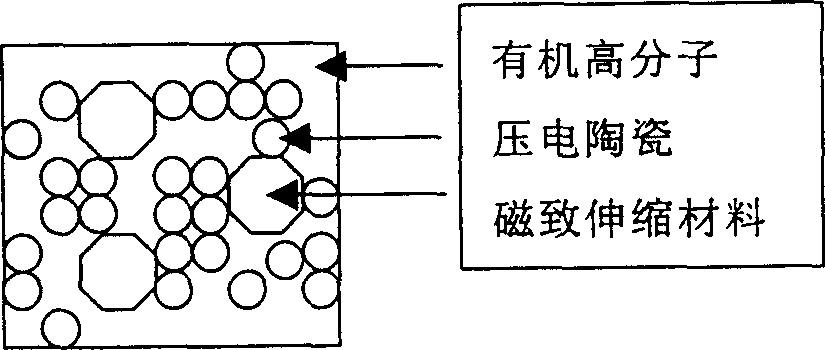

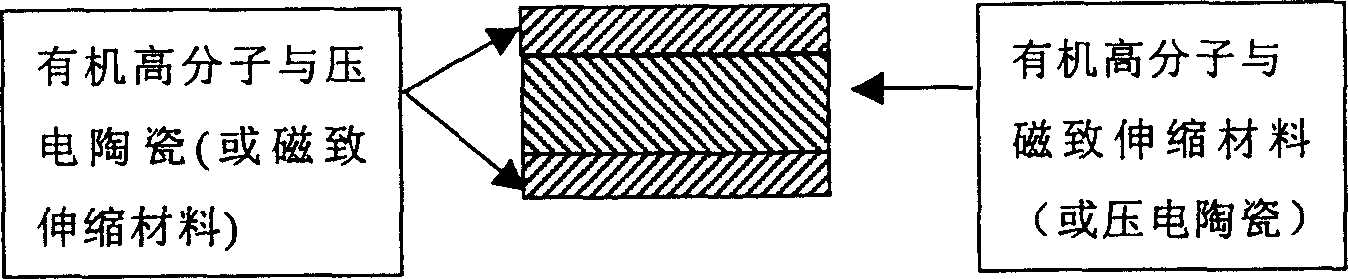

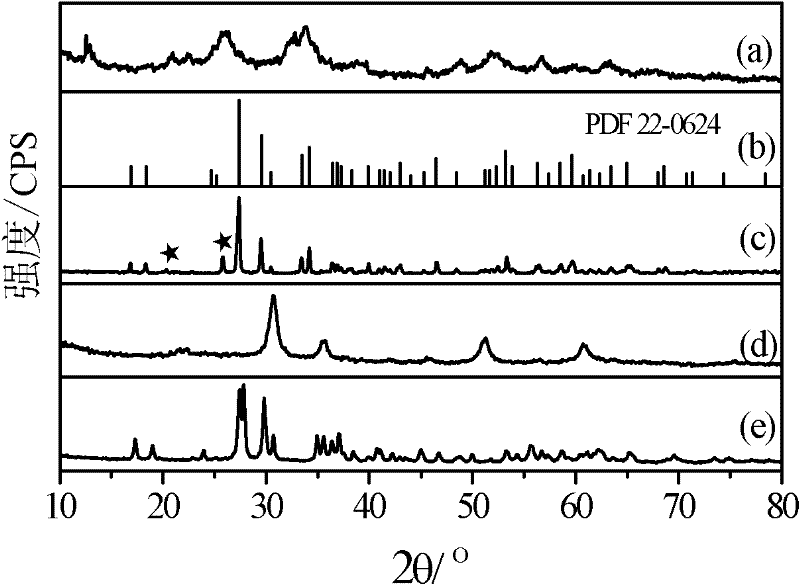

Three-component compound magnetoelectric material using organic polymer as adhesive and its preparation method

InactiveCN1395325AImprove mechanical propertiesHigh magnetoelectric conversion coefficientPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyLead zirconate titanateBarium titanate

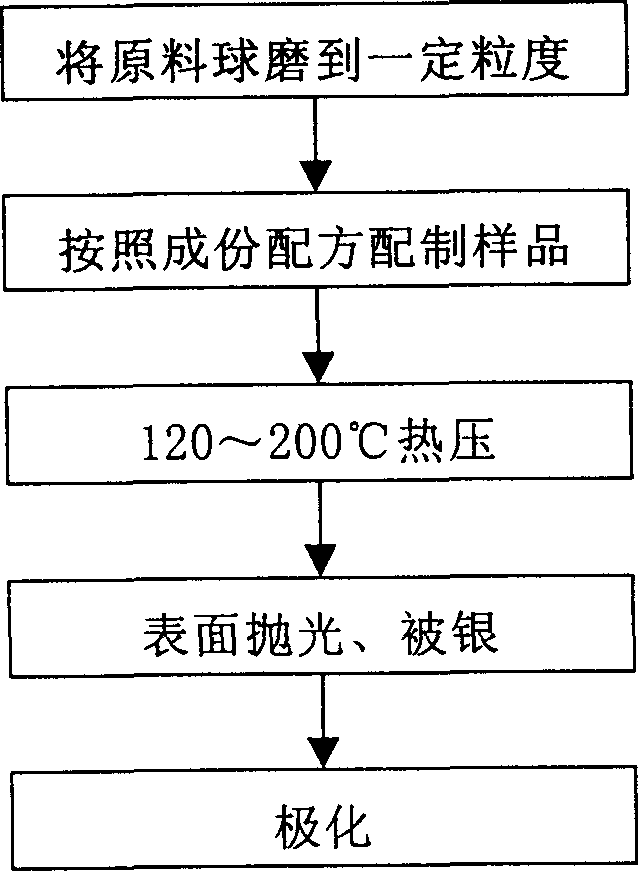

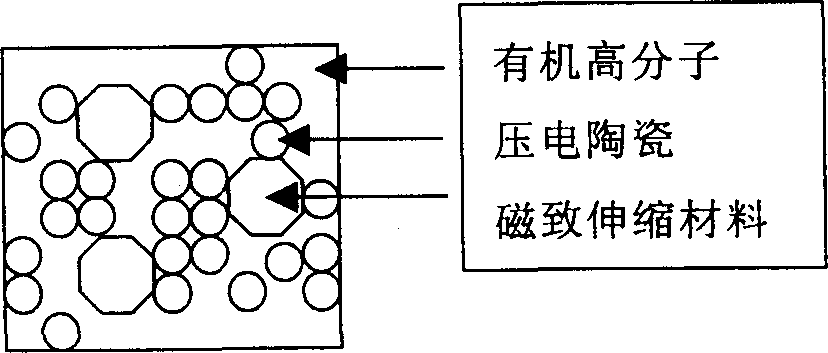

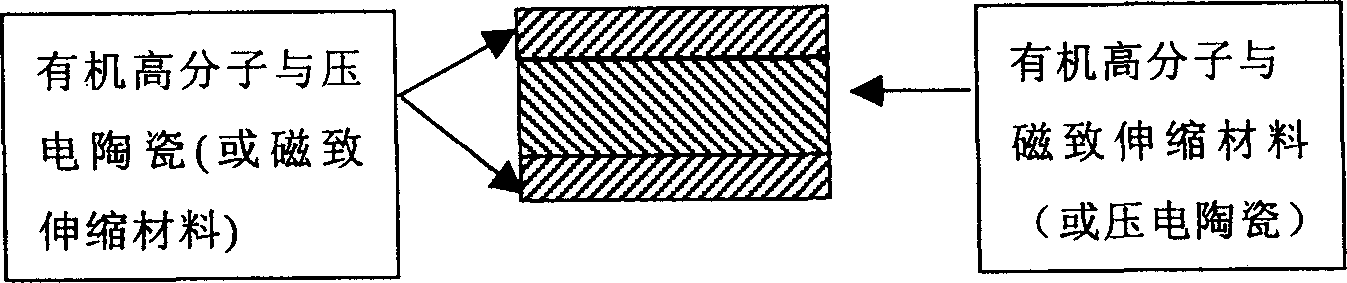

The invention relates to the ternary compound magneto-electric material by use of the organic macromolecule as the agglomerant as well as its preparation method.With the organic macromolecule being as the agglomerant the piezoelectric ceramic(such as lead zirconate titanate etc.)and the magnetostriction material(such as terbium-dysprosium-iron alloy)are taken shape by hot pressing at low temperature.The magneto-electric compound material can be made by the method.Comparing the prior art,the invention possesses the advantages of simple process,good mechanical characters of the material and high magneto-electric transformation factor.The hotpressing technique provides the features of low pressing temperature(about 120-200 deg.C),easy to change the magneto-electric characters by changing the sequence for adding the constituent and the relative content.

Owner:TSINGHUA UNIV

Small fiber balls for solid buoyancy material and preparation method of small fiber balls

The invention discloses small fiber balls for a solid buoyancy material and a preparation method of the small fiber balls. The small fiber balls have nuclear shell structures, nucleating carriers are foam balls, and shell layers are powdery fiber reinforced resin matrix composite layers; the small fiber balls with the nuclear shell structures are prepared by adopting the expandable polystyrene foam balls as the nucleating carriers, uniformly coating the surfaces of the expandable polystyrene foam balls with powdery fiber reinforced resin systems, solidifying and washing. The physical performance of the small fiber balls can be conveniently and effectively controlled and improved by changing the foam diameter, the fiber and resin type and the coating thickness according to different environmental usage requirements.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

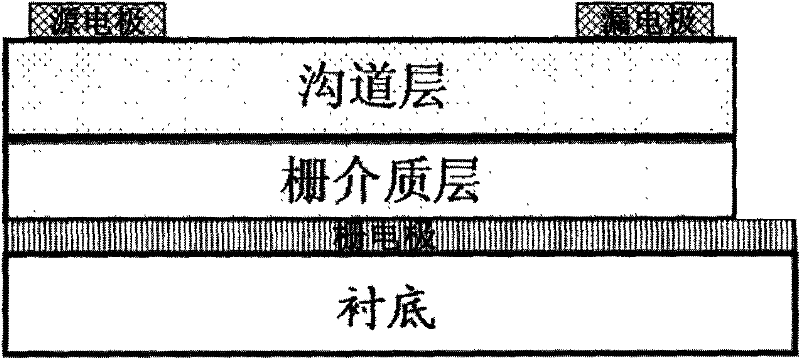

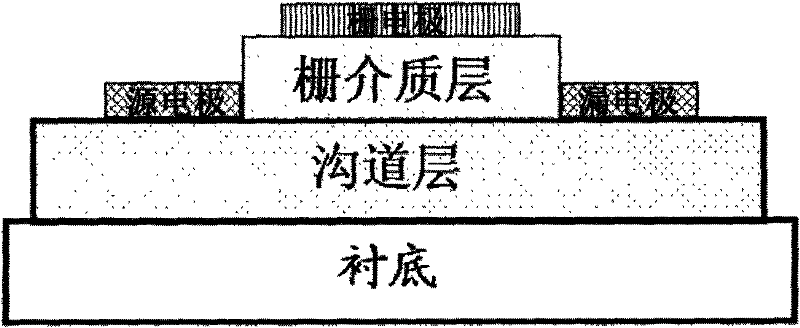

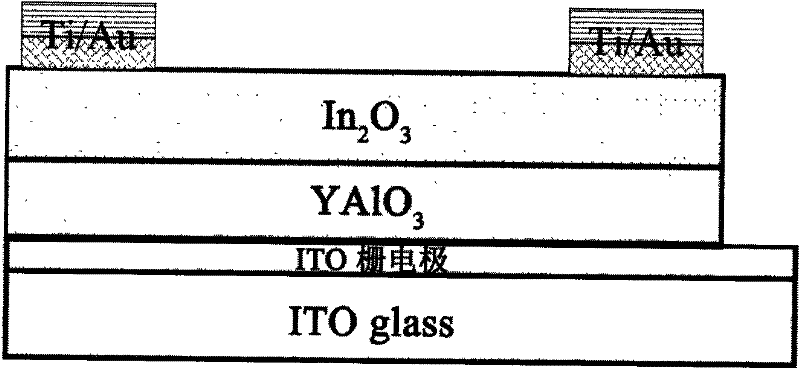

Preparation method of yttrium aluminum oxygen composite oxide high K medium thin film transistor

InactiveCN102683208AEasy to operateThe experimental process is precise and controllableSemiconductor/solid-state device manufacturingGate dielectricSource material

The invention discloses a preparation method of a YAIO3 composite oxide high K medium thin film transistor, which comprises the following steps of: taking a metal yttrium target (Y) and an aluminum target (A1) as source materials, preparing a gate dielectric layer material of a YAIO3 composite oxide high K medium as the thin film transistor by adopting a magnetron sputtering and rapid annealing technology, taking ITO (Indium Tin Oxide) glass as a substrate and taking source and drain electrodes as Ti / Au double-layered metal film electrodes; and the prepared thin film transistor can adopt a top gate structure or a bottom gate structure. The preparation method is simple and controllable, the low-temperature preparation can be realized, and the manufacturing cost is lower; and the prepared thin film transistor is excellent in performance, has smaller leakage current and larger capacitor, can be developed into a full-transparent thin film transistor and has very wide application prospect in the technical field of display devices.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of titanium oxide and its application

InactiveCN1442366AExcellent adhesionNot easy to fall offPigmenting treatmentTitanium dioxideTitanium hydroxideTitanium

A process for preparing titanium oxide includes such steps as converting the Ti-contained aqueous solution to titanium hydroxide, adding hydrogen peroxide and generating thermal reaction to obtain the solution of anatase-type titanium oxide solution with complex group, and drying. It can be used to prepare coating solution, while has high adhesion and no corrosion to substrate.

