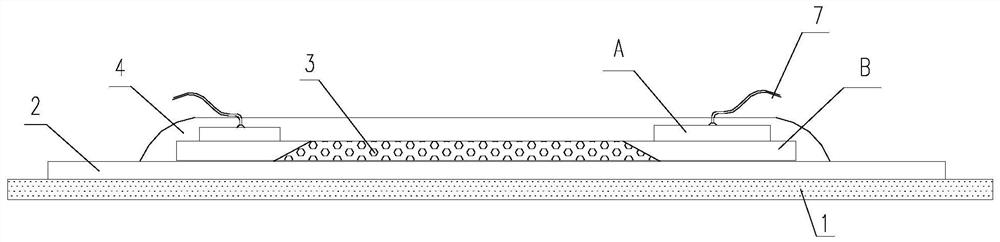

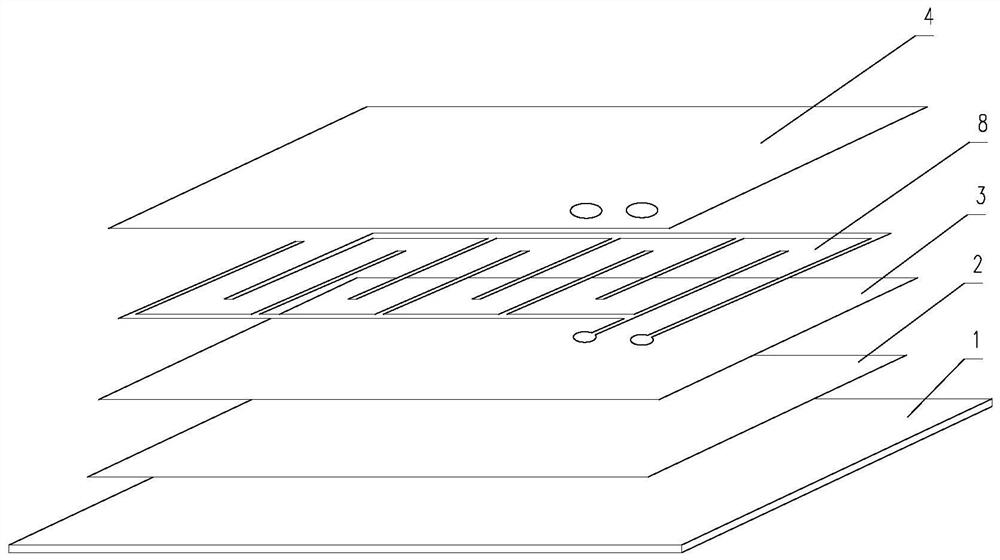

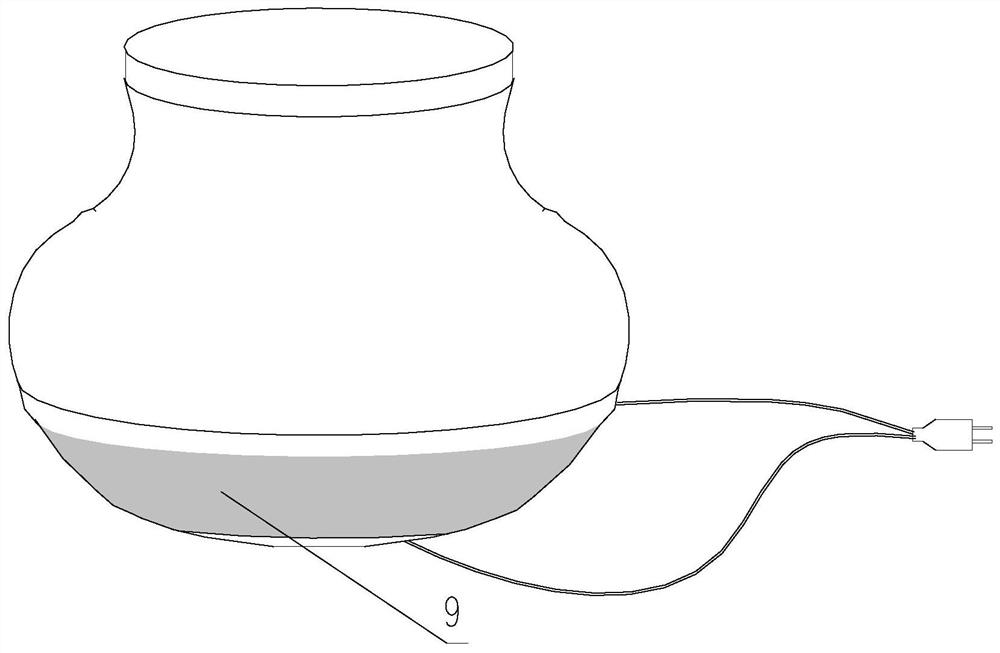

a heating element

A heating element and heating layer technology, which is applied to electric heating devices, ohmic resistance heating, heating element materials, etc., can solve the problems of large occupied volume and narrow application area of heating elements, and achieves convenient application, wide application area and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] The preparation method of embodiment 1 is:

[0079] Step A, preparation of functional slurry:

[0080] Mix the solvent, filler modification, dispersant, and functional filler in proportion, then ball mill for 5 minutes to 168 hours, control the temperature of the slurry during the mixing and grinding process to not be higher than 45°C, and analyze the particle size to reach the qualified particle size range to obtain the filler slurry; the filler slurry, Inorganic nano-SiO 2 Resin film-forming agent and regulator are mixed in proportion, ball milled or high-speed sheared for 10 minutes to 30 minutes, then filtered through a 100-mesh sieve, and the settled part is discarded to obtain the remaining part to obtain the functional slurry;

[0081] The inorganic nano film-forming agent is prepared by ion exchange method.

[0082] Step B, coating preparation and maintenance:

[0083] First, clean and roughen the base surface, and then apply layer by layer in the order of th...

Embodiment 2

[0089] The preparation method of embodiment 2 is:

[0090] Step A, preparation of functional slurry:

[0091] Mix the solvent, filler modification, dispersant, and functional filler in proportion, then ball mill for 5 minutes to 168 hours, control the temperature of the slurry during the mixing and grinding process to not be higher than 45°C, and analyze the particle size to reach the qualified particle size range to obtain the filler slurry; the filler slurry, Inorganic nano-SiO 2 Resin film-forming agent and regulator are mixed in proportion, ball milled or high-speed sheared for 10 minutes to 30 minutes, then filtered through a 100-mesh sieve, and the settled part is discarded, and the remaining part is obtained as a functional slurry;

[0092] The inorganic nano film-forming agent is prepared by alkoxide hydrolysis.

[0093] Step B, coating preparation and maintenance:

[0094] First, clean and roughen the base surface, and then apply layer by layer in the order of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com