Owner:广东奥因环保科技有限公司

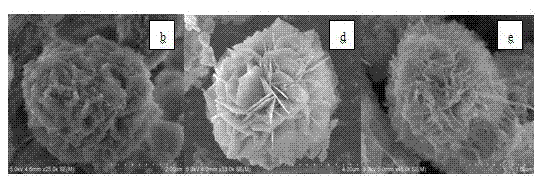

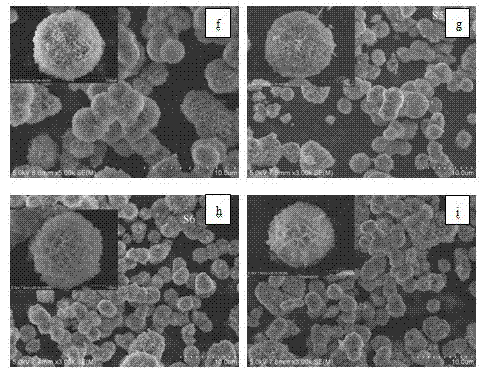

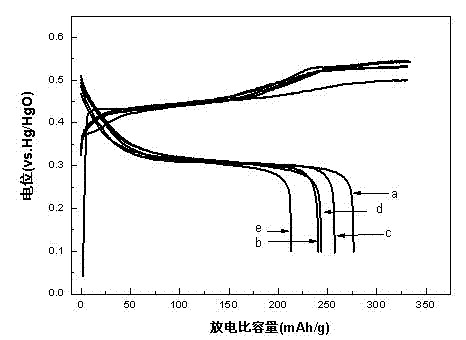

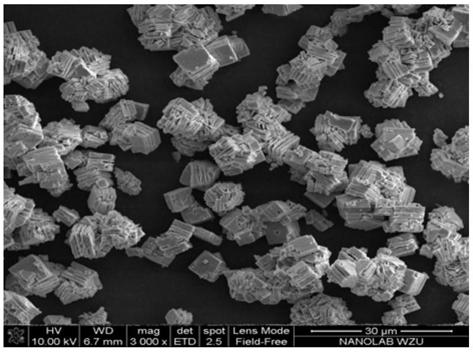

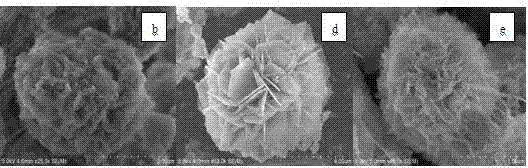

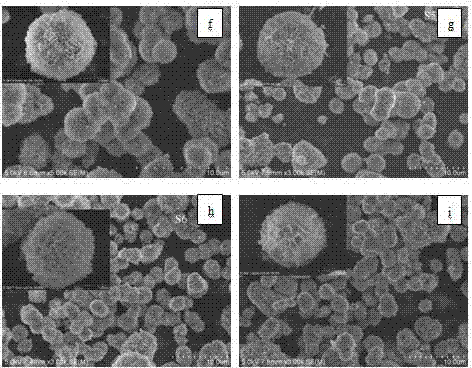

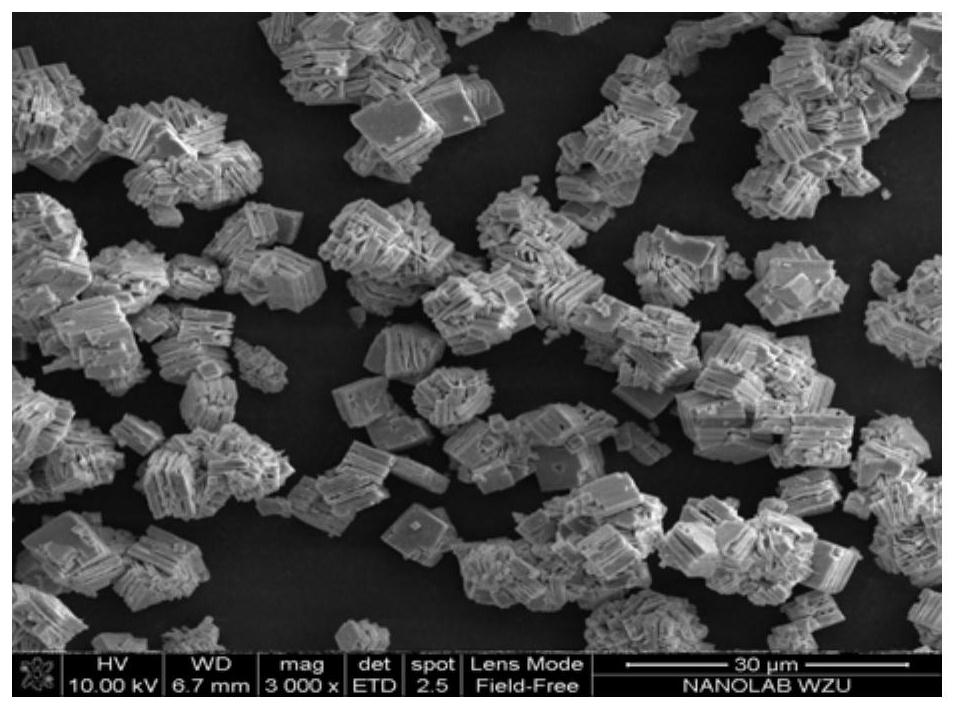

Preparation method of nano petaline Ni(OH)2

InactiveCN102774893AHigh particle purityUniform grain sizeNanotechnologyNickel oxides/hydroxidesMicrosphereSulfate

The invention discloses a preparation method of nano petaline Ni(OH)2. The method comprises the steps of taking nickel sulfate and urea as materials, preparing mixed solution of which the molar ratio of nickel to urea is 1:1 to 1:6 and then transferring the mixed solution to a 200mL of self-pressure lining polytetrafluoroethylene stainless steel reaction kettle, wherein the loading degree of a hydrothermal reaction kettle can be up to 80%; covering an inner cover and an outer cover to feed to an electric heating constant-temperature tank, heating the solution to 170 DEG C, reacting for 2-20 hours at constant temperature, then naturally cooling the solution to room temperature, filtering and washing the solution into a neutral state by deionized water; drying the solution into constant weight at 80 DEG C, and thinning the petals to prepare the nano petaline Ni(OH)2. According to the preparation method, the urea is taken as a precipitator, and a nano petaline Ni(OH)2 microsphere is directly prepared by hydrothermal syntheses; the method is simple in process, low in cost and easy to control without high-temperature sintering or a template agent, the obtained product crystal particle has the advantages that the size is uniform; the particle purity is high; the dispersity is good, and the crystalline form is good and controllable.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

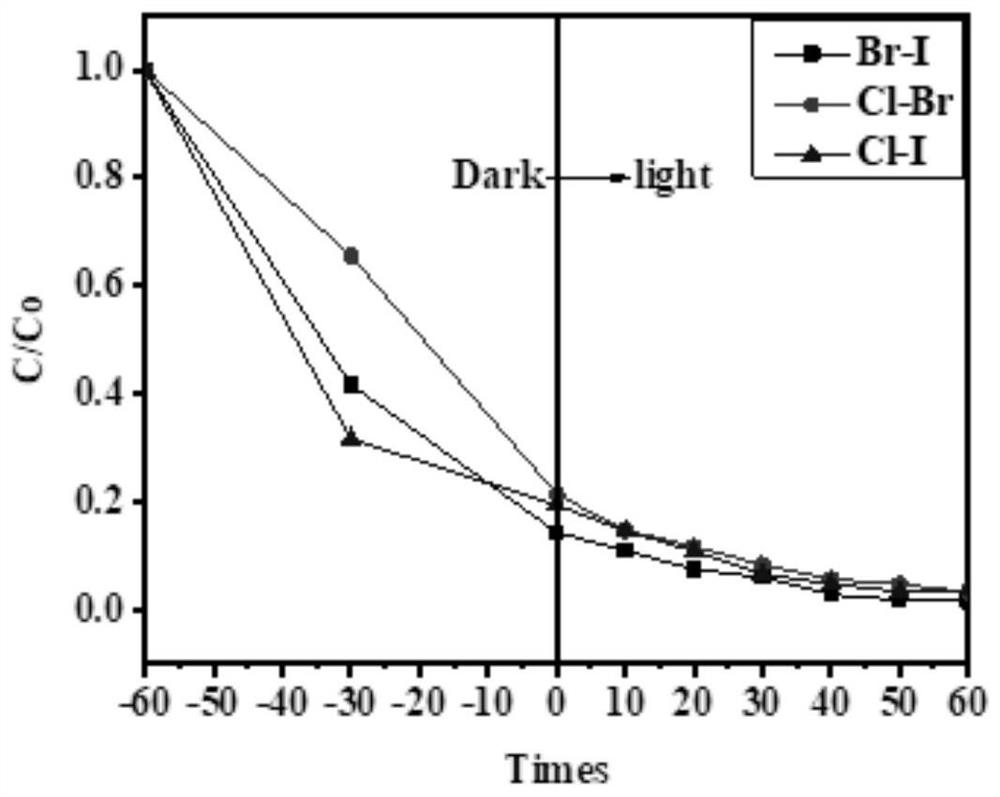

Preparation method of Bi2O2SiO3-Si2Bi24O40-BiOX double-heterojunction composite photocatalyst

InactiveCN112536050AEfficient separationUnique hierarchical structureWater/sewage treatment by irradiationWater contaminantsHeterojunctionSodium metasilicate

The invention relates to a preparation method of a Bi2O2SiO3-Si2Bi24O40-BiOX double-heterojunction composite photocatalyst. X is two of Cl, Br and I. The preparation method comprises the following steps of by taking bismuth nitrate as a bismuth source, sodium metasilicate nonahydrate as a silicon source, absolute ethyl alcohol and deionized water as solvents and polyethylene glycol 400 or ethyleneglycol and the like as a dispersing agent, carrying out hydrothermal reaction for 11-13 hours, and compounding the obtained composite material powder with NaX (X=Cl, Br, I). According to the method,high-temperature sintering is not needed, the process is simple, the particle size of the product is easy to control, the synthesized product is high in crystallinity, high in purity and free of agglomeration, and the obtained composite material powder shows high photocatalytic performance due to the synergistic effect of double heterojunctions.

Owner:SHAANXI UNIV OF SCI & TECH

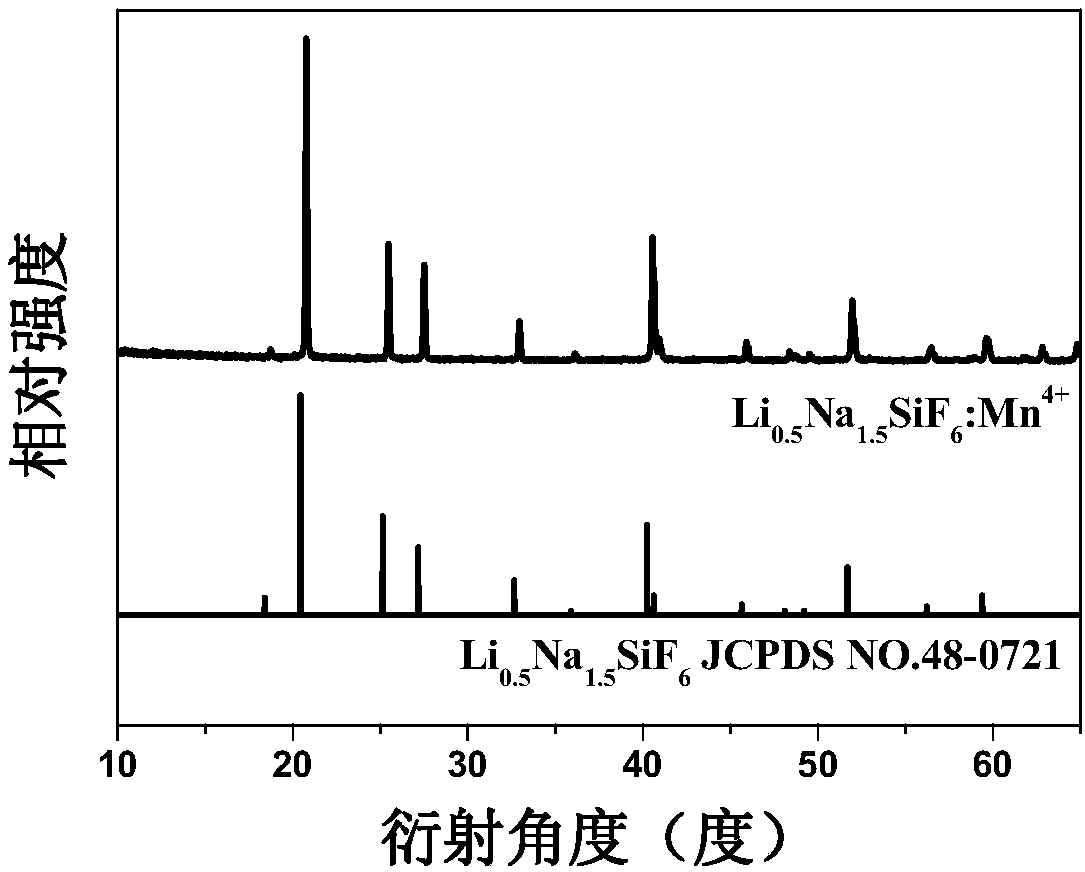

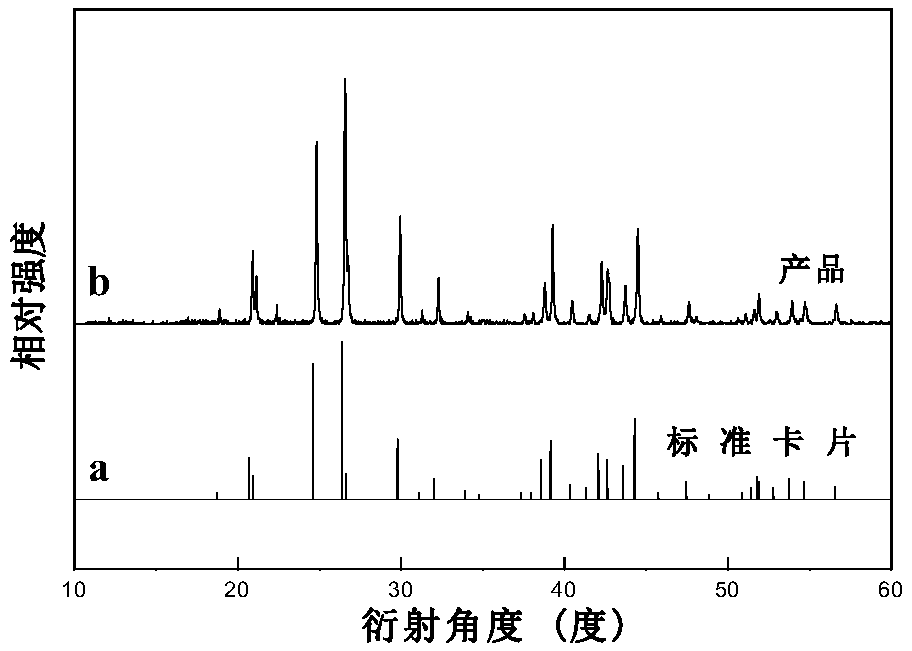

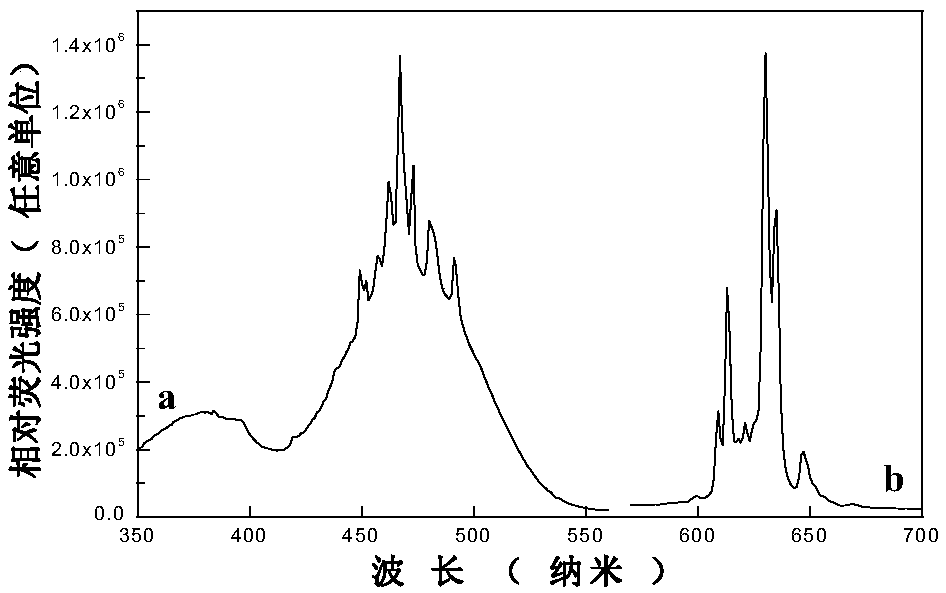

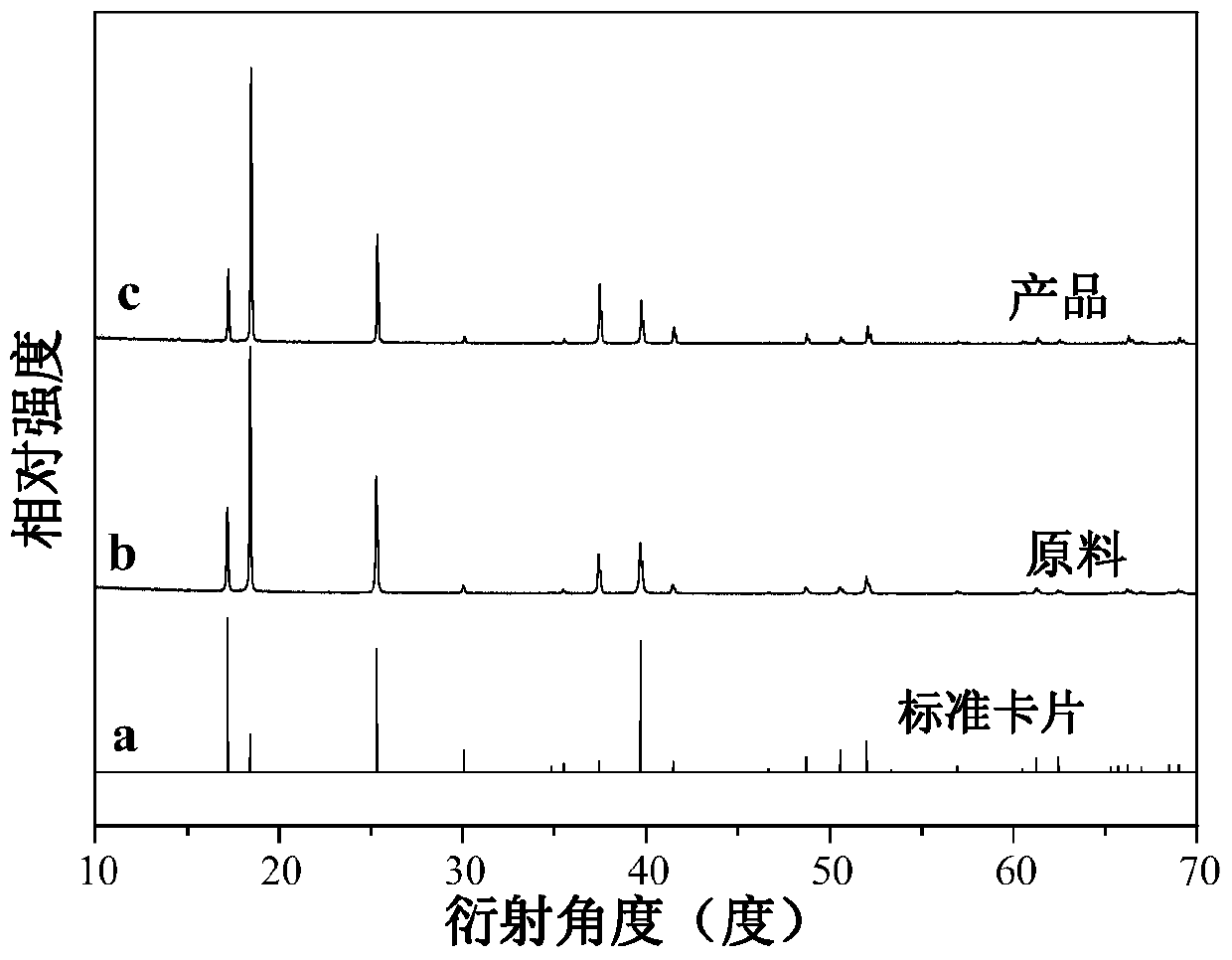

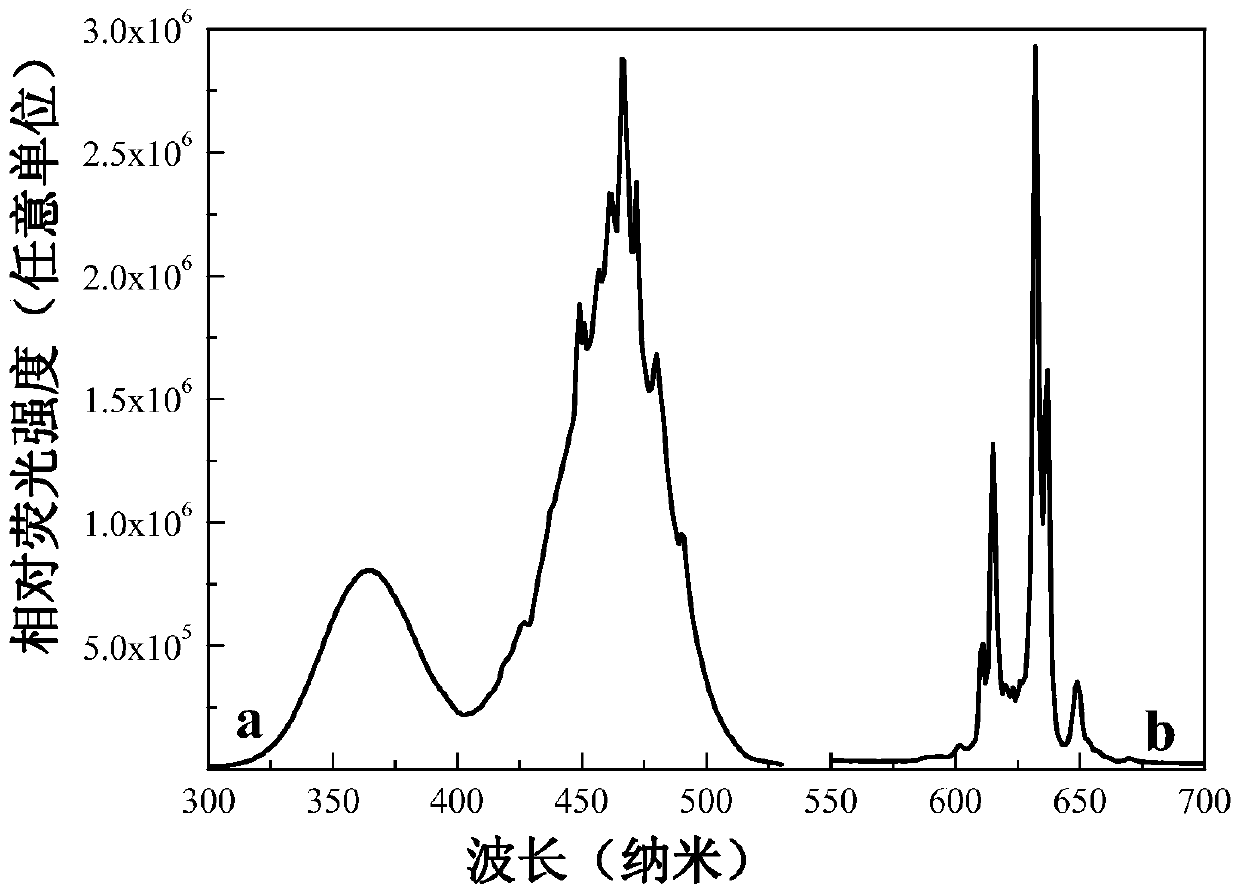

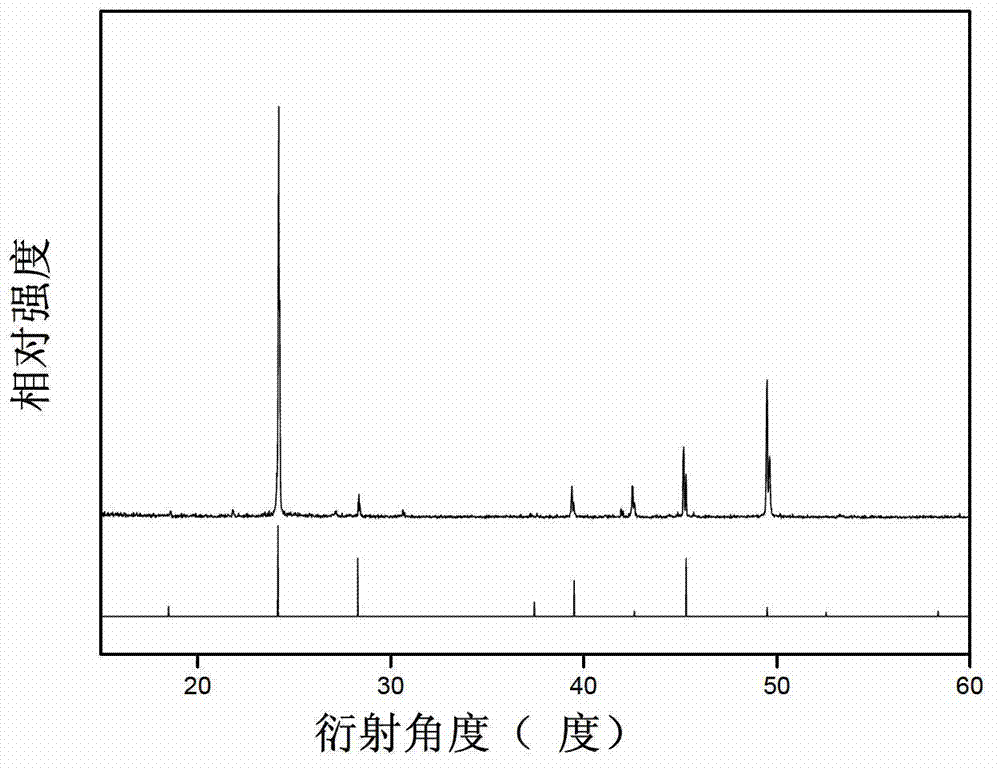

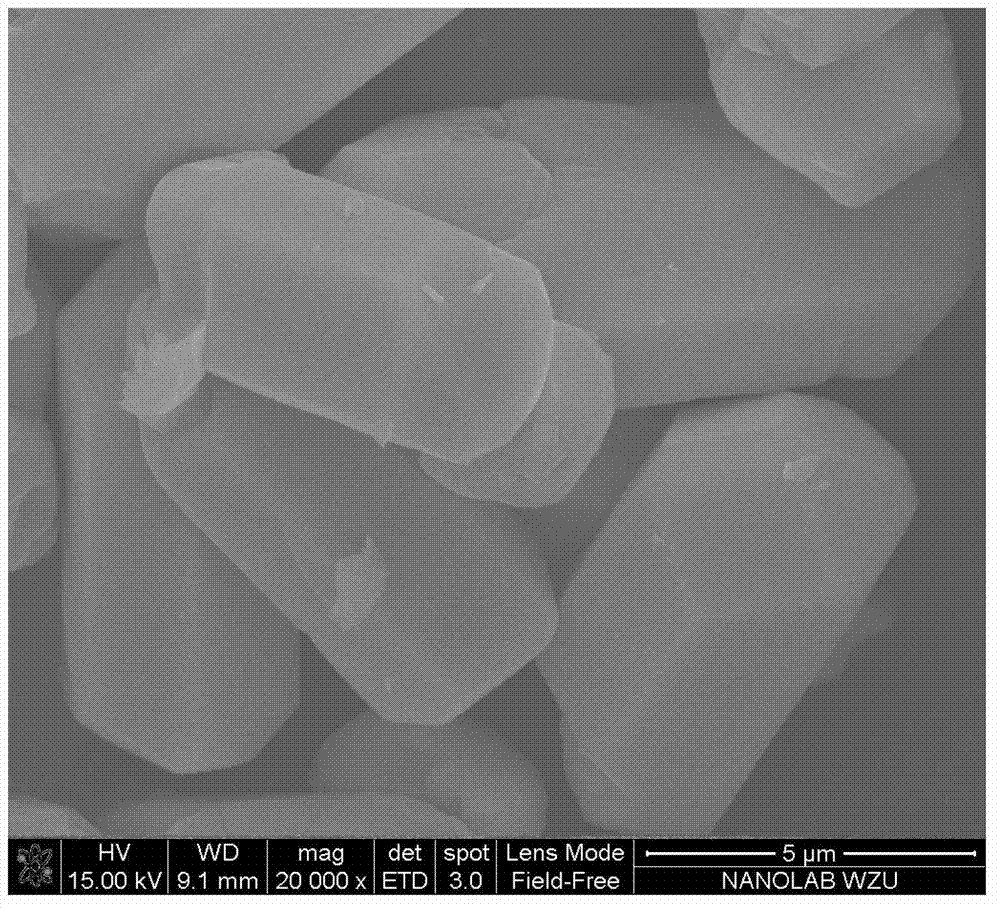

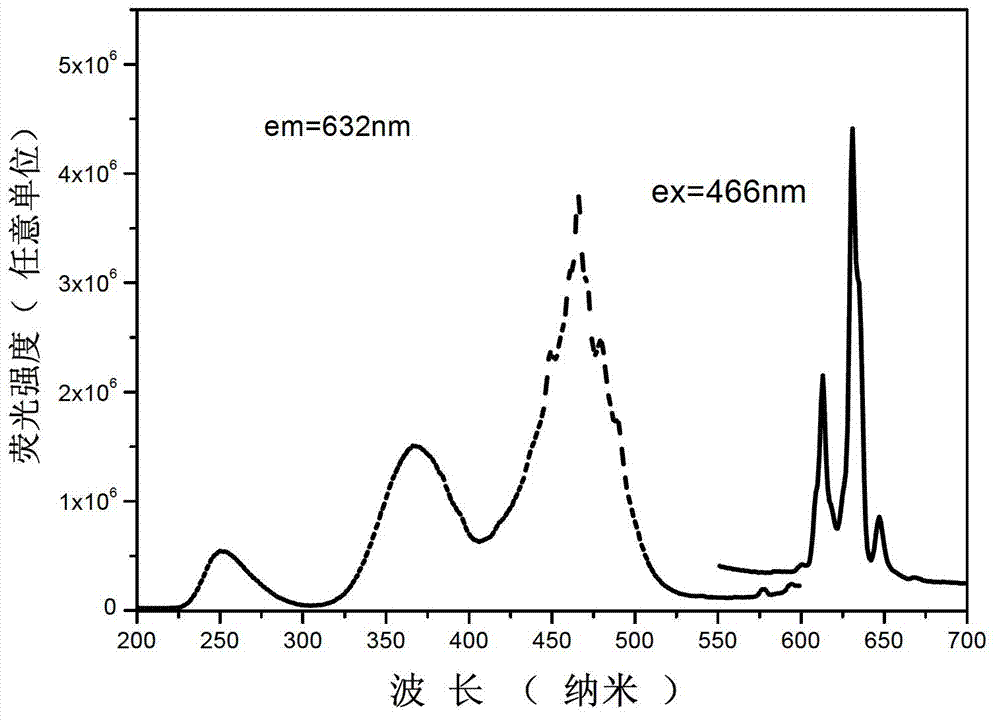

Lithium sodium fluosilicate red-light material for white-light LED (Light-Emitting Diode) and preparation method thereof

InactiveCN107686726ADecreased lattice symmetryIncreased intensity of zero photon raysEnergy efficient lightingLuminescent compositionsChemistryColor rendering index

The invention discloses a lithium sodium fluosilicate red-light material for a white-light LED (Light-Emitting Diode) and a preparation method thereof. The material uses Li0.5Na1.5SiF6 as a substrateand uses Mn<4+> as an activating agent; the chemical composition is Li0.5Na1.5SiF6:Mn<4+>. During preparation, solid lithium nitrate, sodium fluoride, silica and potassium fluoromanganate are accurately weighed according to a stoichiometric ratio; all solids are put into an aqueous solution of HF; the agitation is carried out at normal temperature; afterwards, the suction filtration is carried out; the natural air-drying is carried out, so that the lithium sodium fluosilicate red-light material is obtained. A product has a maximum excitation wavelength located in a 467nm blue-light area, can be effectively excited by a GaN blue-light chip, and emits a red quadrivalent-manganese characteristic emission peak and has an emission spectrum located from 600nm to 650nm. The material can be used for supplementing a red component lacked in the white-light LED, so as to improve the color rendering index of the white-light LED. The product does not contain rare earth; a raw material is low in price and easy to obtain; the high-temperature sintering is not needed, and the lithium sodium fluosilicate red-light material is suitable for industrial production.

Owner:WENZHOU UNIVERSITY

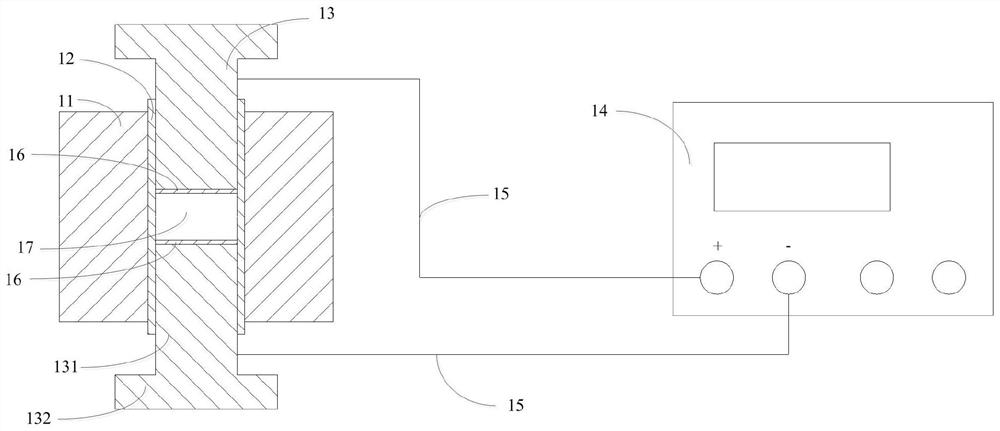

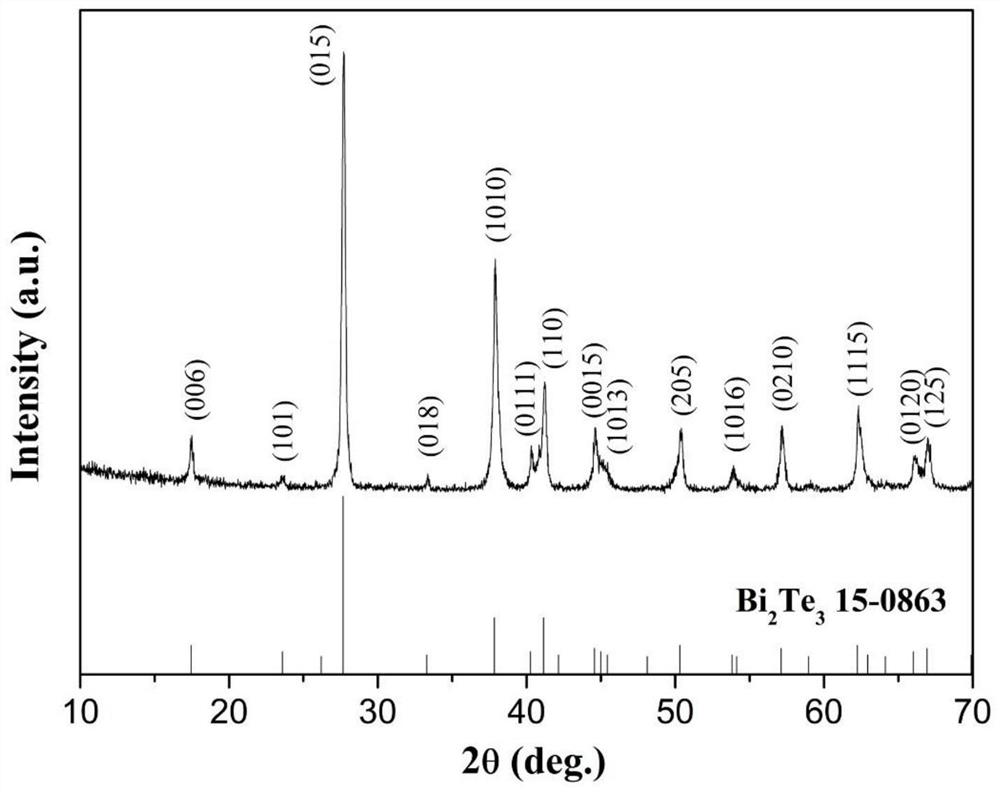

Preparation method and preparation device of bismuth telluride-based thermoelectric material

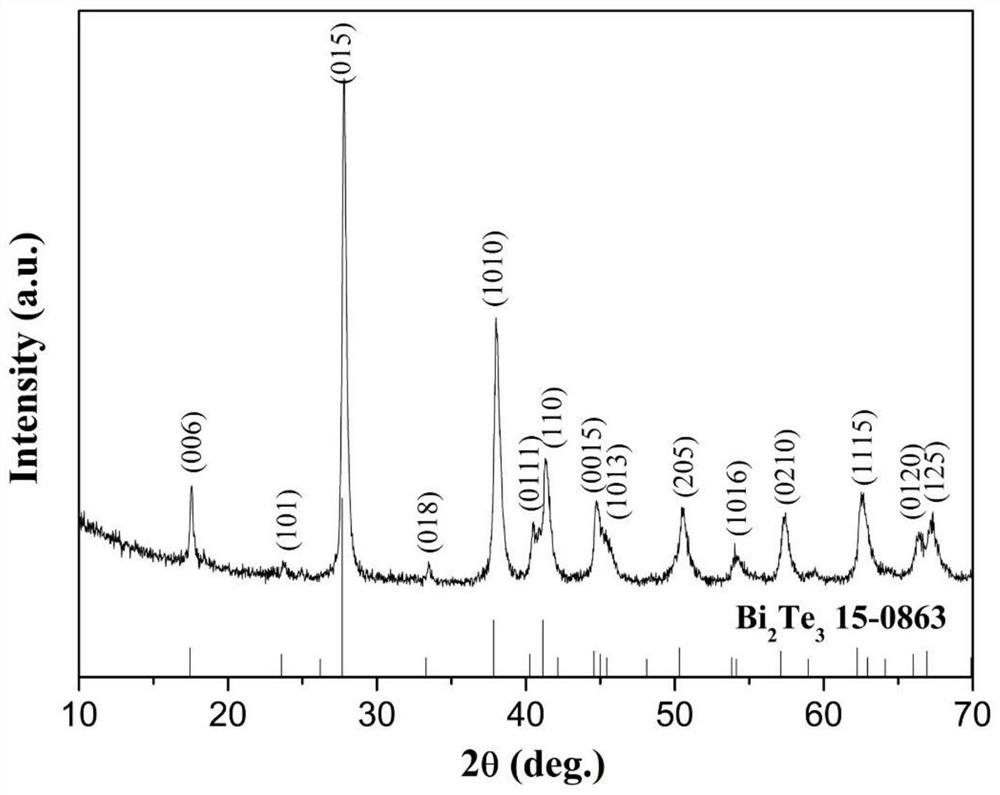

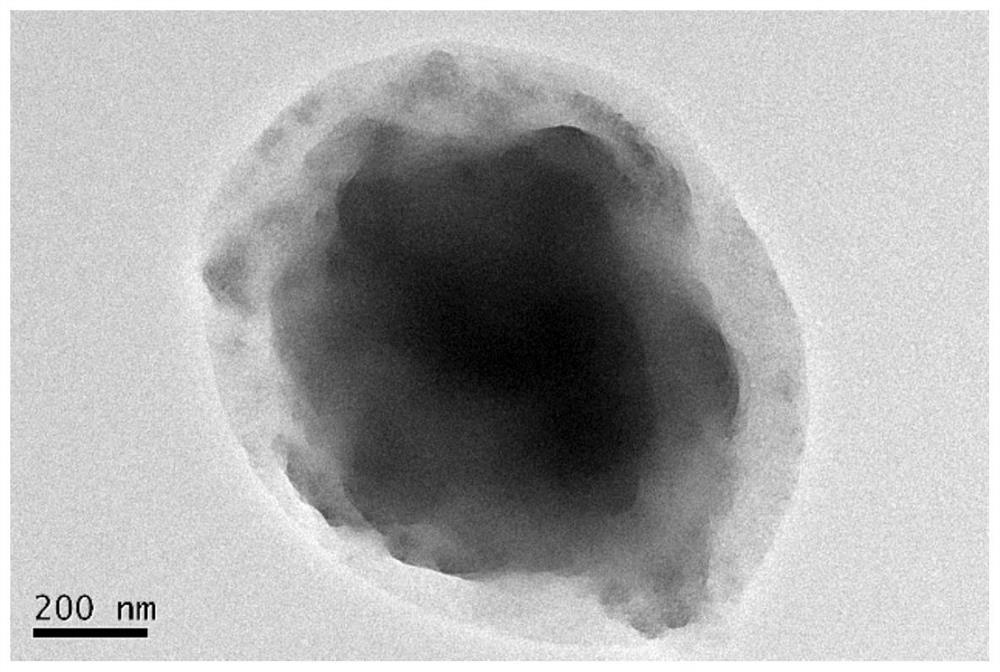

PendingCN112909156AShort preparation timeSimple processThermoelectric device manufacture/treatmentThermoelectric device junction materialsBismuth tellurideGraphite

The invention relates to the technical field of thermoelectric materials, in particular to a preparation method and a preparation device of a bismuth telluride-based thermoelectric material. The method comprises the following steps: weighing Bi powder, Te powder and Se powder according to the stoichiometric ratio of Bi2Te3-xSex, and uniformly grinding; in a forming hole, embedding pressing head columns of two conductive pressing heads into the two ends of the forming hole, locating the ground powder in the forming hole and between the two conductive pressing heads, and separating the ground powder from guide pressing heads through graphite paper; applying pressure to the guide pressing heads, and maintaining the pressure for a first preset time; connecting a wiring terminal of a power supply assembly with the two conductive pressing heads; and controlling the power supply assembly to be electrified for second preset time at preset voltage and preset current density. Therefore, the bismuth telluride-based thermoelectric material is short in preparation time, simple in process and low in equipment requirement, high-temperature sintering is not needed, and rapid large-scale batch preparation can be realized.

Owner:BEIJING INFORMATION SCI & TECH UNIV

Modification method of polymer solid polyelectrolyte

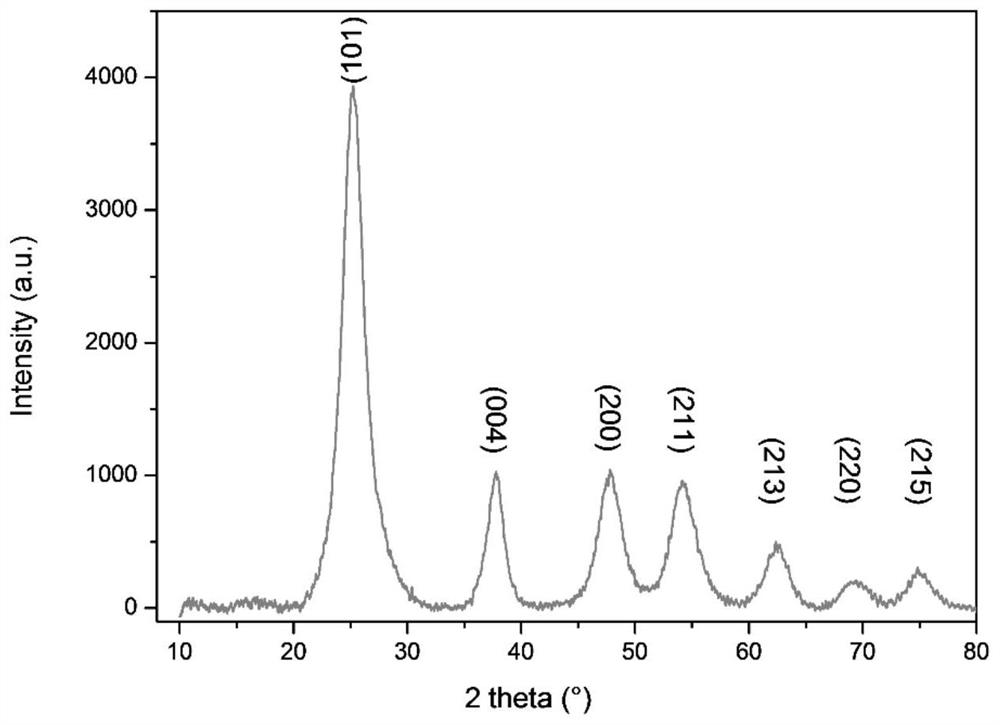

PendingCN112864469AGood compatibilityReduce crystallinityMaterial nanotechnologyFinal product manufacturePolymer scienceIonic conductivity

The invention discloses a modification method of a polymer solid polyelectrolyte, and belongs to the technical field of solid polyelectrolyte diaphragms. The PEO modified nano TiO2 is adopted and then compounded with the polyalkylene oxide-polyphenyl ether copolymer, so that the compatibility of inorganic particles and a PEO polymer matrix is effectively improved, the TiO2 nano particles are more uniformly dispersed in an organic polymer matrix, the movement ability of a PEO chain segment is improved, the crystallinity of a polymer is effectively reduced, and the ionic conductivity is improved.

Owner:BEIJING UNIV OF TECH

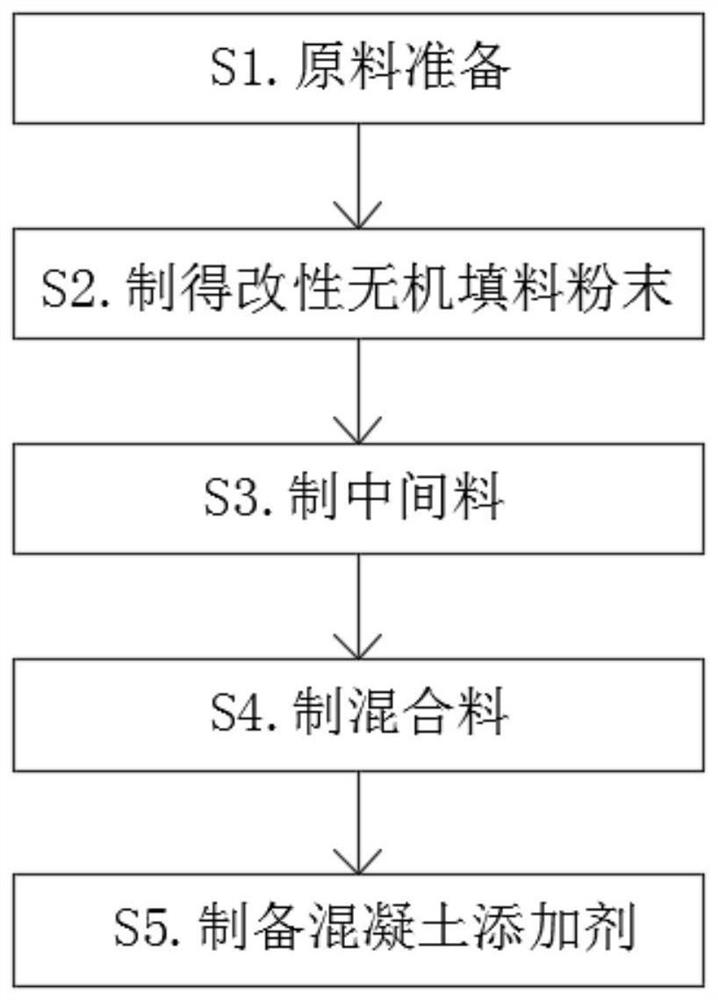

Production process of concrete additive

The invention discloses a production process of a concrete additive. The production process comprises the following steps: S1, raw material preparation: selecting raw materials in parts by weight: 5 to 18 parts of magnesium silicate, 10 to 20 parts of modified cement, 5 to 18 parts of fly ash, 8 to 30 parts of mineral powder, 6 to 20 parts of soil, 18 to 42 parts of quartz sand, 0.5 to 3 parts of KH550 silane coupling agent, 4 to 16 parts of acrylic acid, 14 to 50 parts of ethylene-vinyl acetate copolymer, 1 to 4 parts of fiber, 5 to 12 parts of efficient water reducing agent, 1 to 4 parts of reinforcing agent, 0.4 to 2.4 parts of cross-linking agent, 0.5 to 3.6 parts of free radical initiator, 0.2 to 1.4 parts of antioxidant, 0.1 to 1.2 parts of compound waterproof agent, 1 to 3 parts of ferric oxide and 0.2 to 0.6 part of an ultraviolet light absorber; S2, preparing modified inorganic filler powder; S3, preparing an intermediate material; S4, preparing a mixture; and S5, preparing the concrete additive. The additive disclosed by the invention has the advantages of good waterproofness, no need of high-temperature sintering, low energy consumption and convenience in raw material acquisition, and the working efficiency is improved.

Owner:王允刚

Fiber pellets for solid buoyancy materials and method of making the same

The invention discloses small fiber balls for a solid buoyancy material and a preparation method of the small fiber balls. The small fiber balls have nuclear shell structures, nucleating carriers are foam balls, and shell layers are powdery fiber reinforced resin matrix composite layers; the small fiber balls with the nuclear shell structures are prepared by adopting the expandable polystyrene foam balls as the nucleating carriers, uniformly coating the surfaces of the expandable polystyrene foam balls with powdery fiber reinforced resin systems, solidifying and washing. The physical performance of the small fiber balls can be conveniently and effectively controlled and improved by changing the foam diameter, the fiber and resin type and the coating thickness according to different environmental usage requirements.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

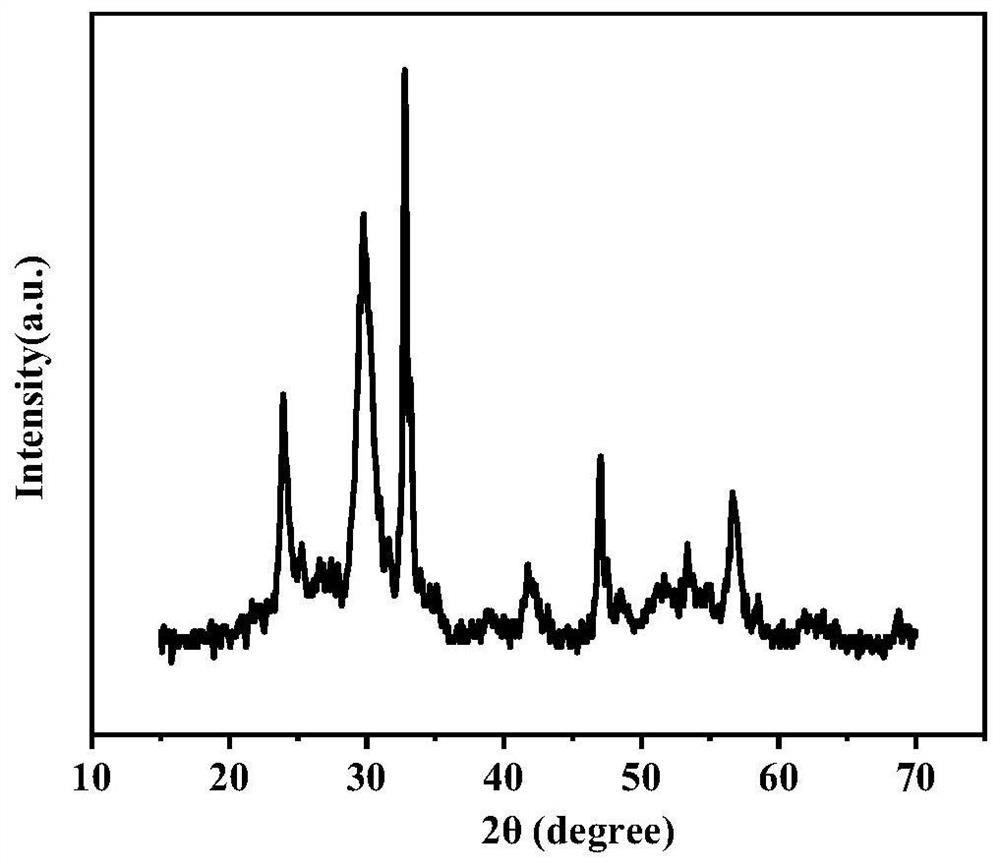

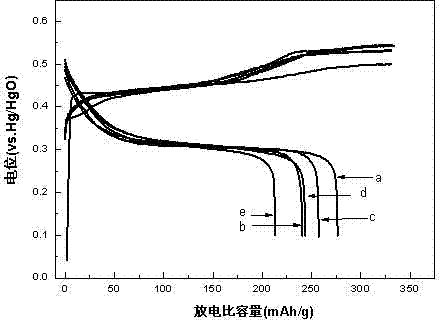

Tetravalent manganese ion-doped barium fluoscandate red light material and preparation method thereof

ActiveCN109179481ANo need to avoid water and oxygenLow costRare earth metal compoundsLuminescent compositionsColor rendering indexFiltration

The invention discloses a tetravalent manganese ion-doped barium fluoscandate red light material and a preparation method thereof. The material is based on Ba3Sc2F12, contains Mn<4+> as an activator and has a chemical composition of Ba3Sc2F12: Mn<4+>. The preparation method utilizes Sc2O3 as a scandium source, Ba(NO3)2 as a barium source, K2MnF6 as an activated ion manganese source and a HF aqueous solution as a medium and a fluorinating agent, and comprises: putting Sc2O3 solids into a container, adding the HF aqueous solution, Ba(NO3)2 and K2MnF6 into the container, carrying out a reaction process in a range of the normal temperature to 180 DEG C for 1-12h, carrying out suction filtration and carrying out natural airing to obtain the tetravalent manganese ion-doped barium fluoscandate red light material. The product has the maximum excitation wavelength in a 467nm blue region, can be effectively excited by the GaN blue chip, can emit a red quaternary manganese characteristic emissionpeak and has an emission spectrum in 600-650nm. The tetravalent manganese ion-doped barium fluoscandate red light material can supply a red light component absent by white LED, can be used for two-primary color white LED, can improve the white LED color rendering index and does not contain rare earth. The preparation method is simple, is free of high temperature sintering and is suitable for industrial production.

Owner:WENZHOU UNIVERSITY

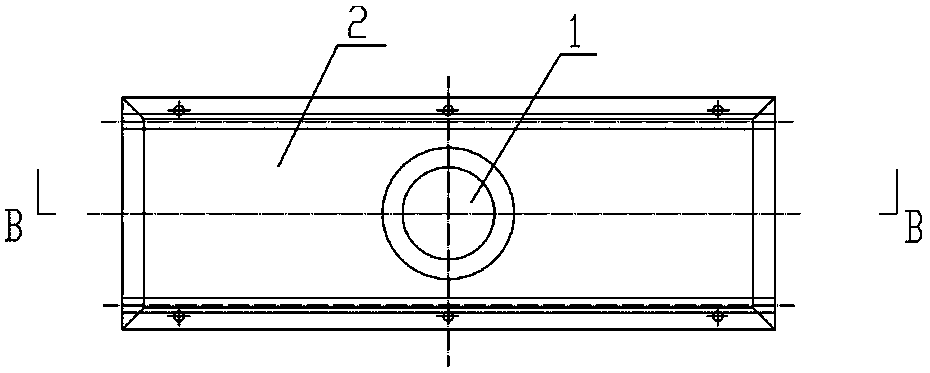

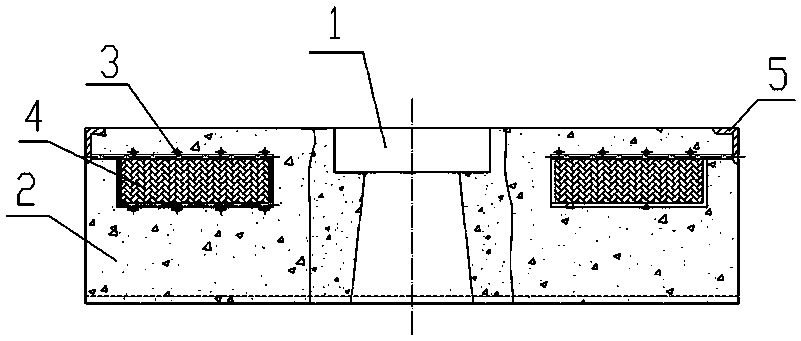

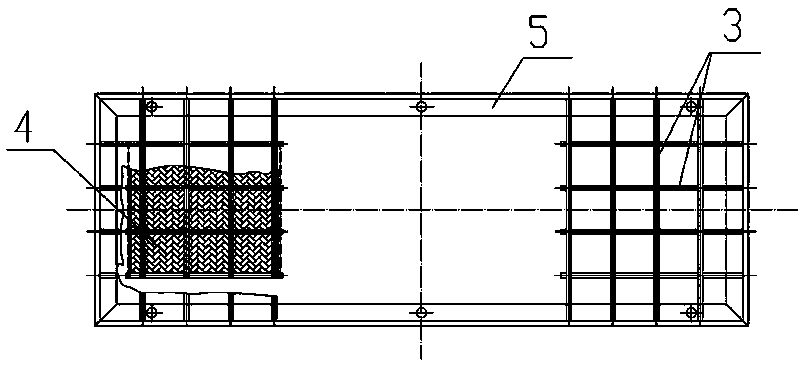

Composite heat-insulated furnace surface prefabricated block for aluminum anode carbon roasting furnace flue wall

ActiveCN105910441BMeet the actual needs of the siteReduce surface temperatureFurnace componentsInsulation layerFire resistance

The invention discloses a composite heat insulation type furnace face prefabricated block for an aluminum anode carbon roasting furnace flue wall. The composite heat insulation type furnace face prefabricated block comprises a prefabricated material pouring body which is of a cuboid structure and is provided with a fire jet opening in the middle, bearing nets and heat insulation layers, wherein the bearing nets and the heat insulation layers are sequentially and horizontally embedded into the portions, located on the two sides of the fire jet opening, of the upper portion of the prefabricated material pouring body from top to bottom. L-shaped reinforcing frames are pressed on the edge of the periphery of the upper surface of the prefabricated material pouring body in a buckled manner. The composite heat insulation type furnace face prefabricated block is a composite body composed of refractory castable, the L-shaped reinforcing frames, the bearing nets, the heat insulation layers and other materials, and the requirements for fire resistance, collision prevention, heat insulation performance, load-bearing performance and anti-skidding performance of the furnace face prefabricated block for the flue wall are met; and the refractory castable sintered bauxite with the high strength and high performance is adopted as a host material for the furnace face prefabricated block, so that the finished prefabricated block has high strength, micropores and the medium or high specific gravity and is high in performance. A manufacturing method of the composite heat insulation type furnace face prefabricated block is simple, the process parameters are easy to control, and high-temperature sintering is not needed; and the pouring material formula is changed for different portions, and the field actual requirements of different portions of the prefabricated block are met.

Owner:郑州汇特耐火材料有限公司

Preparation method of titanium oxide and its application

InactiveCN1326777CNo need for high temperature sinteringStrong adhesionPigmenting treatmentTitanium dioxideTitanium hydroxideAqueous solution

A process for preparing titanium oxide includes such steps as converting the Ti-contained aqueous solution to titanium hydroxide, adding hydrogen peroxide and generating thermal reaction to obtain the solution of anatase-type titanium oxide solution with complex group, and drying. It can be used to prepare coating solution, while has high adhesion and no corrosion to substrate.

Owner:广东奥因环保科技有限公司

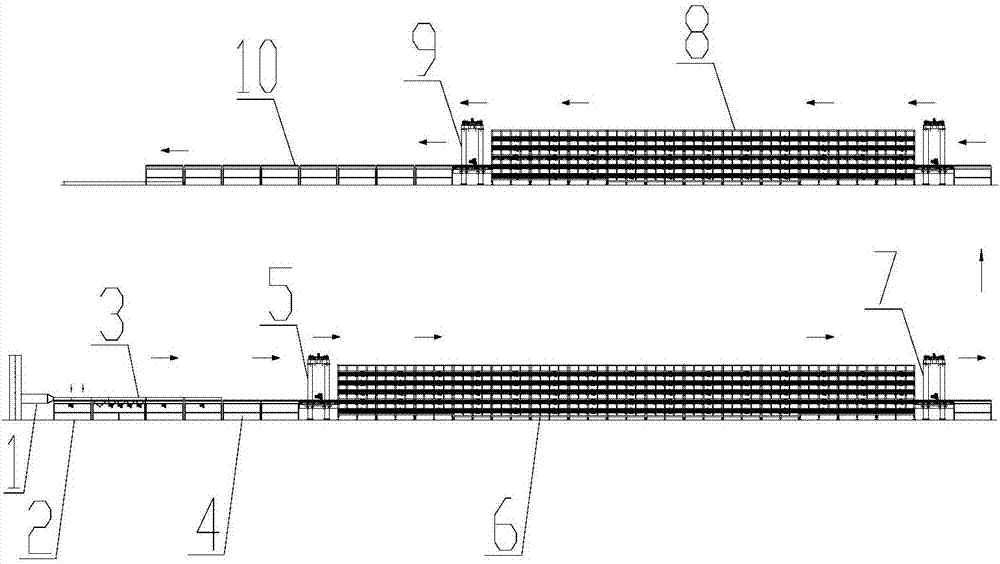

Natural drying system for fireproof building material green body

InactiveCN106945160ANothing producedSufficient chemical reaction timeCeramic shaping apparatusChemical reactionFree cooling

A natural drying system for a fireproof building material green body comprises a pressure extruder, a first roller type conveying mechanism, a second roller type conveying mechanism, a front green body collecting and conveying mechanism, a front lifting unit, a reaction frame, a rear lifting unit, a cooling frame and an output lifting unit. A cutter assembly is arranged on the upper side of the first roller type conveying mechanism. The front green body collecting and conveying mechanism is used for conducting the green body collection work on the formed green body. The front lifting unit is used for conveying the formed green body in the height direction. The reaction frame, the rear lifting unit, the cooling frame and the output lifting unit are subsequently and sequentially arranged. The reaction frame is used for conducting chemical reaction on the green body. The cooling frame is used for conducting natural cooling on the green body. By means of the structural design mentioned above, the green body is unceasingly and naturally dried and enough chemical reaction time is ensured through the reaction frame and the cooling frame, drying and hardening can be conducted, high-temperature sintering is not needed, no smoke is generated, and the energy consumption is lowered. A green body asynchronous collection assembly is arranged, regulation of the conveying speed of the green body on each same conveying mechanism can be achieved, and therefore controllability of the natural drying system is improved, and different production requirements are met.

Owner:FOSHAN XINLICHENG MECHANICAL & ELECTRICAL EQUIP CO LTD

A tetravalent manganese ion-doped ammonium salt red light material and preparation method thereof

InactiveCN105733575BLow costNo need for high temperature sinteringEnergy efficient lightingLuminescent compositionsColor rendering indexFiltration

Owner:WENZHOU UNIV

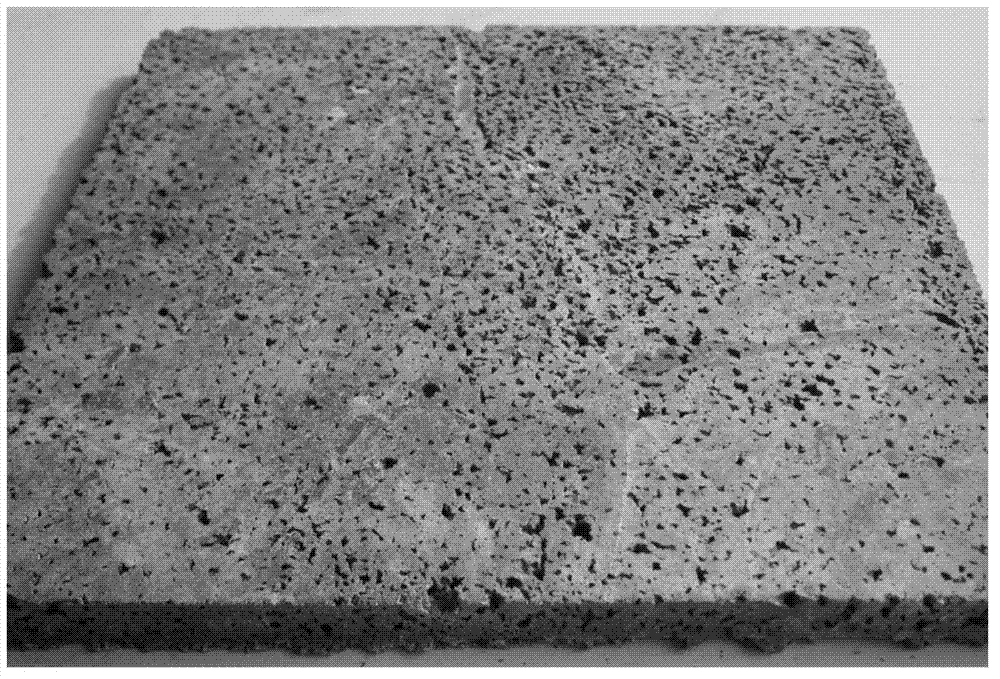

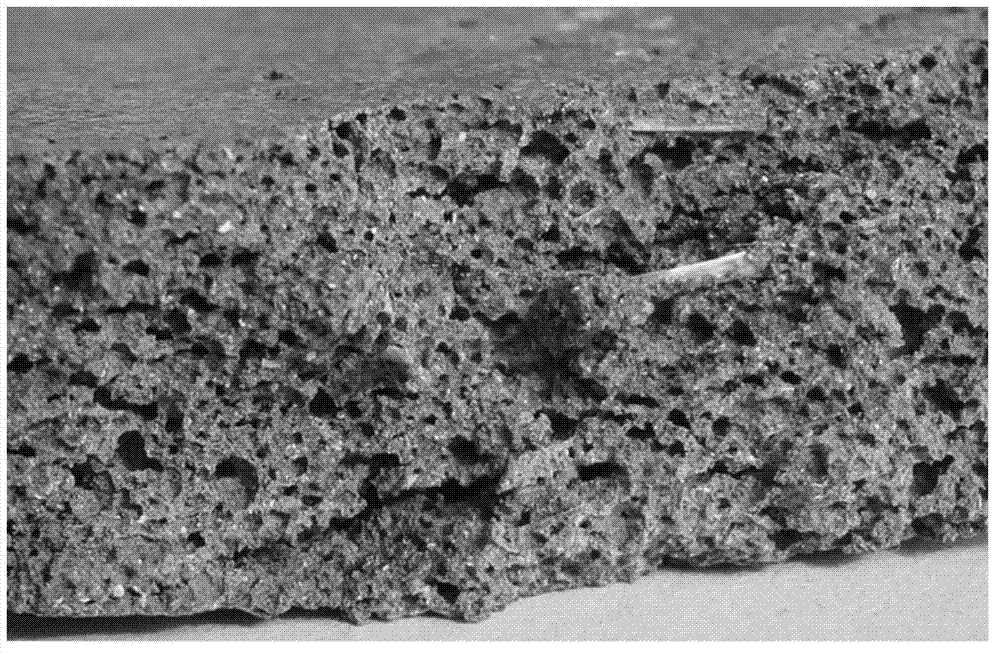

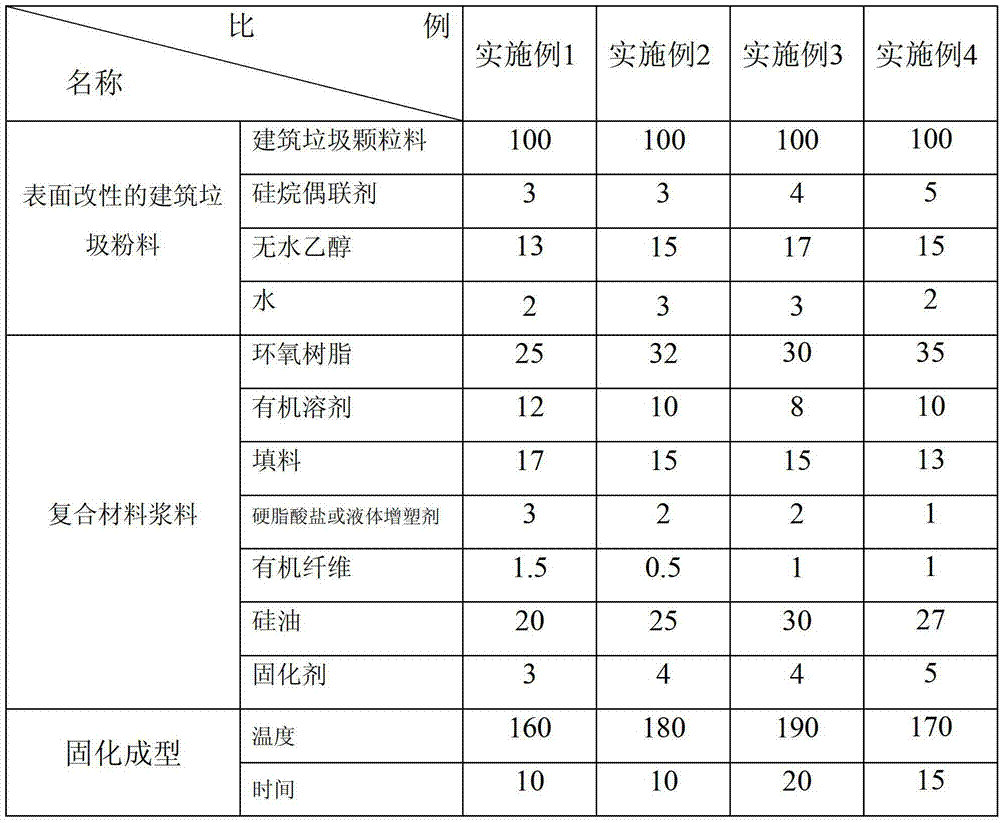

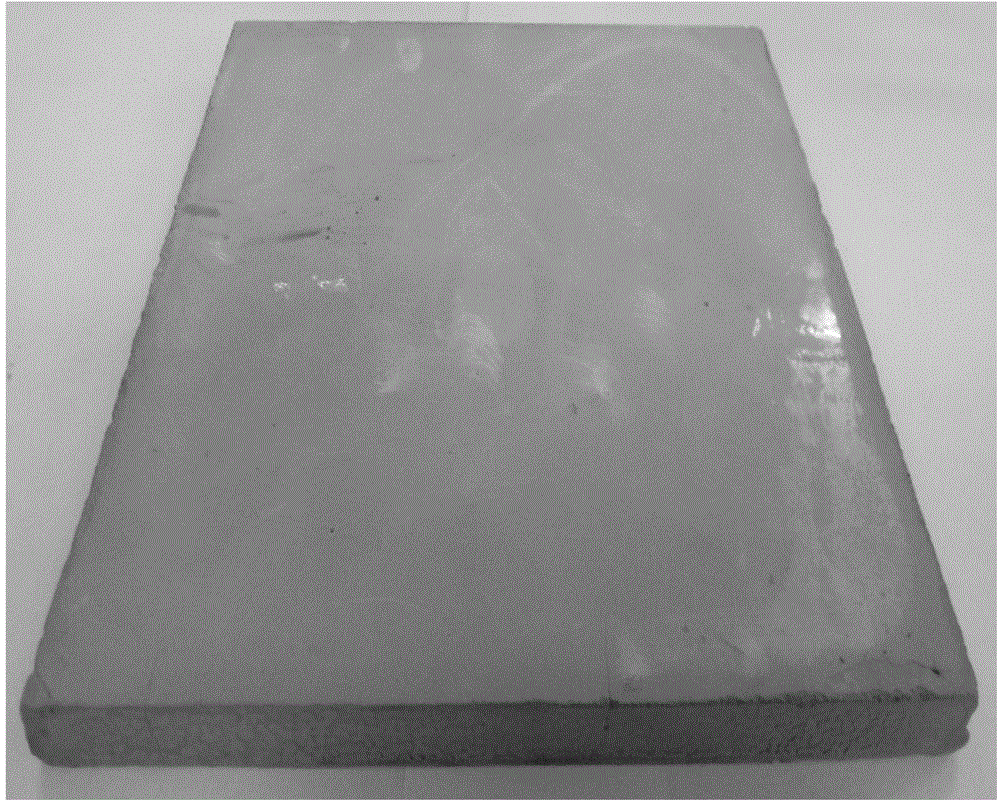

Preparing method for high-strength light multihole construction waste composite

InactiveCN103351112BOutstanding advantages of development and utilizationHigh surface hardnessSolid waste managementCeramicwareFiberEpoxy

The invention discloses a preparing method for high-strength light multihole construction waste composite, which comprises the following steps: 1) smashing and sieving construction waste to acquire construction waste powder, adding water for mixing, using absolute ethyl alcohol to dilute silane coupling agent, dropwise adding the diluent to coal ash, mixing evenly, and drying for standby application; 2) dissolving epoxy resin into acetone, sequentially adding fillers including phenolic resin, stearic acid, fiber and silicone oil, mixing evenly, adding a curing agent, adding the construction waste powder step by step, and using acetone to adjust viscosity of a sizing agent so as to acquire a forming sizing agent of the construction waste composite; 3) pouring the forming sizing agent of the construction waste composite into a steel die, rising temperature, pressurizing and forming to acquire the construction waste composite. The composite adopts a multihole structure, the density is less than that of water, and the compressive strength and flexural strength are high than those of common bricks. The composite has excellent water resistance, water permeability and gas permeability, and can be used in fields, such as quake prevention of buildings, cover plates of drainage channels at towns and cities, and surface hardening of landslide zones.

Owner:SHAANXI UNIV OF TECH

Preparation method of nano petaline Ni(OH)2

InactiveCN102774893BHigh particle purityUniform grain sizeNanotechnologyNickel oxides/hydroxidesMicrosphereSulfate

The invention discloses a preparation method of nano petaline Ni(OH)2. The method comprises the steps of taking nickel sulfate and urea as materials, preparing mixed solution of which the molar ratio of nickel to urea is 1:1 to 1:6 and then transferring the mixed solution to a 200mL of self-pressure lining polytetrafluoroethylene stainless steel reaction kettle, wherein the loading degree of a hydrothermal reaction kettle can be up to 80%; covering an inner cover and an outer cover to feed to an electric heating constant-temperature tank, heating the solution to 170 DEG C, reacting for 2-20 hours at constant temperature, then naturally cooling the solution to room temperature, filtering and washing the solution into a neutral state by deionized water; drying the solution into constant weight at 80 DEG C, and thinning the petals to prepare the nano petaline Ni(OH)2. According to the preparation method, the urea is taken as a precipitator, and a nano petaline Ni(OH)2 microsphere is directly prepared by hydrothermal syntheses; the method is simple in process, low in cost and easy to control without high-temperature sintering or a template agent, the obtained product crystal particle has the advantages that the size is uniform; the particle purity is high; the dispersity is good, and the crystalline form is good and controllable.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Fluorine titanium salt red-light material for white LED with two primary colors and preparation method of material

InactiveCN103275711BEvenly dispersedImprove absorption efficiencyLuminescent compositionsColor rendering indexFiltration

The invention discloses a fluorine titanium salt red light material for a white LED with two primary colors and a preparation method of the material. The chemical composition of the material is Bati(1-x)F6: xMn <4+>, wherein x ranges from 0.25% to 2.5%. The preparation method comprises the steps as follows: tetrabutyl titanate or TiO2 is taken as a titanium source, BaF2 is taken as a barium source, KMnO4 is taken as an active ion manganese source, an HF aqueous solution with the concentration ranging from 4% to 10% is taken as a medium or a fluorinating agent, a reaction is performed for 3-12 hours at the temperature ranging from the room temperature to 180 DEG C, then suction filtration and drying are performed, and white powder is obtained. The product emits bright red light under an ultraviolet lamp, the maximum excitation band of the product is matched with blue light emitted by a GaN blue light chip completely, and the emission spectrum is located in a red zone. The material can be applied to the white LED with two primary colors to improve the CRI (color rendering index) of the LED. The product has uniform and slight particles, contains no rare earth, has a simple preparation method and is suitable for industrial production.

Owner:WENZHOU UNIV

Three-component compound magneto electric material using organic polymer as adhesive and its preparation method

InactiveCN1224115CImprove mechanical propertiesHigh magnetoelectric conversion coefficientPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyLead zirconate titanateBarium titanate

Owner:TSINGHUA UNIV

Efficient plane perovskite solar energy cell preparation method based on low temperature lithium ion doping with titanium dioxide compact layer

ActiveCN107240644AImprove photoelectric conversion efficiencySimple preparation processSolid-state devicesSemiconductor/solid-state device manufacturingAg electrodeTitanium tetrachloride

The invention discloses an efficient plane perovskite solar energy cell preparation method based on low temperature lithium ion doping with a titanium dioxide compact layer; the method comprises the following steps: hydrolyzing a titanium tetrachloride solution so as to obtain a TiO2 colloid; depositing the titanium tetrachloride hydrolyzed colloid on a FTO conductive glass so as to form a TiO2 compact layer film; using a lithium silicate solution to process the TiO2 compact layer film, and forming a CH3NH3PbI3-x(SCN)x layer or a CH3NH3PbI3 layer on the compact layer film; spin coating a cavity conducting layer on a perovskite layer, and heat vapor plating to form an Ag electrode, thus obtaining the perovskite cell. Compared with a CH3NH3PbI3-x(SCN)x and CH3NH3PbI3 perovskite cell with no doped lithium ions, the method dopes lithium ions with the TiO2 compact layer, thus promoting electron conduction and collection, and further improving the perovskite cell photoelectric conversion efficiency; the method needs no extra equipment and complex process, and is simple to operate.

Owner:SOUTH CHINA NORMAL UNIVERSITY

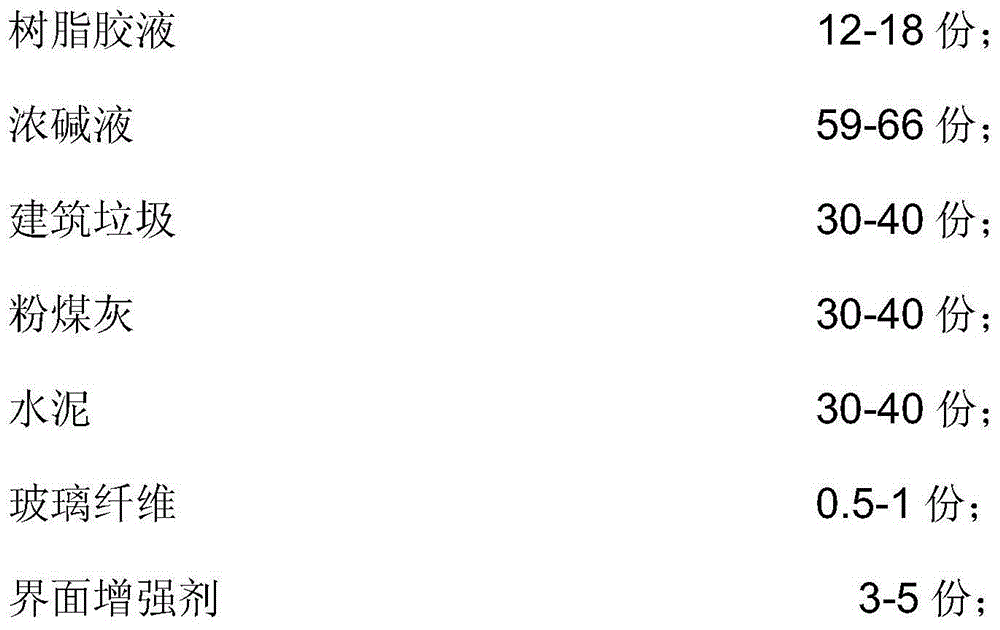

Cement wall component and manufacturing process thereof

PendingCN113666678AHigh flexural strengthImprove workabilityBuilding componentsCeramicwareBuilding materialProcess engineering

The invention provides a cement wall component and a manufacturing process thereof, and relates to the technical field of building materials. The cement wall component provided by the invention has the advantages of light weight, sound insulation, heat preservation and the like, and is applied to a wall structure of a building, so that the self weight of the building is reduced, the requirement of energy conservation of the building is met, and materials are saved. The invention further provides a manufacturing process of the cement wall component, the manufacturing process is easy to operate, achieves large-scale production, improves the dispersity and production efficiency of all the components and improves the comprehensive performance of the cement wall component.

Owner:吴南昌

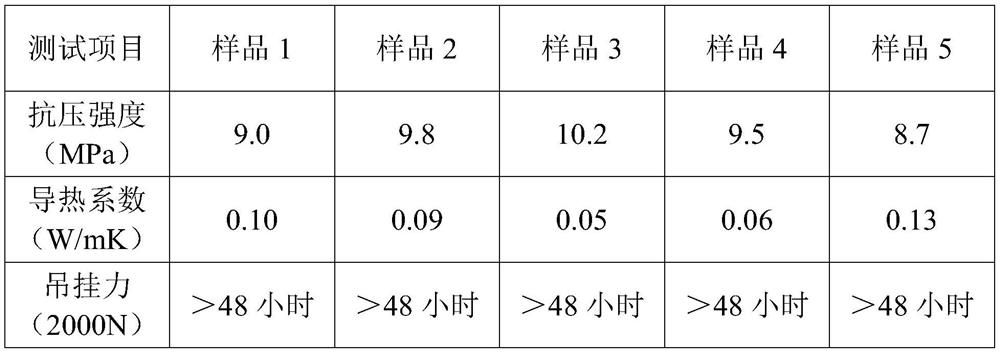

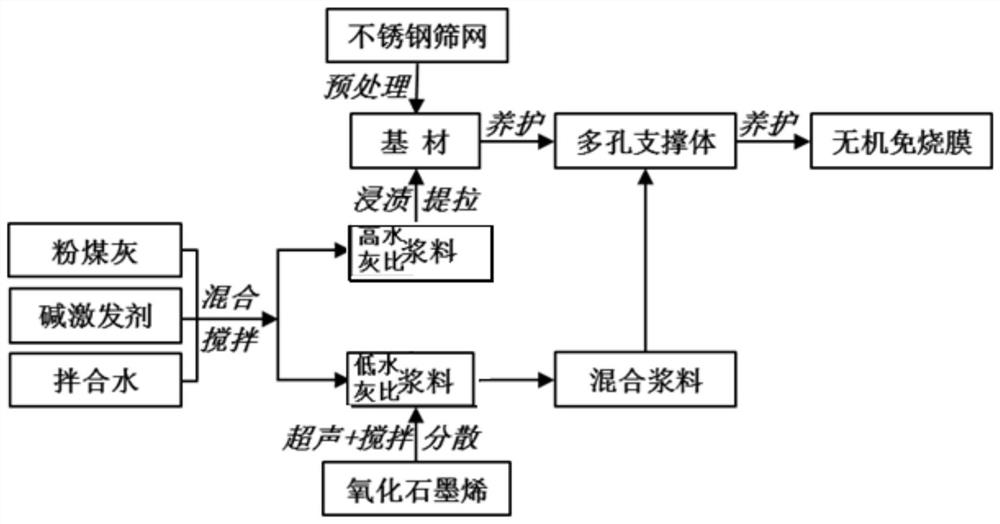

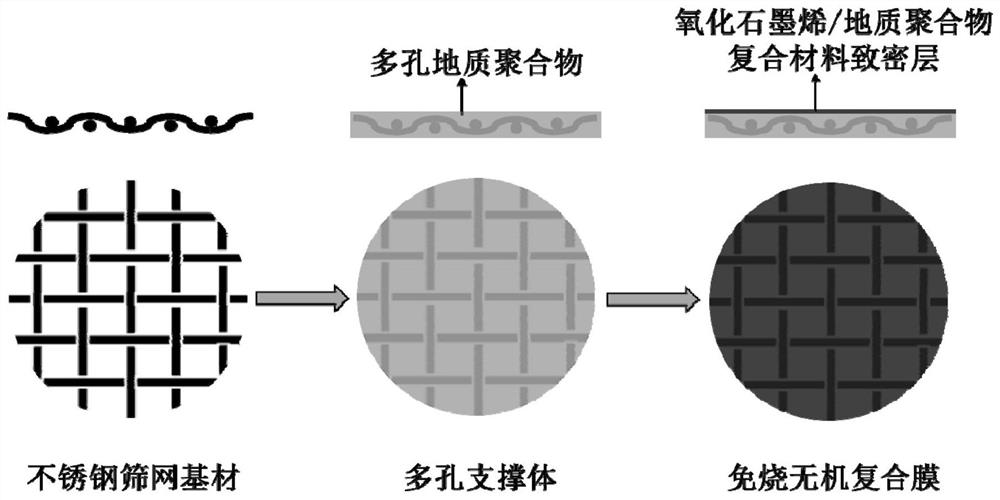

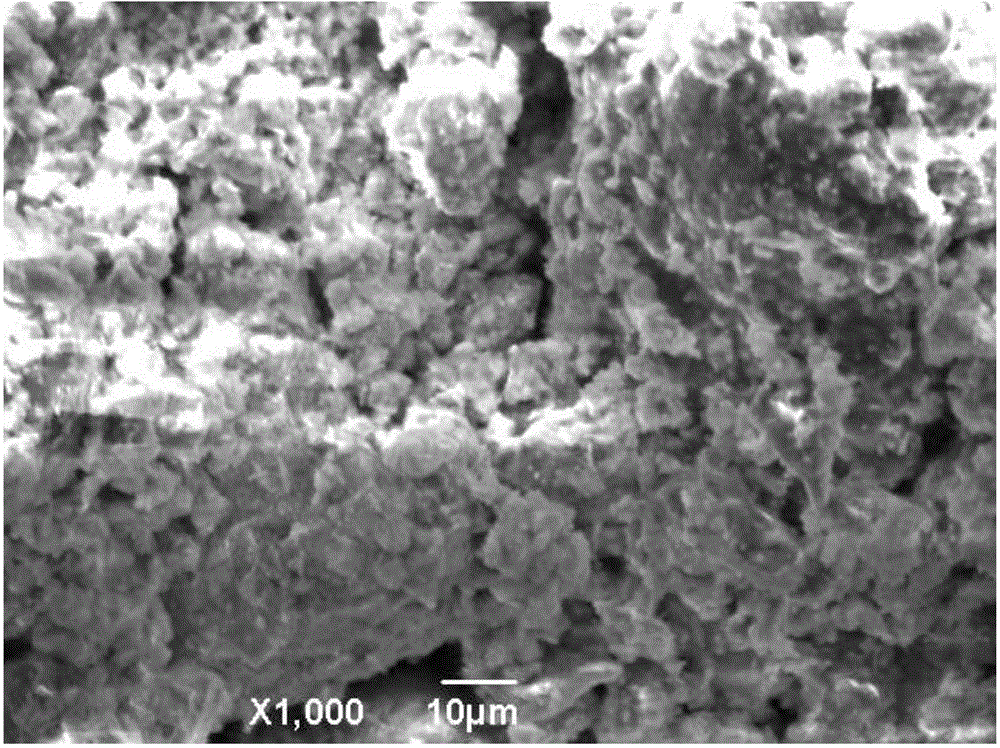

Preparation method of baking-free inorganic composite membrane

The invention discloses a preparation method of a baking-free inorganic composite membrane, which comprises the following steps: by using fly ash as a raw material and a stainless steel screen as a base material, filling and covering geopolymer slurry on pores and surface of the stainless steel screen by a dip-coating method, and curing to obtain an inorganic composite membrane support body; then preparing the geopolymer slurry with a small amount of deionized water and graphene oxide into mixed slurry to be applied to the surface of the inorganic composite membrane support body in a dip-coating mode, and finally obtaining the baking-free inorganic composite membrane through thermal curing. The method is simple in process, low in cost, simple and feasible, does not need high-temperature sintering, and has a potential application prospect. And a new thought is provided for low-cost preparation of the inorganic composite membrane.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A kind of self-enhancing ceramic cold glaze and preparation method thereof

The invention provides a self-enhanced ceramic cold glaze and a preparation method thereof. The cold glaze is prepared by the following steps: preparing the following raw materials: phosphate / polyphosphates, meta-kaolin, silicon dioxide, zinc oxide, sodium silicate, an alkaline compound, and water, mixing raw materials according to a certain ratio, evenly stirring the mixture by a mechanical stirrer to form slurry, evenly painting the slurry on a blank, which needs to be decorated, and drying the blank at a room temperature or low temperature (40 to 100 DEG C). The glaze, which is obtained by the provided formula and preparation method, can be used to repair the glaze of blanks made of various porcelains. The glaze and the blank interface are well combined together. The glaze has excellent mechanical properties, the compressive strength can reach 150 MPa or more, the surface of the glaze is smooth, the color is white-grey and transparent, no defect exist on the surface, and the market needs can be met. Compared with the conventional glaze production technology, the provided preparation method has the advantages of simple technology, energy saving, environment-friendliness, low cost, and easy operation.

Owner:四会市石易金陶瓷原料有限公司

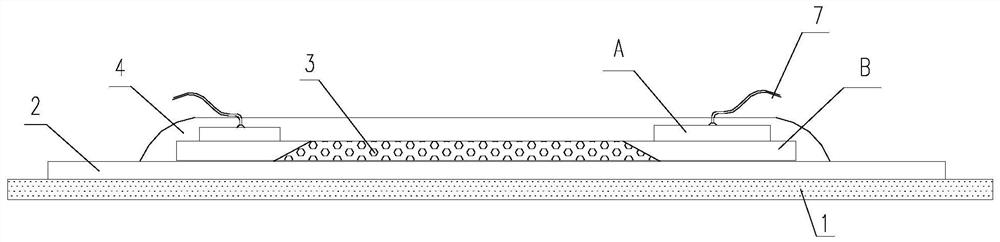

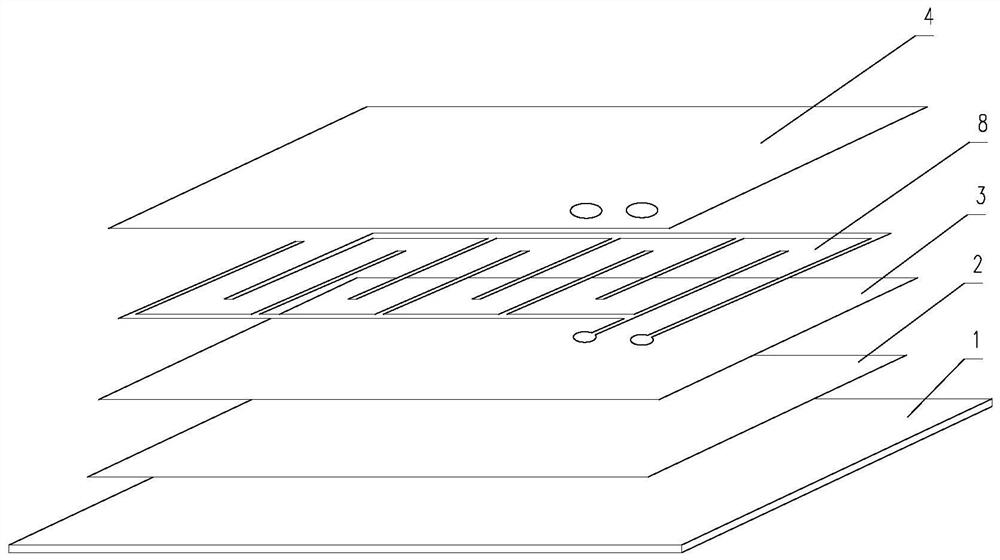

a heating element

ActiveCN107454691BSimple preparation processMild drying and curing conditionsOhmic-resistance electrodesHeating element materialsCurrent distributionEngineering

The invention provides a heating body, which includes a first insulating layer, a heating layer, a second insulating layer, and an input electrode and a plurality of current distribution electrodes arranged on the heating layer in addition to a base surface; the first insulating layer, the heating layer and the second The insulating layer is a continuous coating; the input electrode and the current distribution electrode are superimposed on the heating layer in the form of discontinuous islands, and a plurality of the current distribution electrodes are connected as required, and some of the current distribution electrodes are interconnected by wires or Connect directly through metallization; connect the electrode wires to the input electrodes; the base surface is any geometric surface including plane, curved surface and folded surface. In the present invention, the heating element obtained after curing is made of high-strength all-inorganic material, high temperature resistance and aging resistance, no gap heating layer design, wide application and flexible application.

Owner:湖南源创高科工业技术有限公司

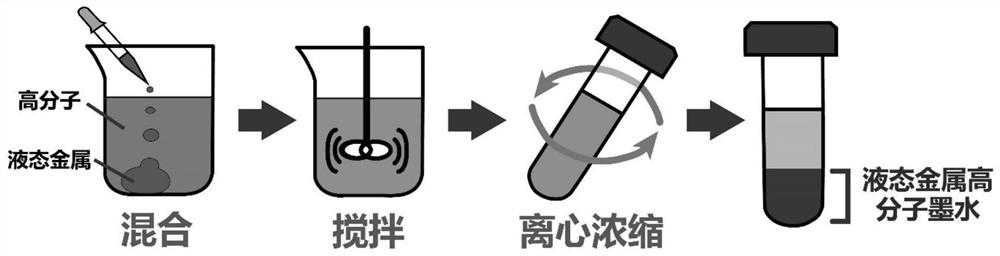

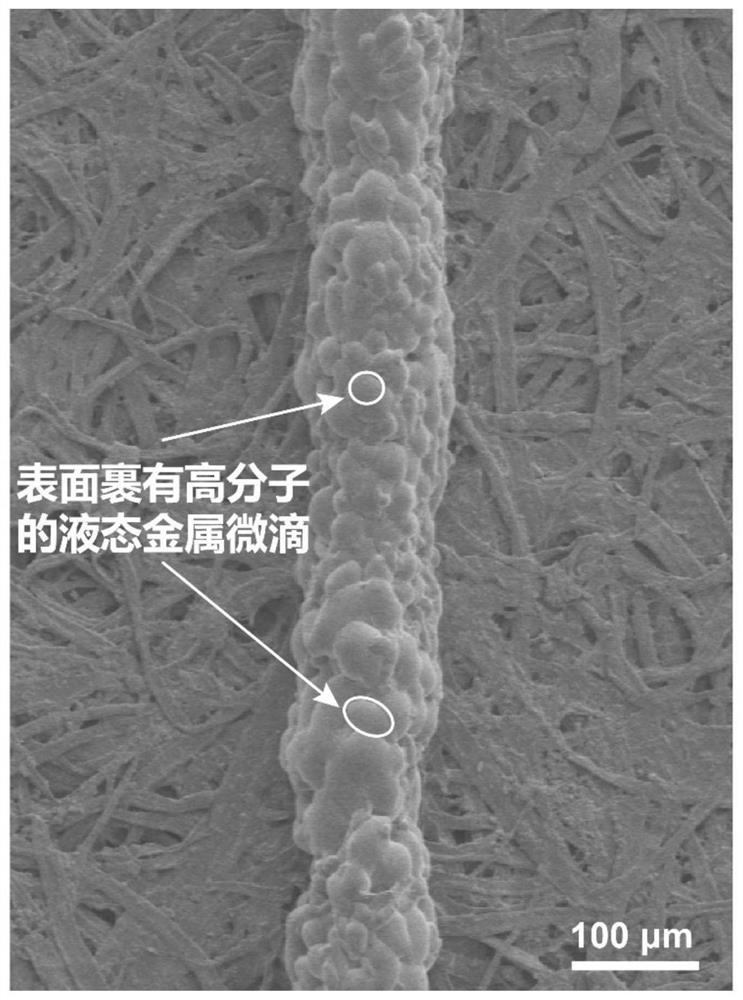

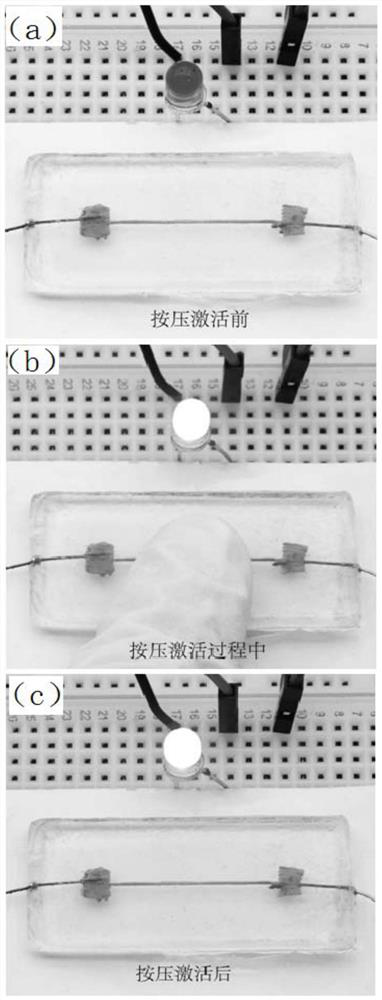

A kind of liquid metal-polymer printable ink and its preparation and printing method

ActiveCN110677984BGood printabilityImprove wettabilityConductive pattern formationMetallic pattern materialsPolymer scienceLiquid metal

The invention discloses a liquid metal polymer printable ink, which is formed by mixing liquid metal and a curable polymer system, wherein the weight percentage of the liquid metal is 75-95%. The invention also discloses the preparation method and application of the liquid metal polymer printable ink. The liquid metal polymer printable ink of the invention has good conductivity and is an ideal conductive ink that can be used in flexible electronic devices. At the same time, it has excellent printing performance, creating the possibility of high-speed, high-precision printing of liquid metal-based flexible electronics. The polymer components of the liquid metal polymer printable ink of the present invention can be flexibly converted according to the flexible substrate material of the flexible electronic device during actual implementation, thereby ensuring strong adhesion between the ink and the flexible substrate and improving the flexibility of the flexible electronic device. reliability. The liquid metal polymer printable ink of the invention has simple components, convenient preparation, good printability, low cost and broad application prospects.

Owner:ZHEJIANG UNIV

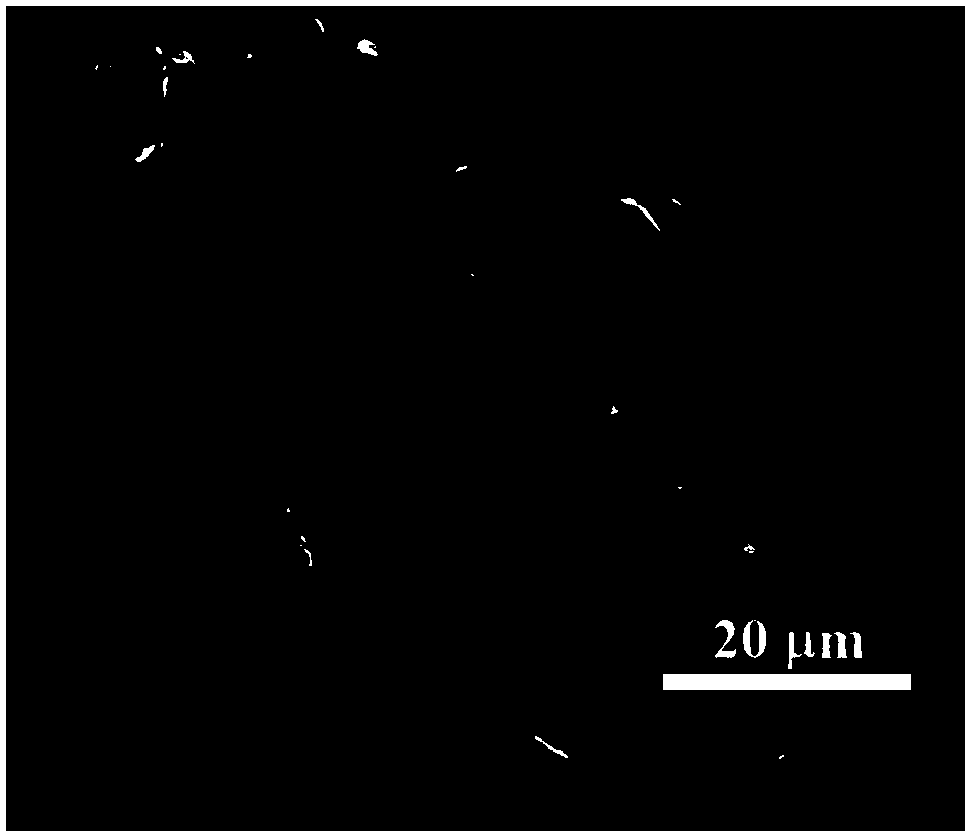

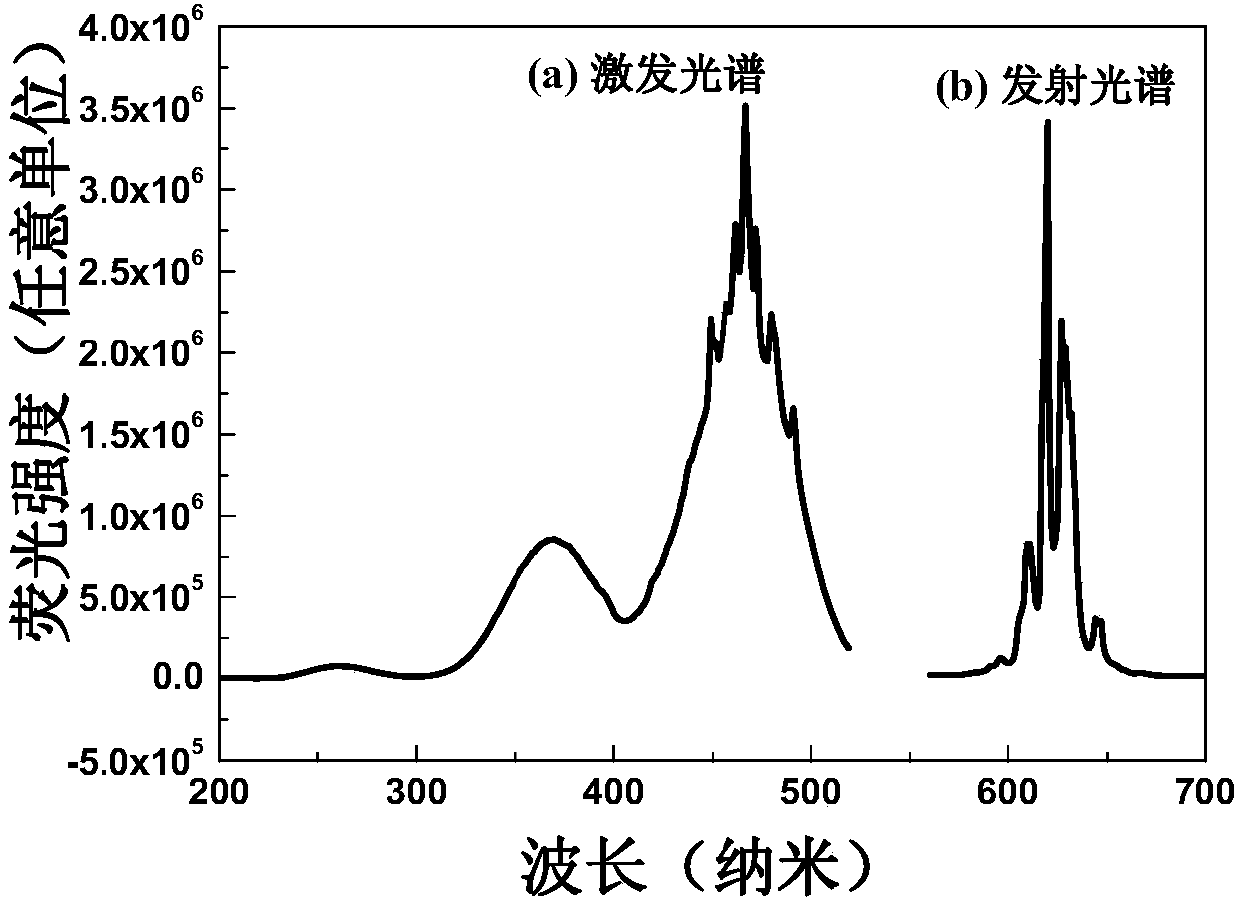

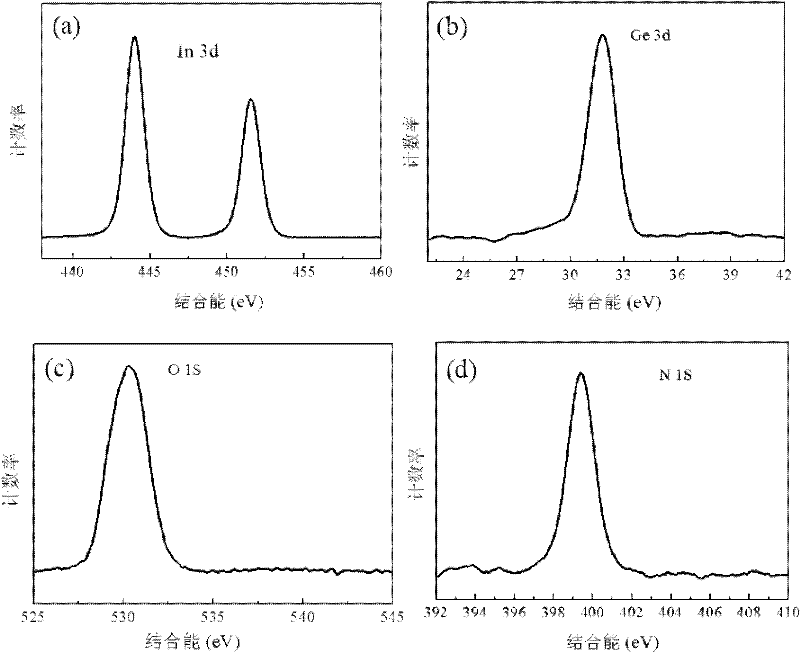

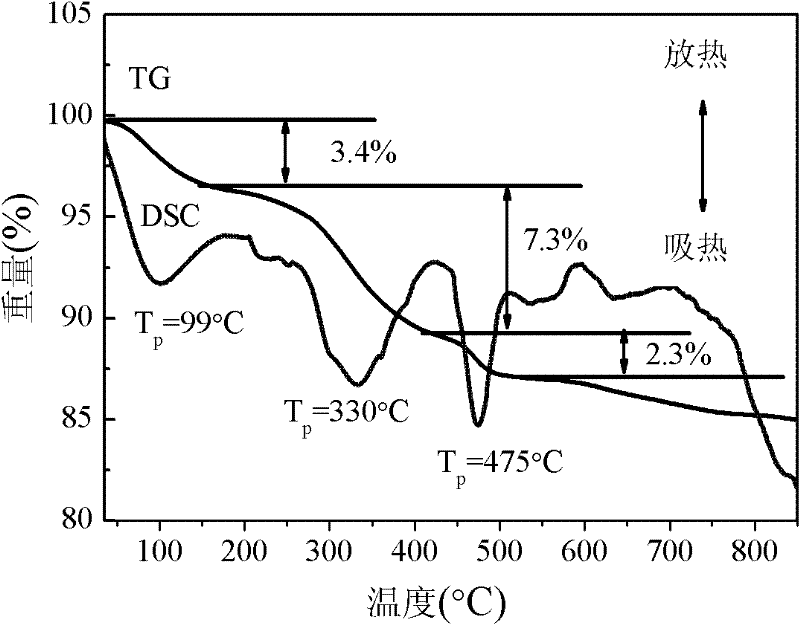

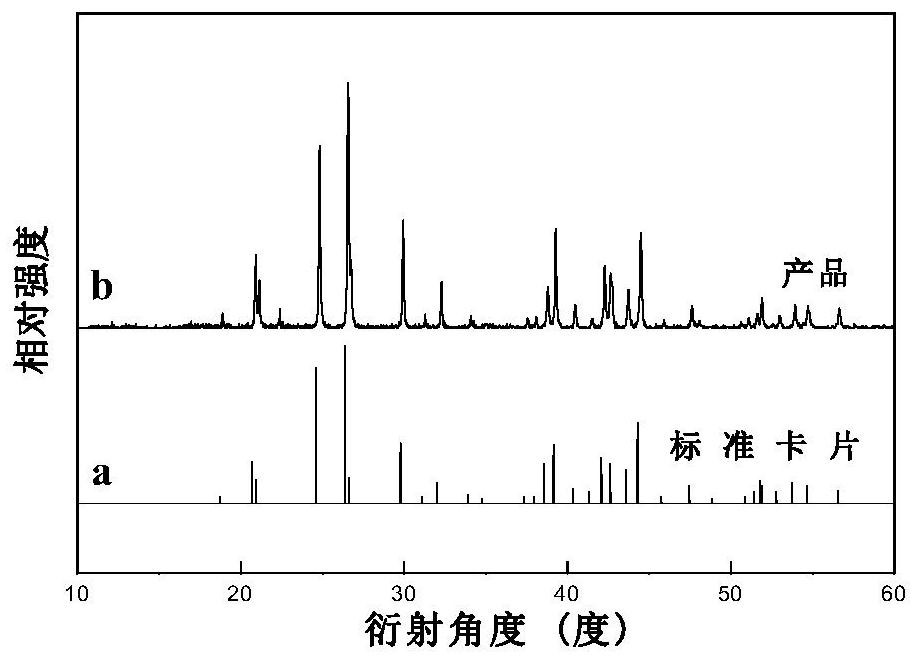

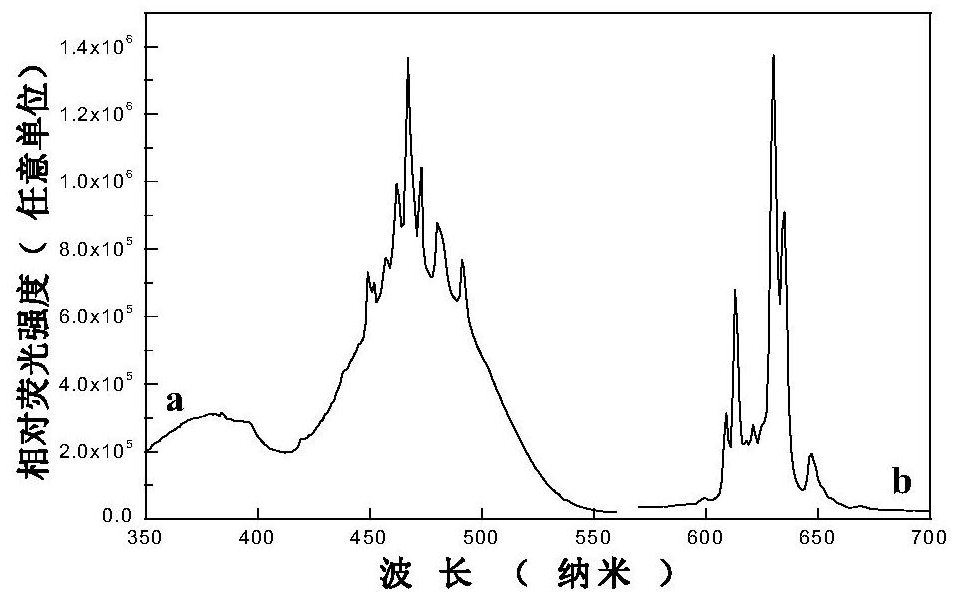

Preparation method for ultrafine In2Ge2O7(En) hybrid nano-wire, and nano-wire prepared by the same

InactiveCN102225782AMild preparation conditionsNo need for high temperature sinteringMaterial nanotechnologyGermanium compoundsEthylenediamineIndium

The invention relates to a preparation method for a ultrafine In2Ge2O7(En) hybrid nano-wire. The method comprises the following steps: adding indium acetate and germanium oxide to a mixing solvent comprising ethylenediamine and water, followed by uniform dispersing, then carrying out a reaction at a temperature of 160-200 DEG C, finally carrying out centrifugal separation, washing and drying to obtain the ultrafine In2Ge2O7(En) hybrid nano-wire, wherein a molar ratio of the indium acetate to the germanium oxide is 2:3-2:2, a molar concentration of the indium acetate is 0.013-0.13mol / L, a volume ratio of the ethylenediamine to the water in the mixing solvent is 10:5-14:1. According to the present invention, a solvent thermal process is adopted, the preparation condition is mild and does not require high temperature sintering, and the preparation process is simple and energy saving; the prepared nano-wire has a diameter of only 2-3 nm, and contains organic groups so as to provide a material comprising hybridization of the organic groups and the inorganic groups; the nano-wire can generates fluorescence and wavelength blue shift, and has certain photocatalytic activity for reduction of CO2 after supporting Pt.

Owner:NANJING UNIV

A kind of tetravalent manganese ion-doped barium fluoroscandate red light material and preparation method thereof

ActiveCN109179481BNo need to avoid water and oxygenLow costRare earth metal compounds preparation/treatmentLuminescent compositionsChemical compositionColor rendering index

The invention discloses a tetravalent manganese ion-doped barium fluoroscandate red light material and a preparation method thereof. The material is Ba 3 sc 2 f 12 as matrix, with Mn 4+ As an activator, the chemical composition is Ba 3 sc 2 f 12 :Mn 4+ . The preparation method is as follows: with Sc 2 o 3 Scandium source, Ba(NO 3 ) 2 as barium source, with K 2 MnF 6 In order to activate ion manganese source, HF aqueous solution is used as medium and fluorinating agent. During preparation, the Sc 2 o 3 The solid was placed in a container, and then HF aqueous solution, Ba(NO 3 ) 2 and K 2 MnF 6 , react at room temperature to 180 degrees for 1 to 12 hours, filter with suction, and dry naturally to obtain the product. The material may be applied to dichroic white LEDs to improve the color rendering index of white LEDs. The product does not contain rare earth, has a simple preparation method, does not need high-temperature sintering, and is suitable for industrial production.

Owner:WENZHOU UNIV

A kind of flexible metal powder for three-dimensional printing and its preparation method and application method

ActiveCN104801703BImprove flexibilityHigh strengthAdditive manufacturing apparatusNetwork structureMetal powder

A flexible metal powder for three-dimensional printing, characterized in that it is mainly composed of metal powder embedded in a rubber body with a network structure, and is prepared from the following raw materials in parts by weight: 80-85 parts of metal powder, rubber body 10-15 parts, 2-3 parts of metal oxide, 1-3 parts of softener, 1-2 parts of interface modifier, 0.2-0.5 parts of anti-aging agent, 0.05-0.1 part of accelerator; Powder adhesion, using a double-rotor continuous mixer with longitudinal meshing and transverse stretching, the metal powder is completely embedded in the rubber body with a network, and the flexibility of the rubber body network is obtained by extrusion granulation and colloid grinding machine. metal powder. Flexible metal powder can be used to obtain green metal products through three-dimensional printing, and flexible metal products with excellent strength, flexibility and wear resistance can be obtained through thermal cross-linking treatment. It can be used to 3D print flanges, connectors, architectural models, etc. of special structures.

Owner:山东宏阳型材科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com